Patents

Literature

80results about How to "Guaranteed support rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

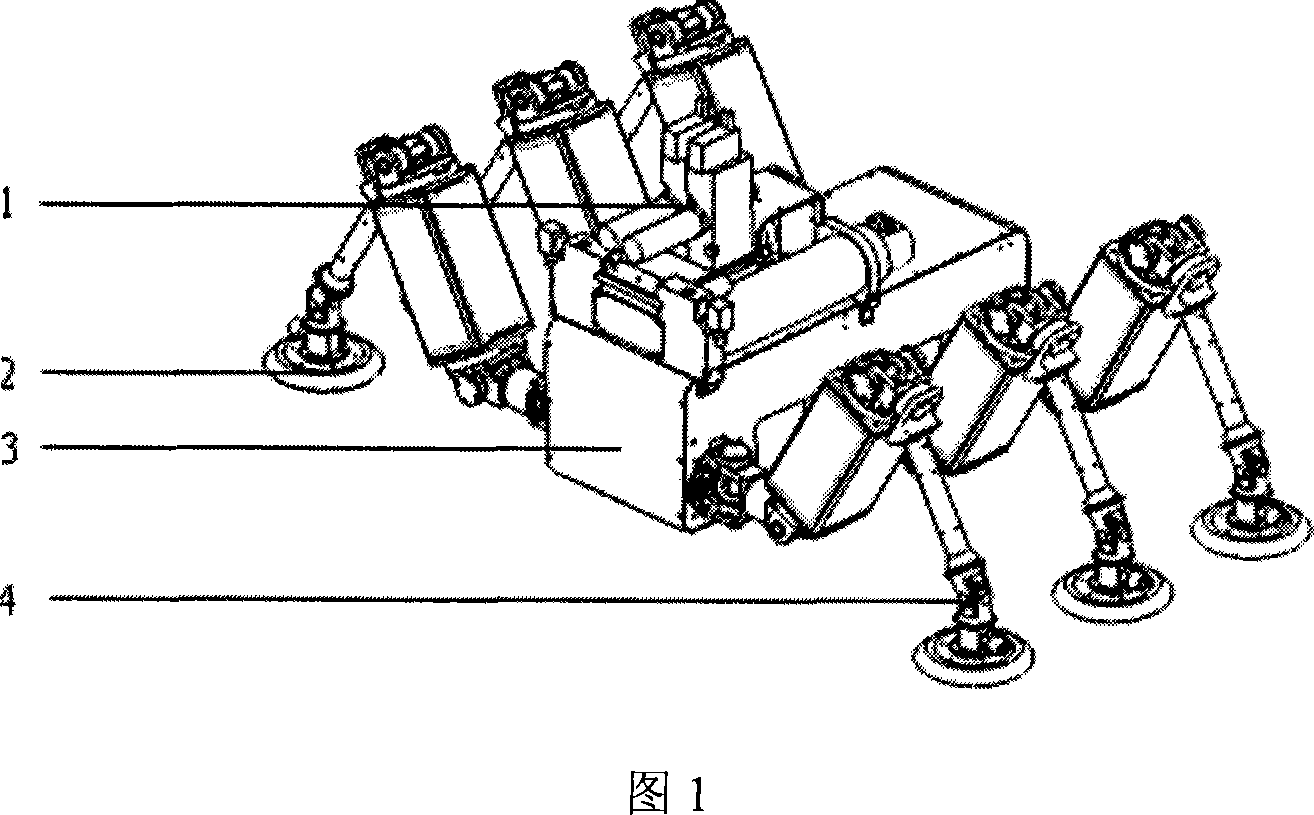

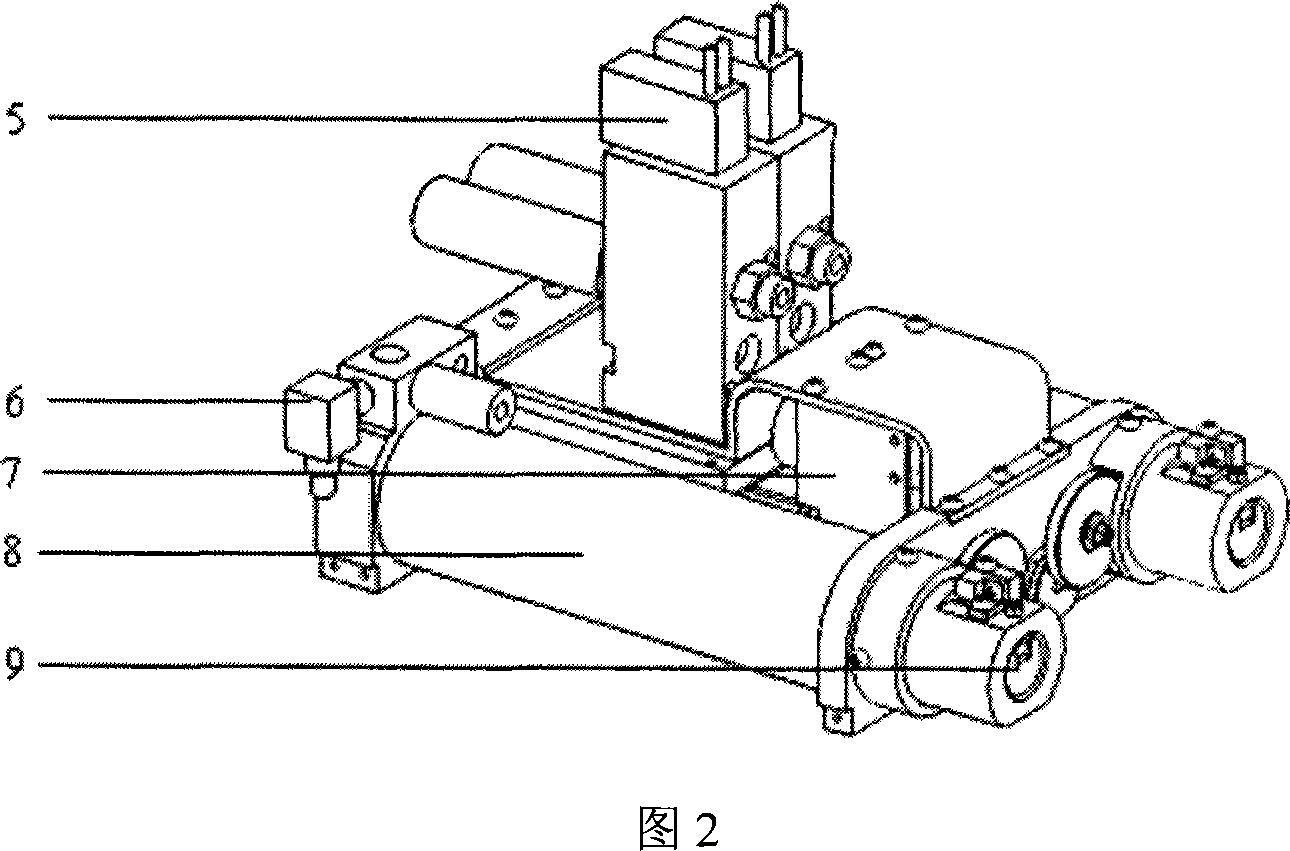

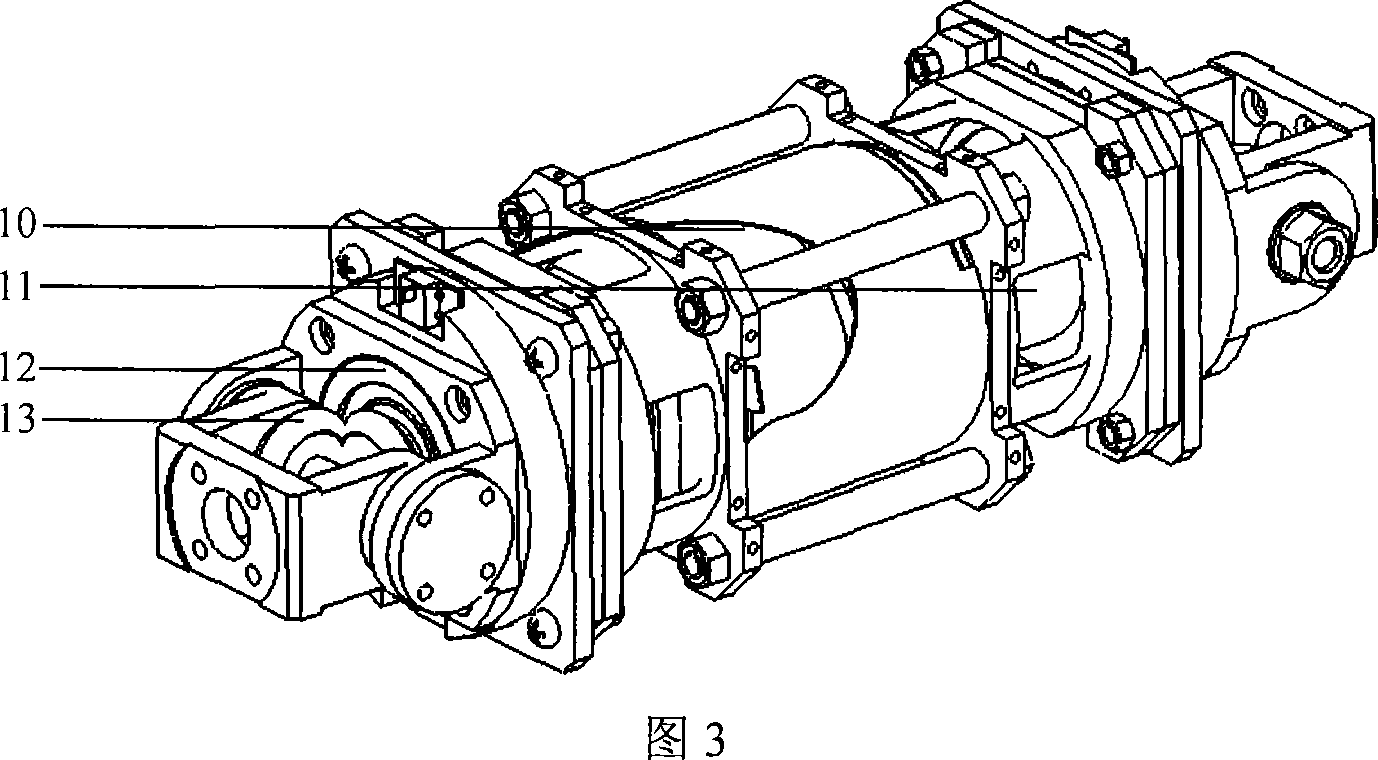

Mini micro-acoustic wall-climbing robot based on vacuum adsorption principle

The invention relates to a small scale micro sound wall climbing robot based on vacuum absorption principle, comprising the vacuum generator installed on the displacement structure, and the sucker on the displacement structure, the said vacuum generator composed of drive generator single post plug pump and the film pump connected with it, and the two position three way valve. The said displacement structure is six leg walking structure, with each leg's drive joint made of the generator, harmonic decelerator installed at both ends of the generator and the planetary reducer connected to it and they are forming into a module with the umbrella gear connected to the planetary reducer, with both ends of the module linked with the passive pole through the joint with the machine, the sucker installed on the passive pole through the passive joint and connected to the two position three way valves. It is small in size, low in noise, free from cables. It has extensive applications.

Owner:HARBIN INST OF TECH

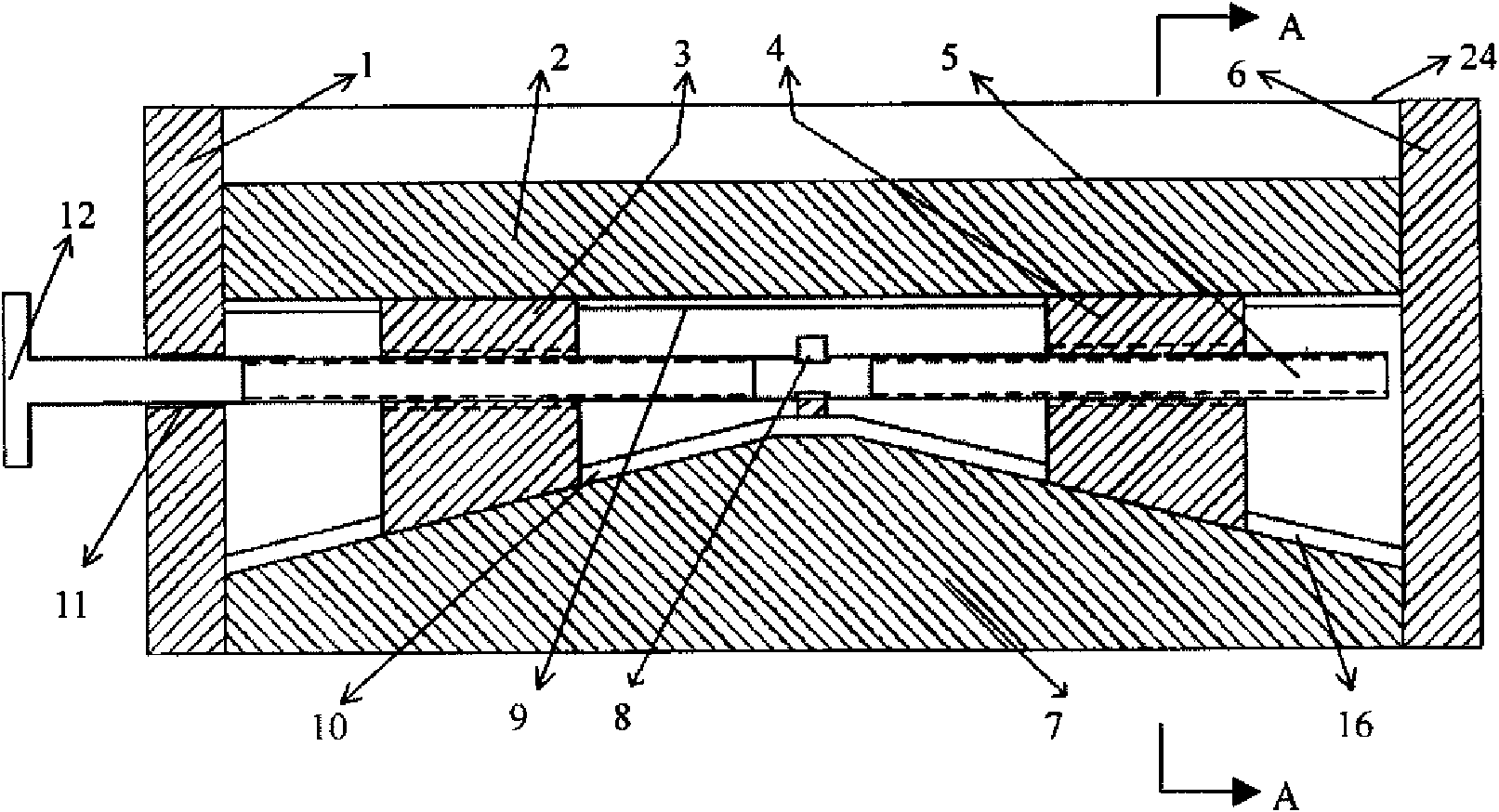

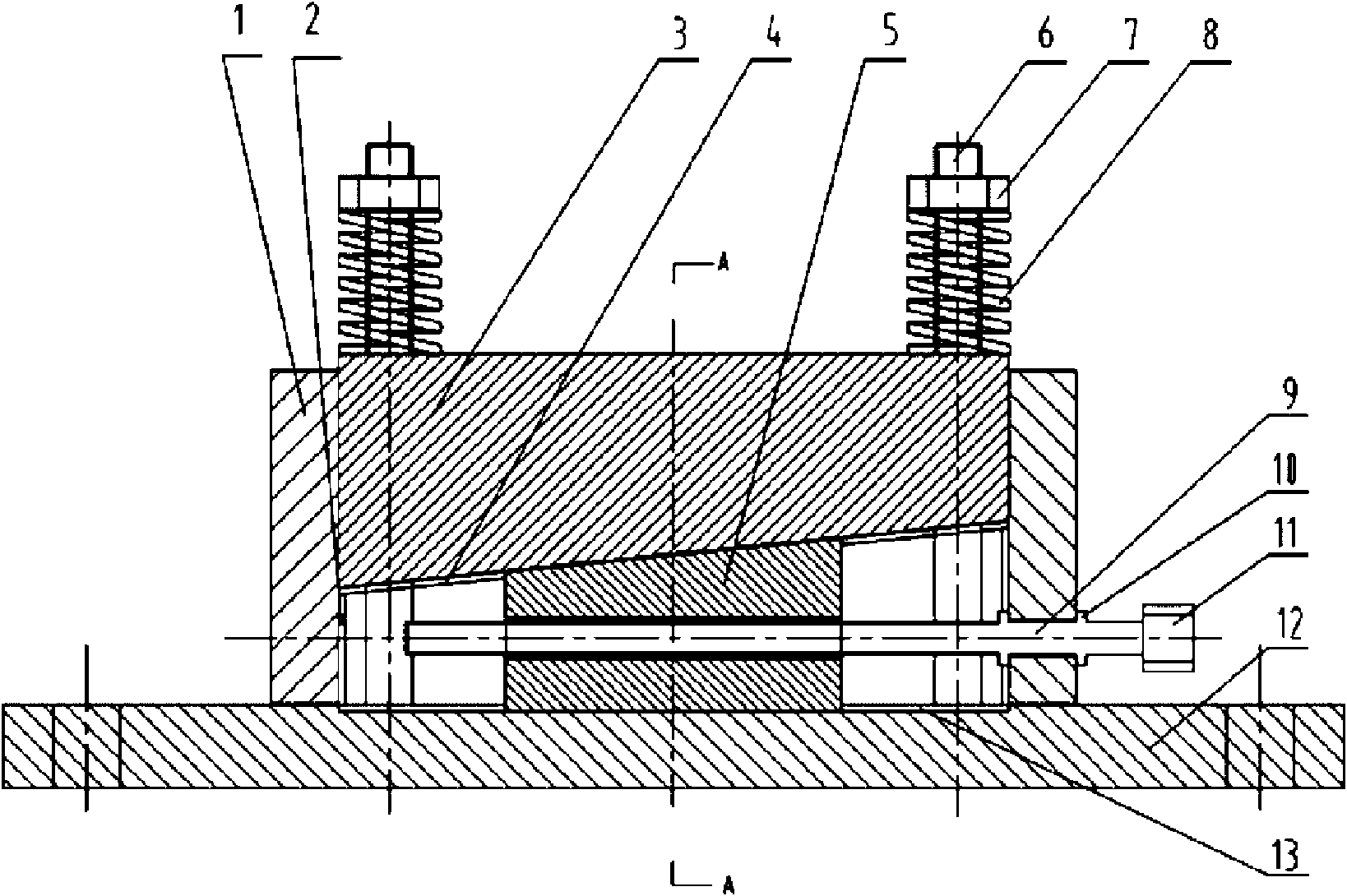

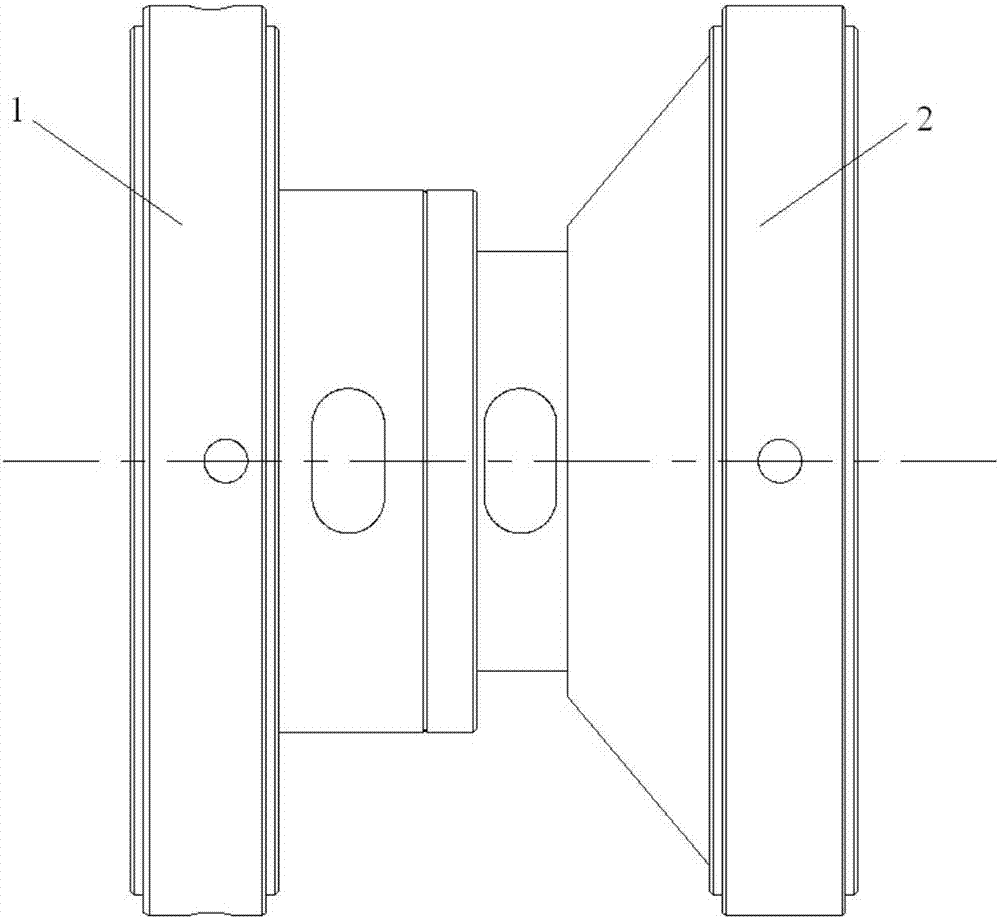

Device for adjusting elevation of bearing in rotating machinery on line

InactiveCN101576126AGuaranteed support rigidityHigh adjustment accuracyBearing unit rigid supportEngineeringMechanical engineering

The invention discloses a device for adjusting the elevation of a bearing in rotating machinery on line and belongs to the technical field of power machinery. The invention is characterized in that the elevation of a supported body can be changed by the relative movement of cone-shaped slide blocks; the device consists of a vertical plate, an upper slide block, a lower slide block, a lead screw rod, a base and a compressing piece, wherein, the contact surfaces of the upper slide block and the lower slide block have the same taper; the lower slide block is pulled by the lead screw rod, so that the lower slide block can move in the horizontal direction in the slide ways of the upper slide block and the base only; and the upper slide block is pushed by the lower slide block or the compressing piece, so that the upper slide block can move in the vertical direction along the slide way of the vertical plate. By guaranteeing the supporting stiffness of a bearing pedestal, the invention is applicable to the adjustment to the elevation of bearings in rotating machinery, such as engines, generators and compressors; the adjustment of the elevation can be made without shutting down the machine, using a crane or lifting the rotors and the bearing pedestal; and the device has the advantages of simple structure, convenient use and high adjustment accuracy.

Owner:DALIAN UNIV OF TECH

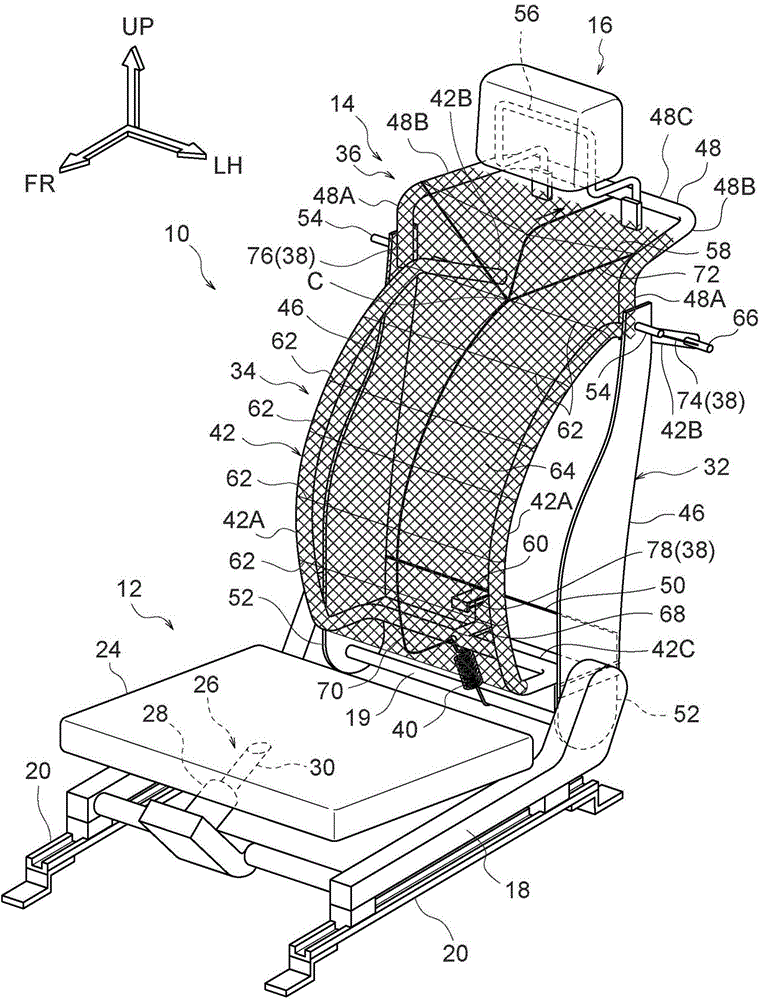

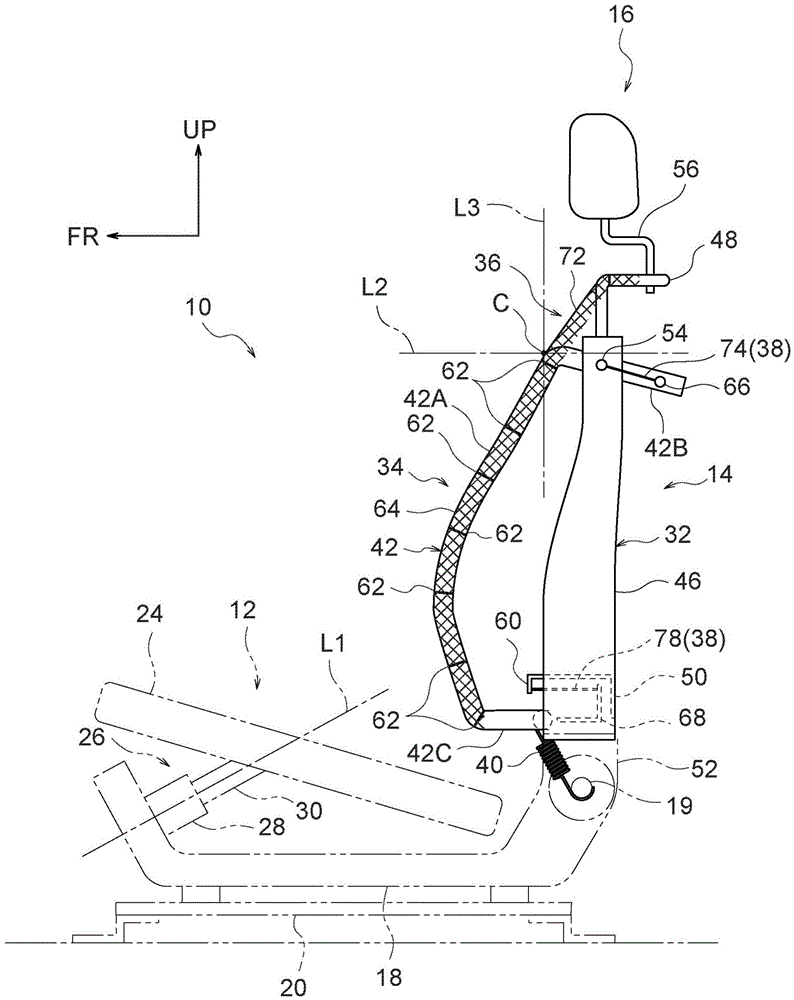

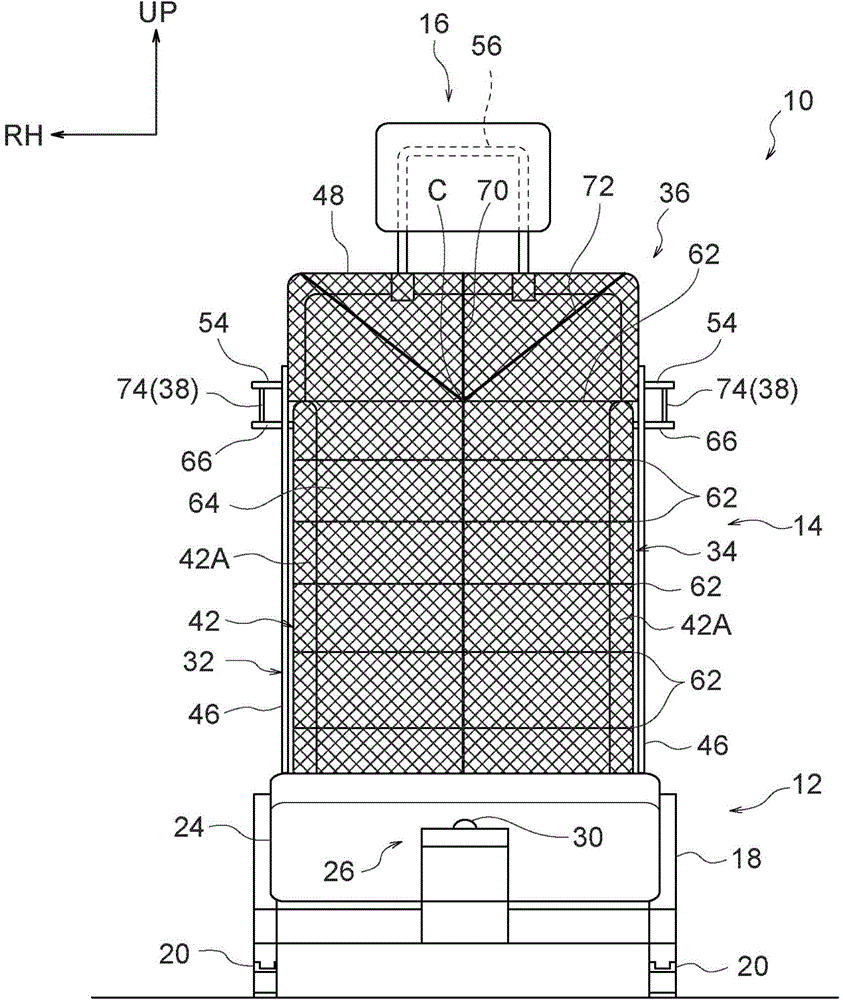

Vehicle seat

Owner:TOYOTA JIDOSHA KK

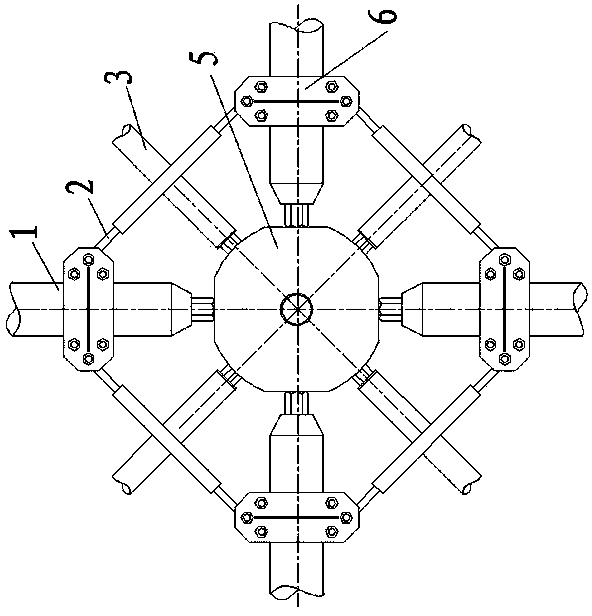

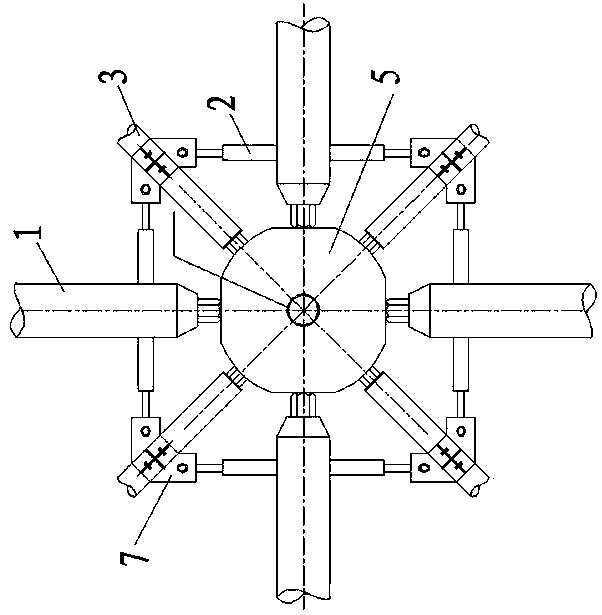

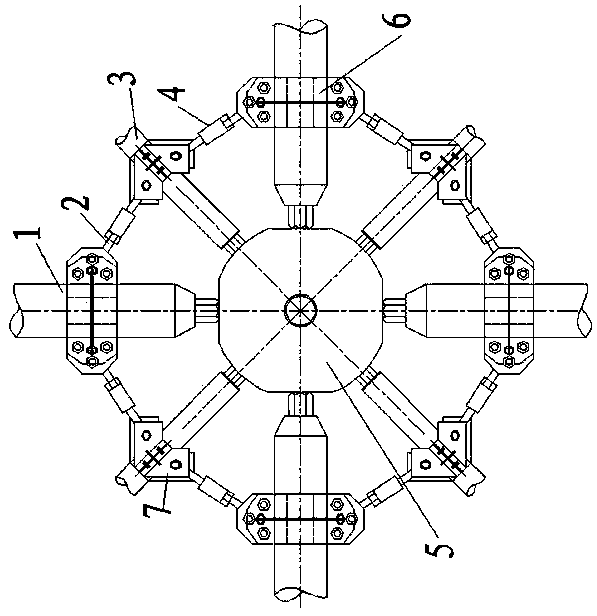

Reinforcement method for grid structure rod piece

ActiveCN103774861AImprove bearing capacityShorten the lengthBuilding repairsSupport groupEngineering

The invention relates to a reinforcement method for a grid structure rod piece, which comprises the following steps that a pressed rod piece which needs to be reinforced is selected, chord member reinforcing frames are arranged on four chord members connected with each spherical joint by using the spherical joint at the end part of the pressed rod piece as the center, each chord member reinforcing frame is formed by four supporting rods arranged between each two adjacent chord members, and both ends of each supporting rod are connected with the corresponding chord members by chord member connecting seats; web member reinforcing frames are arranged on four web members connected with each spherical joint, each web member reinforcing frame is formed by four supporting rods arranged between each two adjacent web members, and both ends of the supporting rod are connected with the corresponding web members by web member connecting seats; and diagonal bars are arranged between each chord member connecting seat and two adjacent web member connecting seats and one reinforcing supporting group is formed by the chord member reinforcing frames, the web member reinforcing frames and the diagonal bars at the position of each spherical joint, so that bearing capacity of the pressure-resistant rod piece is improved.

