Light composite sabot and manufacturing method thereof

A technology of composite materials and manufacturing methods, applied in warheads, ammunition, weapon accessories, etc., can solve the problems of large negative mass and achieve low cost, strong practicability, and good consistency in shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

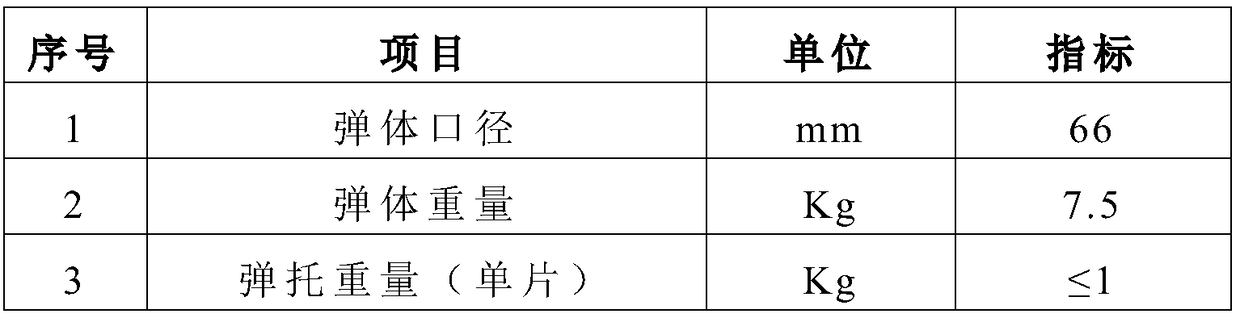

[0032] This embodiment requires the preparation of a lightweight composite material bullet holder with a projectile body diameter of 66mm, and its working conditions and requirements are shown in Table 1 below:

[0033] Table 1 Working conditions and requirements of Example 1

[0034]

[0035]

[0036] The manufacturing method of this lightweight composite bullet holder comprises the following steps:

[0037] Step 1: According to the external structure size and working condition requirements of the bullet support product, the finite element model of the composite material bullet support is established through the Abaqus analysis software, and the strength of the bullet support at launch is calculated through the dynamic display algorithm, and the reinforcing rib is determined according to the calculation result The quantity is 5, the thickness is 5mm, and the skin thickness is 2mm, and then the number of PMI (polymethacrylimide) foam boards is 6, and the thickness is 12m...

Embodiment 2

[0045] This embodiment requires the preparation of a lightweight composite material bullet holder with a projectile body diameter of 73mm, and its working conditions and requirements are shown in Table 1 below:

[0046] Table 1 Working conditions and requirements of Example 1

[0047] serial number

project

unit

index

1

mm

73

2

Projectile weight

kg

8.46

3

Bullet weight (single piece)

kg

≤1.5

4

Work with maximum acceleration

/

25,000g

[0048] The manufacturing method of this lightweight composite bullet holder comprises the following steps:

[0049] Step 1: According to the external structure size and working condition requirements of the bullet holder, the finite element model of the composite material bullet holder is established through the Abaqus analysis software, the strength of the bullet holder during launch is calculated through the dynamic display algorithm, ...

