Method for forming anticorrosive coating on surfaces of metal parts

A technology for metal parts and anti-corrosion coatings, which is applied in the coating process of metal materials, devices for applying liquid to the surface, coatings, etc., can solve the problems of liquid metal corrosion, limit the application range of liquid metal, etc. , Good anti-cold and thermal shock performance, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

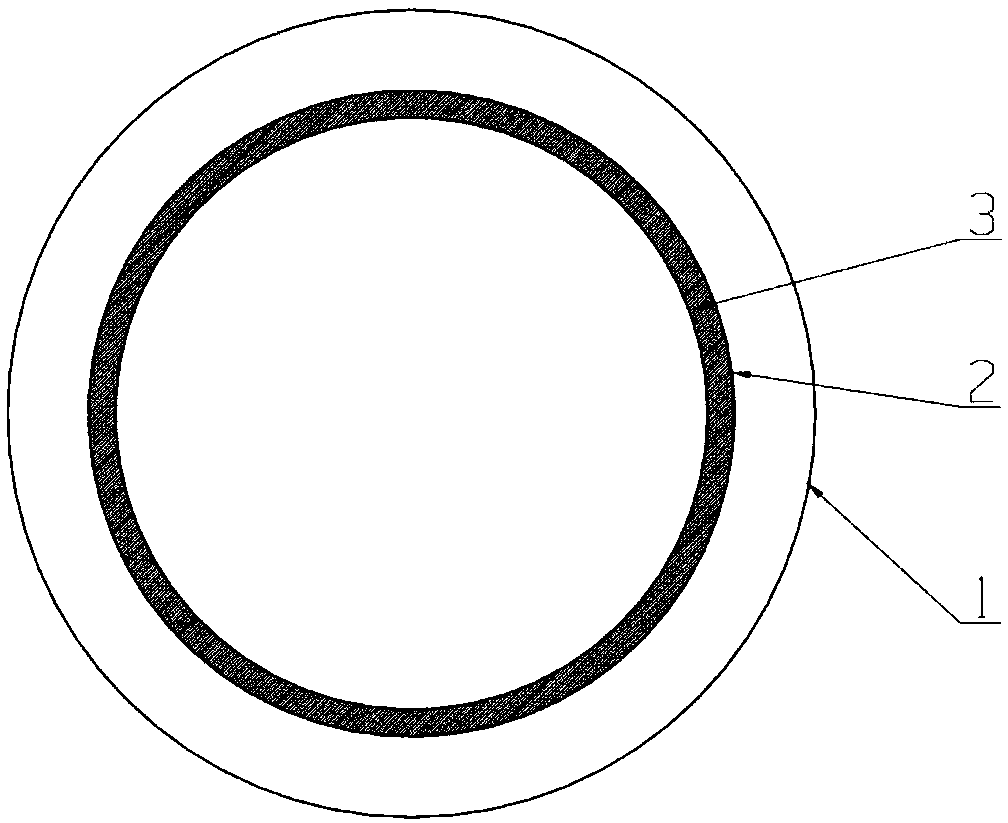

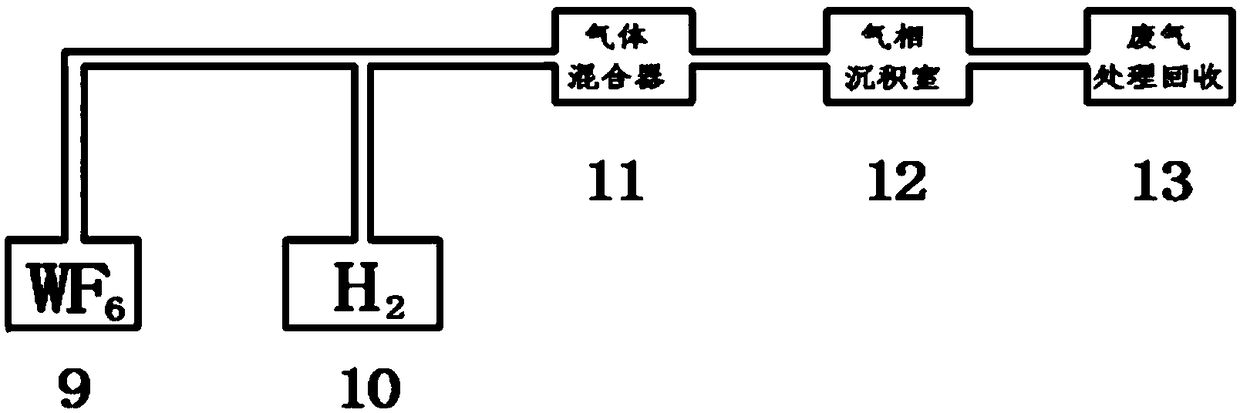

[0040] Refer to attached figure 1 , 2 , the present embodiment provides a method of forming a liquid metal corrosion-resistant anticorrosion coating on the surface of a metal component by chemical vapor deposition. The metal pipeline 7 is used as the metal component, and the inner wall of the pipeline 7 is coated. figure 1 Schematic diagram of the cross-section after the anti-corrosion coating is applied to the inner wall of the metal pipeline, figure 2 Flow diagram of tungsten plating for chemical vapor deposition.

