Modularized multifunctional drill jambo system

A rock drilling rig and multi-functional technology, applied in drilling equipment, drilling equipment and methods, earthwork drilling and other directions, can solve the problems affecting the operation and accuracy of the drilling rig, low reliability, unreliable structure, etc., and achieve the transmission mode. Simple and reliable, meet the requirements of passing vehicles, and facilitate transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

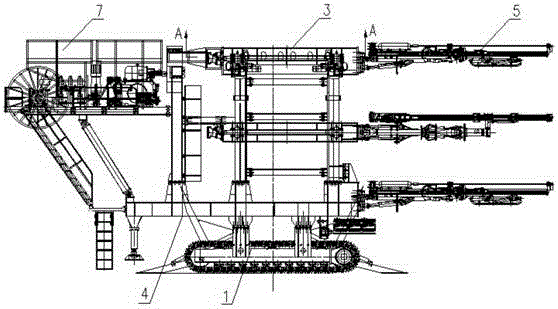

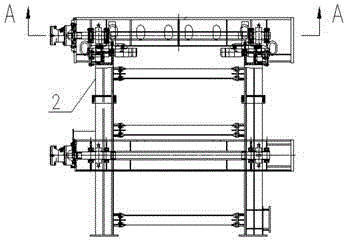

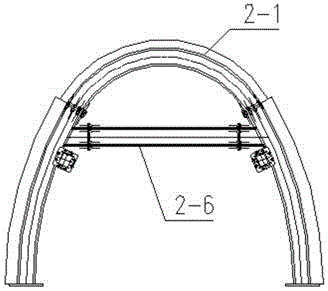

[0040] The modular portal type multifunctional rock drilling jumbo of the present invention is as Figure 1-2 shown. Including: crawler running system 1; ring rail frame 2; drilling rig driving device 3; chassis assembly 4; hydraulic drilling rig 5; working platform 6; electric hydraulic system 7 and other components.

[0041] Track walking system 1 such as image 3 , Pic 4-1 , Figure 4-2shown. The crawler running system 1 is the running and supporting device of the trolley, with its own running platform and folding flaps, which can not only meet the requirements of passing the vehicle, but also overcome the impact of the steering load generated when the crawler turns. The system includes a crawler device 1-1, a connecting flange seat 1-2, a folding flap 1-3, a running platform 1-4, an overturning oil cylinder 1-5, a first oil cylinder support, and a second oil cylinder support. Two sets of crawler devices 1-1 are connected with the lower parts of four sets of connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com