Patents

Literature

43results about How to "Resolve Motion Interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

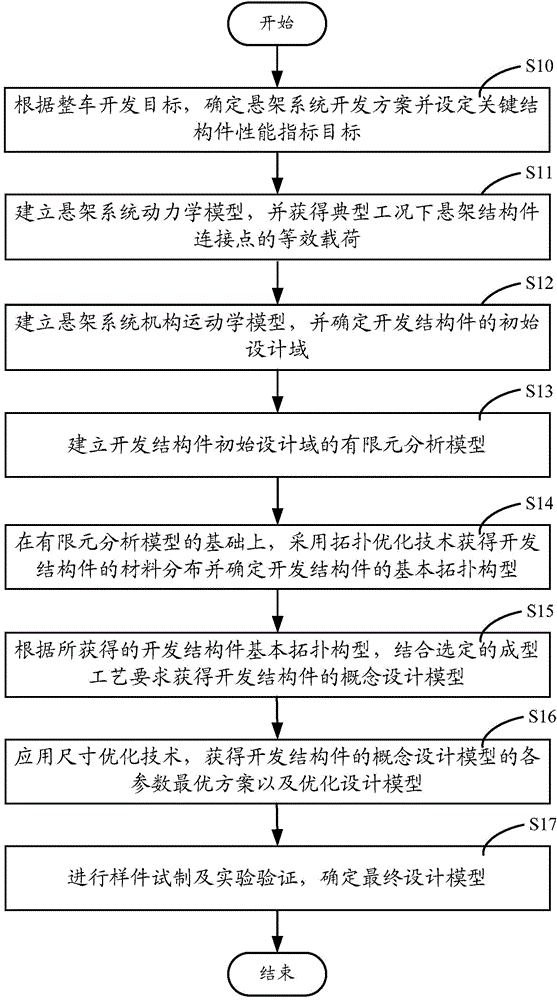

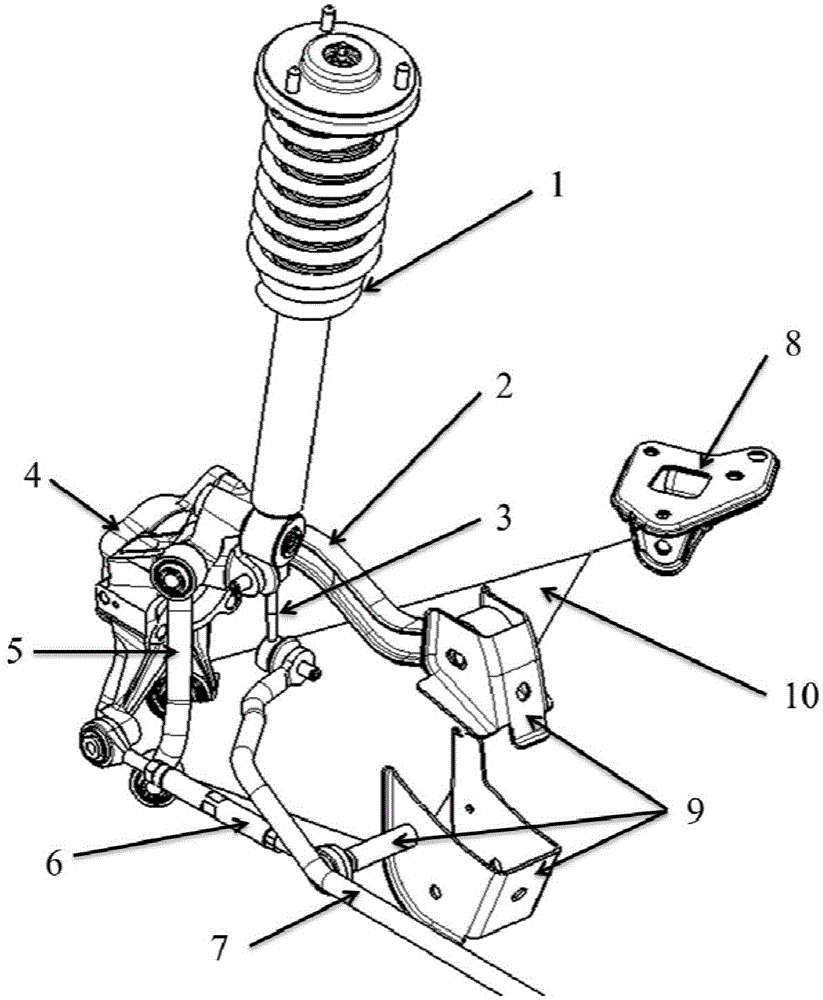

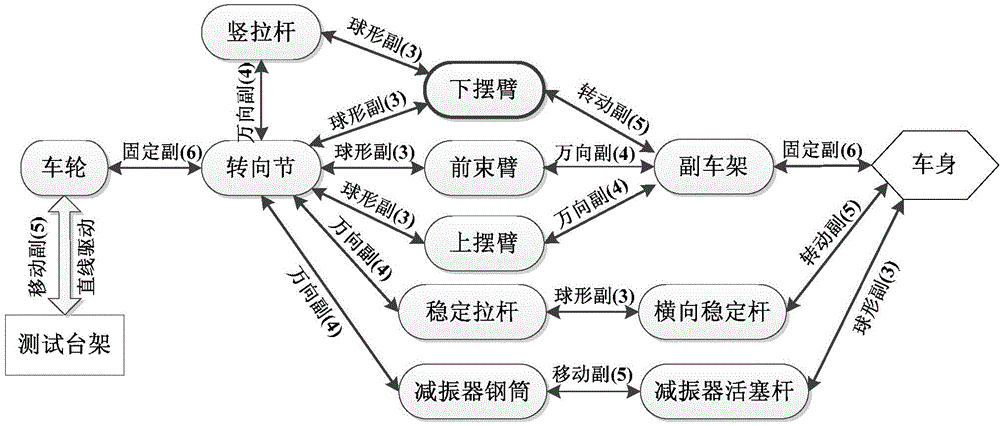

Automobile suspension key structure element optimization design method

ActiveCN105095542ASolve the problem of prone motion interferenceResolve Motion InterferenceSpecial data processing applicationsElement analysisMaterial distribution

The invention provides an automobile suspension key structure element optimization design method, which comprises the following steps of: building a suspension system kinetic model according to a pre-determined suspension system development scheme, and obtaining an equivalent load of a suspension structure element connecting point under a typical work condition; building a suspension system mechanism kinetic model, and determining an initial design domain of a development structure element; building a limited element analysis model of the initial design domain of the development structure element; obtaining the material distribution of the development structure element and determining a basic topological configuration of the development structure element; obtaining a conceptual design model of the development structure element; and obtaining each parameter optimum scheme of the conceptual design model of the development structure element and an optimization design model. When the embodiment of the invention is implemented, the development period of the suspension key structure element can be effectively shortened; and the reference can be provided for the optimization design of other system parts of an automobile.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