Embodiment 3

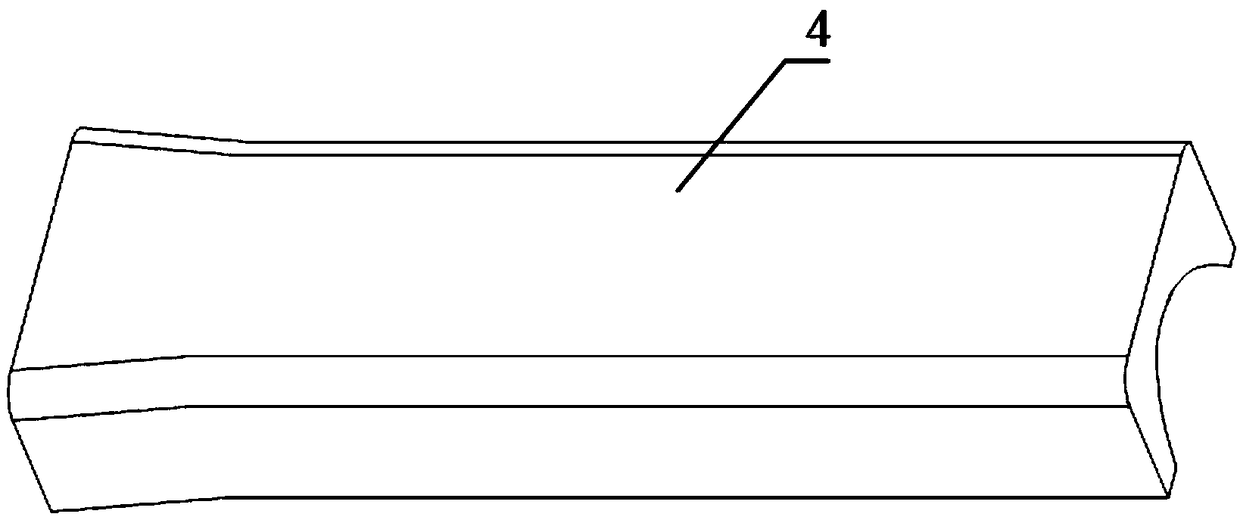

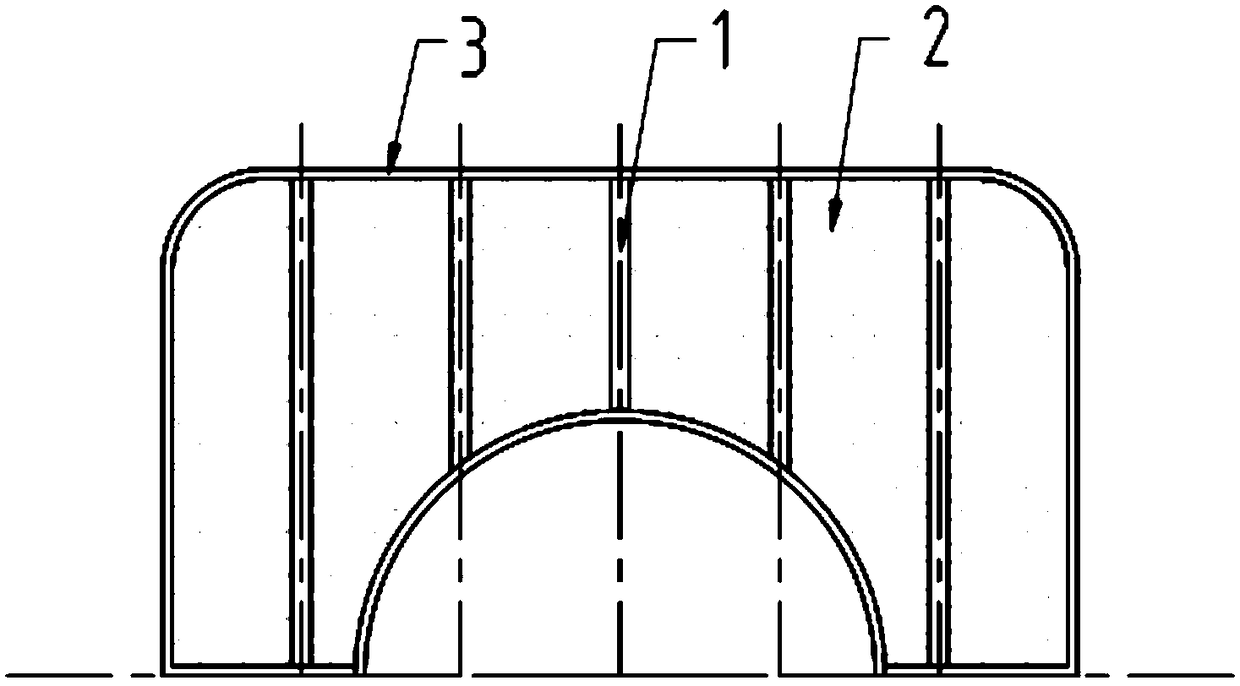

[0057] Such as Figure 1~2 As shown, this embodiment discloses the specific structure of the lightweight composite bullet holder prepared in Example 1, including a bullet holder sandwich structure made by alternately bonding and processing 5 reinforcing ribs 1 and 6 foam boards 2 , and the skin 3 covered on the surface of the bullet holder sandwich structure, the specific materials, dimensions and processing technology are shown in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com