Owner:HUAIHAI INST OF TECH

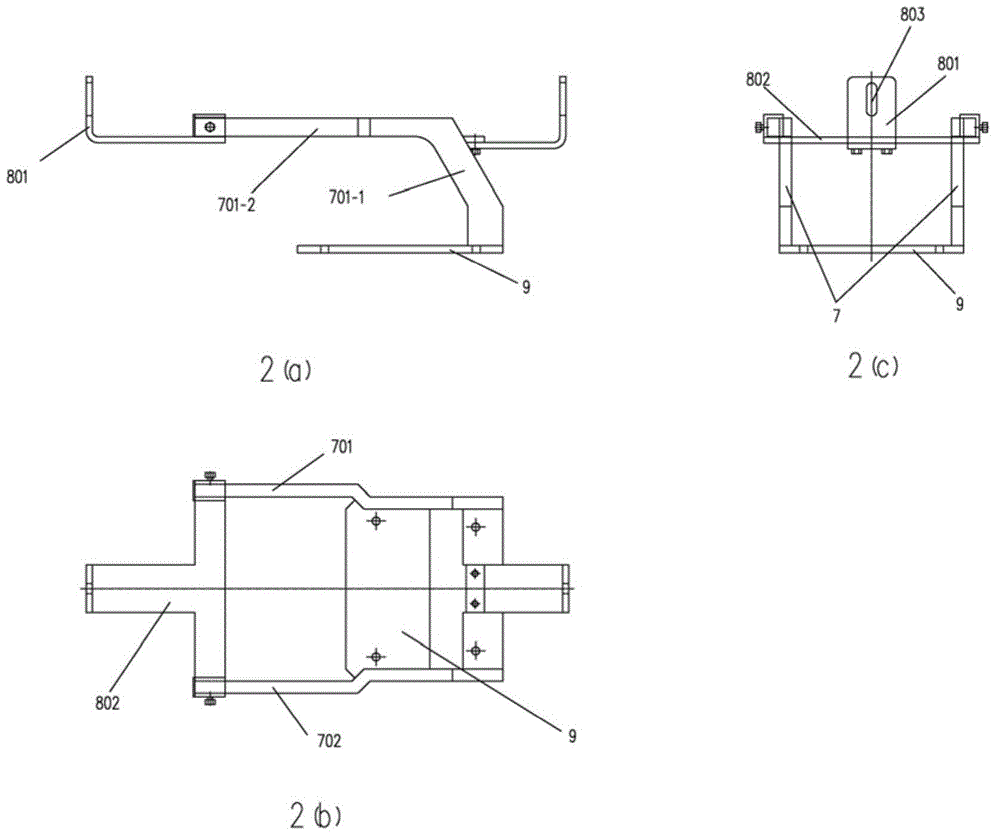

Support structure for planar reflection mirror on movement platform

ActiveCN103529537AReduce surface errorGuaranteed Surface Error RequirementsMountingsEngineeringOptical instrument

The invention belongs to a support structure for a planar reflection mirror on a movement platform. The support structure is formed by a flange ring, pressure blocks, a sleeve, a top plate, a locking ring, a ball head rod and a linear motor; the back of the planar reflection mirror is supported on the flange ring by an edge supporting mode; the planar reflection mirror is pressed by the multiple pressure blocks fixed on the flange ring; the sleeve is fixed at the back of the planar reflection mirror; the top plate is fixedly connected with the sleeve; one end of the ball head rod is supported on the top plate; the ball head rod is locked by the locking ring; the other end of the ball head rod is connected with the linear motor fixed on the flange ring. The support structure for the planar reflection mirror on the movement platform is suitable for supporting the planar reflection mirror in an optical instrument on the movement platform.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

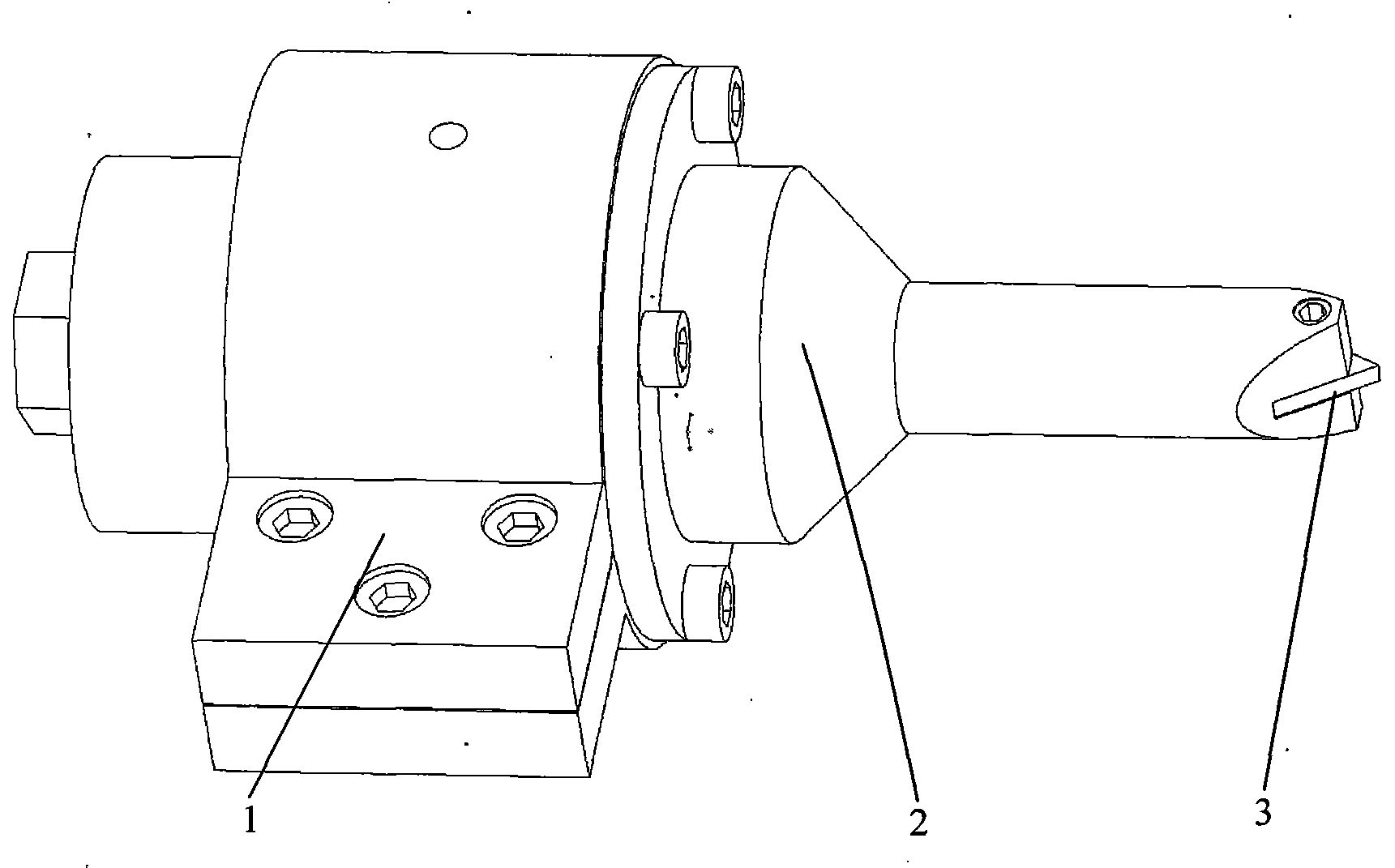

Bending mode supersonic vibration auxiliary cutting device for precision or ultra-precision turning

InactiveCN103817355ANo noise pollutionEffective protectionAuxillary equipmentMechanical vibrations separationEngineeringUltrasonic vibration

The invention relates to the technical field of precision or ultra-precision machining, provides a supersonic vibration machining device and mainly consists of a supersonic vibration unit, a shell and a tool. Two node positions of the supersonic vibration unit are fastened by the shell of a shrink ring structure; the length of the shell is very easy to adjust, and an inner annular boss of the shell is fastened at the node positions of the supersonic vibration unit all along. The working frequency of the device is 38+ / -0.5KHz, so that noise pollution cannot be produced; the machining efficiency is high; moreover, assembly links of the device are few, and a blade is convenient to install and uninstall; meanwhile, the device is high in rigidity and good in airtightness. The device provided by the invention has a remarkable effect in the aspects of machining of materials which are hard to machine and cutting of low-rigidity parts, such as slender axles, thin-walled workpieces and the like; a cutting force, the cutting temperature, tool wear and the material cutting deformation of workpeices can be obviously reduced; the quality of finished surfaces and the accuracy of forms and positions of the workpieces are improved; subsequent processes are reduced, and further, the machining efficiency and the economical efficiency are improved.

Owner:HARBIN INST OF TECH

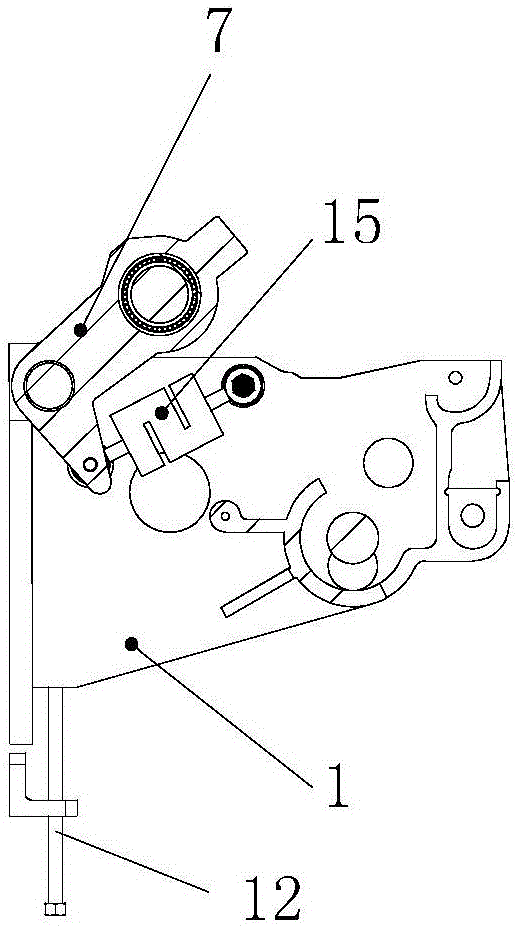

Positive warp loosening device of water jet loom

The invention discloses a positive warp loosening device of a water jet loom. The positive warp loosening device comprises a left support, a right support, a linkage shaft, a swinging beam and a fixed back beam, wherein the linkage shaft, the swinging beam and the fixed back beam are sequentially arrayed between the left support and the right support from front to back, the linkage shaft is located above the swinging beam, the warp loosening device further comprises only one positive warp loosening mechanism used for driving the linkage shaft to rotate, the positive warp loosening mechanism comprises an eccentric adjusting portion and a warp loosening swinging arm, one end of the warp loosening swinging arm is connected with one end of the linkage shaft, and the other end of the warp loosening swinging arm is connected with the eccentric adjusting portion. The single-side positive warp loosening structure drives the linkage shaft to rotate to drive the swinging beam to swing, and therefore the performance of the whole loom is more reasonable.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

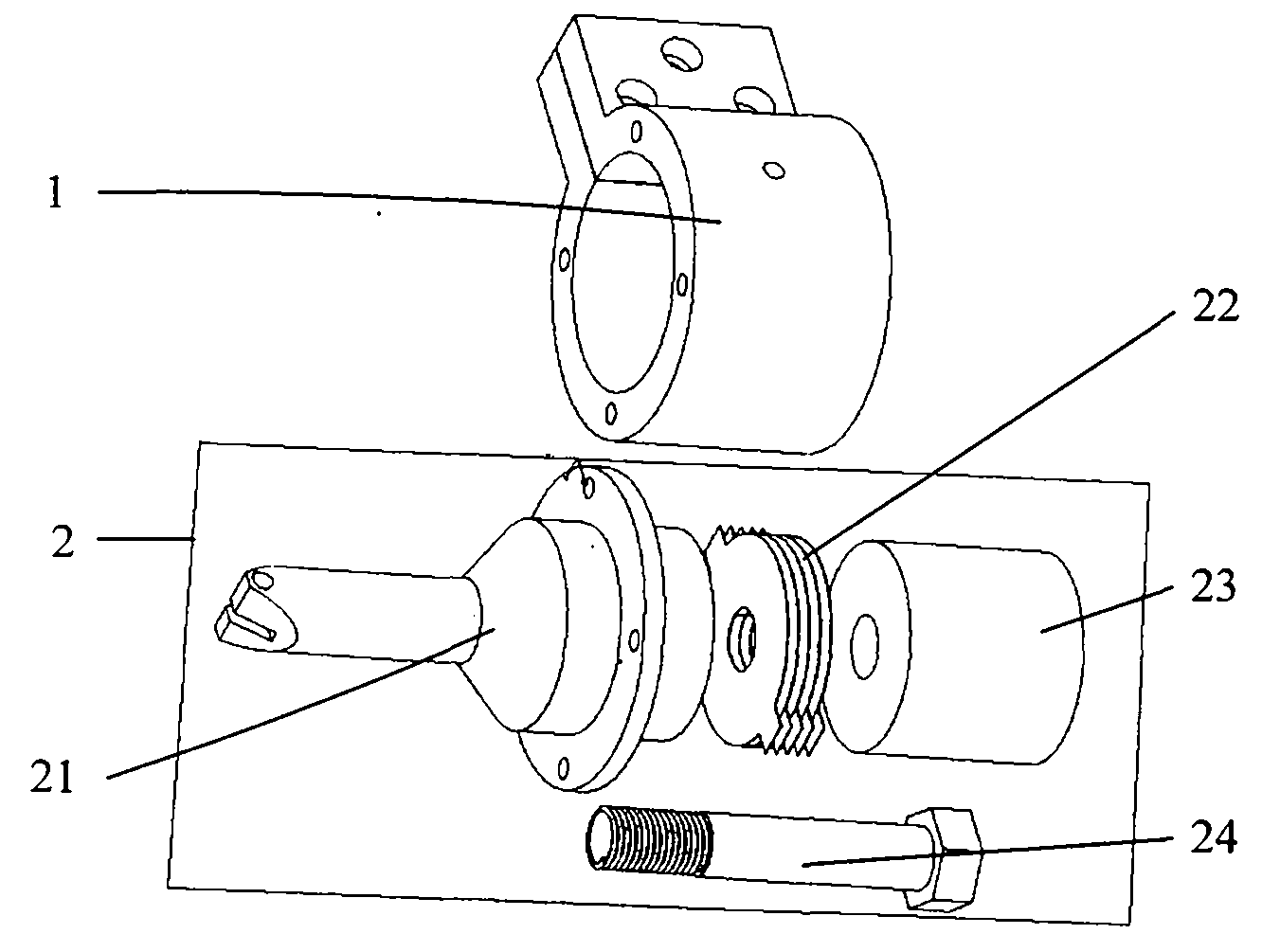

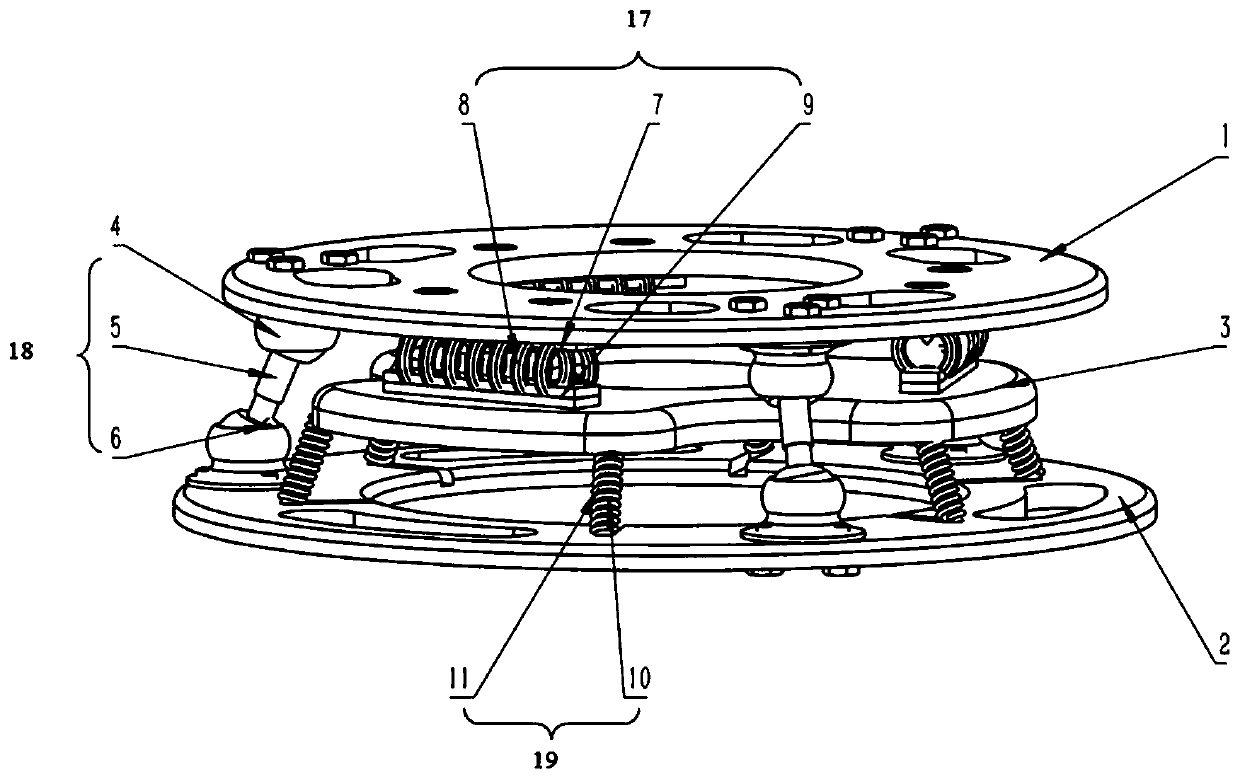

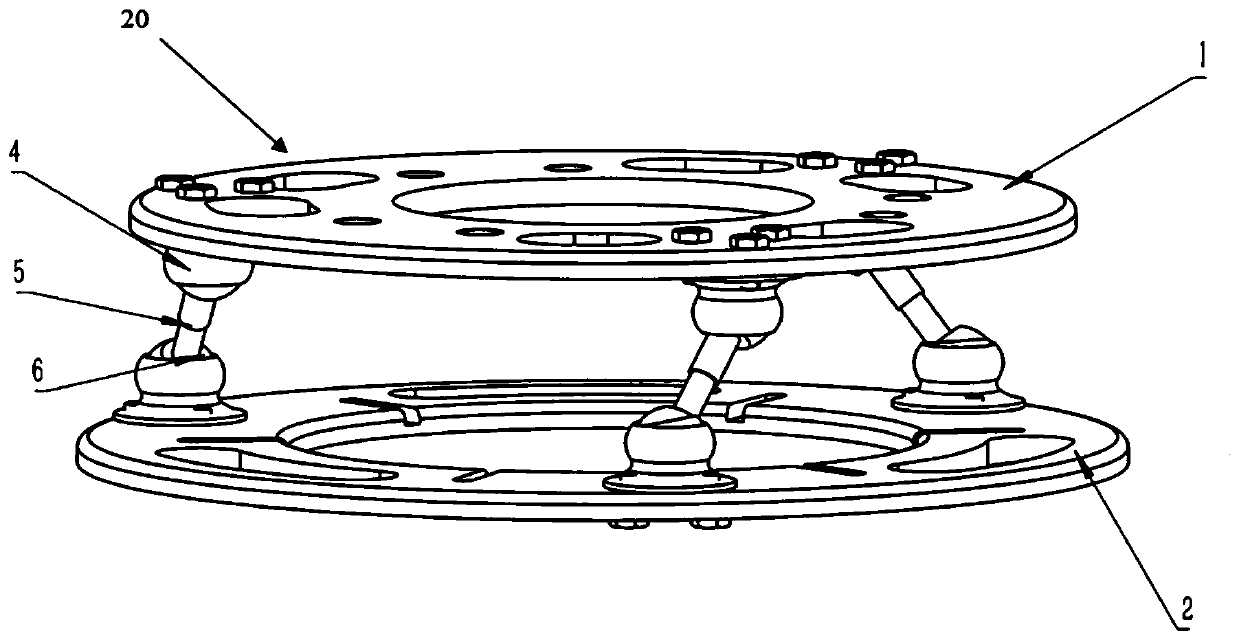

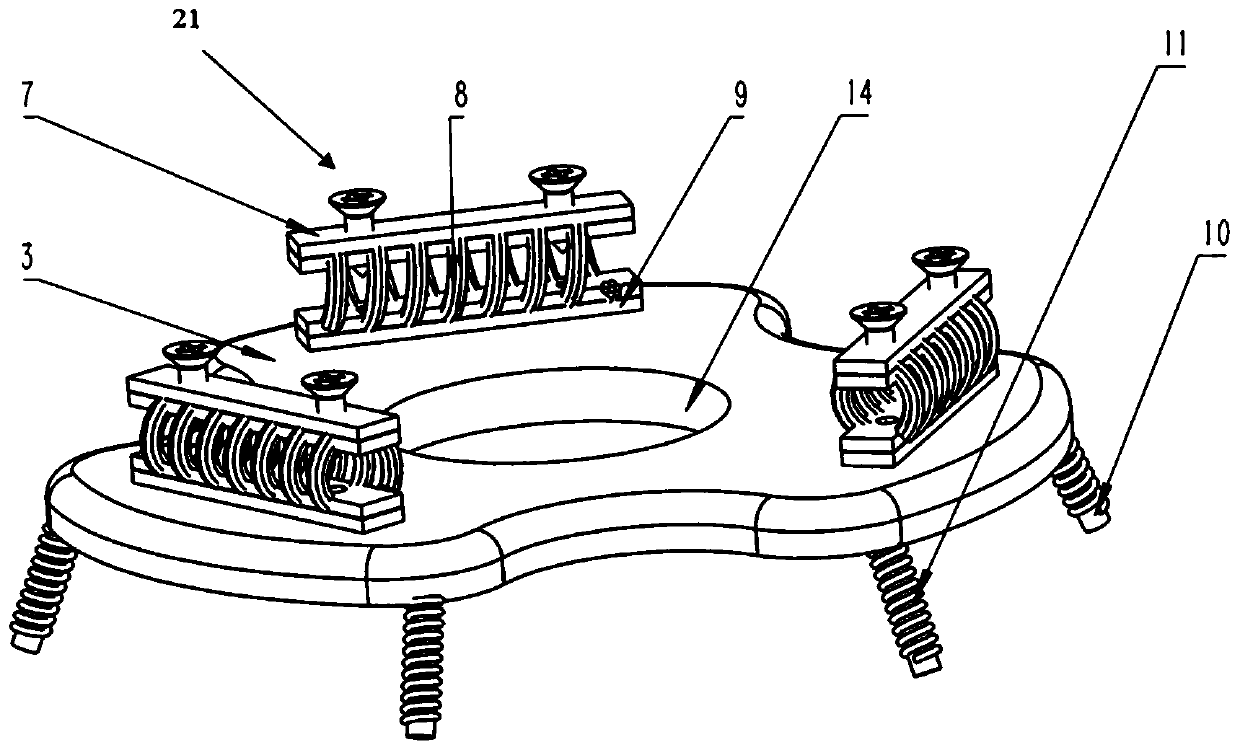

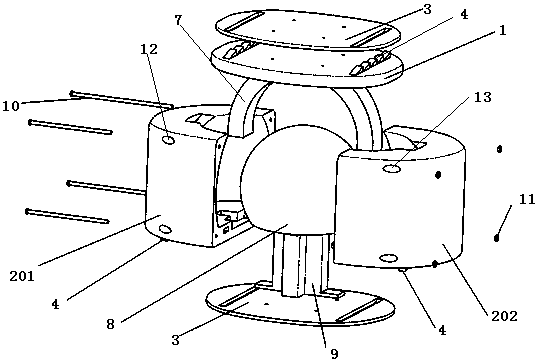

Pan-tilt damping mechanism of mobile robot

ActiveCN111043232AEnsure stabilityGuaranteed lifeNon-rotating vibration suppressionStands/trestlesBall bearingReducer

The invention discloses a pan-tilt damping mechanism of a mobile robot. The pan-tilt damping mechanism comprises an upper damping connecting plate, a lower damping connecting plate, a transfer plate and a steel wire rope speed reducer assembly which are embedded. The steel wire rope reducer assembly comprises steel wire rope dampers and a spring supporting piece. The spring supporting piece is formed by connecting a supporting rod and a spring in a nested mode, and the two ends of the supporting rod are fixedly connected with the transfer plate and the lower damping connecting plate respectively. The upper damping connecting plate, the lower damping connecting plate and the transfer plate form a multi-stage damping support; three groups of upper ball bearing supporting seats are fixedly mounted on the upper damping connecting plate; three sets of lower ball bearing supporting bases are fixedly installed on the lower damping connecting plate, and the upper damping connecting plate, thelower damping connecting plate and the flexible supporting assembly are assembled to form a first-stage damping mechanism. The upper damping connecting plate is fixedly connected with the three sets of steel wire rope dampers at the same time, and the transfer plate, the upper damping connecting plate and the steel wire rope dampers are assembled into a second-stage damping mechanism.

Owner:ZHEJIANG UNIV

Integrated construction method of cast-in-place box beam inclined web formwork

InactiveCN109537459AQuick installationSimple construction methodBridge erection/assemblyEngineeringUltimate tensile strength

Owner:THE SECOND CONSTR OF CTCE GROUP +1

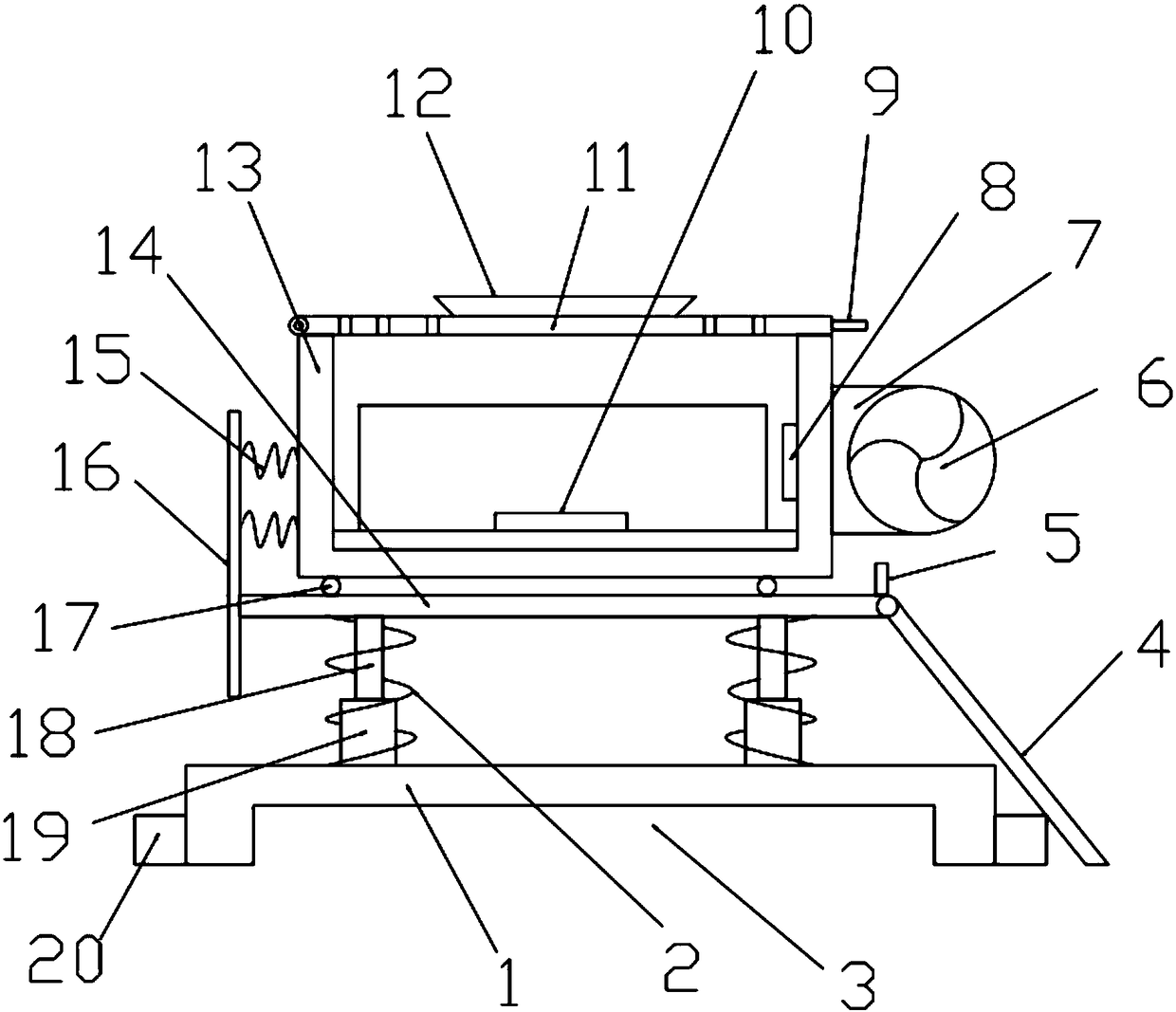

Computer hardware fixing device

InactiveCN108089658ACleverly structuredReasonable arrangementDigital processing power distributionVertical vibrationSlide plate

The invention discloses a computer hardware fixing device. The computer hardware fixing device comprises a fixing base, a groove is formed in the lower end face of the fixing base, and a supporting plate is arranged above the fixing base. The computer hardware fixing device is ingenious in structural arrangement and reasonable in layout, a computer hardware body is placed in a mounting box, a temperature sensor is used for measuring the temperature inside the mounting box, and when the temperature of the mounting box reaches a certain value, a motor is electrified to efficiently cool the interior of the mounting box; meanwhile, the supporting plate at the bottom of the mounting box is supported on the fixing base through compression springs, and vertical vibration is effectively reduced; besides, through vertical sleeves and telescopic rods in telescopic springs, the supporting rigidity of the compression springs is effectively guaranteed, the stability of the supporting plate is improved, besides, the left side of the mounting box is fixed to a lateral plate through connecting springs, horizontal vibration can be effectively alleviated, and when the mounting box needs to be dismantled, the mounting box is conveniently dismantled vertically through pulleys at the bottom and a sliding plate arranged at the right end of the supporting plate.

