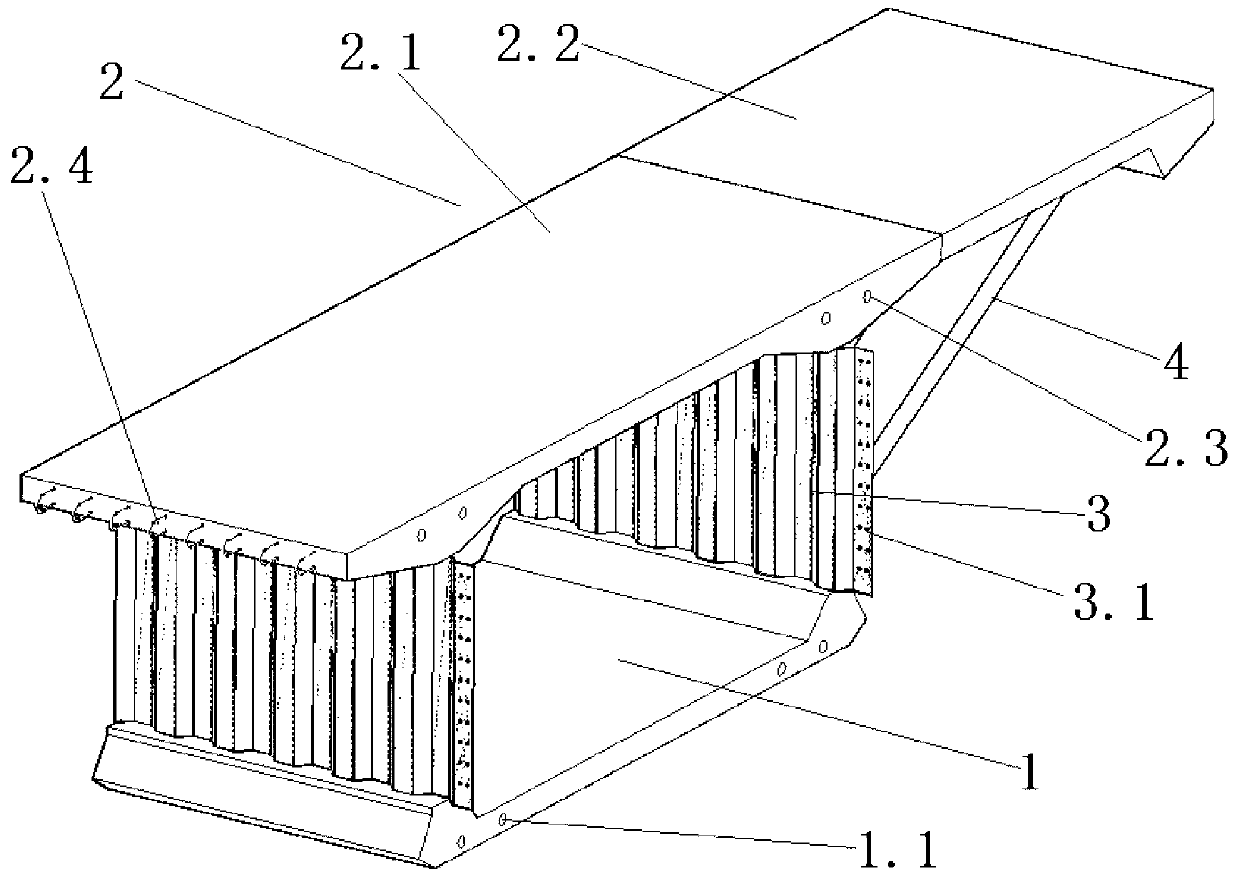

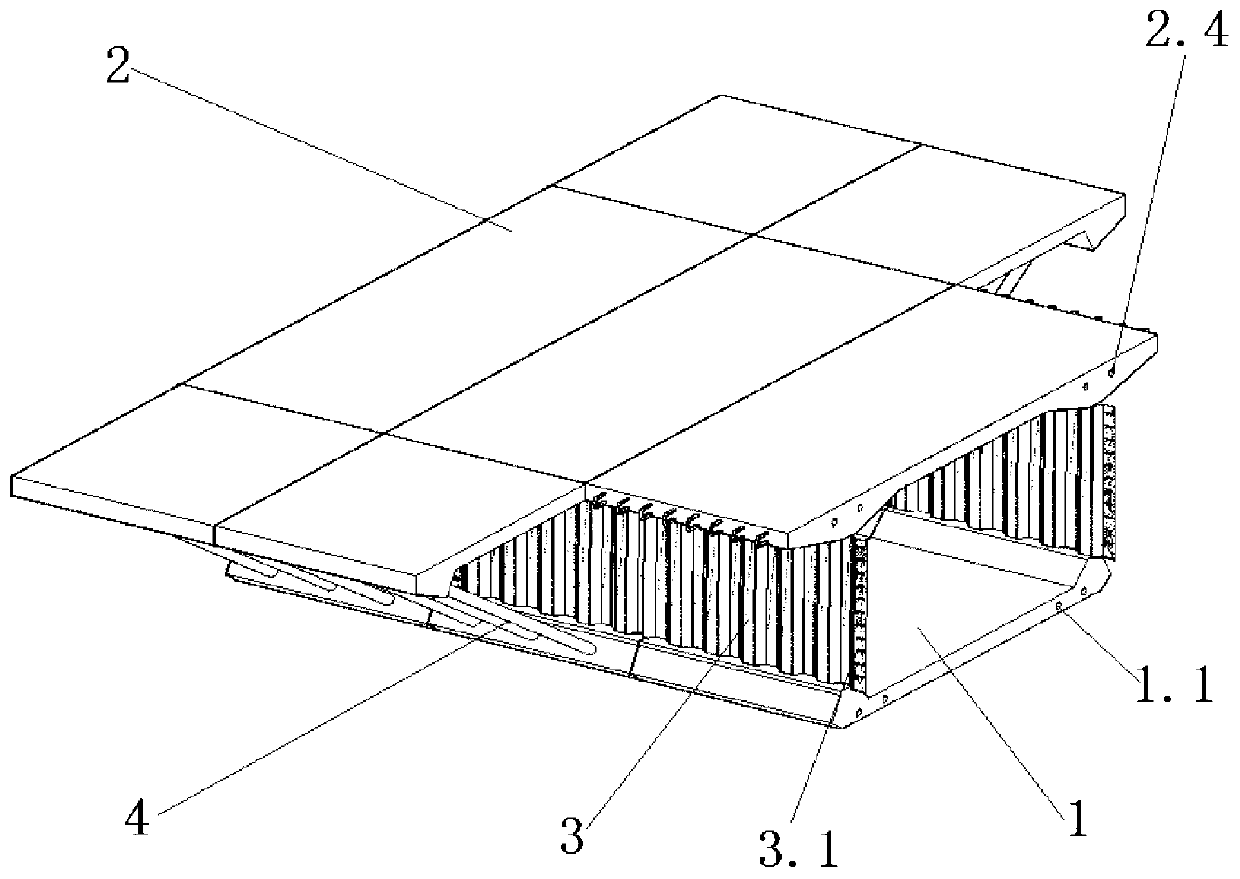

Large-cantilever steel web spinal box beam segment and construction technology

A technology of steel webs and segments, applied in the field of large cantilever steel web spine box girder segments and construction technology, can solve the problems of inconvenient transportation and hoisting of concrete webs and steel webs, poor structural performance of concrete webs, Increase the total cost of the project and other issues to achieve the effect of facilitating factory construction, improving prestressing efficiency, and improving structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

