Micro-structure corneal contact lens and preparation method thereof

A contact lens and microstructuring technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of increasing wearer's discomfort, shortening wearing time, and low diagnosis and treatment efficiency, so as to improve oxygen permeability and diagnosis Efficiency, ensuring wearing comfort, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

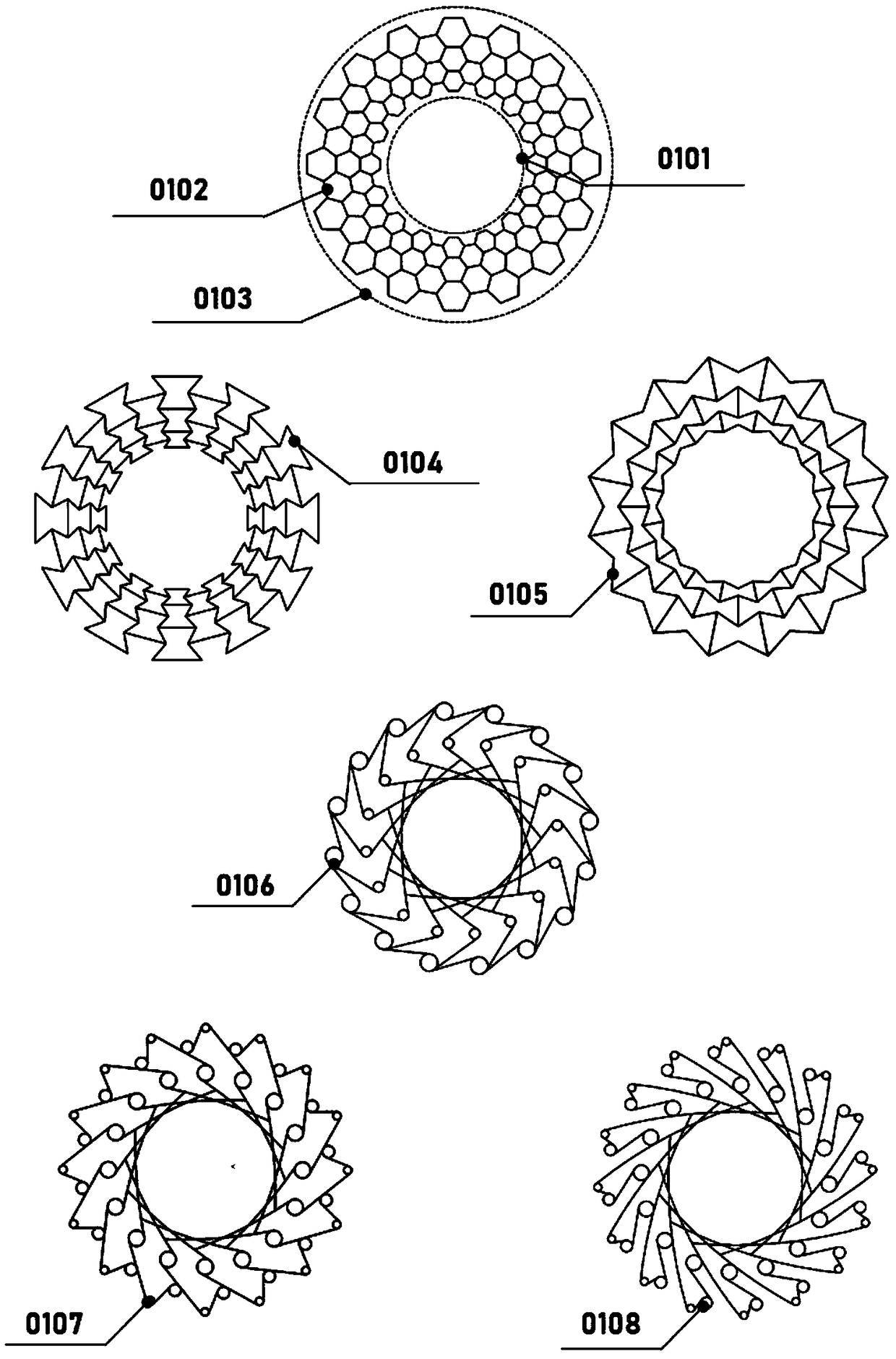

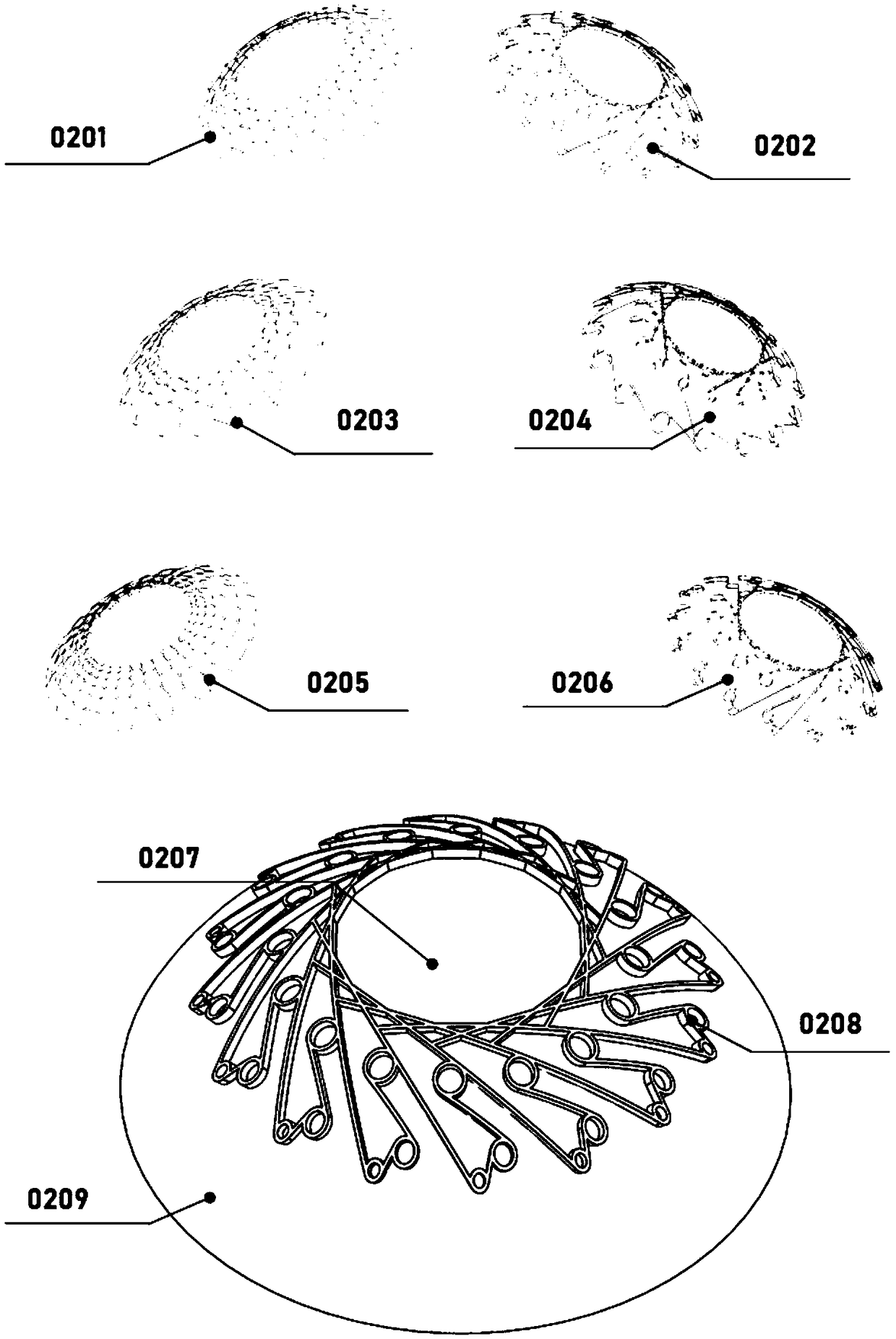

[0031] refer to Figure 1 to Figure 2 , in one embodiment, a microstructured mechanically flexible smart contact lens, comprising a porous grid in a hollow ring layout formed by one or more deformable elastic mechanical units according to one or more distribution rules structure, wherein the annular layout is formed by the periodic combined arrangement of the deformable elastic mechanics units in the circumferential and radial directions or in an orthogonal manner. This kind of microstructure design keeps the main curvature fluctuation low under the loads of extrusion, torsion and shearing imposed by the blinking movement of the human eye, and weakens or eliminates the obvious continuum annular thin shell near geometric defects. buckling phenomenon. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com