Precise positioning and welding system for cutting teeth of cutting head of heading machine and welding method thereof

A cutting head picking and precise positioning technology, which is applied in the field of coal and rock excavation machinery, can solve the problems of pick damage, reduced work efficiency, and increased pick difficulty, so as to reduce errors, ensure accurate positioning, and reduce precision positioning. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

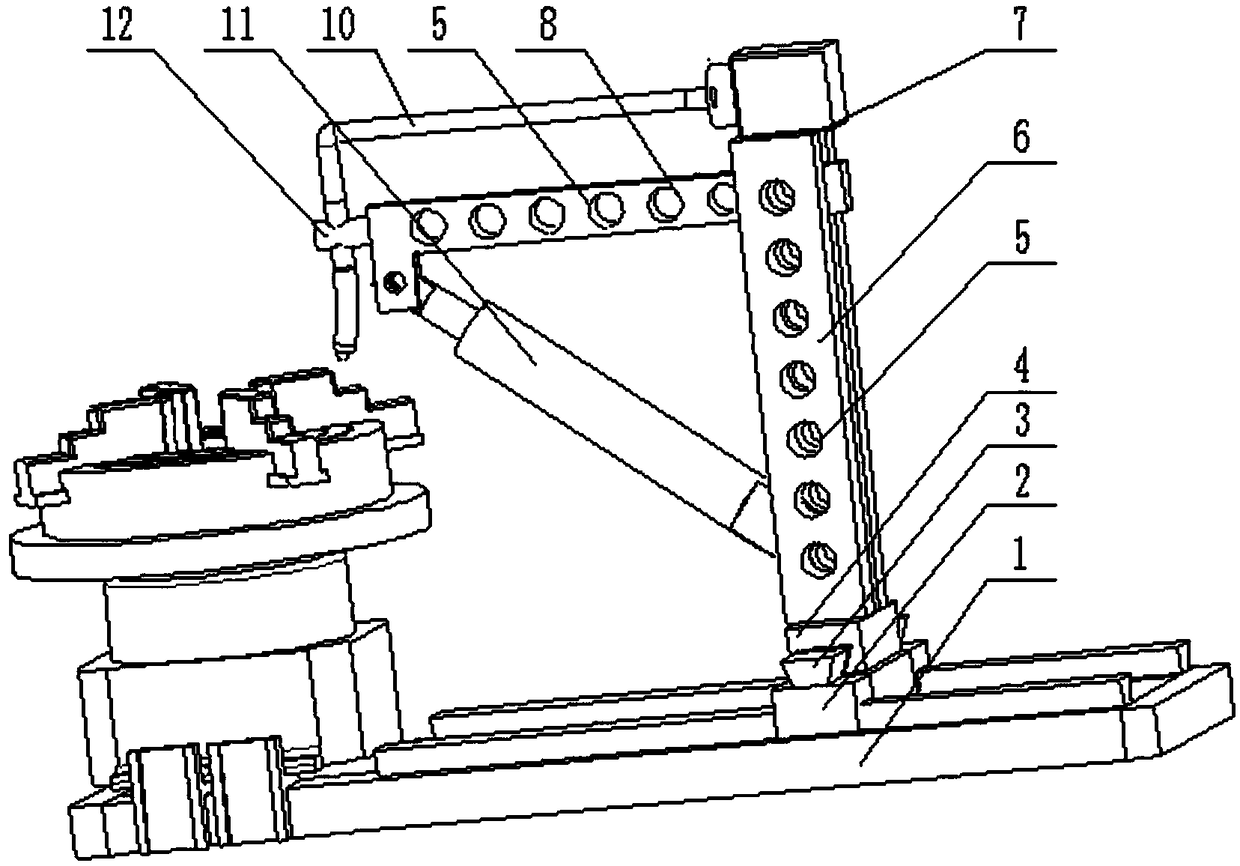

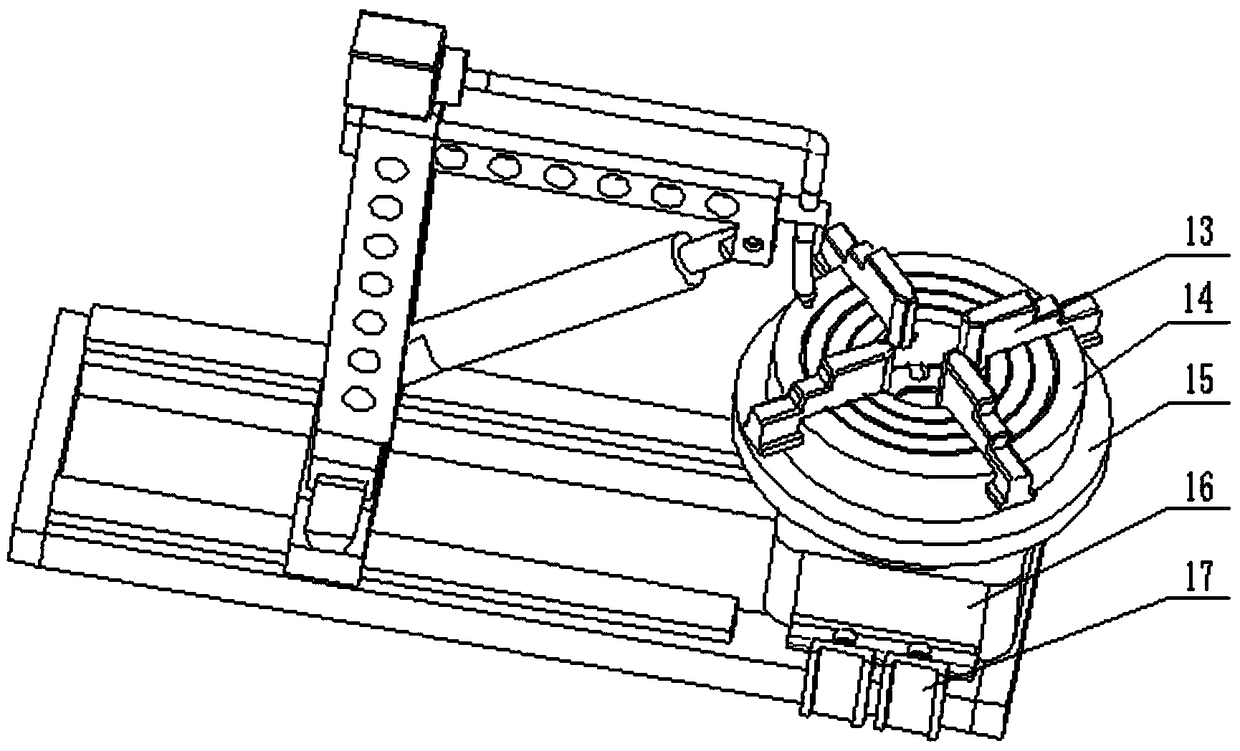

[0035] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

[0036] Such as Figure 1-2 As shown, the precise positioning welding system of the cutting head pick of the roadheader of the present invention includes a first guide rail 1, and one end of the first guide rail 1 is fixedly connected with a supporting device for supporting and fixing the cutting head of the roadheader; The support device includes a fixed bracket 17 fixed at one end of the first guide rail 1, on which a chuck 14 and a connecting flange 15 are arranged in turn from top to bottom, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com