Patents

Literature

146results about How to "Guaranteed structural rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

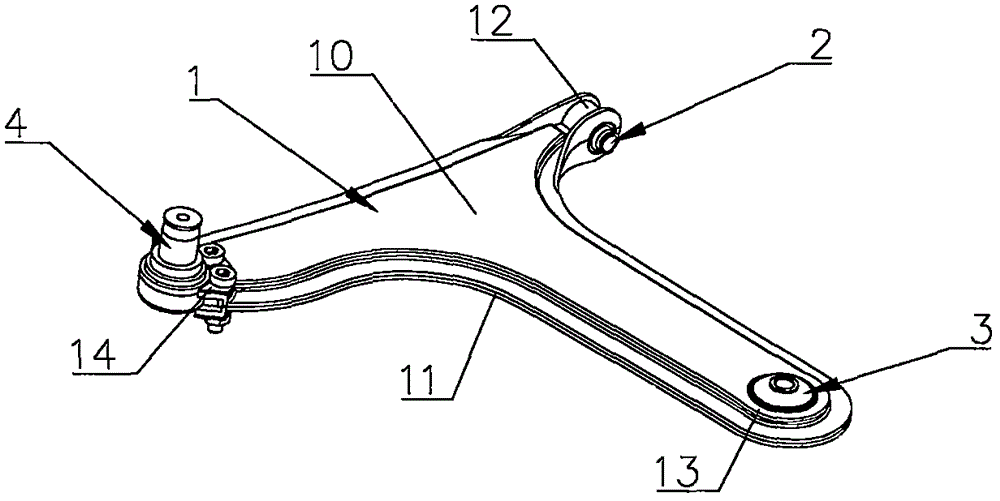

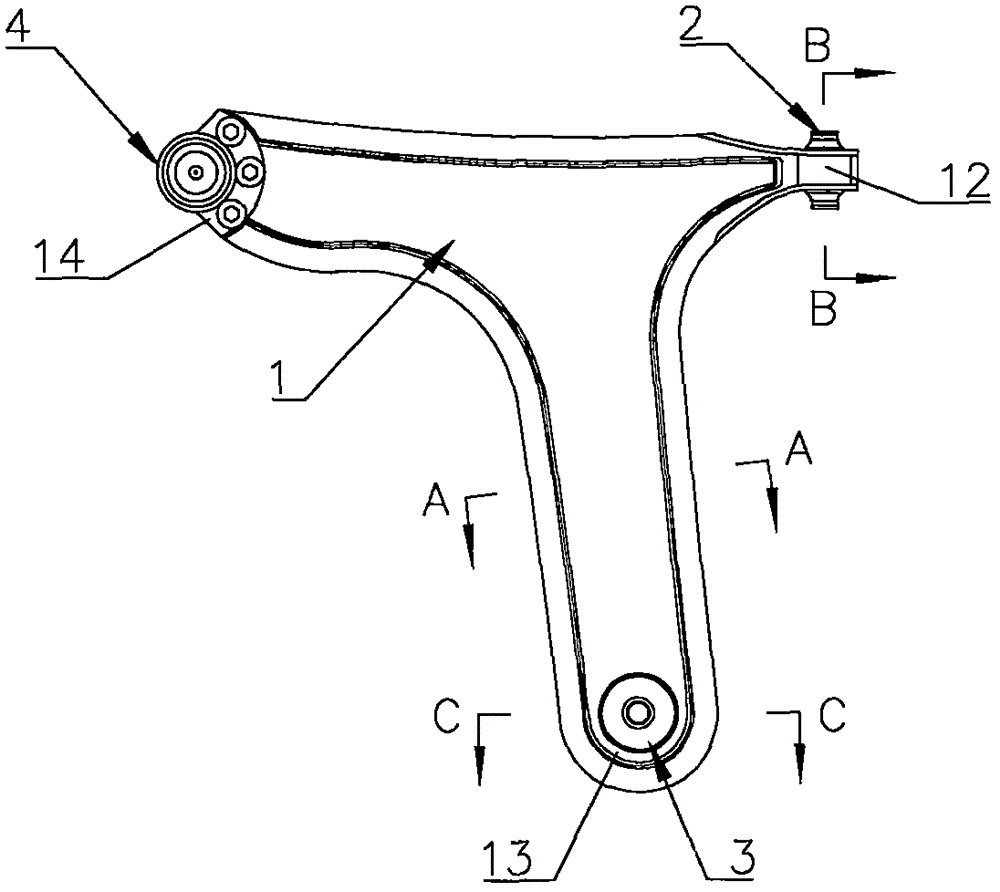

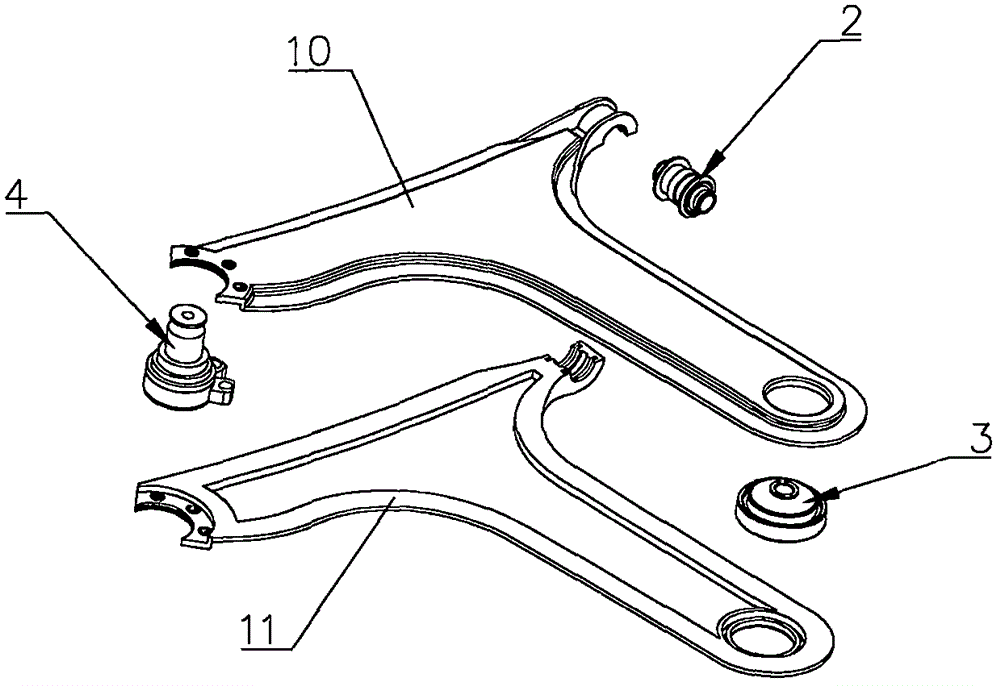

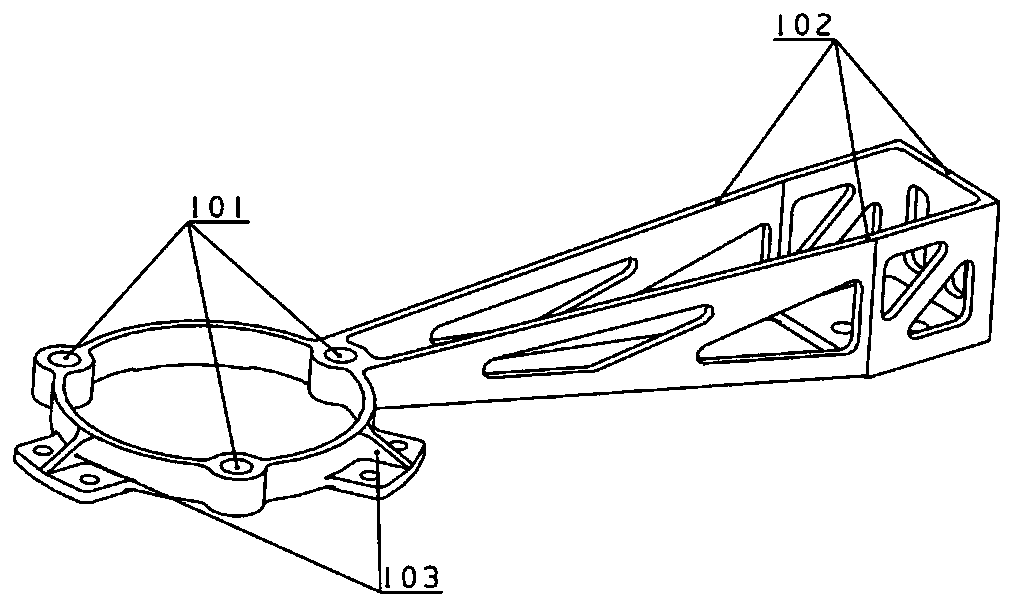

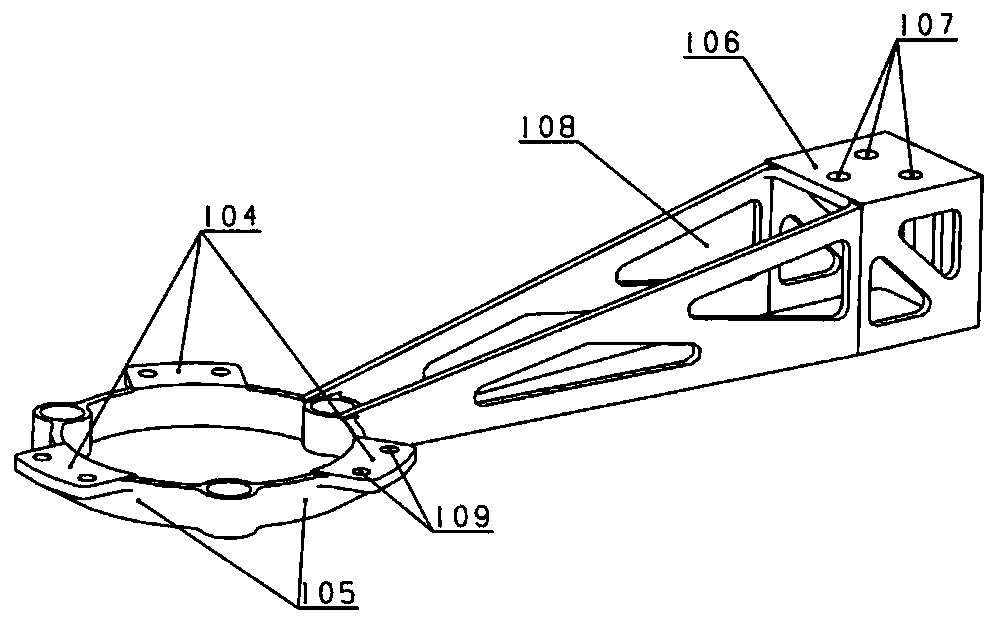

Carbon fiber composite McPherson suspension control arm and preparation method thereof

ActiveCN105730174ALow costGuaranteed structural strengthPivoted suspension armsControl armEngineering

The invention relates to a light-weight suspension system of an automobile, in particular to a carbon fiber composite McPherson suspension control arm. The carbon fiber composite McPherson suspension control arm comprises a control arm body, a first bushing connected with an automobile body, a second bushing connected with a steering knuckle and a ball pin, wherein the control arm body is made of a carbon fiber composite and is hollow in the middle part; a first bushing end on which the first bushing is mounted, a second bushing end on which the second bushing is mounted, and a ball pin end to which the ball pin is connected are respectively arranged on the control arm body. The control arm disclosed by the invention has the advantages of being light in mass, high in intensity, high in impact resistance and the like, and the thickness can be designed, realization of the light weight of automobile parts is facilitated, and the development requirements of a conventional automotive technology for the respects of being energy-saving, environmentally-friendly, safe and the like are met; in addition, the invention further provides a preparation method of the control arm.

Owner:SUN YAT SEN UNIV

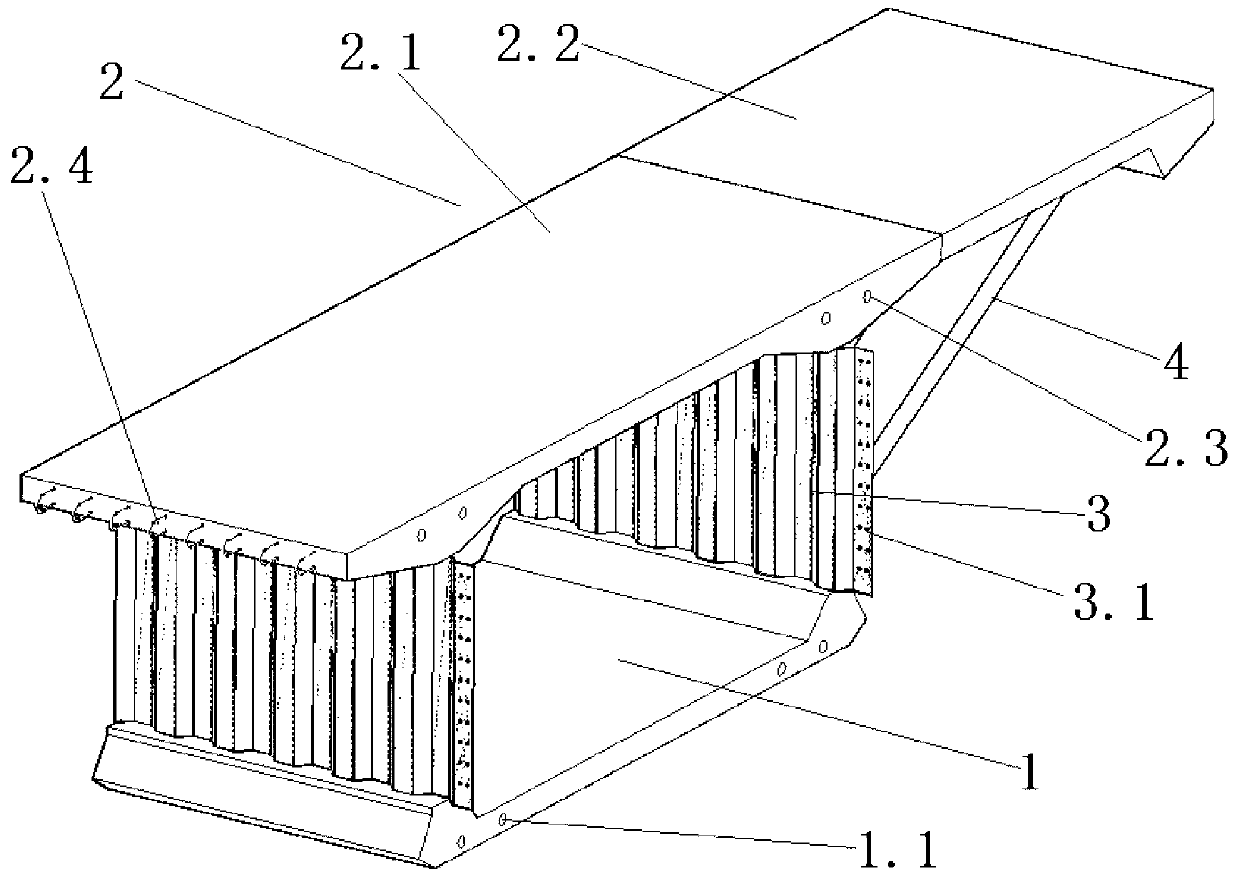

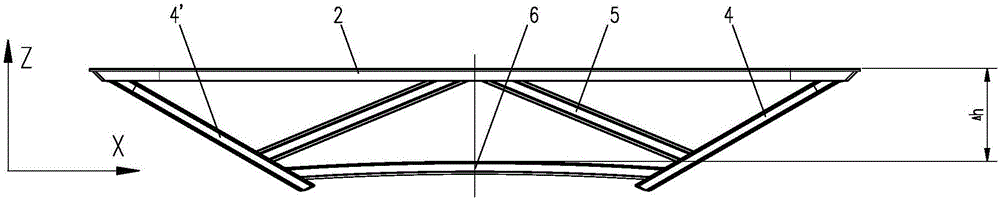

Large-cantilever steel web spinal box beam segment and construction technology

ActiveCN103276662ALow costSmall amount of workBridge structural detailsBridge erection/assemblyPre stressEngineering

The invention discloses a large-cantilever steel web spinal box beam segment and a construction technology. The large-cantilever steel web spinal box beam segment comprises a unit box beam bottom plate and a unit box beam top plate, wherein two steel webs are arranged between the unit box beam bottom plate and the unit box beam top plate, the unit box beam top plate comprises a top plate cross beam arranged in the middle of the unit box beam top plate and wing plates fixedly connected to the two transverse sides of the top plate cross beam, a reinforcing system is arranged between the transverse outer side of each wing plate and the unit box beam bottom plate, a top plate prestressed pore channel is formed in the unit box beam top plate in the longitudinal direction, bolting preformed holes are formed in the two longitudinal ends of each steel web, and a bottom plate prestressed pore channel is formed the unit box beam bottom plate in the longitudinal direction. According to the large-cantilever steel web spinal box beam segment and the construction technology, each component is of a sectional type structure, fractional hoisting can be adopted, the weight of hoisting is light, the requirements for transportation and hoisting equipment are greatly reduced, and construction can be directly finished by means of matching of a conventional truck-mounted crane or a crawler crane and a small-tonnage beam transporting vehicle.

