Liquid rocket engine turbopump flexible rotor high-speed dynamic balance supporting device

A high-speed dynamic balancing, turbo pump rotor technology, applied in static/dynamic balance testing, measuring devices, machine/structural component testing, etc., can solve the problem of low positioning accuracy, inability to set positioning surfaces, and reduce high-speed dynamic balancing efficiency and other problems, to achieve the effect of ensuring the support stiffness and structural stiffness, avoiding a large amount of oil participating in useless circulation, and simplifying the number of adapters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

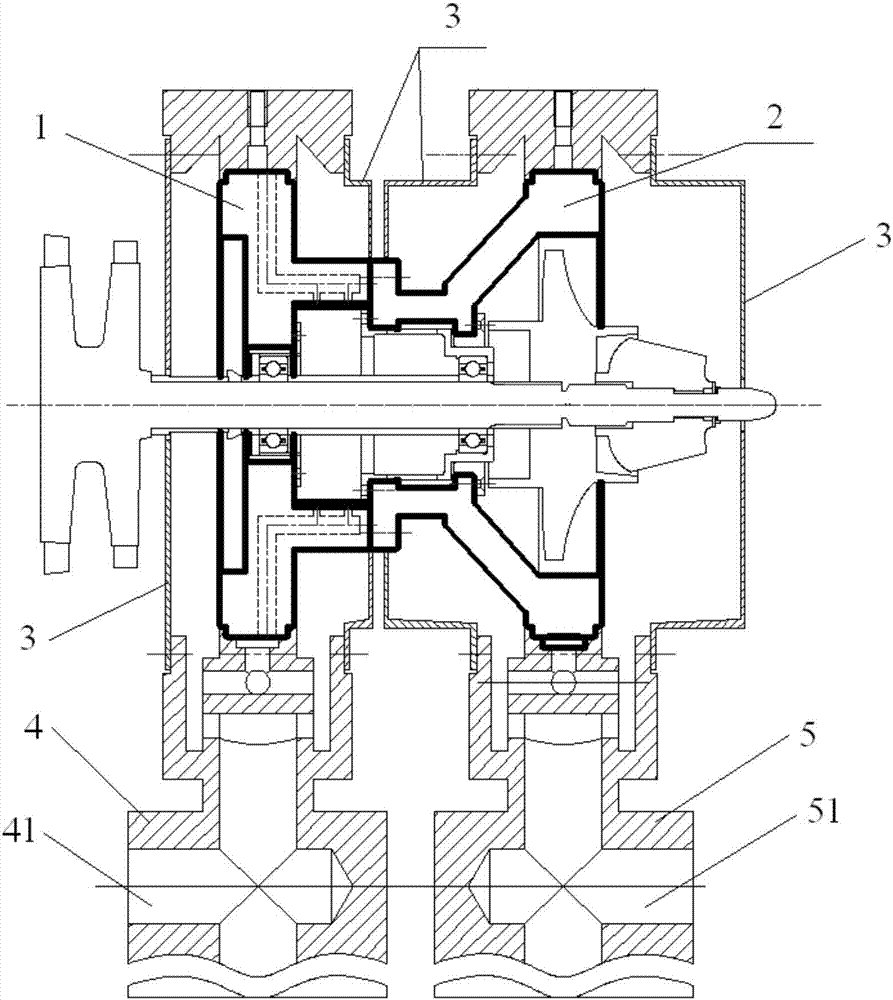

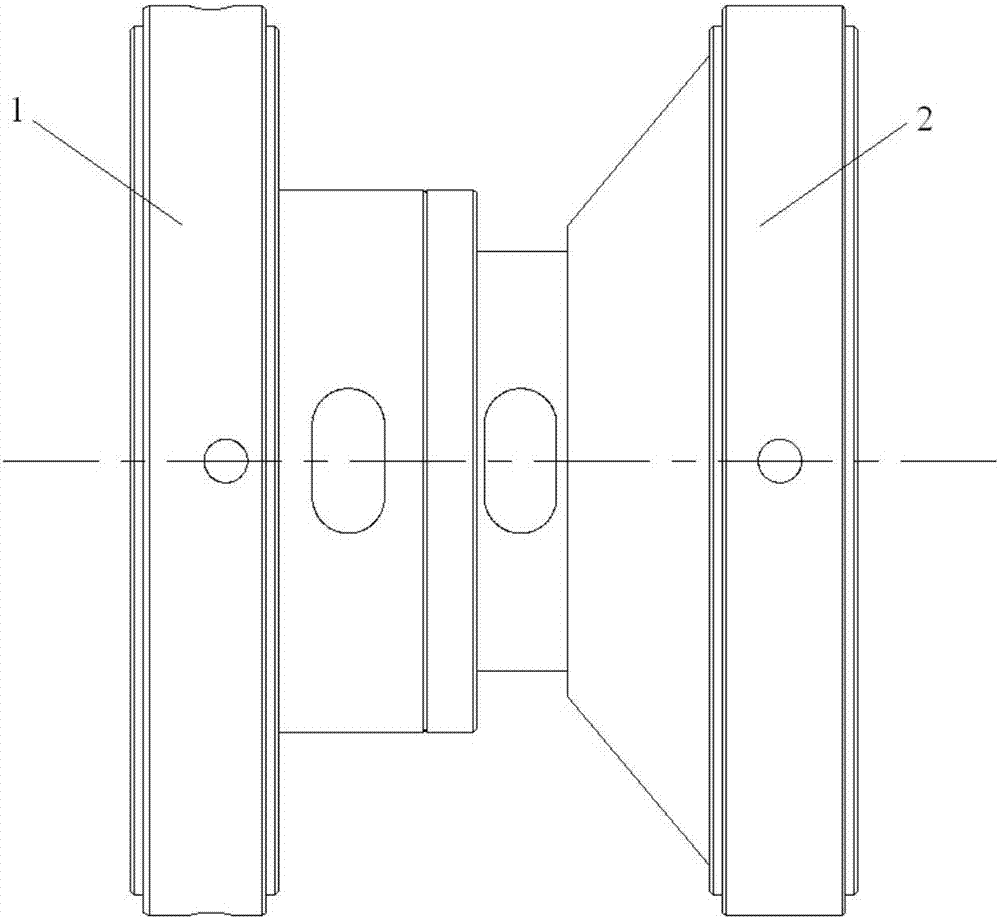

[0026] Such as figure 1 , figure 2 As shown, a high-speed dynamic balance support device for a flexible rotor of a liquid rocket engine turbopump includes a main support