Owner:苏州德特尼罗电子科技有限公司

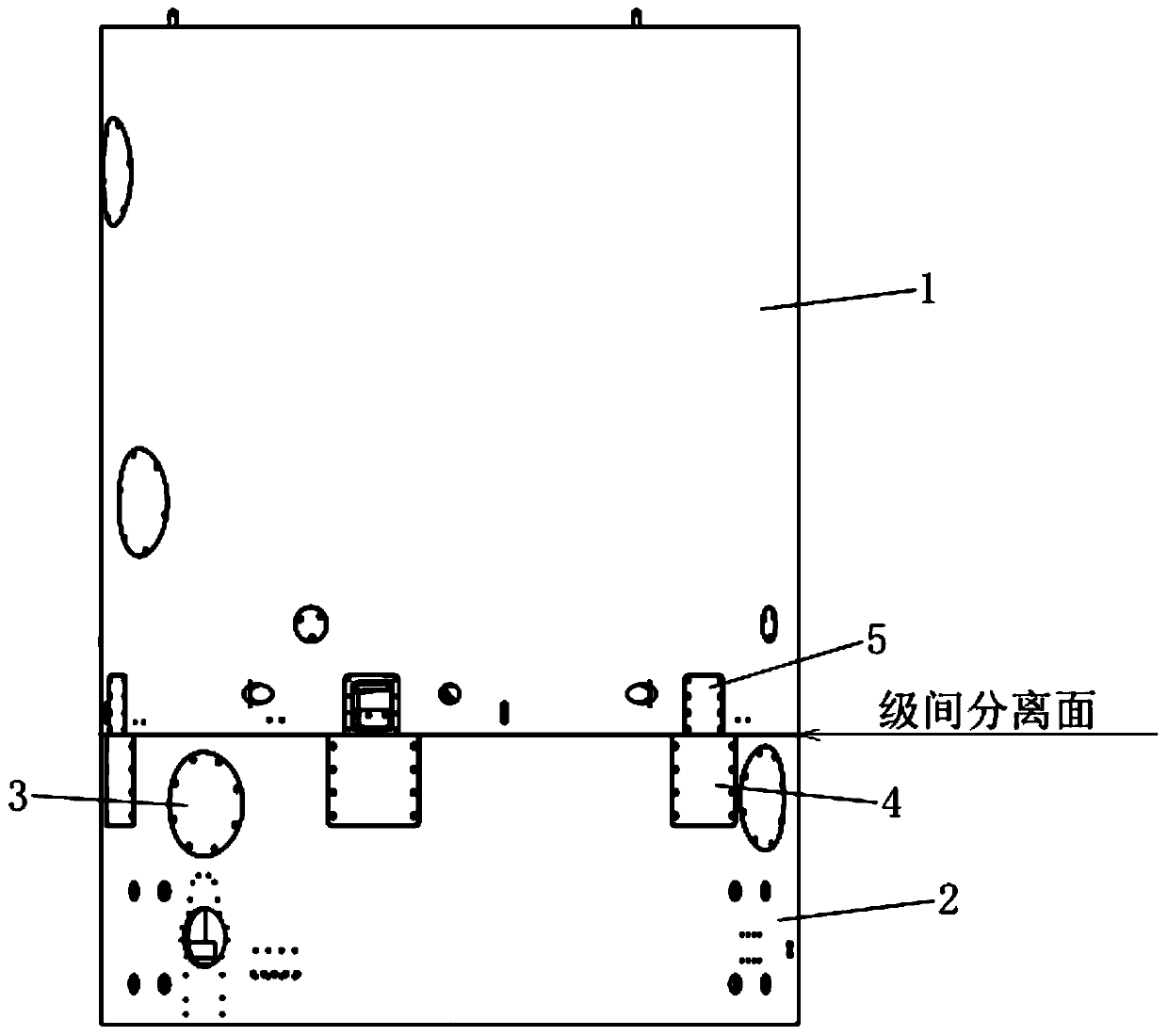

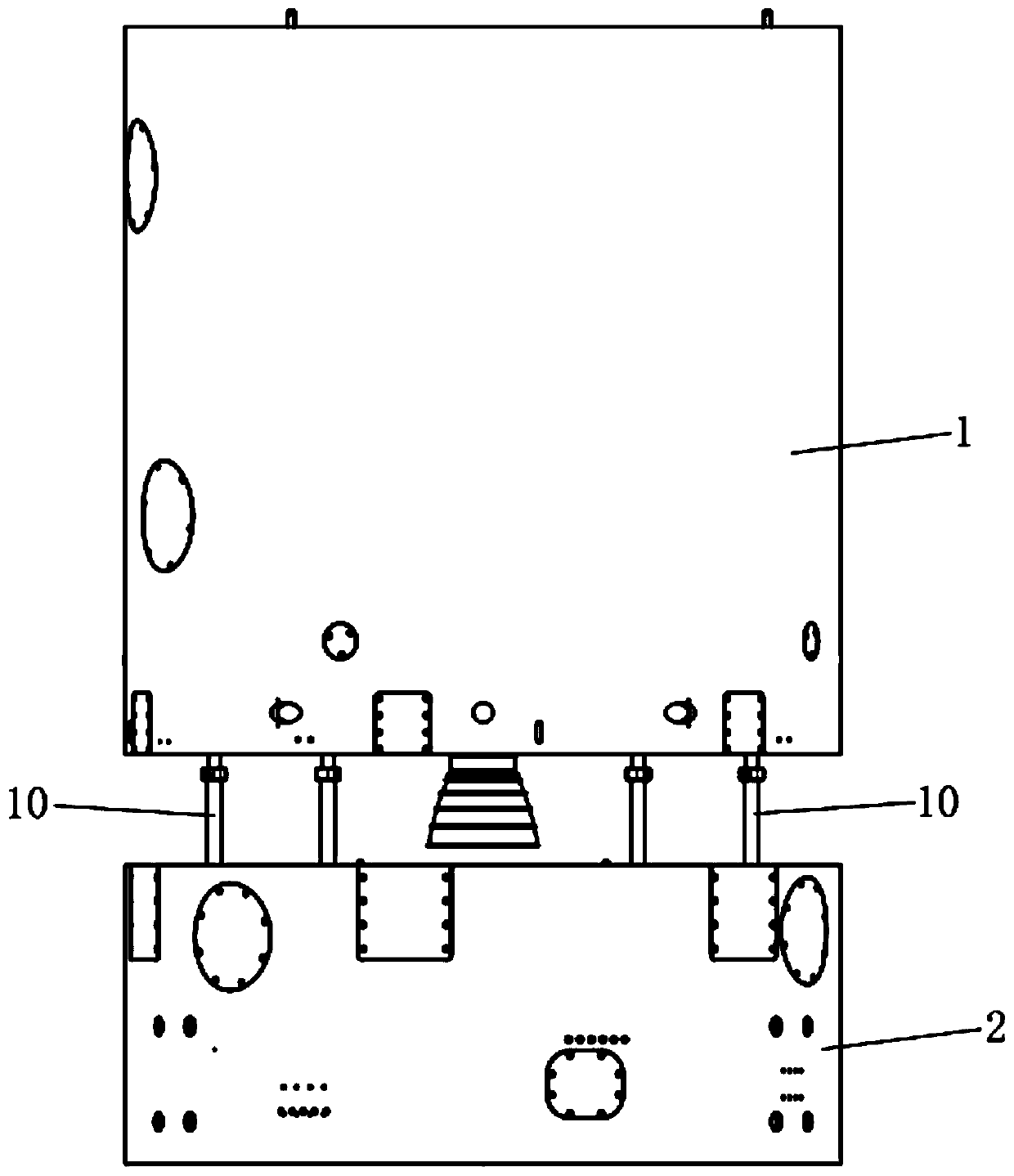

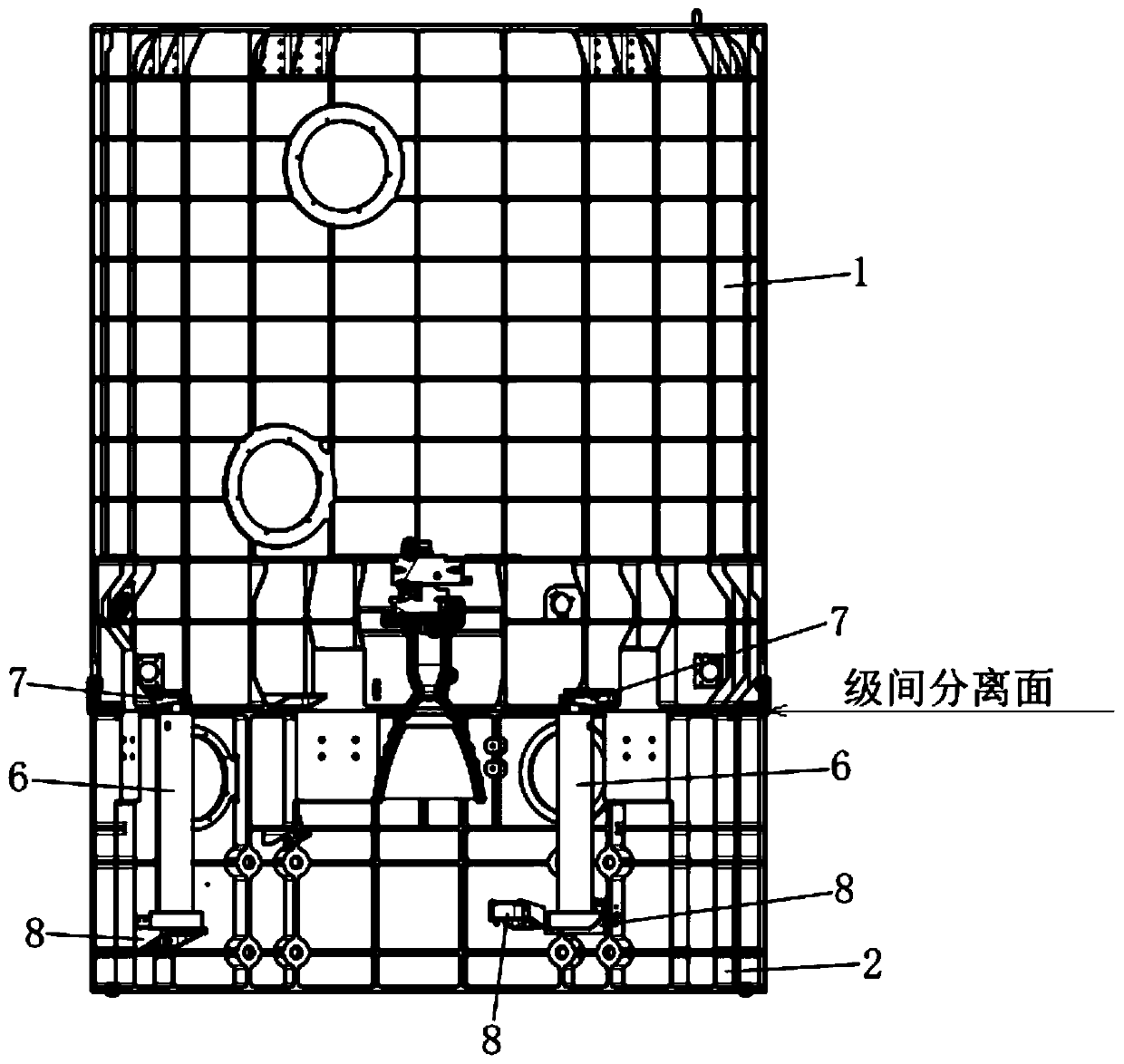

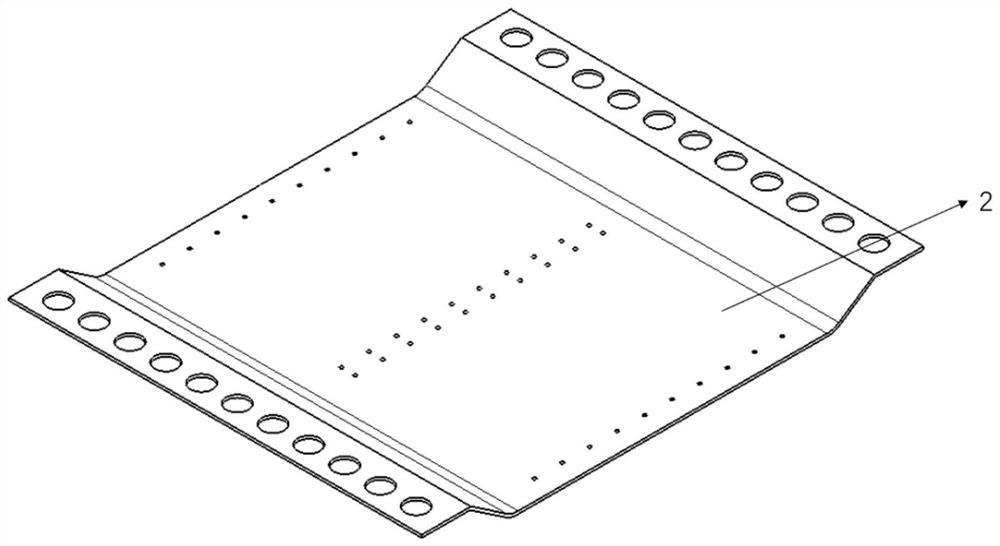

Interstage cold separation structure of carrier rocket

PendingCN111017272AFast separationImprove securityCosmonautic vehiclesCosmonautic component separationEngineeringRocket

The invention discloses an interstage cold separation structure of a carrier rocket. The interstage cold separation structure comprises a front cabin body, a rear cabin body, and a separation spring assembly. The tail end of the front cabin body is connected with a separation spring ejector rod support. The front end of the rear cabin body is connected with the tail end of the front cabin body through an interstage separation connection unlocking device; and the rear cabin body is connected with a separation spring support base corresponding to the position of a separation spring ejector rod bracket; the interstage separation connection unlocking device is used for locking the front cabin body and the rear cabin body and unlocking the front cabin body and the rear cabin body after receiving a separation instruction. The separation spring assembly is elastically supported between the separation spring support base and the separation spring ejector rod bracket and is provided with an elastic piece for providing a separation impulse for the front cabin body and the rear cabin body. Since the separation spring assembly is arranged between the front cabin body and the rear cabin body, when the interstage separation connection unlocking device is disconnected under fire work, the elastic piece of the separation spring assembly generates an acting force for driving the front cabin body and the rear cabin body to be away from each other, so that the separation speed of the front cabin body and the rear cabin body is increased, and the safety during rocket body separation is improved.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +1

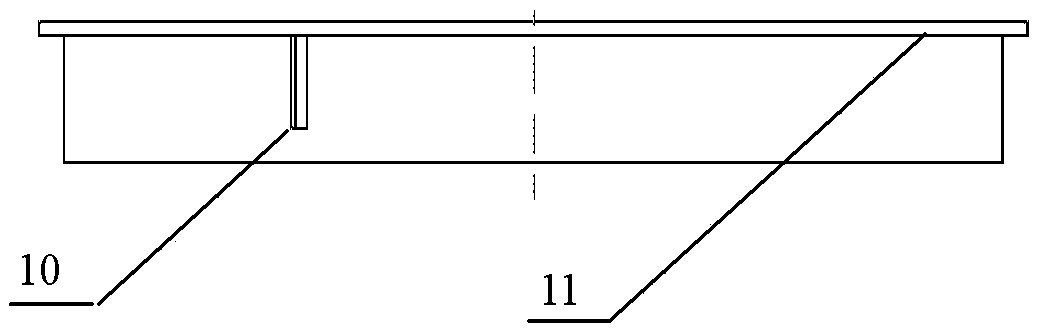

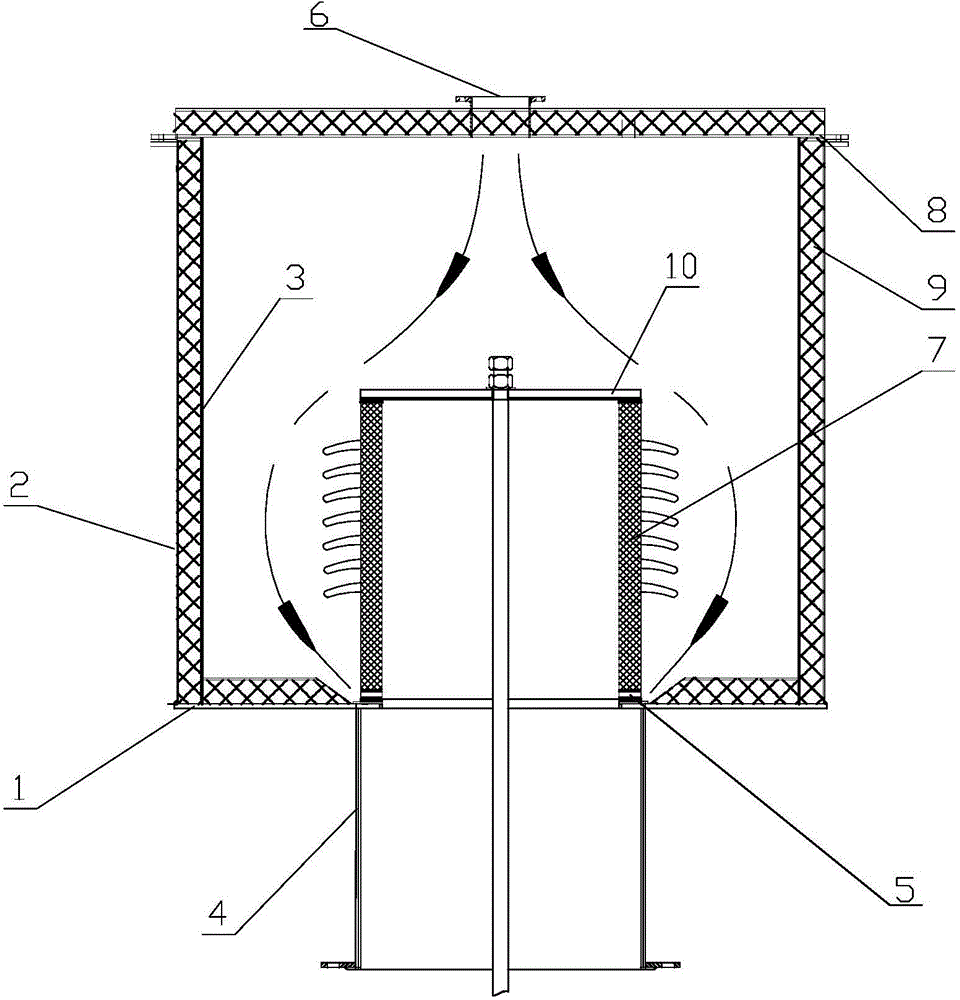

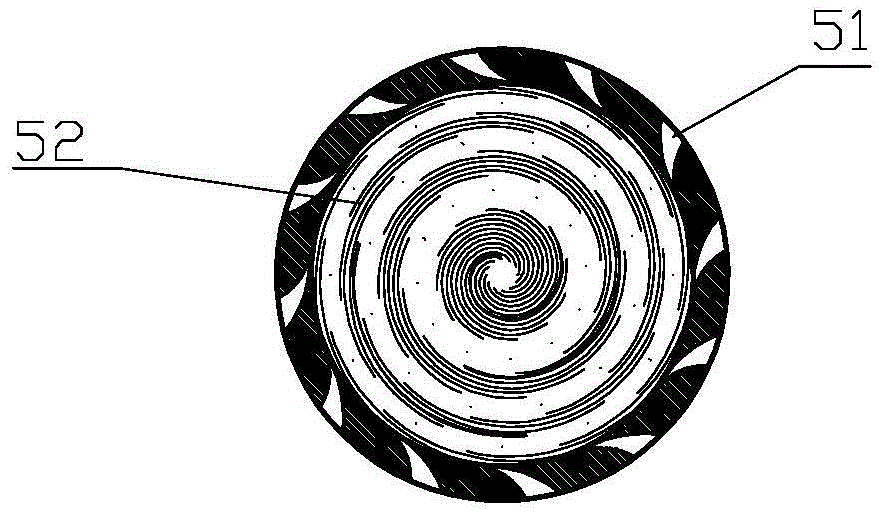

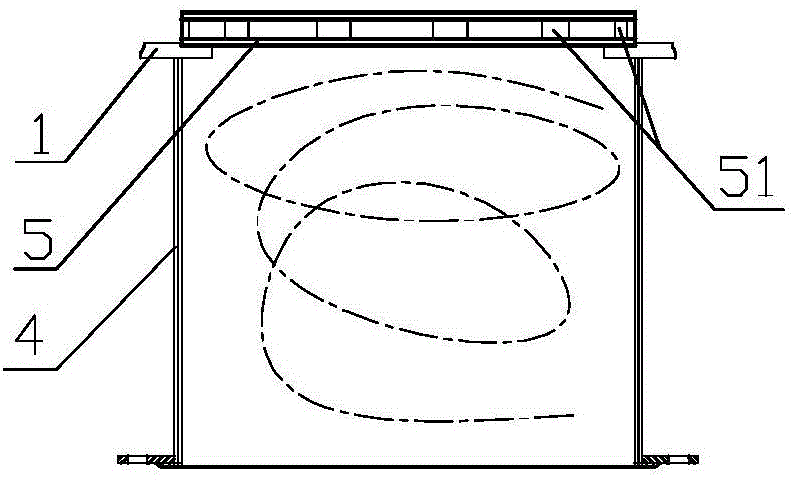

Hanging type insulating device of wet electric precipitator insulating box

ActiveCN104971825AImprove recycling ratesImprove surface smoothnessElectric supply techniquesCycloneElectricity

A hanging type insulating device of a wet electric precipitator insulating box comprises an insulating cover, an insulating box base, an insulator, a hanging rod and a cyclone disc. The insulating cover is arranged on the insulating box base through a bottom disc flange. A conical hole is formed in the center of a bottom plate of the insulating cover, and the large opening end of the conical hole faces upwards. The cyclone disc is a circular ring. A plurality of air flues are evenly distributed on the circumferential wall of the cyclone disc. The air flues are inclined air flues with the large outer ports and the smaller inner ports and are consistent in inclination direction. The cyclone disc is arranged in the conical hole of the bottom plate of the insulating cover, is coaxial with the bottom disc flange and is arranged at the upper end of the bottom disc flange. The insulator is placed at the upper portion of the cyclone disc. An air inlet is formed in the top of the insulating cover. After entering a cavity of the insulating cover through the air inlet, the hot air enters the insulating box base through the air flues on the cyclone disc, and a backspin cyclone curtain can be formed after hot air enters the insulating box base; partition is formed for an insulating box base inner cavity where wet smoke invades, the short circuit between the hanging rod with high-voltage electricity and the cavity of the insulating cover so that electric conduction can be avoided, and the short-circuit access among the hanging rod, a gland and the insulating box base is blocked.

Owner:SHANDONG GUOSHUN CONSTR GRP

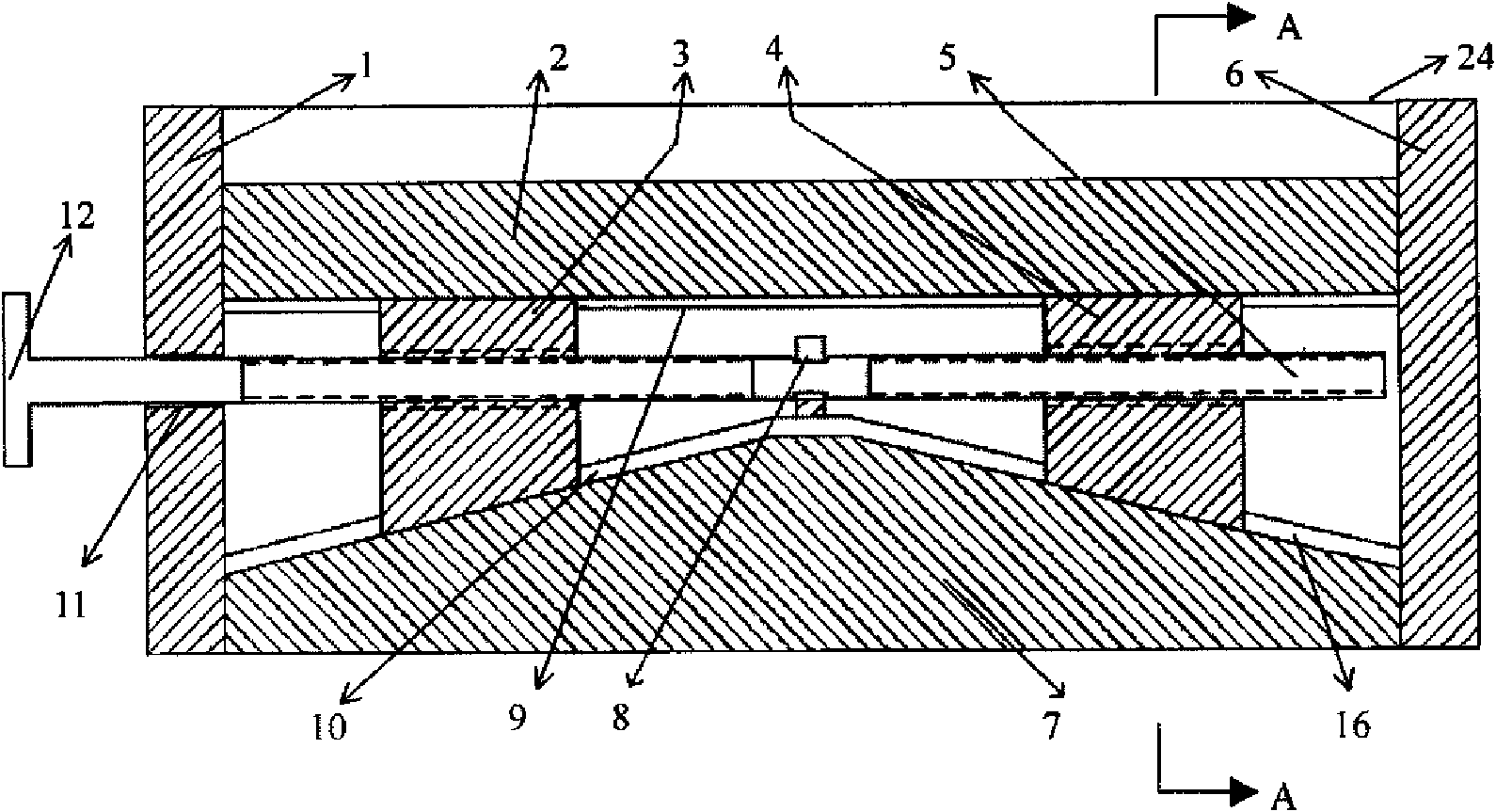

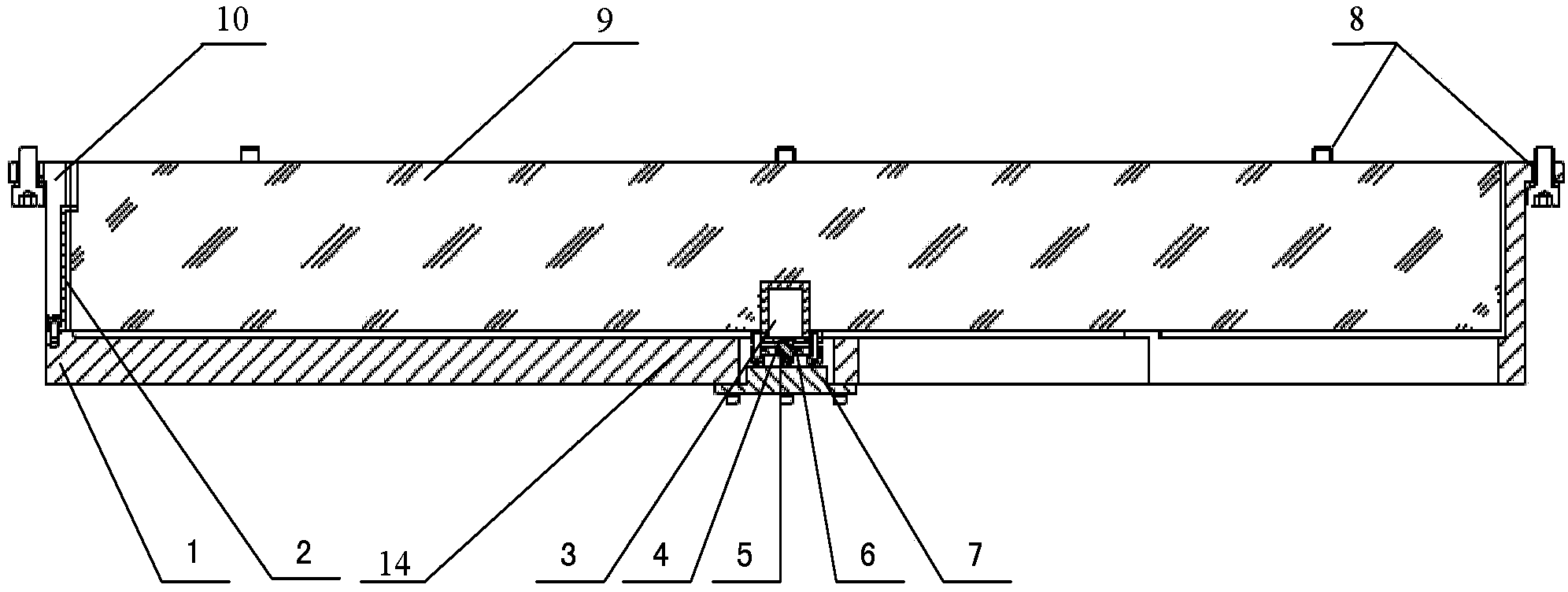

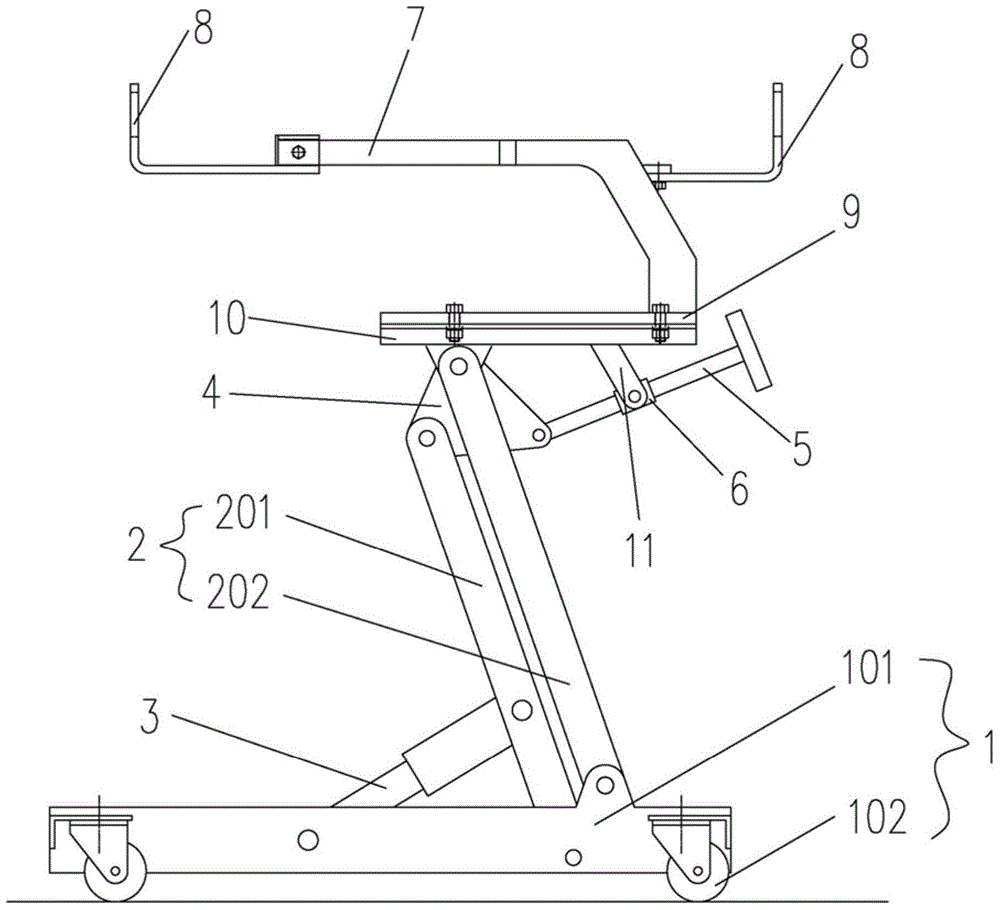

Oblique block-type elevating platform

InactiveCN106586895AImprove support rigidityGuaranteed support rigidityLifting framesGear wheelEngineering

The invention discloses an oblique block-type elevating platform. A threaded shaft performing fixed-axis rotation is provided with left and right sections of external threads with opposite rotary directions. Left and right sliding blocks matching the threaded shafts are respectively provided with internal threads with left and right rotating directions. A small hand wheel at the right end is fixedly connected with the threaded shafts. By rotating the hand wheel, the left and right sliding blocks perform motion in the opposite directions. With positions of the sliding blocks changing, a platform surface can ascend and descend. A bottom plate of the platform is provided with chutes having adjustable gaps in which the sliding blocks can slide. Left and right support plates are used for locating the threaded shafts. Holes of the support plates are beset with copper sleeves. Two oblique blocks are linked by a linkage plate and placed on the two sliding blocks. Upper pressing plates and upper blocking plates of the sliding blocks can play a falling-prevention and guiding effect. The platform surface is fixedly connected with the oblique blocks. After the height is adjusted, screws are tightened so that the platform is locked. Four bolt through holes are arranged in the bottom plate of the platform. The oblique block-type elevating platform has following beneficial effects: the oblique block-type elevating platform is compact in structure; compared with an ordinary oblique-gear elevating mechanism and a shear-type elevating mechanism, the platform is high in support rigidity and low in cost.