Owner:CCCC SECOND HARBOR ENG

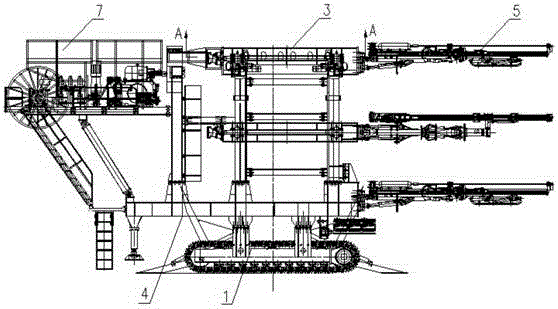

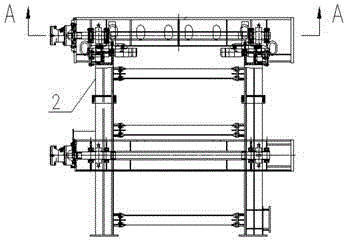

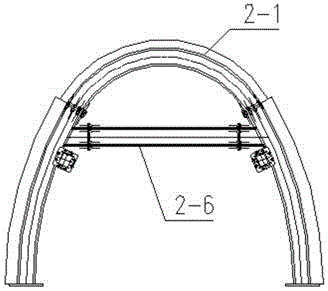

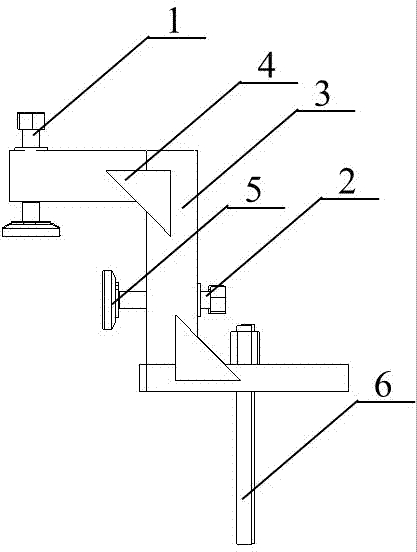

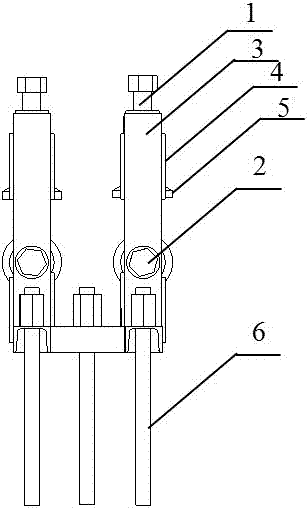

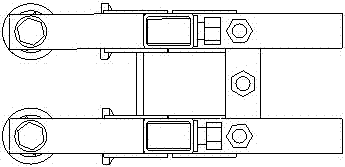

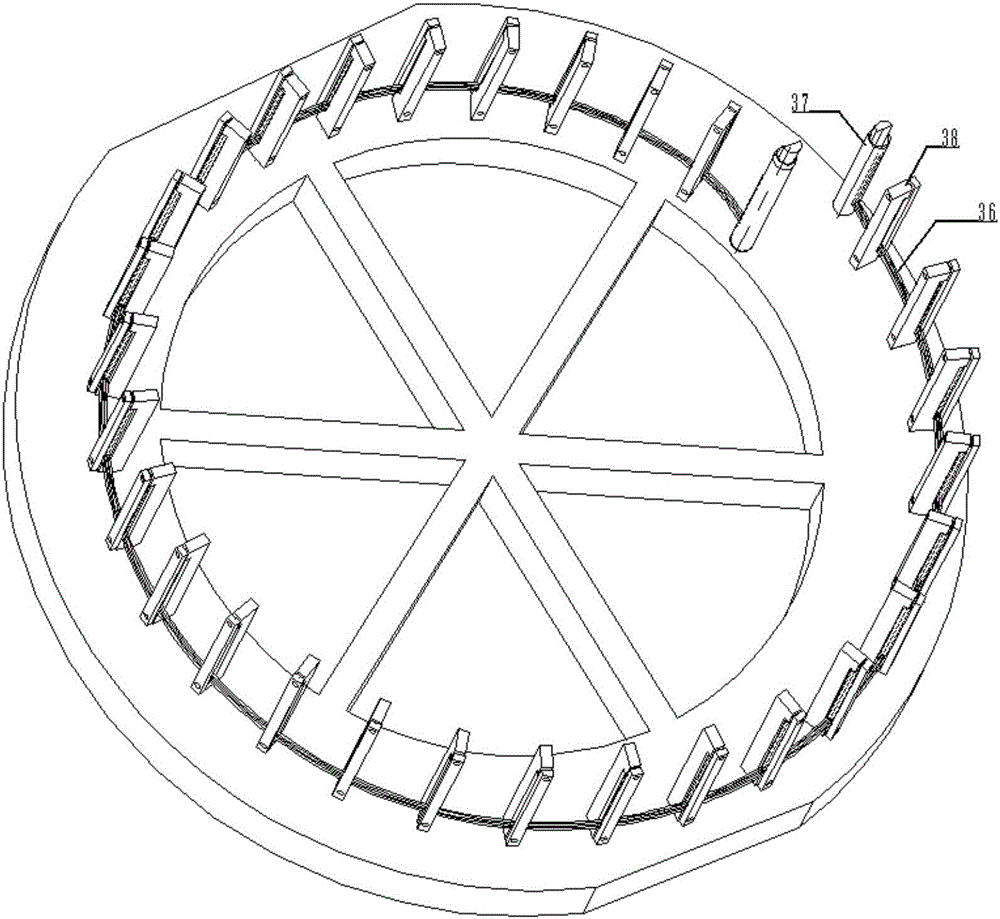

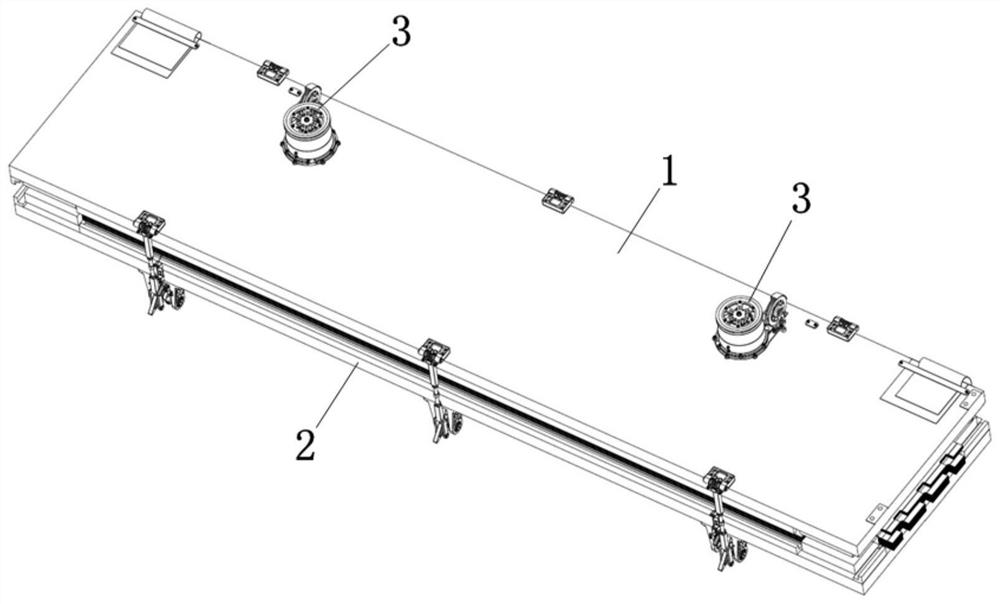

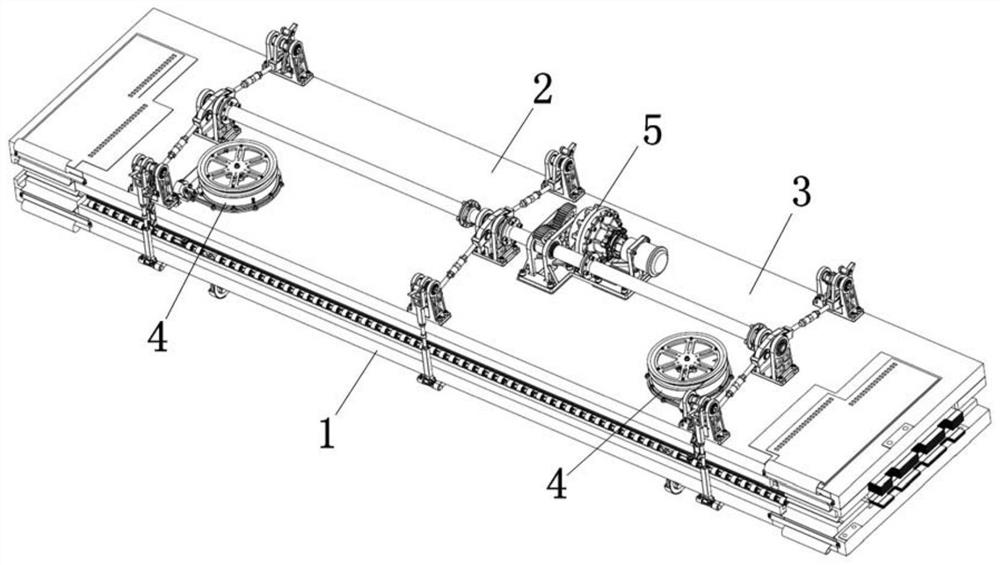

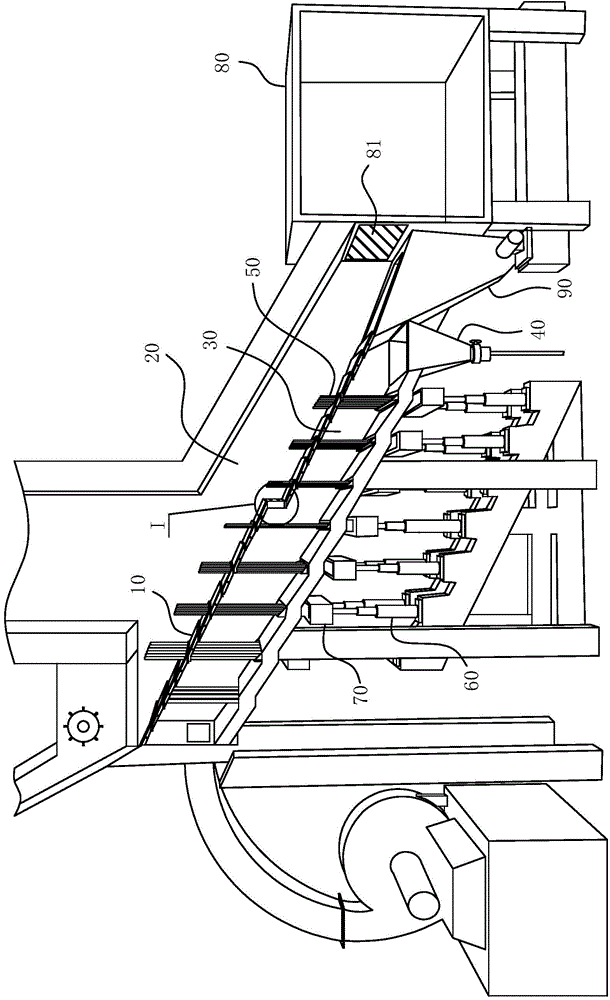

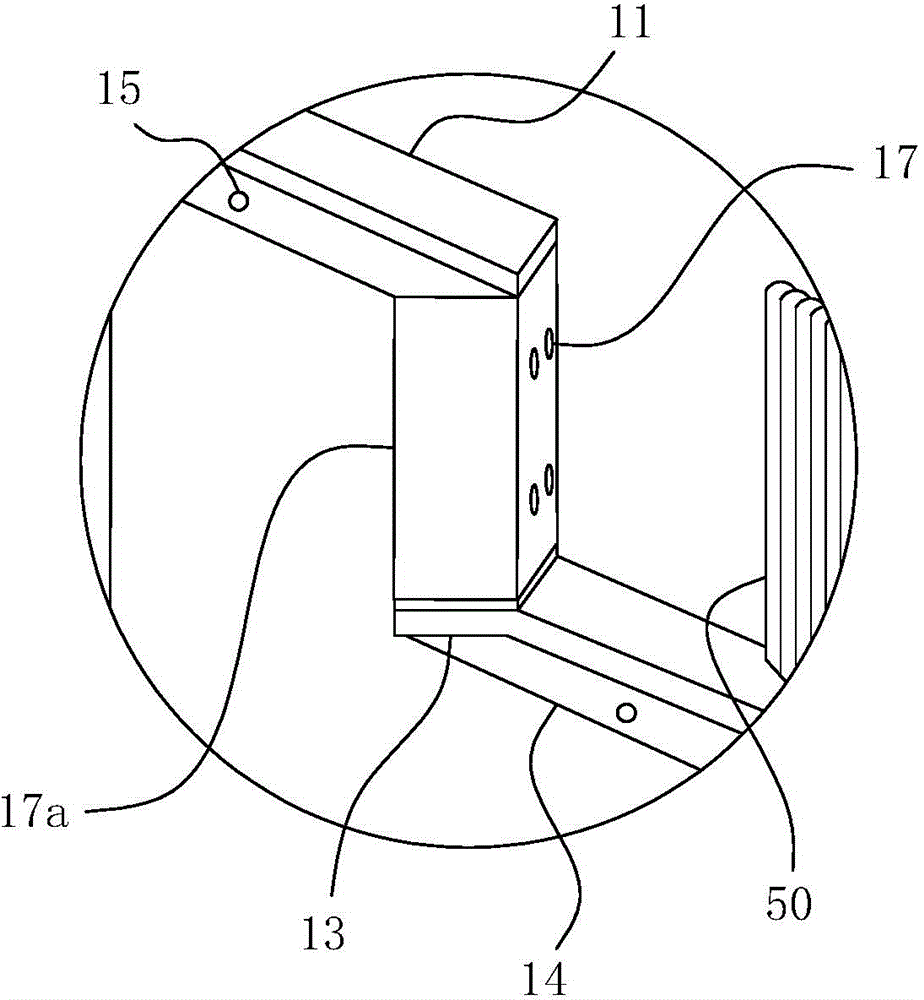

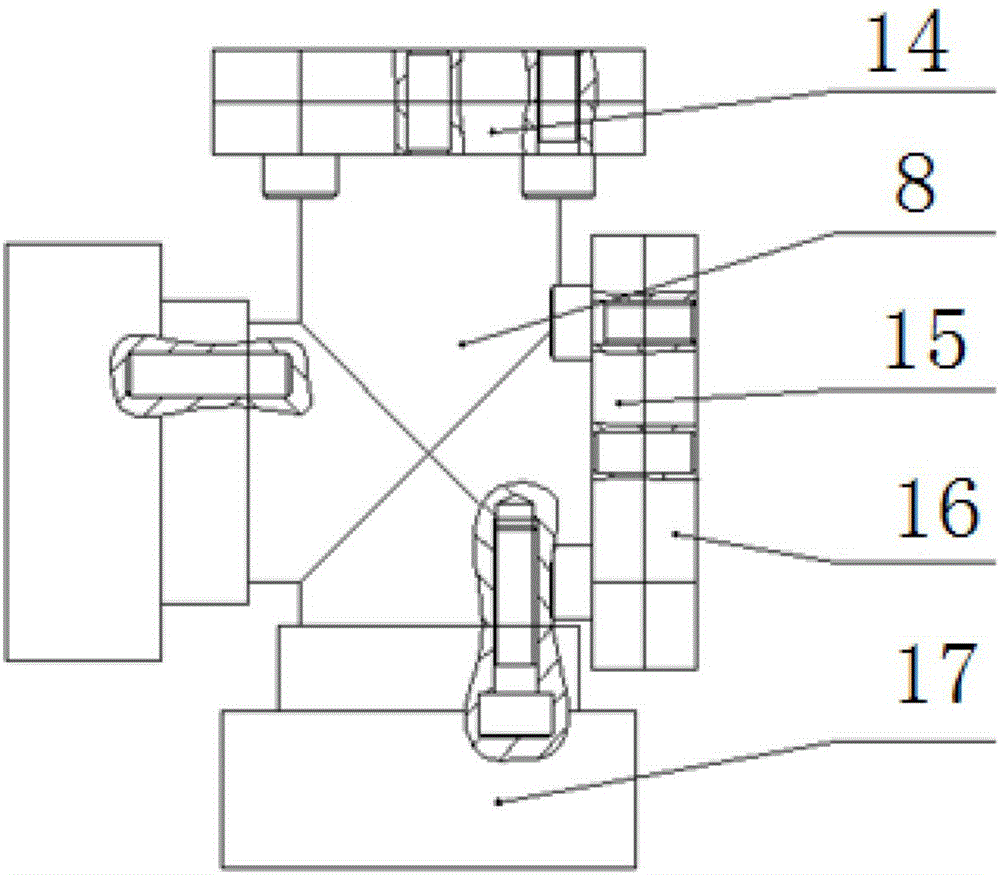

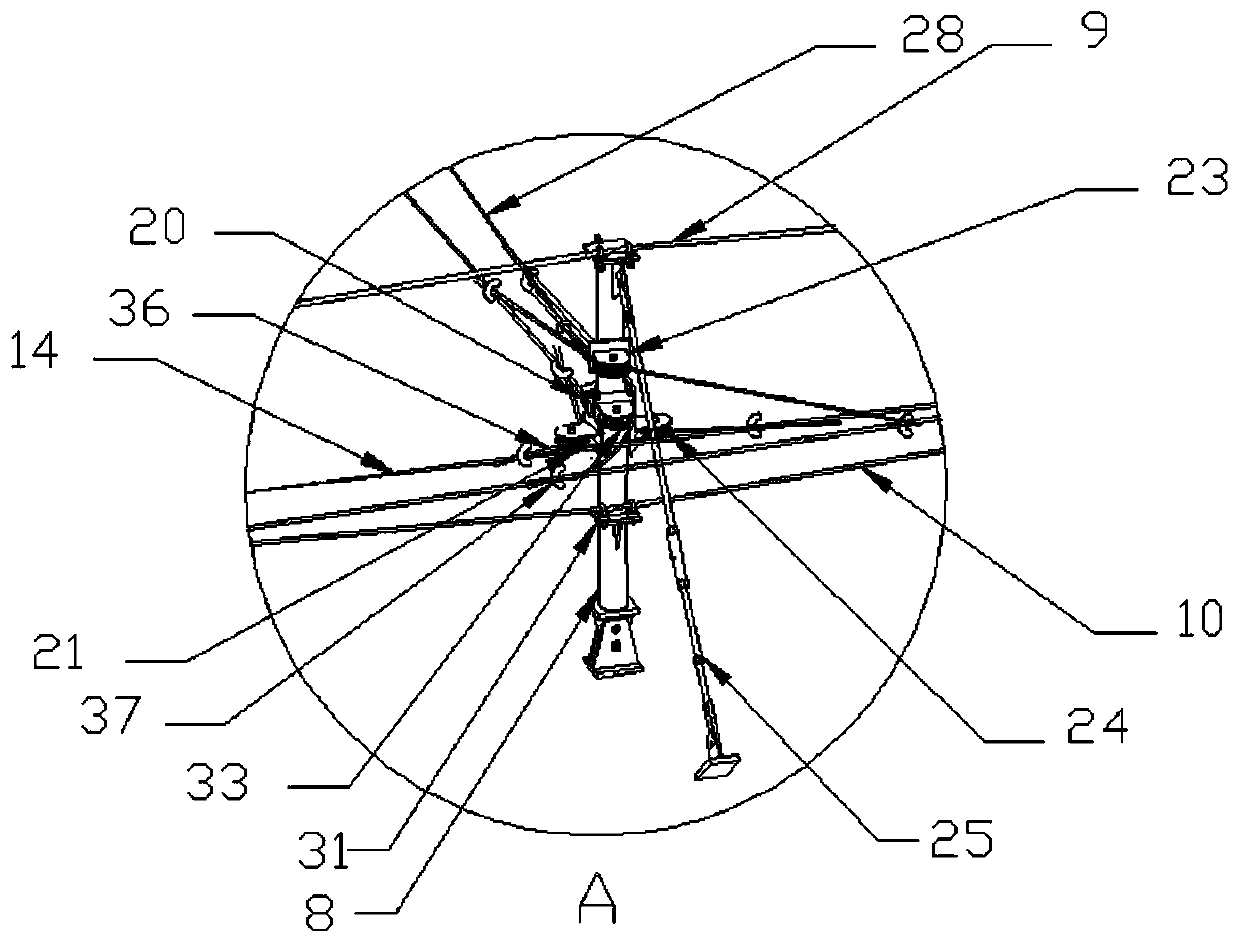

Modularized multifunctional drill jambo system

ActiveCN106437511AGuaranteed structural strengthGuaranteed structural rigidityDerricks/mastsDrilling machines and methodsEngineeringDrill

The invention relates to a modularized multifunctional drill jambo system which at least comprises a track running system, a chassis, a circular track rack, a drilling rig driving device, a hydraulic drilling rig, a rotating operation platform and an electric hydraulic system, wherein the track running system of the jambo is equipped with a walking platform and a foldable turning plate, can meet the vehicle-passing requirement and also can overcome the turning load impact generated in the turning process of the track; the overall shape of the circular track rack of the jambo is similar to the shape of a corresponding tunnel section; the limited space in the tunnel is fully utilized to design the whole vehicle and the vehicle-passing requirement can be met; more shot holes can be covered when the drilling rig driving device relatively runs around the circular track rack; a chassis assembly of the jambo is equipped with a hydraulic stretching support leg capable of adjusting the levelness of the jambo and a rotatable operation platform; the operation platform is arranged, so that the operation platform is supplied to the operator for measuring the marking line close to the tunnel face, filling explosive, and the like.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD +1

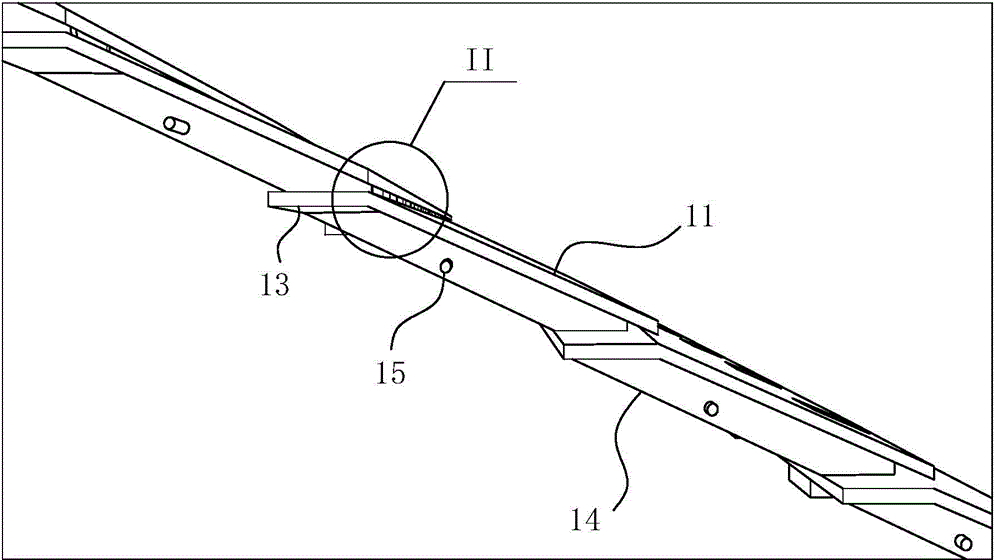

Pressing limiting device and method for slab ballastless track structure

ActiveCN108004855AMeet the needs of compression limitSmall and lightBallastwayStructural engineeringEngineering

The invention discloses a pressing limiting device and method for a slab ballastless track structure, which are used for solving problems of upwarp and warping diseases of the slab ballastless track structure of an operating line, realizing synchronous and integral deviation rectification of the laminated slab ballastless track structure and avoiding the dislocation of the laminated structure andupwarp secondary disease of a track slab in the deviation rectifying process.

Owner:沪杭铁路客运专线股份有限公司 +3

Titanium-alloy special section and its production

ActiveCN101029703AGuaranteed StrengthGuaranteed stiffnessSheets/panelsInvestment castingTitanium alloy

The invention discloses a kind of titanium alloy profile wire. The related tianium alloy profile wire is a board with multilayer titanium alloy hollow structure which involves interlayer with cooling slots. It is made up of the inner scale board with the thickness from 0.3mm to 1.0mm, the outer layer's titanium alloy board with the thickness from 0.3mm to 1.0mm, and the titanium alloy interlayer board with cooling slots between the above mentioned two boards. The molecule infilterating between layers forms a homogeneous matrix with no interface with the thickness from 2.0mm to 10.00mm.The process for manufacturing the board includes following steps: the manufacture of the mould, the preparing and manufacture of the board, installing and molding of the mould with rising temperature, diffusing connection, the first molding, the second molding, cooling and incising process border. It makes use of the technology of combination of SPF and DB, makes application of the technology of the dissolveable screw-demolding core in the investment casting production process. Through twice molding, it accomplishes the processing of the titanium alloy profile wire, makes it the functional material. It provides the aircraft's cabin with the material which has the cooling function under the assurance of the intensity and stiffness. It has a good perspective for its wide application.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

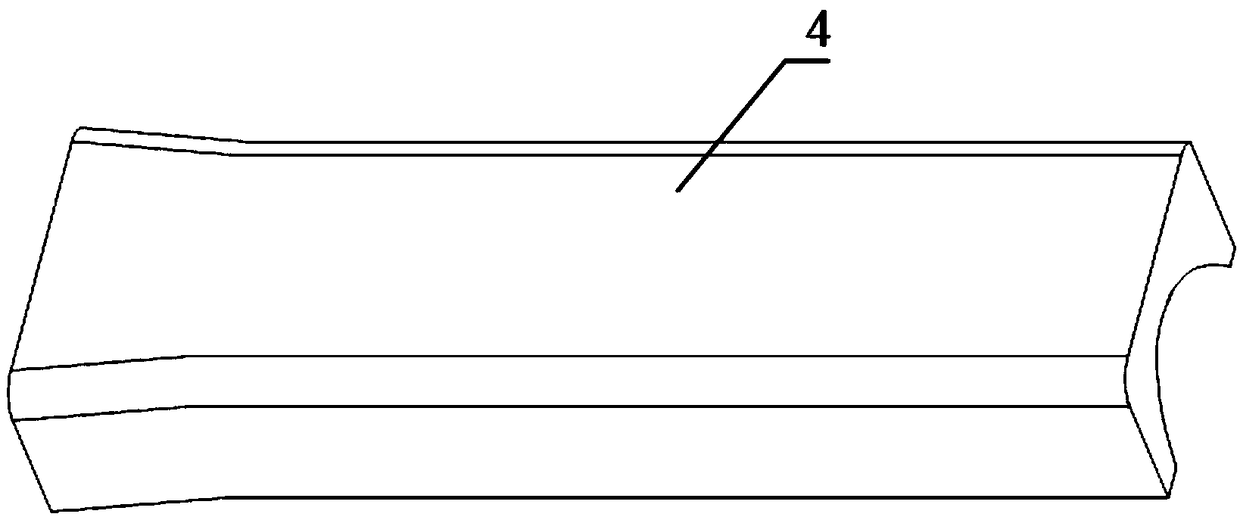

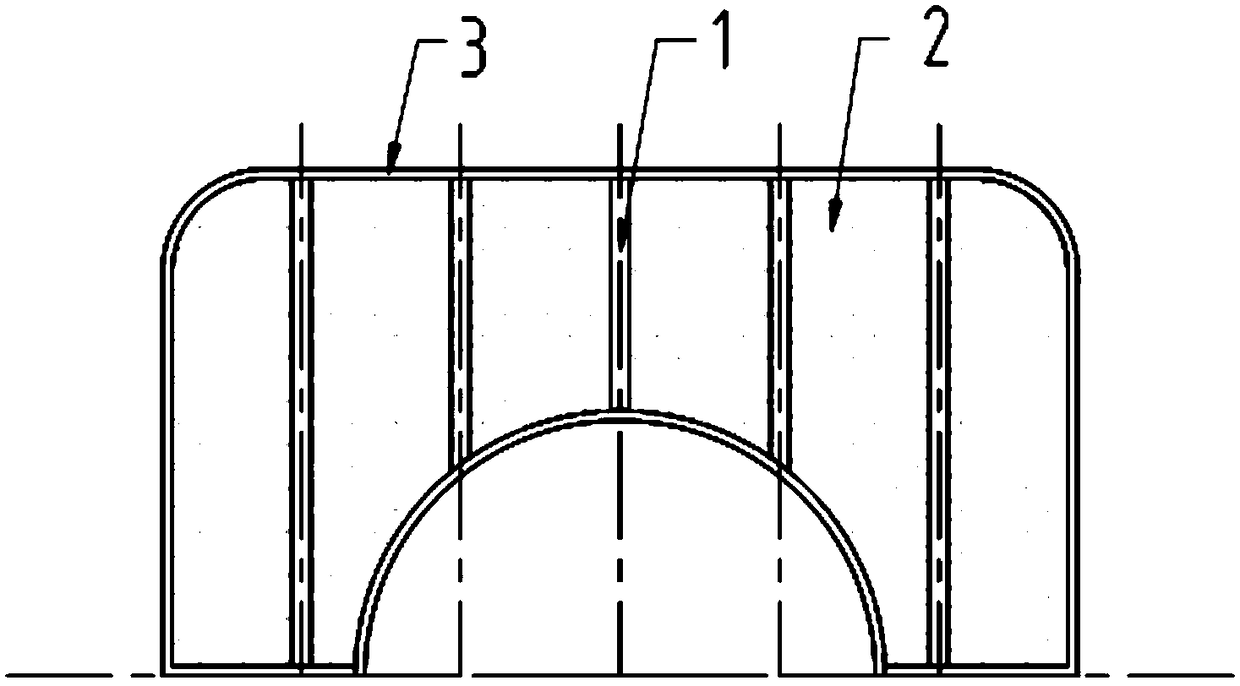

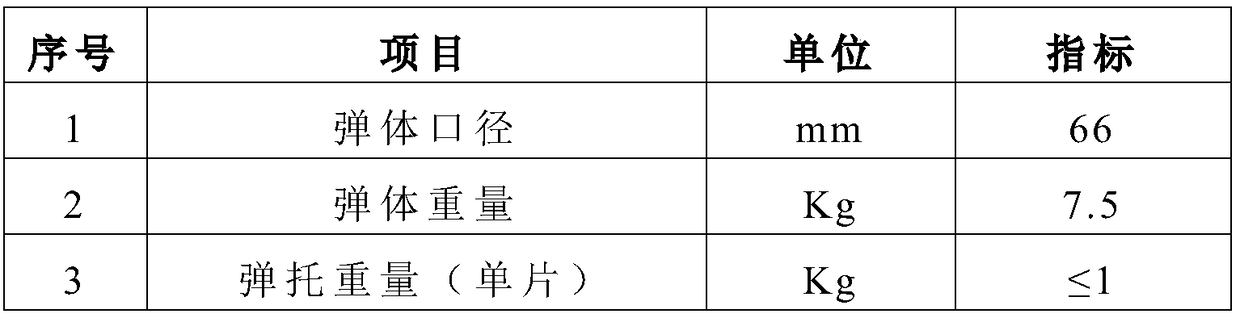

Light composite sabot and manufacturing method thereof

The invention discloses a light composite sabot and a manufacturing method thereof. The light composite sabot comprises a sabot sandwich structure and a skin laying on the surface of the sabot sandwich structure, wherein the sabot sandwich structure is manufactured by alternately bonding and processing n reinforcing ribs and (n+1) foam boards. The manufacturing method comprises the following stepsthat (1) the thickness of the skin, and the thickness and number of the reinforcing ribs and the foam boars are set; (2) the reinforcing ribs are manufactured through fiber materials A in a layer laying mode; (3) the foam boards and the reinforcing ribs are bonded together alternately through adhesives and heat and solidified into a sandwich structure blank board; (4) a sabot sandwich structure with the needed structural size are machined; (5) the skin is manufactured through fiber materials B in a layer laying mode, and the fiber materials B coated with shaping agents are laid on the surfaceof the sabot sandwich structure coated with the adhesives layer by layer, and a preformed body of the sabot is obtained; and (6) product forming is conducted through a resin transfer molding technology, and then the sabot product is obtained. According to the light composite sabot and the manufacturing method thereof, the weight reduction effect is remarkable, under the same using condition, thespeed of ammunitions is higher, and the power of the ammunitions is larger.

