High-power medium-speed generator

A generator and high-power technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of low power-to-weight ratio, poor load performance, and high price, and achieve high power-to-weight ratio and strong load capacity , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

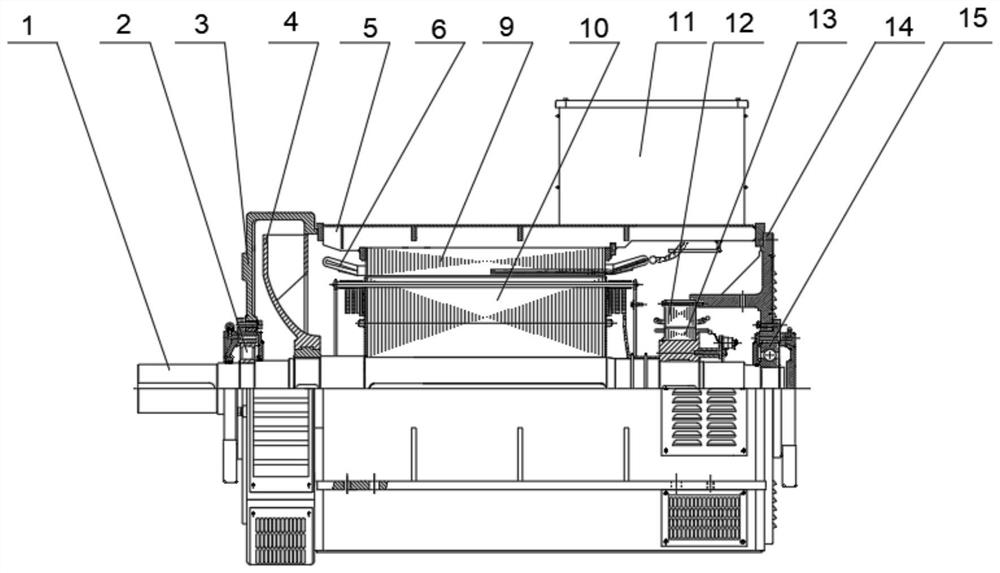

[0025]Such asFigure 1 - Figure 4As shown, the present invention provides a high power medium speed generator.

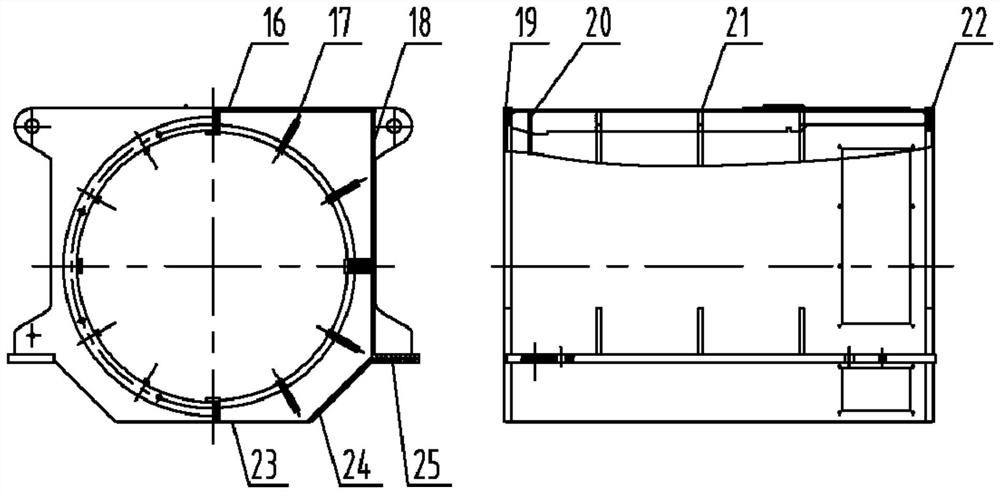

[0026]Including a motor body, the motor body includes a rotating shaft 1, a front bearing 2, a front end cap 3, a fan 4, a seat 5, a stator winding, a stator core 9, a rotor core 10, a casing bond group 11, excitation machine stator 12 , The excitor rotor 13, the rear end cover 14, the rear bearing 15, the base 5 is made of the upper cover plate 16, the rib 17, the side cover 18, the front end plate 19, the air winding plate 20, the support plate 21, and then The end plate 22, the lower cover plate 23, the sloping plate 24, the bottom foot plate 25 welded into a square structure, the structure is simple and stable, the strength is good;

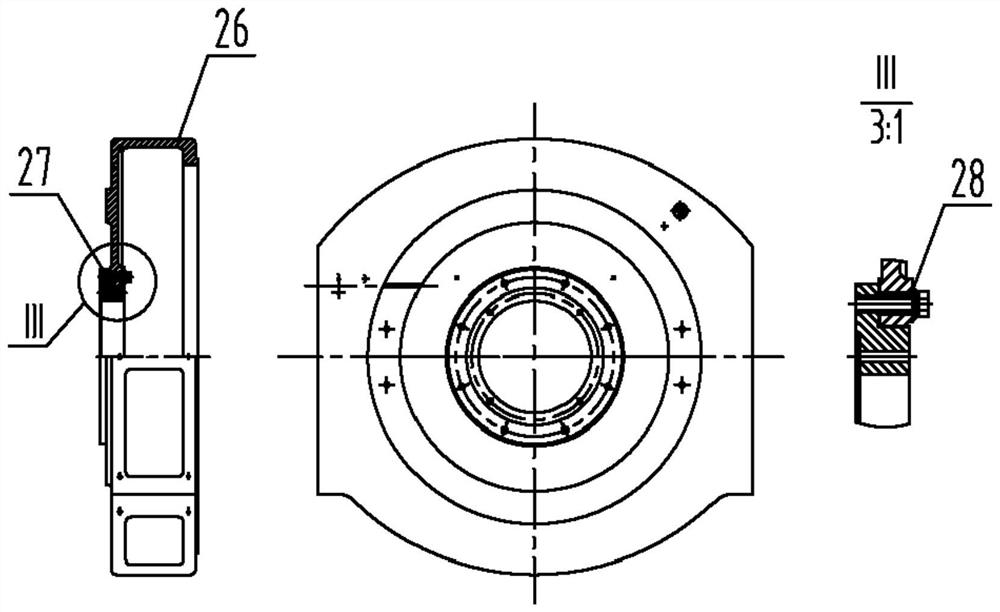

[0027]The front end cap 3 is formed by a front end cap stub member 26, a front bearing sleeve 27, and an insulating pad 28. The front end cap 3 has an insulating function, which can effectively prevent the production of the shaft current.

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com