Single-phase linear-motion inserting sheet type electromagnet

A plug-in, electromagnet technology, applied in the direction of magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problems of useless loss of electromagnets, increased temperature rise, high processing cost, eddy current, etc. The effect of reducing structural strength and stiffness, improving power-to-weight ratio, and reducing eddy current losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

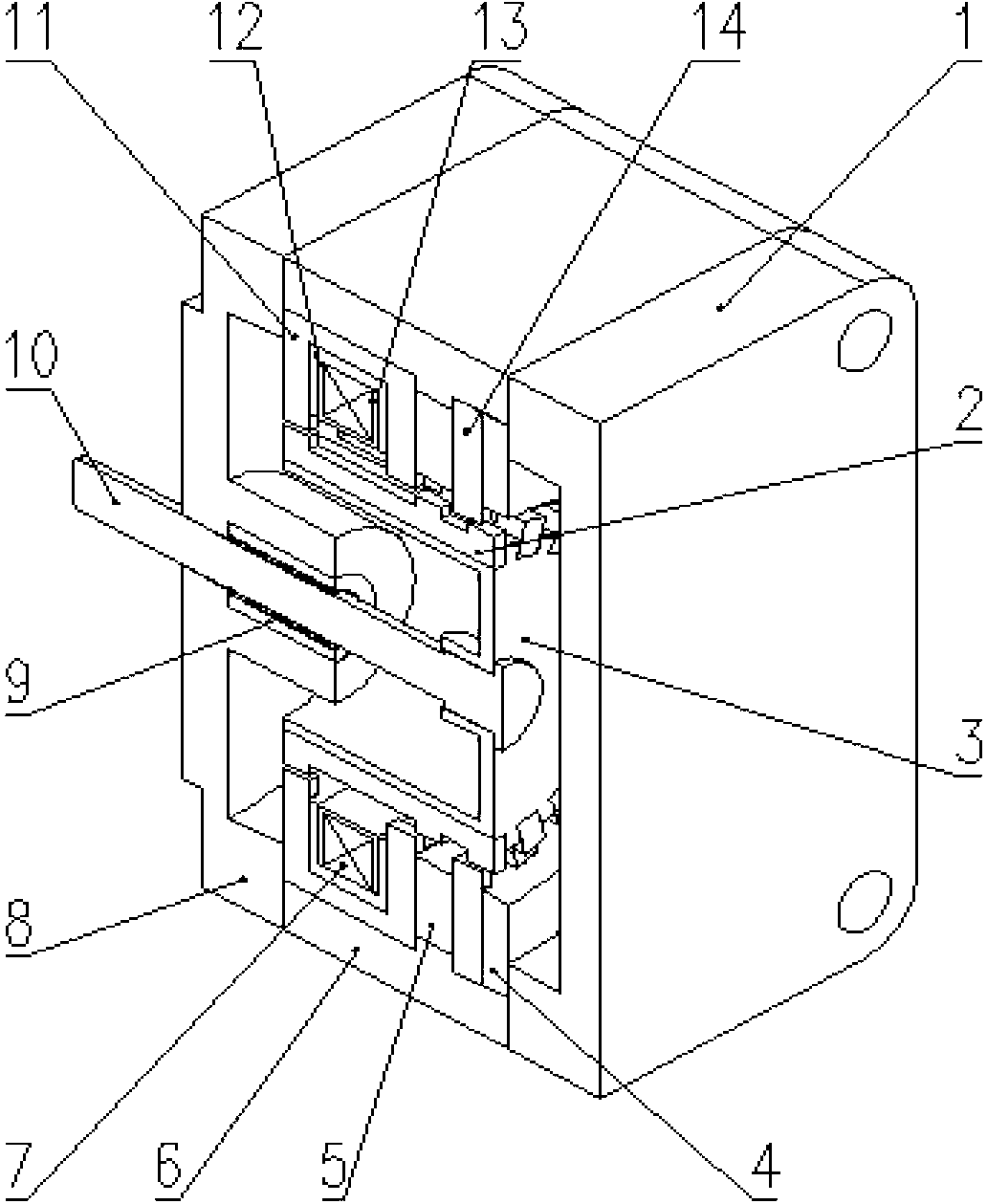