Owner:湖北三江航天江北机械工程有限公司

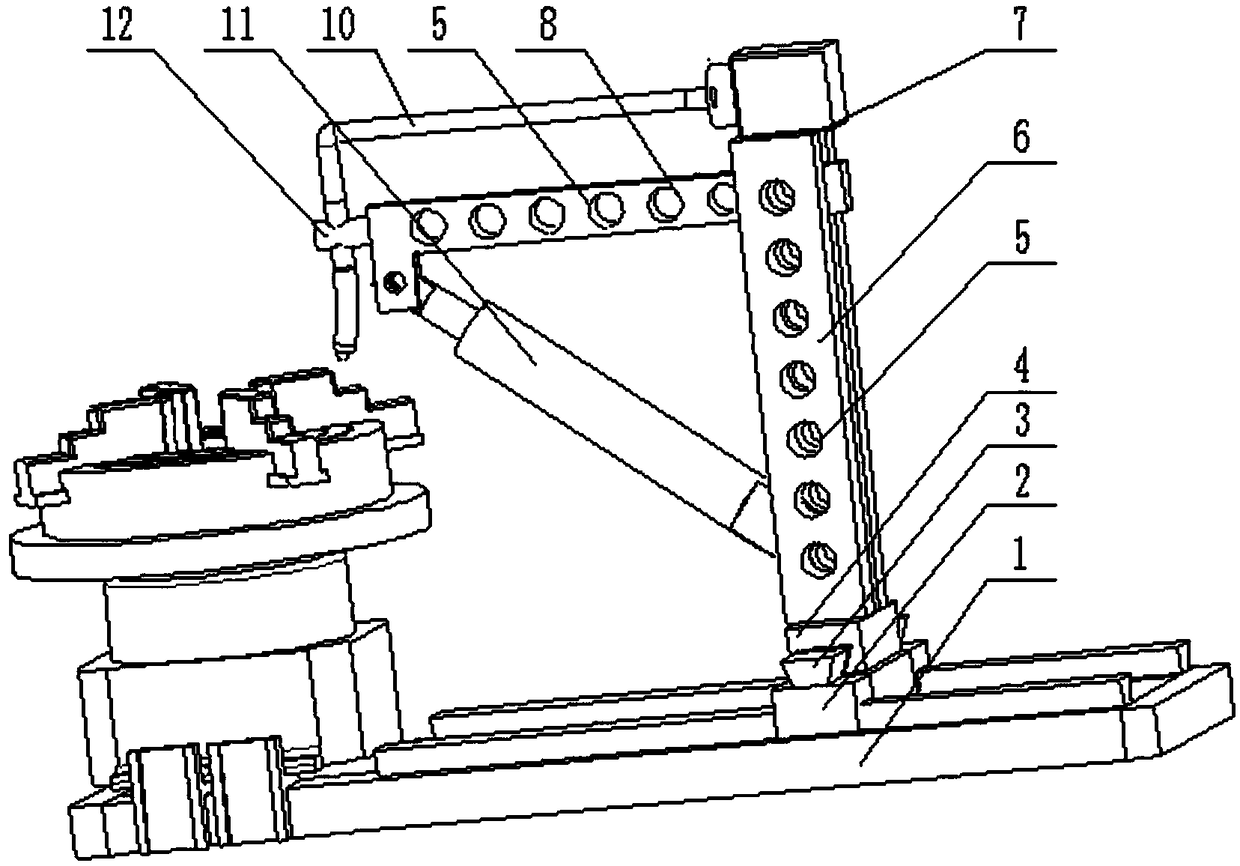

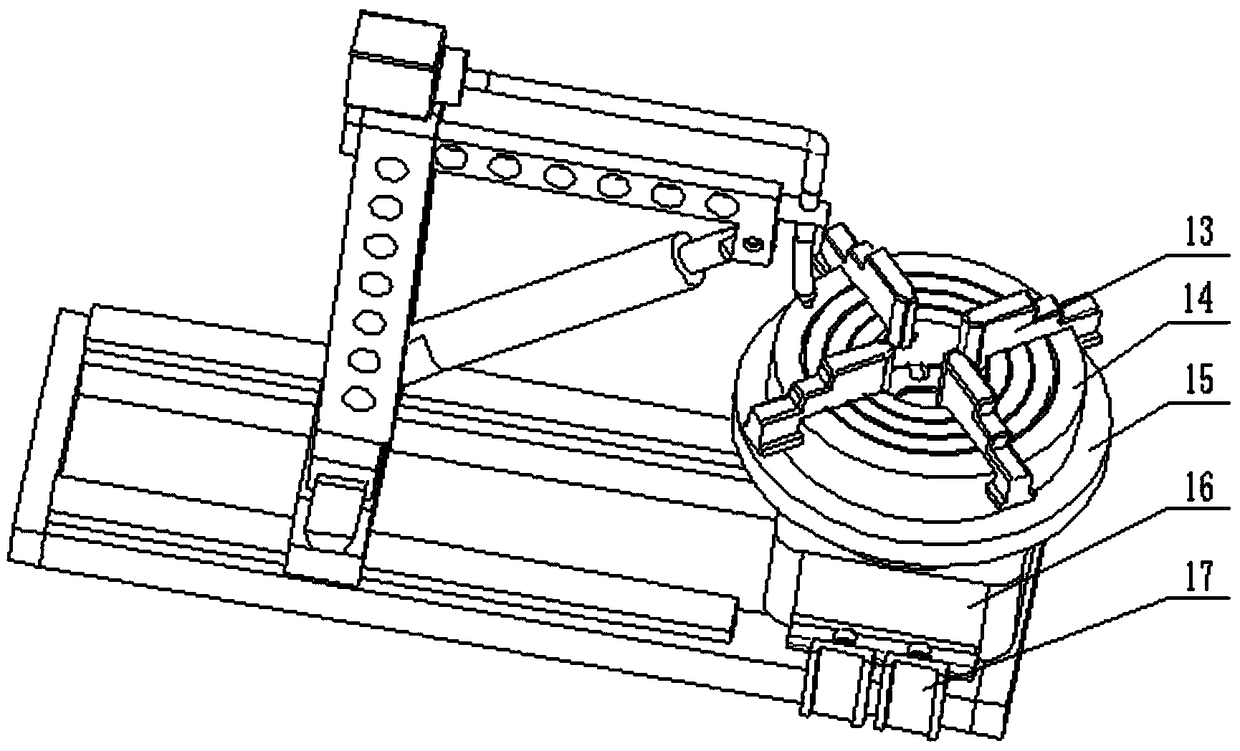

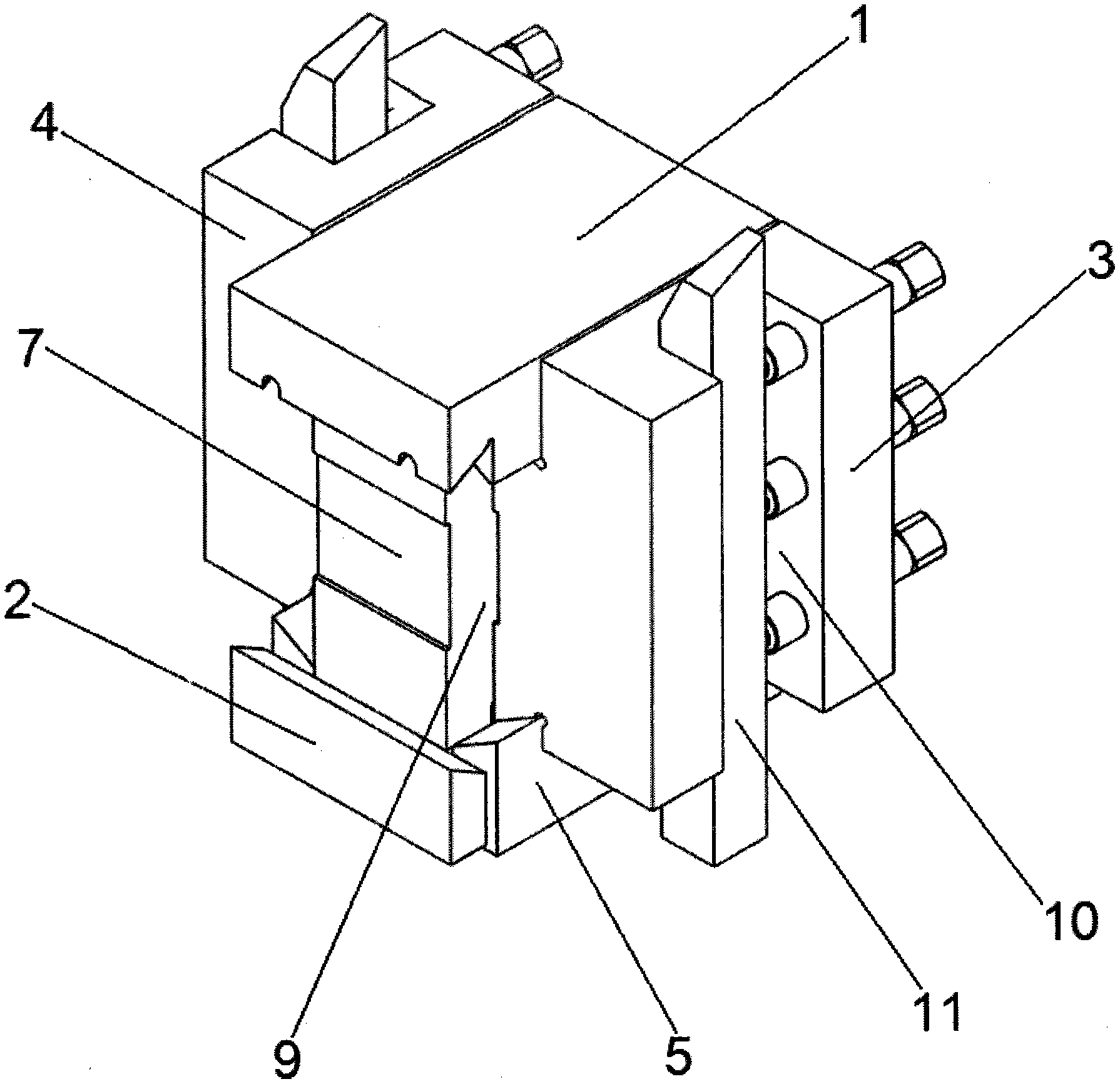

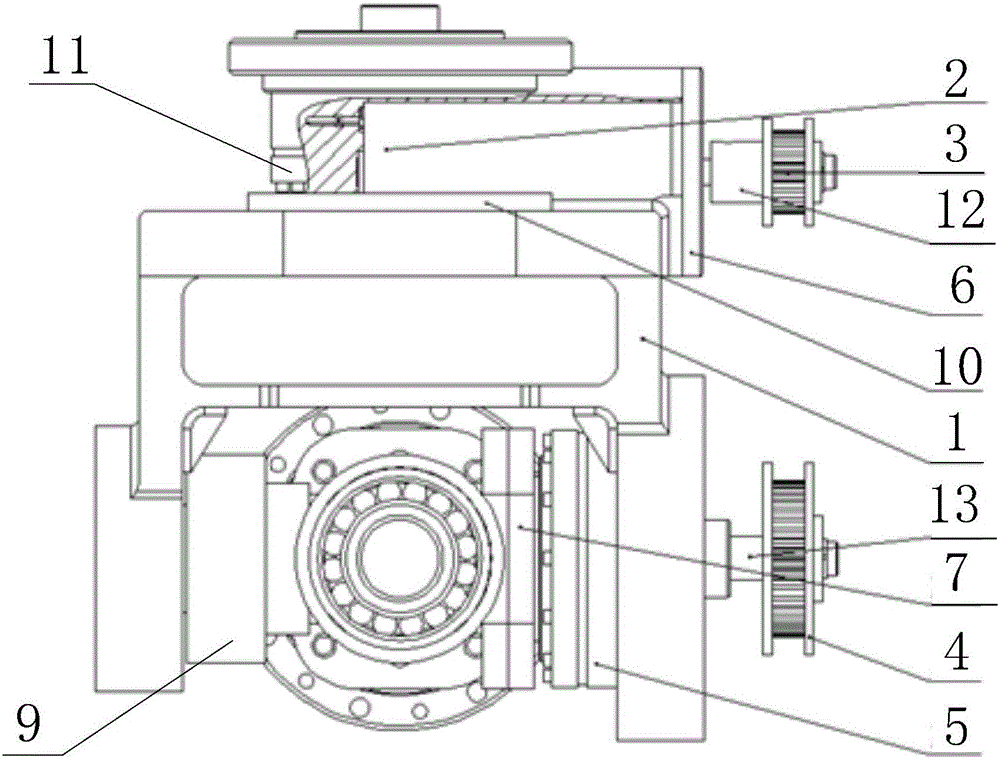

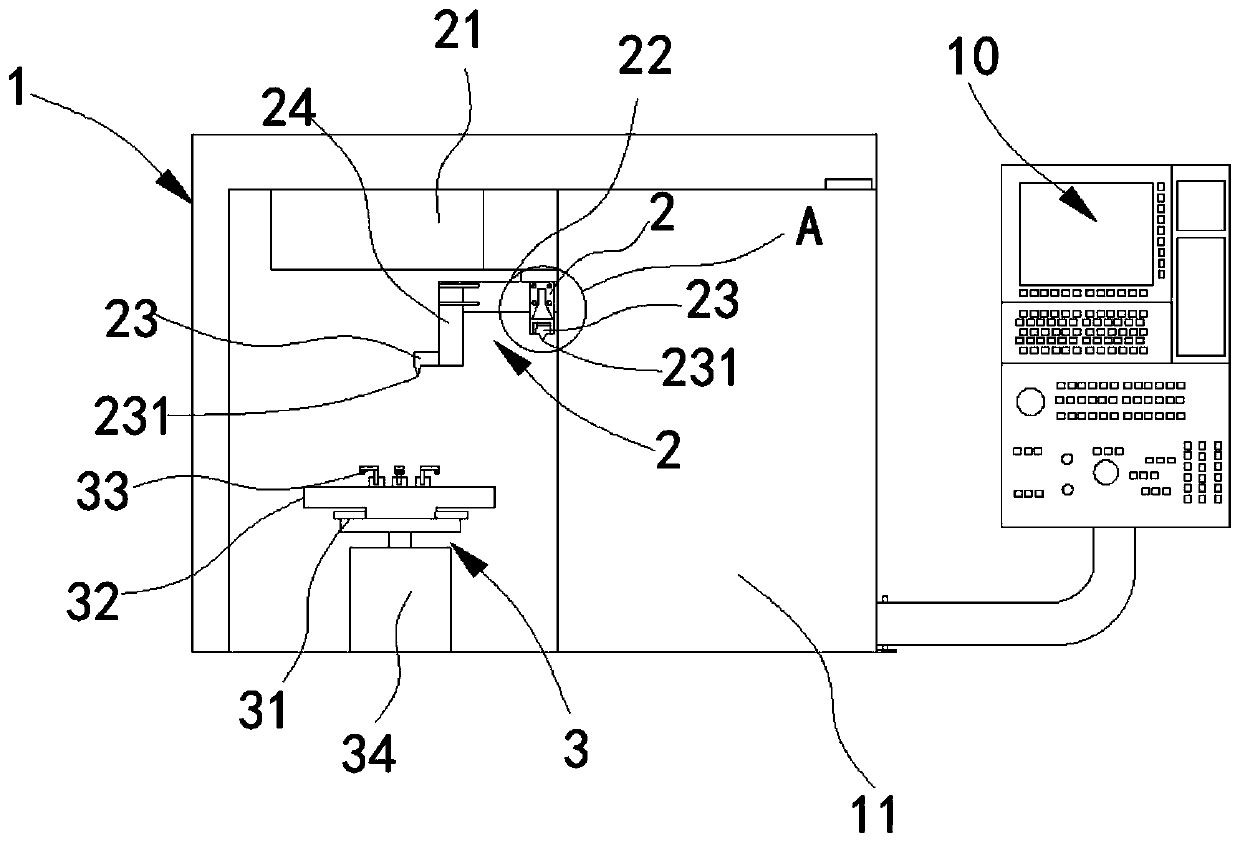

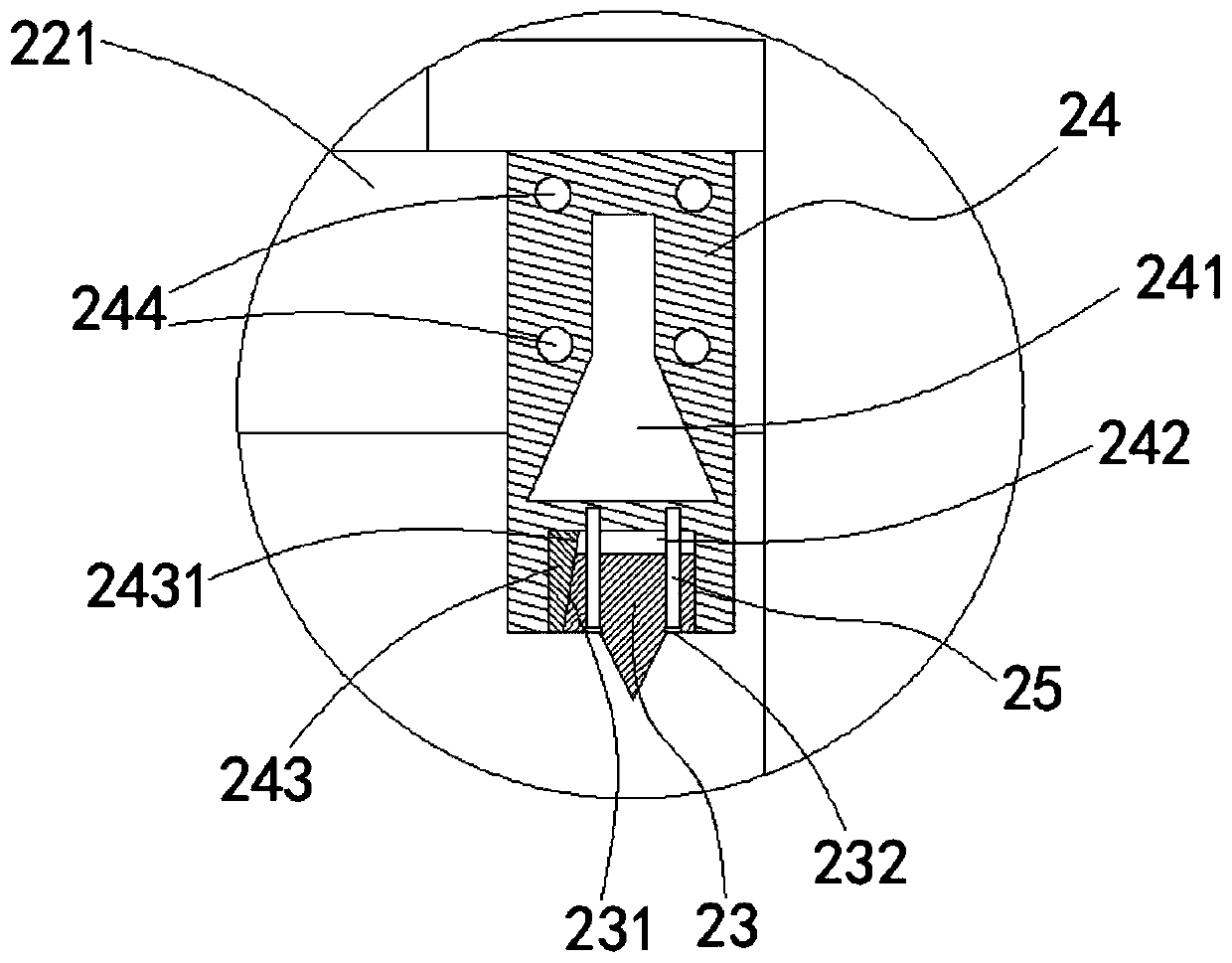

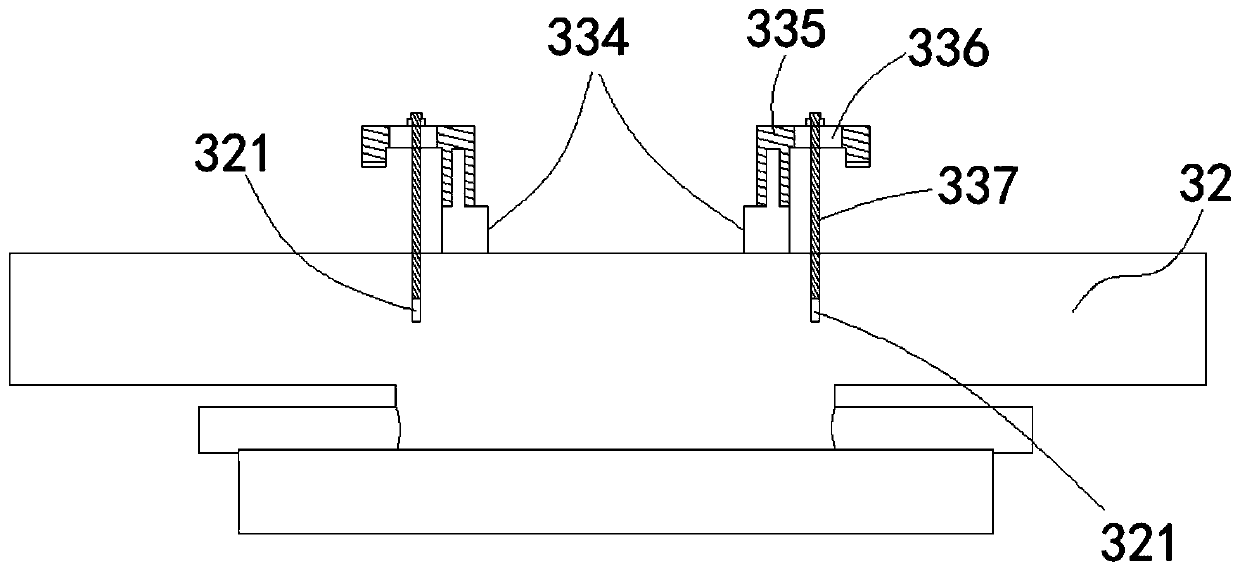

Precise positioning and welding system for cutting teeth of cutting head of heading machine and welding method thereof

ActiveCN109048147AChange angle of liftGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderControl system

The invention discloses a precise positioning and welding system for cutting teeth of a cutting head of a heading machine and a welding method thereof. The system comprises a first guide rail; one endof the first guide rail is fixedly connected with a support device for supporting and fixing the cutting head of the heading machine; an adjustable bracket capable of sliding in the length directionof the first guide rail is arranged at the other end of the first guide rail; and a welding gun for welding the cutting teeth of the cutting head of the heading machine is mounted on the adjustable bracket. The system controls a rotating motor connecting chuck to drive the cutting head to rotate; through sliding of a slide block on the corresponding guide rail, the distance from the welding gun toa cutting tooth base is controlled; a control system controls the oil inlet quantity and the oil outlet quantity of a hydraulic cylinder to guarantee extension of an extension rod, so that a liftingangle of the welding gun is changed, and the welding of the cutting teeth with different angles is realized; the connection between each cutting tooth and the cutting tooth base is controlled by the control system; and through movement and rotation of corresponding parts, no deviation is generated in any angle direction, so that the precise positioning is guaranteed, and the errors are reduced tothe greatest extent.

Owner:SHANDONG UNIV OF SCI & TECH

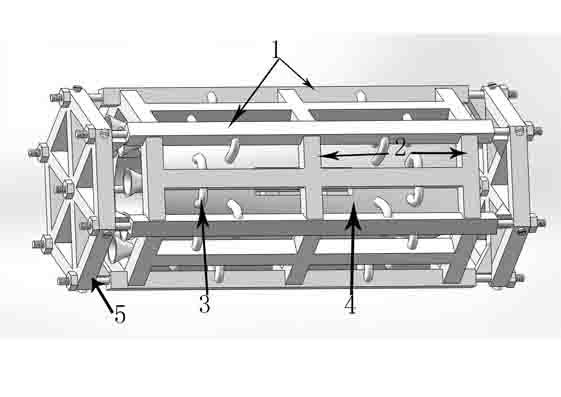

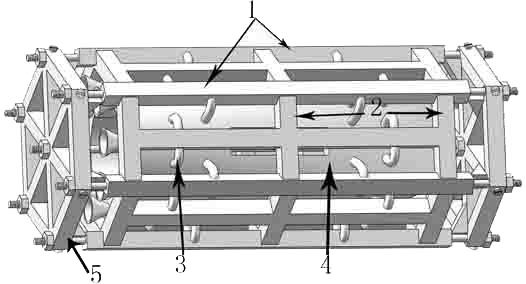

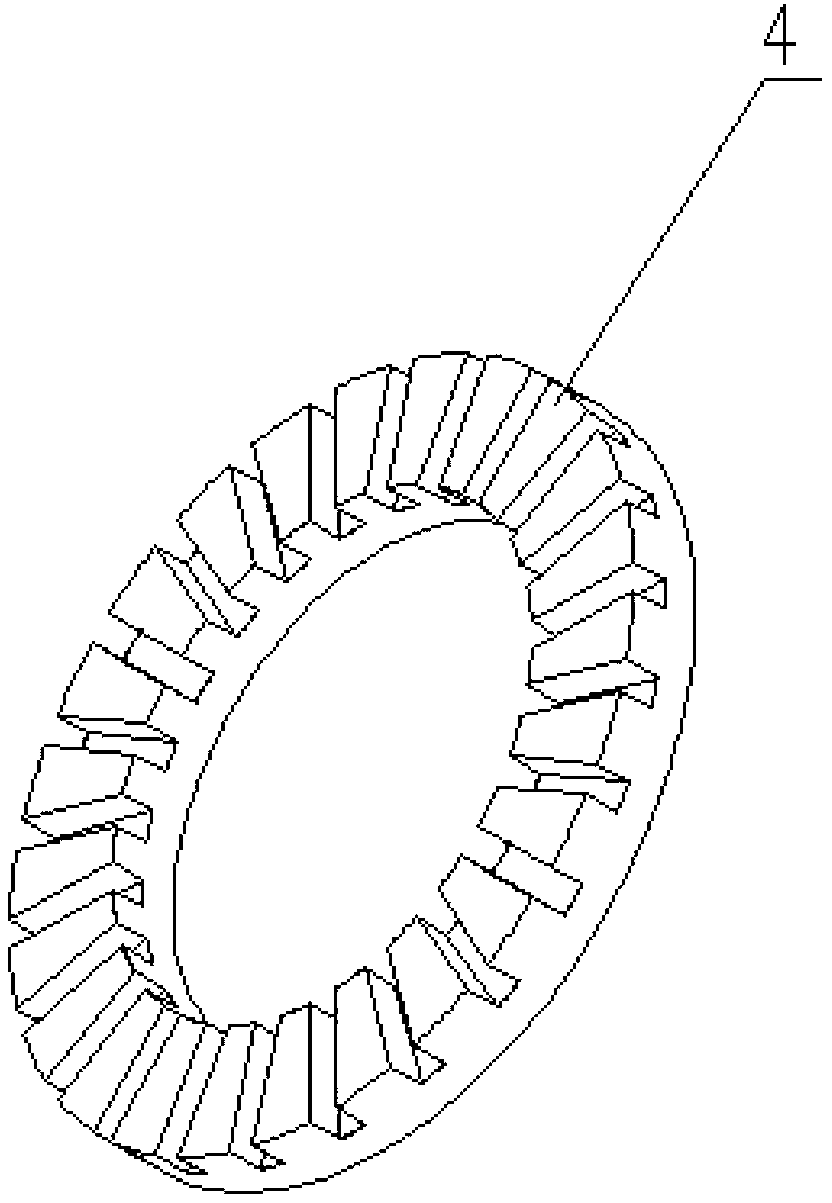

Squirrel-cage shell load bearing structure integrated with runner film tire

ActiveCN102658355ANo deformationGuaranteed structural strengthFoundry mouldsFoundry coresMechanical engineeringPrecision casting

The invention discloses a squirrel-cage load bearing structure integrated with a runner film tire in a fusible pattern precision cast shell manufacturing process. The squirrel-cage load bearing structure comprises an embedded primary-secondary runner film tire 1, a transverse runner film tire 2, an inner runner film tire 3 and a bracket 5, wherein the primary-secondary runner film tire is a main shell load bearing member, passes through the bottom of a runner, is connected with the transverse runner film tire in a wax welding way, and is tightly fixed on the bracket, so that a squirrel-cage structure is formed; and the primary-secondary runner film tire, the transverse runner film tire and a wax pattern 4 are connected together by using the inner runner film tire (inner water port shape) in a wax welding way. Due to the adoption of the structure, load bearing in the shell manufacturing process of ultra-conventional large-sized and super large-sized shells is realized, the size is up to 600mm*600mm*1800mm or even larger, the weight is up to hundreds of kilograms or even certain tons, the structural strength and stiffness can be ensured effectively, a pouring system and the wax pattern are prevented from being broken and deformed and are convenient to move, rotate and place, and convenience is brought to shell manufacturing operation of workers.

