Preparation method of weldless type aluminum alloy liquefied petroleum gas cylinder

A technology of liquefied petroleum gas and aluminum alloy, which is applied in mechanical equipment, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve problems such as explosion and air leakage, prolong service life, and have reasonable bottle structure design , the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

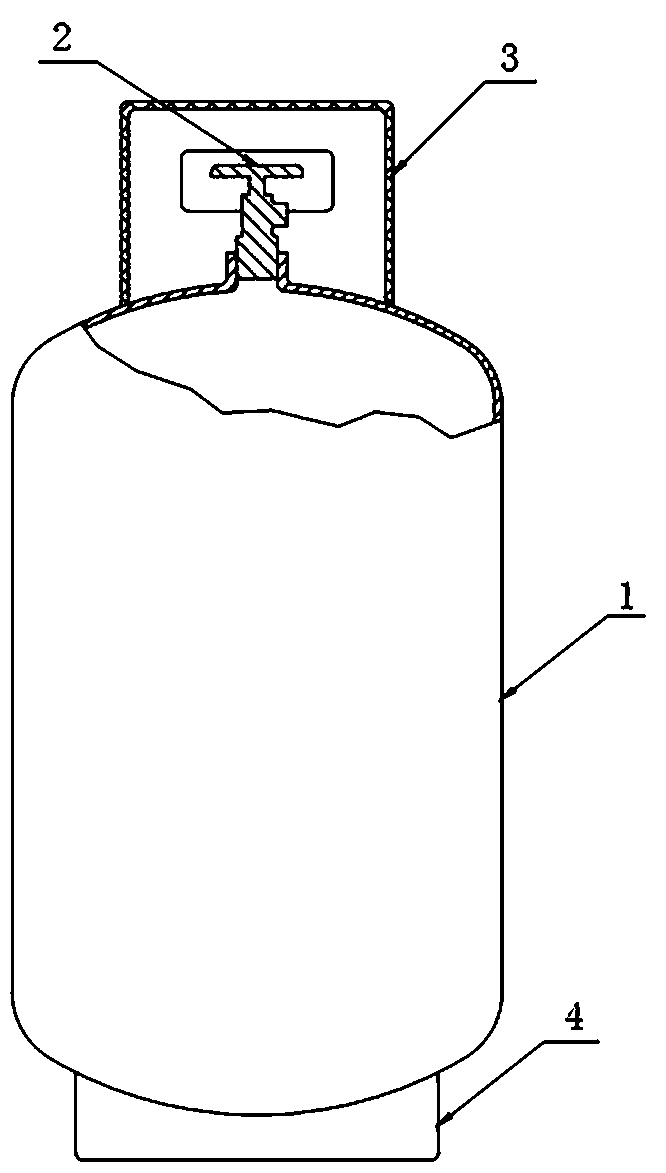

[0022] as attached figure 1 The preparation method of the shown weldless aluminum alloy liquefied petroleum gas cylinder comprises the following steps:

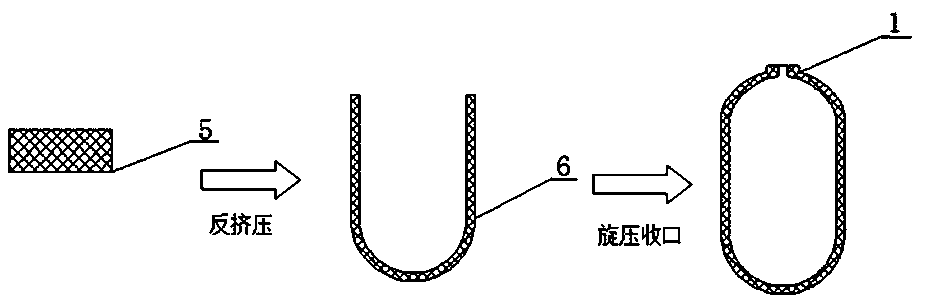

[0023] A. Billet selection: according to the size of the gas cylinder body, the aluminum alloy extruded round bar ingot is cut to the required thickness in advance to become a disc-shaped billet 5;

[0024] B, billet extrusion: after heating the billet 5, put it into the mold cavity and extrude it through the extrusion head to form the rough bottle body 6 of U-shaped structure, and take out the rough bottle body 6 from the mold cavity;

[0025] C. Closure of the rough blank 6 of the bottle body: put the rough blank 6 of the bottle body into the spinning machine for closing to become a semi-finished gas cylinder 1;

[0026] D. Semi-finished product assembly: assemble the valve 2, handle 3, and base 4 on the semi-finished gas cylinder 1 to become a finished gas cylinder;

[0027] E. Finished product performance test: carry ou...

Embodiment 1

[0041] Example 1: 1) Calculate the raw material size required for the preparation according to the size of the petroleum liquefied gas cylinder to be prepared, and cut the aluminum alloy extruded round bar billet to the required thickness to form a disc-shaped billet according to the calculated size 5 , put the blank 5 into a heating furnace with a temperature of 200°C~550°C and heat it for 30~60min;

[0042] 2) Apply lubricant to the heated billet 5, mold cavity and extrusion head respectively, and put the billet 5 into the mold cavity, lower the extrusion head at a speed of 3mm / s to extrude the billet 5, and the extrusion head The pressure is 1800KN, so that the blank 5 starts to slide and deform along the inner surface of the mold cavity. When the lower surface of the blank 5 contacts the upper surface of the concave plug at the bottom of the mold cavity, the extrusion is stopped and the extrusion is forward. End transfer to reverse extrusion;

[0043] 3) At this time, kee...

Embodiment 2

[0048]Example 2: 1) Calculate the raw material size required for the preparation according to the size of the liquefied petroleum gas cylinder to be prepared, and cut the aluminum alloy extruded round bar billet to the required thickness to form a disc-shaped billet according to the calculated size 5 , put the blank 5 into a heating furnace with a temperature of 200°C~550°C and heat it for 30~60min;

[0049] 2) Apply lubricant to the heated billet 5, mold cavity and extrusion head respectively, and put the billet 5 into the mold cavity, lower the extrusion head at a speed of 4mm / s to extrude the billet 5, and the extrusion head The pressure is 1850KN, so that the blank 5 begins to slide and deform along the inner surface of the mold cavity. When the lower surface of the blank 5 contacts the upper surface of the concave plug at the bottom of the mold cavity, the extrusion is stopped and the extrusion is forward. End transfer to reverse extrusion;

[0050] 3) At this time, keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com