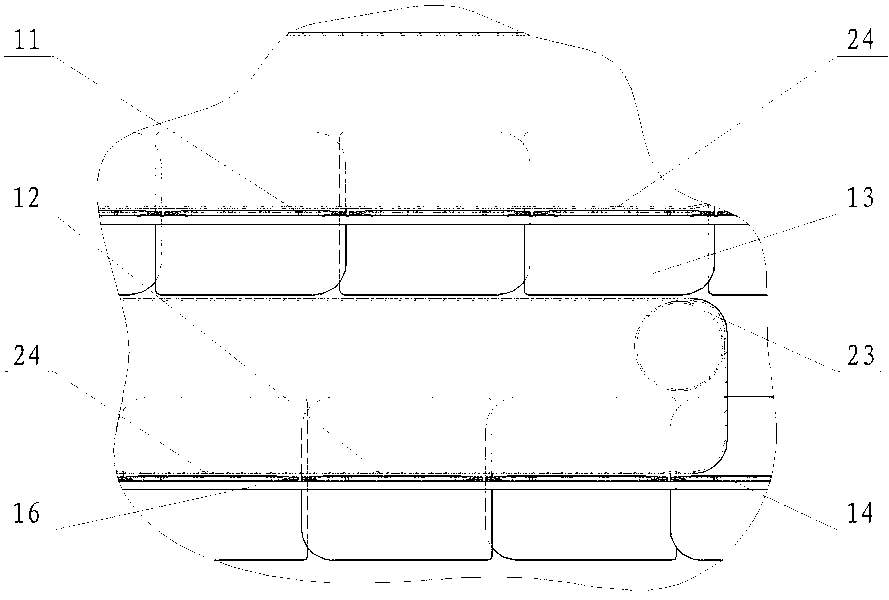

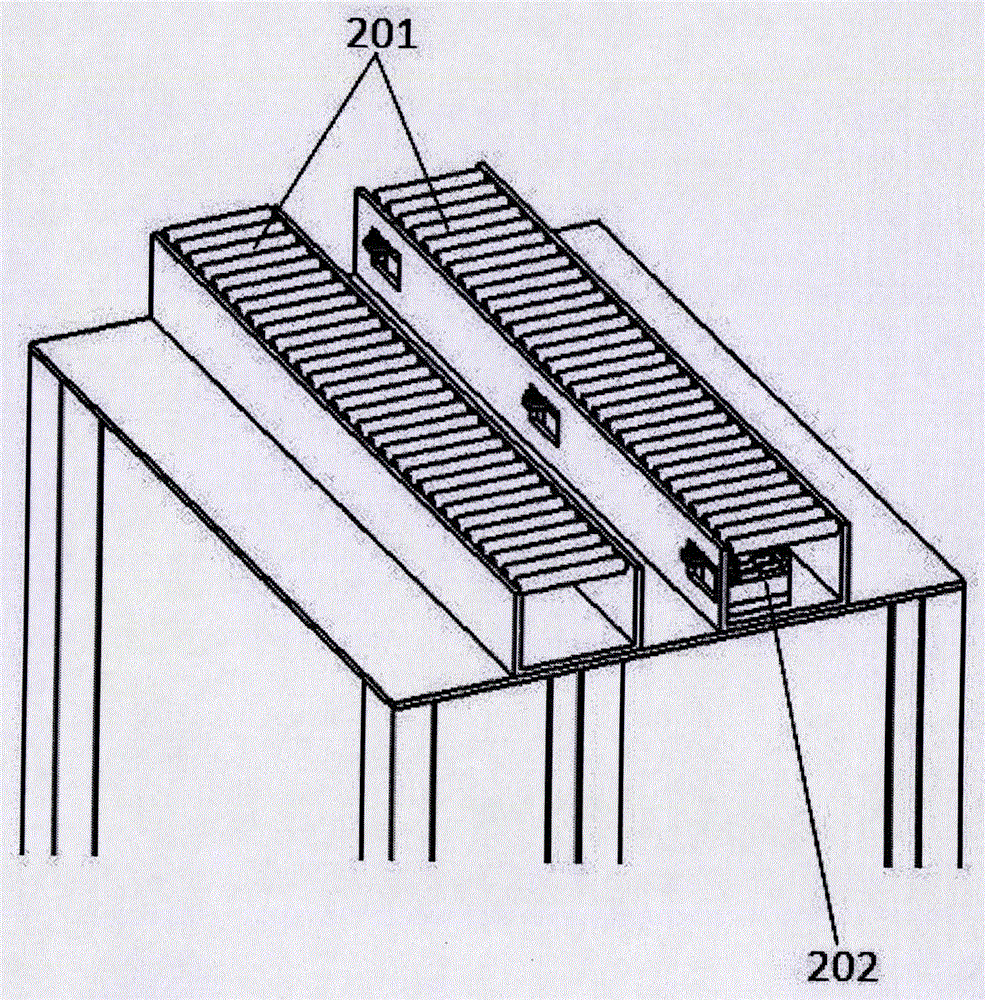

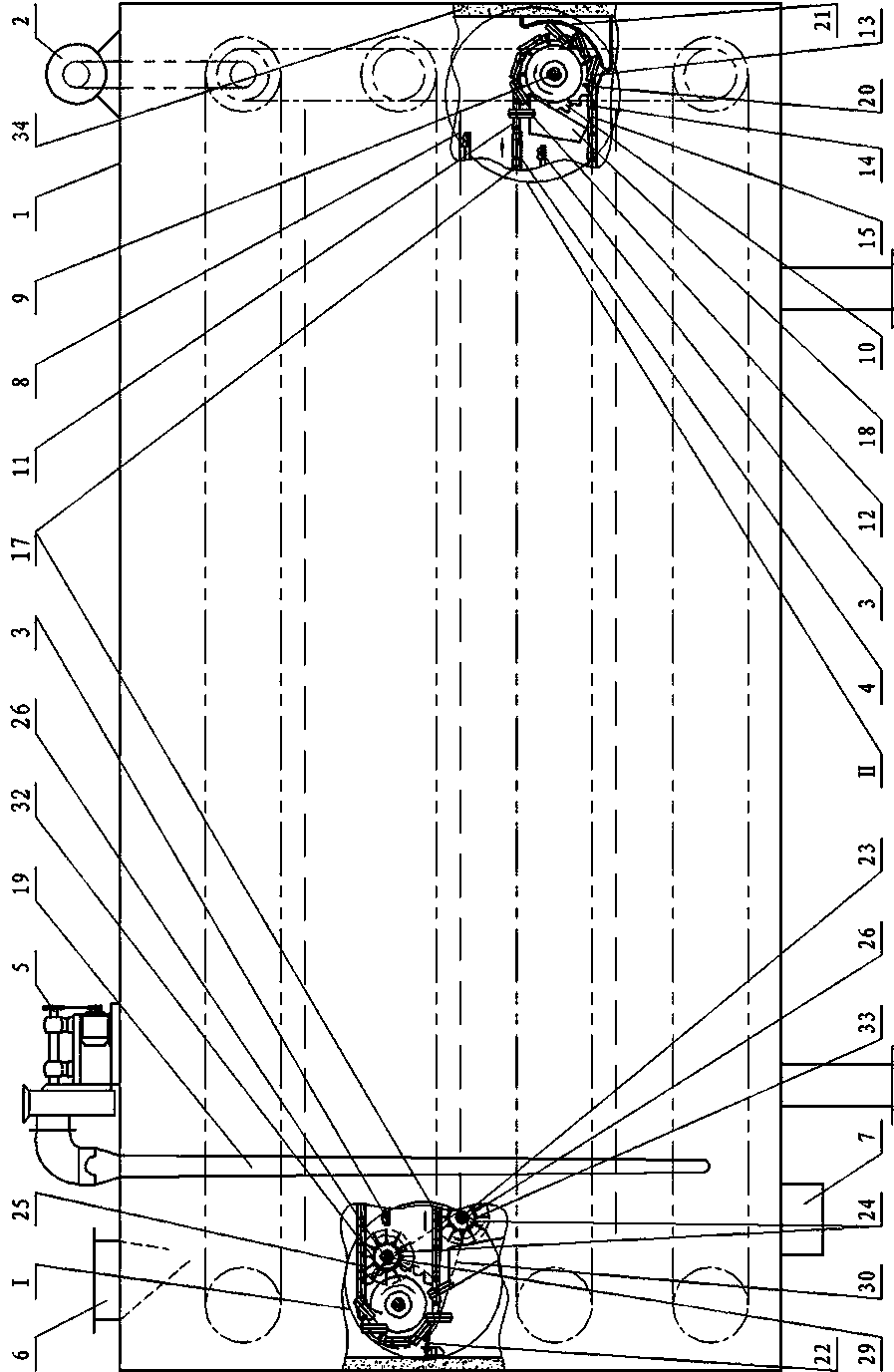

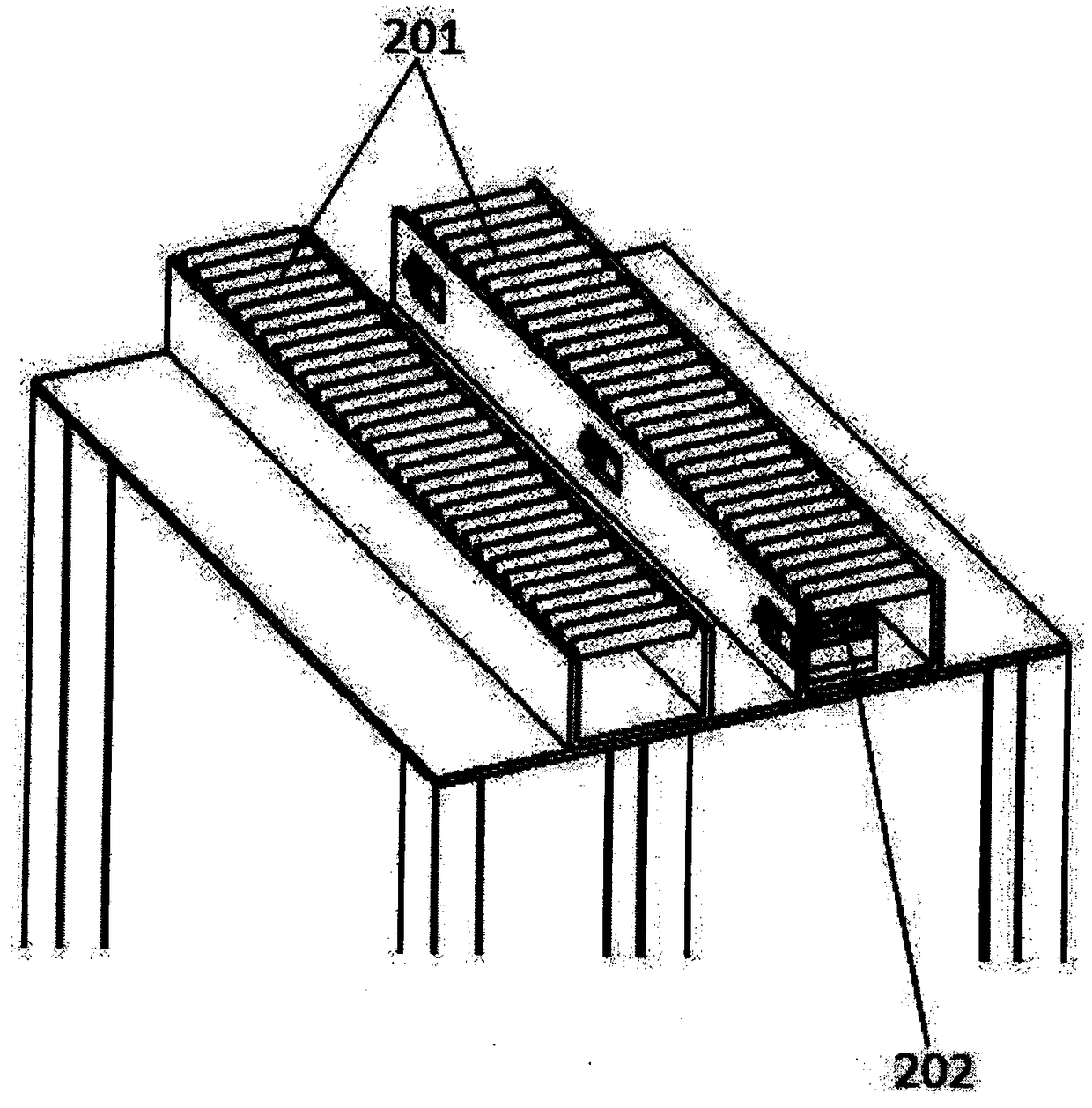

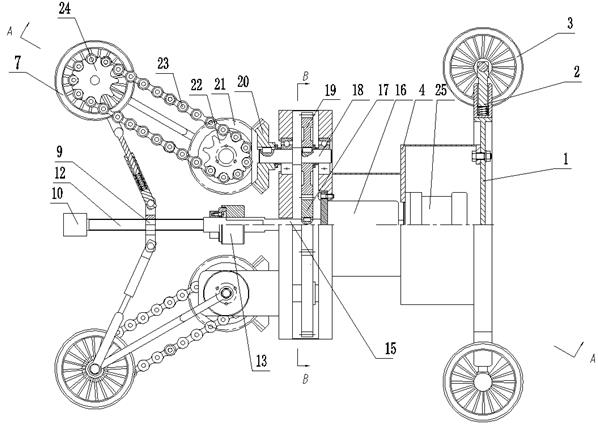

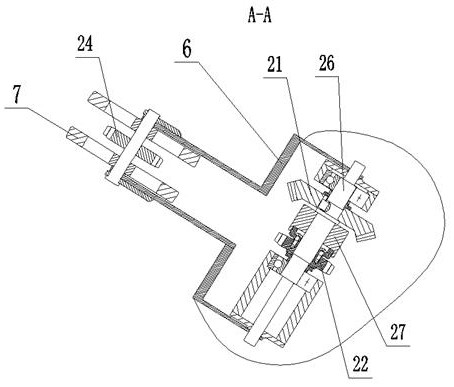

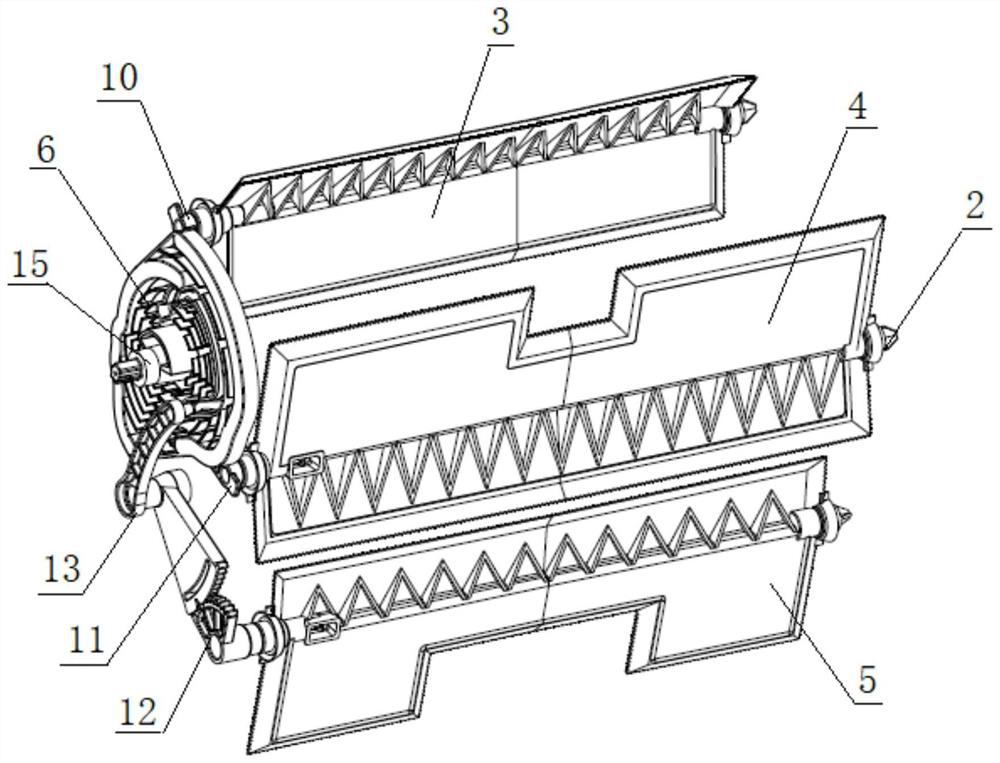

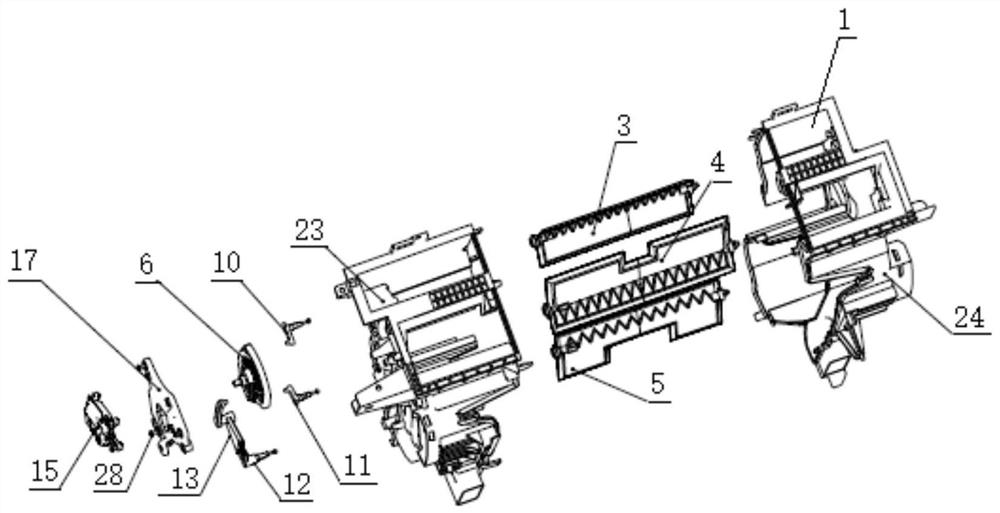

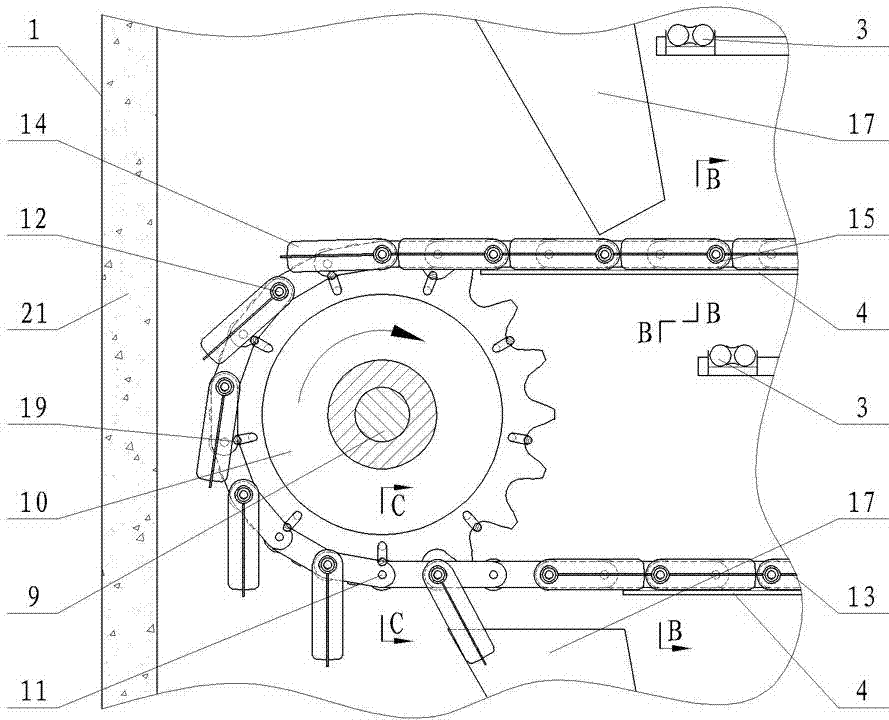

Waste heat recovering ear-corn drying machine

InactiveCN103070234AOptimized drying programKeep dryFood processingClimate change adaptationChinese charactersEngineering

The invention provides a waste heat recovering ear-corn drying machine, which is characterized in that the chamber of the drying machine is divided into an upper area and a lower area by a partition I; the lower area is divided into three parts by partitions II; the bottom of the middle chamber is provided with an air heater with a blower; a plurality of heat exchange boxes are arranged in the upper area and are communicated with one another by annular air pipes; the heat exchange boxes on the lower part are communicated with the middle of the lower area of the chamber; the heat exchange boxes on the upper part are connected with an induced draft fan mounted at the top of the chamber; a water pump at the top of the chamber is connected with a straight pipe inserted in each heat exchange box by a water pipe which is shaped like a Chinese character 'YUE'; a plurality of conveying devices running under the driving of a driving device are arranged in the chamber; molding link plates of I and II types are hung on a pin shaft extending out of the inner side of a conveying chain at intervals and are arrayed and supported on a guide rail to form a trough material channel; a guide chute is arranged below the tail end of the channel; and a feed inlet and a discharge port are formed at the top and the bottom of the chamber respectively. The waste heat recovering ear-corn drying machine is large in moisture reducing range, good in preheating effect and reliable in working.