Owner:SUS LAB FOR IND SCI & TECH

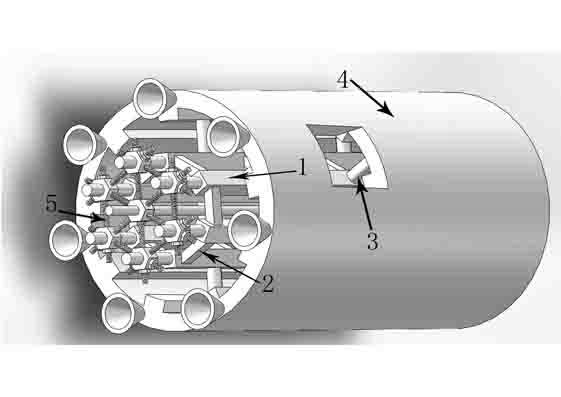

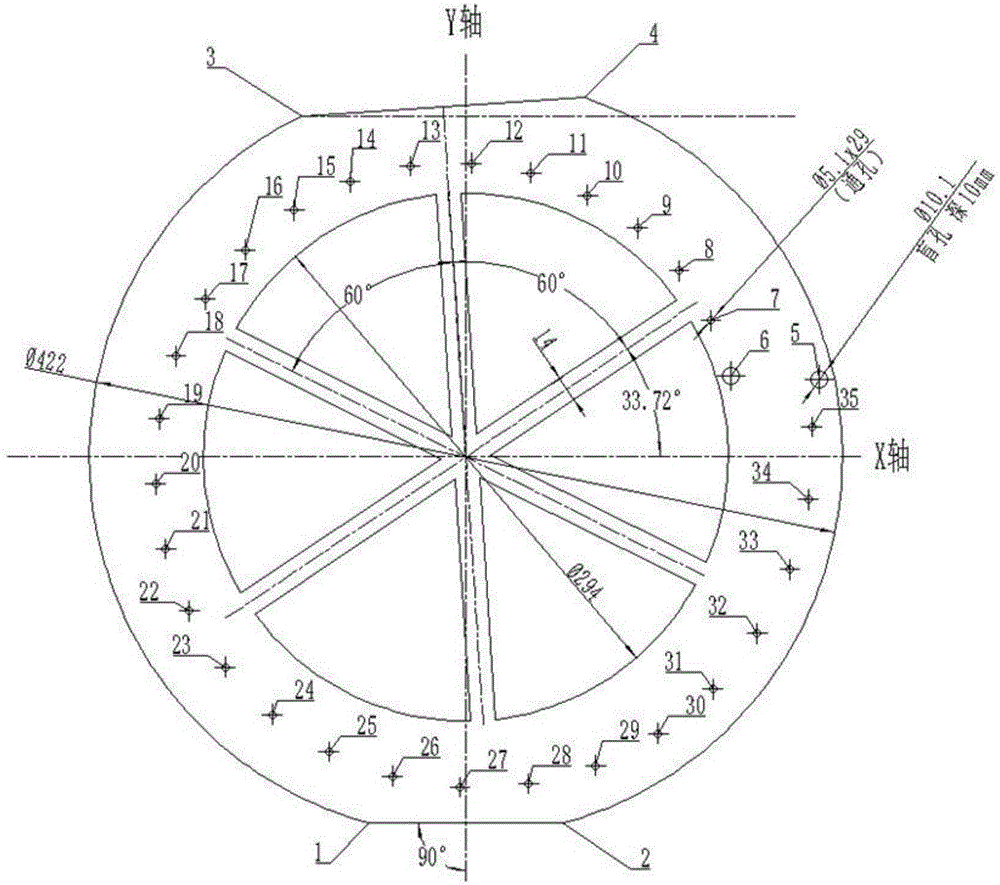

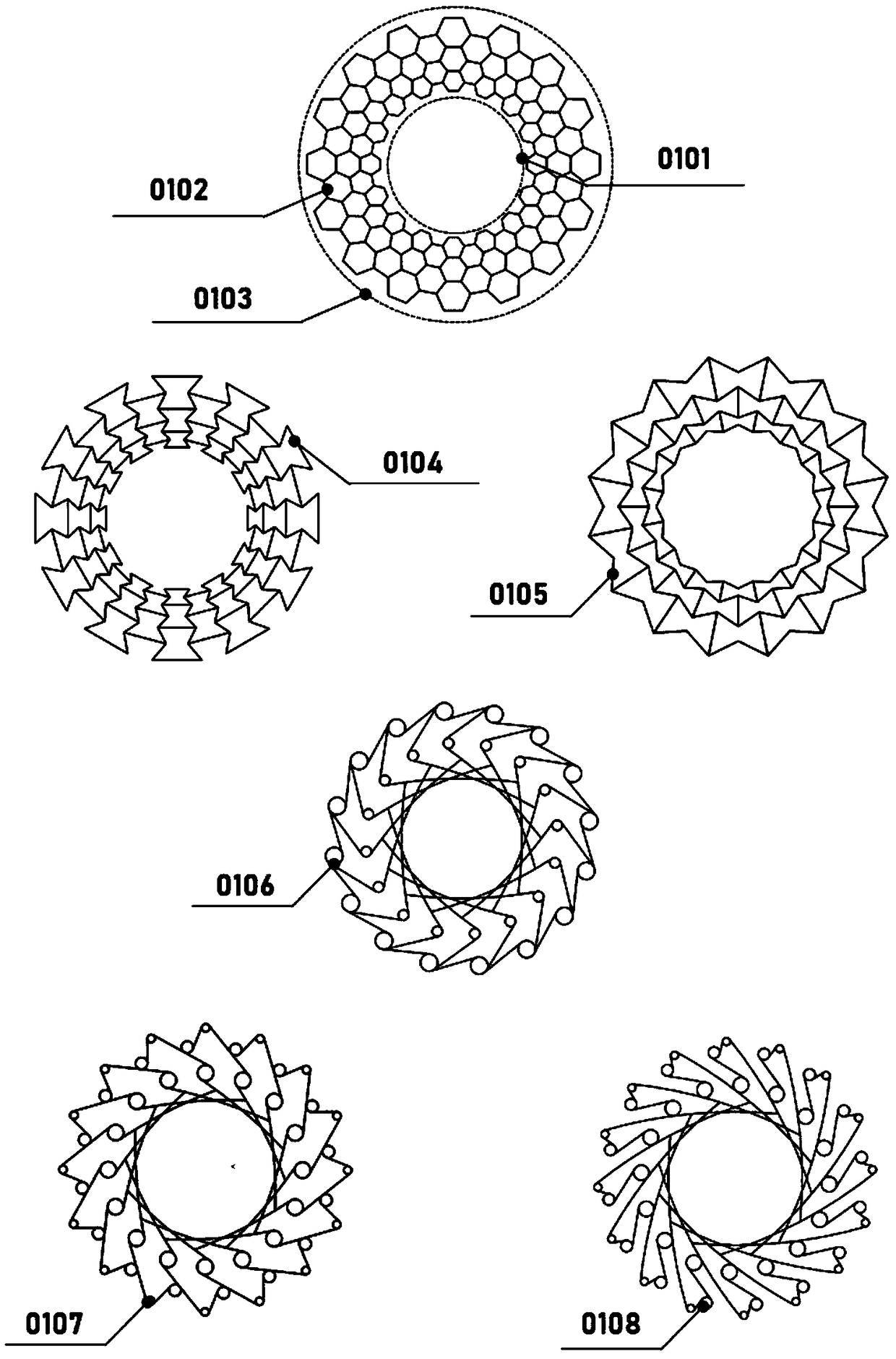

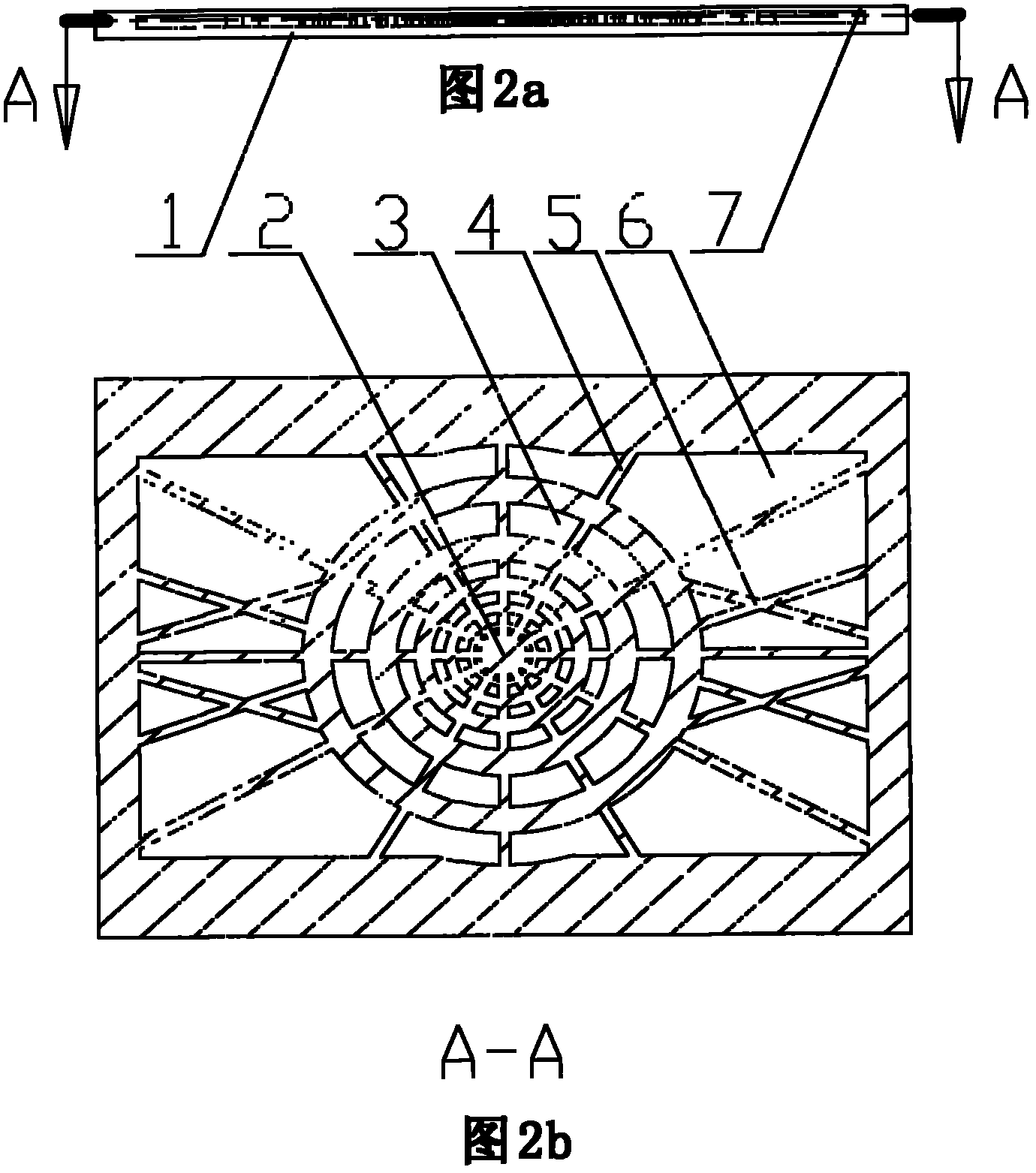

Supporting disk for soldering tool clamp of micro-diameter thin-walled tube of heat exchanger

ActiveCN106392246APrecise positioningGuaranteed positioningHeat exchange apparatusMetal working apparatusPlate heat exchangerEngineering

Provided is a supporting disk for a soldering tool clamp of a micro-diameter thin-walled tube of a heat exchanger. As for the main structure, the supporting disk is in a spoke wheel disk shape. The supporting disk comprises round positioning holes distributed in a spiral mode, round diode mounting holes and two positioning planes. The supporting disk is formed by carrying out cutting and drilling on a panel part. Firstly, the boundary dimension of the disk is obtained through machining, specifically, an internal ring, an external ring and a spoke wheel in the middle are included, and the axis of the disk is determined as the origin of coordinates; then the twenty-nine through holes are evenly distributed along the spiral central axis of the micro-diameter thin-walled tube in the thickness direction of the disk; the two blind holes for mounting of diodes are obtained in the thickness direction of the disk through machining; and finally, the two positioning planes are formed on the upper portion and the lower portion of the disk through cutting. According to the supporting disk, the structure is simple, manufacturability is good, structure rigidity of the integral disk can be ensured, and the structure weight can be lowered.

Owner:BEIHANG UNIV

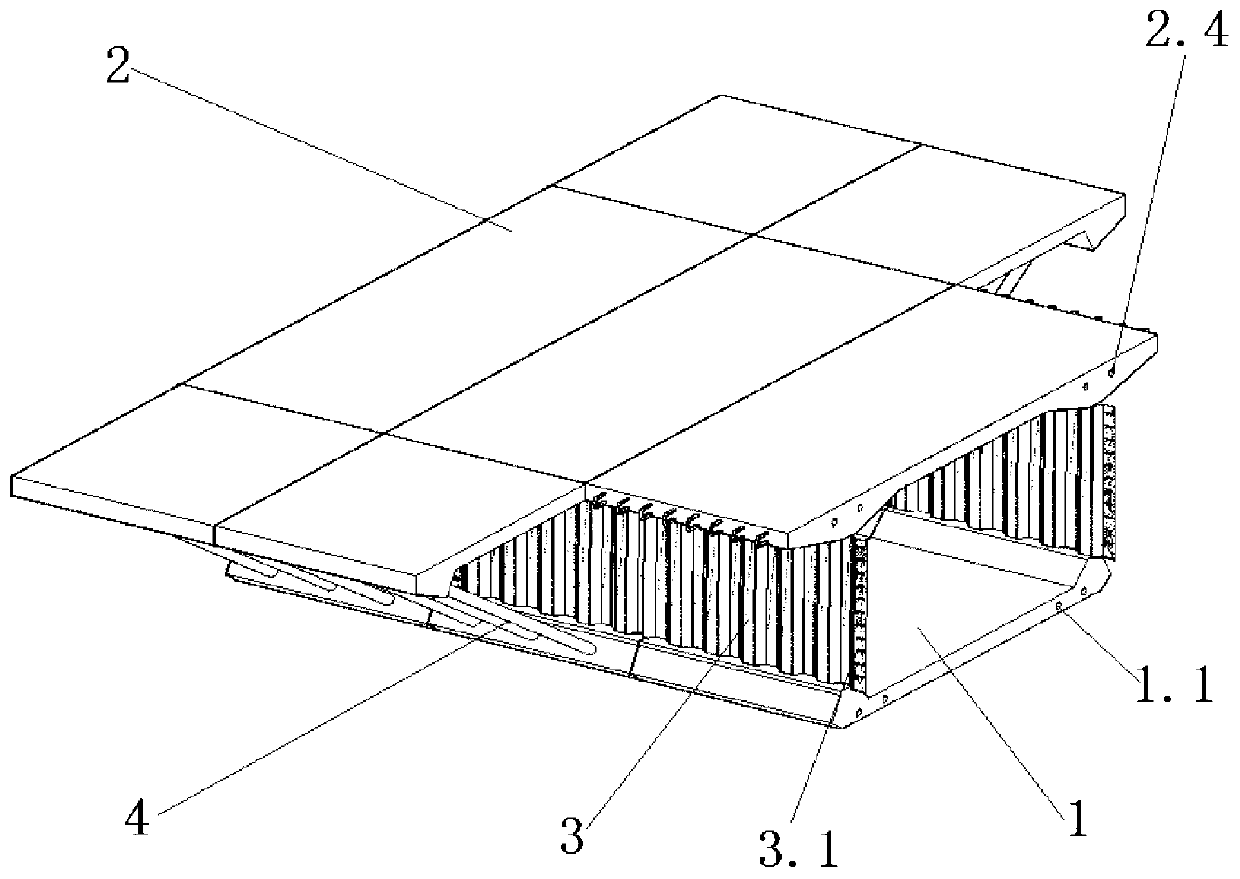

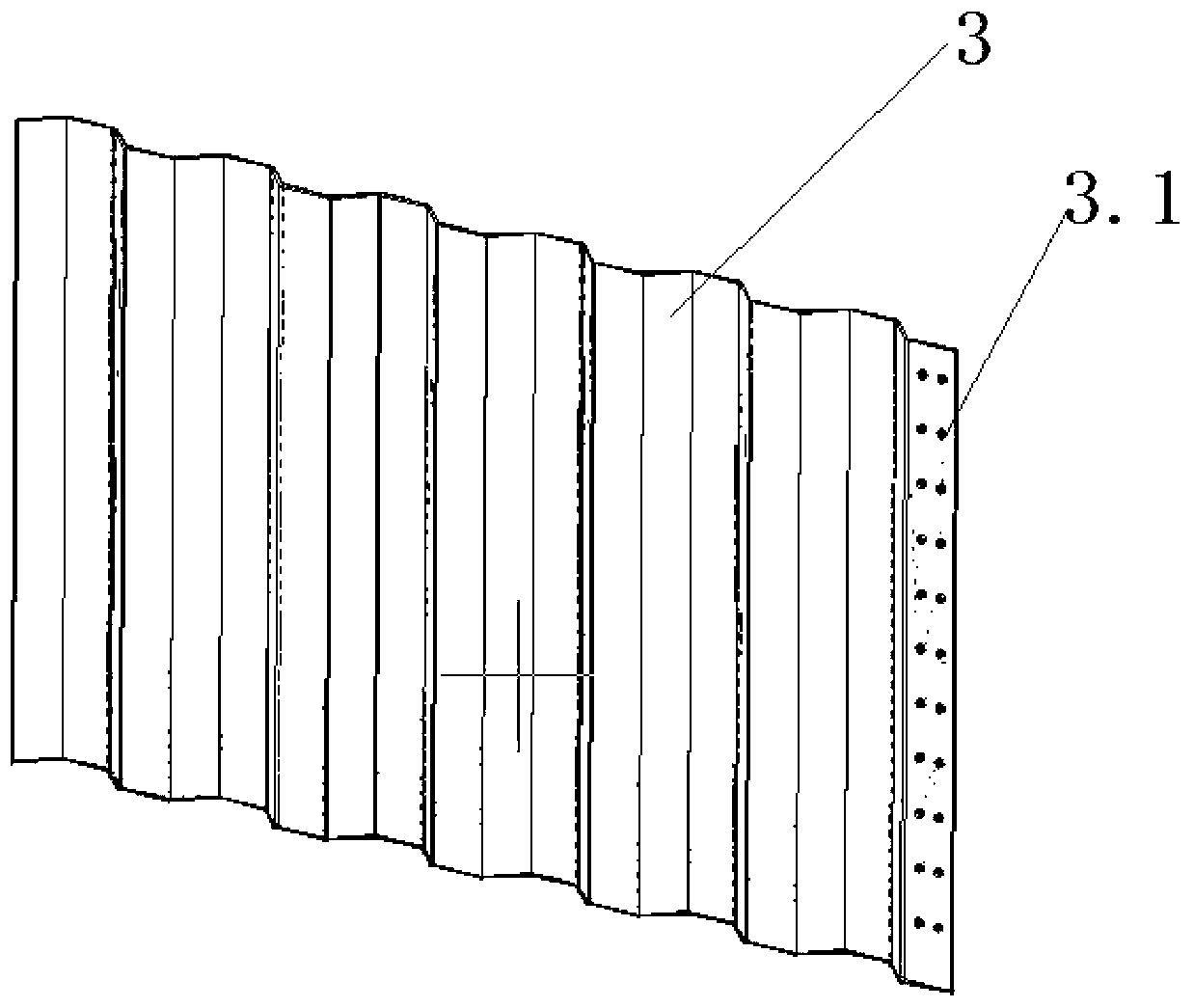

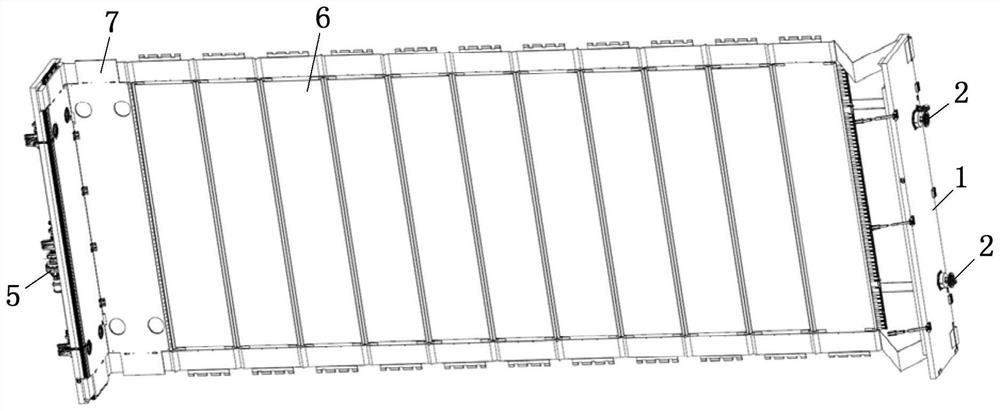

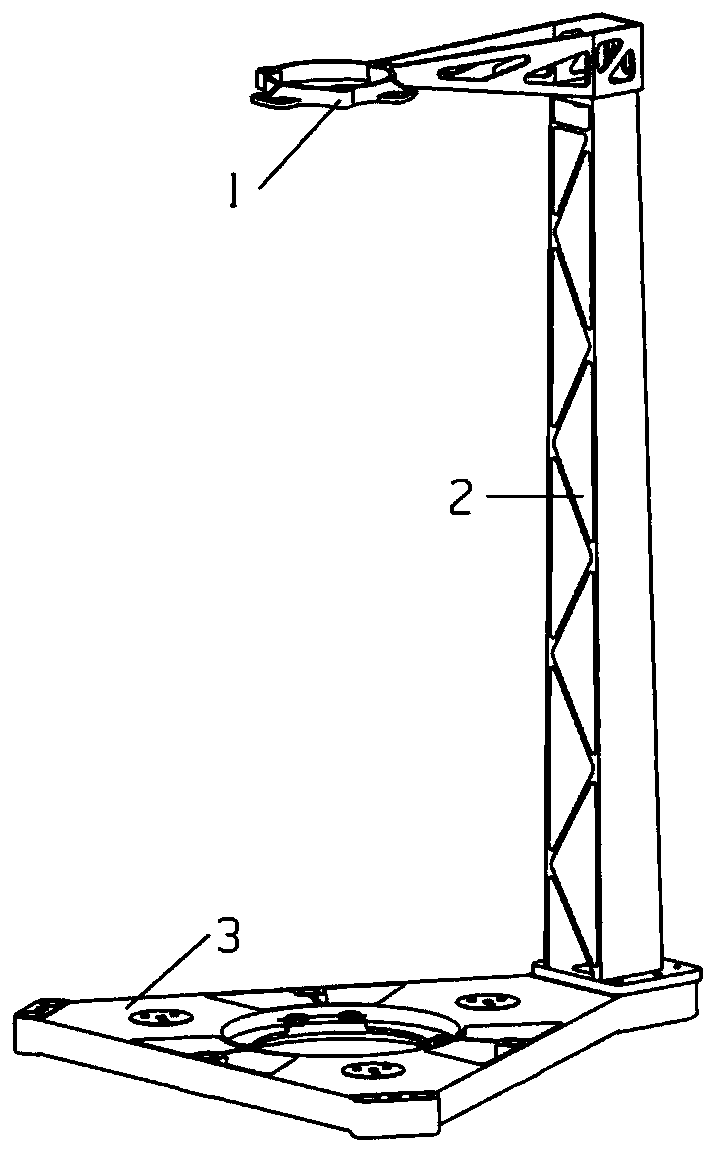

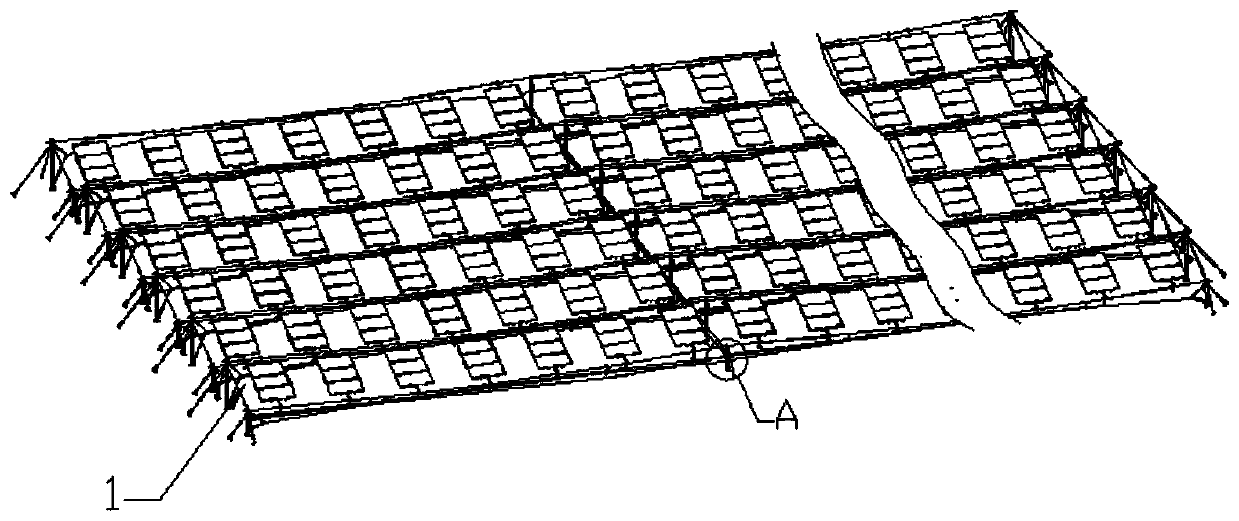

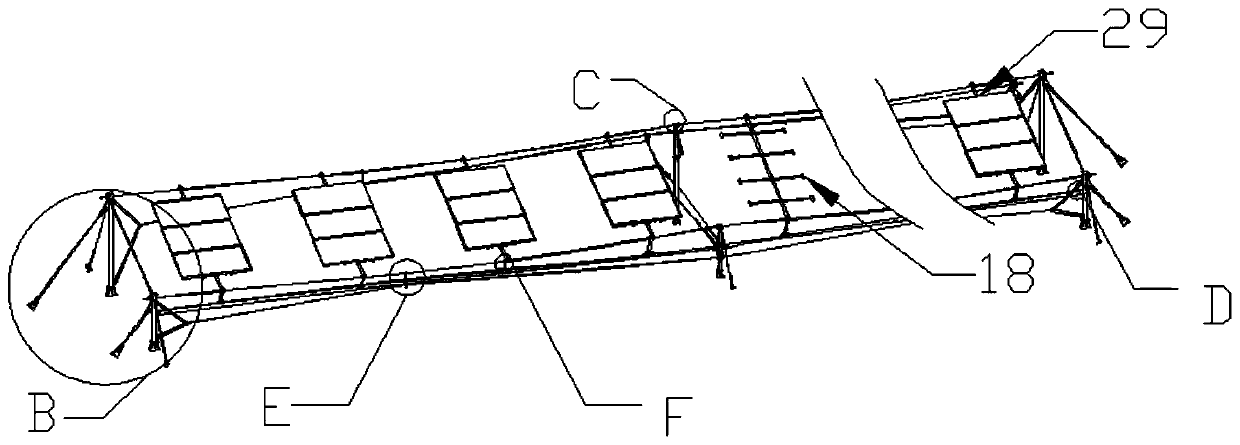

Flexible solar cell array unfolded step by step

ActiveCN111824461AGuaranteed structural rigidityMeet power generation requirementsCosmonautic vehiclesCosmonautic power supply systemsEngineeringSolar cell

The invention relates to a flexible solar cell array unfolded step by step. The flexible solar cell array is composed of an upper storage box, a lower storage box, a tensioning mechanism, a guide mechanism, a pressing and releasing mechanism, a flexible solar cell panel, a secondary unlocking device and the like. The flexible solar cell array is used as a power generation device of a spacecraft, can bear a mechanical environment of a spacecraft launching section, has force energy for keeping two unfolding lengths and structural rigidity under the cooperation of an external unfolding mechanism,and meets a requirement of orbital transfer at an initial stage of orbital injection of a spacecraft, the requirement of a butt joint stage for a unfolding fundamental frequency of a solar cell arrayand the requirement of long-term on-orbit operation for generating power of the solar cell array at the same time.

