Composite material reinforced part and forming process method

A composite material and molding process technology, which is used in the field of solid rocket motors to ensure structural integrity, improve overall stiffness, and improve overall strength and stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment adopts a kind of composite material reinforcement molding process method, and described composite material is carbon fiber / epoxy resin type, comprises the following steps:

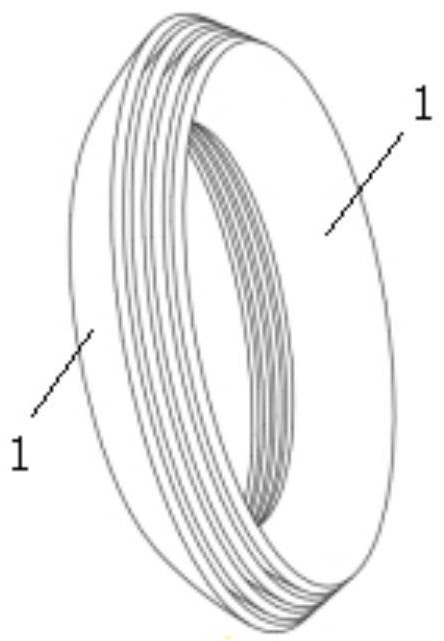

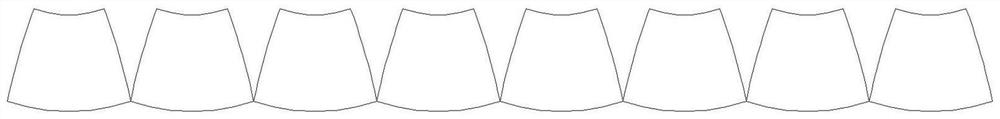

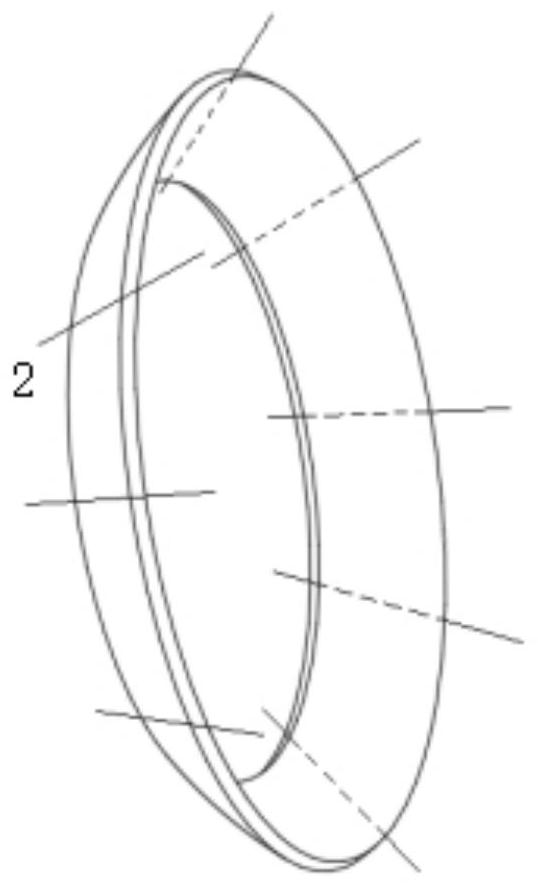

[0042] S1. According to the 3D diagram of the reinforcement, make a 2D expansion diagram, such as Figure 1-2 Shown, and mark the cutting part, such as image 3 As shown, the carbon fiber prepreg is manually cut according to the size of the process design and marked one by one; the carbon fiber volume content of the reinforcement is 65%; as Figure 4 As shown, the inner and outer surfaces of the reinforcement are partly made of 3k carbon fiber satin fabric, and the inside is made of 3k unidirectional prepreg, and the prepreg is epoxy resin type;

[0043] S2. Lay-up design for carbon fiber composite flexible joint reinforcements. The ratio of large mouth, middle section and small mouth is 1:2:1, and each part overlaps and overlaps without obvious boundaries; in the large mouth...

Embodiment 2

[0050] The present embodiment adopts a kind of composite material reinforcement molding process method, and described composite material is carbon fiber / epoxy resin type, comprises the following steps:

[0051] S1. According to the 3D diagram of the reinforcement, make a 2D expansion diagram, such as Figure 1-2 Shown, and mark the cutting part, such as image 3 As shown, the carbon fiber prepreg is manually cut according to the size of the process design and marked one by one; the carbon fiber volume content of the reinforcement is 65%; as Figure 4 As shown, the inner and outer surfaces of the reinforcement are made of 12k carbon fiber plain fabric, and the interior is made of 1k unidirectional prepreg, and the prepreg is epoxy resin type;

[0052] S2. Lay-up design for carbon fiber composite flexible joint reinforcements. The ratio of large mouth, middle section and small mouth is 1:2:1, and each part overlaps and overlaps without obvious boundaries; in the large mouth, mi...

Embodiment 3

[0058] The present embodiment adopts a kind of composite material reinforcement molding process method, and described composite material is carbon fiber / epoxy resin type, comprises the following steps:

[0059] S1. According to the 3D diagram of the reinforcement, make a 2D expansion diagram, such as Figure 1-2 Shown, and mark the cutting part, such as image 3 As shown, the carbon fiber prepreg is manually cut according to the size of the process design and marked one by one; the carbon fiber volume content of the reinforcement is 65%; as Figure 4 As shown, the inner and outer surfaces of the reinforcement part are made of 6k carbon fiber twill fabric, and the inside is made of 3k unidirectional prepreg, and the prepreg is epoxy resin type;

[0060] S2. Lay-up design for carbon fiber composite flexible joint reinforcements. The ratio of large mouth, middle section and small mouth is 1:2:1, and each part overlaps and overlaps without obvious boundaries; in the large mouth, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com