Owner:SHANDONG UNIV OF TECH

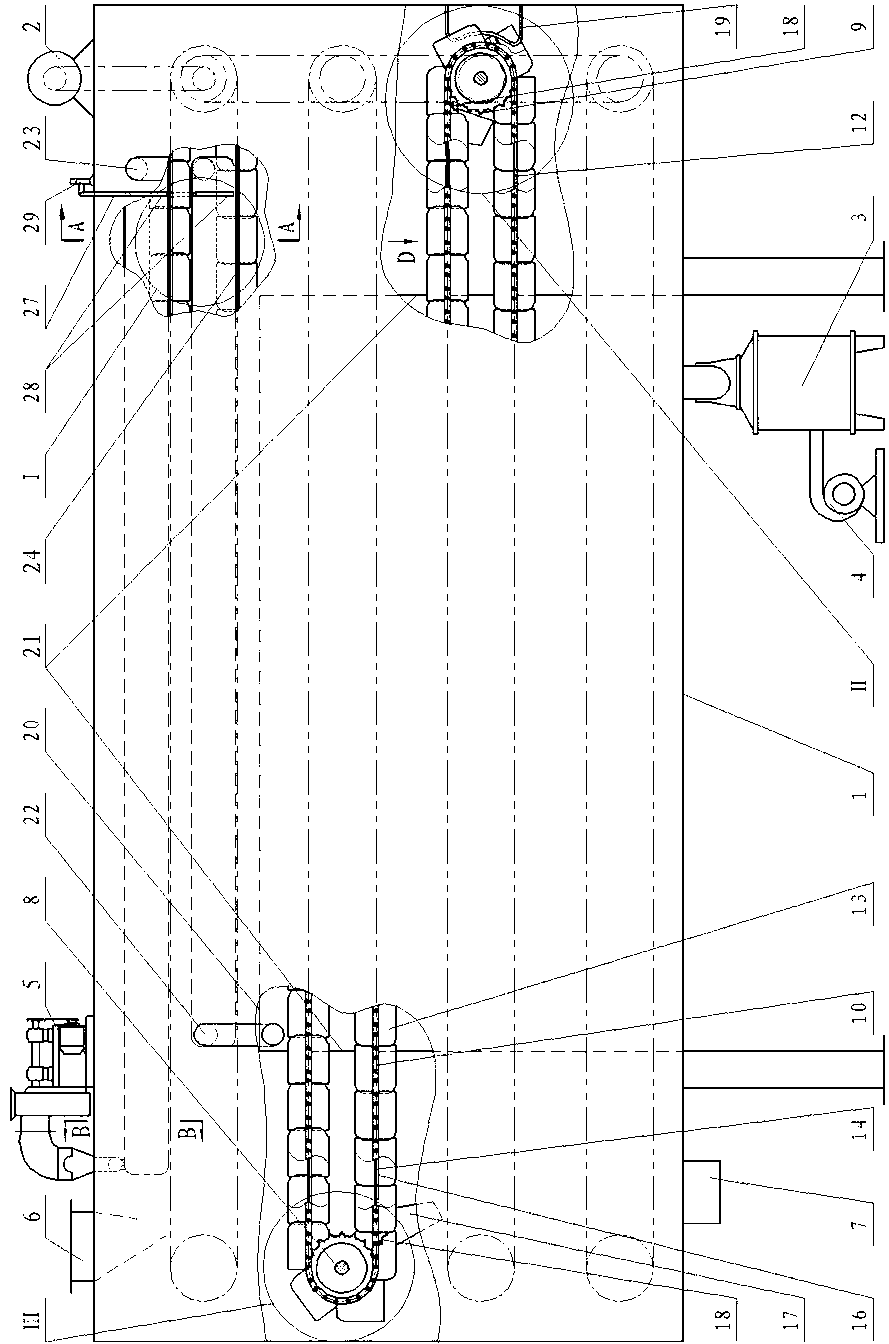

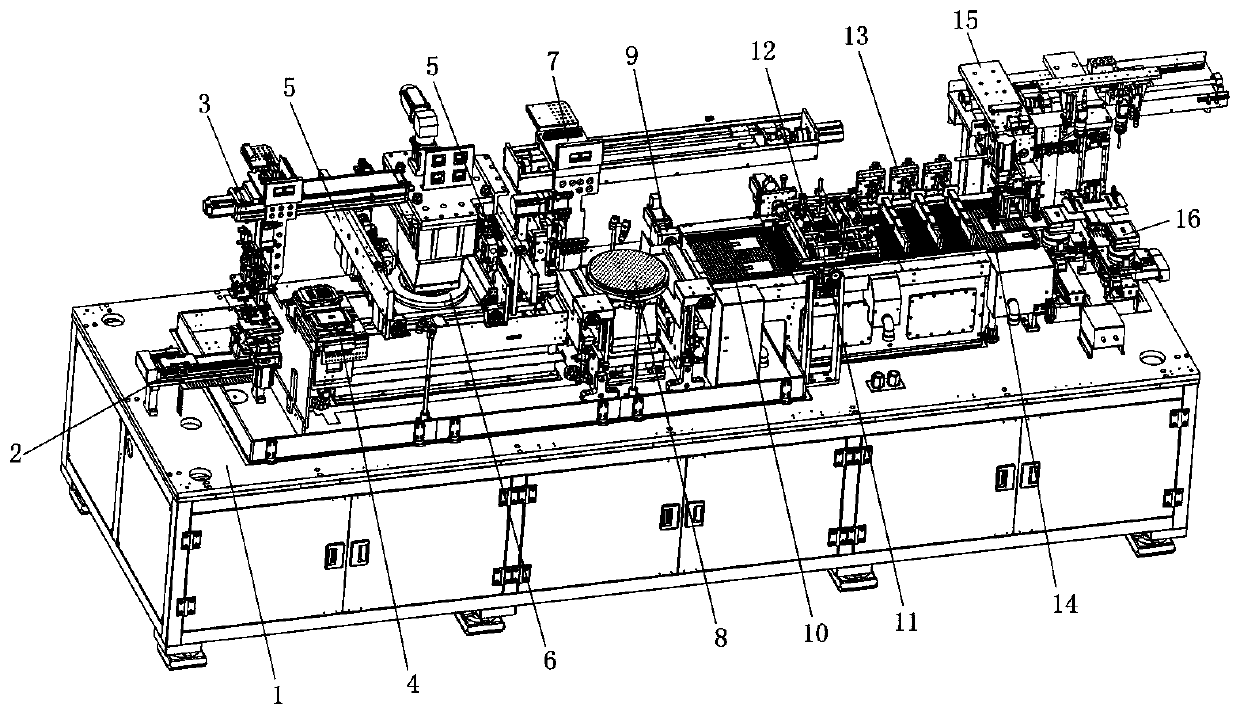

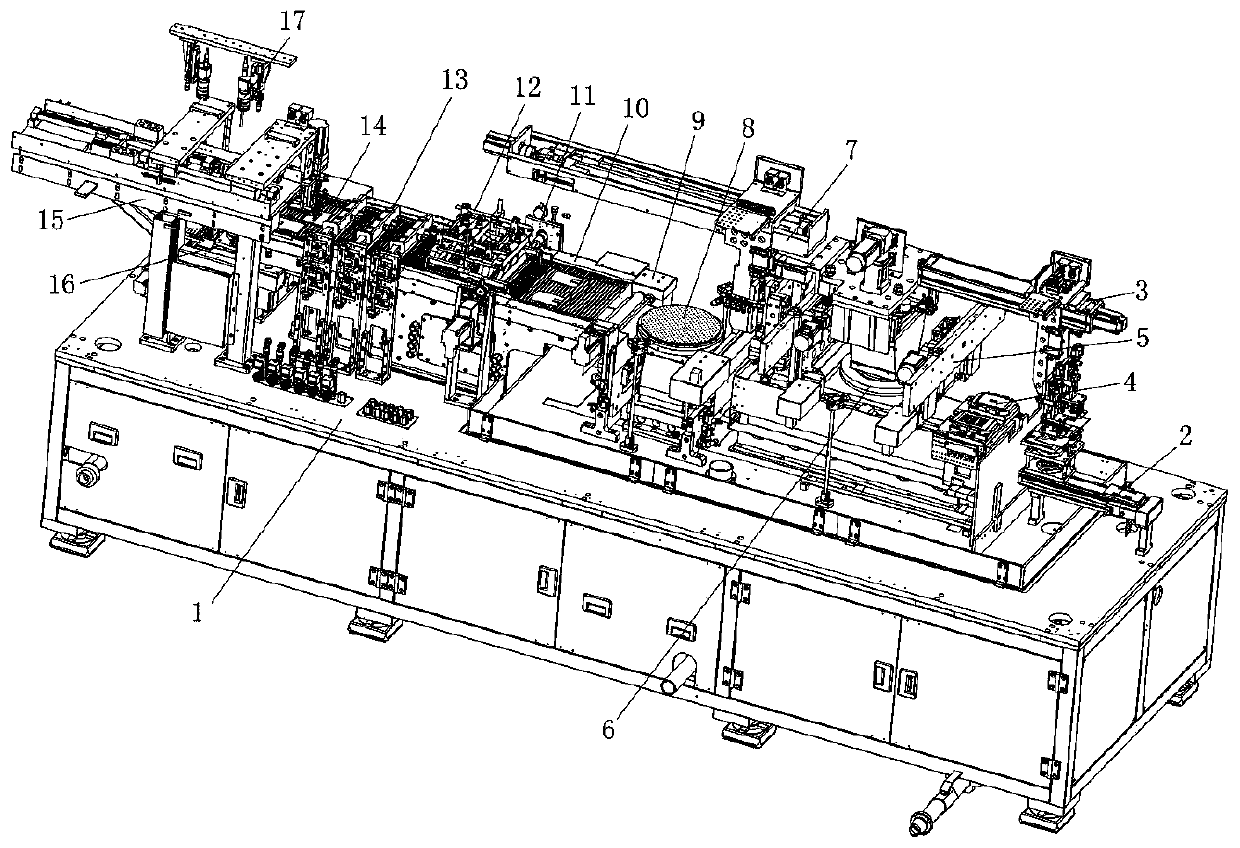

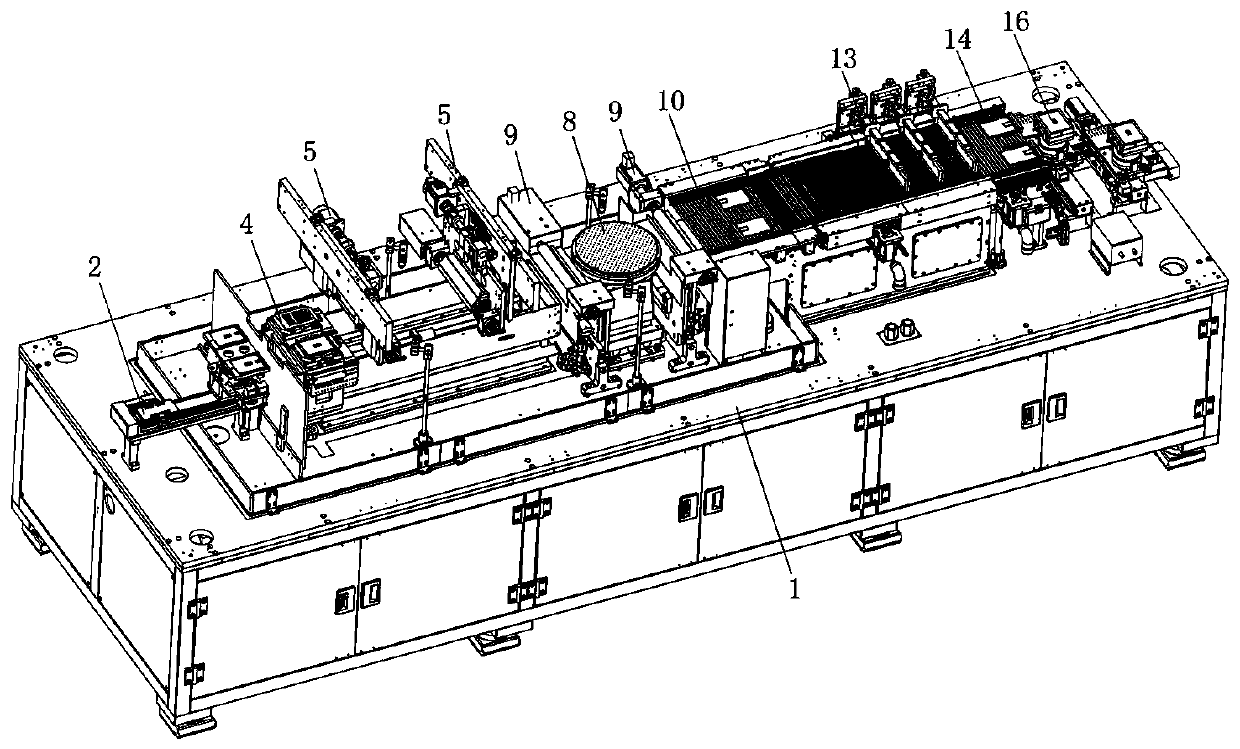

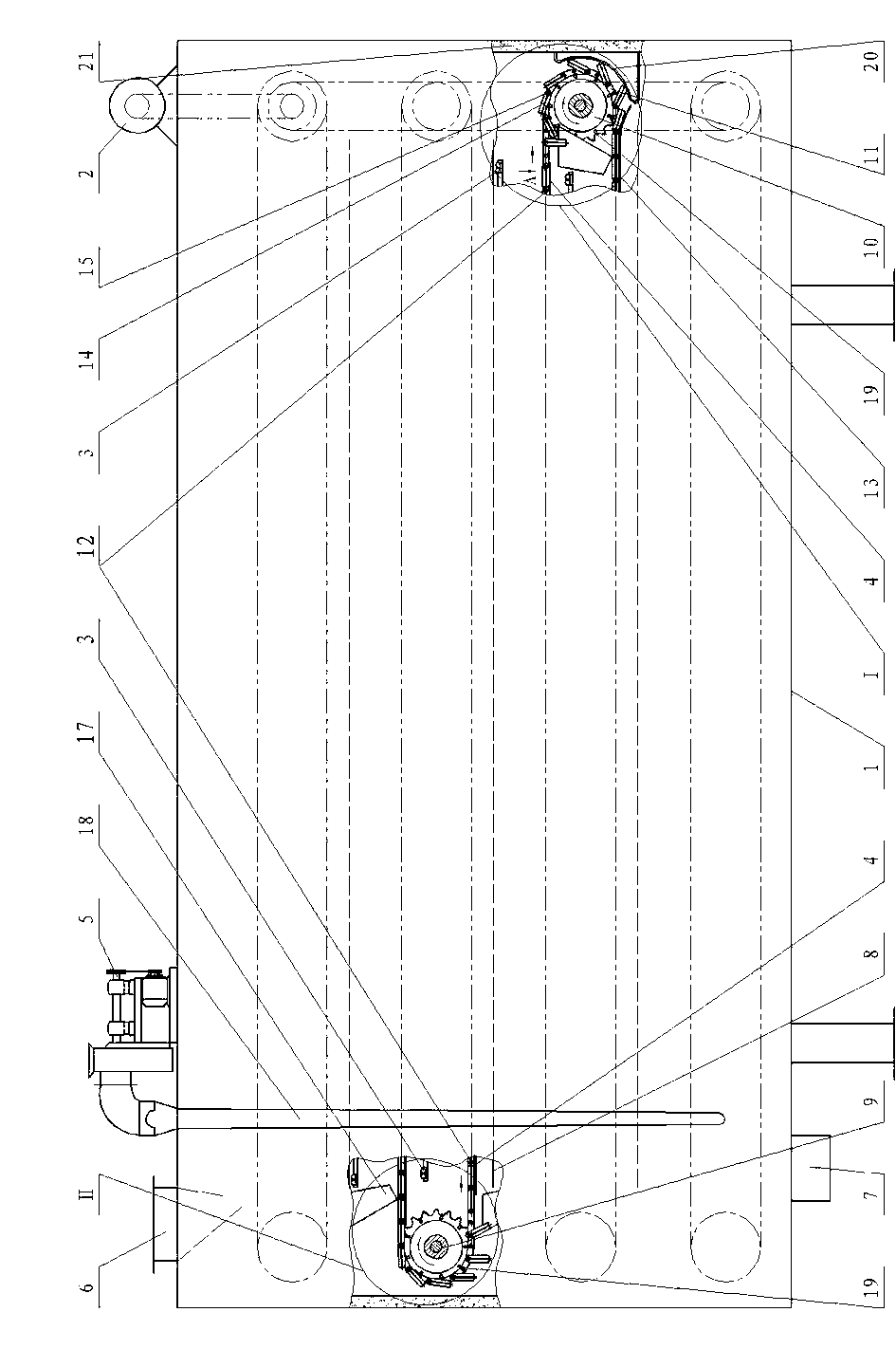

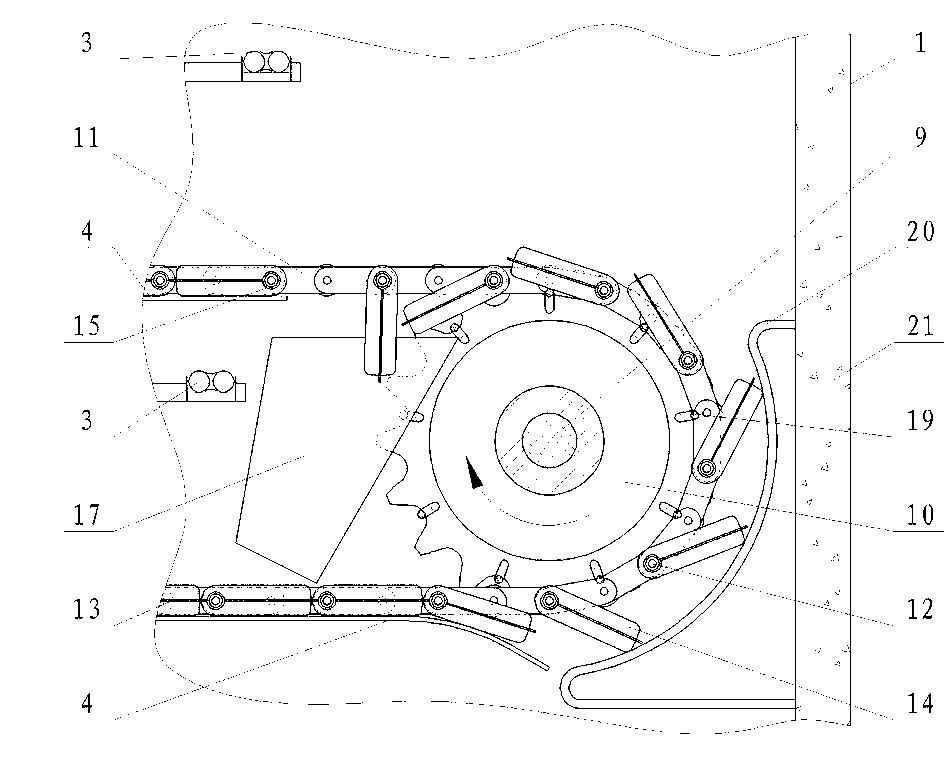

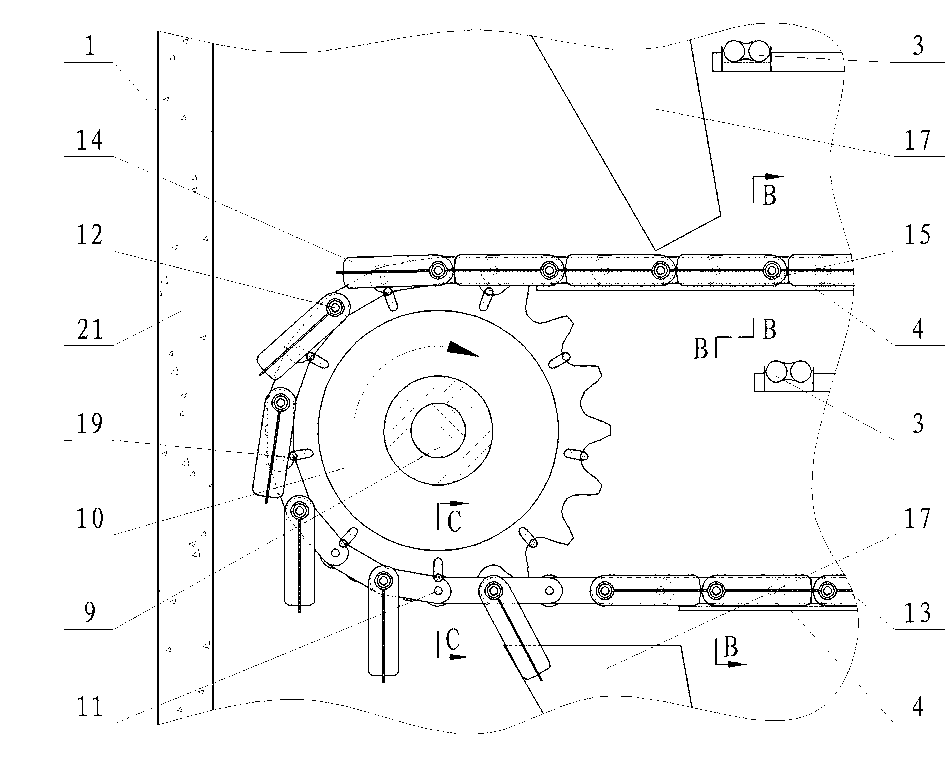

Full-automatic grinding and cleaning machine and grinding and cleaning technology thereof

ActiveCN109955145AAvoid position shiftAvoid positionLapping machinesFlexible article cleaningTransmission channelManipulator

The invention discloses a full-automatic grinding and cleaning machine and a grinding and cleaning technology thereof. The full-automatic grinding and cleaning machine comprises a feeding part, a CF cleaning part, a TFT cleaning part, a two-fluid cleaning and drying part, and a discharging part, wherein the feeding part, the CF cleaning part, the TFT cleaning part, the two-fluid cleaning and drying part and the discharging part are sequentially arranged on a machine table in the flow direction of glass pieces; the to-be-cleaned glass pieces are sequentially transported from the feeding part tothe CF cleaning part, a CF surface is cleaned through the CF cleaning part, the TFR surface is cleaned through the TFT cleaning part, and the CF surface and the TFT surface are cleaned by the two-fluid cleaning and drying part simultaneously and then dried, and the dried glass pieces are discharged and exported through the discharging part. According to the full-automatic grinding and cleaning machine and the grinding and cleaning technology thereof, transmission of the small and micro-sized glass pieces is effectively realized, and the problems of positional displacement and motion interference of the glass pieces in the two-fluid cleaning and drying process are effectively avoided; and rotating, material splitting, and exporting of the glass pieces are realized through cooperation of adouble-glass transmission channel formed by a gap between adjacent conveying rollers in an upward extending mode and a discharging mechanical arm, the height of a brush can be controlled in real time,displacement of the glass pieces is avoided, and the cleaning efficiency of the brush and the real-time cleaning versatility of the brush are effectively improved.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

Shifting rod type infrared vegetable dehydrator

The invention provides a shifting rod type infrared vegetable dehydrator. The shifting rod type infrared vegetable dehydrator is characterized that the inner portion of a box body is separated into a plurality of layers through partition plates, a set of conveying devices which is driven by a transmission device to run are arranged inside each layer, a pin shaft correspondingly protrudes towards the inner side from both chain pins of two chains of the same conveying device at intervals, baffle plates are fixed at both ends of a strengthening pipe and panels of chain plates, each chain plate is hung on each pin shaft, protruding out towards the inner sides, of the chains, baffle plates are supported on a guide rail so as to form a groove-shaped material channel, an infrared radiation appliance is arranged on each channel, a material guiding chute is arranged below the tail end of the channel, an air inducing port is formed in the upper portion of the side wall of each layer of the box body and is connected with a draught fan through an air inducing pipe, J-shaped shafting rods are evenly fixed on the end face of each chain wheel, a limiting rod is arranged between each chain wheel, placed below the transmission device, of each conveying device and the inner wall, close to the transmission device, of the box body, a material feeding port is formed in the top portion of the box body, and a material feeding port is formed in the bottom portion of the box body. The shifting rod type infrared vegetable dehydrator is reliable in work, stable in performance, and good in dried vegetable quality.