Owner:SHANGHAI AEROSPACE SYST ENG INST

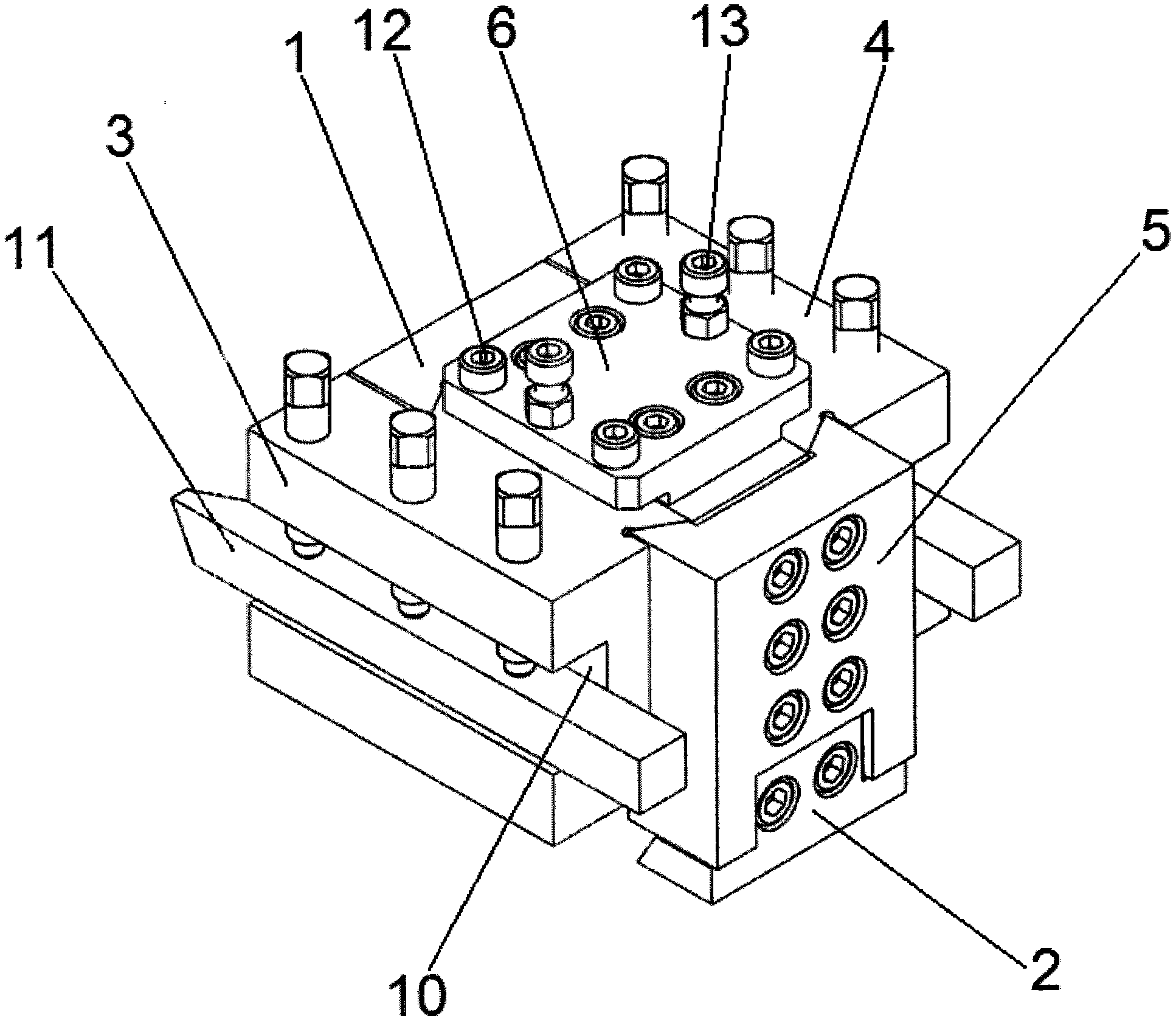

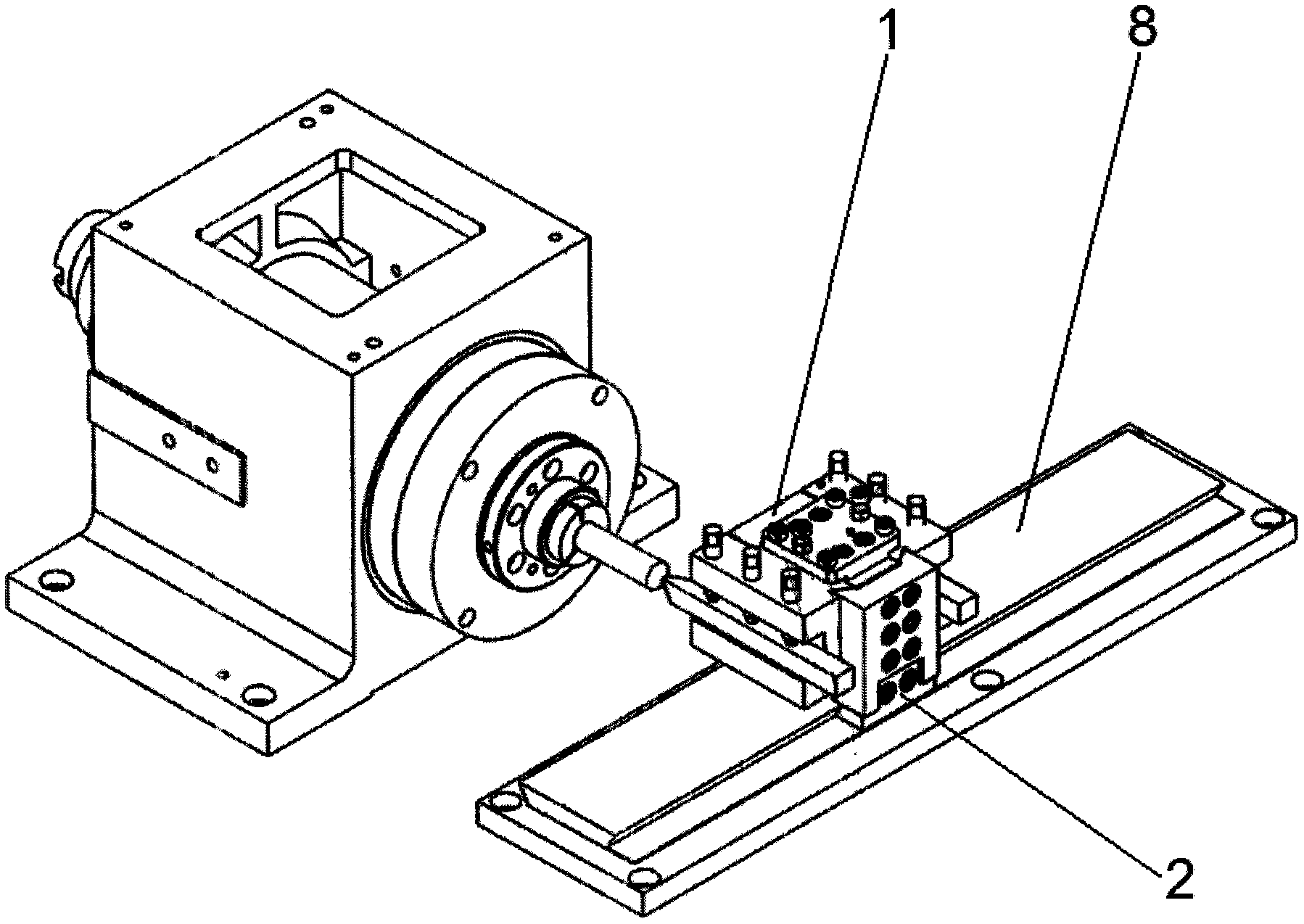

Dual-connection tool apron of row tool lathe

InactiveCN104384542AGuaranteed structural rigidityGuaranteed positionTool holdersLocking mechanismEngineering

The invention discloses a double-connection tool apron of a row tool lathe. The tool apron comprises a T-shaped tool apron body a tool plate pressing block, a left tool handle base, a right tool handle base, a tool handle base pressing block and an adjusting plate. A mature dovetail guide rail structure, wide guide layout, a double-screw pulling self-locking mechanism and a back pressure type clearance removing structure are adopted in the double-connection tool apron; on the basis of ensuring the whole structural rigidity and the position retaining of the tool apron, the problem that the height of a tool in the machining process cannot be adjusted is effectively solved; within the large adjusting range (+ / -5mm) and precise positioning, the use range of the tool apron is greatly widened; the implementation means of a machining technology is broadened; meanwhile, the double-connection side-by-side tool design is adopted; the problem that due to adding of an adjusting structure, the size of a tool apron mechanism becomes large, and consequently the usable space of the tool apron is reduced is effectively solved; in the same space, the number of tools cannot be reduced; and therefore the normal operating of the machining technology is ensured.

Owner:西安鸣士数控机床有限公司

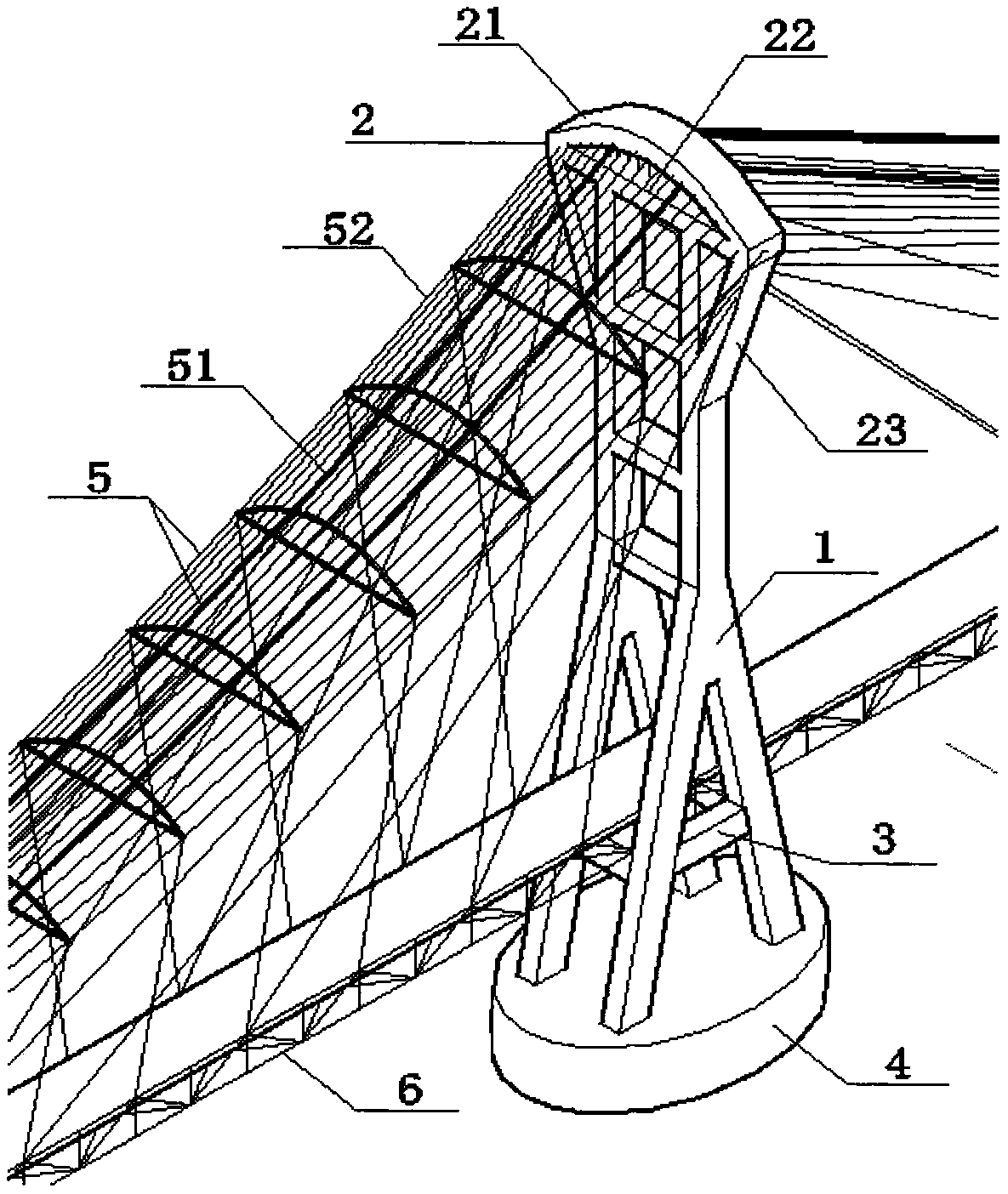

Tube-in-tube bridge tower of space hybrid cable net suspension bridge with parabolic arched tower cap

PendingCN109898415AImprove space rigidityImprove wind stabilitySuspension bridgeBridge structural detailsEarthquake resistanceFiber

The invention provides a tube-in-tube bridge tower of a space hybrid cable net suspension bridge with a parabolic arched tower cap. The tube-in-tube bridge tower of the space hybrid cable net suspension bridge with the parabolic arched tower cap is characterized in that the parabolic arched tower cap with a rigid tie rod is arranged at the top of a tube-in-tube herringbone tower column; one end ofa giant diagonal bracing is anchored to the waist of the tube-in-tube herringbone tower column; the giant diagonal bracing supports the arch foot of the parabolic arched tower cap and forms a racket-like bridge tower structure; a load-bearing steel cable is placed on the tube-in-tube herringbone tower column, and a carbon fiber space cable net is anchored on the parabolic arched tower cap to enhance the spatial stiffness of the suspension bridge and realize the cooperation between two groups of cables; a concrete-filled rectangular steel tube corner column and a grille tubular double-steel concrete composite shear wall are adopted to form a tube structure; the tube-in-tube herringbone tower column comprises an outer tube structure, a core tube structure and multiple rigid diaphragms. Thetube-in-tube bridge tower of the space hybrid cable net suspension bridge with the parabolic arched tower cap has various advantages, such as strong structural rigidity, good wind resistance stability, rich facade modeling, strong earthquake resistance, and capability of being adopted as a bridge tower structure of a space cable net suspension bridge with a super-long span of 4000 meters.

Owner:江苏交通工程咨询监理有限公司

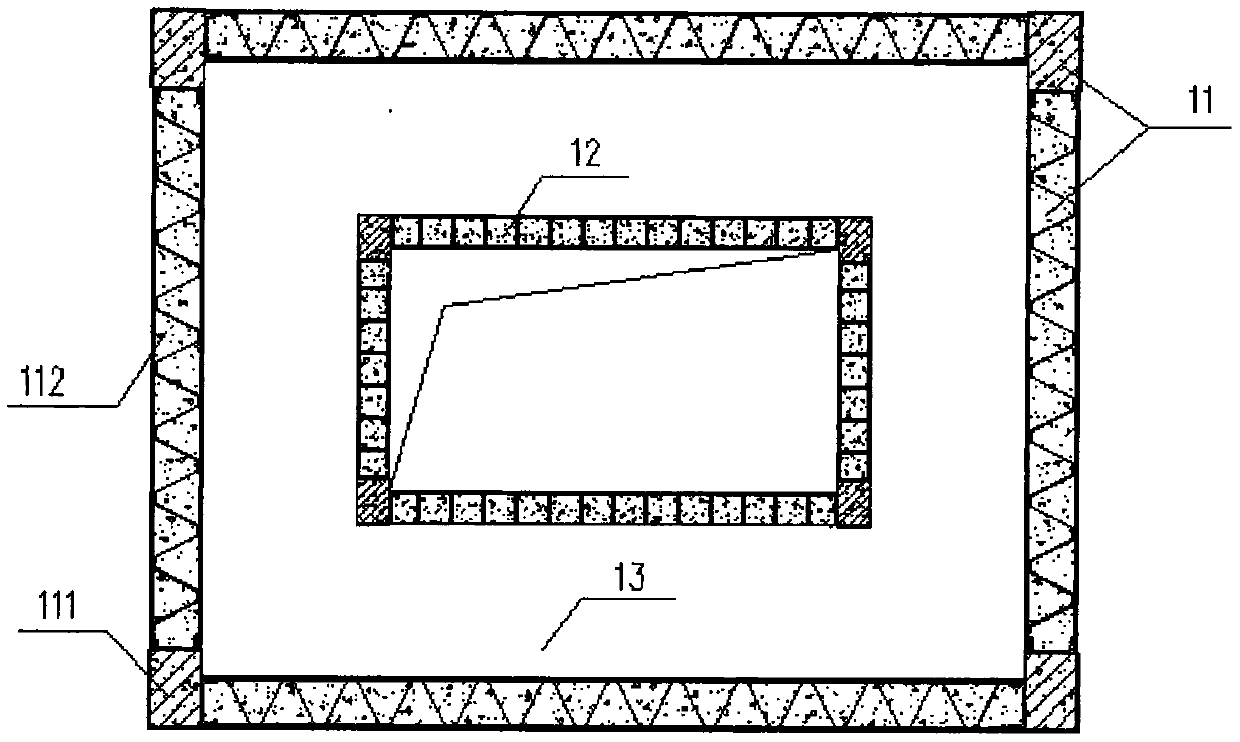

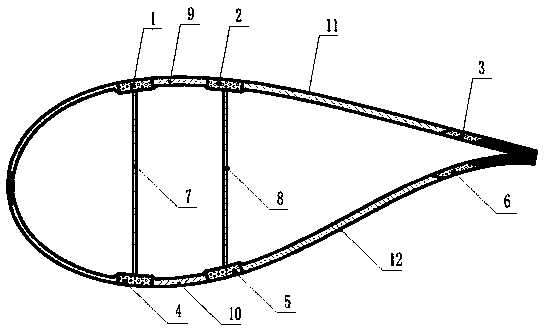

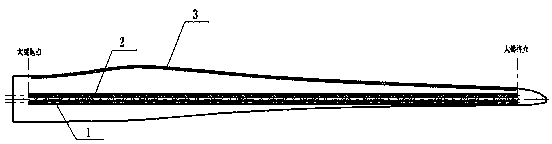

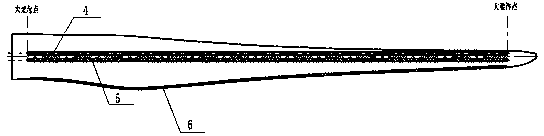

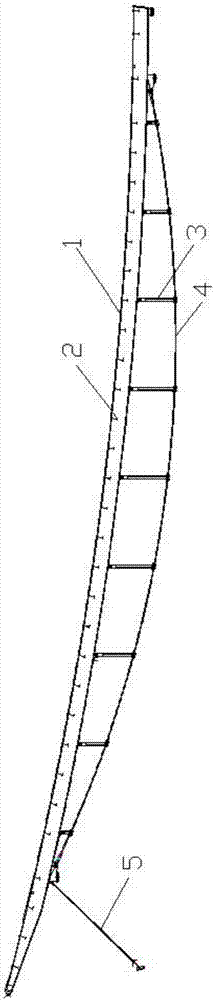

Multi-girder structure large size wind power blade and production method thereof

ActiveCN105508142AImprove the ability to resist buckling instabilityImprove structural rigidityEngine manufactureFinal product manufactureFiberCarbon fibers

The invention discloses a multi-girder structure large size wind power blade and a production method thereof. The multi-girder structure large size wind power blade is in a hollow layout structure, and comprises a blade envelope suction edge, a blade envelope pressure edge, main load-carrying construction girders and shearing-resistant web plates, wherein the blade envelope suction edge and the blade envelope pressure edge are combined to form a cavity structure of which the cross section is streamlined; a supporting structure formed by the main load-carrying construction girders and the shearing-resistant web plates is arranged in the cavity structure formed by the blade envelope suction edge and the blade envelope pressure edge; and the blade envelope suction edge and blade envelope pressure edge are in multisection combination structures, and are connected with the side surfaces of the main load-carrying construction girders through a plurality of edge sections respectively to form a blade envelope suction edge and blade envelope pressure edge integrated body. On the premise of ensuring the rigidity and strength of the blade, the resistance to buckling instability of the blade is improved; and by adopting a high-module carbon fiber spread layer, the weight of the blade can be reduced obviously, and loads, particularly a fatigue load, of the blade are reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

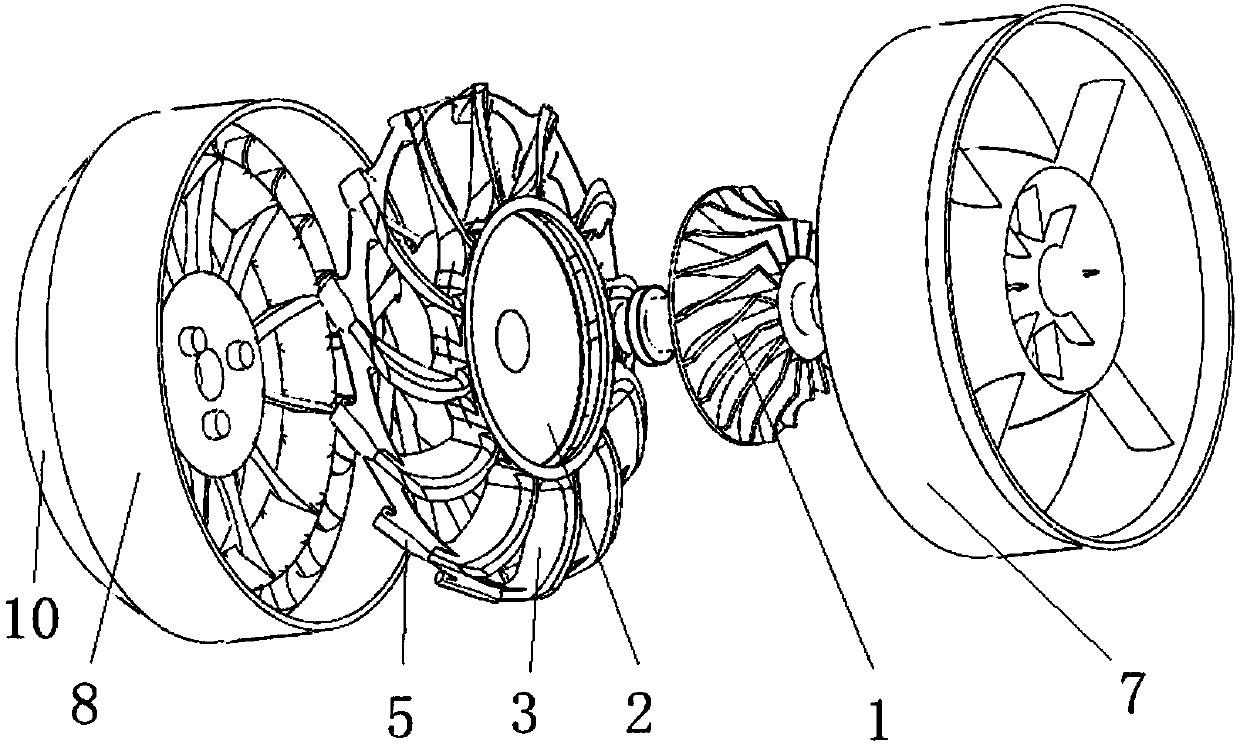

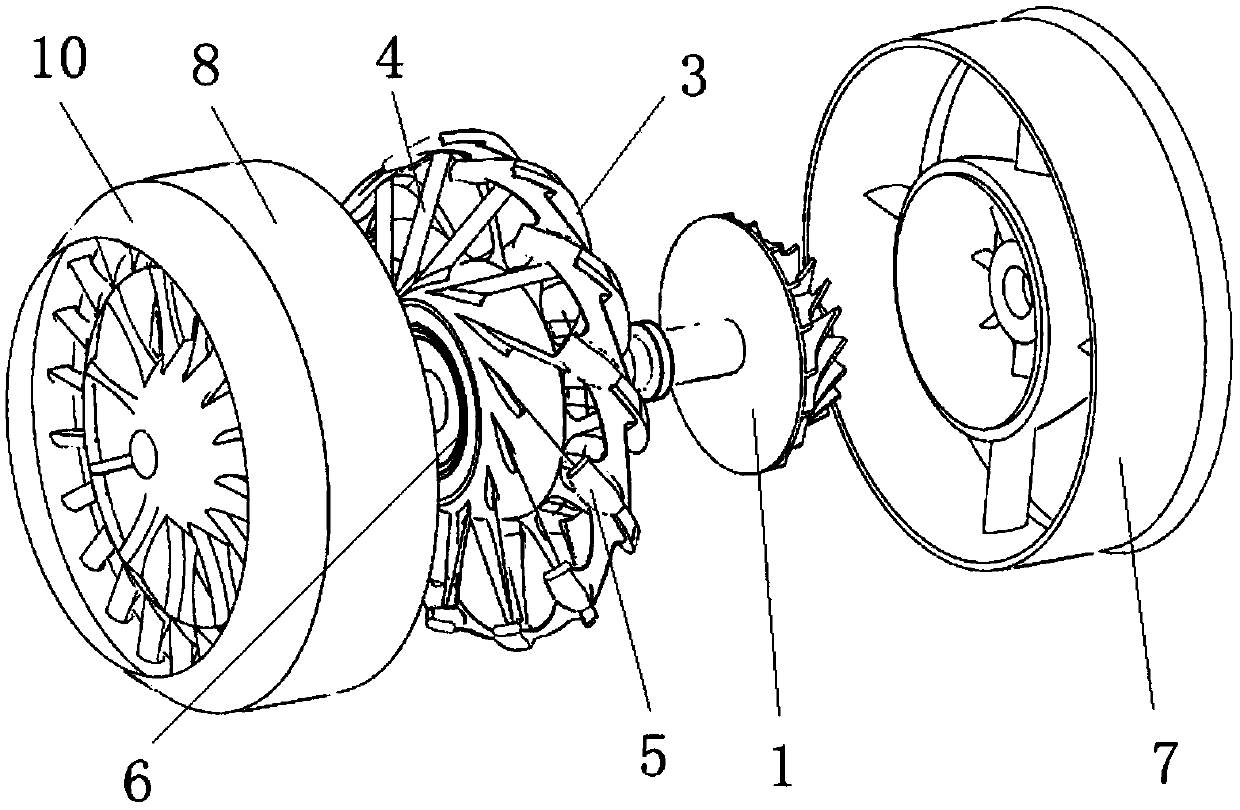

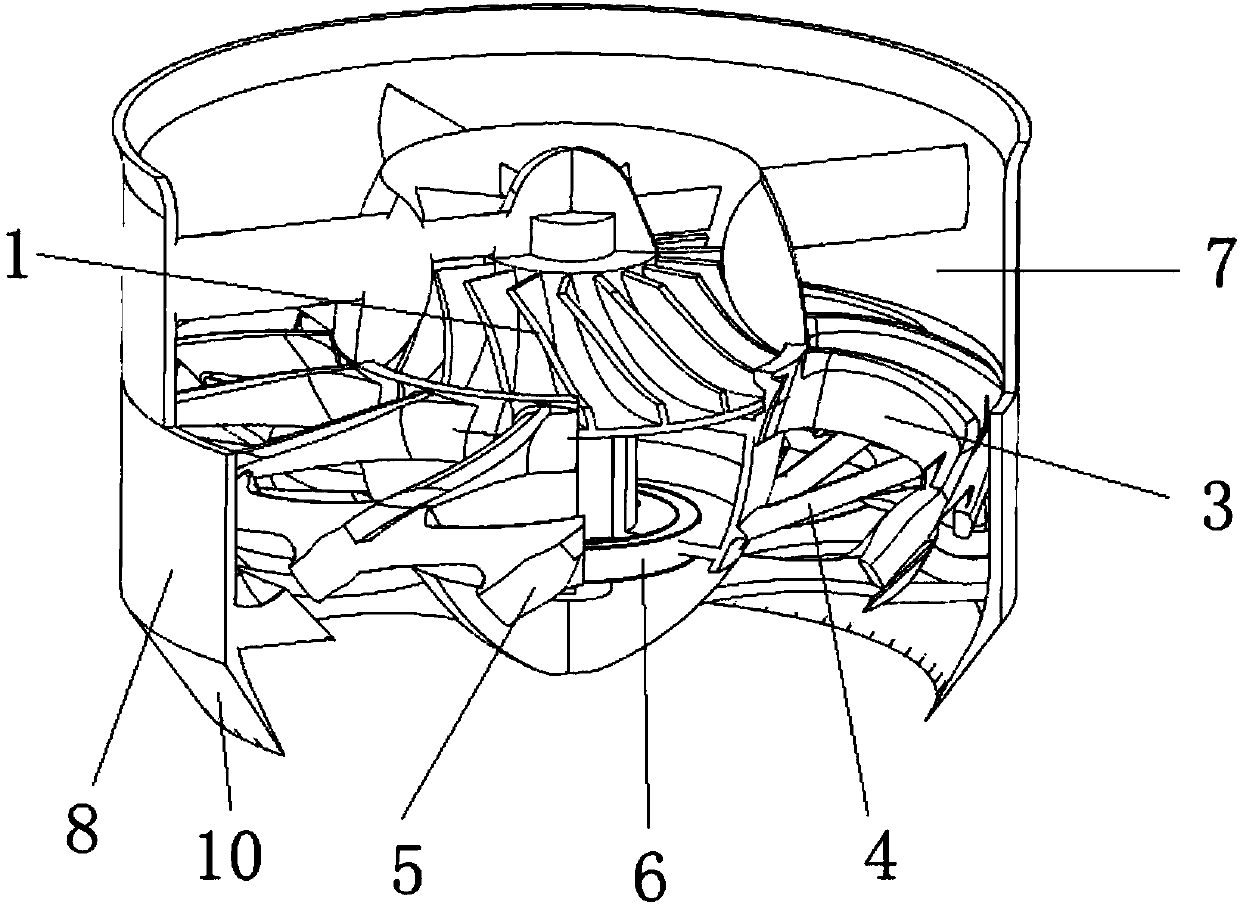

Blade tip ejecting self-driven wheeled fan engine

PendingCN108518289AIncrease profitReduce fuel consumptionGas turbine plantsJet propulsion plantsCombustion chamberGas compressor