case 1, a main support case 2, and an oil seal case 3; a main support case 1 and a main support case 2 2 are complete rotary structures, and the oil seal housing 3 is a rotary structure that is divided into upper and lower halves. During high-speed dynamic balancing, the main support shell 1 and the main support shell 2 are connected as a whole with bolts and installed on the pendulum frame 1 4 and the pendulum frame 2 5, and the supporting structure of the rotor is assembled on the main support shell on the bore flange.

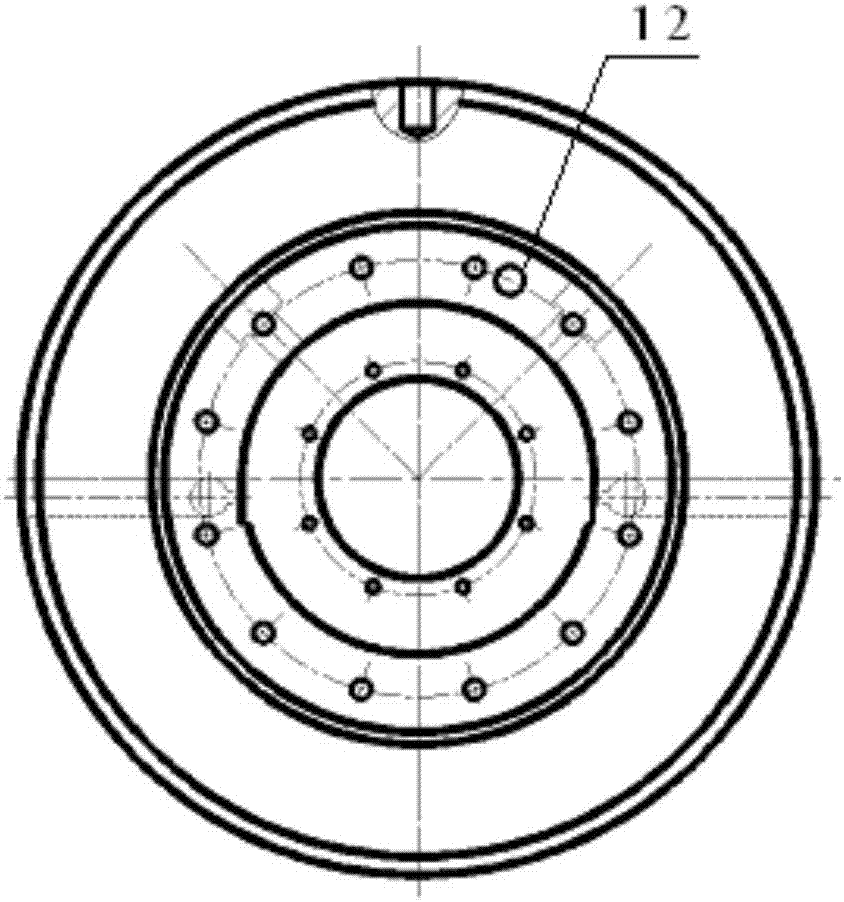

[0027] Such as Figure 3 ~ Figure 6 As shown, the main supporting shell-1 is a stepped rotary body, and the through hole along the axis of the main supporting shell-1 includes three sections, the diameter of the middle section of the through hole is smaller than the diameter of the remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com