Owner:NANJING UNIV OF SCI & TECH

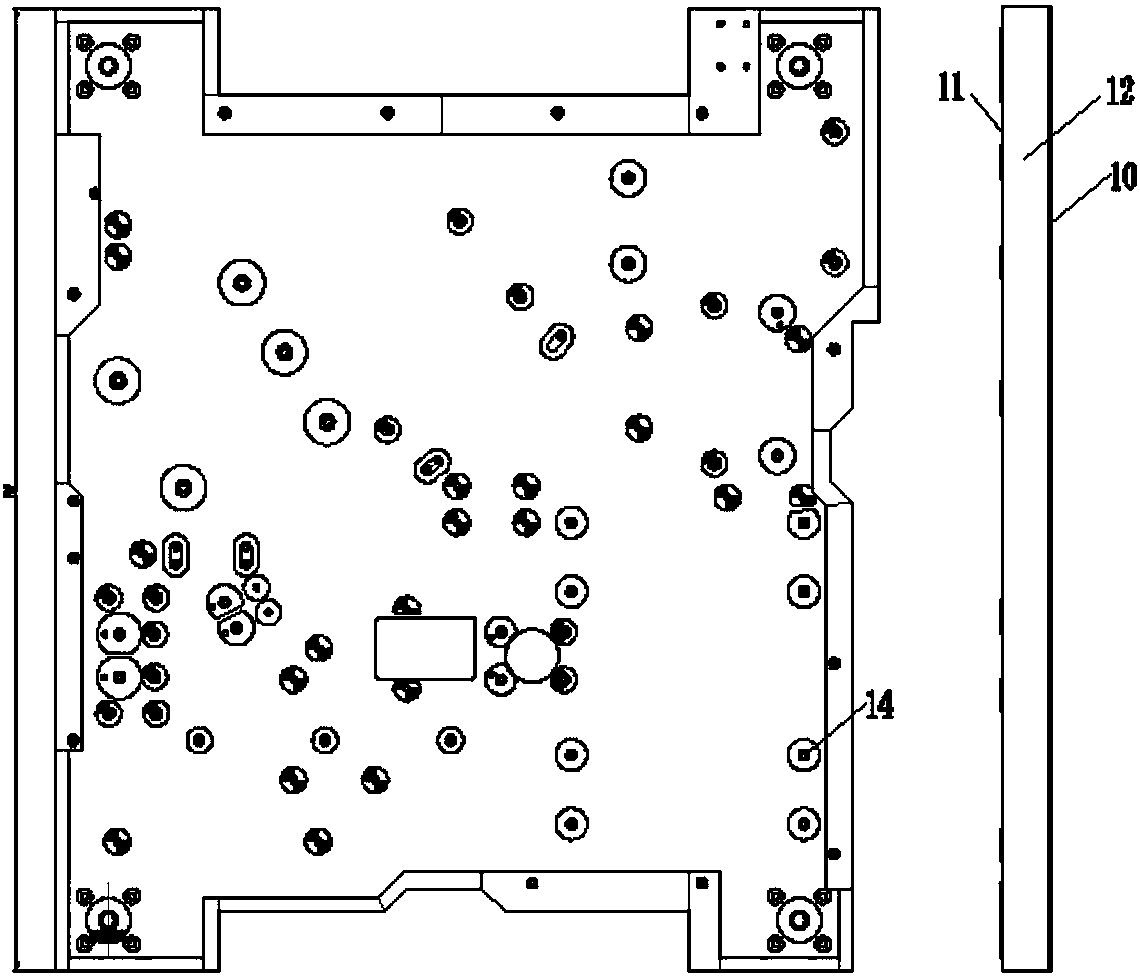

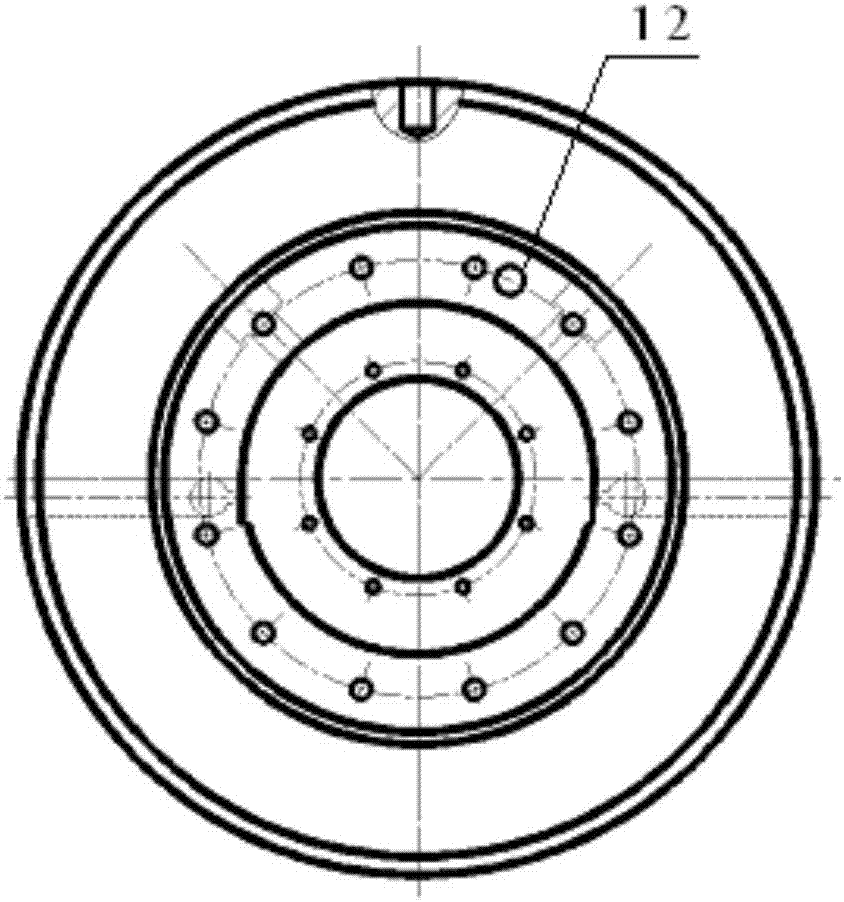

Ultra-compact and high-stability double-layer main body structure of optical remote sensor

InactiveCN108190052AGuaranteed support rigidityFirmly connectedCosmonautic vehiclesCosmonautic partsTemperature controlChinese characters

The invention discloses an ultra-compact and high-stability double-layer main body structure of an optical remote sensor. The double-layer main body structure comprises a composite panel, a main bodybase, cover plates, a bottom plate, an outer cover, a light shield assembly, vibration isolators and fire work locks. The main body base and the outer cover are connected to the upper and lower planesof the composite panel respectively; the main body base is of a frame structure, the side face is provided with reinforcing rib structures shaped like a Chinese character 'mi', the cover plates are connected between the reinforcing rib structures, the bottom is connected with the bottom plate, and thus a sealed space is formed inside; the four fire work locks are symmetrically connected to a bottom frame of the main body base, the vibration isolators are connected to the four corners of a lower panel of the composite panel, and the remote sensor is connected with a satellite capsule plate through the fire work locks and the vibration isolators; heating sheets are pasted on the surfaces of the cover plates, the bottom plate and the outer cover, and temperature control over the heating sheets is conducted by a temperature controller so that the temperature in the main body base and the outer cover can be 20+ / -3 DEG C.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

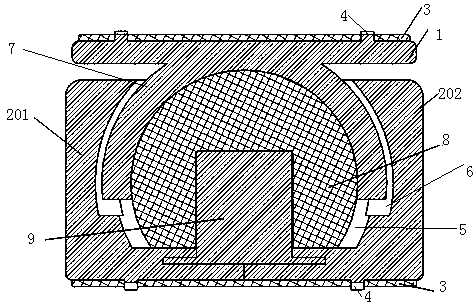

Non-merging cervical vertebra intercalated disc prosthesis and assembly method thereof

The invention relates to a non-merging cervical vertebra intercalated disc prosthesis and an assembly method thereof. The non-merging cervical vertebra intercalated disc prosthesis comprises an upperendplate and a lower endplate, wherein the lower endplate is a housing of which the upper end is not closed; a spherical cavity is formed in the housing; a spheroidal pulpy nucleus prepared from metaland rubber is arranged in the spherical cavity; a cross guide rail is vertically mounted in the middle part of the inner bottom of the housing; the lower end of the spheroidal pulpy nucleus is arranged on a guide rail in a sleeving manner; the upper endplate is located above the lower endplate; a C-shaped sleeving rod is arranged on the lower side surface of the upper endplate, and sleeves the outer surface of the spheroidal pulpy nucleus; and arc-shaped notches for giving ways to two ends of the C-shaped sleeving rod are arranged at the middle parts of the left side and the right side of theinner part of the spherical pulpy nucleus. The non-merging cervical vertebra intercalated disc prosthesis disclosed by the invention is simple in structure and reasonable in design, and the problem that in a conventional artificial cervical vertebra intercalated disc replacement technique, a common prosthesis cannot meet double requirements of cervical vertebra biological mechanics for an elasticity function and a moving function is solved.