Owner:SHANDONG UNIV OF TECH

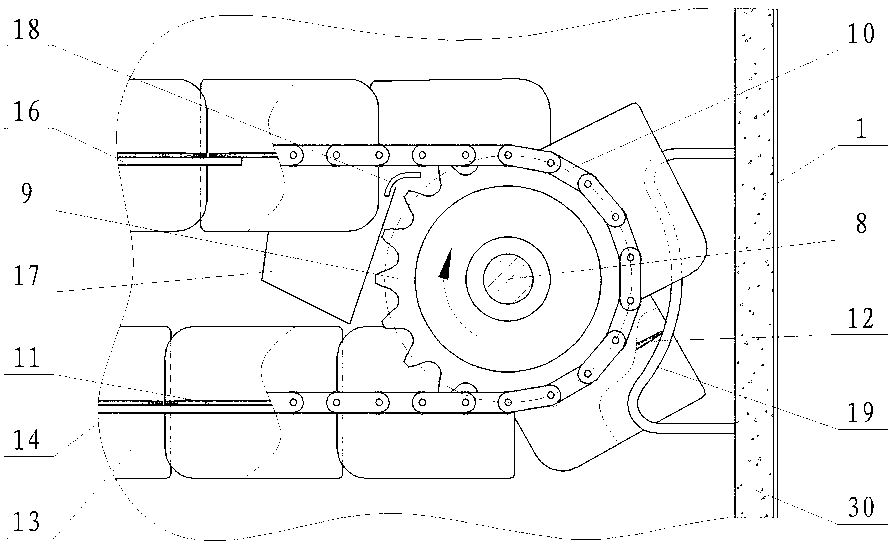

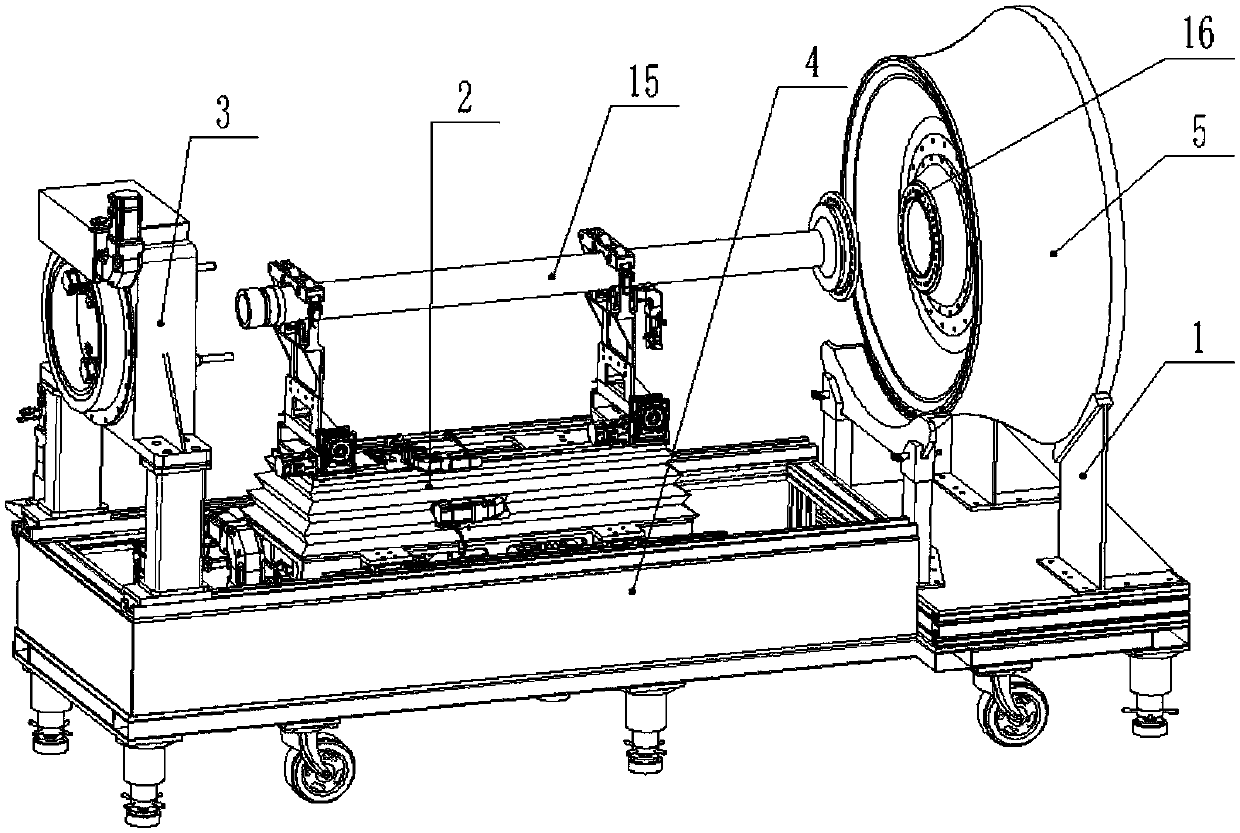

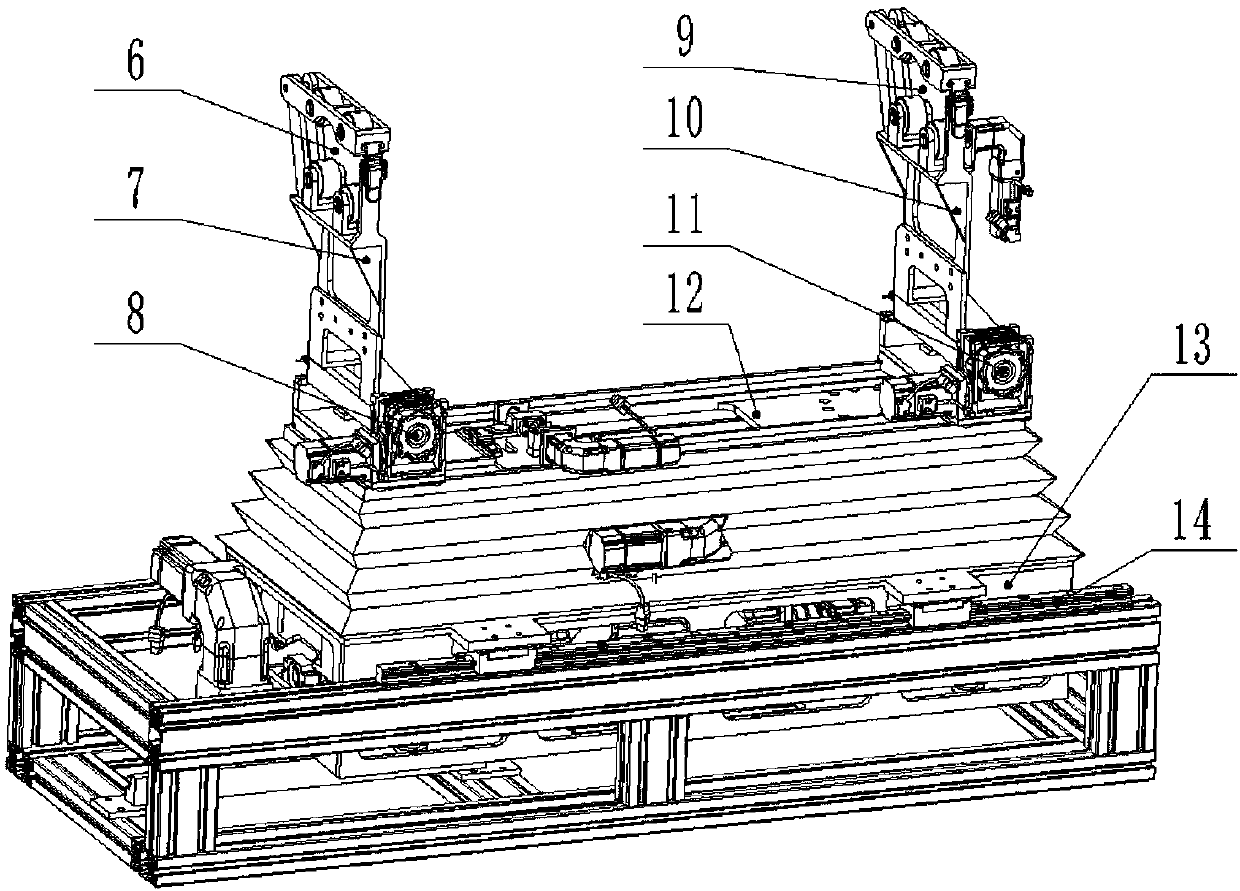

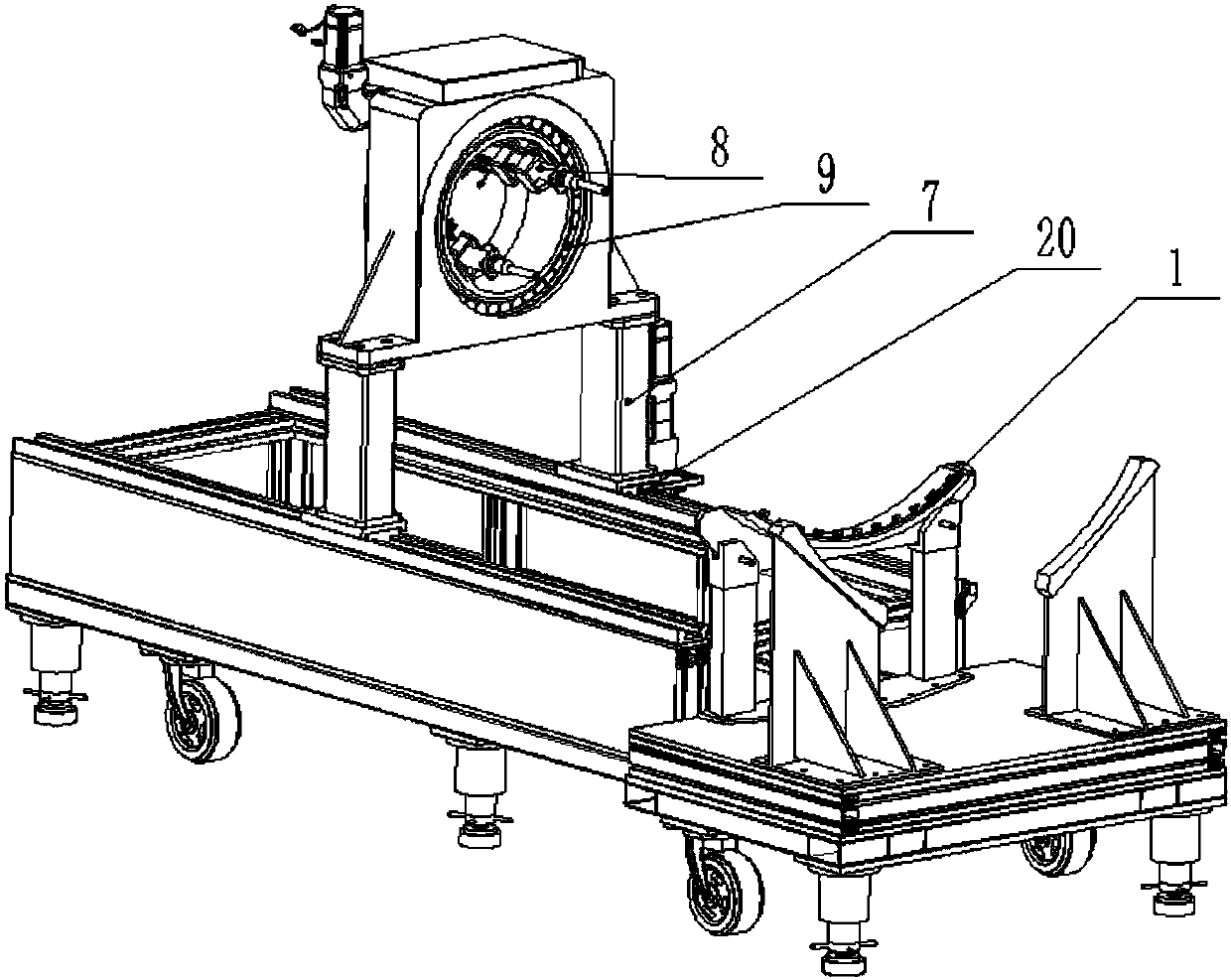

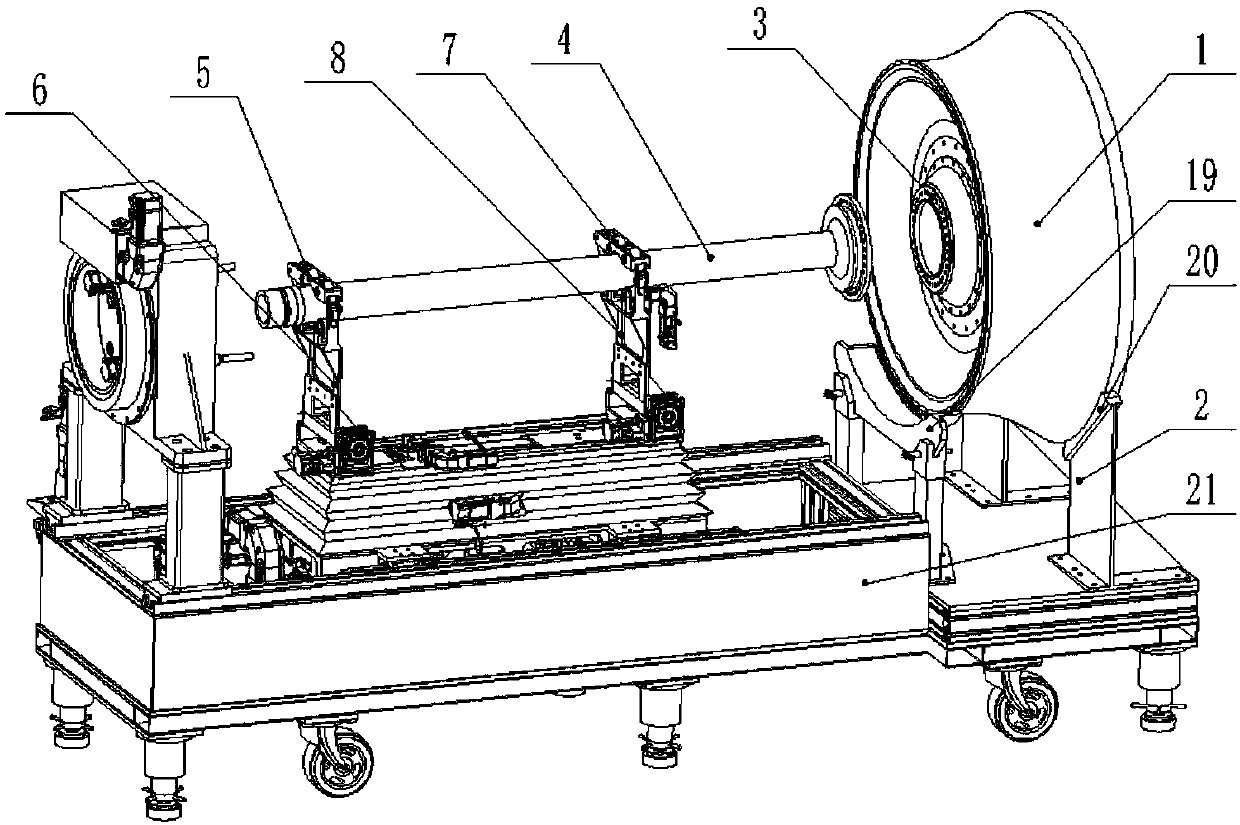

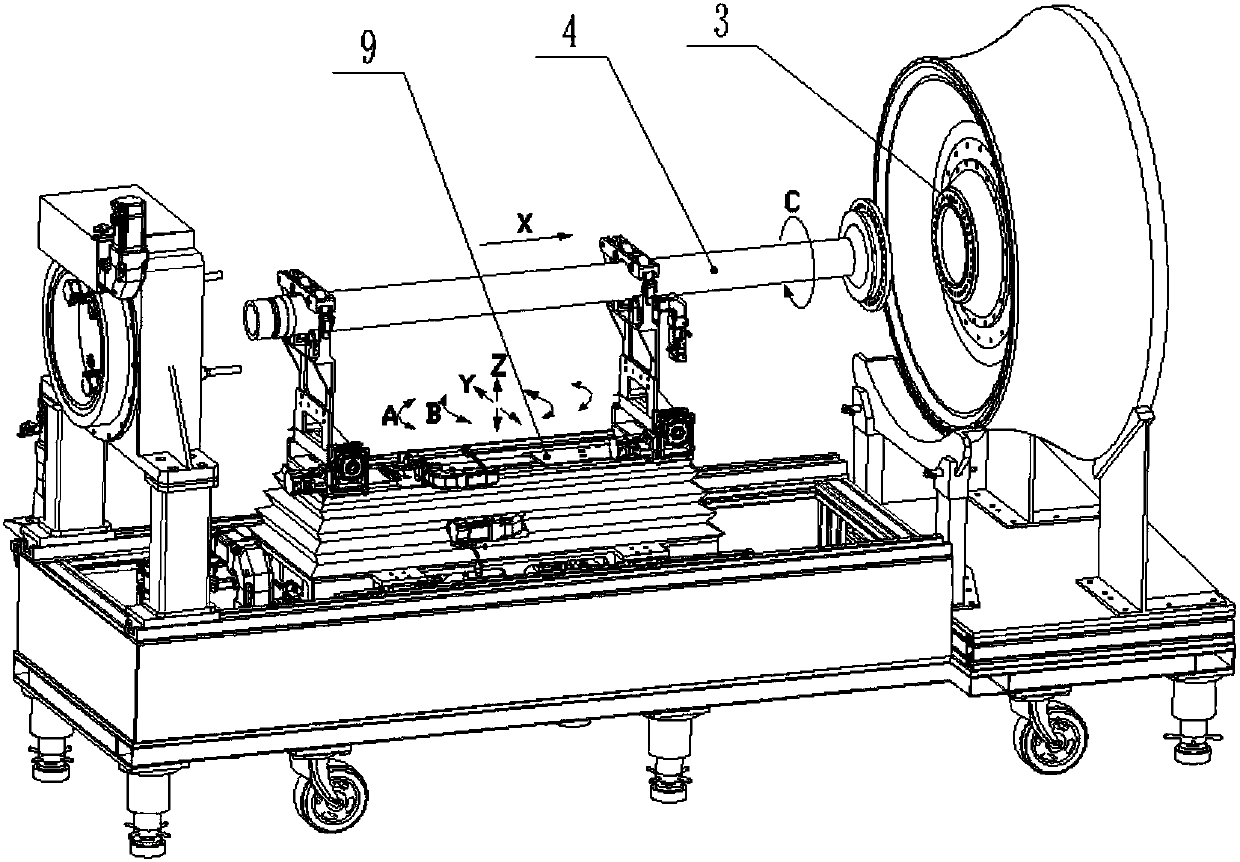

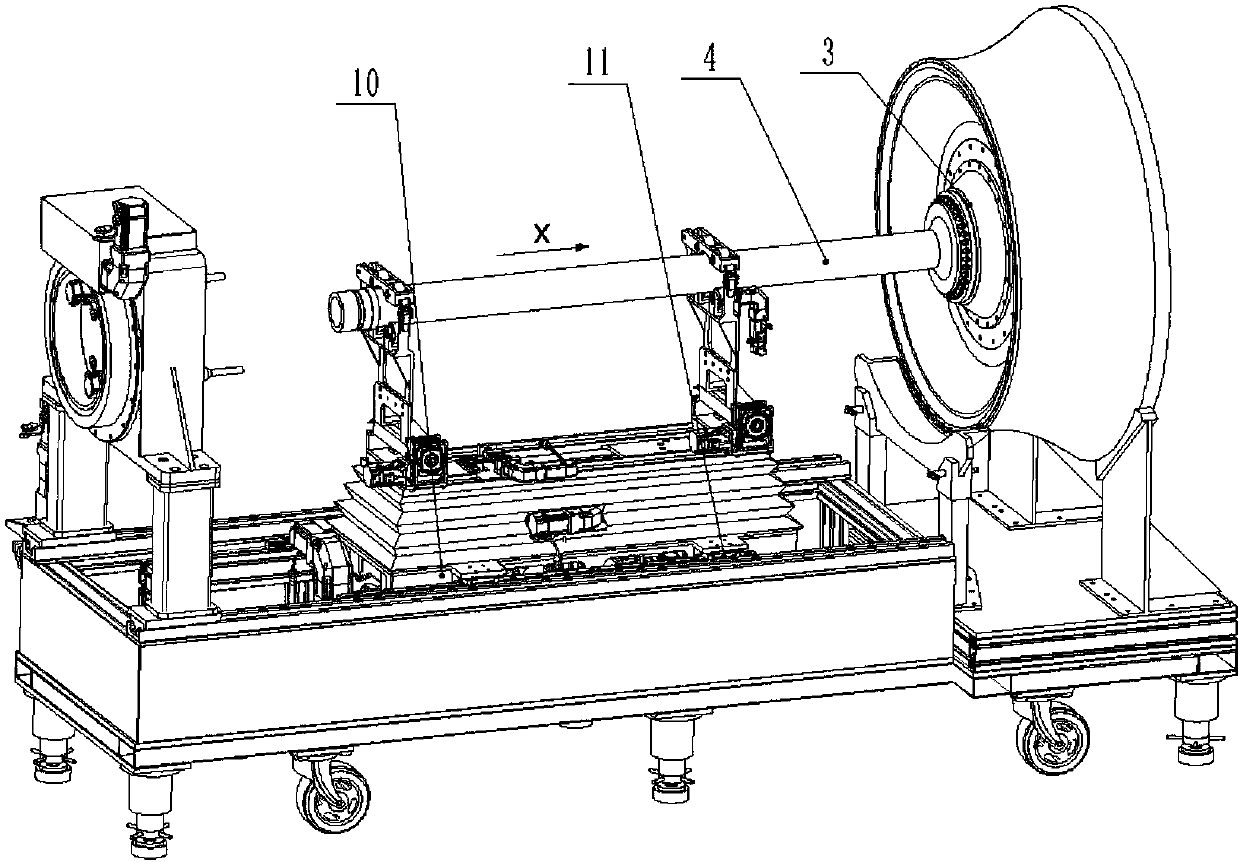

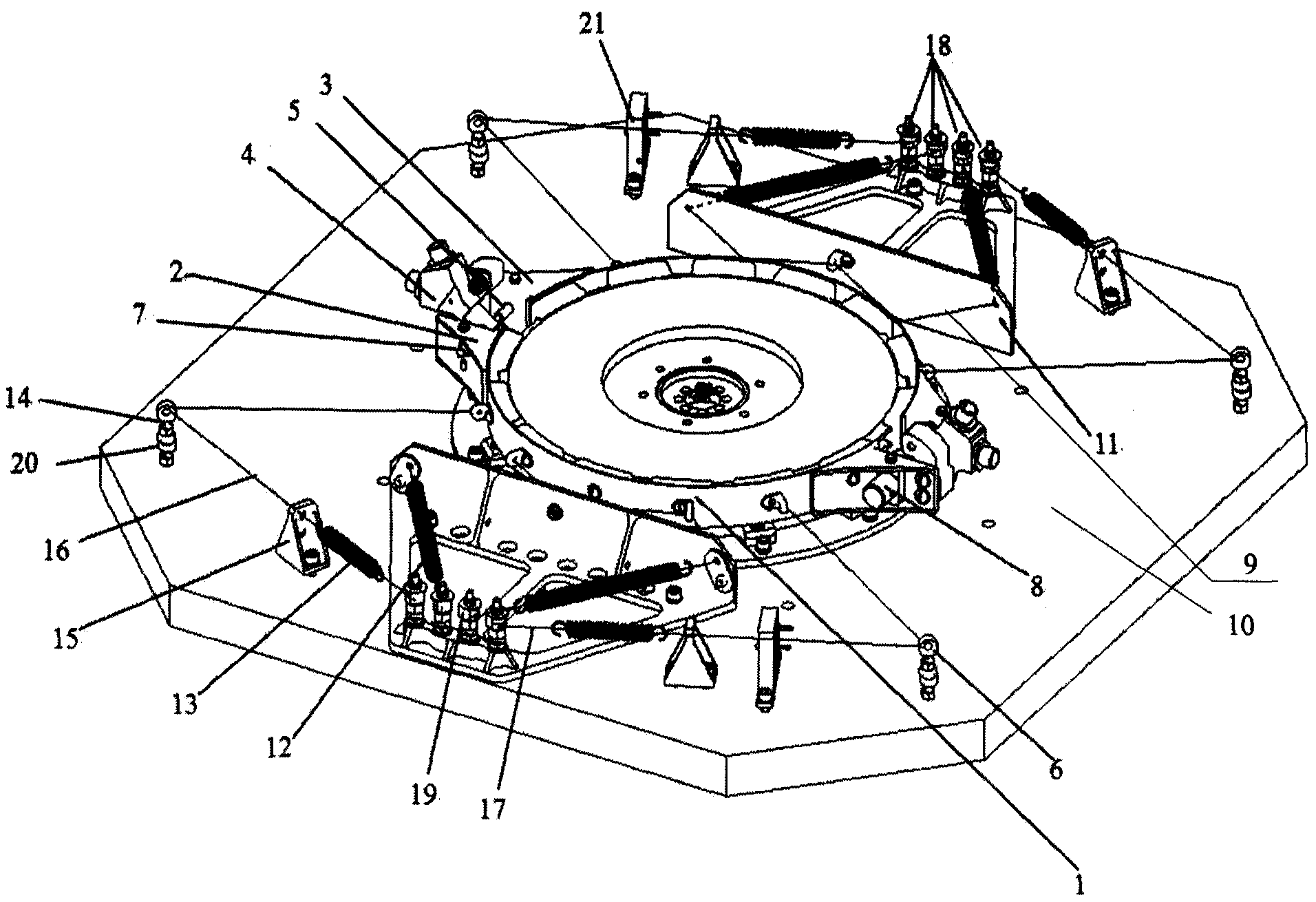

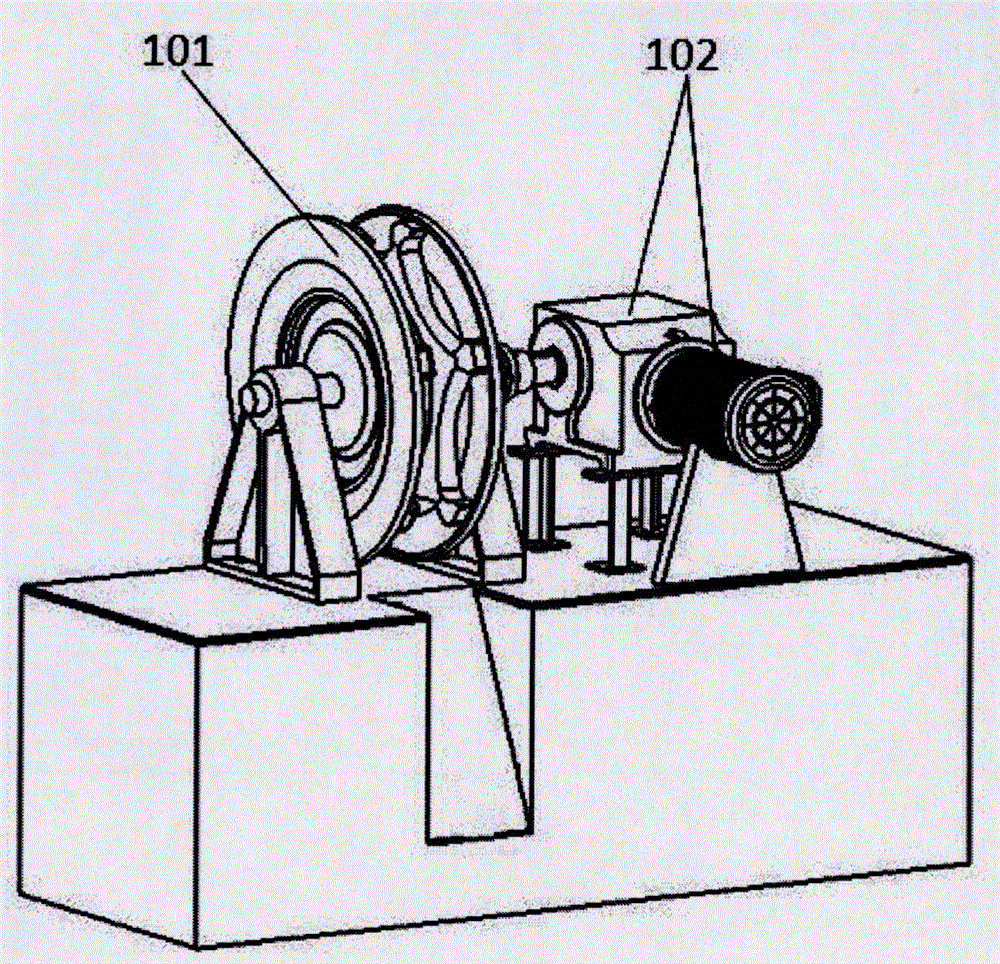

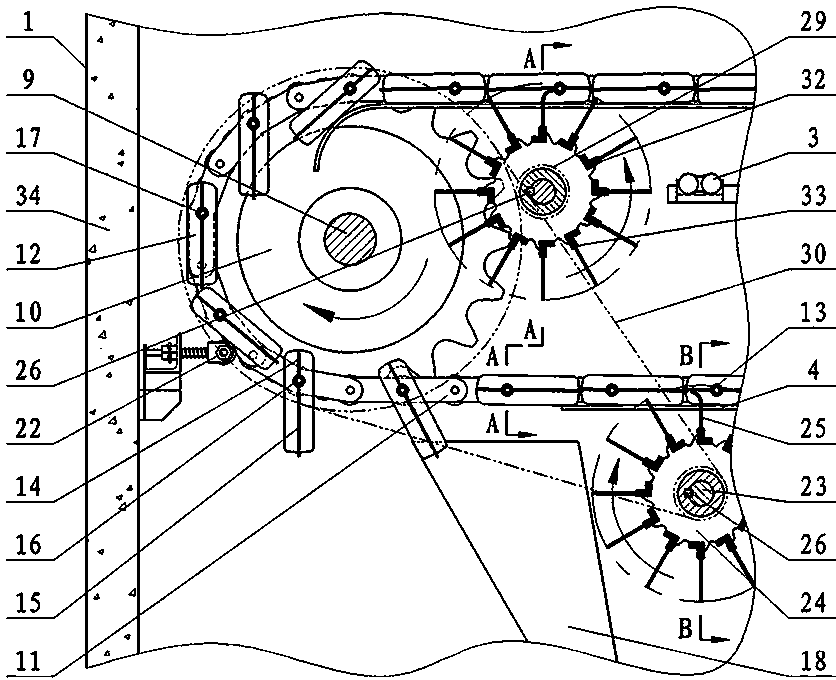

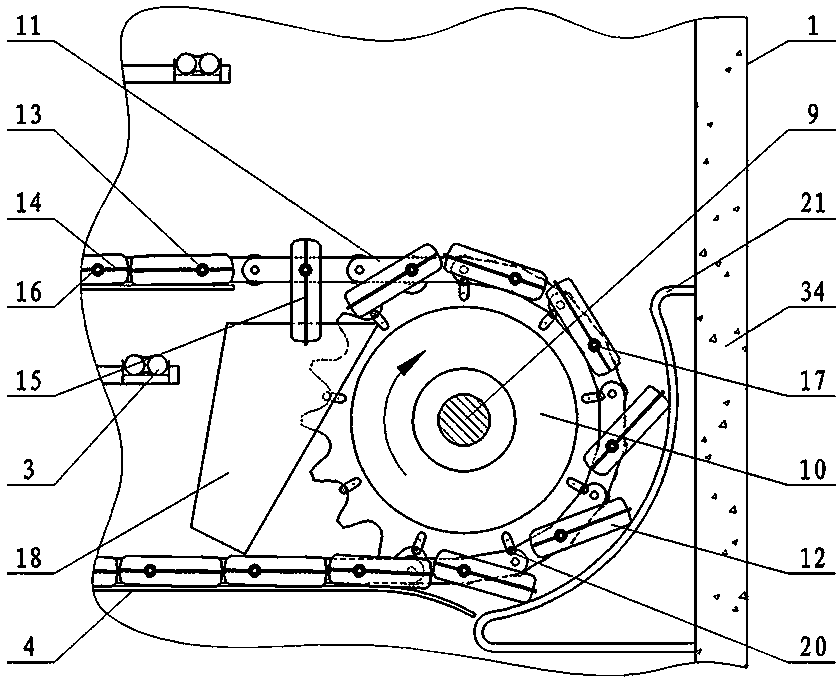

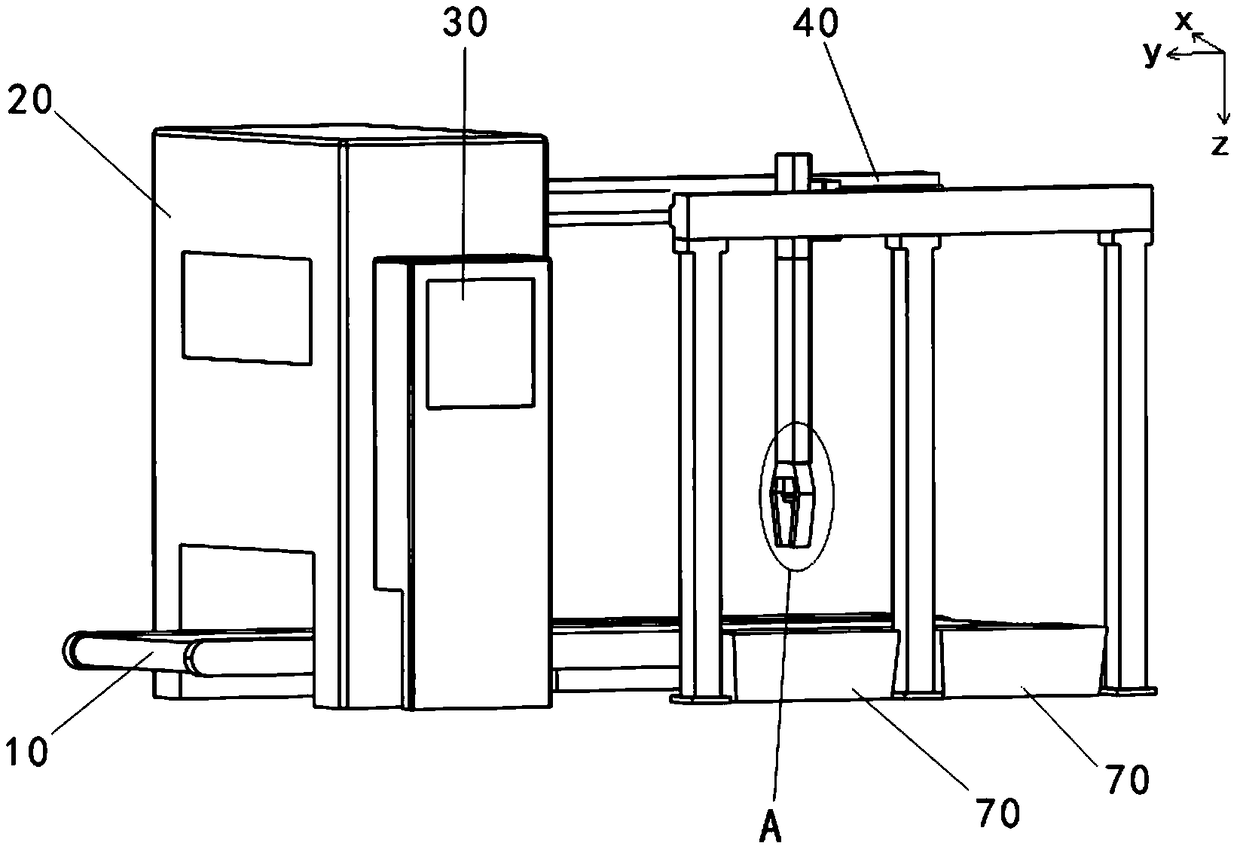

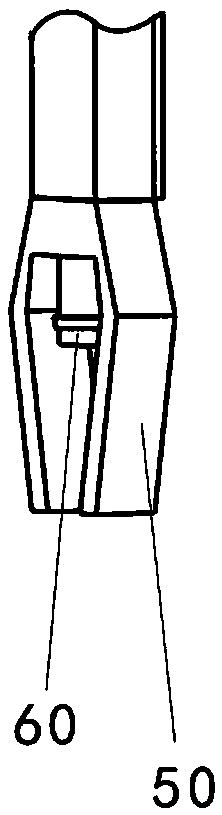

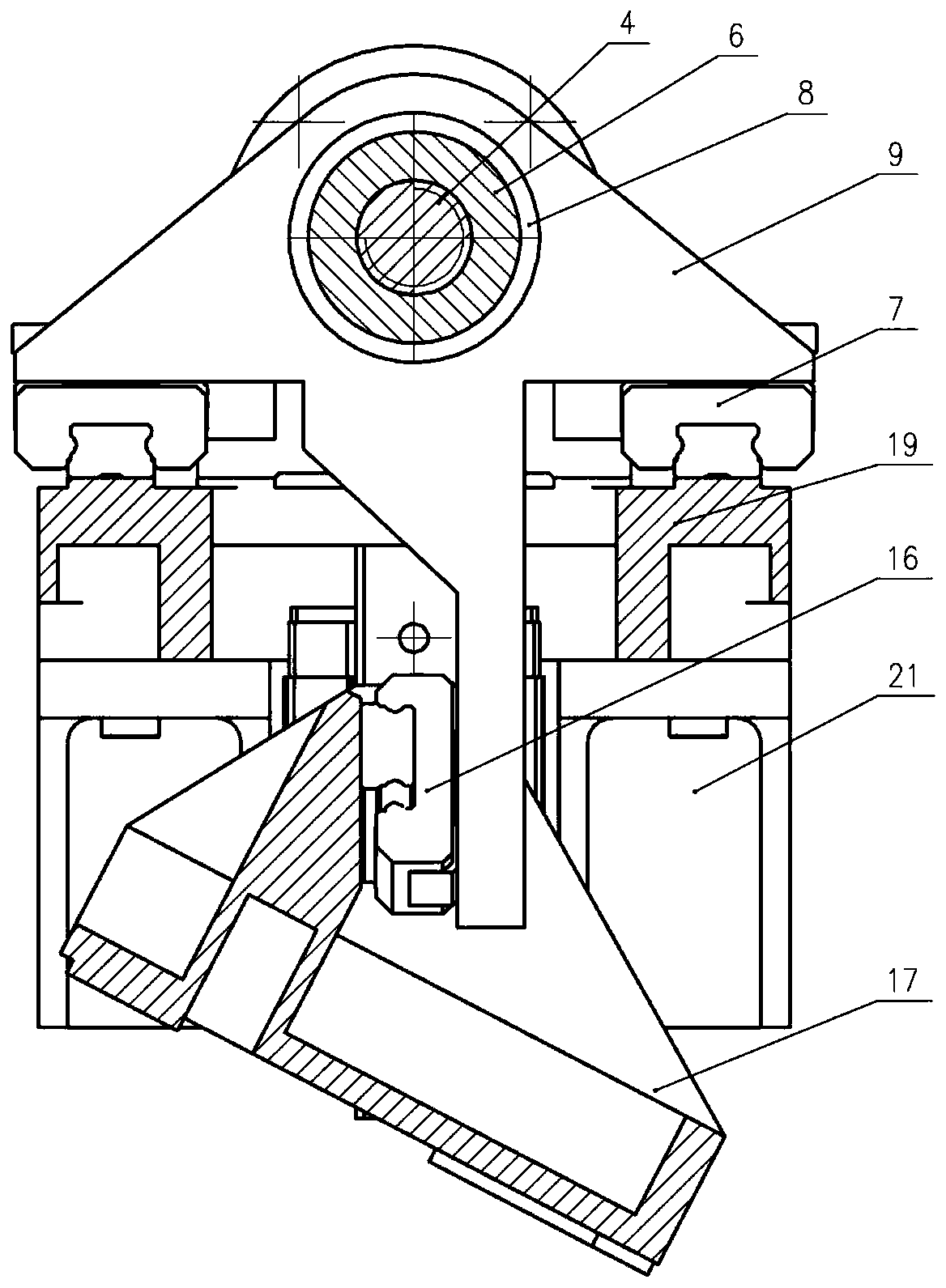

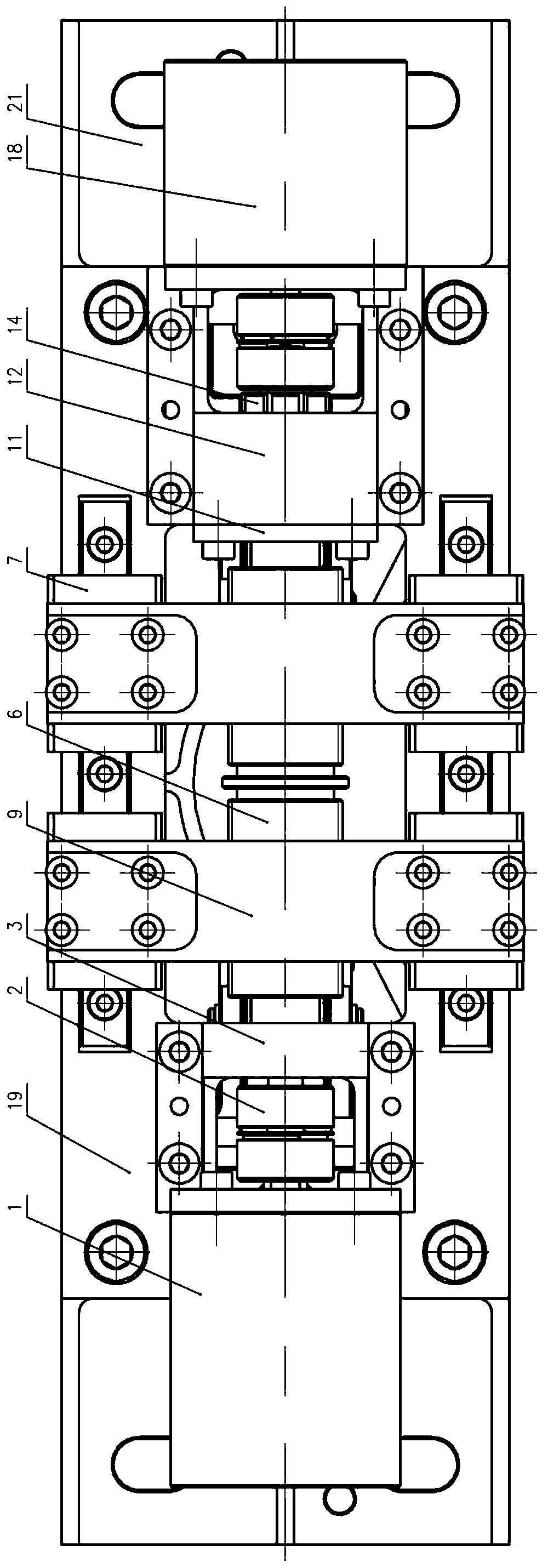

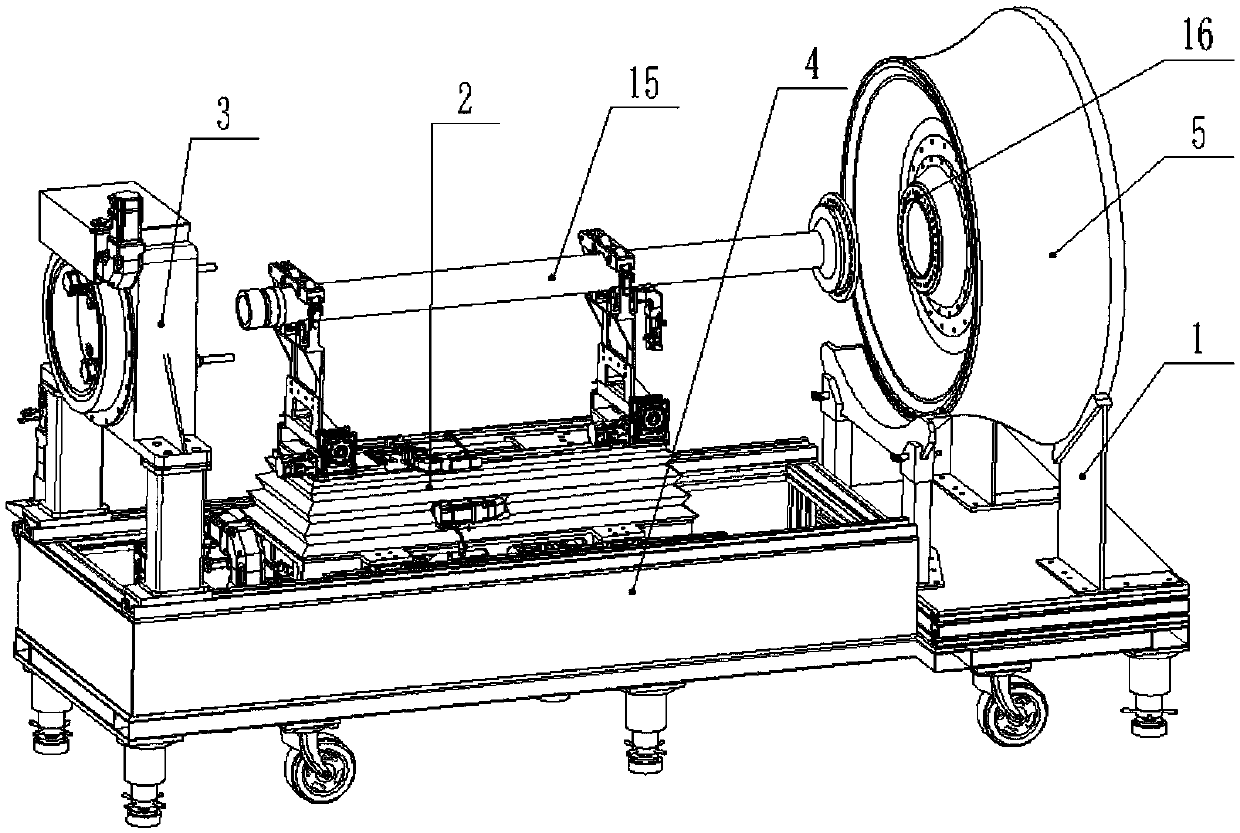

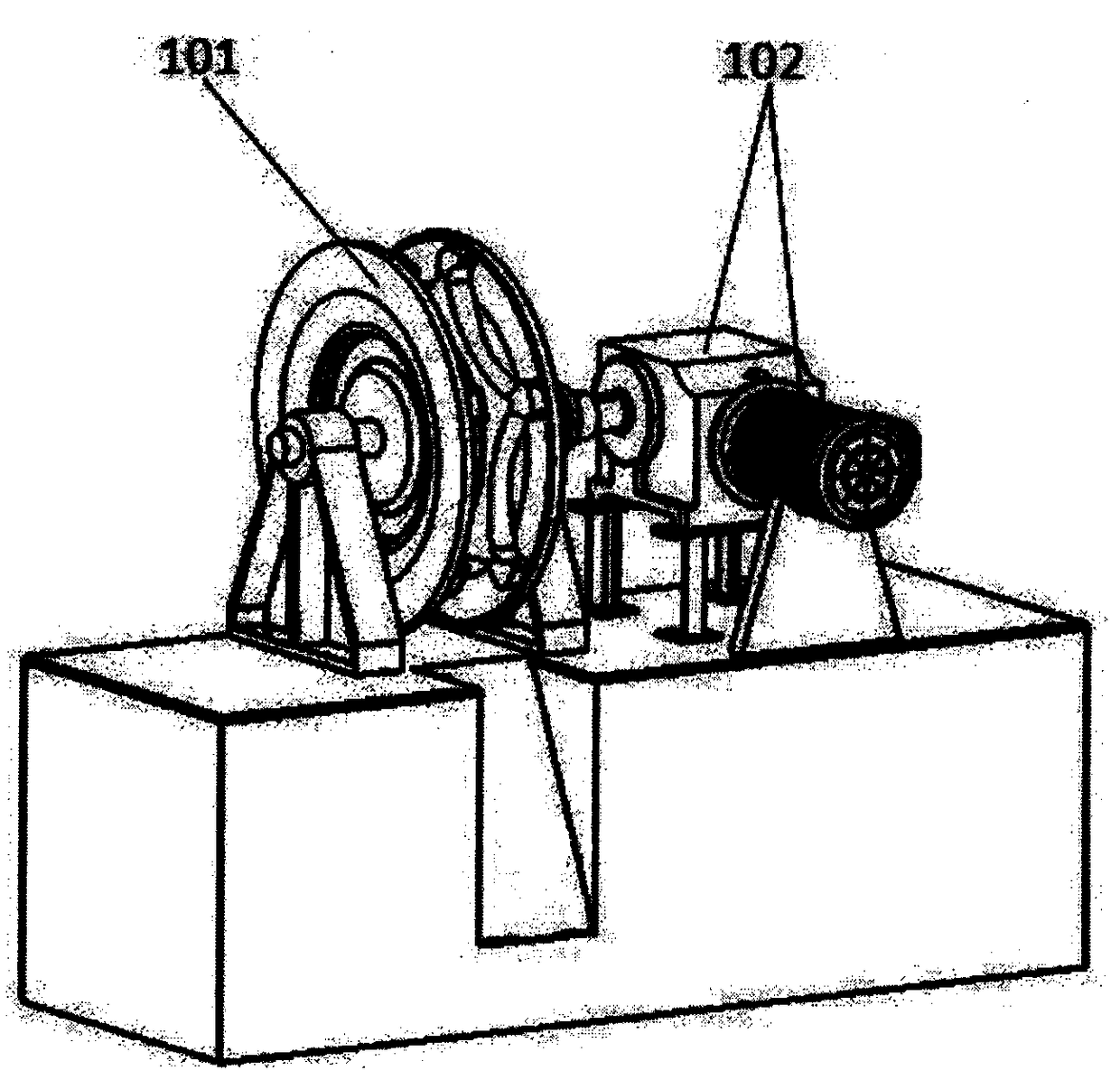

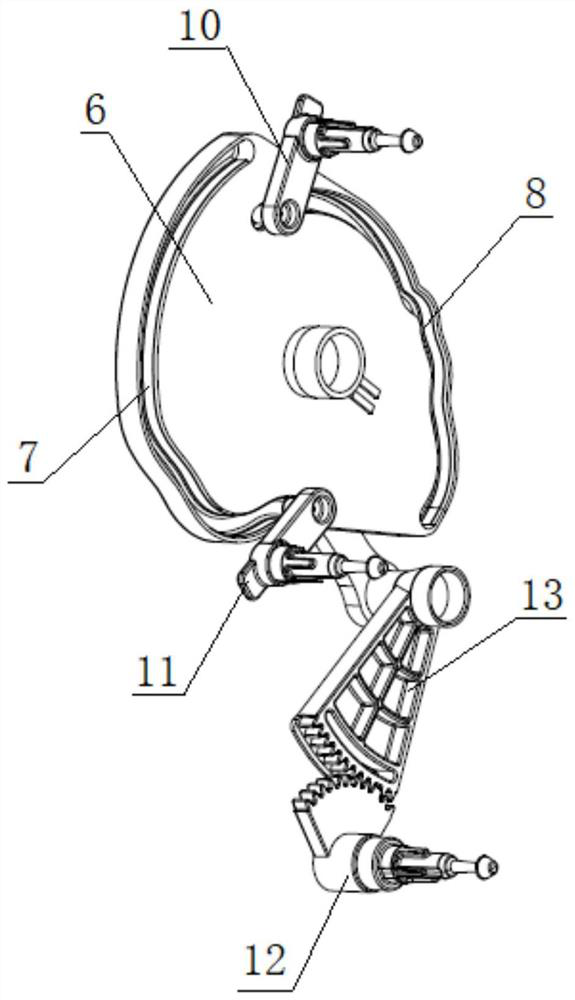

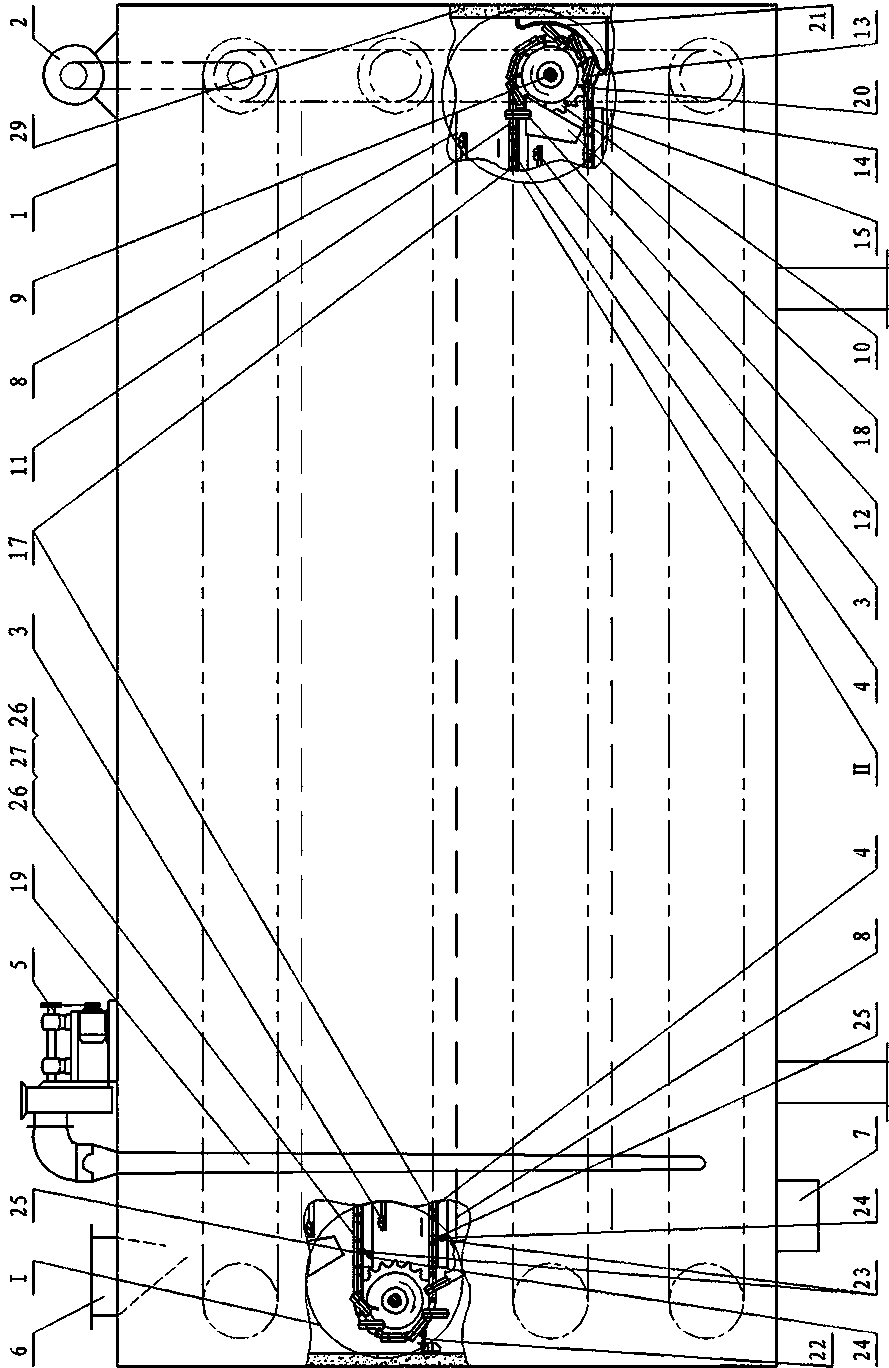

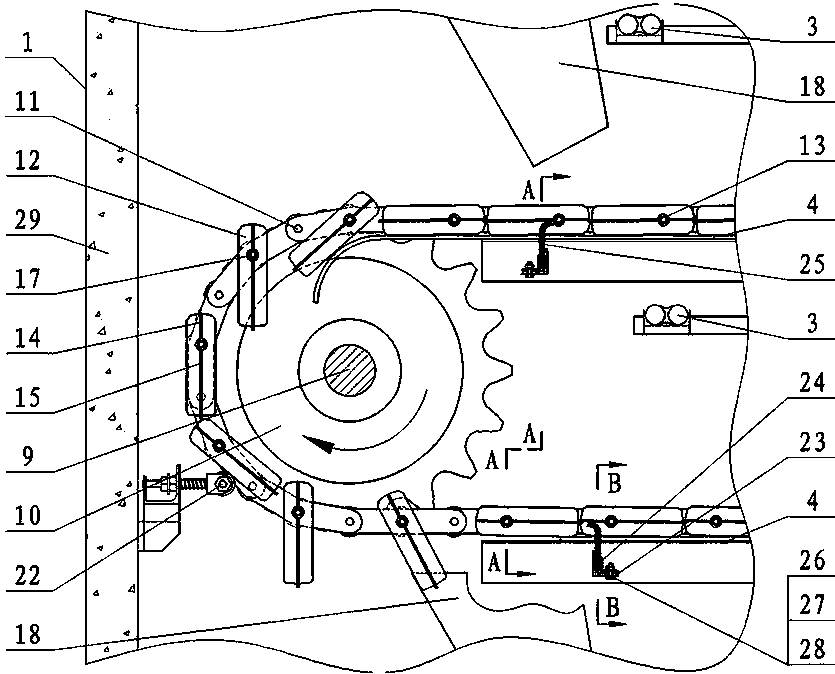

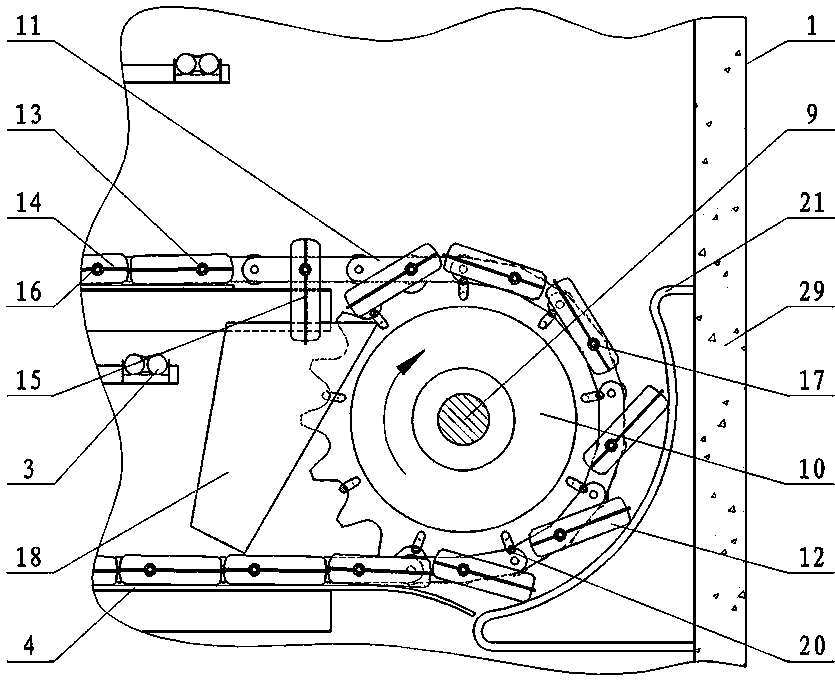

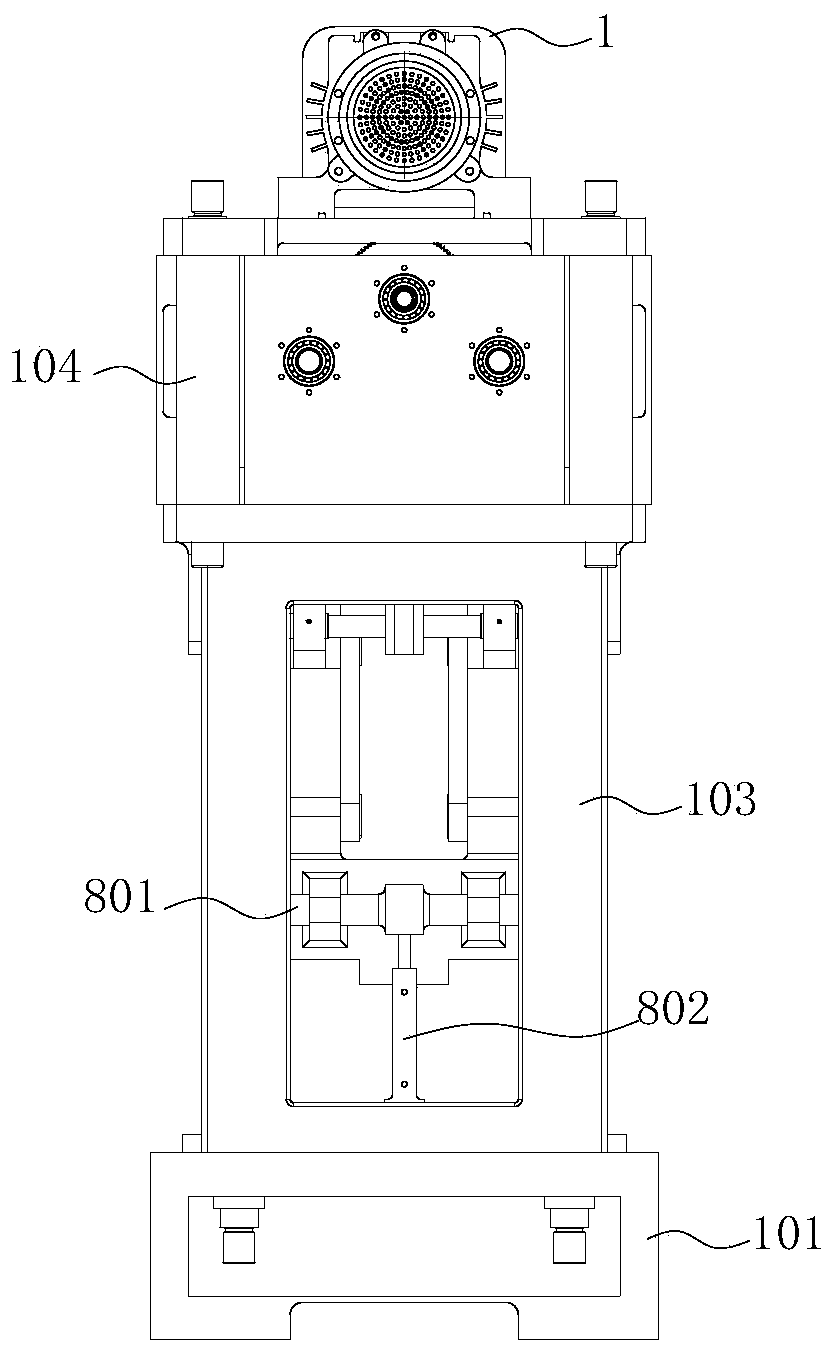

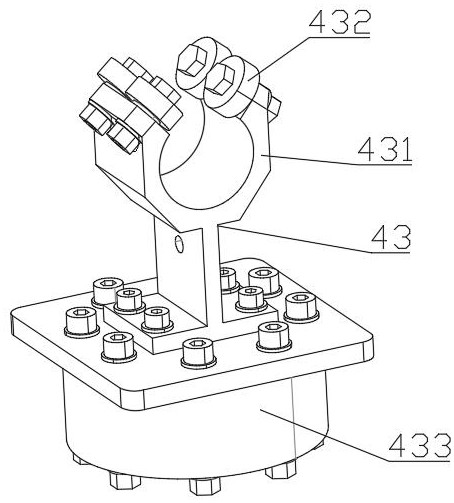

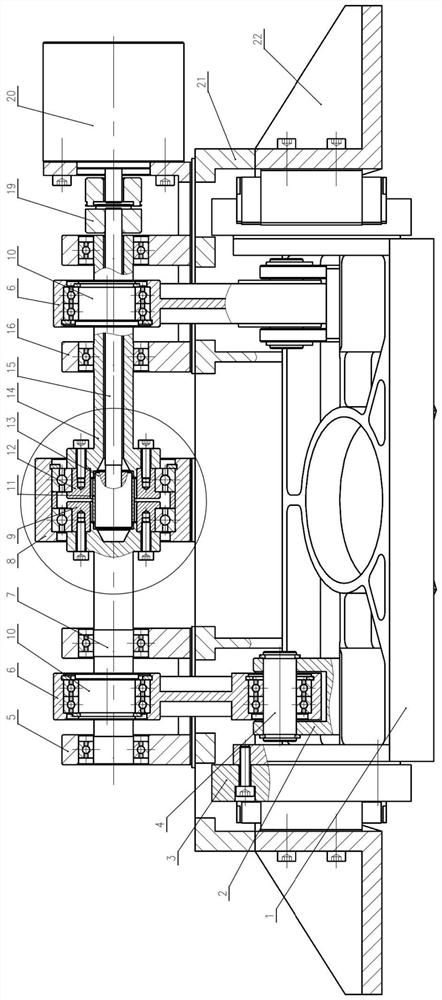

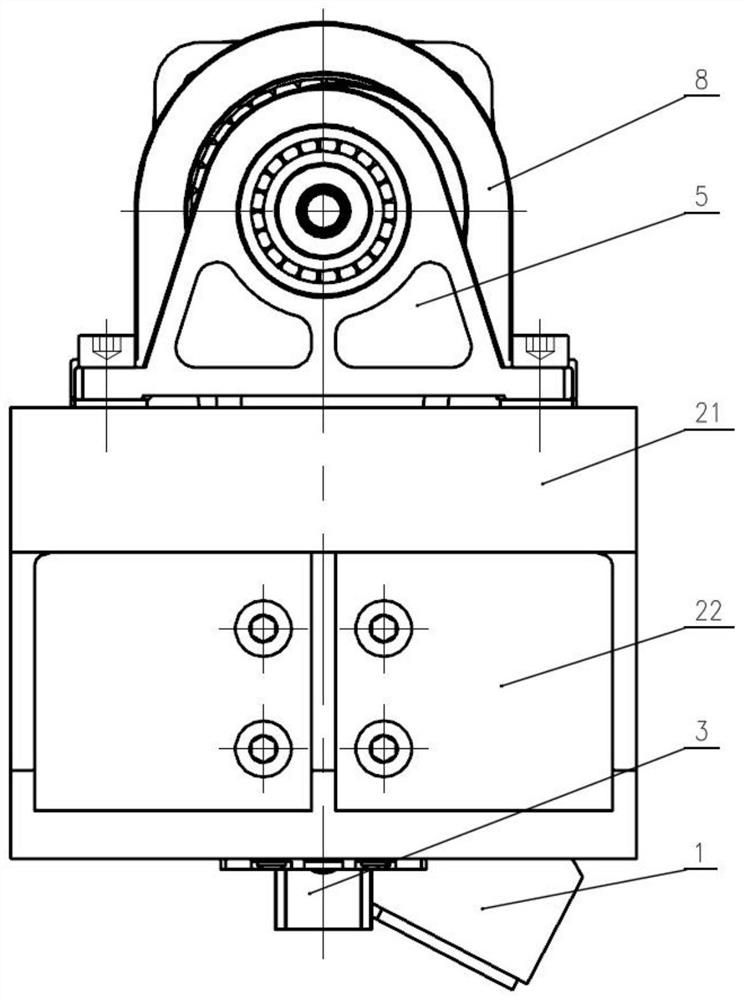

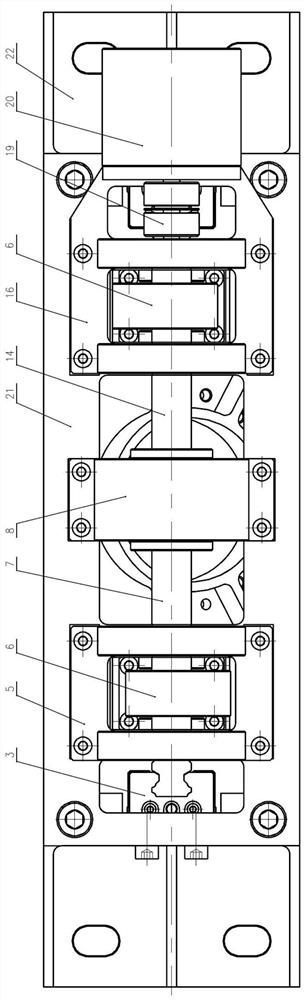

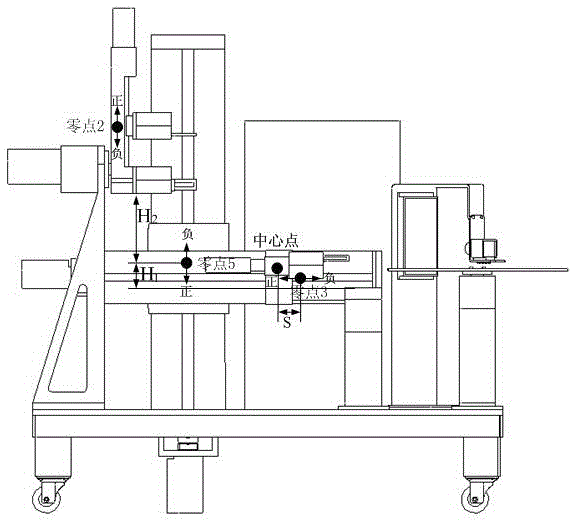

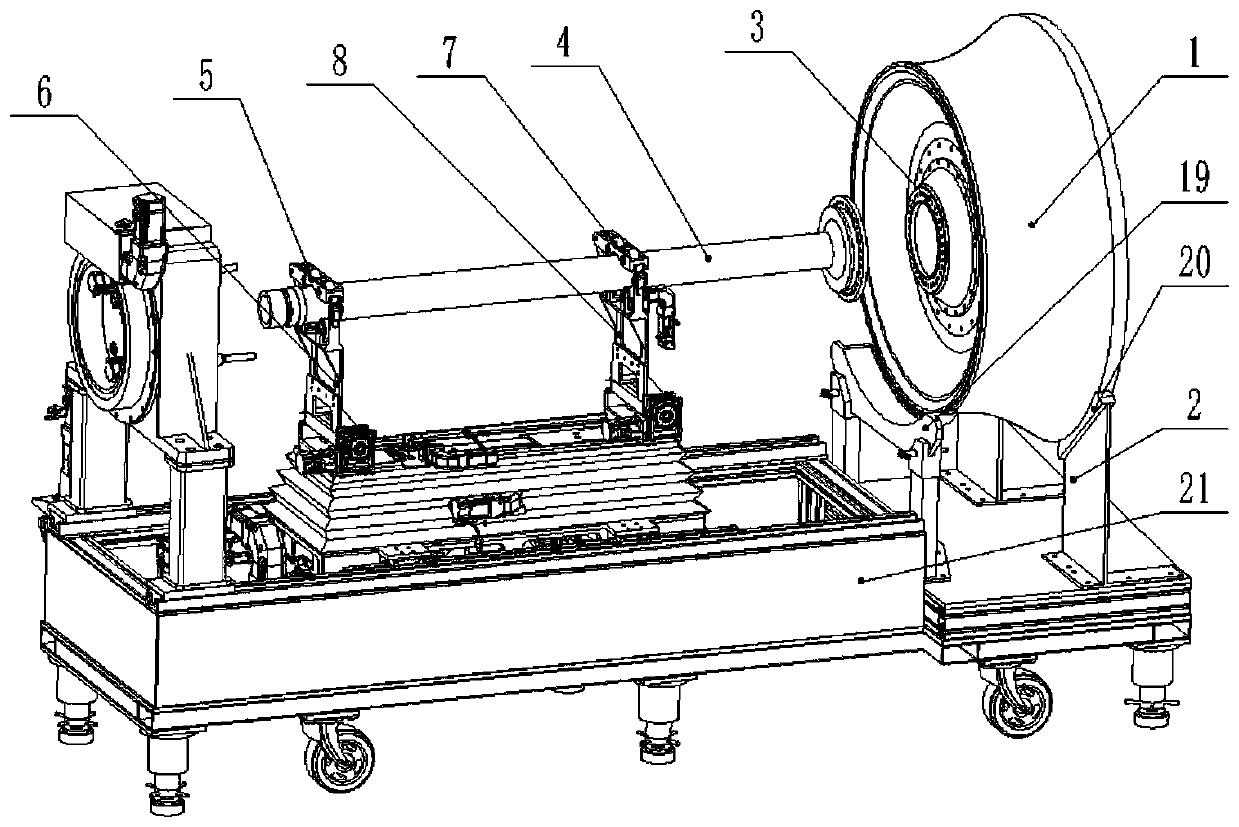

