Blade tip ejecting self-driven wheeled fan engine

A self-propelled, engine-based technology, applied in the direction of gas turbine devices, machines/engines, jet propulsion devices, etc., can solve the problems of multi-stage turbines with heavy weight, complex and uncompact structures, etc., and achieve mass reduction, weight reduction, and structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

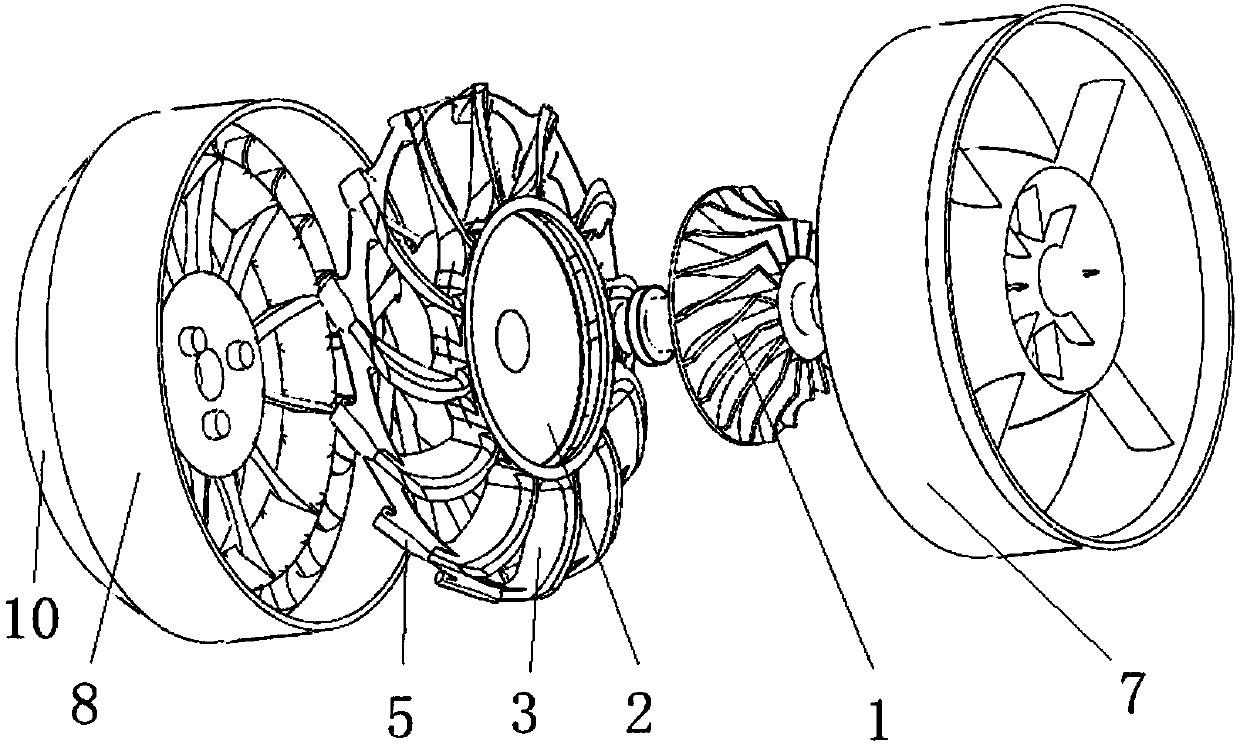

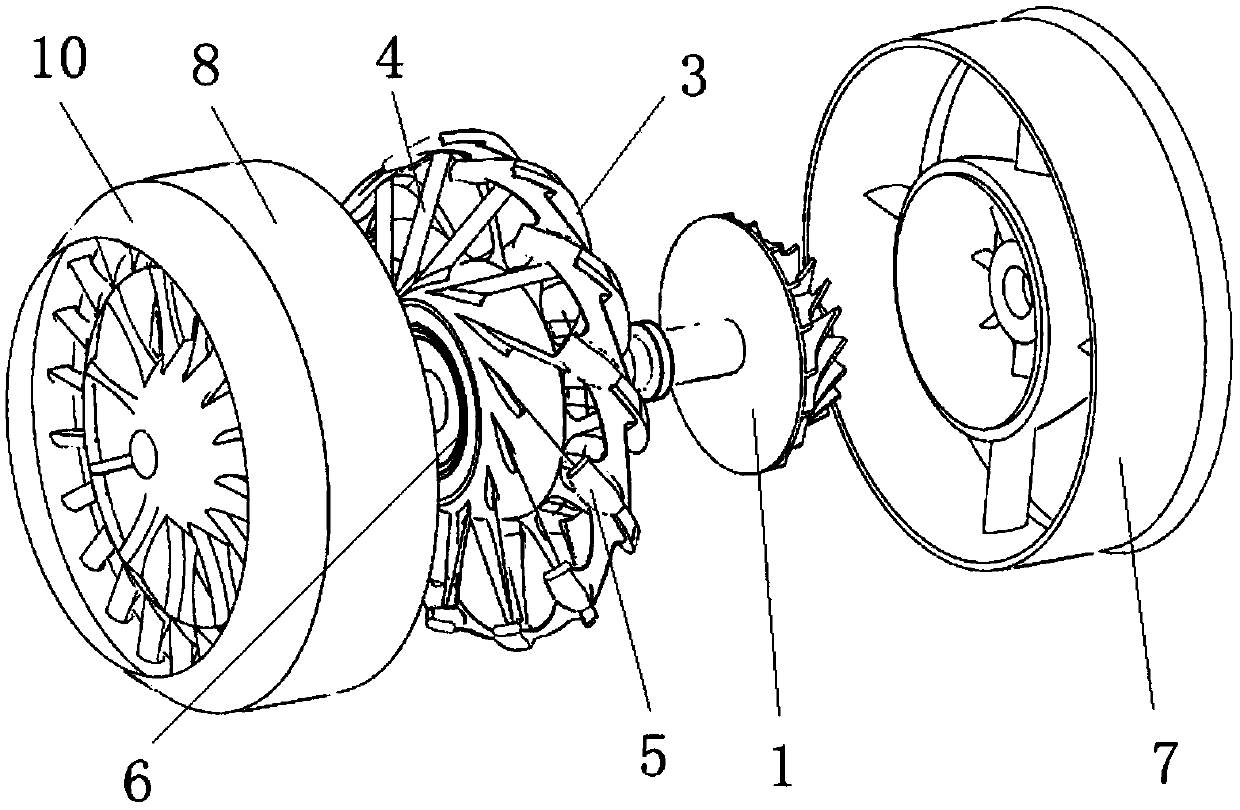

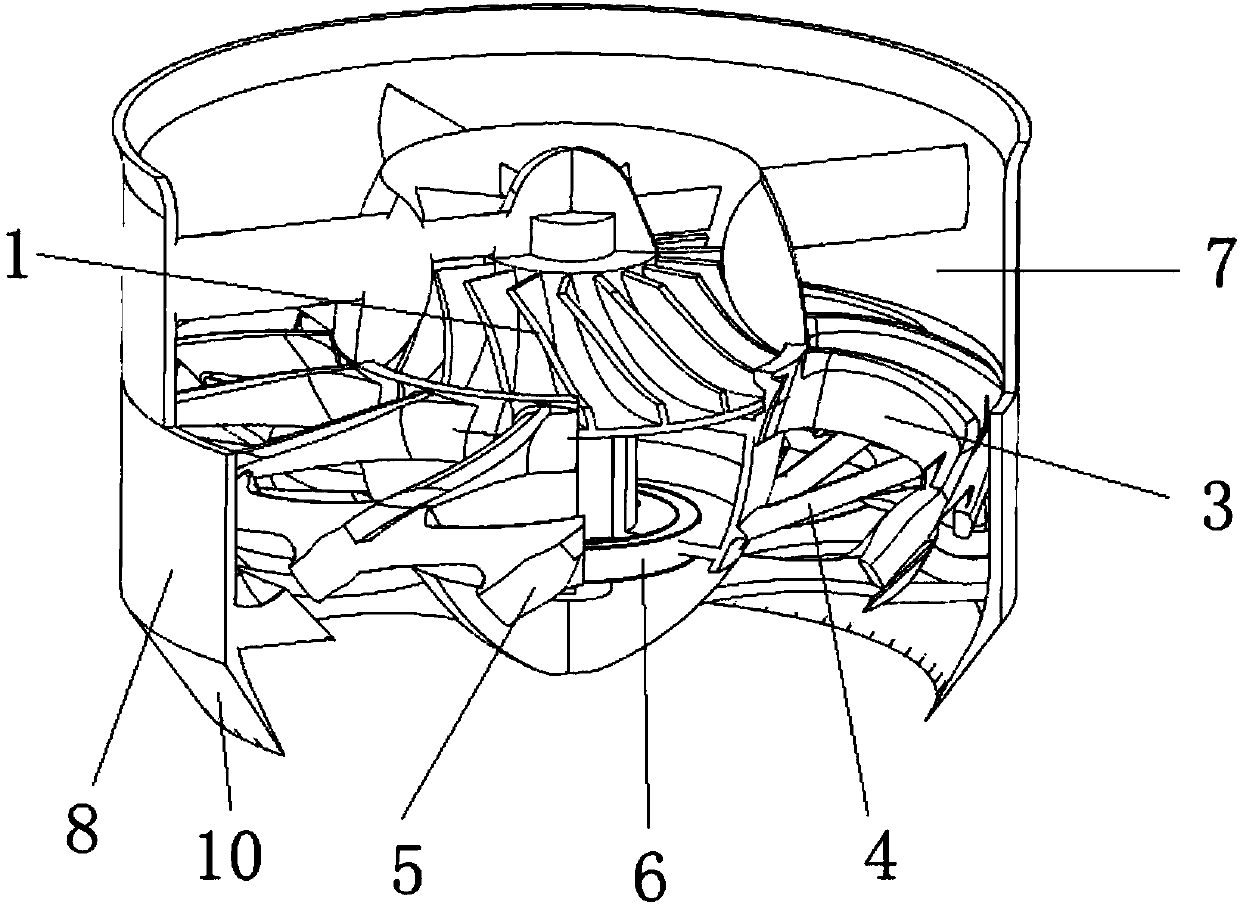

[0036] like figure 1 , 2 Shown is a blade-tip jet self-driven wheel fan engine, including a front casing 7, a rear casing 8, and two counter-rotating rotors wrapped between the front casing 7 and the rear casing 8, and the two The counter-rotating rotors are compressor rotor 1 and self-driven wheel fan 2 respectively;

[0037] like Figure 4 As shown, the compressor rotor 1 includes an integrally connected compressor shaft and impeller; Figure 5 , 6 As shown, the self-driven wheel fan 2 includes a central sleeve, 2 to 100 hollow fan blades 3, a tip combustion chamber 5, an oil supply pipe 4 and a fan hoop 9; the hollow fan blade 3 and the oil supply pipe 4 Evenly distributed on the outside of the center sleeve along the circumference, the hollow fan blades 3 are connected to the front end of the outer wall of the center sleeve, the oil supply pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com