A positive warp easing device for a water jet loom

A technology of warp loosening device and water jet loom, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problem that the warp loosening time is difficult to adjust the diversification of fabrics, the performance of the loom is reduced, and the mechanism of the whole machine is unreasonable. and other problems, to achieve the effect of solving the difficulty of adjusting the amount of loose warp and loose warp time, solving the diversification of fabrics, and rationalizing the structure of the loom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

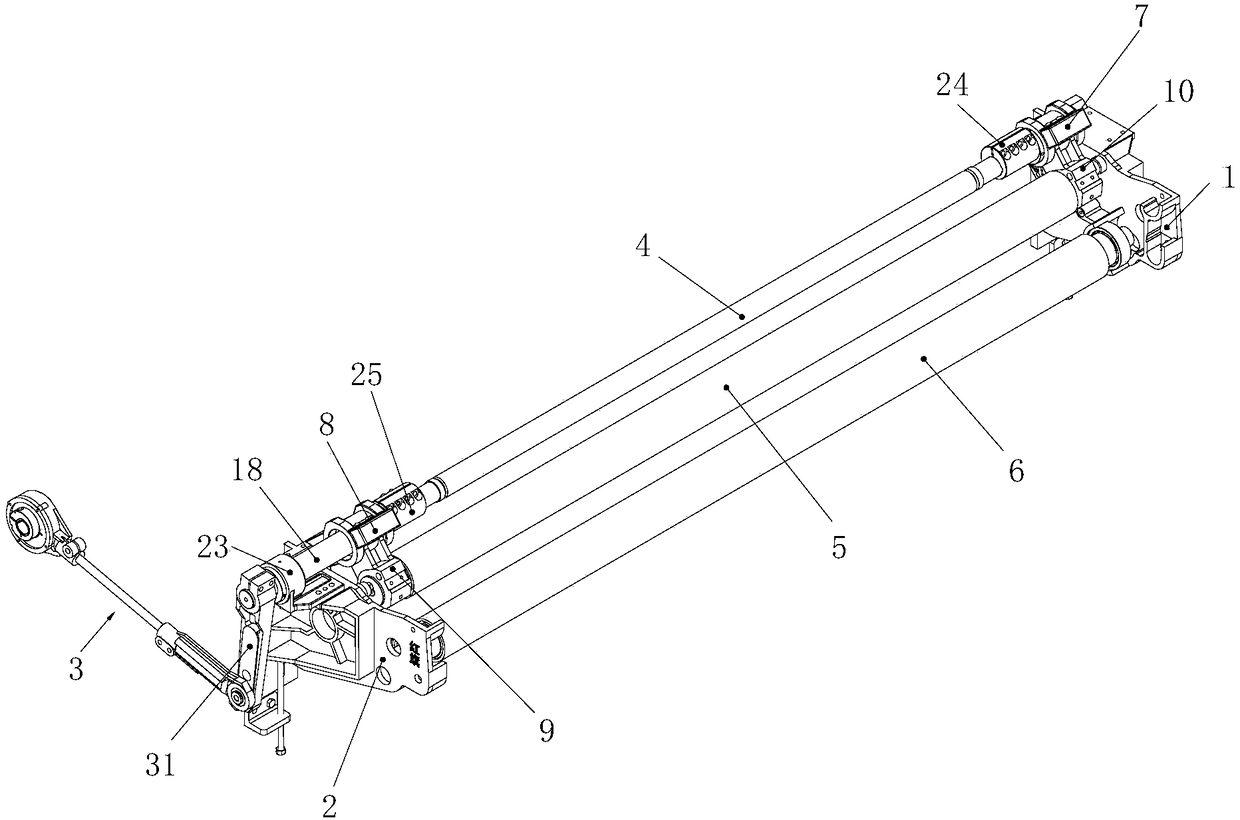

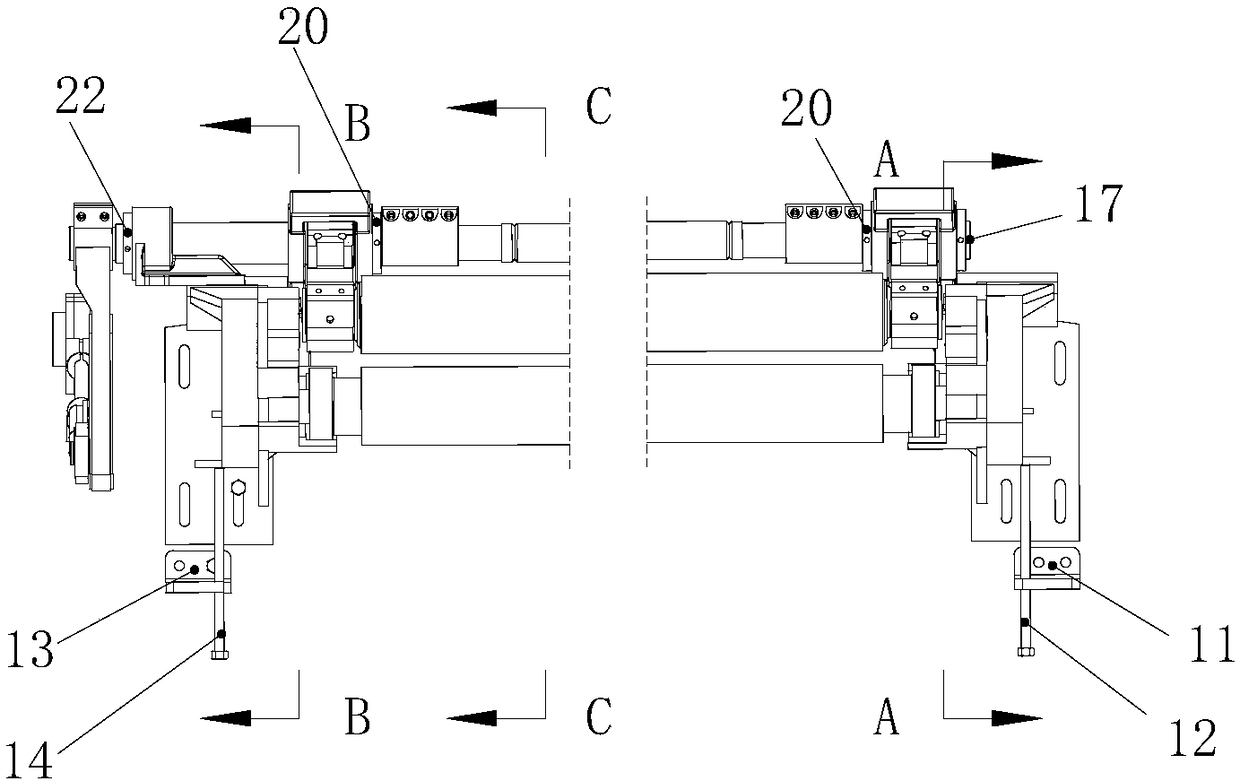

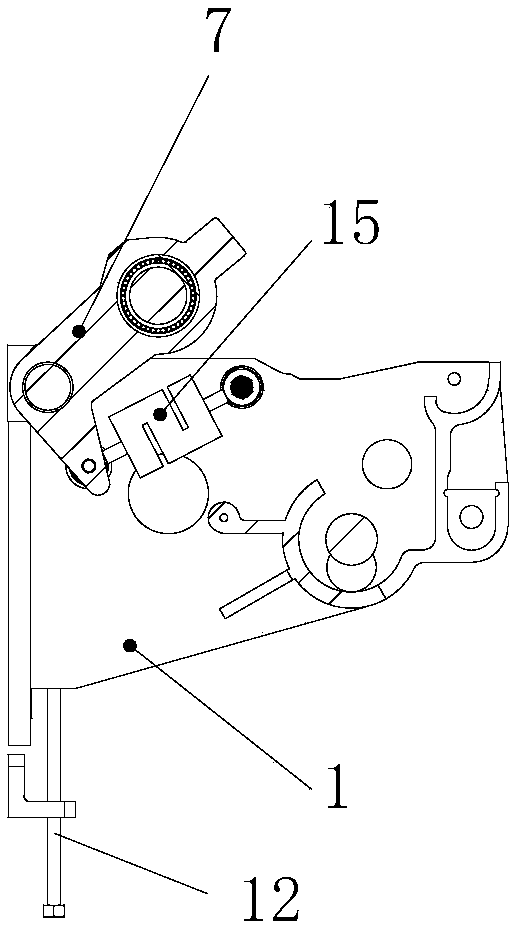

[0028] Such as Figure 1 to Figure 9 As shown, a positive warp loosening device of a water jet loom includes a left support 1, a right support 2, and a linkage shaft 4 and a swing beam 5 arranged between the left and right supports and arranged in sequence from front to back. And fix the rear beam 6, the linkage shaft 4 is located above the swing beam 5, the warp loosening device also includes a positive warp warp loosening mechanism 3 for driving the linkage shaft to rotate, the positive warp warp loosening mechanism 3 has one and only one set, and the positive warp warp loosening mechanism 3 has only one set. The warp loosening mechanism 3 includes an eccentric adjustment part and a warp loosening swing arm 31, one end of the warp loosening swing arm 31 is connected to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com