The invention discloses a blade tip ejecting self-driven wheeled fan engine. The blade tip ejecting self-driven wheeled fan engine comprises a hollow fan with a combustion chamber being arranged at ablade tip. High-pressure gas is provided by a central gas compressor, flows to the blade tip combustion chamber along hollow blades to be combusted and then is ejected out to the lateral rear portion,and the fan is driven by reactive force of jet flow to rotate; and the rotating fan drives the central gas compressor through a planet gear device in a rear casing, and thus circulation operation ofthe whole engine is established. Through the bicycle-wheel-like design that the fan blades, an oil supply pipe and a circumferential band of an outer ring of the fan are combined together, the good stiffness and strength can be maintained under high speed rotation. Compared with existing high-bypass-ratio turbofan engines, a turbine part is omitted, and the structure is lighter and more compact; compared with existing propeller tip ejecting rotor wings of helicopters, the thermal efficiency of the engine is higher; and meanwhile, due to the fact that the turbine is omitted, thermal limiting ofturbine materials is avoided, and the temperature of the combustion chamber of the engine can be further increased compared with that of existing engines.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

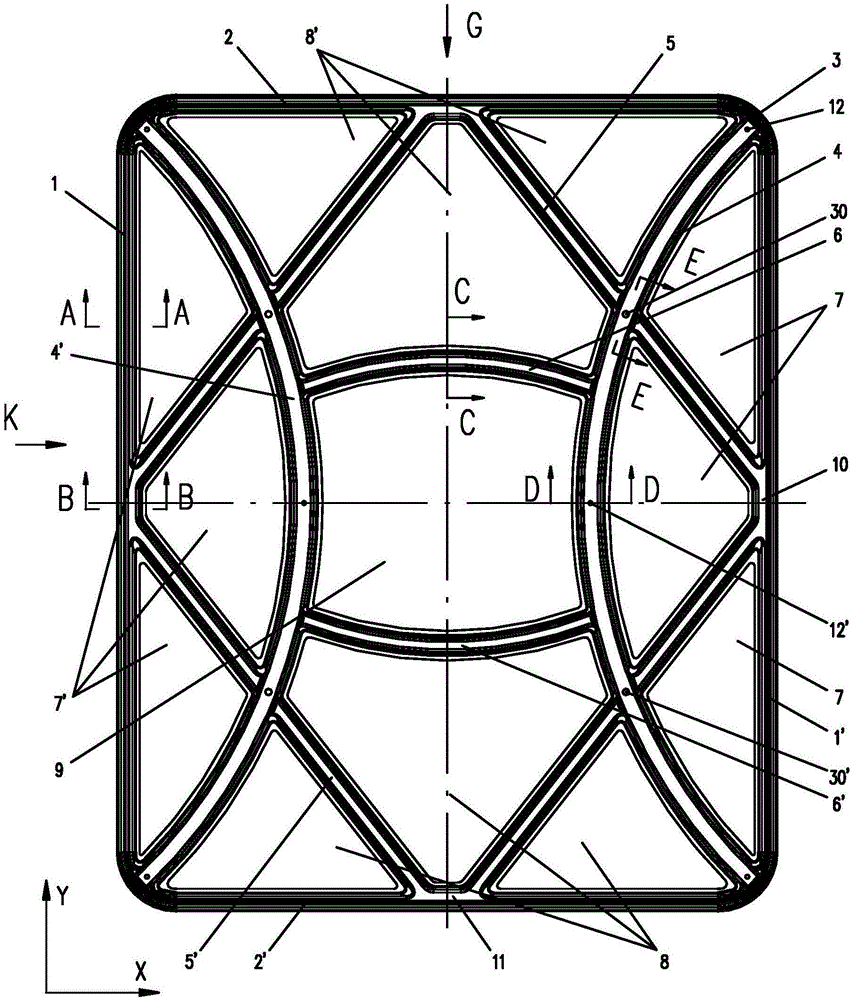

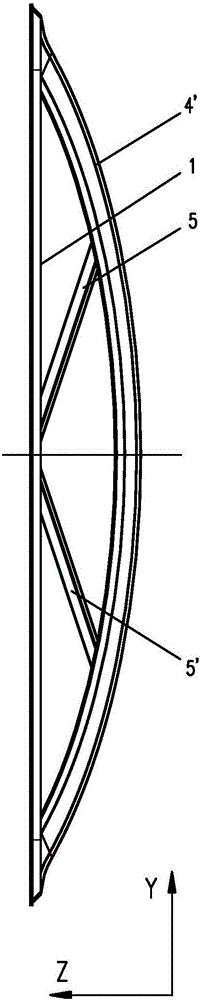

Micro arc surface reflector punching backplane

ActiveCN106125254ATo achieve the spotlight effectGuaranteed integritySolar heating energySolar heat devicesHeliostatSolar concentrator

The invention discloses a micro arc surface reflector punching backplane, which belongs to the field of solar concentrator reflector back support. The micro arc surface reflector punching backplane comprises an annular shaping part, two arc forming parts, upper and lower two symmetrical arc connection arms, and reinforced supporting arms, wherein the annular shaping part is around one circle of the reflector edge; the two arc forming parts are distributed at the left side and the right side inside the annular shaping part, are symmetrical bilaterally and protrude inwardly in an arc mode; the upper and lower two symmetrical arc connection arms are connected with the central area of the two arc forming parts; the reinforced supporting arms are connected with at least four points distributed uniformly on the circumference of the annular shaping part, and after the reinforced supporting arms are intersected or crossed with the arc forming parts, a diamond or a regular polygon is formed; and the annular shaping part forms a planar structure in a surrounding mode, and the arc forming parts, the connection arms and the reinforced supporting arms form micro arc surfaces sunk towards to the central area relative to the plane. The surface figure precision of a heliostat reflecting surface and the reflecting spot quality are improved, the reflector supporting structure making efficiency and the part size consistency are improved, and the making cost of the heliostat structure is reduced.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Micro-structure corneal contact lens and preparation method thereof

ActiveCN109116578AImprove eyesightFunctional expansion of eyesightOptical partsMicro structureEngineering

The invention relates to a micro-structure corneal contact lens and a preparation method thereof. The corneal contact lens adopts a mechanical flexible material and comprises a porous grid structure of a hollow annular layout formed by one or more deformable elastic mechanical units according to one or more distribution rules, wherein the annular layout is formed by periodically annularly and radially combining and distributing or orthogonally combining and distributing the deformable elastic mechanical units. The micro-structure corneal contact lens and the preparation method thereof with certain biological tearful eyes detection capacity are low in cost, expandable, capable of being customized and capable of realizing the mass production and wide in application range of people.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

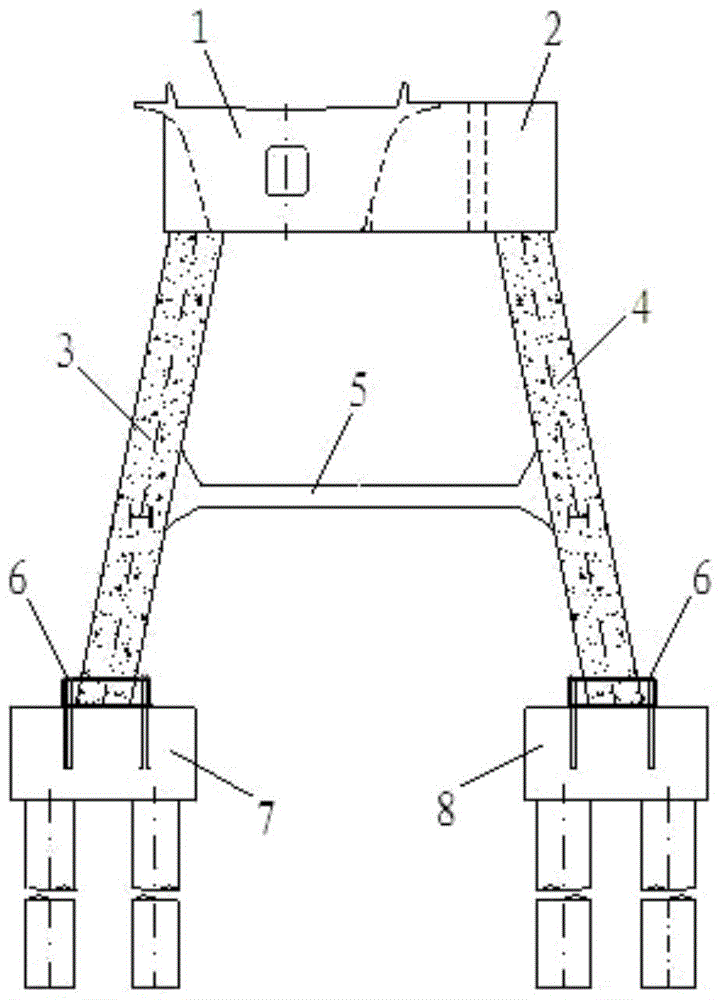

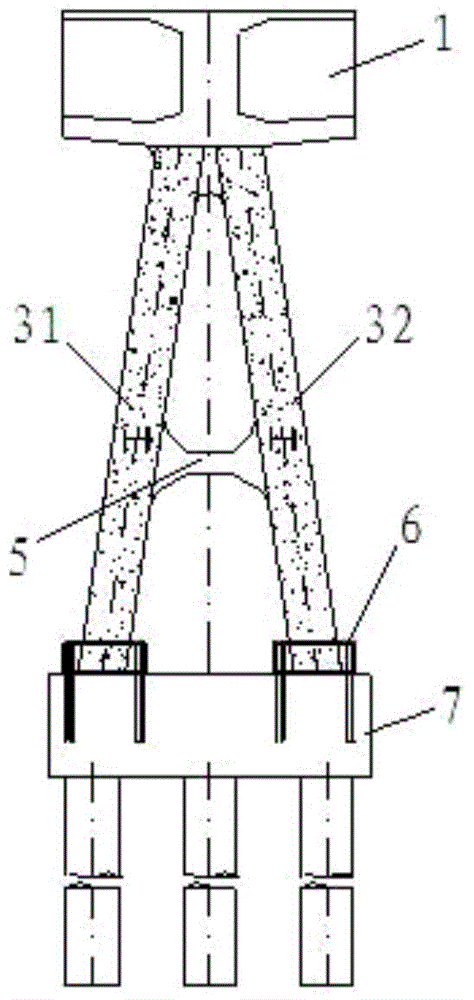

Double-row four-slanting-leg steel-structure gate-type pier

The invention belongs to the technical field of bridge pier columns, and particularly relates to a double-row four-slanting-leg steel-structure gate-type pier. The double-row four-slanting-leg steel-structure gate-type pier comprises a NO. 0 block and a steel bent cap; the two ends of the bottom of the steel bent cap are respectively connected with a left-row pier column and a right-row pier column; a left bearing platform and a right bearing platform are respectively arranged at the bottoms of the left-row pier column and the right-row pier column; the left-row pier column comprises a first left pier column and a second left pier column, the tops of the first left pier column and the second left pier column intersect at one end of the bottom of the steel bent cap, and the bottoms of the first left pier column and the second left pier column are respectively connected with the two ends of the left bearing platform; the right-row pier column comprises a first right pier column and a second right pier column; the tops of the first right pier column and the second right pier column intersect at the other end of the bottom of the steel bent cap, and the bottoms of the first right pier column and the second right pier column are respectively connected with the two ends of the right bearing platform. By the adoption of the double-row four-slanting-leg steel-structure gate-type pier, a large-span bridge structure can be eliminated, so that the investment is reduced, the construction schedule is accelerated, and interference to existing roads is reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

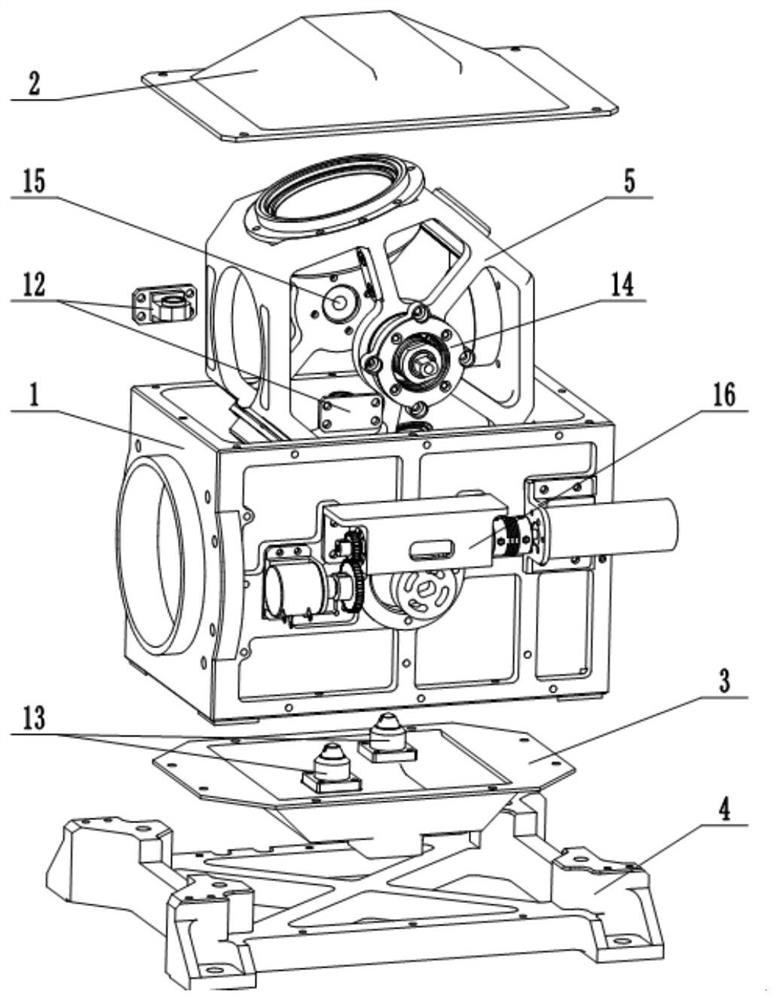

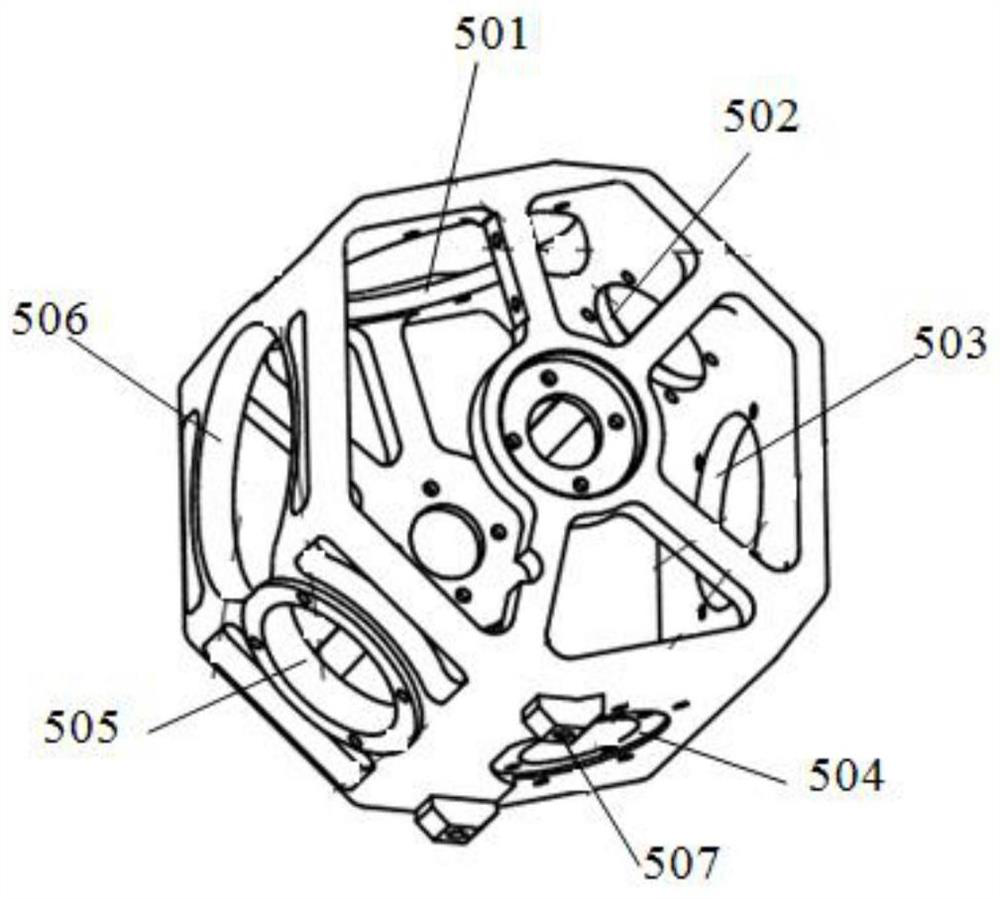

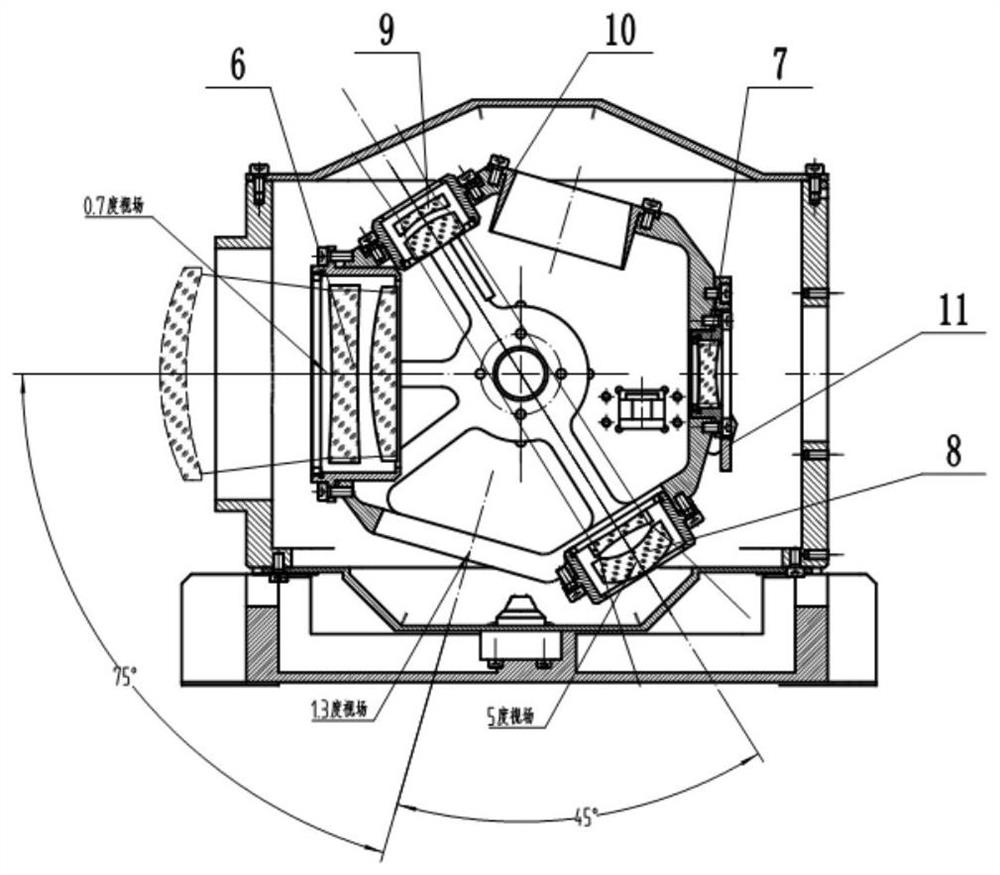

A three field of view switching mechanism for optical equipment

ActiveCN111796390AContinuous switchingHigh positioning accuracyMountingsLens hoodTelevision equipment

The invention relates to a field-of-view switching mechanism for optical equipment, in particular to a three-field-of-view switching mechanism for optical equipment, and solves the problem that the positioning and repeated positioning precision of an existing switching mechanism cannot meet the use requirements under the condition of visible light television equipment and in a severe environment.The switching mechanism is characterized by comprising a main frame assembly, a rotating lens barrel assembly and a limiting assembly which are arranged in a main frame, and a driving assembly; the rotating lens barrel assembly comprises a rotating lens barrel, a first switching lens group, a fourth switching lens group, a light shield, a second switching lens group, a third switching lens group,a first inner shaft and a second inner shaft, wherein the first switching lens group, the fourth switching lens group, the light shield, the second switching lens group and the third switching lens group are sequentially installed on the circumferential side face of the rotating lens barrel clockwise, and the first inner shaft and the second inner shaft are fixedly connected to the two ends of therotating lens barrel respectively and rotationally connected with the main frame; a light through hole is formed in the circumferential side surface of the rotary lens barrel; the first switching lens group and the second switching lens group, the fourth switching lens group and the third switching lens group, and the light shield and the light through hole are separately coaxial; the limiting assembly comprises two magnet limiting assemblies and a plunger limiting assembly.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

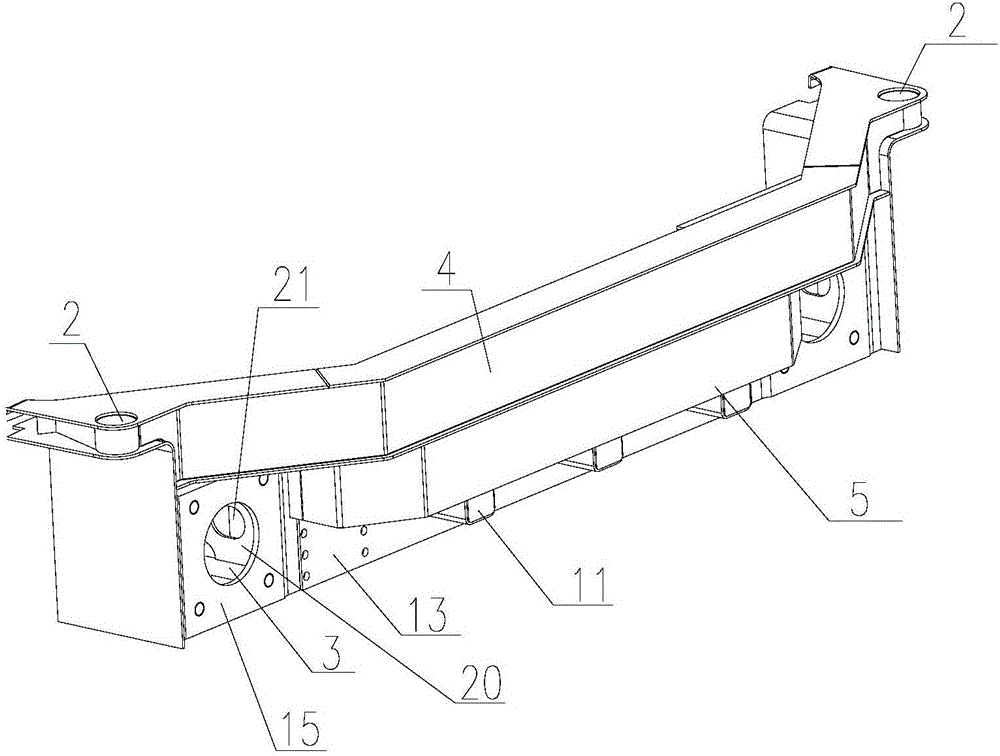

Anticreeper mounting base for low-floor rail vehicle

ActiveCN106347405ASmall footprintGuaranteed structural rigidityRailway wheel guards/bumpersEngineeringUltimate tensile strength

The invention relates to an anticreeper mounting base for a low-floor rail vehicle. The anticreeper mounting base is of a box structure; a vehicle hook mounting joint and / or a driver cab mounting port and / or an anticreeper mounting port is arranged on the mounting base, the vehicle hook mounting joint is fixedly connected with a vehicle hook mounting base, the driver cab mounting port is fixedly connected with a driver cab vehicle body, and the anticreeper mounting port is used for mounting an anticreeping energy absorbing element. The anticreeper mounting base has the advantages that the structure is simple, the occupation space of the whole mounting base is small, and the installation requirement of the narrow space of a chassis of the low-floor rail vehicle is met; at the premises of guaranteeing the structure rigidity and connecting strength of the mounting base, the maximum light-weight design is realized, and the higher light-weight requirement of the vehicle is met.