Owner:FUZHOU UNIVERSITY

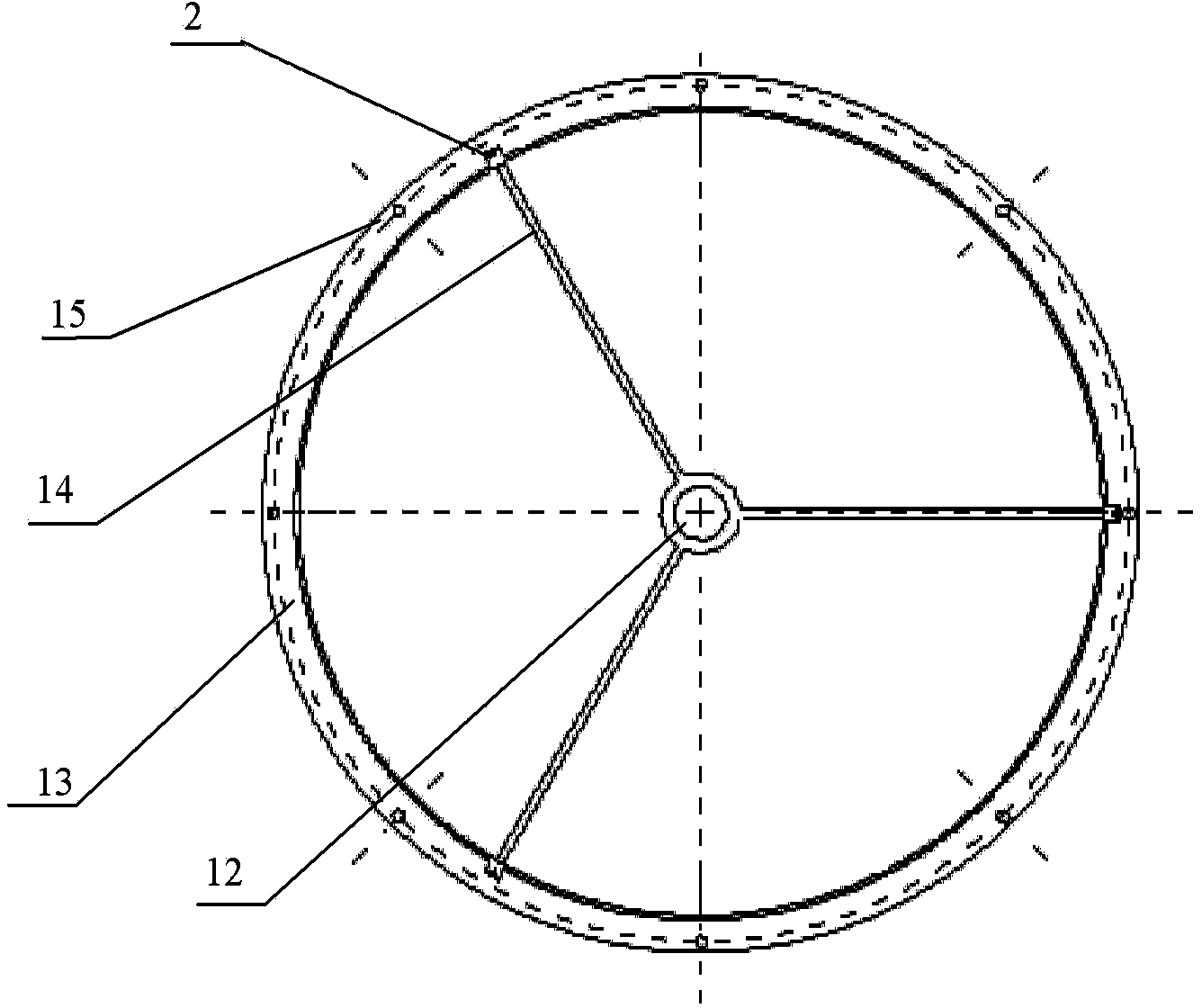

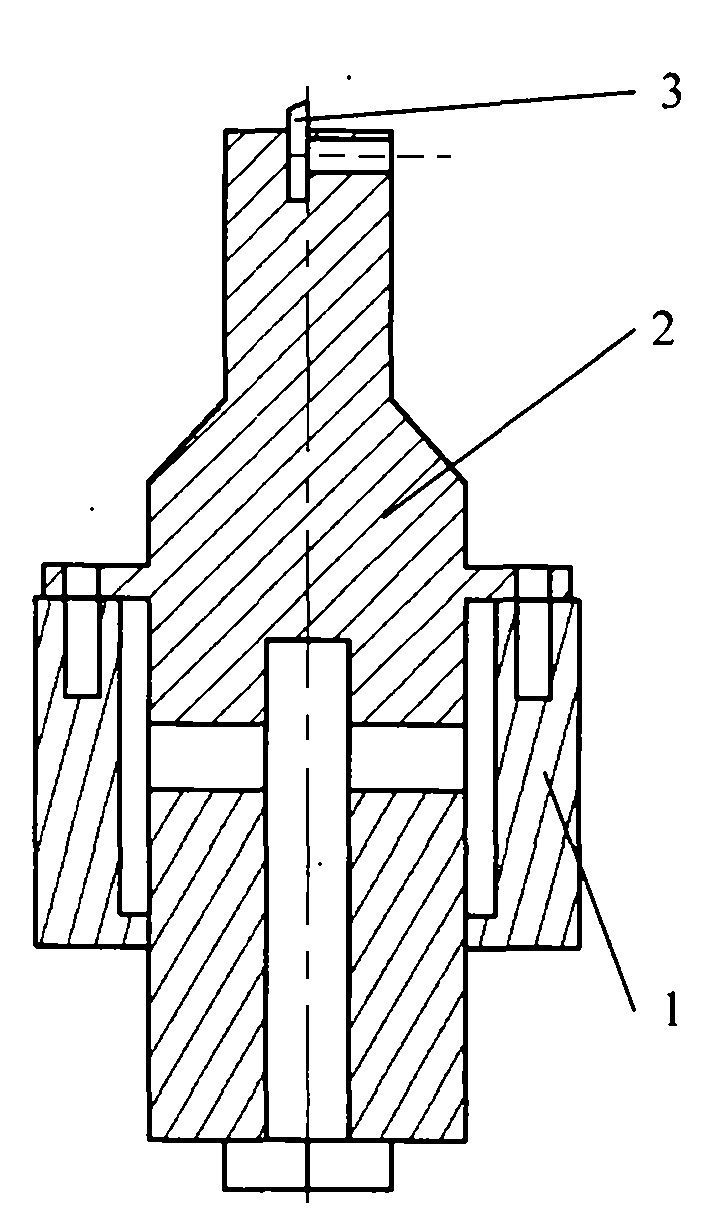

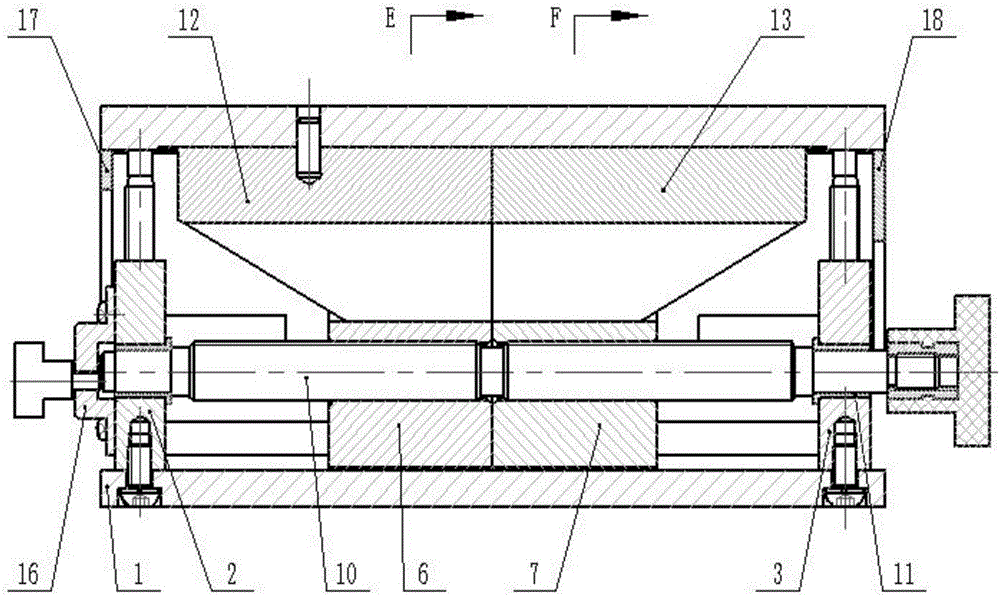

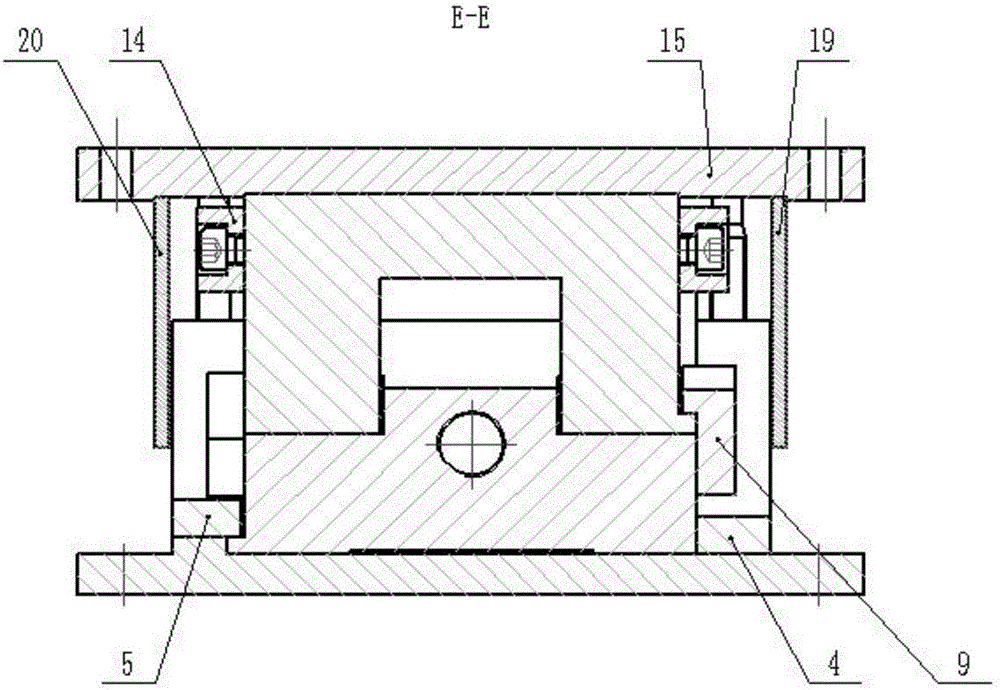

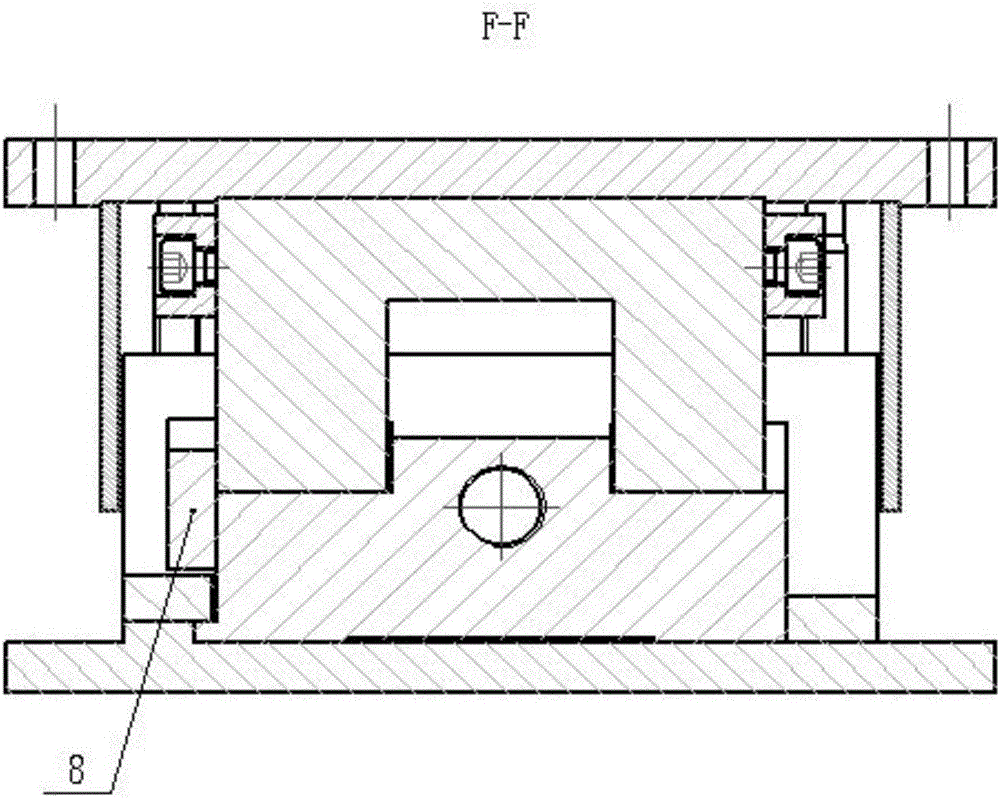

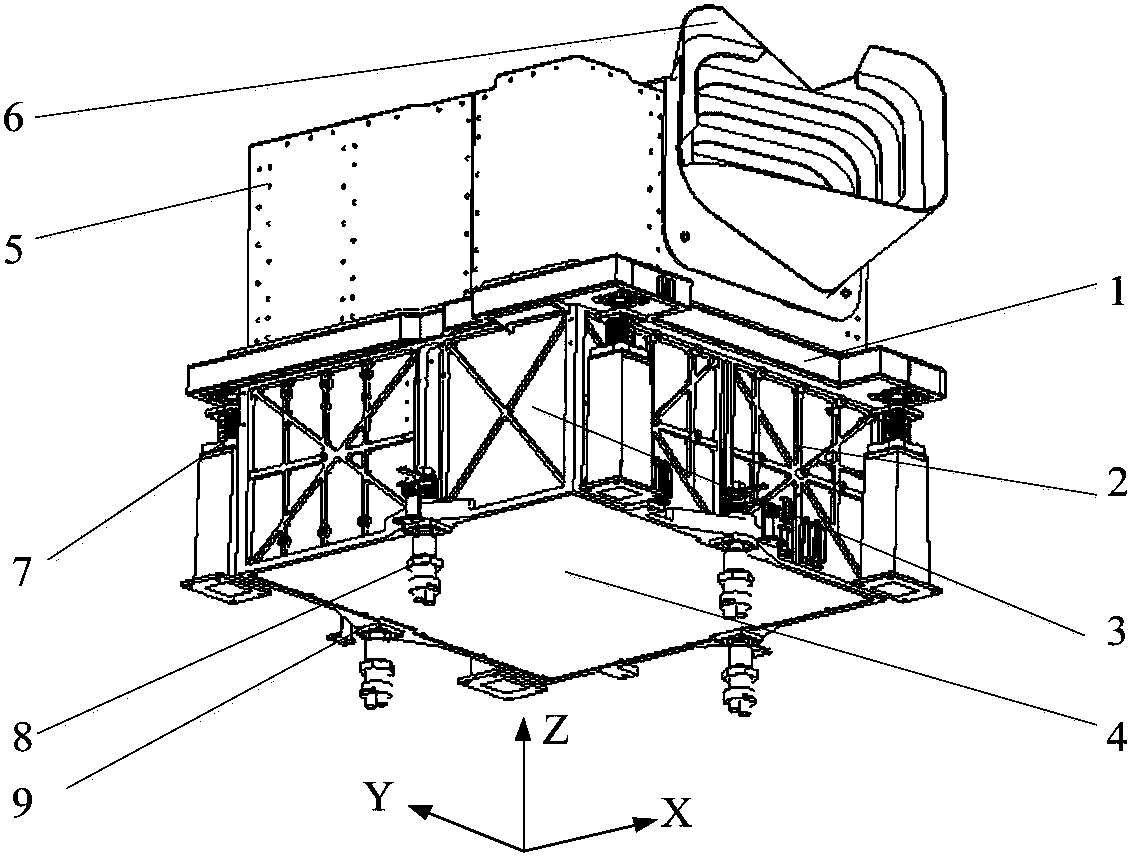

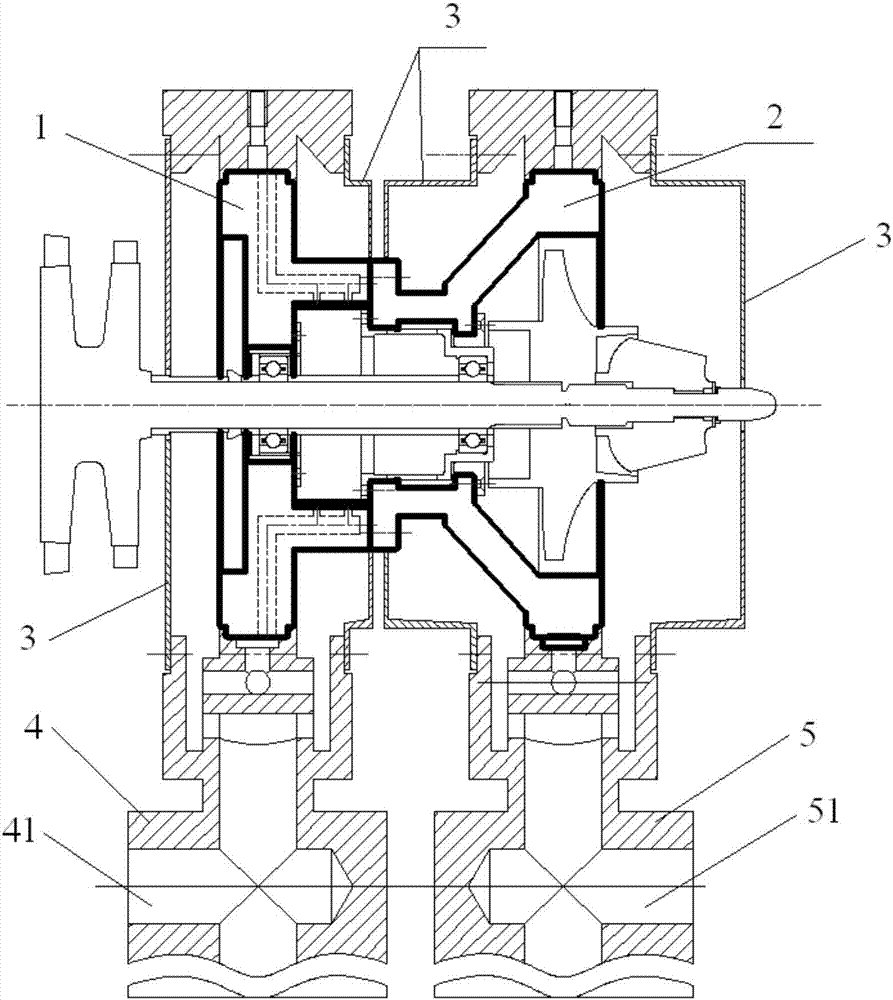

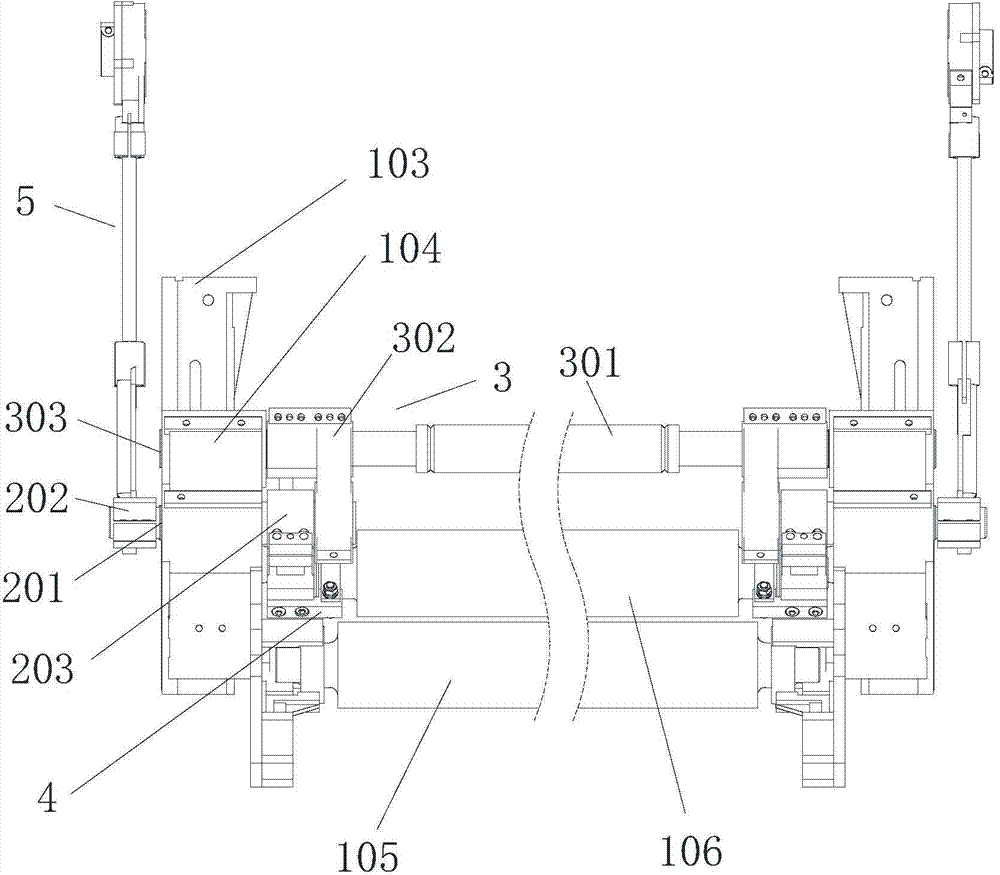

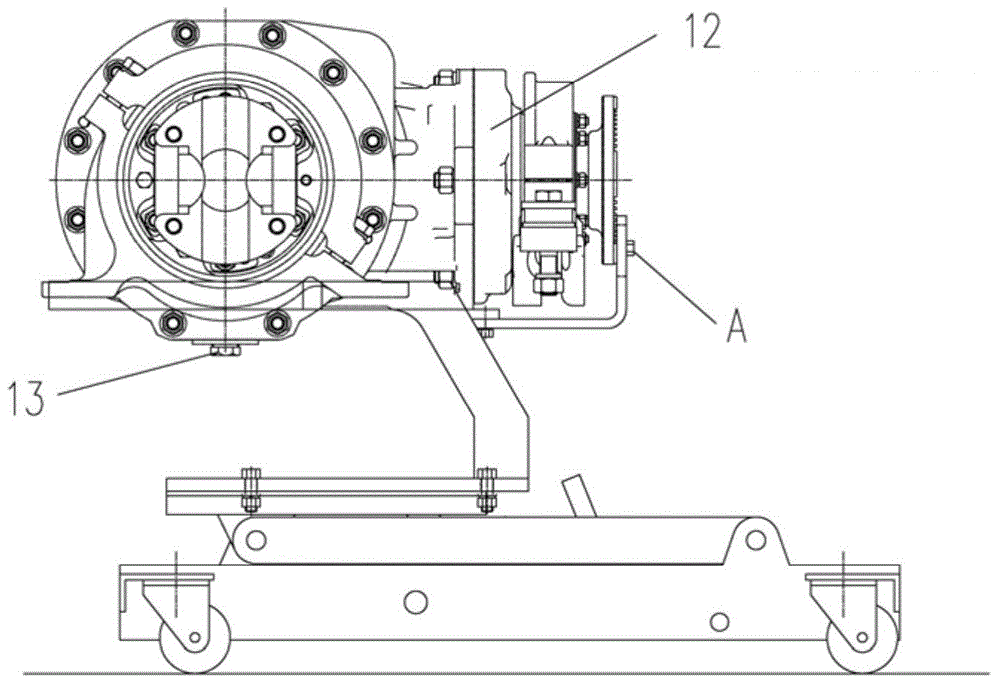

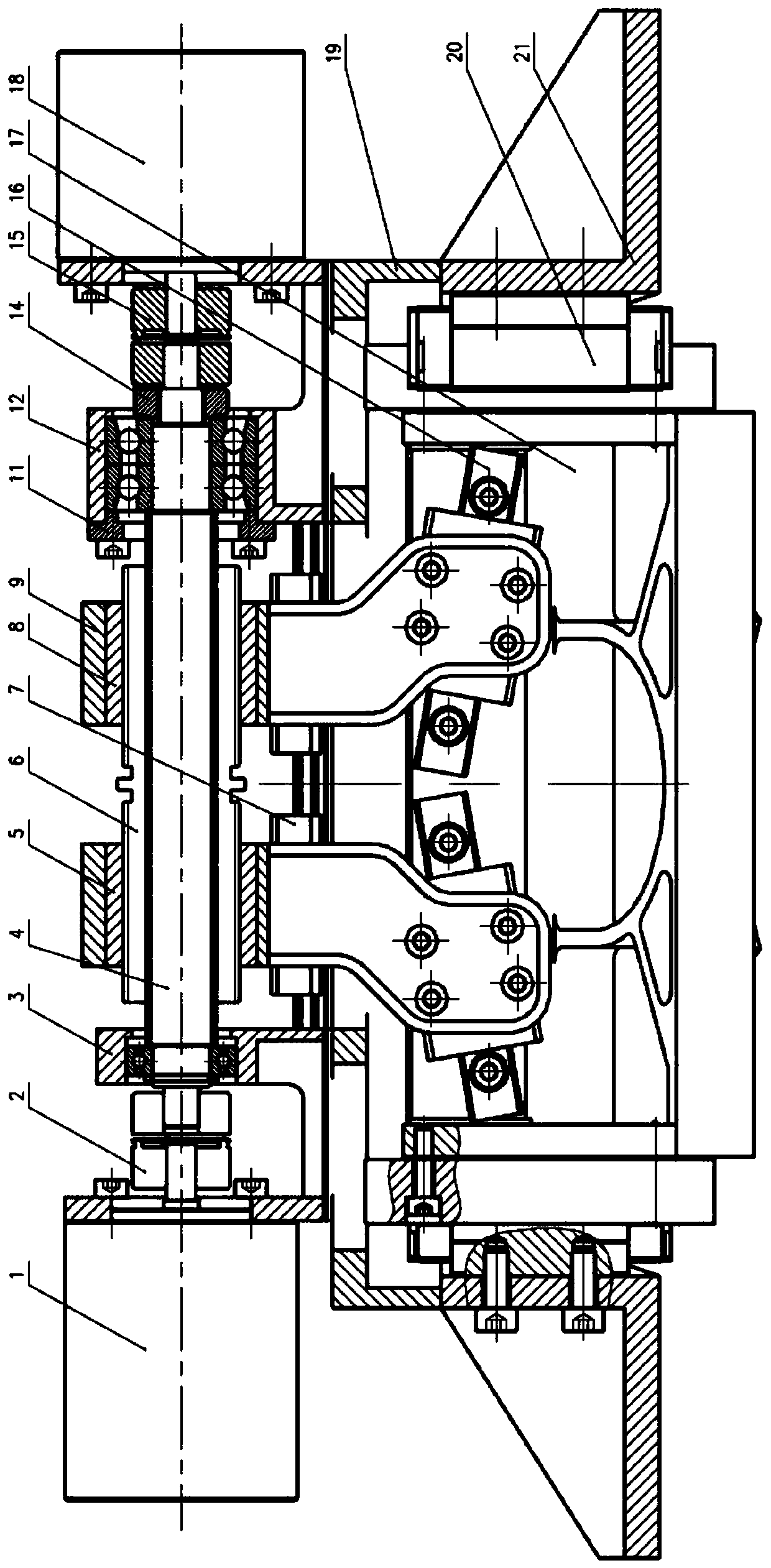

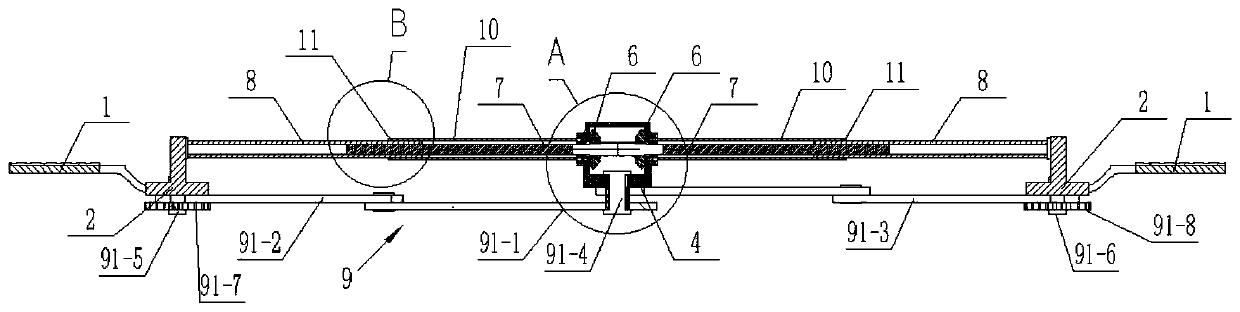

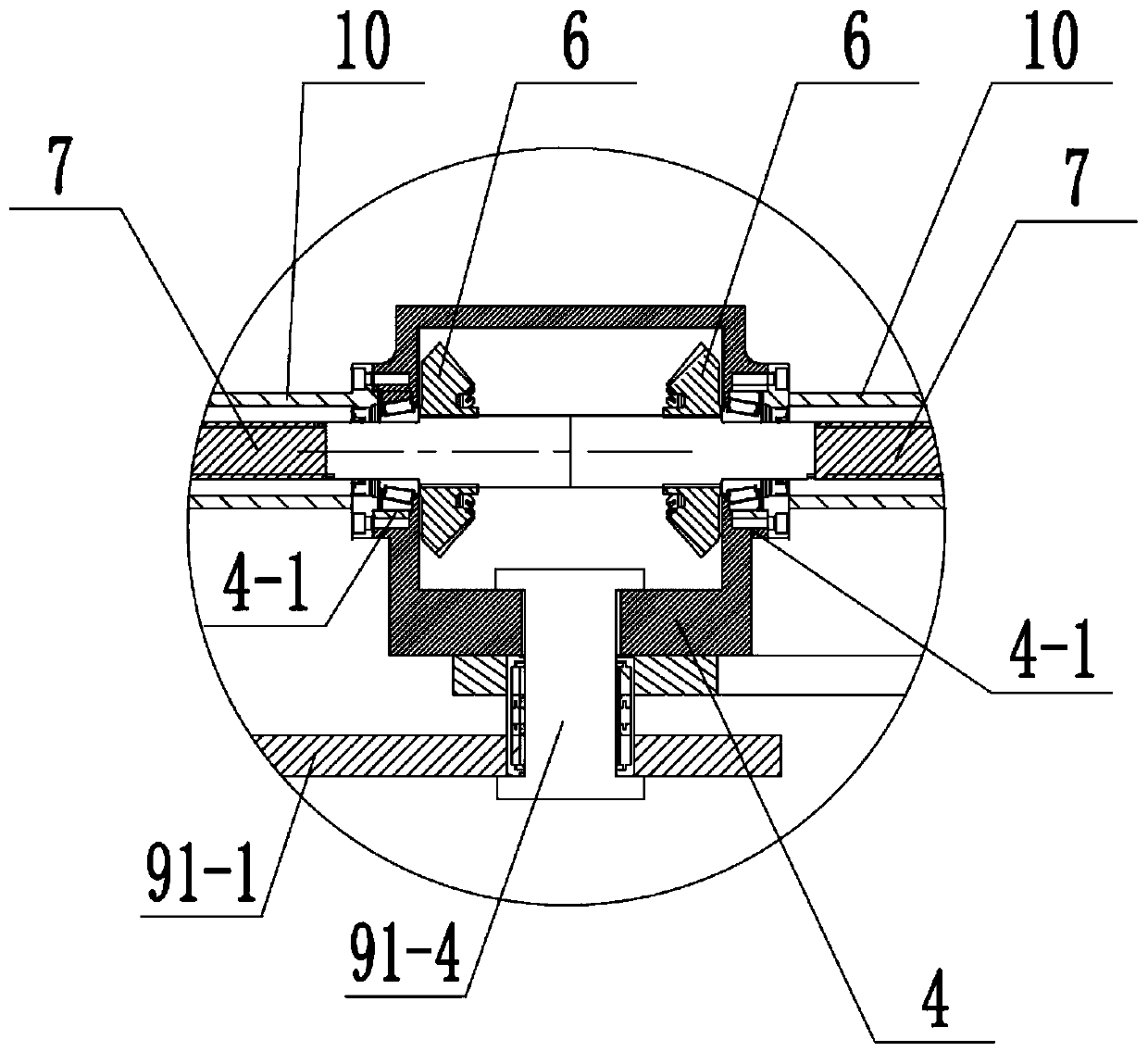

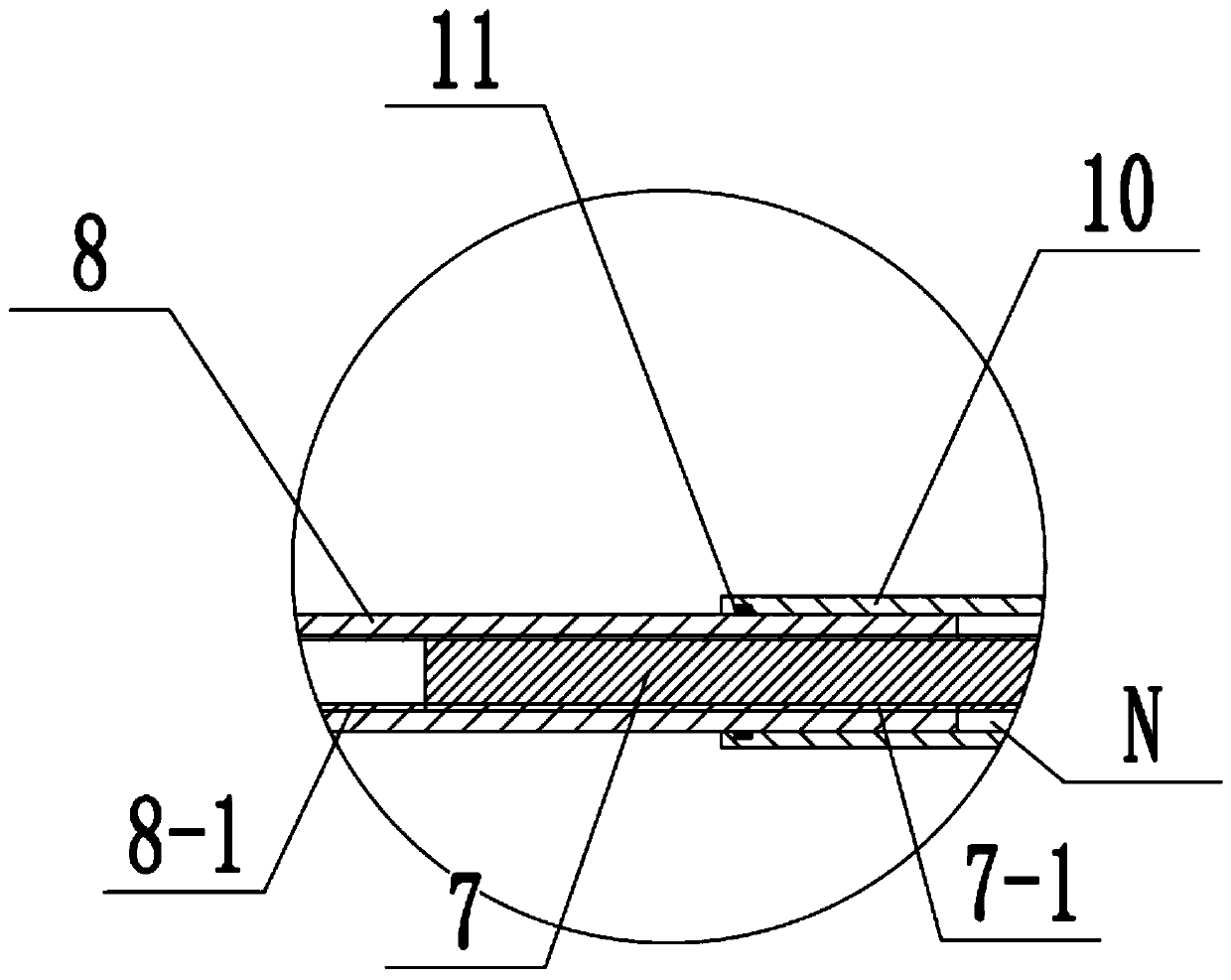

Liquid rocket engine turbopump flexible rotor high-speed dynamic balance supporting device

ActiveCN107014562AImprove assembly reliabilityImprove balanceStatic/dynamic balance measurementDynamic balanceEngineering

The invention provides a liquid rocket engine turbopump flexible rotor high-speed dynamic balance supporting device, including a main support shell I (2), a main support shell II (2) and an oil seal shell (3). The small end of the main support shell II (2) is connected with the small end of the main support shell I (1) through a flange plate of an end part; a turbopump rotor is mounted in a combination structure of connected main support shell I (1) and main support shell II (2) through a bearing; the large ends of the main support shell I (1) and the main support shell II (2) are fixed in annular frames of a swing frame I (4) and a swing frame II (5) respectively; and the oil seal shell (3) is connected with the main support shell I (1), the main support shell II (2), the turbopump rotor, the swing frame I (4) and the swing frame II (5) to form a seal cavity. The liquid rocket engine turbopump flexible rotor high-speed dynamic balance supporting device has a function of lubricating and cooling the bearing with single-support oil taking and bidirectional oil injection and a function of vibration displacement measurement of a rotor.

Owner:BEIJING AEROSPACE PROPULSION INST

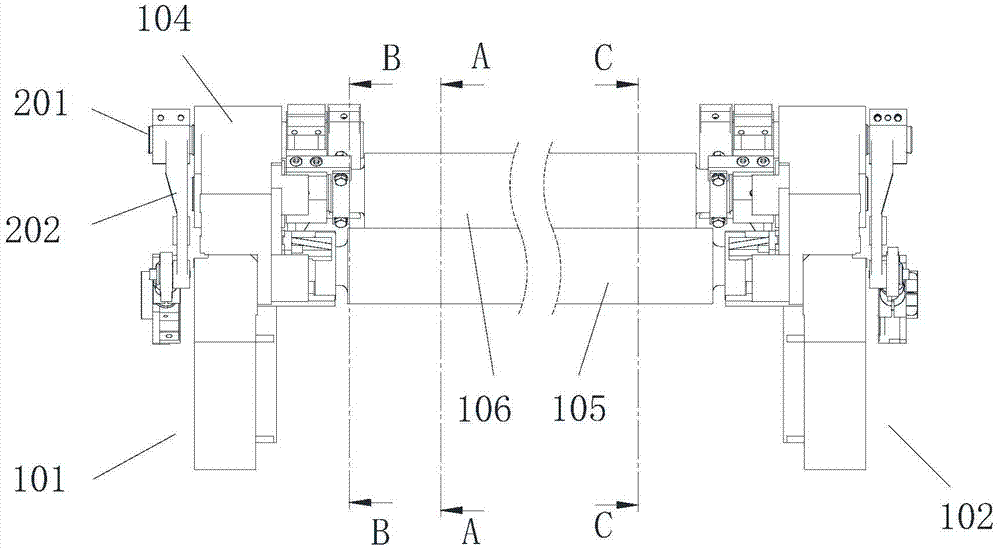

Let-off device of air jet loom

The invention discloses a let-off device of an air jet loom. The let-off device comprises a left machine frame and a right machine frame, wherein the left machine frame and the right machine frame are the same in structure. A tension roller and a transition roller are installed between the left machine frame and the right machine frame. The left machine frame and the right machine frame respectively comprise a lifting support and a positioning base installed on the upper portion of the lifting support. The two positioning bases are respectively provided with a tension roller supporting mechanism. The tension roller supporting mechanisms respectively comprise a rocking shaft, a rocking arm is installed at one end of each rocking shaft, a movable supporting arm is installed at the other end of each rocking shaft, the rocking arms are located outside the left machine frame and the right machine frame, the movable supporting arms are located inside the left machine frame and the right machine frame, the outer sides of the rocking arms are connected with positive warp loosening mechanisms or negative tension mechanisms, and the movable supporting arms are respectively provided with a lining and a bearing for installing the tension roller. Power of the positive warp loosening mechanisms or the negative tension mechanisms is transmitted to the inner sides of the machine frames from the outer sides of the machine frames, and the complete air jet loom is reasonable in mechanism and stable and reliable in performance.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

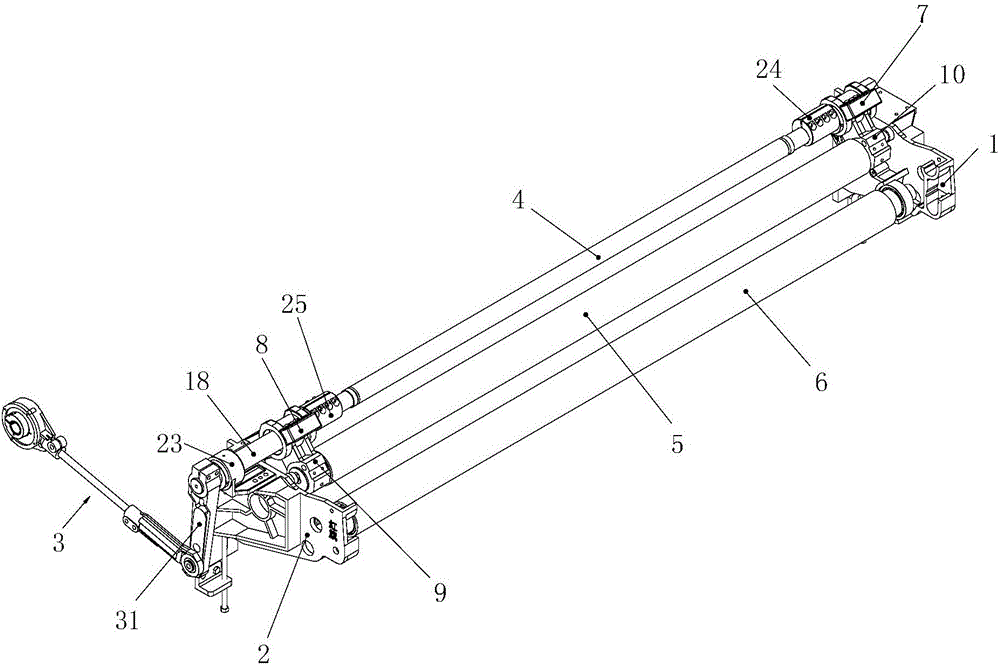

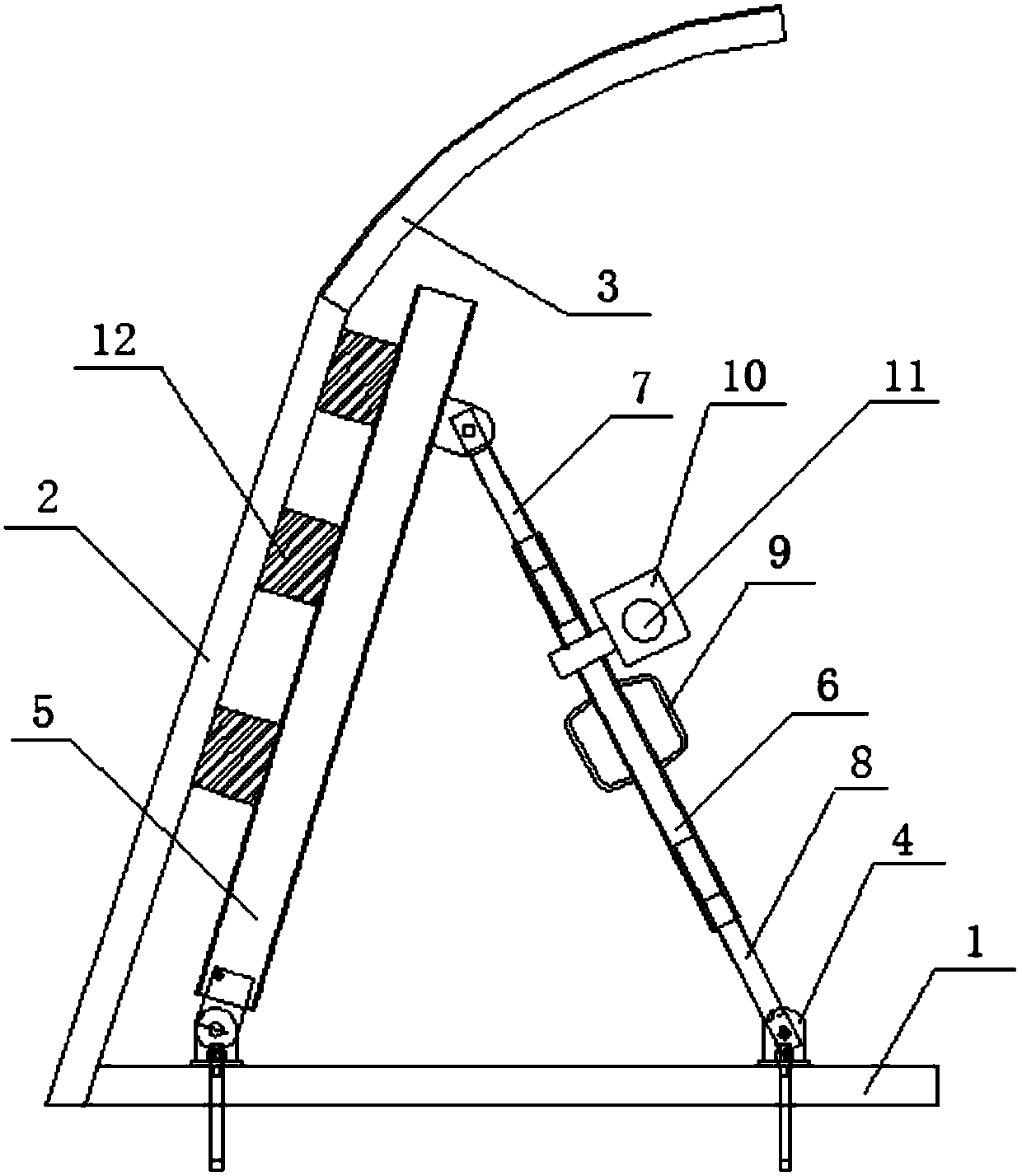

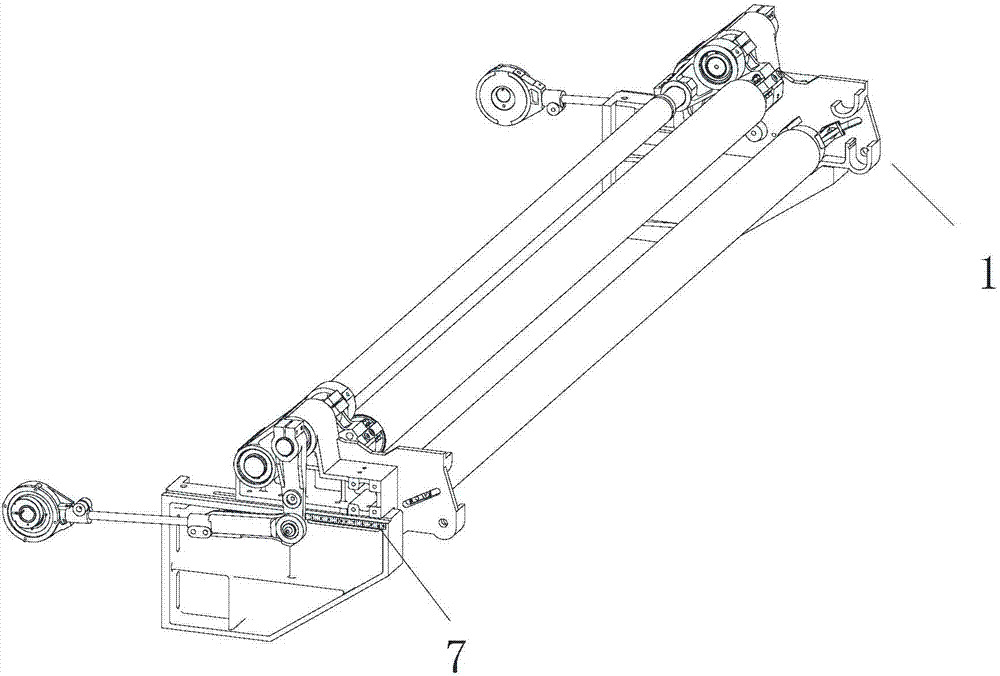

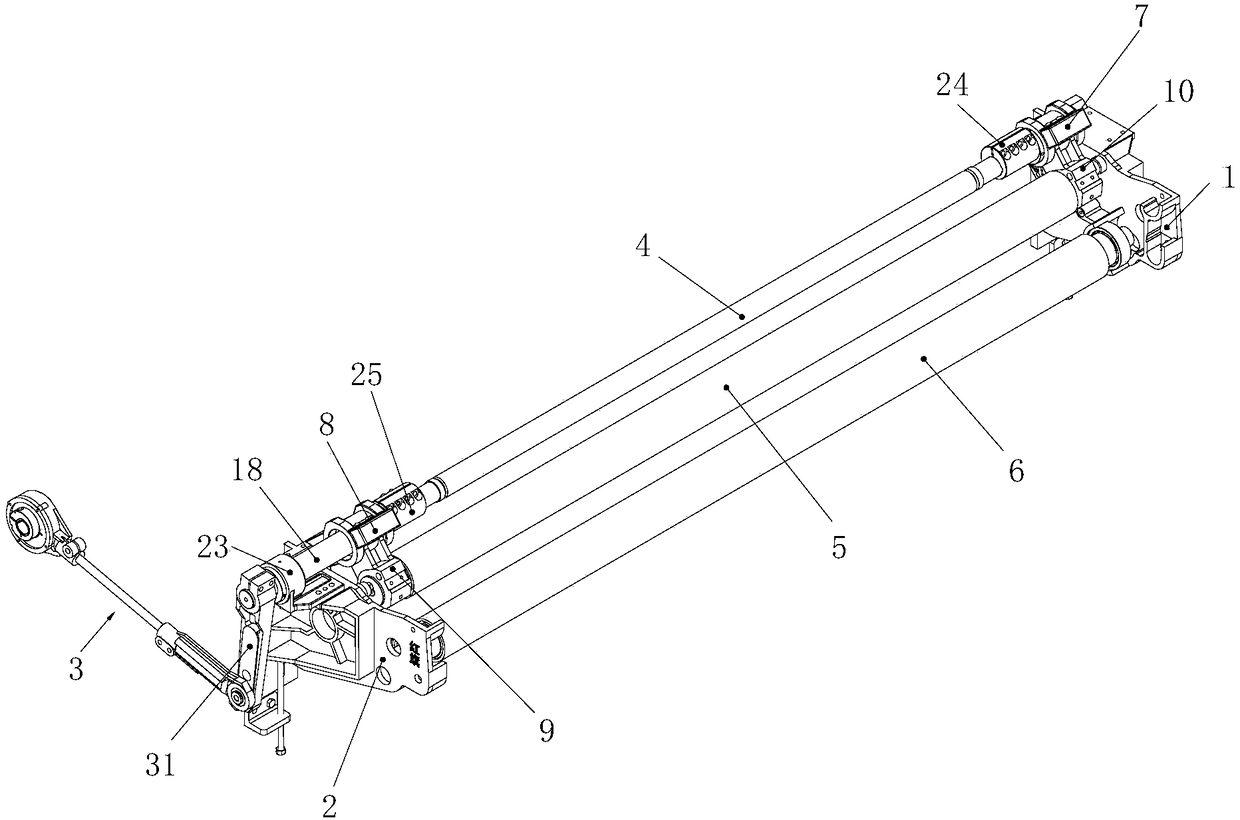

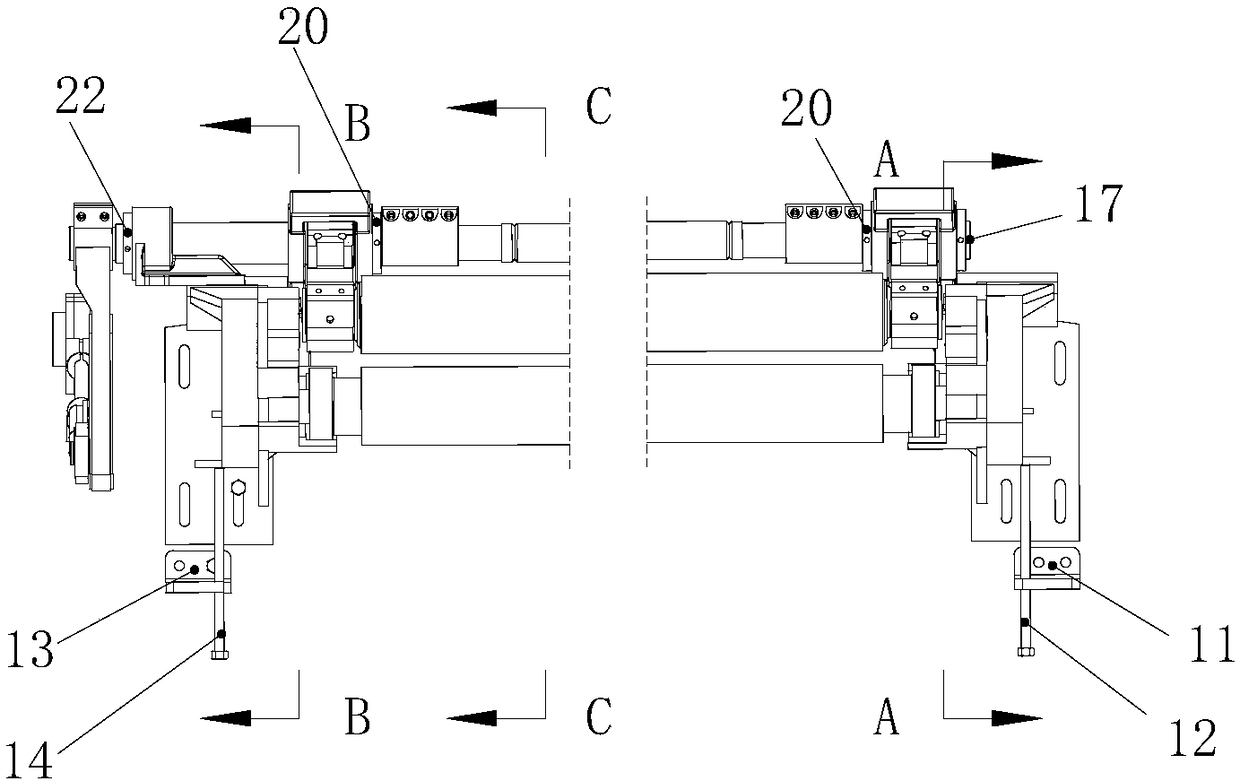

Supporting device for assembling/disassembling non-penetrable divided axle

ActiveCN104417499AEasy to operateReasonable structureLifting framesVehicle servicing/repairingEngineeringChassis

The invention provides a supporting device for assembling / disassembling a non-penetrable divided axle. The supporting device comprises a movable hoisting mechanism, an angle adjusting mechanism and an axle clamping mechanism. The supporting device utilizes the movable hoisting mechanism to hoist, the angle adjusting mechanism to turn and the axle clamping device to clamp and fix; with adoption of the supporting device, the non-penetrable divided axle can be assembled / disassembled only by one person; the support device is simple to operate, does not need an external power source or a gas source and is very flexible to use; the supporting device solves the bondage of assembling / disassembling the non-penetrable divided axle resulting from inadequate chassis space, gets rid of the operators' dependence on cranes and has the advantages of rational structure, high reliability, low manufacturing cost and good practical effect; the supporting device is not only suitable for indoor use, but embodies flexibility in field rush-repairing operation.

