Device for adjusting elevation of bearing in rotating machinery on line

A technology of rotating machinery and adjusting devices, which is applied in the field of power machinery, can solve problems such as contact surface line contact, and achieve the effects of ensuring support rigidity, simple structure, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

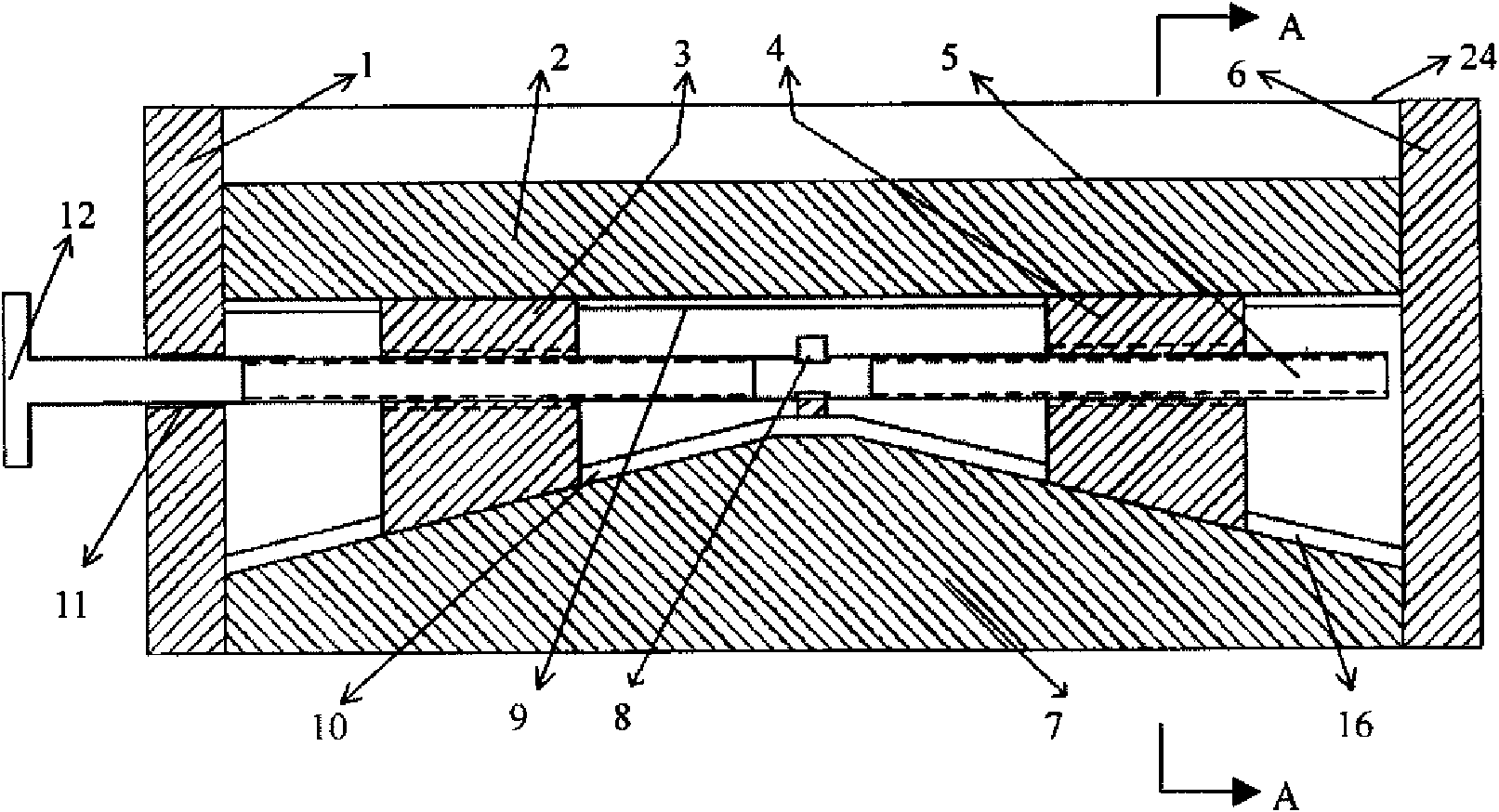

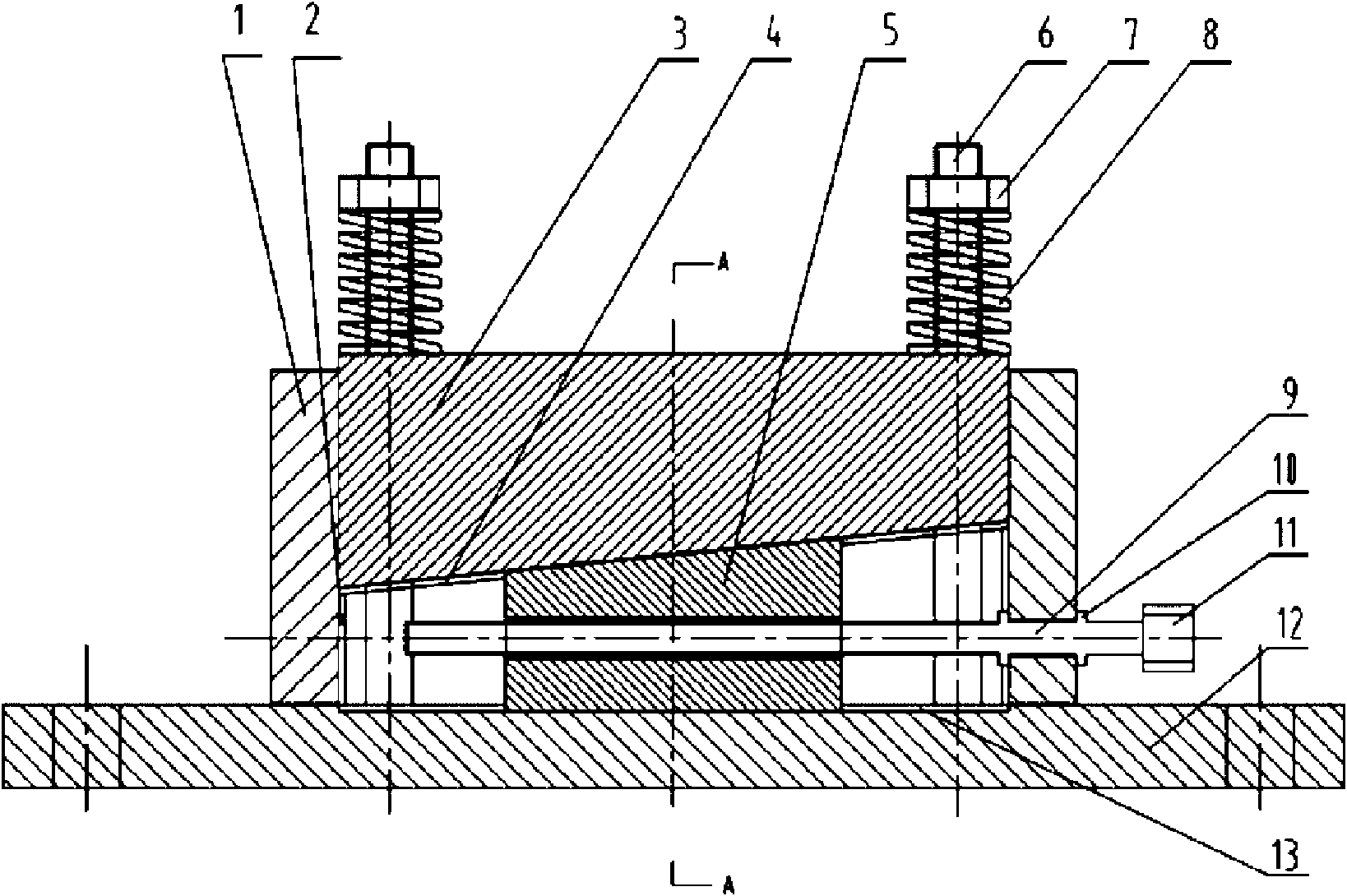

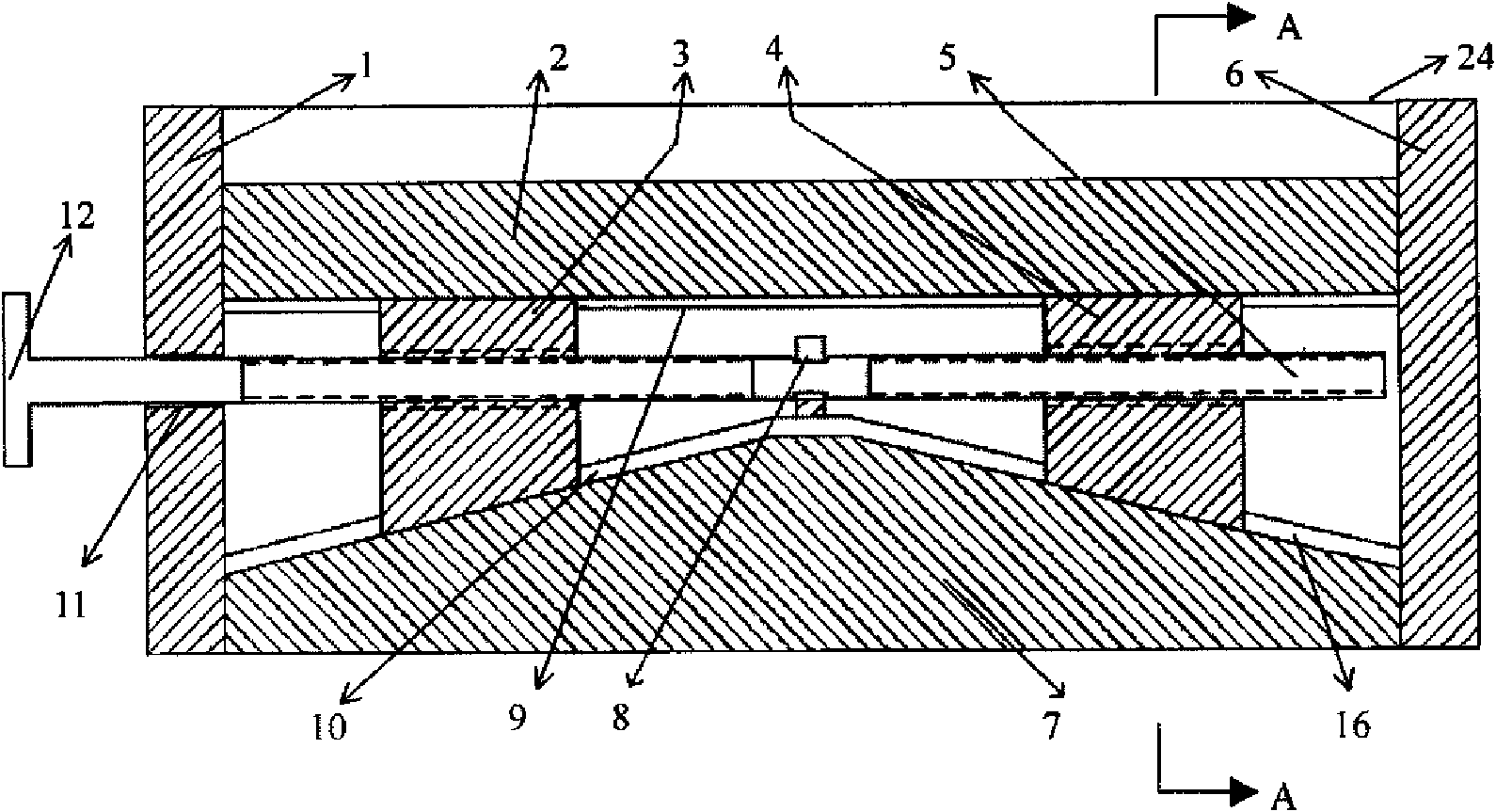

[0015] Such as figure 2 , image 3 and Figure 4 As shown, this embodiment is made up of vertical vertical board 1, upper slider 3, lower slider 5, lead screw 9, base 12; Left and right two vertical vertical boards 1 are fixed on the base 12, upper slider 3 Cooperate with the vertical riser guide rails 2 of the two vertical risers 1, it can only move vertically along the vertical riser guide rails 2, the bottom of the upper slider 3 is in contact with the lower slider 5; the lower slider 5 is in contact with the upper slide The block 3 and the base 12 cooperate, and can only move horizontally along the upper slider guide rail 4 of the upper slider 3 and the base guide rail 13 of the base 12; Inside the plate 1, the lead screw 9 cooperates with the lower slider 5 through threads, and the lead screw 9 can only rotate but cannot move; the rotation of the lead screw 9 drives the lower slider 5 to move horizontally to the left or right, and the lower slider 5 Drive the upper sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com