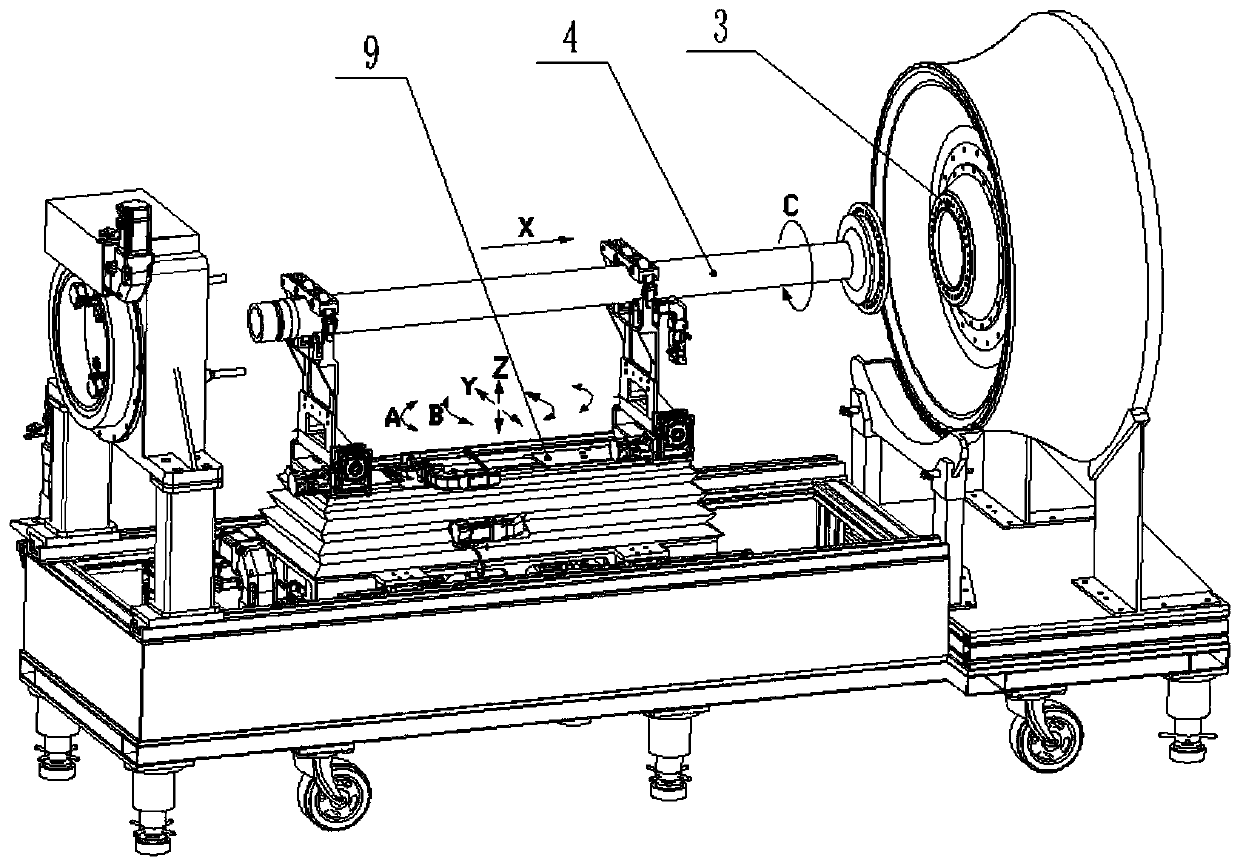

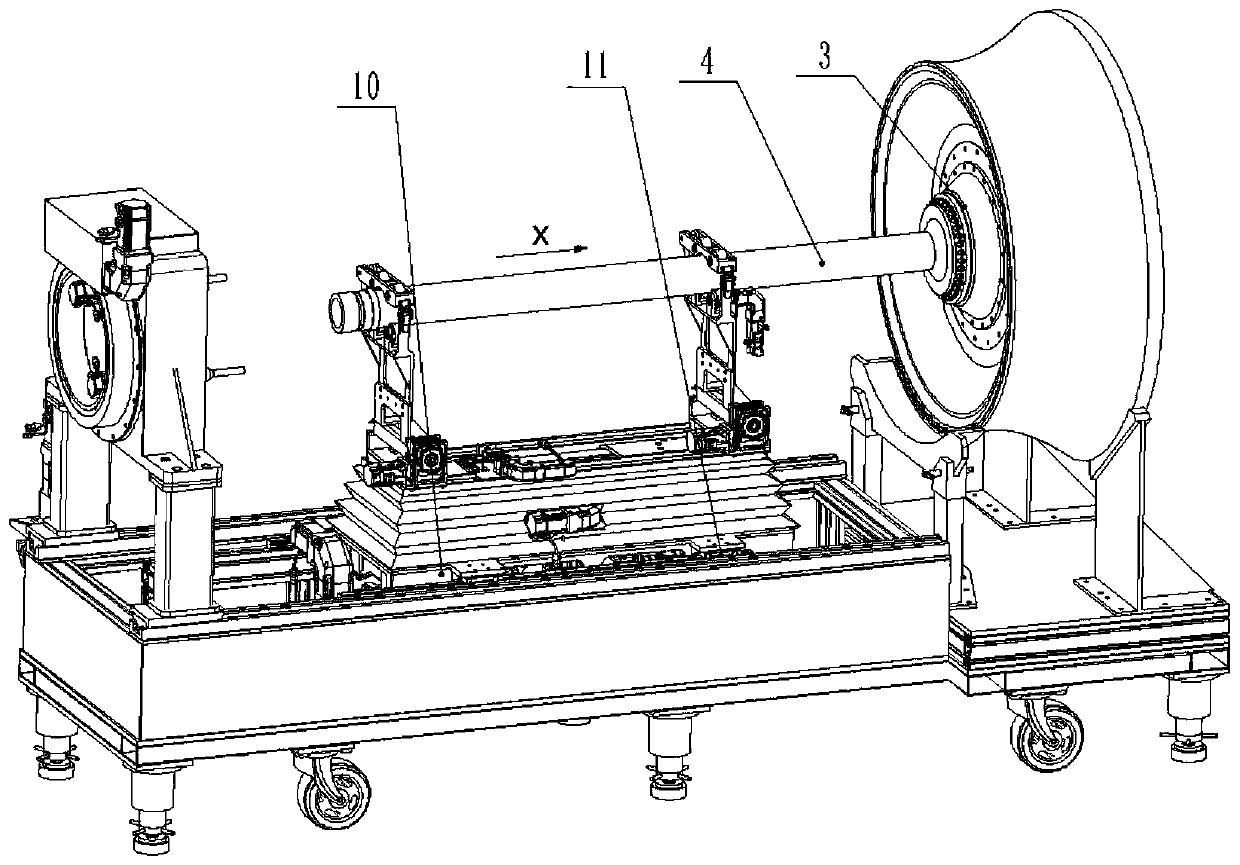

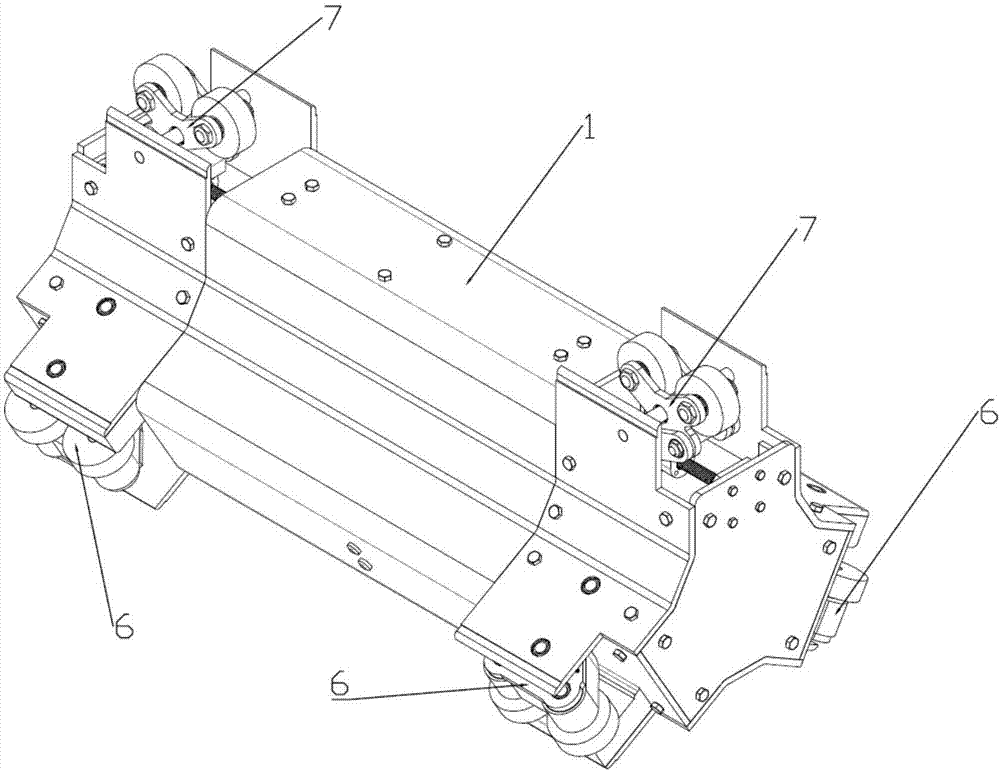

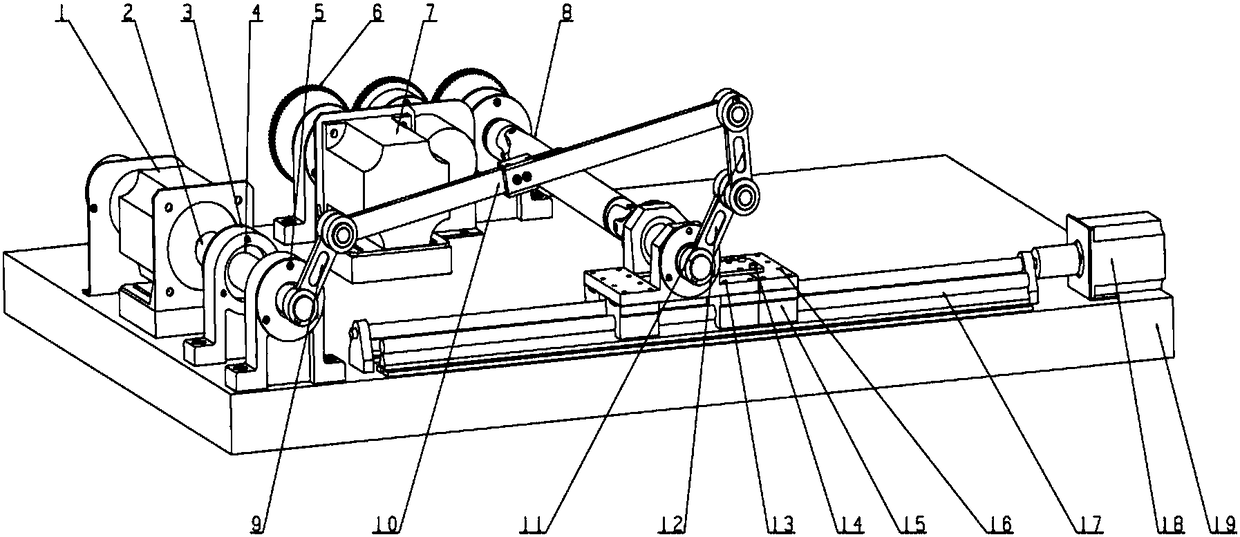

Assembly device for low-pressure turbine shaft-disc assembly of aero-engine

The invention discloses an assembly device for a low-pressure turbine shaft-disc assembly of an aero-engine. The assembly device comprises a turbine clamp, a turbine shaft posture adjustment and buttjoint system, a transposition type tightening system and a lathe bed. According to the assembly device, the turbine clamp realizes horizontal installation of the axis of a turbine unit body; the turbine shaft attitude adjustment and butt joint system realizes parallel calibration movement and concentric calibration motion of the contact end surface of a turbine shaft relative to a connecting discand realizes feeding butt joint motion of the turbine shaft relative to the connecting disc; the transposition type tightening system realizes transposition of a tightening shaft to a tightening station corresponding to bolts distributed circumferentially. The assembly device has the advantages that a horizontal installation mode of