Owner:SANJIANG VOLAT SPECIAL VEHICLE

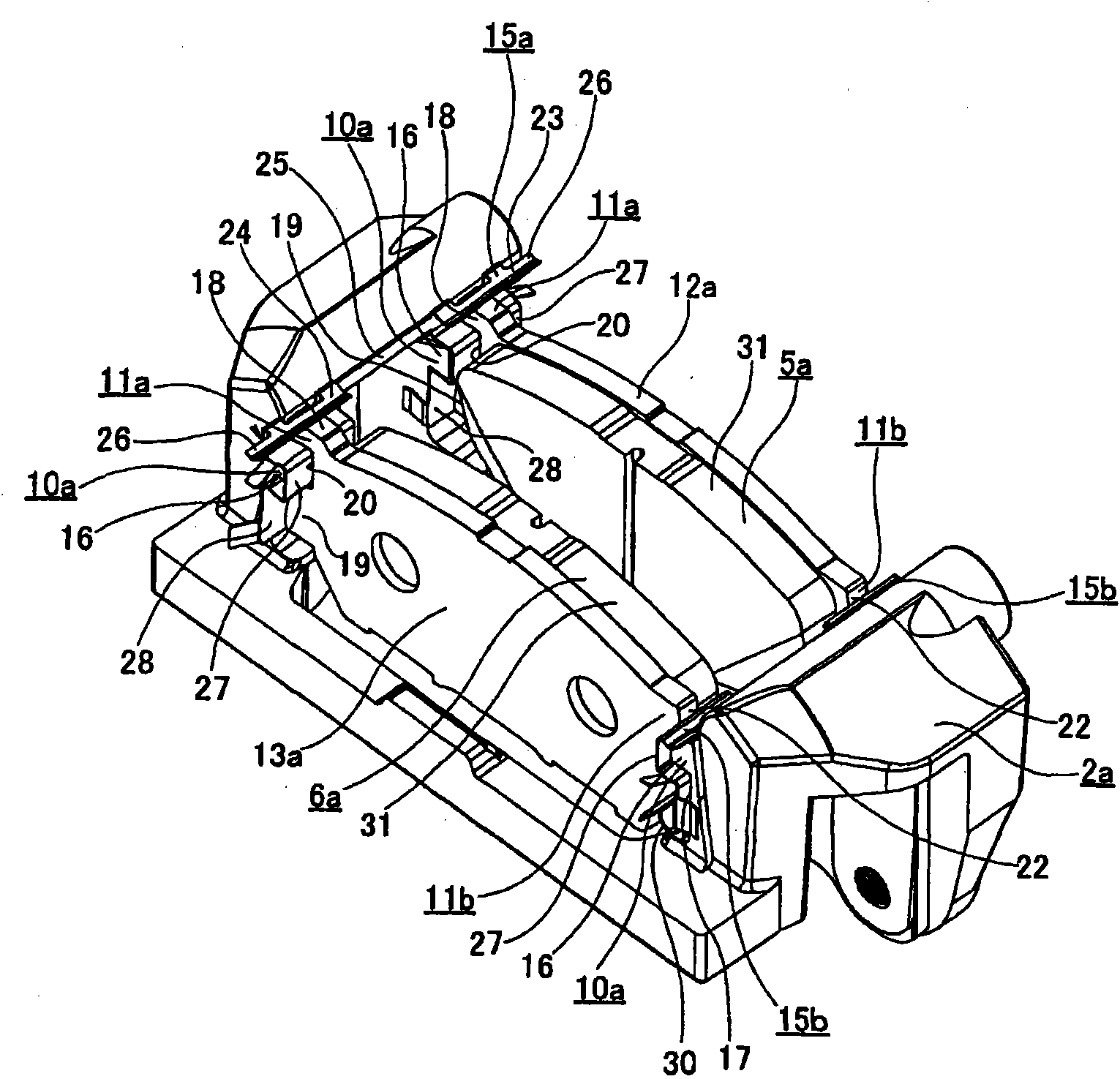

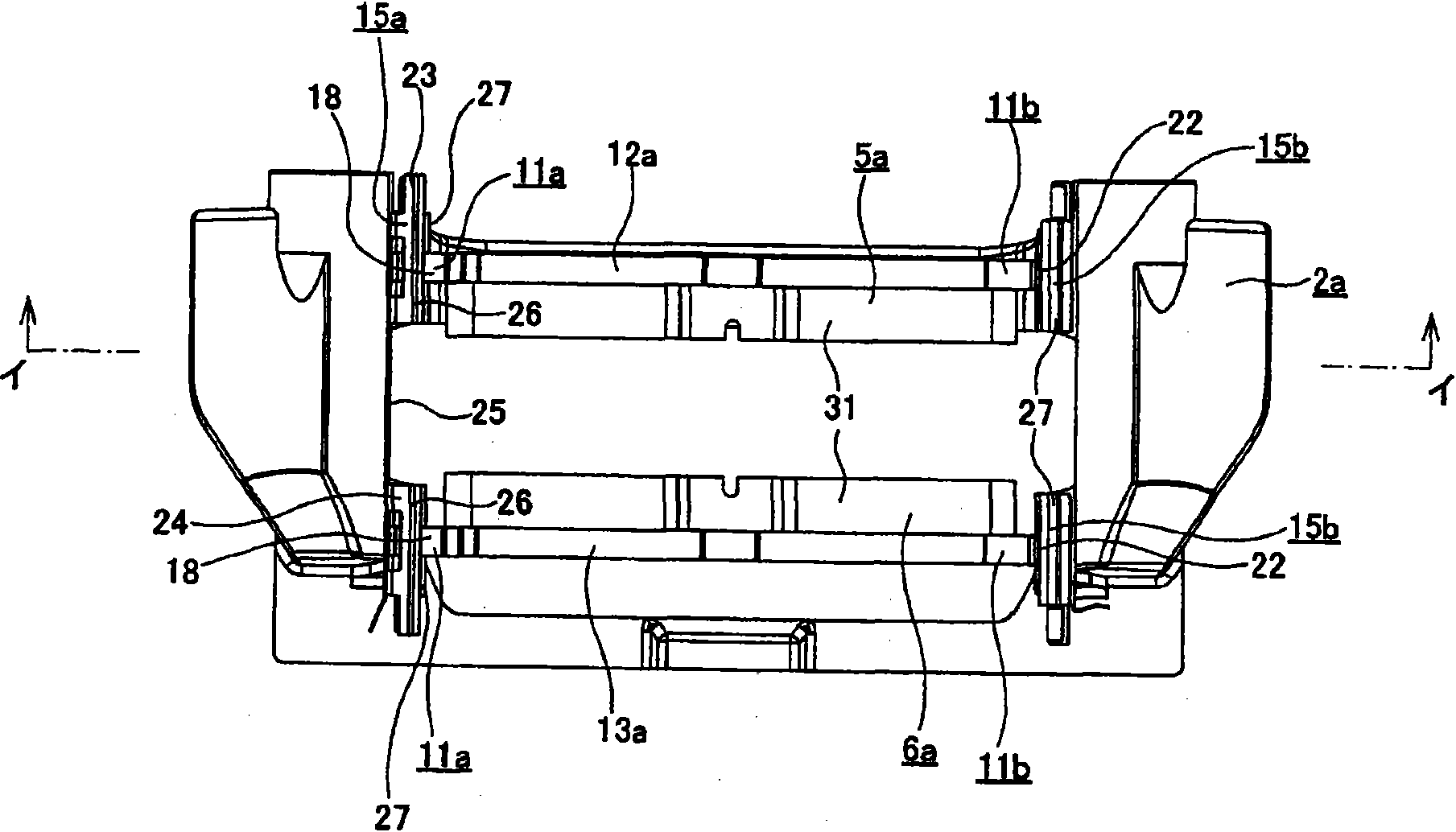

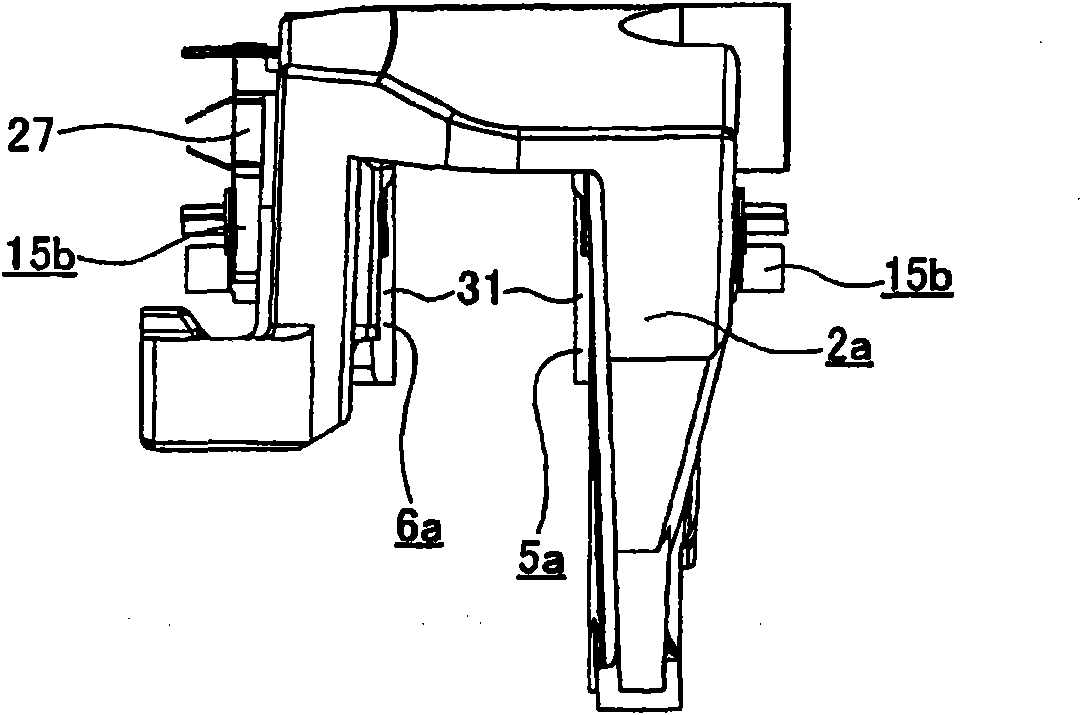

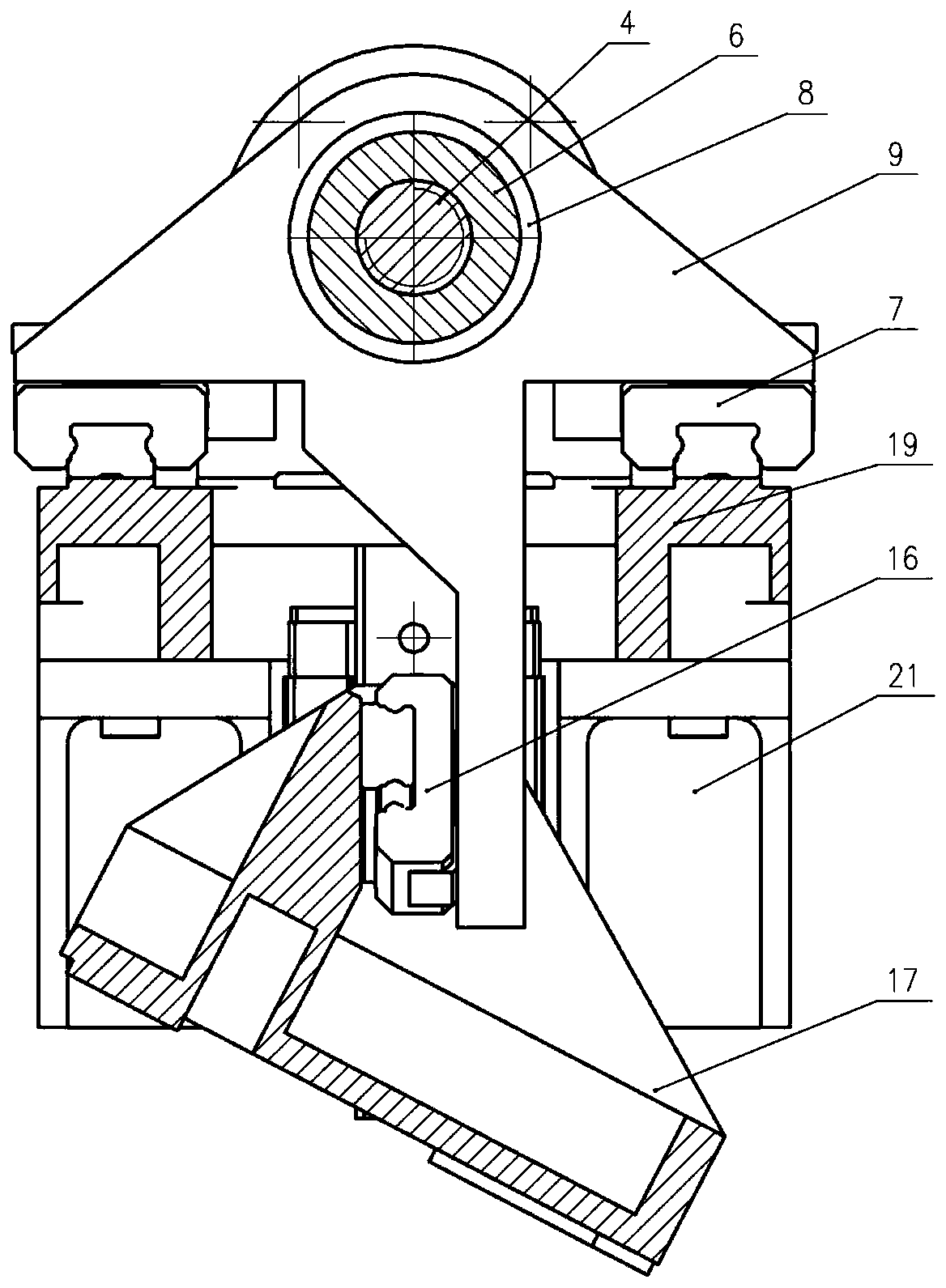

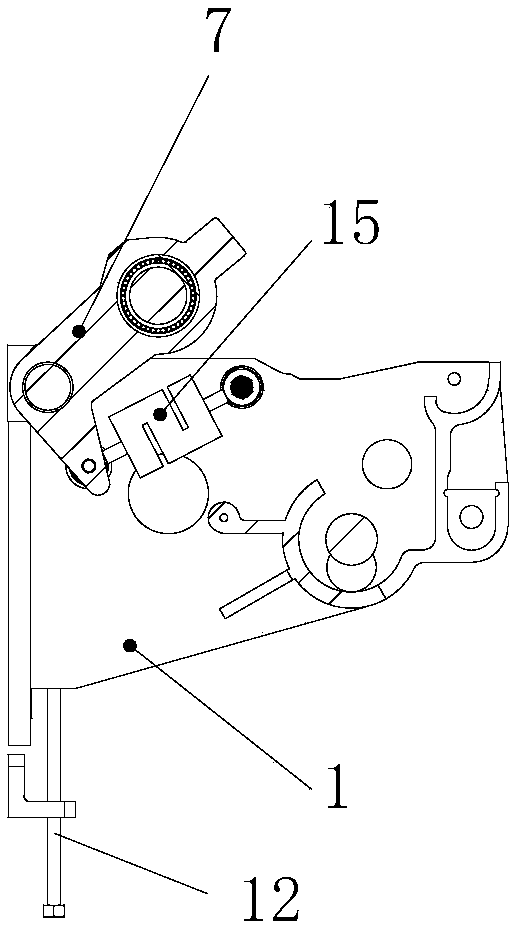

Disc brake

InactiveCN101846148AGuaranteed support rigidityAchieving form stabilizationAxially engaging brakesBraking elementsTangential forceMechanical engineering

The invention provides a disc brake which realizes a structure capable of achieving the sharp stabilization for the inward and outward pads (5a), and reducing pulling and vibration (noise, tremble) for the pads (5a). Among abutment parts of pad-side engagement parts (11a, 11b) and support-member-side engagement parts (10a, 10a), a portion (Af) which bears a tangential force (Ff) applied to the pad (5a, 6a) during a forward rotation of the rotor on a forward side of the forward rotation of the rotor is positioned inwardly in a radial direction of a rotor with respect to a virtual tangent (k) at a centroid (O) of the pad (5a, 6a) of a virtual circle having a center identical with a center of the rotor and passing through said centroid (O). Among the abutment parts, portions (Bf, Cf) which bear a rotational moment (Mf) applied to the pad (5a, 6a) during the forward rotation of the rotor are positioned at the circumferential both end parts of a support member (2a) and outwardly in the radial direction of the rotor with respect to the virtual tangent (k).

Owner:AKEBONO BRAKE IND CO LTD

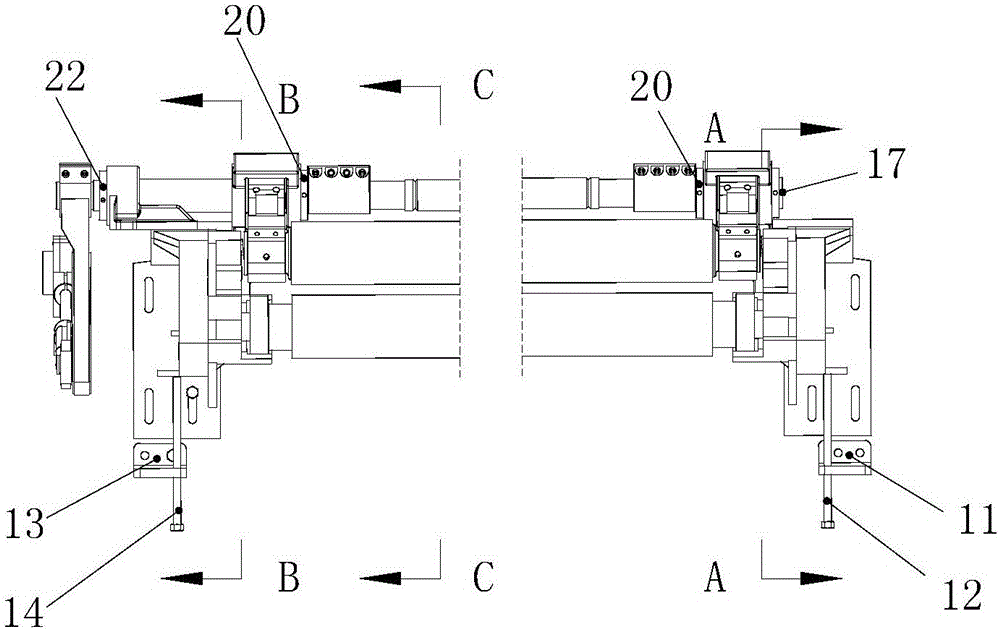

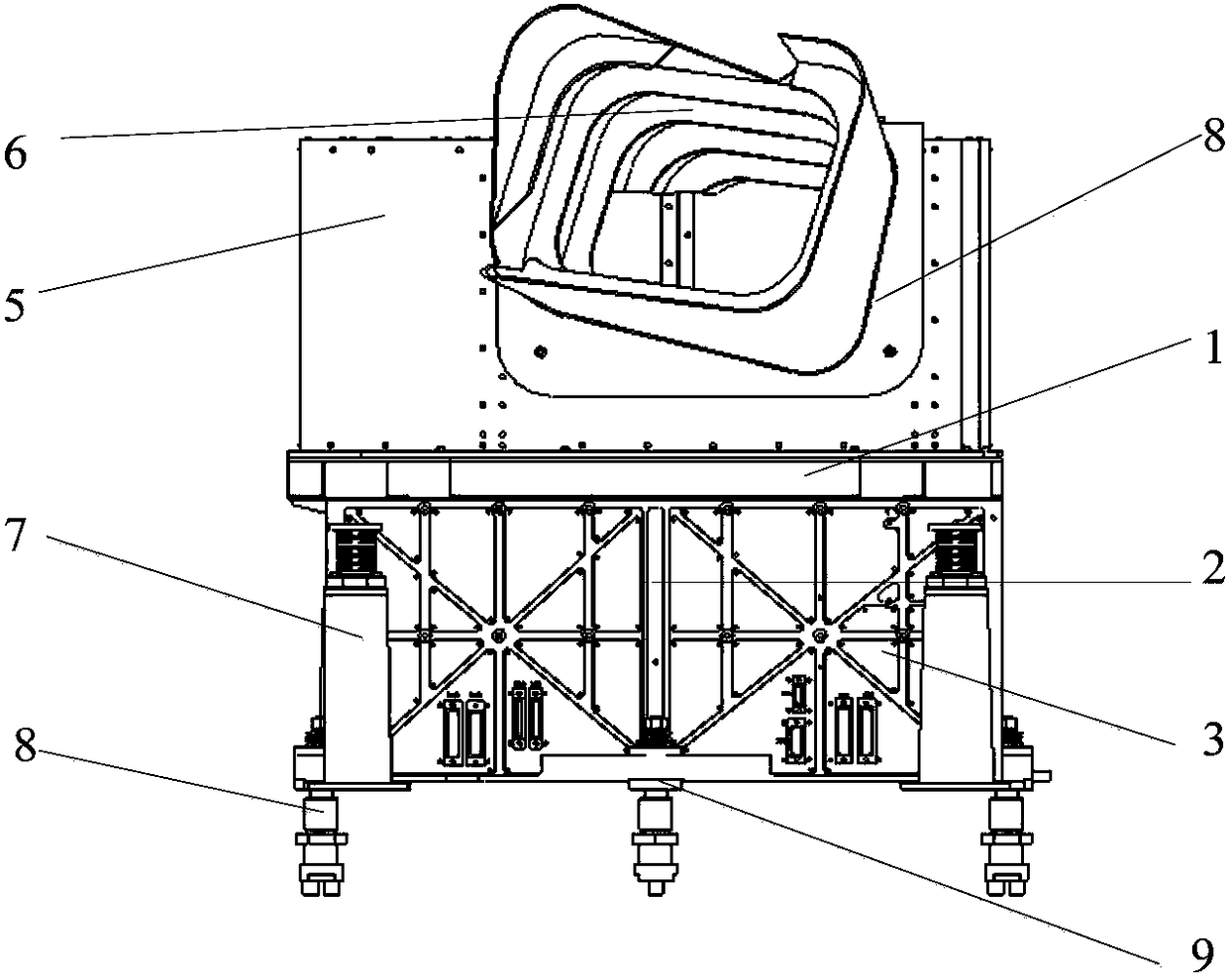

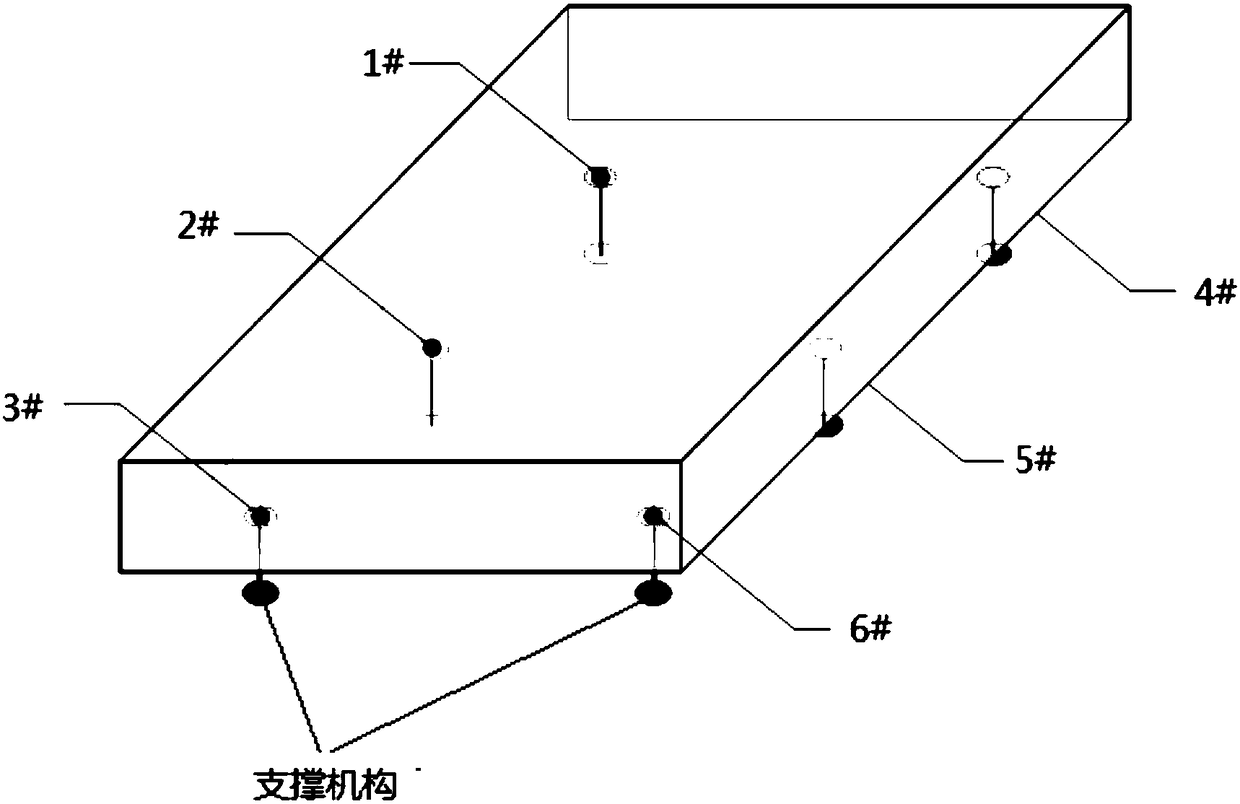

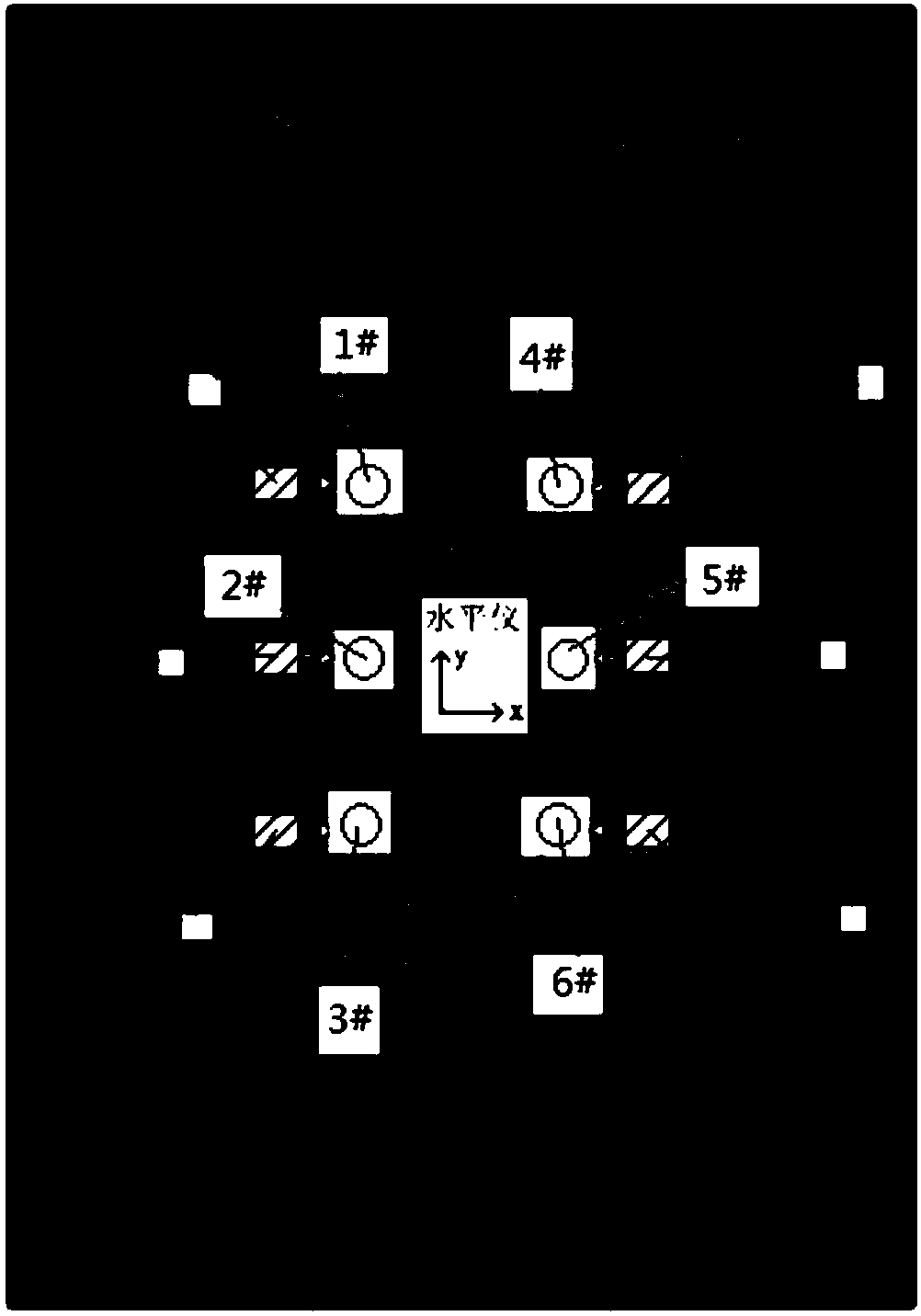

Leveling method for air-floating platform based on six-point support

ActiveCN108438262AReliable support at six pointsGuaranteed support rigidityCosmonautic condition simulationsEngineeringFloating platform

The invention provides a leveling method for an air-floating platform based on six-point support. The leveling method for the air-floating platform based on the six-point support comprises the following steps that (20) six supporting points from 1# to 6# are arranged on the air-floating platform in a square matrix mode, and six supporting mechanisms are jointly used for supporting the air-floatingplatform; (30) height variation of the six supporting points from 1# to 6# is measured by an altimeter when counterweight blocks are placed alone; (40) according to the air-floating platform, six-points support is changed into three-point support, and the height value of the six supporting points from 1# to 6# are recorded by the altimeter; (50) three-point support is changed into four-point support, and the height variation is measured; and (60) four-point support is changed into four-point support, and the supporting mechanisms are adjusted. According to the leveling method for the air-floating platform based on the six-point support, the air-floating platform is evenly supported by six points, the support rigidity and levelness requirements of the air-floating platform are ensured, andthe stable support of the air-floating platform for space equipment is ensured.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