Owner:CRRC QINGDAO SIFANG CO LTD

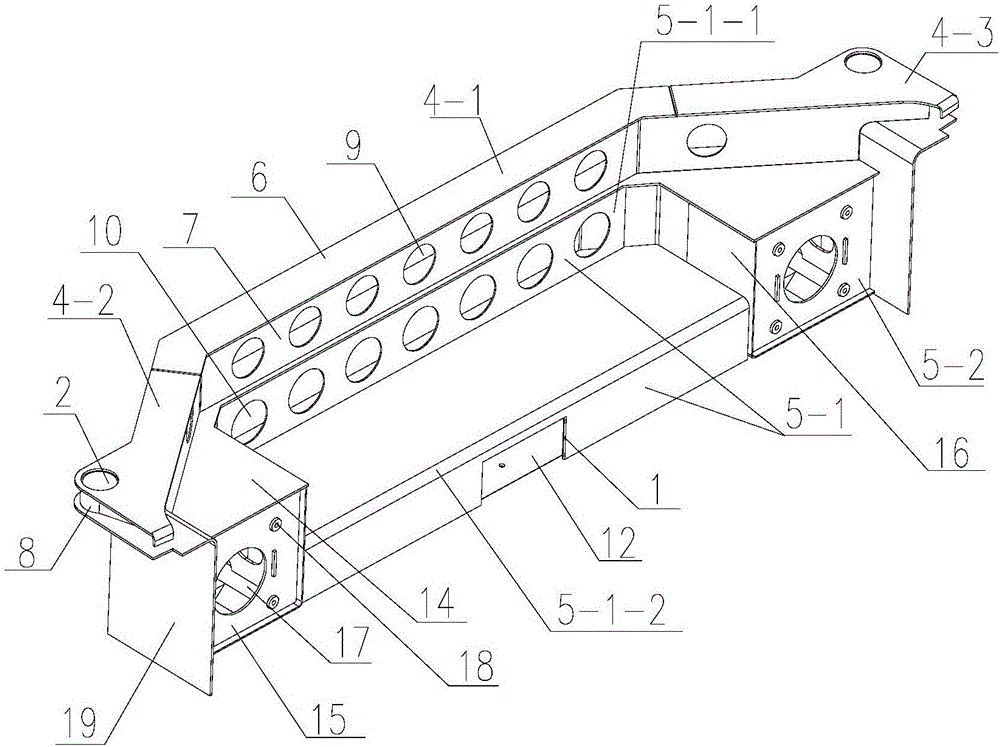

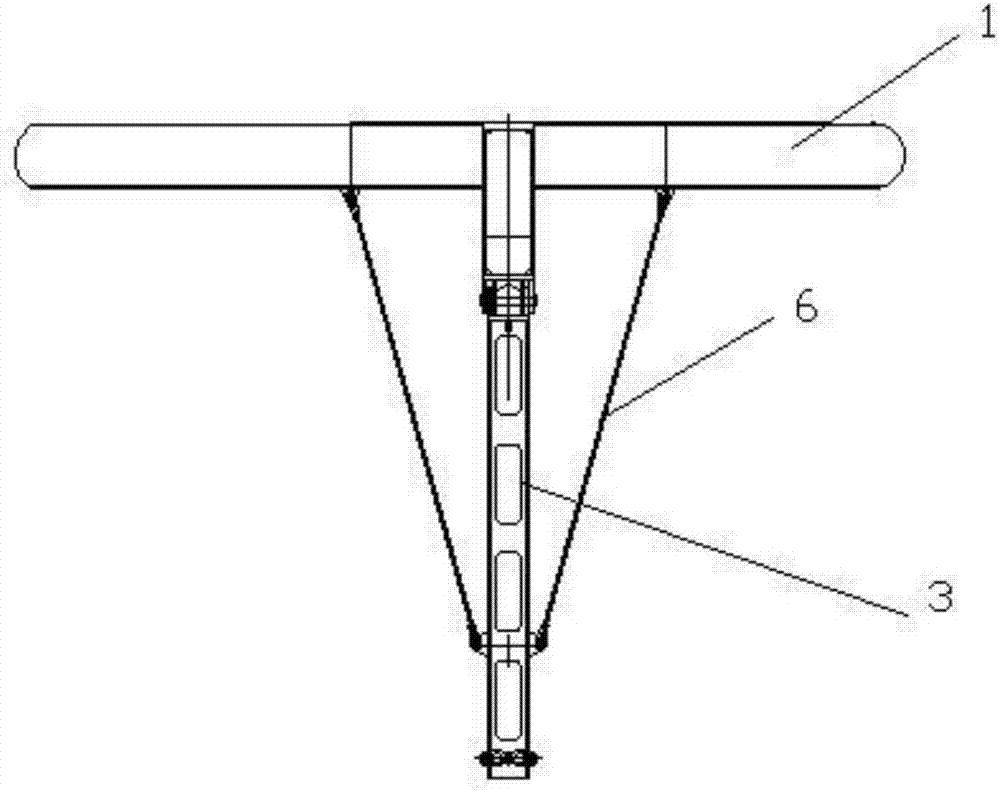

Single rod type main bearing structure applicable to micro-nano remote sensing camera

The invention discloses a single rod type main bearing structure applicable to a micro-nano remote sensing camera, relates to the technical field of space optical remote sensing, and solves the problems that the existing coaxial space camera main support structure is high in weight and large in shading ratio and process difficulty, an integrated formation structure is too high in production cost and long in processing period and the like. According to the single rod type main bearing structure applicable to the micro-nano remote sensing camera disclosed by the invention, a secondary mirror bracket and a support rod are in flanged connection; the support rod and a main backplate are in flanged connection; due to adoption of a split type structure, instead of an integrated structure, the processing difficulty of silicon carbide can be greatly reduced; the production period and the manufacturing cost are greatly reduced; the low-cost and short-period requirements of micro-nano load are satisfied; a countersunk bottom hole and an embedded part are pre-punched on a silicon carbide material; an epoxy resin adhering manner is adopted; and the problems that the process of directly processing a threaded hole in the silicon carbide material is high and damage is easily caused can be avoided. By means of the single rod type main bearing structure applicable to the micro-nano remote sensing camera disclosed by the invention, the structural precision and the stability are improved; the structural part number and the manufacturing process are simplified; and the processing period and theprocessing cost are shortened.

Owner:CHANGGUANG SATELLITE TECH CO LTD

Fixed grate and incineration system applying same

InactiveCN104595907AGuaranteed structural rigidityGuaranteed to be constantInclined grateIncinerator apparatusCombustion chamberHot blast

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate and an incineration system applying the same. The fixed grate at least comprises grate plates; the arrangement heights of the grate plates are gradually reduced so as to form a step type grate body structure of the fixed grate; a spacing is formed between plate bodies of each two adjacent grate plates in the perpendicular direction so as to form a ventilation pore running through a grate body; the grate plates are provided with extending plates; the plate faces of each extension plate and the plate body of the previous grate plate are crossed mutually to form a wind guide port structure. The incineration system comprises a main combustion chamber, the fixed grate and a grate ejector rod, wherein the main combustion chamber is isolated and divided into a combustion cavity and a hot blast cavity by the fixed grate; the air inlet end of the hot blast cavity is also the feed end of the fixed grate; the grate ejector rod is used for overturning and ejecting materials on the incineration face; the grate ejector rod passes through a through hole and runs through the material layer on the fixed grate in the maximum lift range. The fixed grate and the incineration system have reasonable and practical structures; the grate body has a good ventilation effect; material incineration efficiency is high.

Owner:安徽盛燃焚烧炉科技有限公司

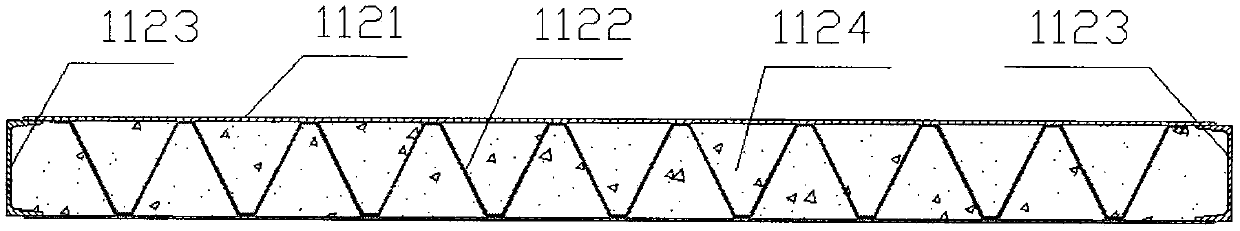

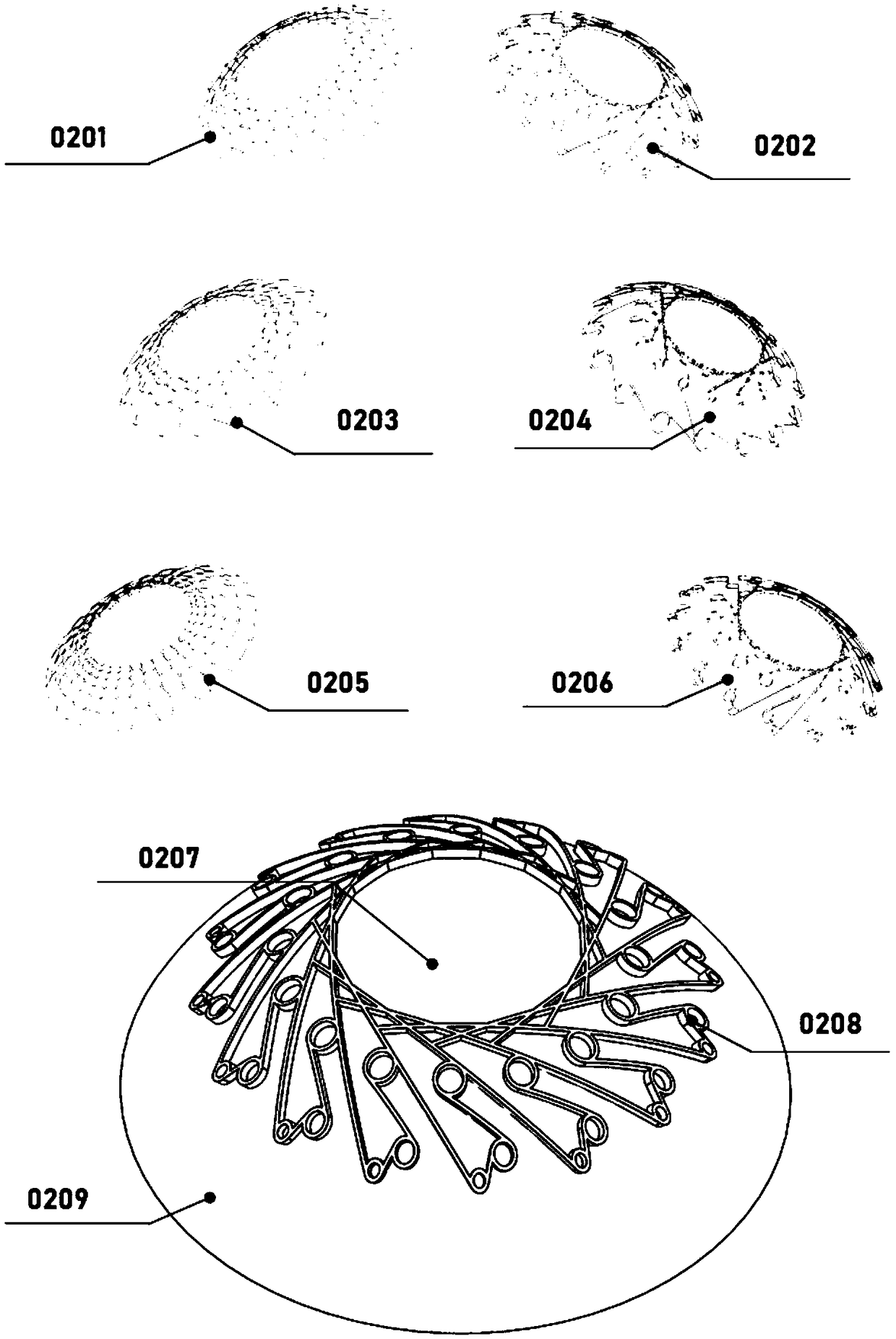

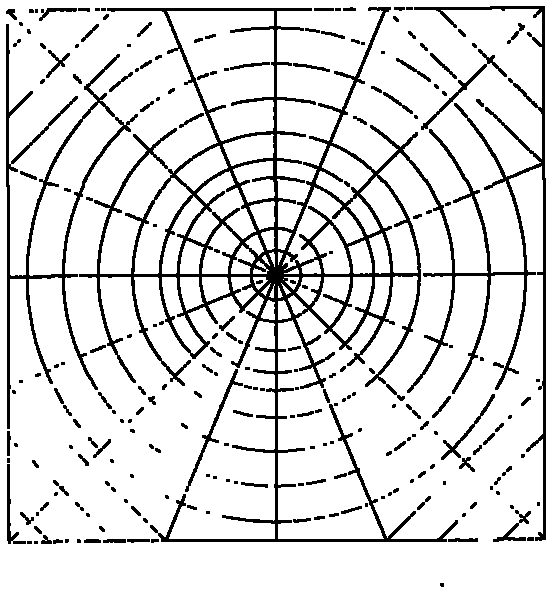

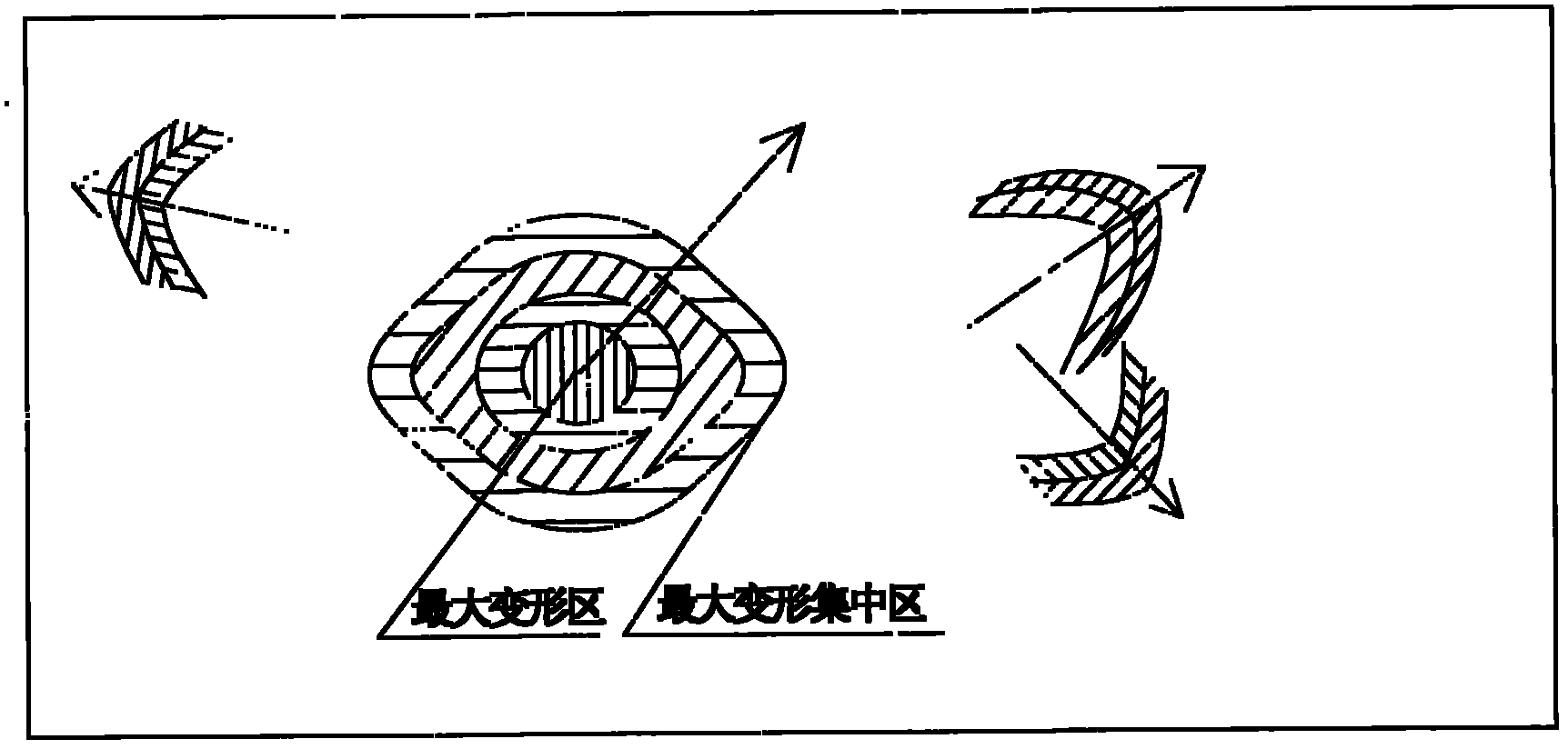

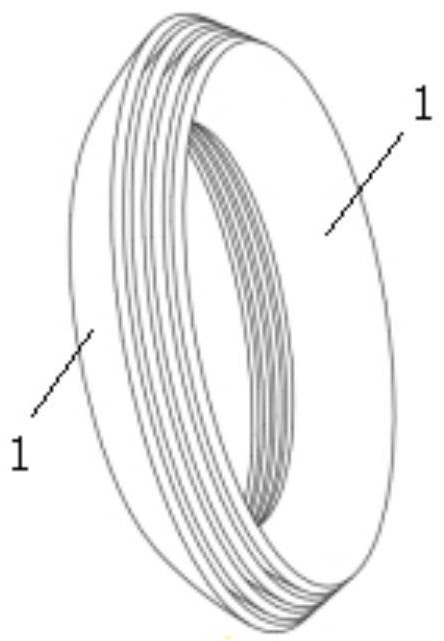

Topology optimization-based cobweb-like interlayer rib plate composite structure design method

InactiveCN101980222AReduce quality problemsSave materialSpecial data processing applicationsTopology optimizationThin layer

The invention discloses a topology optimization-based cobweb-like interlayer rib plate composite structure design method, which comprises the following steps of: 1, performing a static analysis on an original structural component to obtain a deformation cloud chart; 2, performing a topological optimization design on the structural component to obtain a topological optimization unit pseudo-density diagram; 3, finding the position of a largest deformation zone from the deformation cloud chart of the structural component; 4, arranging annular regular parallels and regular meridian lines of the structural component; 5, determining the arrangement density of the regular meridian lines; 6, arranging irregular meridian lines on some parts of the component; 7, combining the topology optimization to obtain a hollow component structure; 8, making a thin layer plate on the upper layer of the cobweb-like interlayer rib plate to fully envelope the cobweb-like rib plate, so that the middle interlayer becomes a composite structure of the cobweb-like rib plate; and 9, repeatedly improving the original component according to the steps. The invention has scientific concept and a novel structure, can meet the requirement of aerospace on light weight design, and has good practical value and wide application prospect in the engineering and technology field.