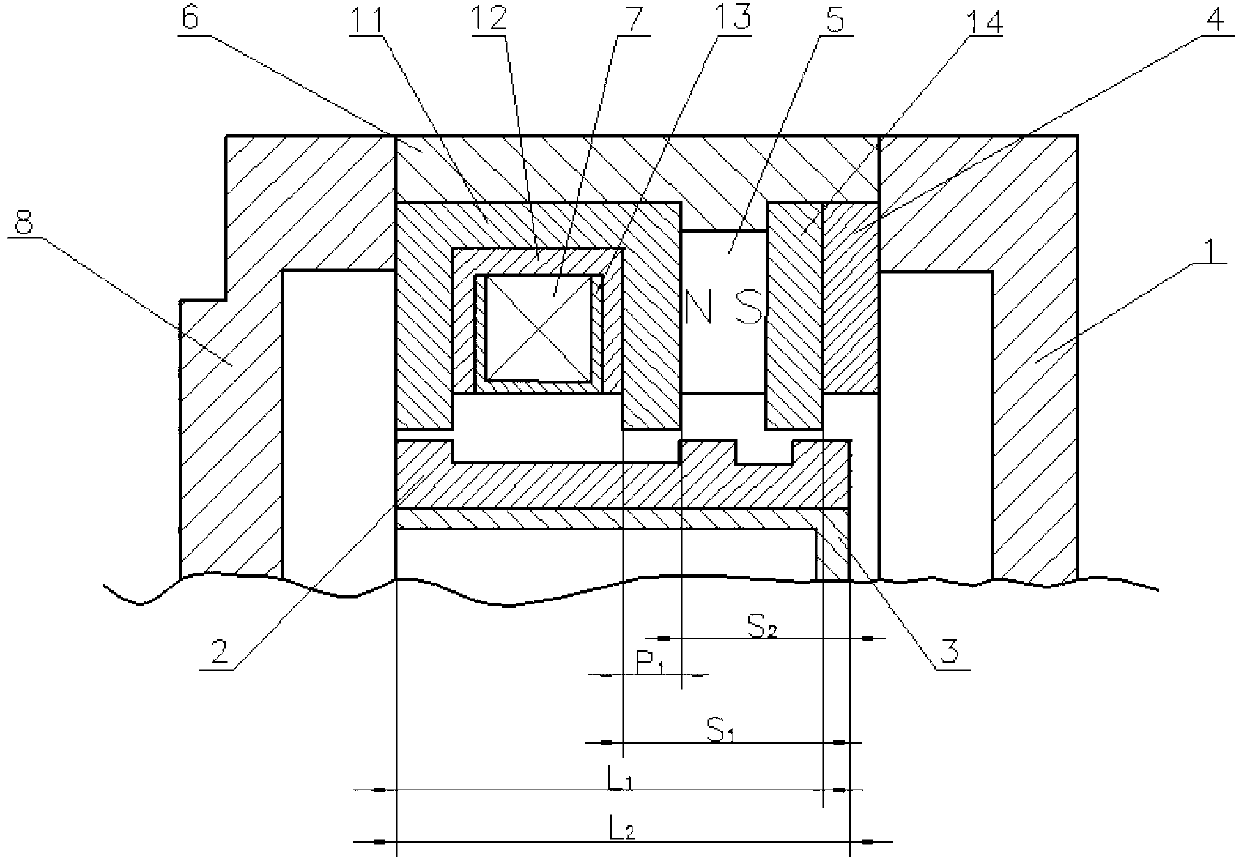

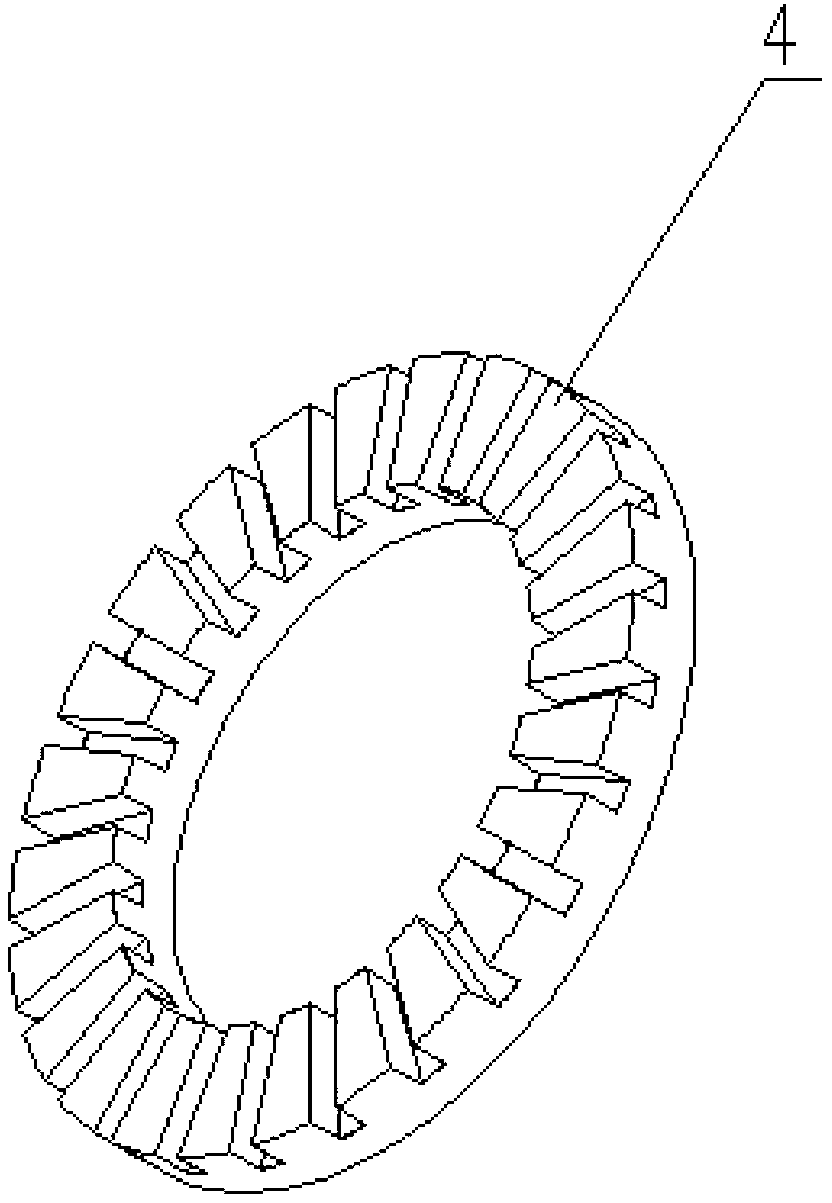

[0027] refer to Figure 1 ~ Figure 9-c , a single-phase direct-acting insert type electromagnet, its main structure includes an armature part, a stator part, a housing, a front end cover and a rear end cover. The stator part includes a stator left retainer 12, a stator left insert 11, a stator right retainer 4, a stator right insert 14, a coil retainer 13, a control coil 7 and an annular permanent magnet 5; the stator left retainer 12 The stator right cage 4 is injection-molded with high-strength reinforced nylon material, which can greatly reduce the weight of the whole machine while maintaining a certain strength and rigidity, and is conducive to improving the power-to-weight ratio of the whole machine; the stator left cage 12 There are equally spaced slots distributed in the radial direction for inserting the left stator insert 11, which is a flat 匚 shape formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com