[0041] Specific steps are as follows:

[0042] (1) Clean the pipeline 7 with a metal-specific cleaning agent for degreasing and rust removal, and then dry it for later use.

[0043] (2) Using tungsten hexafluoride 9 as the reaction source gas, heat tungsten hexafluoride 9 to be vaporized above the boiling point, fully mix it with hydrogen gas 10 in the gas mixer 11, and then pass it into the chemical vapor deposition reaction chamber 12. They are: tungsten h...

Embodiment 2

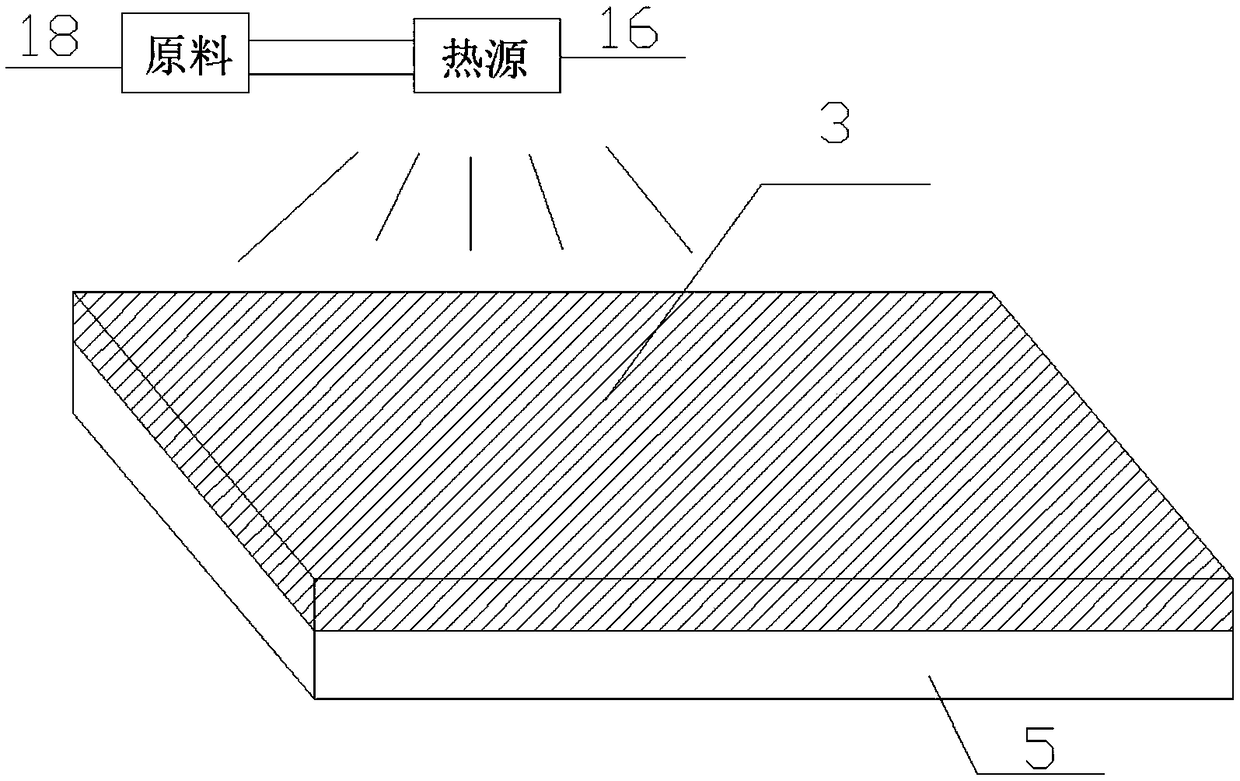

[0046] Refer to attached image 3 , the present embodiment provides a method of forming a liquid metal corrosion-resistant anticorrosion coating on the surface of the metal component by thermal spraying, and the outer surface of the metal component 5 is treated with aluminum oxide coating, image 3 Flow chart for preparing anti-corrosion coating by spraying method;

[0047] The specific steps are as follows: (1) Degrease and derust the metal parts with a general-purpose cleaning agent, dry them after cleaning, and set aside.

[0048] (2) Perform pretreatment on the surface of component 5, which includes roughening the surface and pre-spraying a layer of nickel-aluminum bonding primer to enhance the bonding strength between the coating and the substrate (conventional means in this field can be used).

[0049] (3) Use alumina powder as raw material (thermal spraying raw material 18), through heat source 16, be heated to melting or semi-molten state (according to the judgment of...

Embodiment 3

[0054] Refer to attached Figure 4 , this embodiment provides a specific application device after coating treatment, the specific steps are as follows:

[0055] Figure 4 It is a schematic diagram of the hydraulic transmission unit after anticorrosion treatment. Before assembly, the small piston 4, the pipe 7, and the large piston 8 are anti-corrosion treated, and the surface of the pipe 7 is coated with tungsten, and the tungsten coating of the pipe 7 is carried out by the method of embodiment 1. Do a tungsten coating on the surface of small piston 4 and large piston 8, adopt the thermal spraying method of embodiment 2 to carry out.

[0056] In particular, tungsten hexafluoride is highly corrosive and easy to hydrolyze. During the entire vapor deposition process, good airtightness is required, and moisture and air should be removed as much as possible. When necessary, vacuum pumping and inert protective gas should be introduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com