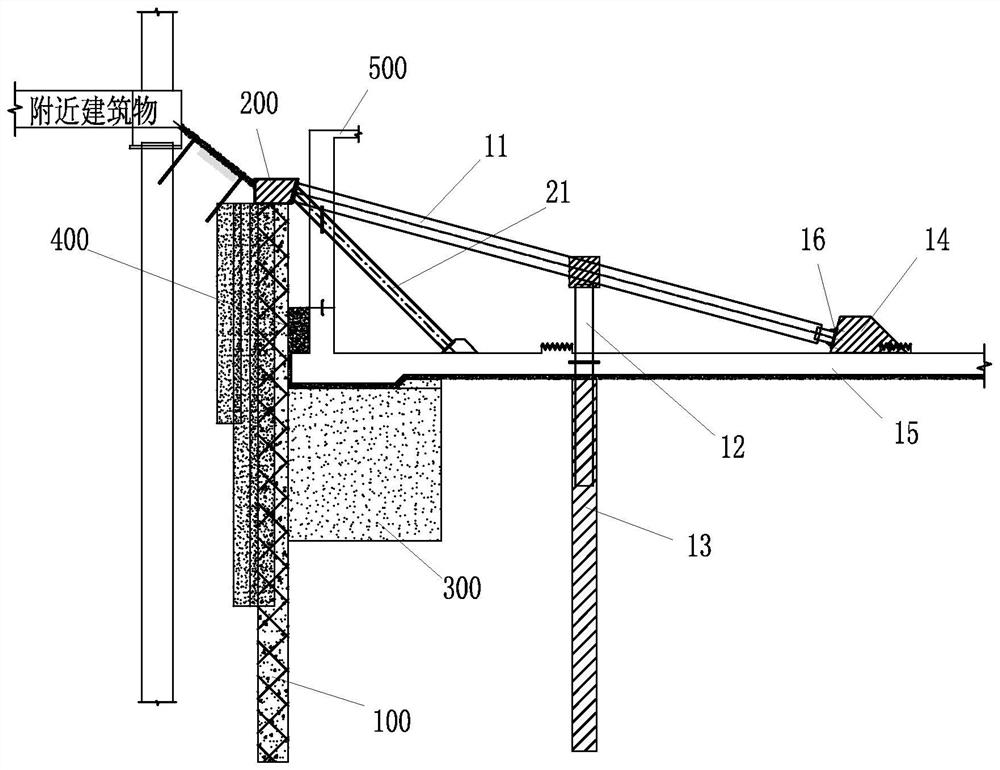

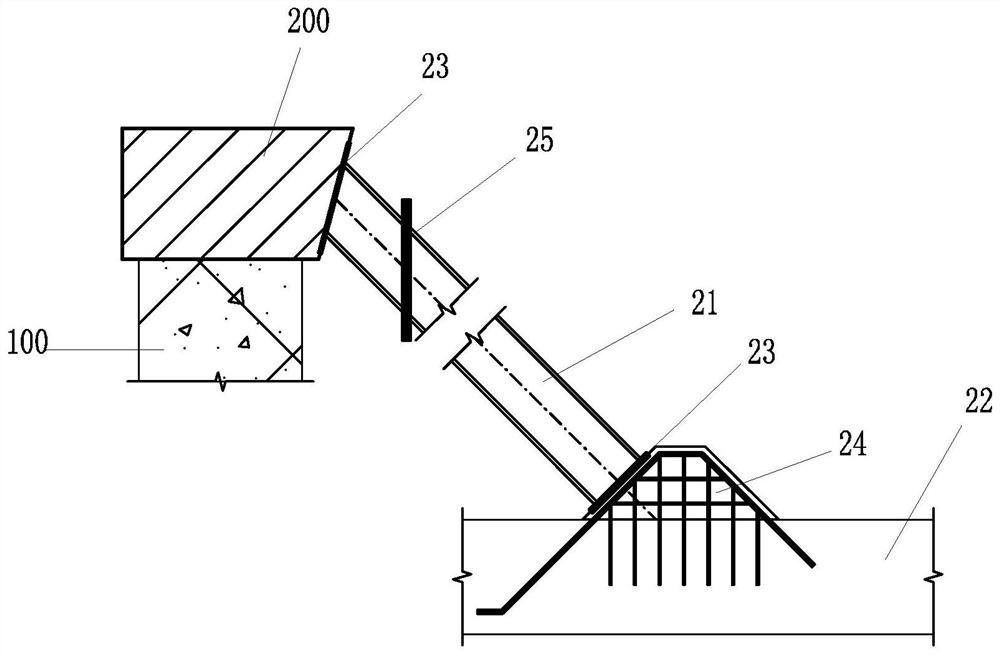

Foundation pit inclined support system and foundation pit inner support construction method

PendingCN113463650AReduce relevanceFast constructionExcavationsSupporting systemArchitectural engineering

The invention discloses a foundation pit inclined support system and a foundation pit inner support construction method. The foundation pit inclined support system comprises a side wall enclosure structure of a foundation pit, a top beam connected with the side wall enclosure structure, a steel pipe inclined strut and a bracket, wherein the bracket is fixedly arranged on a foundation pit bottom plate, the steel pipe inclined strut is arranged between the side wall enclosure structure and the foundation pit bottom plate in an inclined strut mode, one end of the steel pipe inclined strut is fixedly connected with the top beam, and the other end of the steel pipe inclined strut is fixedly connected with the bracket. The foundation pit inner support construction method is based on the foundation pit inclined support system and comprises the following steps of (1) mounting a long type inclined strut; (2) excavating reserved soil and constructing a residual bottom plate; (3) mounting a short type replacement support and removing the long type inclined strut; and (4) constructing a main body structure and removing the short type inclined strut. The foundation pit inclined support system and the foundation pit inner support construction method have the advantages that supporting materials can be recycled, so that the supporting rigidity is increased; and the support construction period is short, the reserved soil excavation difficulty is reduced, the construction cost is reduced, and the construction safety is improved.

Owner:中铁一局集团厦门建设工程有限公司 +1

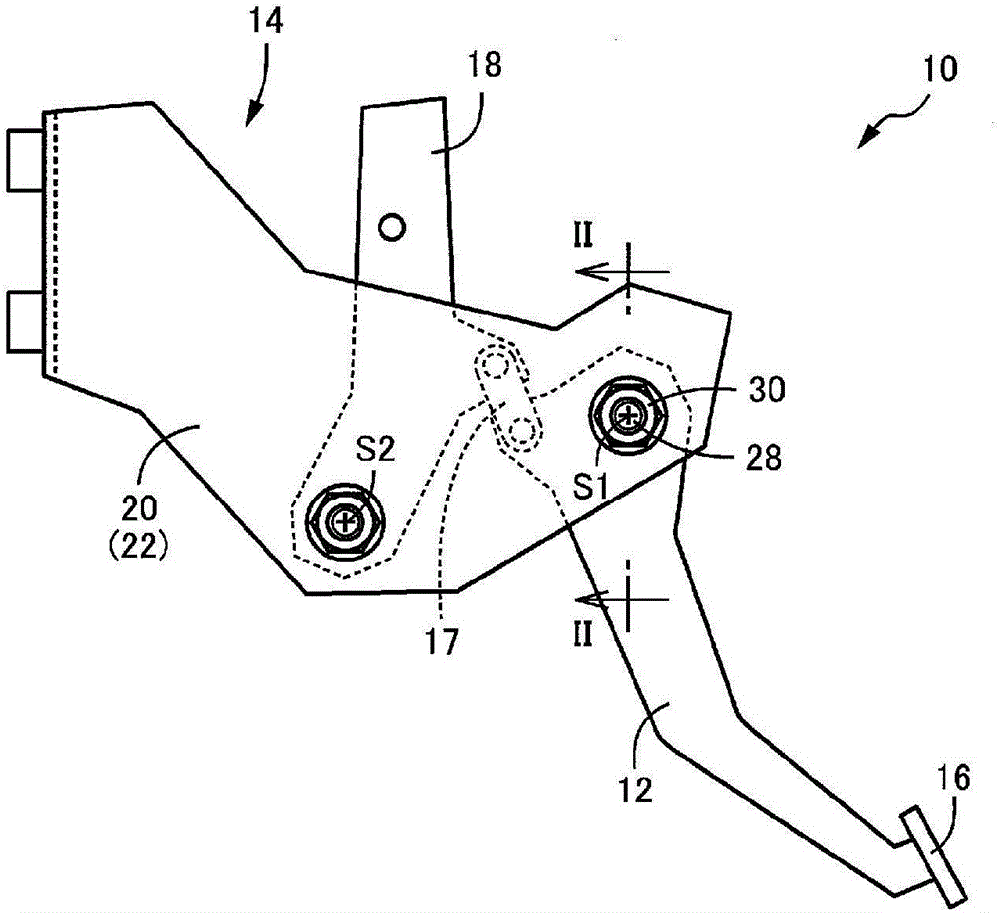

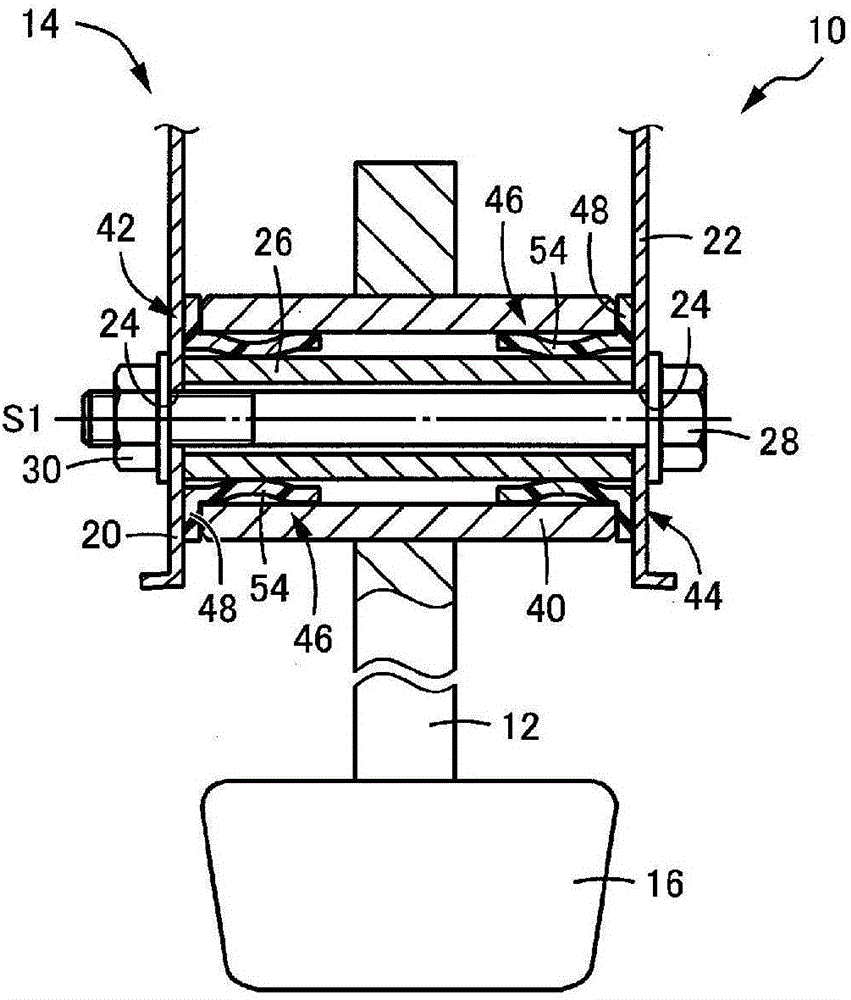

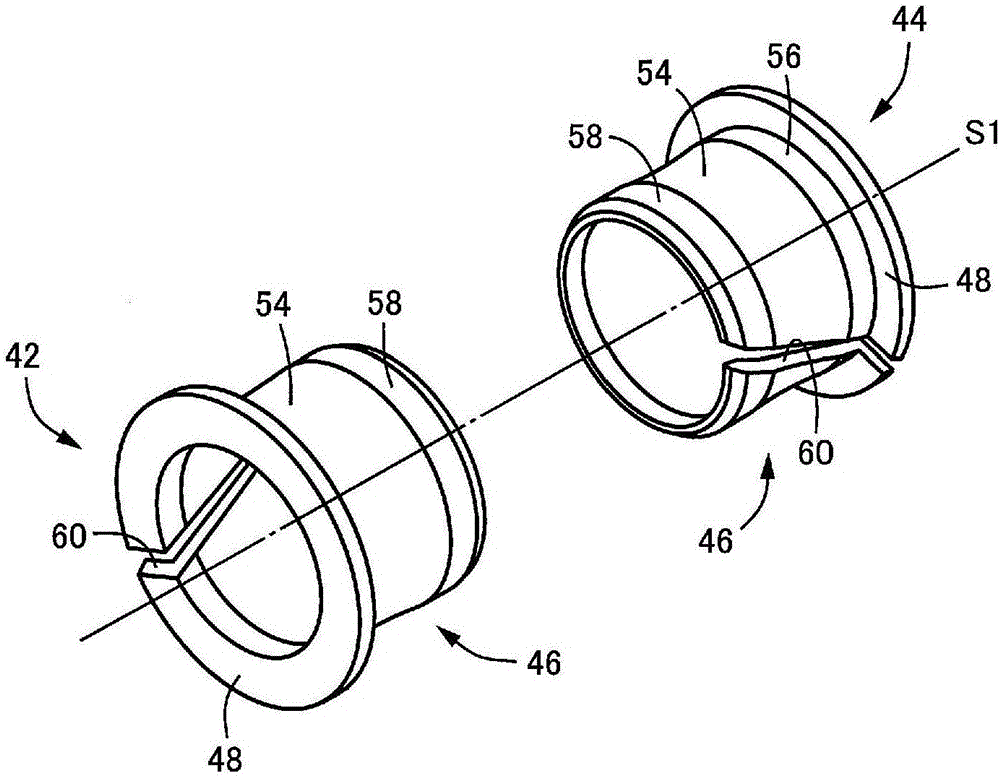

Bearing structure for vehicle pedal device and flanged bushing

InactiveCN106662889APostural stabilityGuaranteed support rigidityControlling membersShaftsMechanical engineeringEngineering

The present invention suppresses the occurrence of abnormal sounds and backlash caused by gaps between each section in a vehicle pedal device in which a flanged bushing is disposed between a support member and a boss. The two ends in the axial direction of the cylindrical section (46) of the flanged bushing (42, 44) are both contacted to the inner peripheral surface of the boss (40), and meanwhile a drum shaped section (54) is provided to the intermediate portion in the axial direction of the cylindrical section (46) and at least the minimum diameter section of the drum shaped section (54) is elastically contacted to the outer peripheral surface of a collar (26), and so the drum shaped section (54) is compressed and bent / deformed in the radial direction between the inner peripheral surface of the boss (40) and the outer peripheral surface of the collar (26). Consequently, the support rigidity of the boss (40) is secured by the reaction force resulting from the bending deformation of the drum shaped section (54), and so abnormal sounds, tilting, and backlash in the radial direction of the boss (40) are suppressed.

Owner:TOYODA IRON WORKS CO LTD

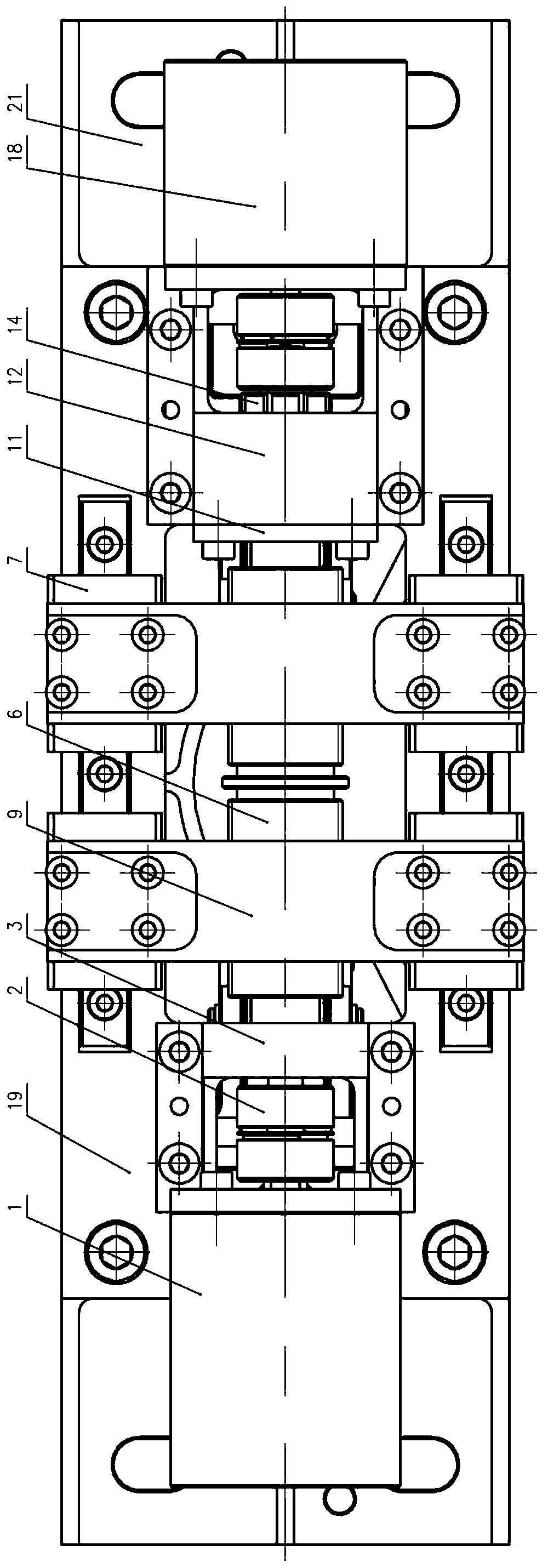

Uniform force focusing mechanism driven by inclined guide rail

ActiveCN111474661AGuaranteed support rigidityResolve Motion InterferenceMountingsEngineeringSupport point

The invention discloses a uniform force focusing mechanism driven by an inclined guide rail. The uniform force focusing mechanism comprises a focusing mounting base, supports slidably connected to thetwo sides of the focusing mounting base through vertical linear guide rails, and bases assembled and fixed to the upper ends of the supports. A horizontal focusing assembly is mounted at the upper part of the bases; the horizontal focusing assembly is provided with a spline shaft and a hollow lead screw which are matched through a sliding pair. The hollow lead screw is matched with the spline shaft through a sliding pair so as to move in the axial direction of the spline shaft, and the hollow lead screw is in transmission connection with a wedge angle sliding block mechanism so as to drive the wedge angle sliding block to slide along the inclined guide rail and drive the focusing mounting base to move along the vertical linear guide rail to adjust the vertical position of an optical element. The hollow lead screw can horizontally move on the spline shaft so that motion interference caused by manufacturing and mounting errors of the left wedge angle sliding block and the right wedge angle sliding block can be compensated, the problem of multi-supporting-point motion interference is solved on the premise that the supporting rigidity is guaranteed and the part machining and assembling difficulty is lowered.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

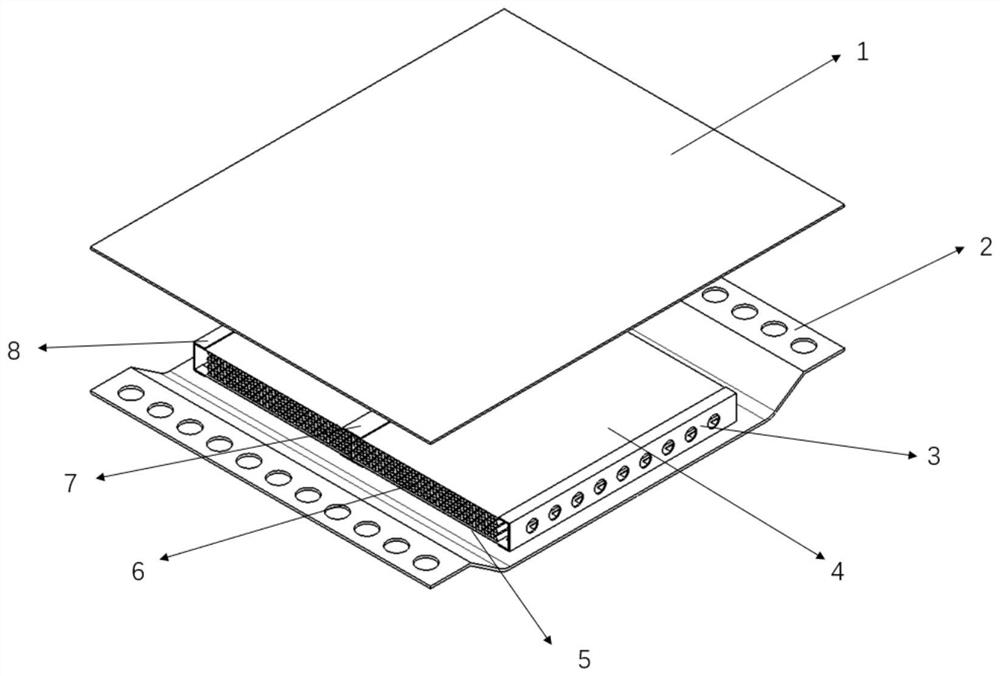

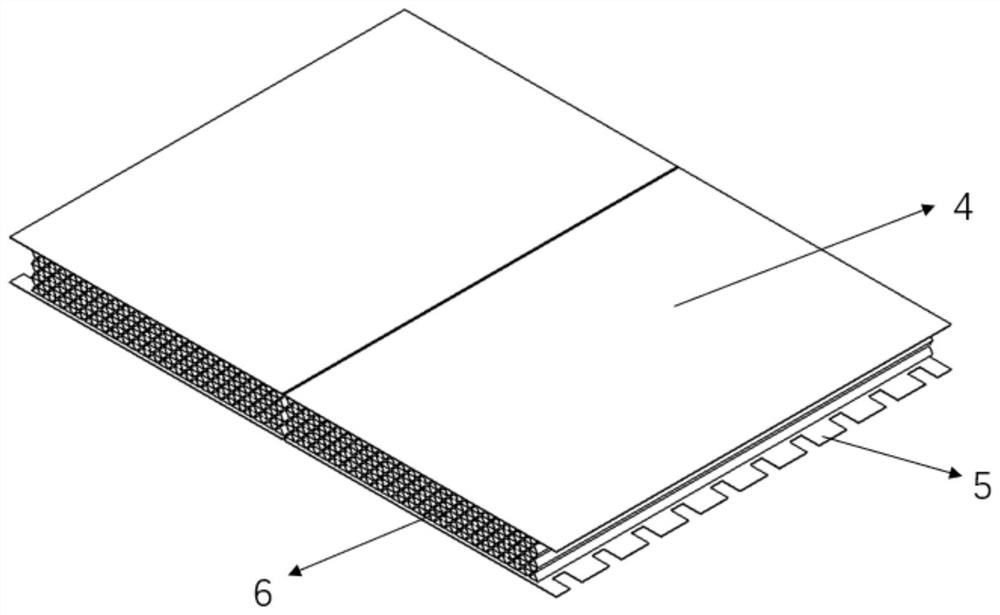

Bottom protection structure containing negative-Poisson-ratio honeycomb material

PendingCN112109398AReduce maximum deflectionReduce the maximum kinetic energyVehicle componentsMetal layered productsEnergy absorptionHoneycomb

The invention belongs to the field of vehicle bottom protection, and particularly relates to a bottom protection structure containing a negative-Poisson-ratio honeycomb material. The bottom protectionstructure comprises a basic protective assembly and a protective assembly sandwich layer, wherein the basic protection assembly comprises an upper plate, a bottom plate and a fixing structure used for fixing the protection assembly sandwich layer; the protection assembly sandwich layer comprises the negative-Poisson-ratio honeycomb material, an upper panel arranged on the negative-Poisson-ratio honeycomb material and a lower panel arranged below the negative-Poisson-ratio honeycomb material; and the protection assembly sandwich layer is fixed by the upper panel and the lower panel through thefixing structure for fixing the protection assembly sandwich layer. According to the protection structure, the bottom plate is designed to be of a trapezoidal structure, and the negative-Poisson-ratio honeycomb material is installed between the upper plate and the bottom plate to serve as a main energy absorption structure, so impact energy generated by explosion can be effectively absorbed; andthe negative-Poisson-ratio honeycomb material and a sandwich lightning protection assembly are combined with each other, so the energy absorption effect of the lightning protection assembly is greatlyimproved, and the safety of passengers is better guaranteed.

Owner:NANJING UNIV OF SCI & TECH

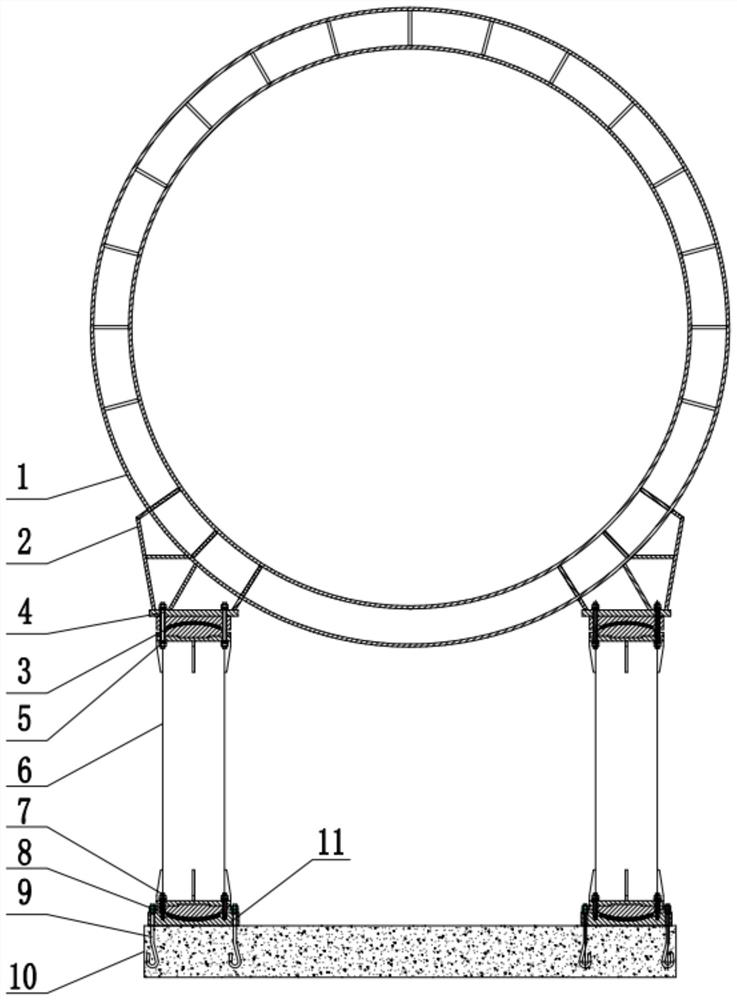

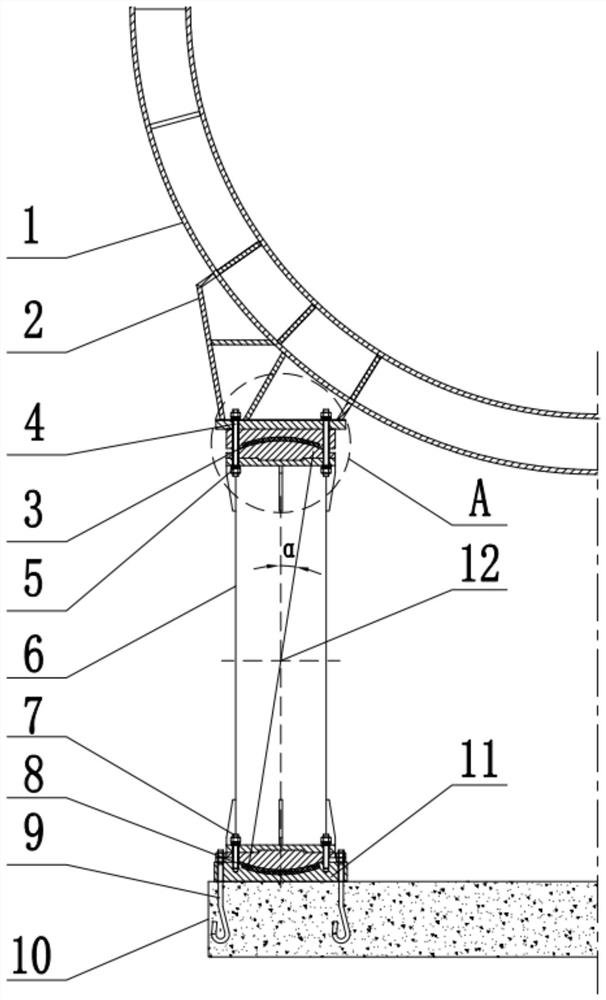

Supporting device for large-diameter pipeline

ActiveCN112963621AGuaranteed support rigidityAchieve compensationPipe supportsPipe elementsPipe supportPhysics

The invention discloses a supporting device for a large-diameter pipeline. The supporting device comprises two sets of symmetrically-arranged supports; each support comprises a supporting stand column, an upper spherical sliding pair is installed at the upper end of the supporting stand column, and a lower spherical sliding pair symmetrical to the upper spherical sliding pair is installed at the lower end of the supporting stand column; a pipeline base is installed at the upper end of each supporting stand column through an upper connecting stud and nut set; the lower end of each supporting stand column is provided with a bottom support through a lower connecting stud and nut set; and each of the upper connecting stud and nut sets and the lower connecting stud and nut sets is provided with a disc spring set. The supporting device is used for supporting the large-size and large-temperature-difference pipeline, and has flexibility adapting to axial and transverse deformation of the pipeline while maintaining the supporting rigidity of the pipeline; compensation and rigidity control of the supports on radial and axial deformation of the pipeline on a supporting section are realized by the aid of the rotational degree of freedom of the spherical sliding pairs in space and the rigidity compensation effect of the disc spring sets.