the axis of a low-pressure turbine shaft-disc is adopted, so thatcentering positioning calibration of the turbine shaft relative to the connecting disc can be realized, the end surfaces can be accurately and tightly attached, and therefore the butt joint assembling precision can be improved; and the transposition type tightening system is adopted, the bolt pre-tightening force deviation can be effectively controlled by using the tightening shaft, and thereforethe tightening quality can be ensured; and a gantry type mobile station is adopted, and therefore the problem of motion interference in the feeding process of the tightening system can be solved.

Owner:DALIAN UNIV OF TECH

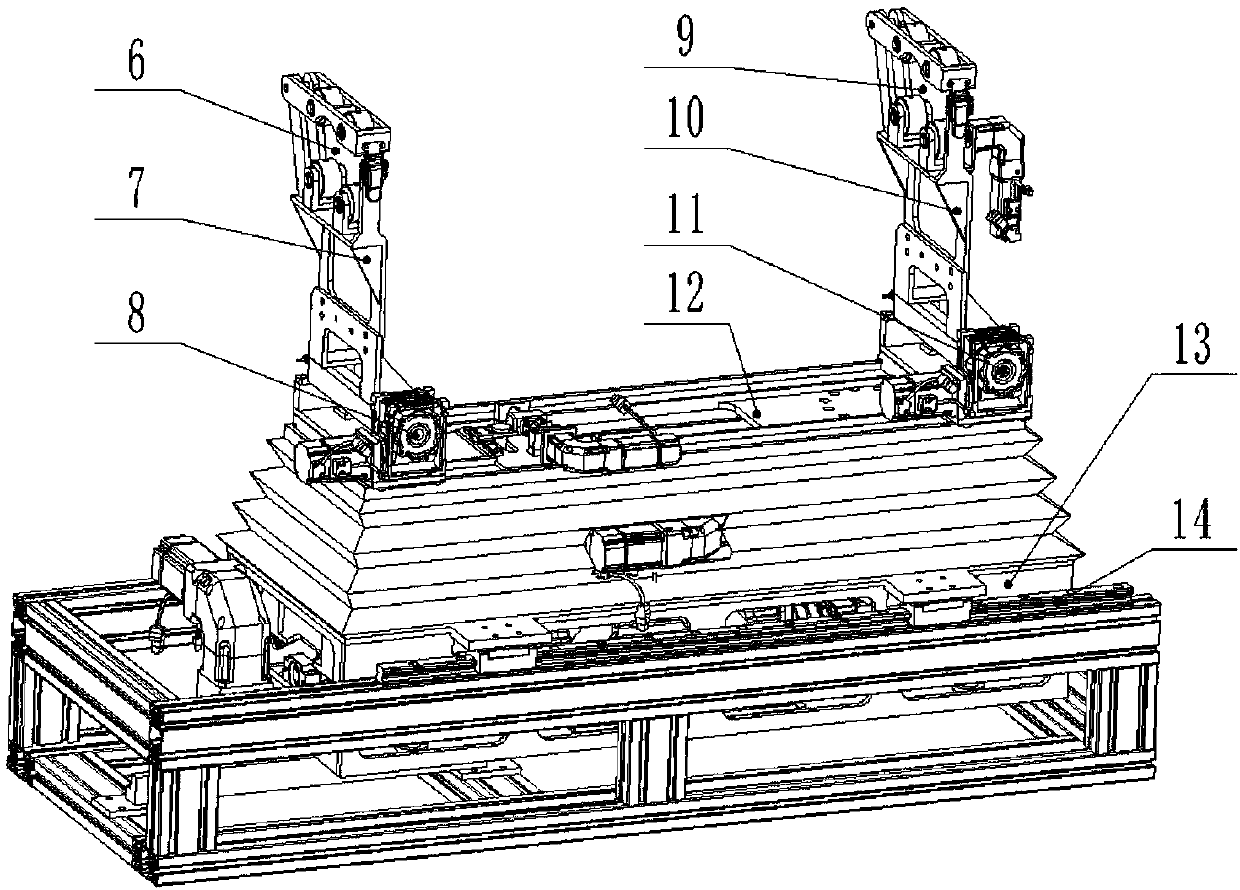

Assembling method for low-pressure turbine shaft-disc assembly of aero-engine

The invention discloses an assembling method for a low-pressure turbine shaft-disc assembly of an aero-engine. The assembling method comprises the following steps that workpieces are installed, the position and the posture of a turbine shaft are adjusted; the turbine shaft butts joint and is pre-installed; an indexable tightening system is fed to a front end operation area; a tightening shaft is tightened; and the indexable tightening system returns back. According to the assembling method for the low-pressure turbine shaft-disc assembly of the aero-engine, an assembly mode that an axis of a low-pressure turbine shaft-disc is horizontal is adopted, the position and the posture of the low-pressure turbine shaft with the large length are adjusted precisely and advantageously in the butt-joint process, centering positioning alignment and end face correct close fitting of the turbine shaft relative to a connecting disc are achieved, and the butt-joint and assembling precision is improved;a turbine shaft position and posture adjusting table is applied, quantitative position and posture adjusting is conducted on the low-pressure turbine shaft through a mechanical way, experiential methods such as traditional manual hanger operating are replaced, manual repeated trial assembly and correction are avoided, the butt-joint efficiency is improved, and assembly consistency requirements ofassemblies are met; and the indexable tightening system is adopted, worker skill requirements and the labor intensity are reduced, and the tightening efficiency is improved.