Owner:BEIHANG UNIV

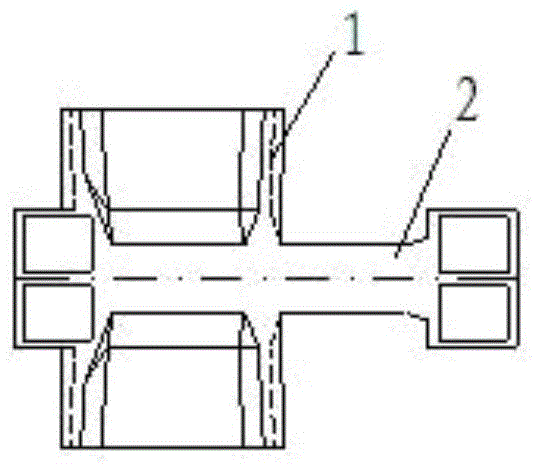

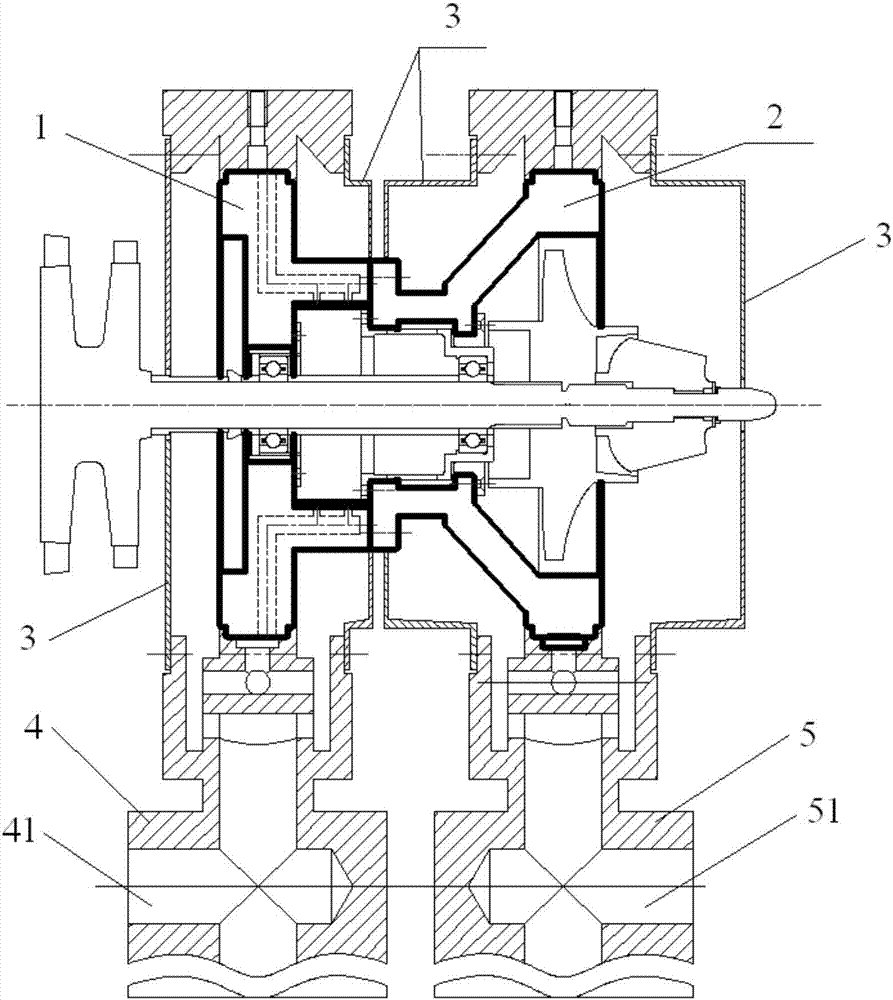

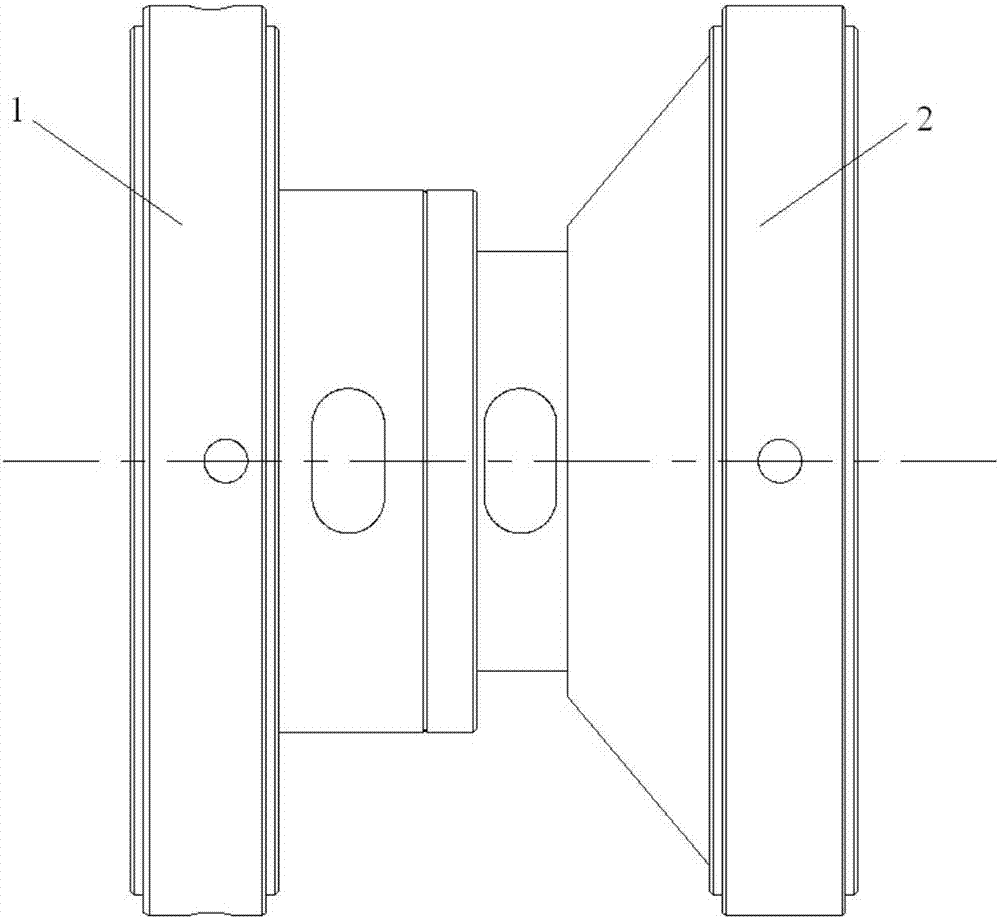

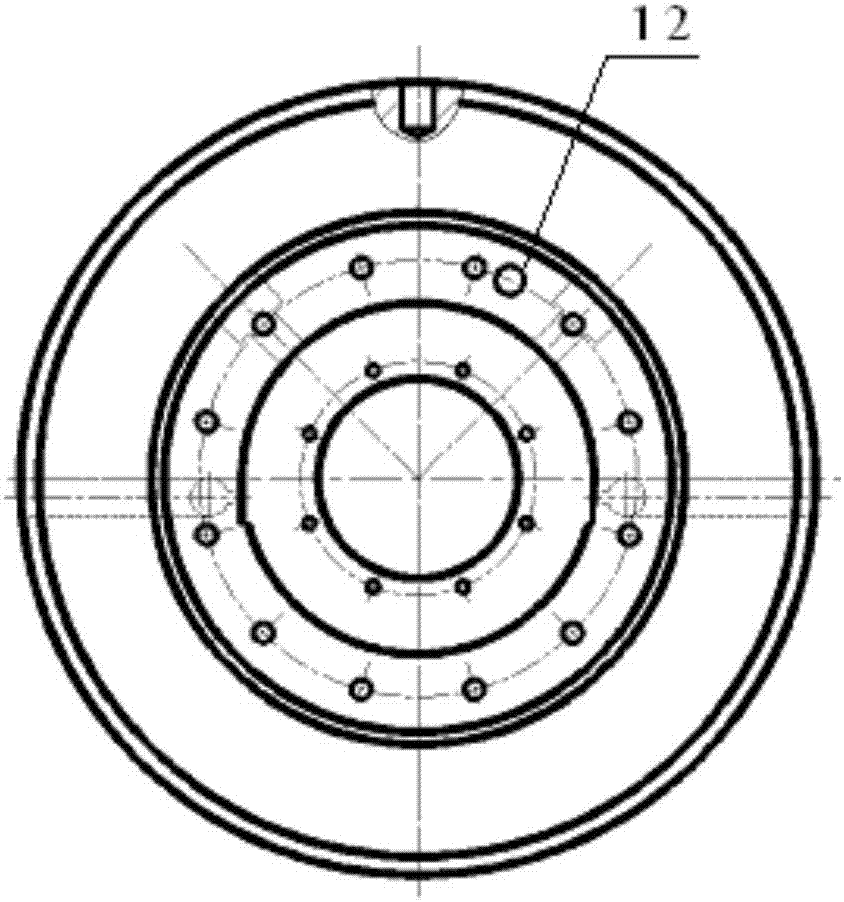

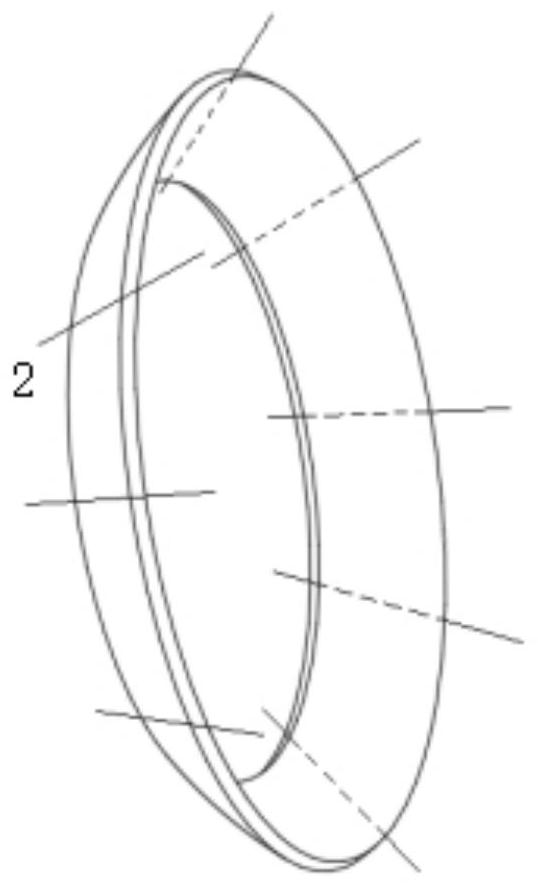

Liquid rocket engine turbopump flexible rotor high-speed dynamic balance supporting device

ActiveCN107014562AImprove assembly reliabilityImprove balanceStatic/dynamic balance measurementDynamic balanceEngineering

The invention provides a liquid rocket engine turbopump flexible rotor high-speed dynamic balance supporting device, including a main support shell I (2), a main support shell II (2) and an oil seal shell (3). The small end of the main support shell II (2) is connected with the small end of the main support shell I (1) through a flange plate of an end part; a turbopump rotor is mounted in a combination structure of connected main support shell I (1) and main support shell II (2) through a bearing; the large ends of the main support shell I (1) and the main support shell II (2) are fixed in annular frames of a swing frame I (4) and a swing frame II (5) respectively; and the oil seal shell (3) is connected with the main support shell I (1), the main support shell II (2), the turbopump rotor, the swing frame I (4) and the swing frame II (5) to form a seal cavity. The liquid rocket engine turbopump flexible rotor high-speed dynamic balance supporting device has a function of lubricating and cooling the bearing with single-support oil taking and bidirectional oil injection and a function of vibration displacement measurement of a rotor.

Owner:BEIJING AEROSPACE PROPULSION INST

Composite material reinforced part and forming process method

The invention provides a composite material reinforced part and forming process method, The composite material is a carbon fiber / epoxy resin type, and the forming process method comprises the following steps of S1, drawing a 2D expanded drawing according to a 3D drawing of a reinforced part; S2, enabling the carbon fiber composite material flexible joint reinforced part to be subjected to laying design, the proportion of a large opening, a middle section and a small opening is 1 to 2 to 1, all the parts to be overlapped, and no obvious boundary to exist; S3, performing layering angle and sequence design on the carbon fiber composite material flexible joint reinforced part according to four layering angle directions of plus 45 degrees, 0 degree, 90 degrees and minus 45 degrees between the carbon fiber composite material flexible joint reinforced part and the axis; S4, manufacturing a to-be-cured reinforced part by adopting a hot-pressing curing process; S5, carrying out vacuum bag combination on the to-be-cured reinforced part, putting the to-be-cured reinforced part into an autoclave, and heating and curing; and S6, carrying out appearance processing on the cured reinforced part to obtain a required product. According to the process method, targeted design is carried out according to the special stress condition of the flexible joint, the advantage of anisotropy of a carbon fiber composite material is fully utilized, the performance is further improved, and the weight is further reduced.

Owner:湖北航泰科技有限公司

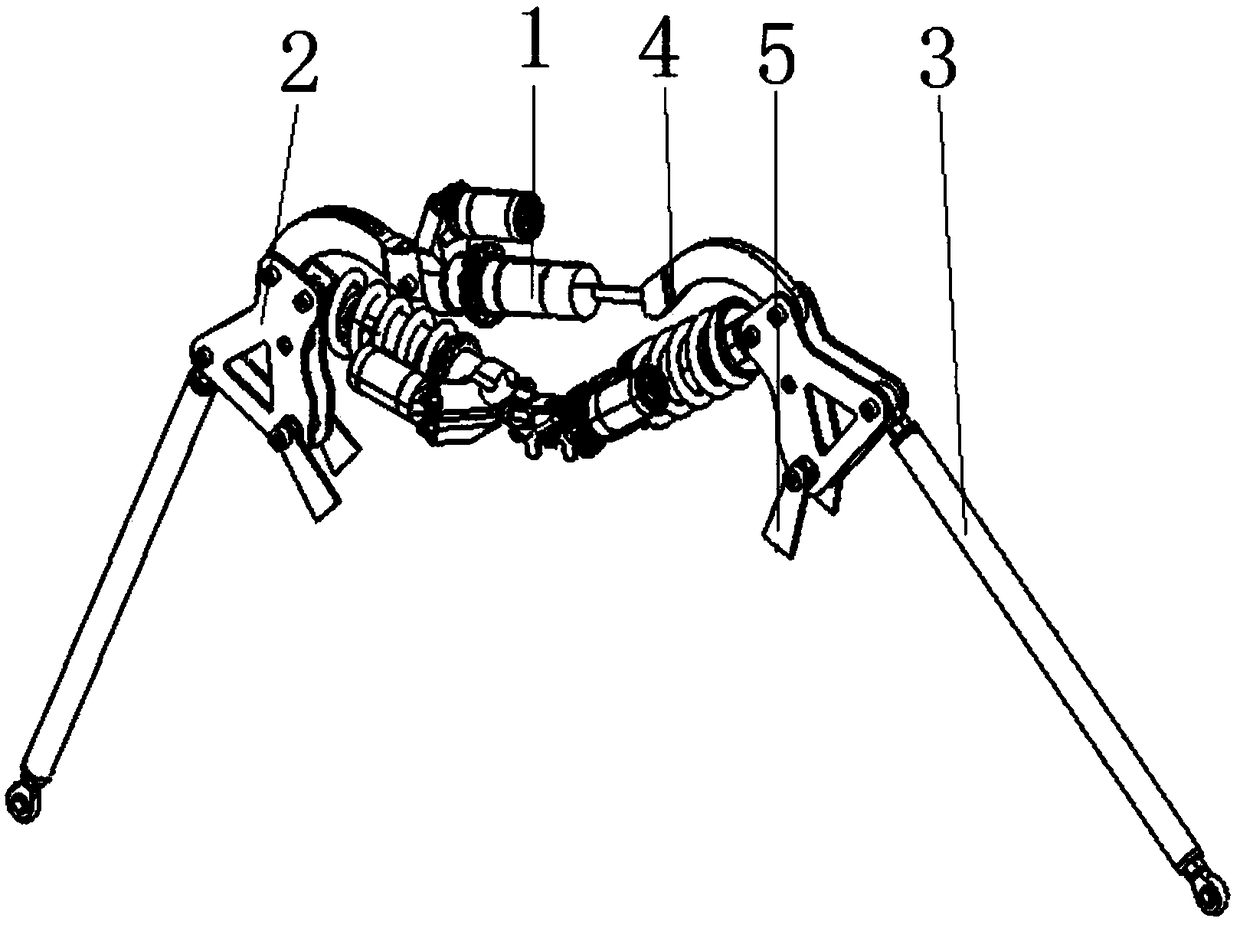

Humanoid robot hip joint mechanism and robot connected with humanoid robot hip joint mechanism

InactiveCN105666521AReasonable structural designAchieve rotationProgramme-controlled manipulatorJointsReduction driveReducer

The present invention relates to the field of robot technology, in particular to a humanoid robot hip joint mechanism and a robot connected with the mechanism, including a hip joint assembly and a drive assembly connected to the hip joint assembly, the hip joint assembly includes a main support, The drive assembly includes a motor, a driving pulley, a driven pulley and a harmonic reducer connected in sequence, and the motor is fixedly connected to the main support. The present invention provides a humanoid robot hip joint mechanism and a robot connected with the mechanism. Its internal main support adopts an integrated structure design, which integrates the mounting parts of the motor and the harmonic reducer, reducing the cost of the entire mechanism. The number of parts is convenient for installation, and the mechanical error caused by installation is reduced. Ribs and ribs are designed inside the main support to effectively ensure the structural strength and rigidity of the parts of the hip joint mechanism of the present invention.

Owner:张锐

Precision part machining numerical control machine tool

PendingCN111168474AShorten the lengthGuaranteed rigidityDispersed particle filtrationTransportation and packagingNumerical controlProcess engineering

The invention discloses a precision part machining numerical control machine tool. The precision part machining numerical control machine tool comprises a machining chamber with an inner cavity. A workpiece machining device and a workpiece fixing and rotating mechanism are arranged in the machining chamber. The workpiece machining device comprises a moving mechanism and a turret capable of being driven to move and rotate by the moving mechanism. A plurality of machining tools are arranged on the turret. Cutting edges of at least two of the machining tools have the height difference. At least part of the machining tools of which the cutting edges have the height difference are detachably connected with the turret through different lengths of tool aprons. According to the precision part machining numerical control machine tool, the machining tools are fixed to the turret through the tool aprons with the different lengths; the requirement for the low position of the cutting edges of the machining tools can be met through the tool aprons; and accordingly, the length of the machining tool can be greatly reduced to ensure the rigidity of the tools, and the machining stability and qualitycan be improved.

Owner:昂拓科技(苏州)有限公司

Pre-stressed flexible support inclined uniaxial tracking system

ActiveCN110535420AIncrease power generationGuaranteed second usePhotovoltaic supportsSolar heating energyPre stressingEngineering

The invention discloses a pre-stressed flexible support inclined uniaxial tracking support system which comprises a flexible support, a tracking device and a transmission device. The flexible supportis arranged by multiple groups of support column structures. Each group of support column structure is composed of two groups of columns and load-bearing steel cables. The tracking device comprises adriving rotary reduction motor. The transmission device is connected with the corresponding photovoltaic module through each driving swing arm. The driving steel cable is annular, and the middle partis wound and fixed on the output shaft of the driving rotary reduction motor and the two ends respectively pass through a driving pulley I and a driving pulley II. The left and right sides of the active steel cable are respectively connected with the corresponding connecting steel cable I and the connecting steel cable II along the front-and-rear direction. Compared with the traditional tracking bracket, the cost is reduced. Compared with the traditional fixed support, the power generation efficiency is improved and the secondary utilization of land can be realized.

Owner:南京市光翔新能源科技有限公司

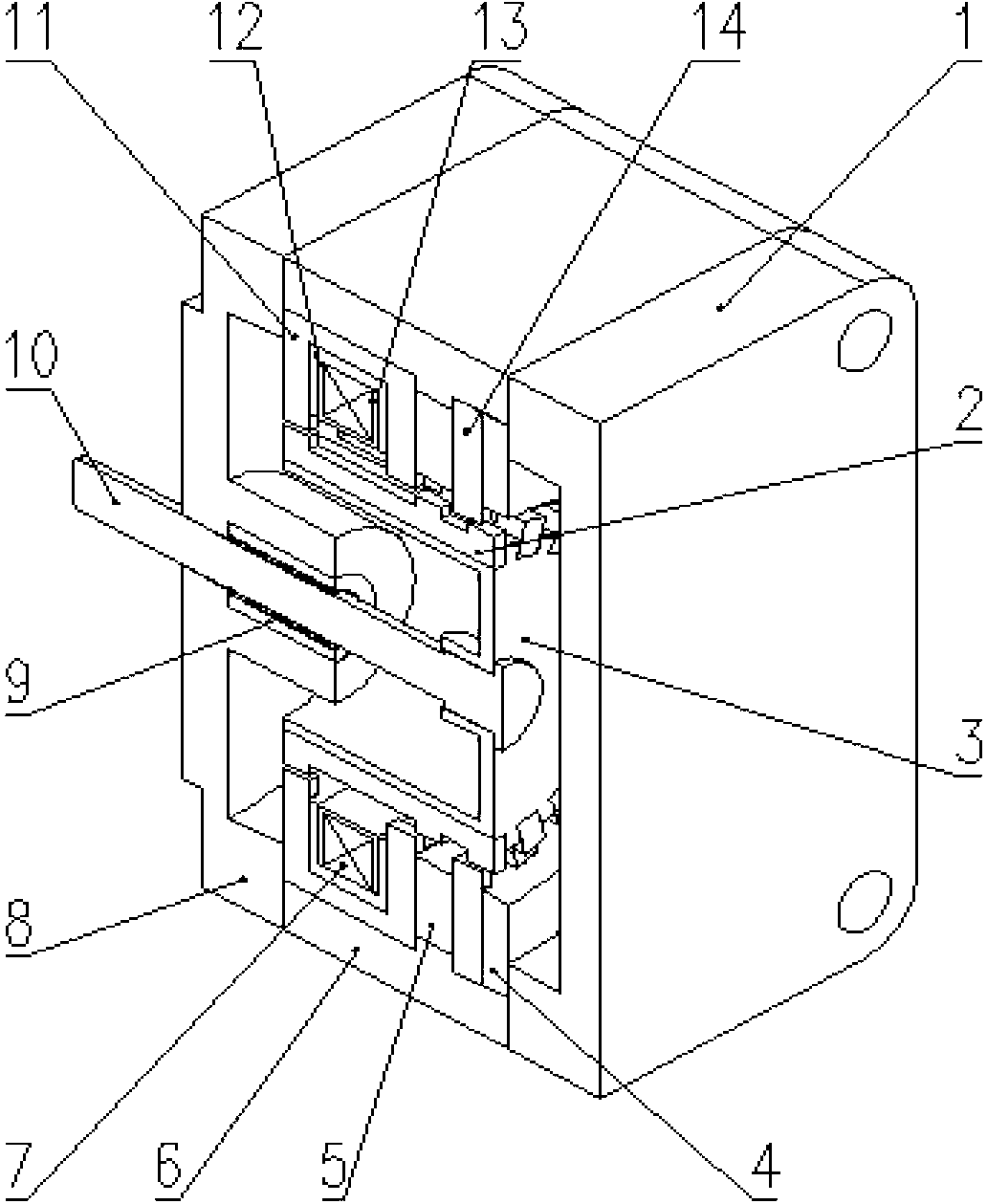

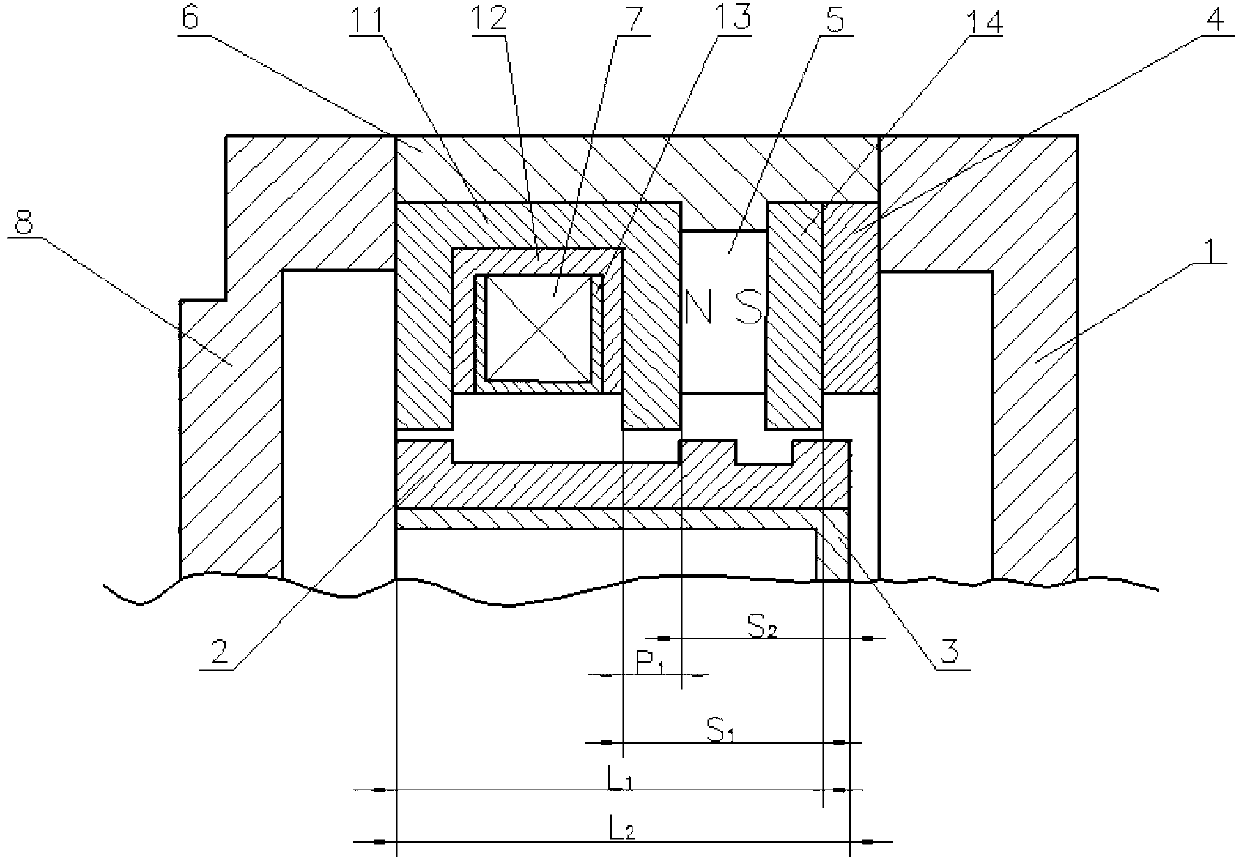

Single-phase linear-motion inserting sheet type electromagnet

ActiveCN103107608AImproved power to weight ratioReduce eddy current lossMagnetic circuit stationary partsLinear motionEngineering

The invention discloses a single-phase linear-motion inserting sheet type electromagnet which comprises an armature assembly, a stator assembly, a shell, a front end cover and a rear end cover, wherein the stator assembly comprises a stator left retainer, a stator left inserting sheet, a stator right retainer, a stator right inserting sheet, a coil retaining frame, a control coil and a circular-ring-shaped permanent magnet. The armature assembly comprises three portions, namely a hollow cup type armature retainer, armature inserting sheets and a push rod, wherein a plurality of inserting slots which are evenly distributed are formed in the radial outer cylindrical surface of the hollow cup type armature retainer, the armature inserting sheets can be inserted into the inserting slots and are made of silicon steel materials. Each arm inserting sheet is in a flat strip shape, is formed in a cold stamping mode and is provided with three rectangular teeth at different intervals, and the widths of the three rectangular teeth are the same. The shell, the front end cover and the rear end cover restraint and fix the stator assembly in the axial direction, and the shell is connected with the front end cover and the rear end cover through bolts.

Owner:ZHEJIANG UNIV OF TECH

A Construction Method of Concave String Beam

ActiveCN106121116BShorten the construction periodGuarantee plane stabilityBuilding roofsBuilding material handlingShaped beamKnee braces

The invention relates to the technical field of beam string structure construction, in particular to a construction method for a U-shaped beam string structure. The construction method comprises the following steps: A, installing a pipe truss of one end, and then, performing section construction of an upper string box beam, wherein a construction sequence is that construction is performed from one end to the other end; firstly, installing the upper string box beam of one end, inserting roof secondary beams into the upper string box beam, and then, installing a pipe truss, an upper string box beam and roof secondary beams of the other end; B, installing struts; and C, installing a lower string stay cable, wherein the stay cable comprises a main cable and knee-bracing tension rods; in a tensioning process of the lower string stay cable, each upper string box beam may produce an upward displacement, and automatically separates from a temporary support frame to realize automatic unloading. According to the construction method, a tensioned unit is enabled to be located below lateral restraints of structures of two sides in a structural plane, and therefore, plane stability of the beam string structure is guaranteed during tensioning construction, and structural stiffness of the beam string structure at the construction stage is guaranteed.

Owner:CHINA CONSTR SCI & IND CORP LTD

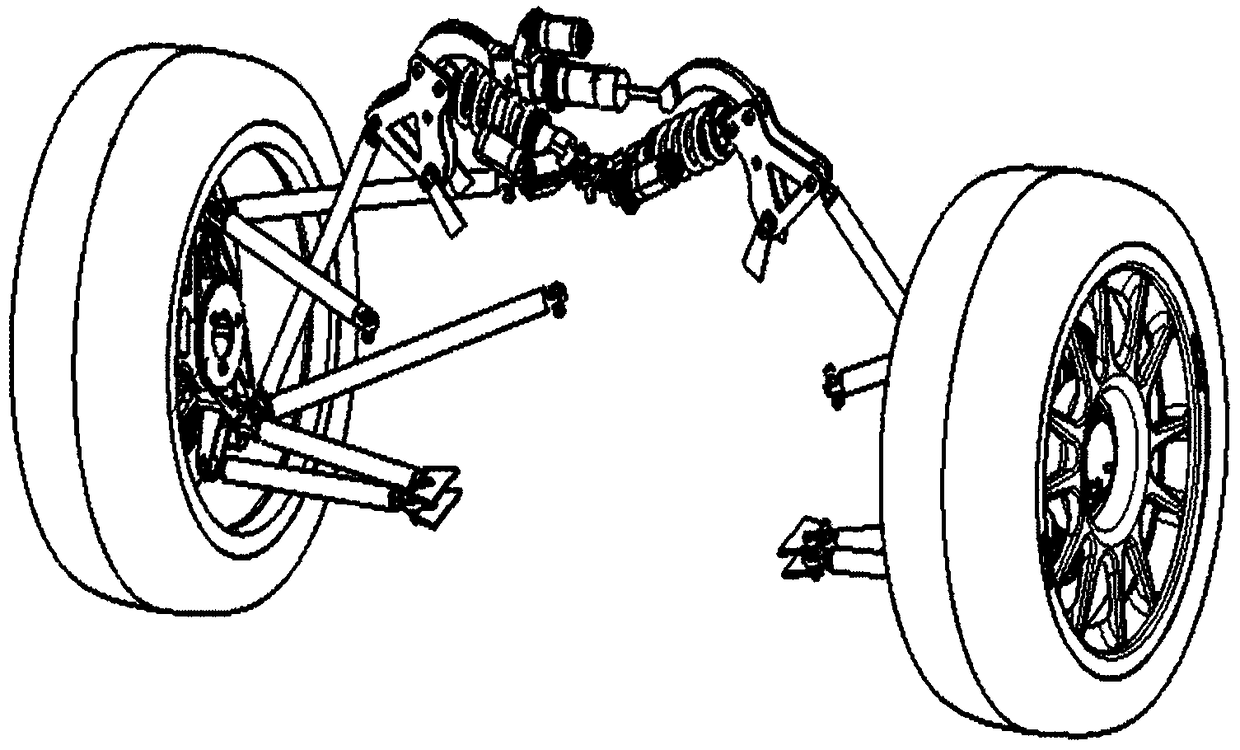

Vehicle longitudinal trim control device

InactiveCN108859649AImprove powerImprove fuel economyResilient suspensionsEngineeringIndependent suspension

The invention discloses a vehicle longitudinal trim control device. The device comprises a damping mechanism, lever mechanisms are symmetrically arranged on the two sides of the damping mechanism androtationally connected with the damping mechanism, transmission rods are connected to one ends of the lever mechanisms on the two sides, and the transmission rods are rotationally connected with the lever mechanism. The device has the advantages that by arranging the damping mechanism of an independent suspension, the damping mechanism can only take effect when wheels hop in the same direction simultaneously for twice, that is to say, the damping mechanism can only take effect when a longitudinal trim tendency exists, and then the purpose that individual control over the longitudinal trim characteristic is conducted while the vehicle longitudinal trim characteristic is not affected can be achieved; therefore, by means of the device, good longitudinal trim control can be provided for a vehicle under the condition of not affecting the vehicle longitudinal trim characteristic; in addition, the device is compact in structure, simple in layout and easy to disassemble, install and adjust, and has an extremely high application value.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com