Owner:中国空气动力研究与发展中心设备设计与测试技术研究所

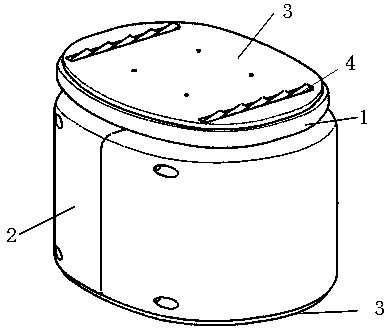

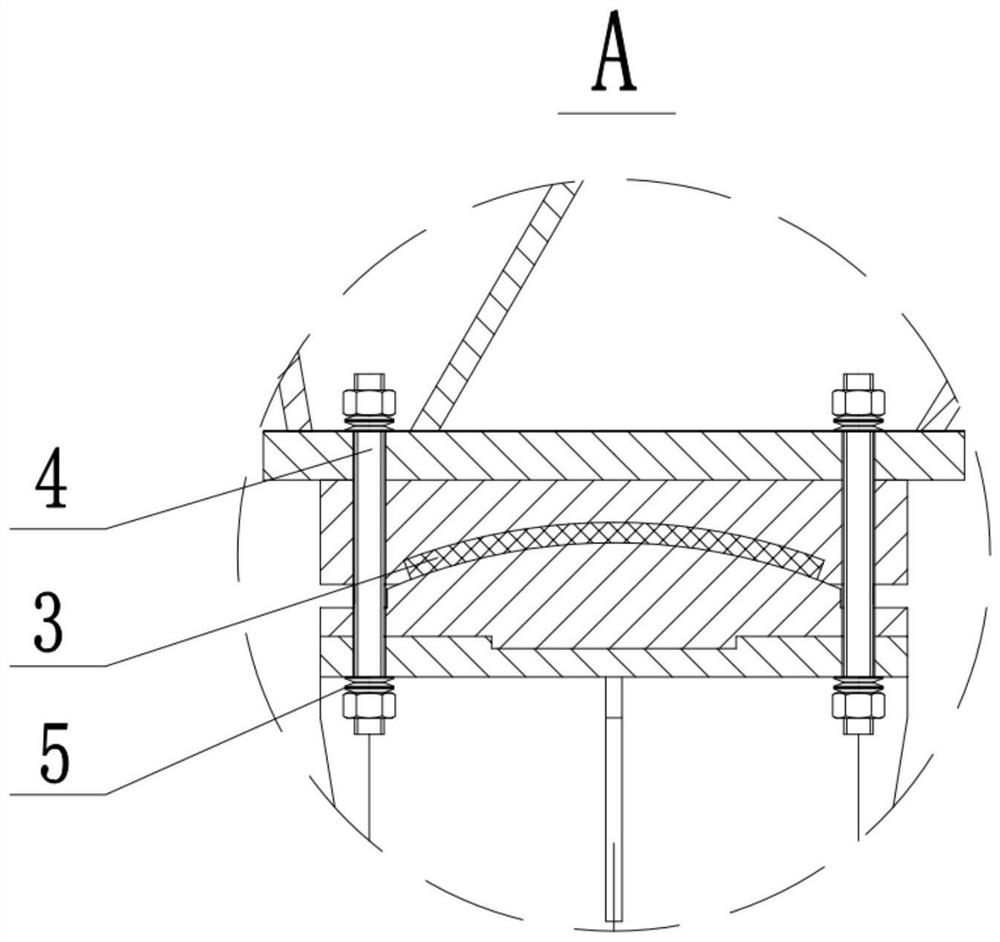

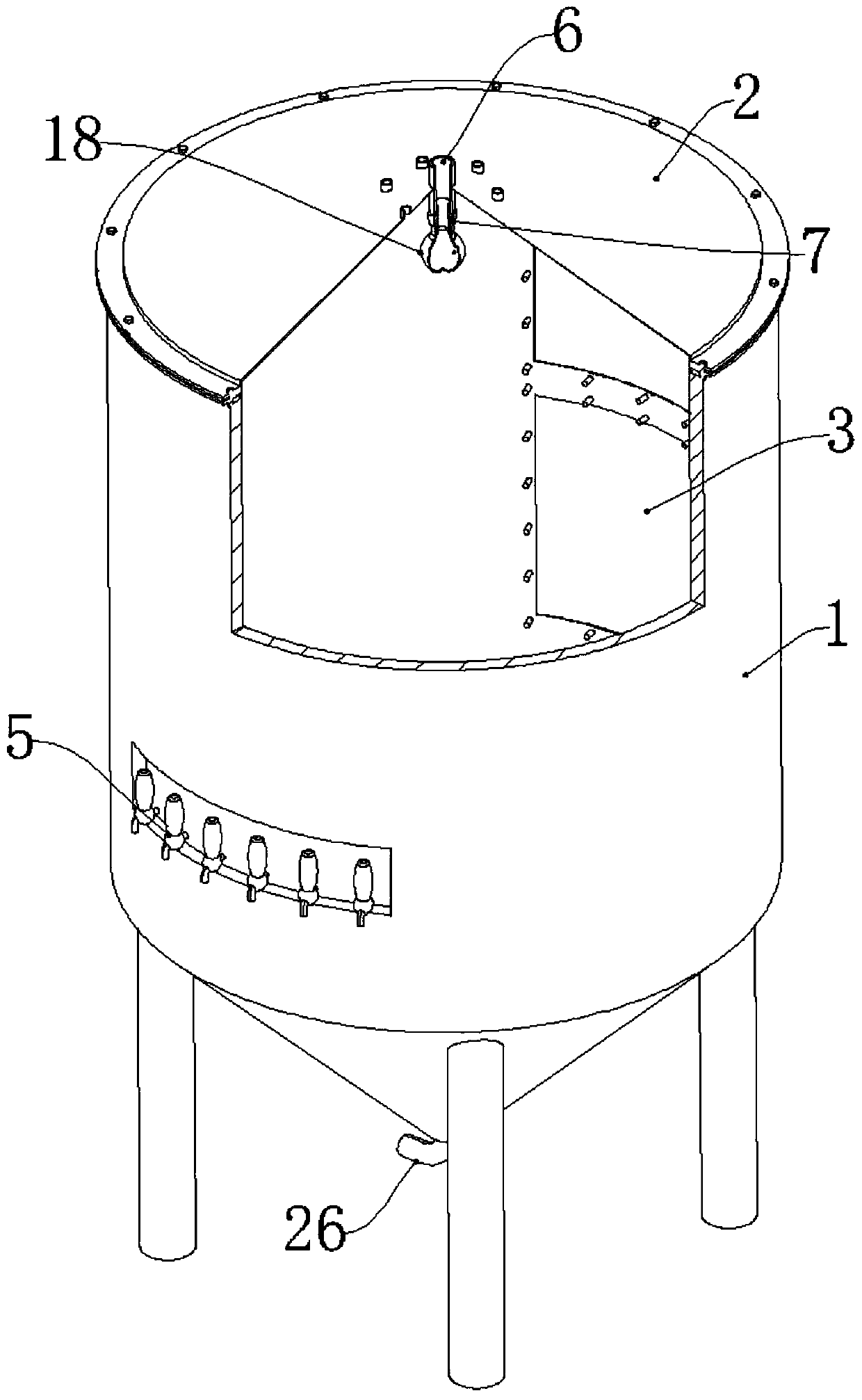

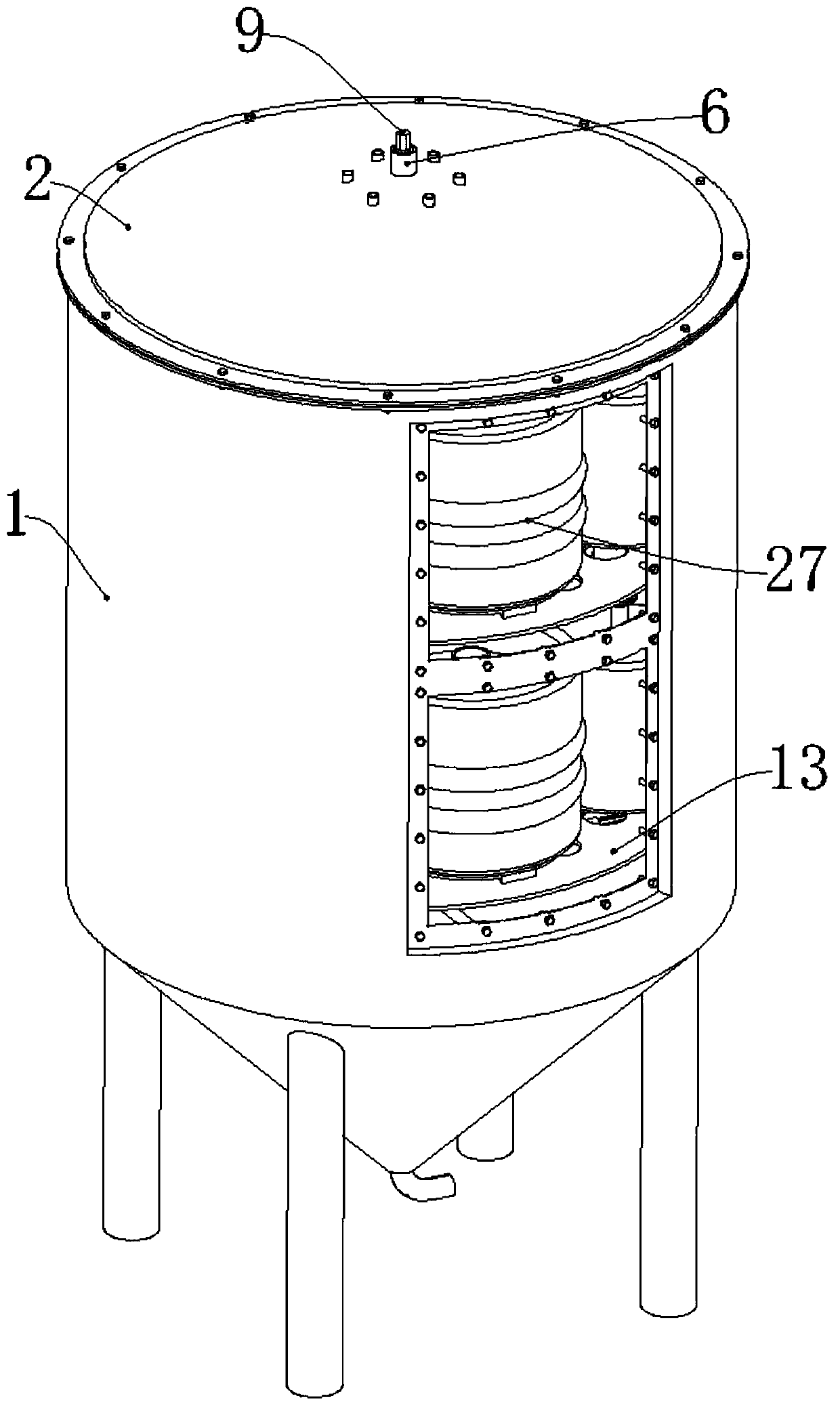

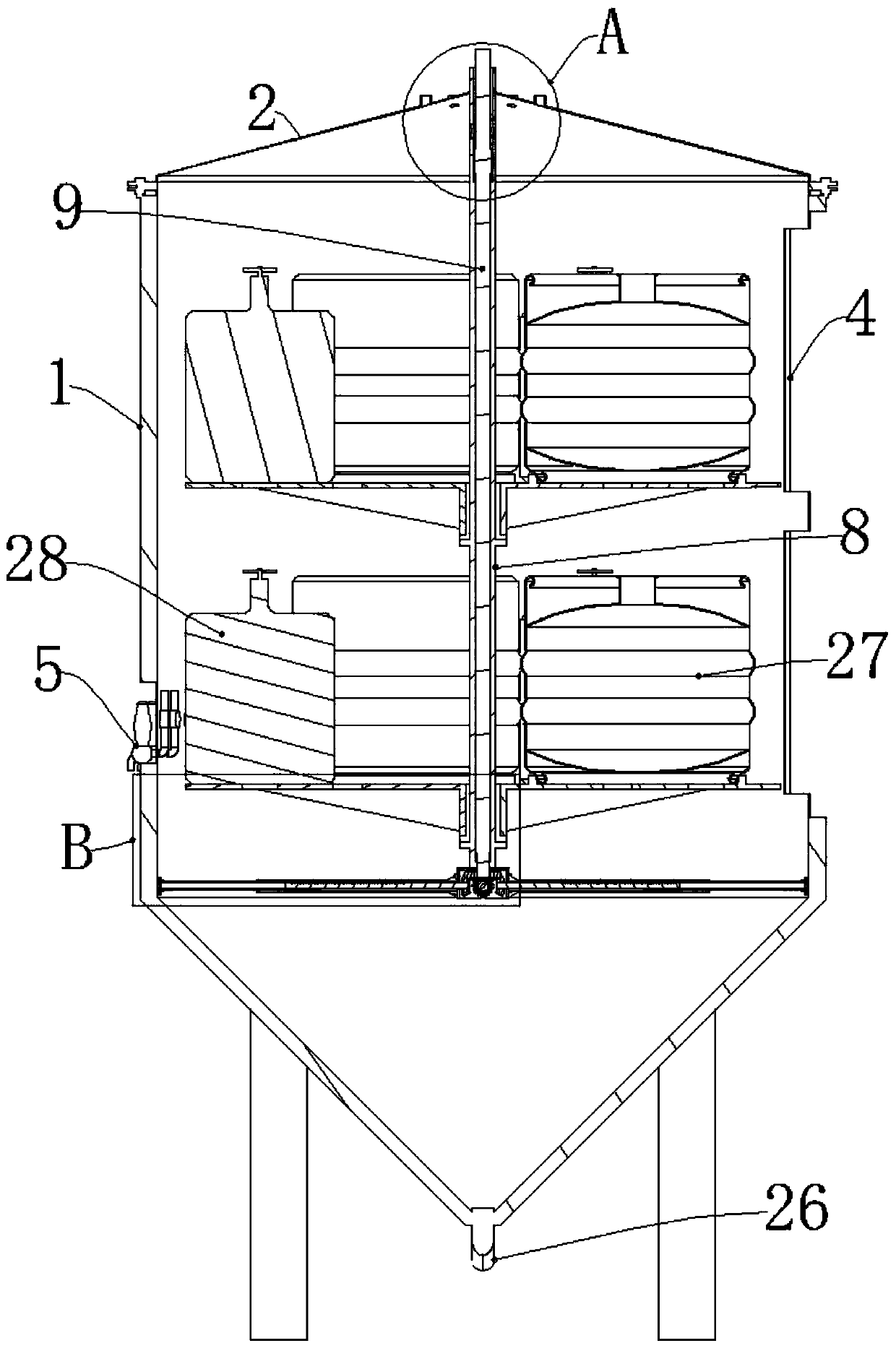

Fermentation and sale dual-use equipment for fermented drinks

ActiveCN110205214APrevent leakageGuaranteed support rigidityBeer brewingCoin/paper handlersBiochemical engineeringBevel gear

The invention relates to the technical field of fermented beverage equipment, in particular to fermentation and sale dual-use equipment for fermented drinks. The dual-use equipment for fermented drinks comprises a tank body and a rotating tray mechanism; the tank body comprises a tank body, a cover body and a sealing door, wherein the tank body is provided with a plurality of outlet valves; a CIPcleaning pipe is fixed in a center of the cover body, and a screw pipe joint is arranged at a lower end of the CIP cleaning pipe; the rotating tray mechanism comprises an outer sleeve, a rotating shaft, a support, a telescopic rod, a driving bevel gear, a driven bevel gear and a tray; the telescopic rod is provided with a plurality of groups along a radial direction of the outer sleeve, and the telescopic rod comprises a fixed sleeve, a sliding sleeve and a screw rod. The dual-use device can not only produce the fermented drinks, but also realize the collinear sale of a plurality of products of the product after the fermentation is finished, the device realizes one device to meet the different needs of manufacturers and sales merchants, and provides more commercial flexibility and reducesequipment investment cost for the integrated production and sales enterprises.

Owner:QILU UNIV OF TECH +1

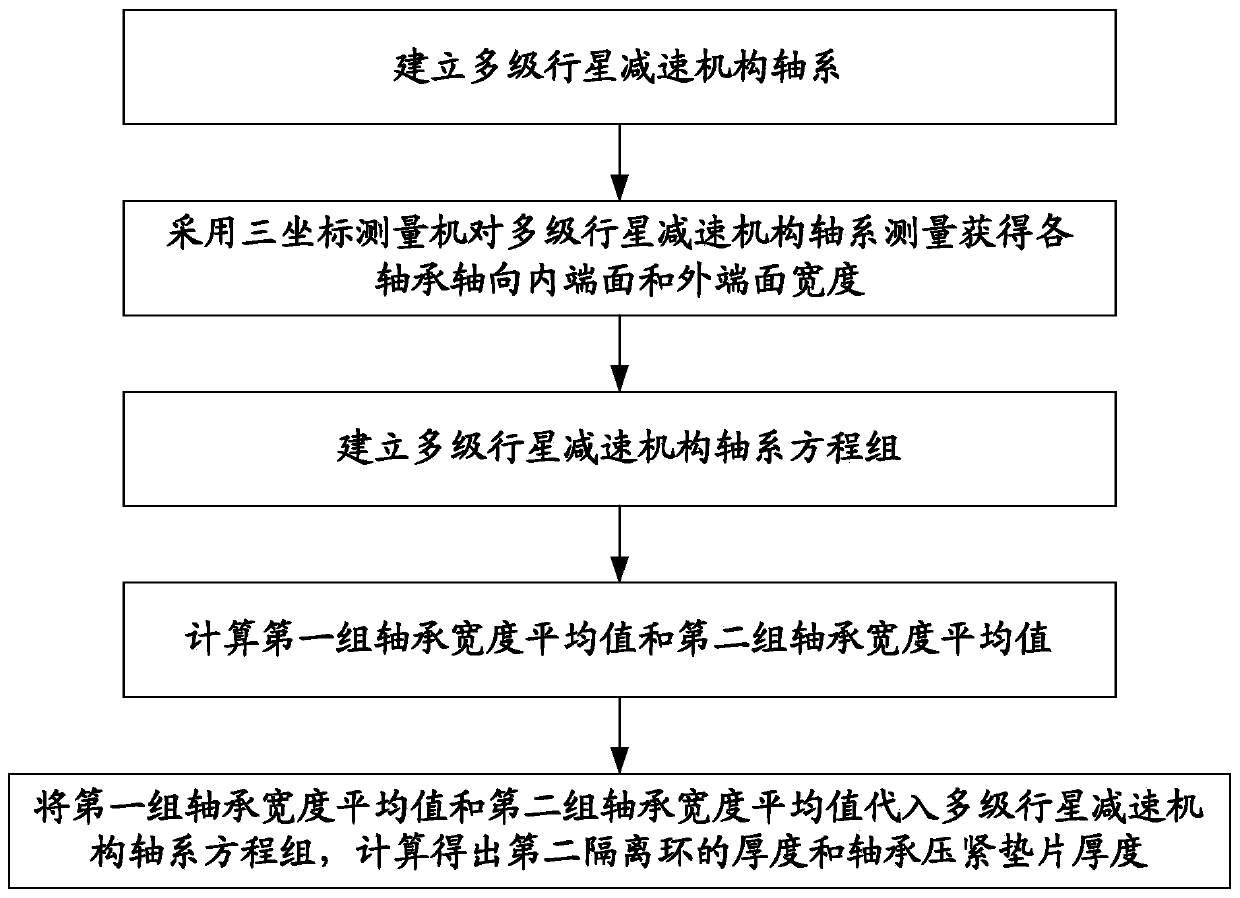

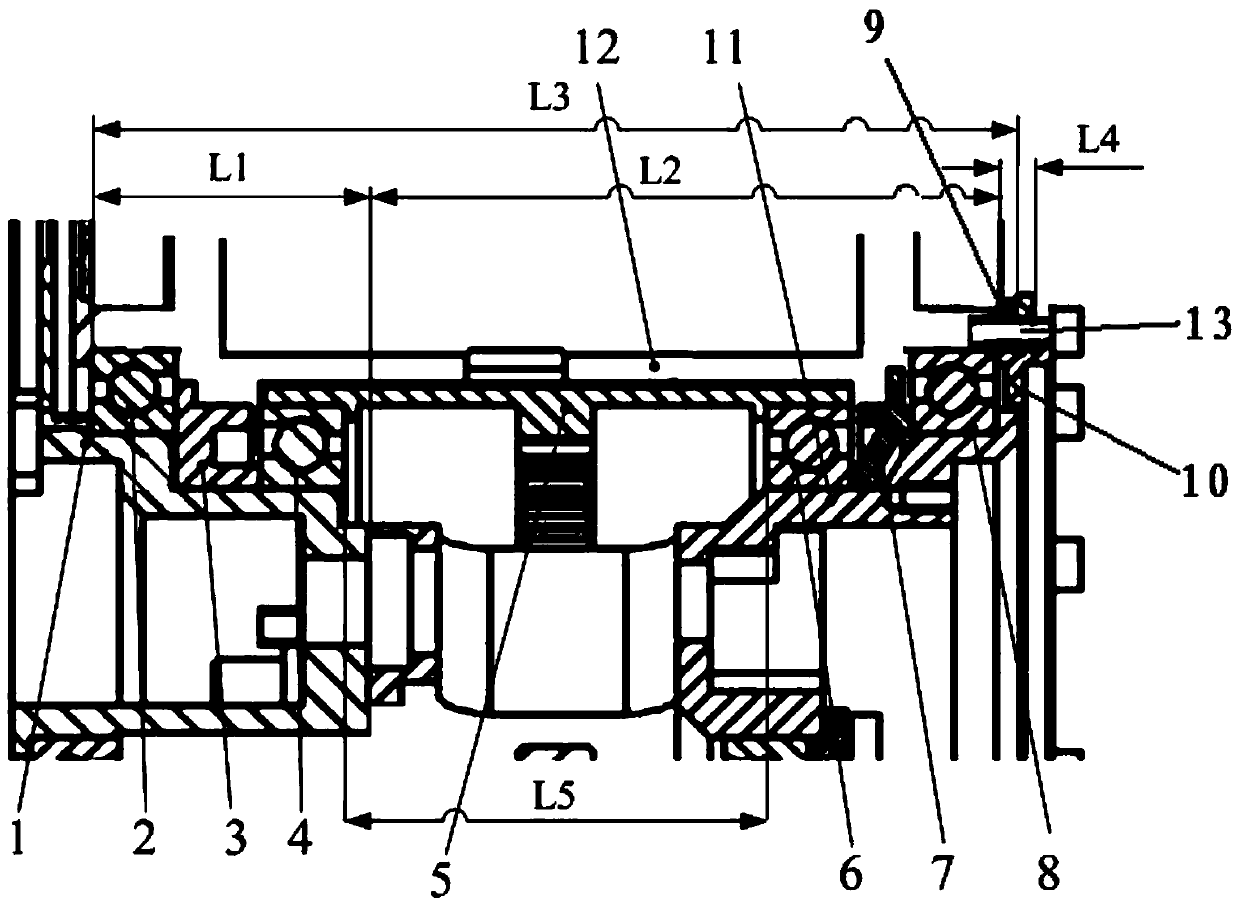

Method for calculating axial clearance of high-precision shafting of multi-stage planetary speed reducing mechanism

InactiveCN111076692AGuaranteed rotation accuracyGuaranteed support rigidityMeasurement devicesEngineeringCoordinate-measuring machine

The invention, which belongs to the field of integrated assembly and testing of space driving mechanisms, relates to a method for calculating the axial clearance of a high-precision shafting of a multi-stage planetary speed reducing mechanism. The method comprises the steps: step 1, establishing a multi-stage planetary speed reducing mechanism shafting is established; step 2, measuring the multi-stage planetary speed reducing mechanism shafting by using a three-coordinate measuring machine to obtain L1, L2, L3, L4 and L5; step 3, establishing a multi-stage planetary speed reducing mechanism shafting equation set; step 4, calculating a width average value H1 of a first group of bearings and a width average value H2 of a second group of bearings; and step 5, substituting the H1 and H2 into the multi-stage planetary speed reducing mechanism shafting equation set, and calculating a thickness d1 of a second isolating ring and a thickness d2 of a bearing pressing gasket. Therefore, accurateand quantitative control over the axial clearance of the shaft system of the space driving mechanism is achieved; and the control precision and efficiency of the axial clearance of the shafting are improved.

Owner:BEIJING SATELLITE MFG FACTORY

A positive warp easing device for a water jet loom

The invention discloses a positive warp loosening device of a water jet loom. The positive warp loosening device comprises a left support, a right support, a linkage shaft, a swinging beam and a fixed back beam, wherein the linkage shaft, the swinging beam and the fixed back beam are sequentially arrayed between the left support and the right support from front to back, the linkage shaft is located above the swinging beam, the warp loosening device further comprises only one positive warp loosening mechanism used for driving the linkage shaft to rotate, the positive warp loosening mechanism comprises an eccentric adjusting portion and a warp loosening swinging arm, one end of the warp loosening swinging arm is connected with one end of the linkage shaft, and the other end of the warp loosening swinging arm is connected with the eccentric adjusting portion. The single-side positive warp loosening structure drives the linkage shaft to rotate to drive the swinging beam to swing, and therefore the performance of the whole loom is more reasonable.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

Vehicle door electric pedal and vehicle

ActiveCN110614955AHigh pedaling pressureAvoid affecting aestheticsSteps arrangementElectric machineryScrew thread

The invention discloses a vehicle door electric pedal which is characterized by comprising two pedals, a motor, a transmission case, a driving bevel gear, two driven bevel gears, two screw rods, two screw rod sleeves and a bidirectional telescopic frame, wherein the transmission case is positioned between the two pedals, the driving bevel gear and the two driven bevel gears are rotatably mounted in the transmission case, and the two driven bevel gears are coaxially arranged; the driving bevel gear is connected with the two driven bevel gears in a meshed manner at the same time, the two lead screws are coaxially and fixedly connected with the two driven bevel gears respectively, and the two lead screw sleeves are in threaded fit with the two lead screws respectively; the two lead screws areidentical in rotation, and the outer side ends of the two lead screw sleeves are fixedly connected with the two pedals respectively; the motor is connected with the driving bevel gear, and the transmission box is separately connected with the two pedals through the bidirectional telescopic frame. Different from an existing structural design, according to the present invention, the single motor isadopted for driving, and the two pedals can automatically extend outwards or retract and can be stored at the same time.

Owner:长春众鼎科技有限公司

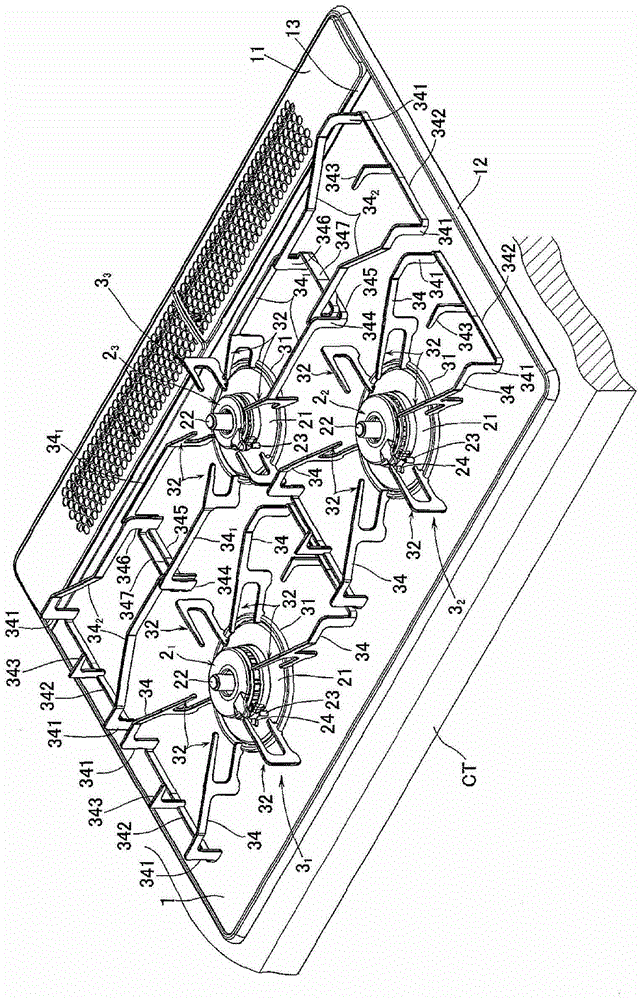

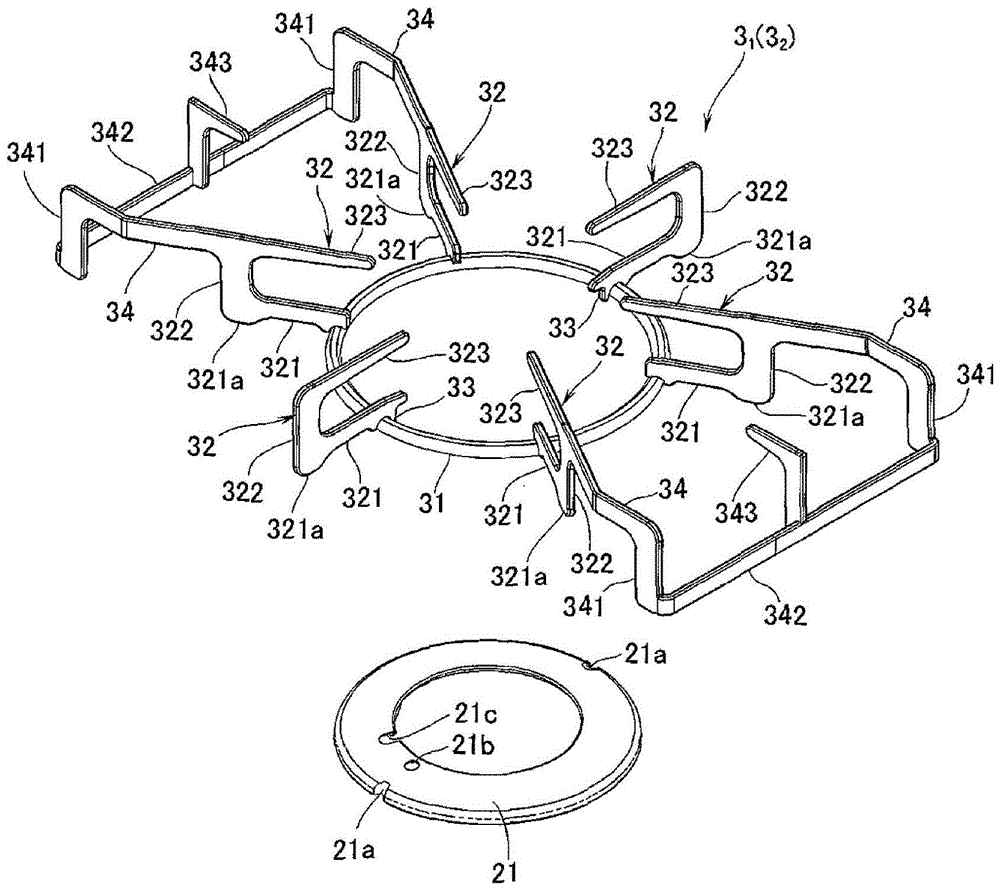

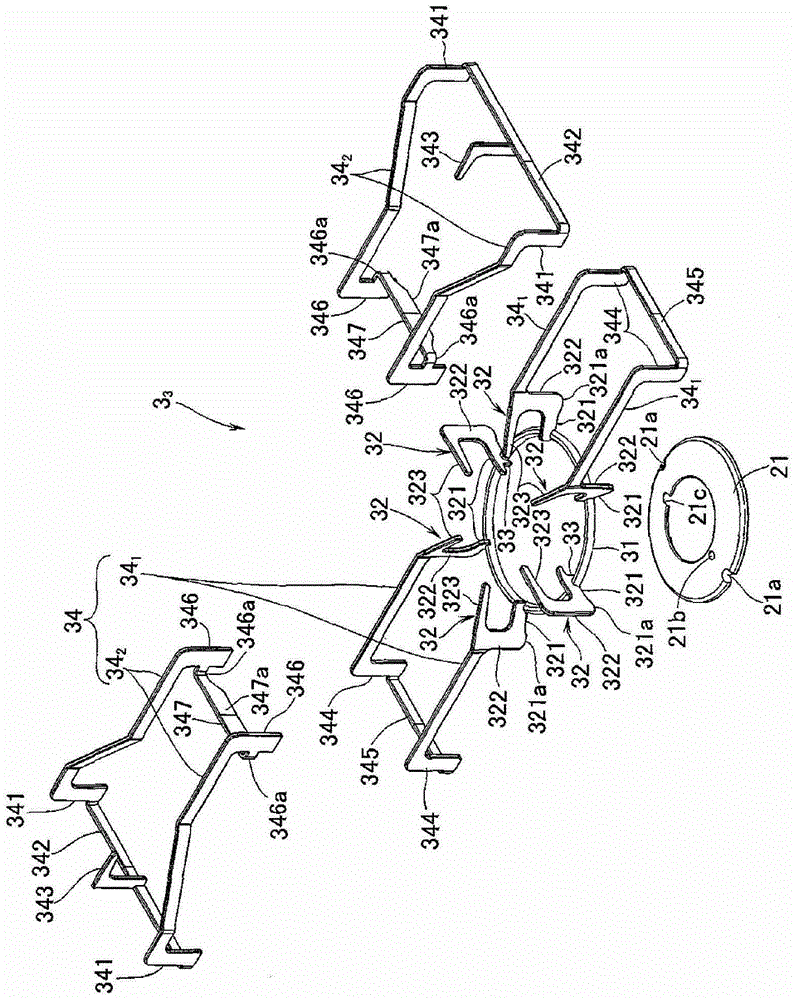

Bracket for gas stove

InactiveCN103090433BStable supportGuaranteed support rigidityStoves/ranges topsEngineeringMechanical engineering

The present invention provides a support for a gas stove which can carry cooking containers such as pots on a lateral deviation position on a combustor, can ensure positional relation relative to the combustor of the gas stove, and can prevent degradation induced by overheating. The support is provided with a support frame externally embedded on a combustor ring assembled on the periphery of the combustor of the gas stove; six support claws radially fixed at a front and a back positions of the crosswise center of the support frame and front and rear positions of crosswise sides deviated from the crosswise center; and a protruding part clamping with a recess formed at the peripheric face of the combustor ring. Each front and rear support claws at the crosswise sides are provided with extending portion extending crosswise outwards. The two extending parts have foot parts which bend downwards from external ends of the two extending parts and arranged on a top plate; a connection part connecting lower ends of the two foot parts and is long in a length direction; and auxiliary support claws rising from a anterior-posterior central part of the connection part and extending crosswise inwards.

Owner:RINNAI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com