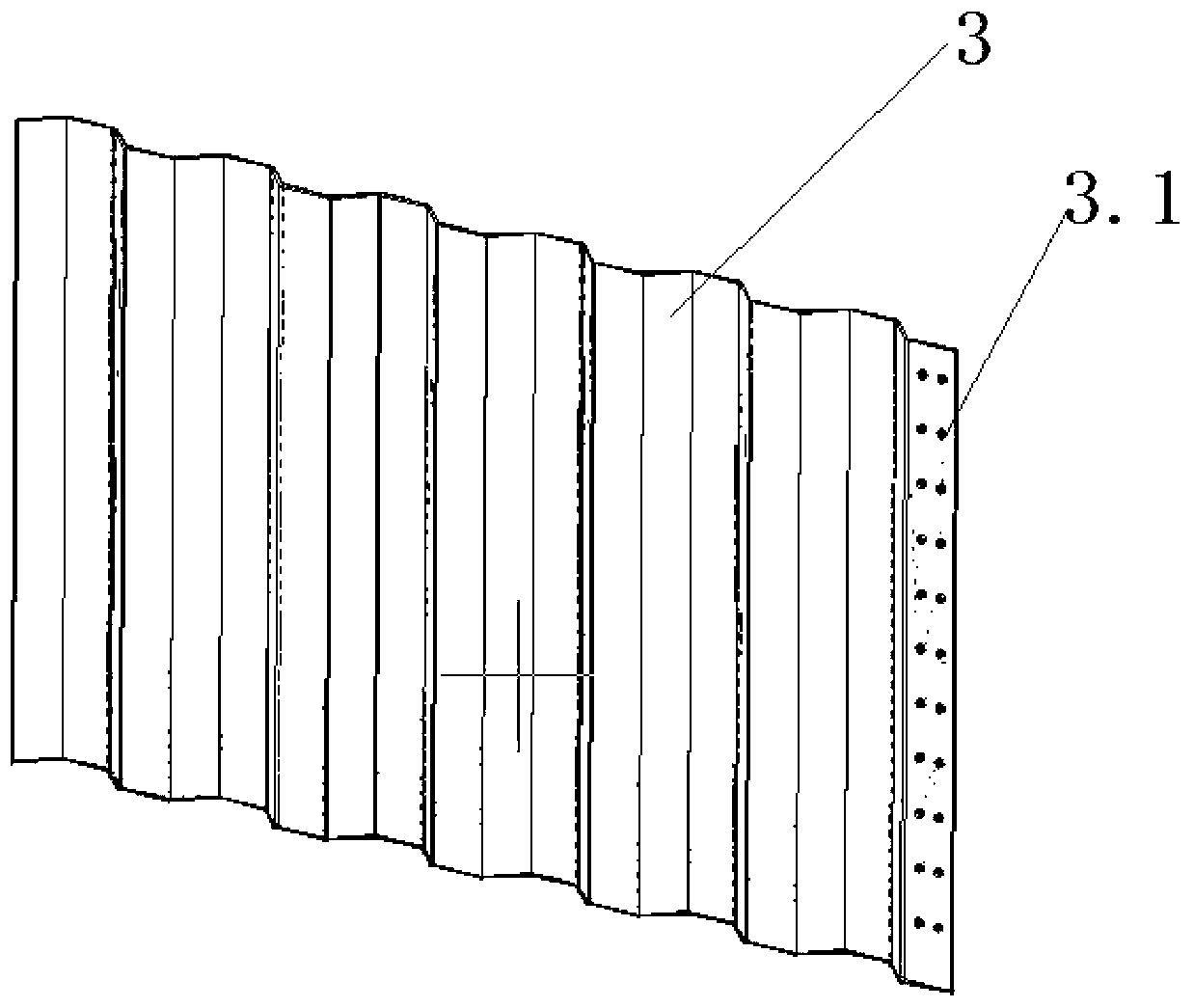

[0044] Such as Figure 4 As shown, the steel web 3 is embedded in the unit box girder bottom plate 1 / unit box girder top plate 2, and a connecting piece 5 is provided between the steel web 3 lateral sides and the unit box girder bottom plate 1 / unit box girder top plate 2. The web 3, the connector 5, the unit box girder bottom plate 1 / the unit box girder top plate 2 are sequentially passed through and fastened horizontally by the connecting steel bar 7.

[0045] Implementation two:

[0046] Such as Figure 5 As shown, the steel web 3 is embedded in the unit box girder bottom plate 1 / unit box girder top plate 2, and the end of the steel web 3 is fixedly welded with a connecting plate 6, and the connecting plate 6 is embedded in the unit box girder bottom plate 1 / unit box girder top plate 2, the connecting plate 6, unit box girder bottom plate 1 / unit box girder top plate 2 are vertically passed through and fastened by studs 8.

[0047] In the present invention, the end faces o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com