Owner:DALIAN UNIV OF TECH

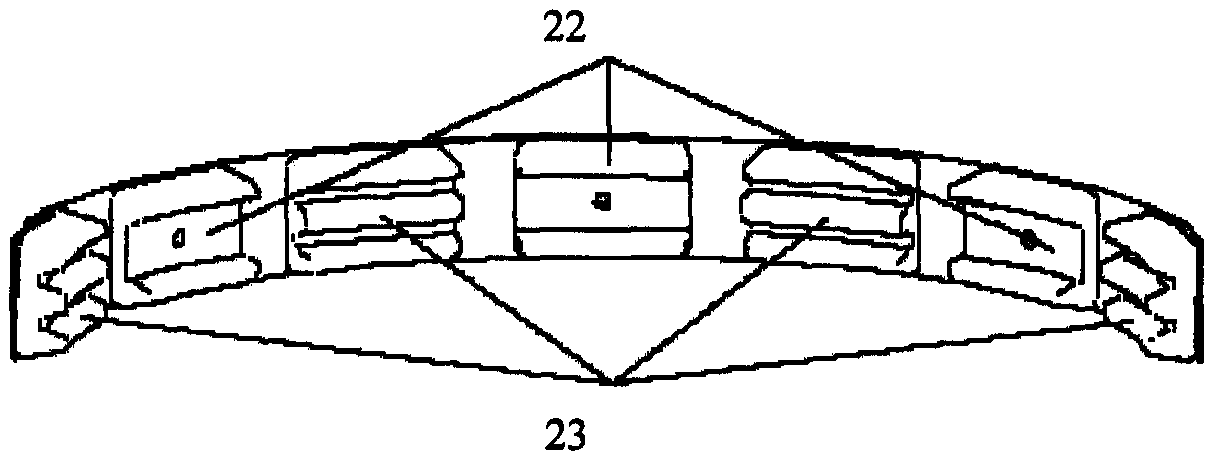

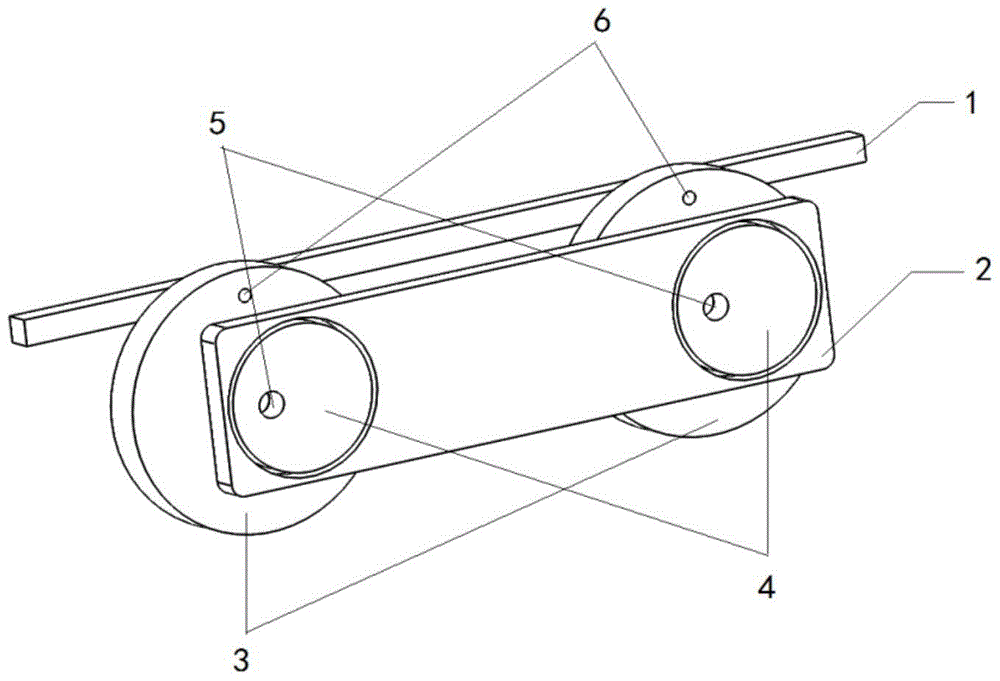

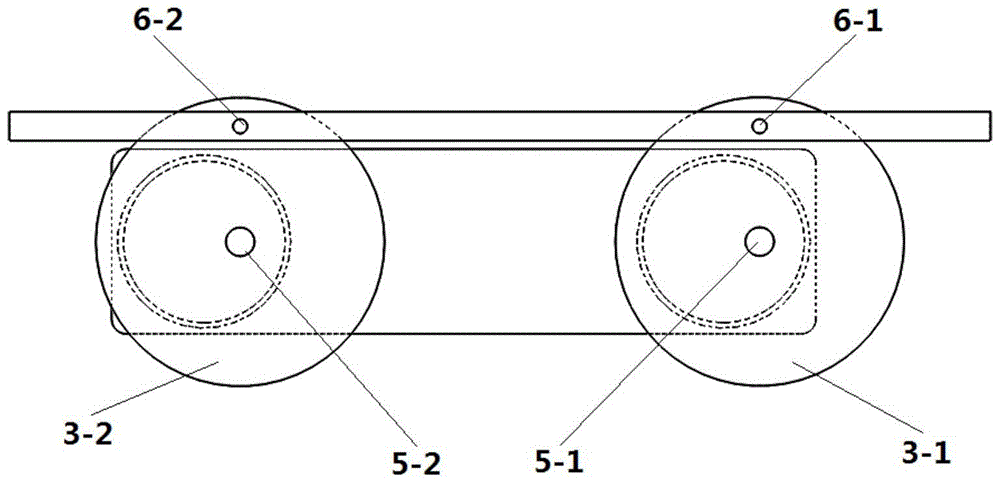

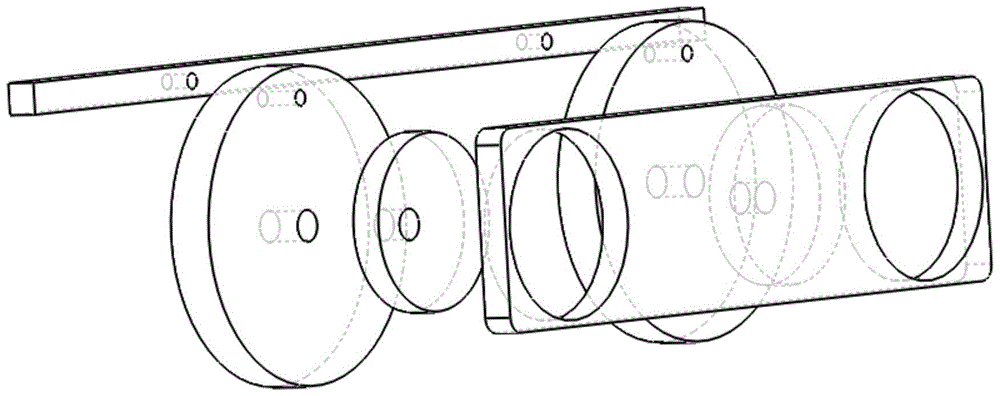

A belt type compression release device for transmission shaft

ActiveCN105659747BReduce loadImprove performanceCosmonautic power supply systemsDrive shaftPress release

The invention discloses a belt-type compression release device for a transmission shaft, which comprises a belt assembly and a storage assembly; the belt assembly is composed of two separated belts (1) butted through belt joints at both ends; two pull rods ( 5) Pass through the pull rod holes and the cutter (4) on the two separation tape heads respectively, connect the two separation tapes (1) bent into a semicircle into a ring, and tighten the drive shaft; each separation tape There are V-shaped clamps (22) and W-shaped clamps (23) staggered and fixed on the inner side of the belt (1); the storage assembly is composed of two sets of the same storage devices, which are symmetrically distributed on both sides of the belt assembly, and fixed on the star (10) superior. The device of the present invention adopts the form of tape + clamping block, which greatly reduces the load on the dual-axis solar wing drive mechanism during satellite launch, protects the dual-axis solar wing drive mechanism from being able to withstand the mechanical environment during launch, and has basically no performance. decline.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

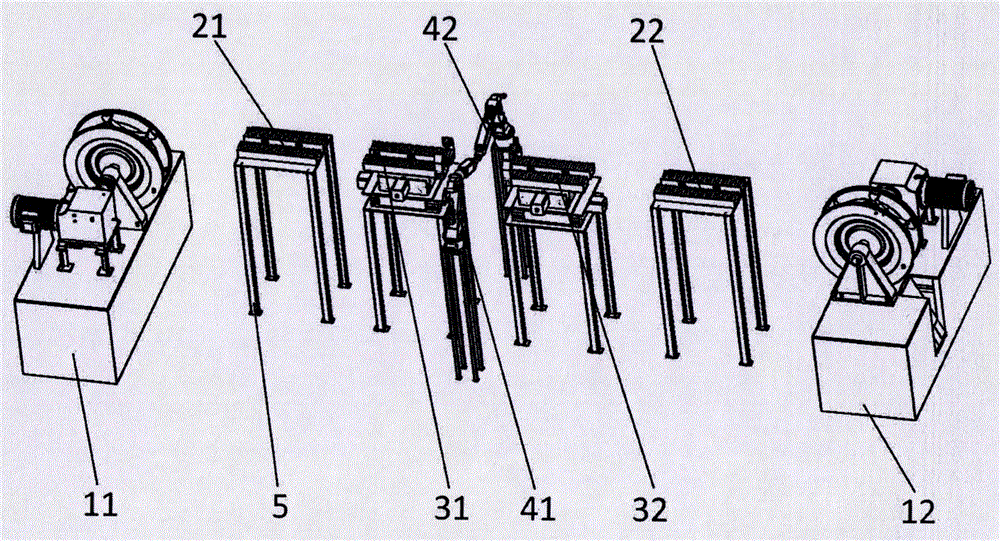

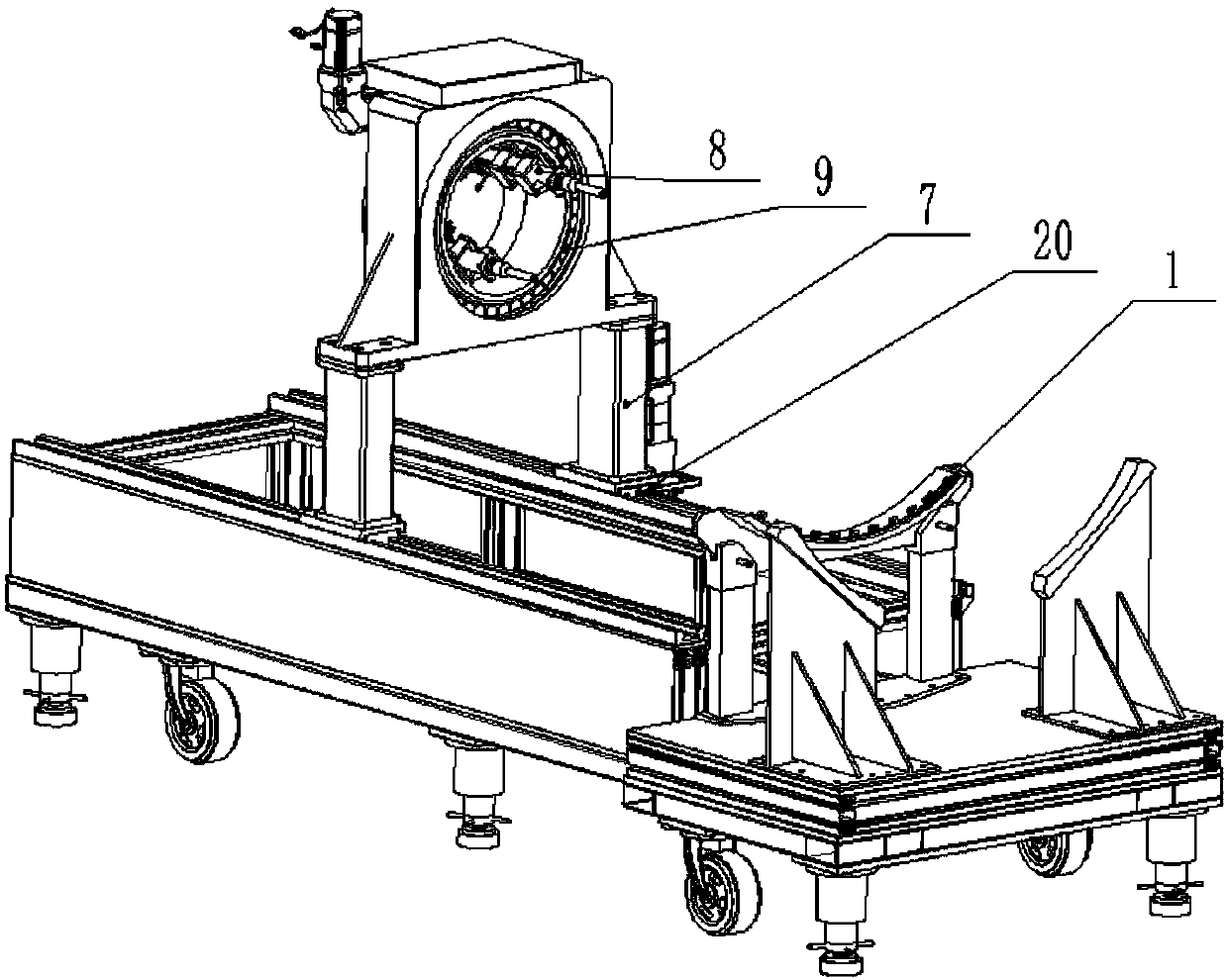

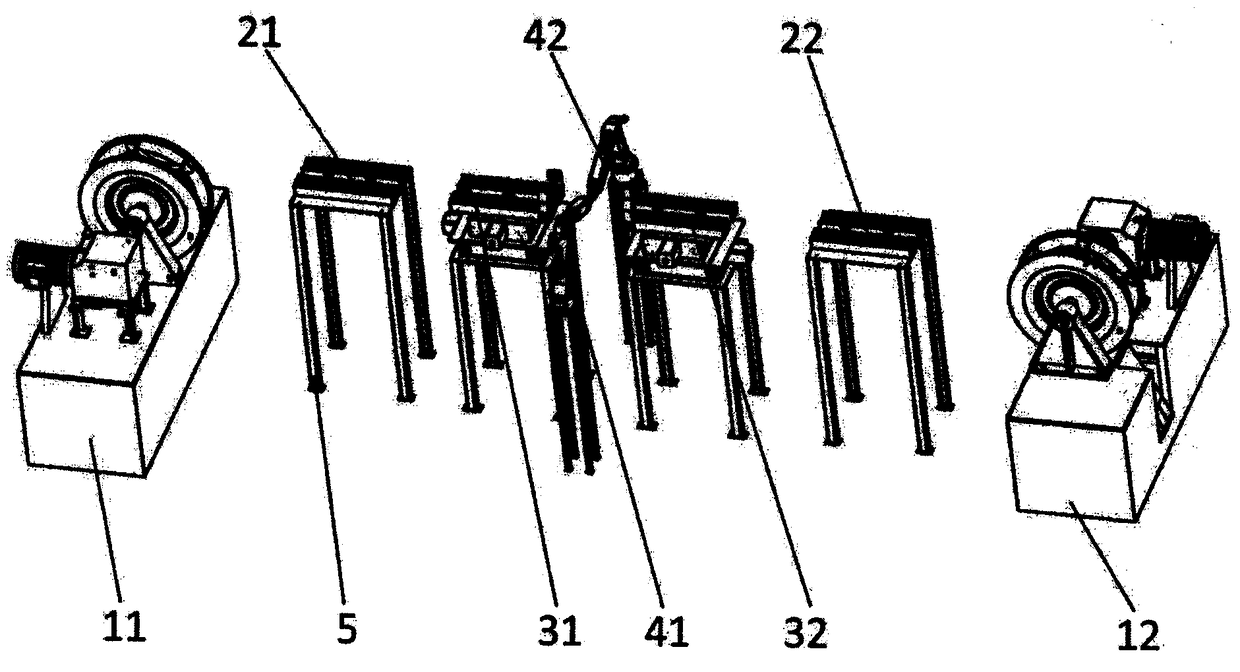

Automatic welding device for anchor chain crosspieces

InactiveCN106624574AResolve positional swapsAchieve 90 degree flipWelding/cutting auxillary devicesAuxillary welding devicesTransfer procedureInterference problem

The invention relates to an automatic welding device for anchor chain crosspieces and is used for solving the automatic welding problem of the anchor chain crosspieces. The automatic welding device comprises traction devices, fixed platforms, movable welding platforms, clamping mechanisms, welding robots and supports, wherein the traction devices are respectively symmetrically arranged at two ends of the automatic welding device and located on two sides of the fixed platforms, the fixed platforms are respectively located on two sides of the movable welding platforms, the opposites sides of the movable welding platforms are provided with the clamping mechanism, the middles of the clamping mechanisms are provided with anchor chain crosspiece welding stations, vertical chain links connected with horizontal chain links in the middle are to-be-welded chain links, and the welding robots are respectively arranged on two sides of the welding stations and used for welding the vertical chain links on the welding stations. The automatic welding device has the advantages that anchor chain conveying stability can be guaranteed, precise anchor chain positioning is guaranteed, the universality of the device is increased, the reverse moving problem of anchor chains and the interference problem of a welding gun and the anchor chains during welding are solved, and the device is applicable to anchor chain conveying and clamping and automatic welding of the anchor chain crosspieces.

Owner:QINGDAO UNIV OF SCI & TECH

Vegetable dehydrator with material clearing devices on lower portion

InactiveCN103404950AResolve Motion InterferenceIncrease stiffnessFood treatmentEngineeringMechanical engineering

The invention provides a vegetable dehydrator with material clearing devices on the lower portion. The vegetable dehydrator is characterized in that a group of conveying devices driven by a transmission device to operate is arranged in each layer of a box body, chains of the conveying device extend inwards to form pin shafts at intervals, chain plates are hung on the pin shafts formed by inward extension of the chains through hanging holes at two ends, and baffles are supported on a guide track to form groove-shaped material channels. An infrared radiation device is arranged above each channel, a material guiding groove is formed in the lower portion of the tail end of each channel, an air inducing port is formed in the upper portion of the lateral wall of each layer of the box body and connected with a fan through an air inducing pipe, poking levers are evenly fixed on a chain wheel end face of each conveying device at the position below each transmission device, a limit rod is arranged between each chain wheel and the inner wall of the box body, an elastic poking plate mechanism is arranged at the chain wheel position of each conveying device at the position below a feeding port, each conveying device is provided with the material clearing devices arranged below an upper groove-shaped material channel and a lower groove-shaped material channel below the feeding port, the feeding port is arranged in the top of the box body, and a discharging port is arranged in the bottom of the box body. The vegetable dehydrator is thorough in material clearing and reliable in working.

Owner:SHANDONG UNIV OF TECH

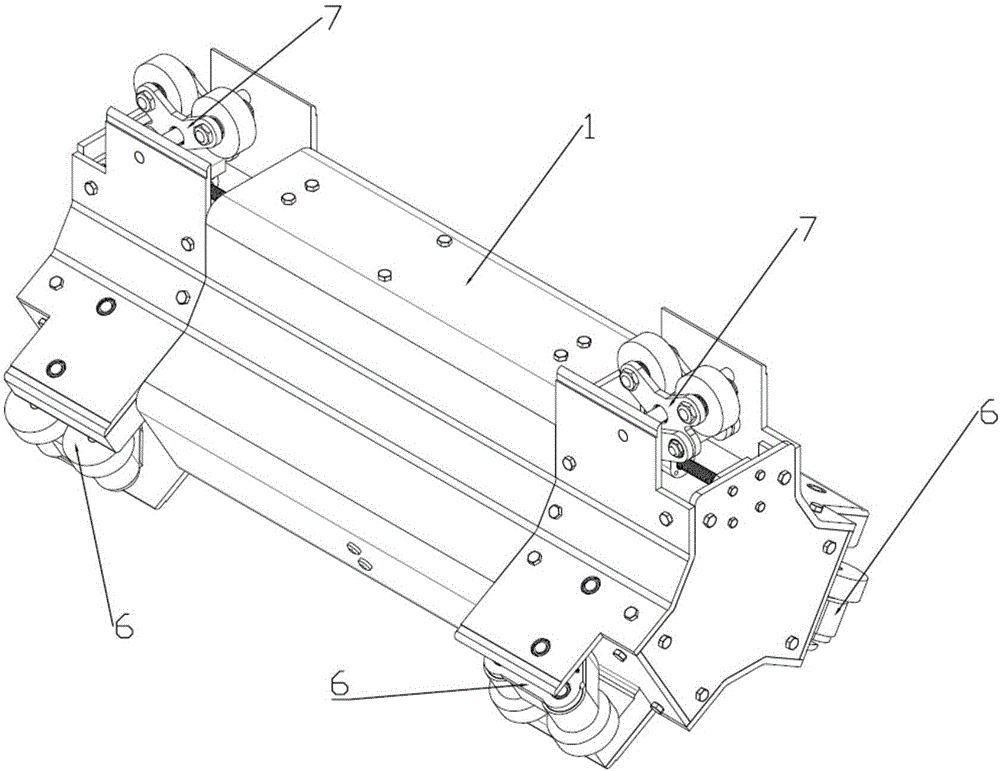

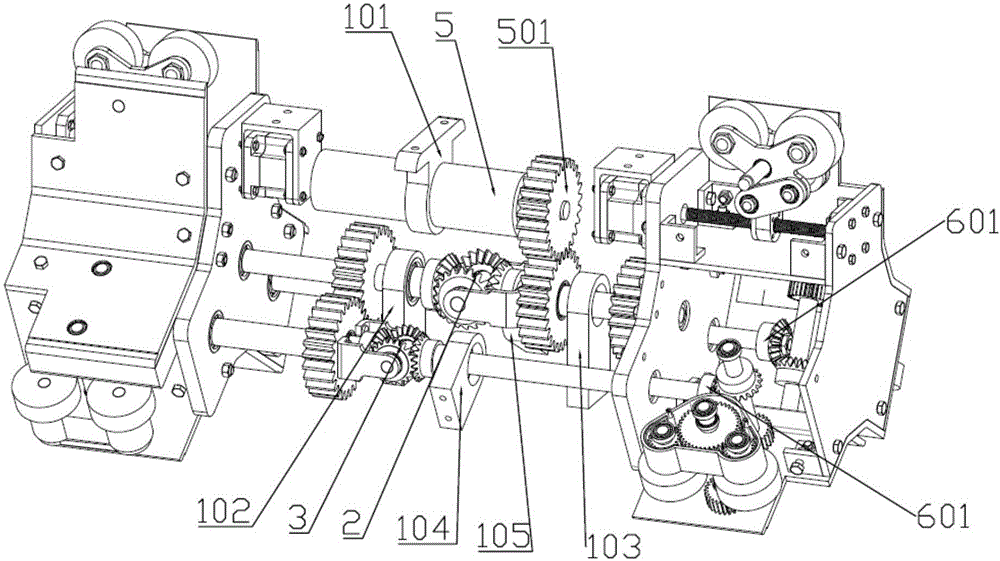

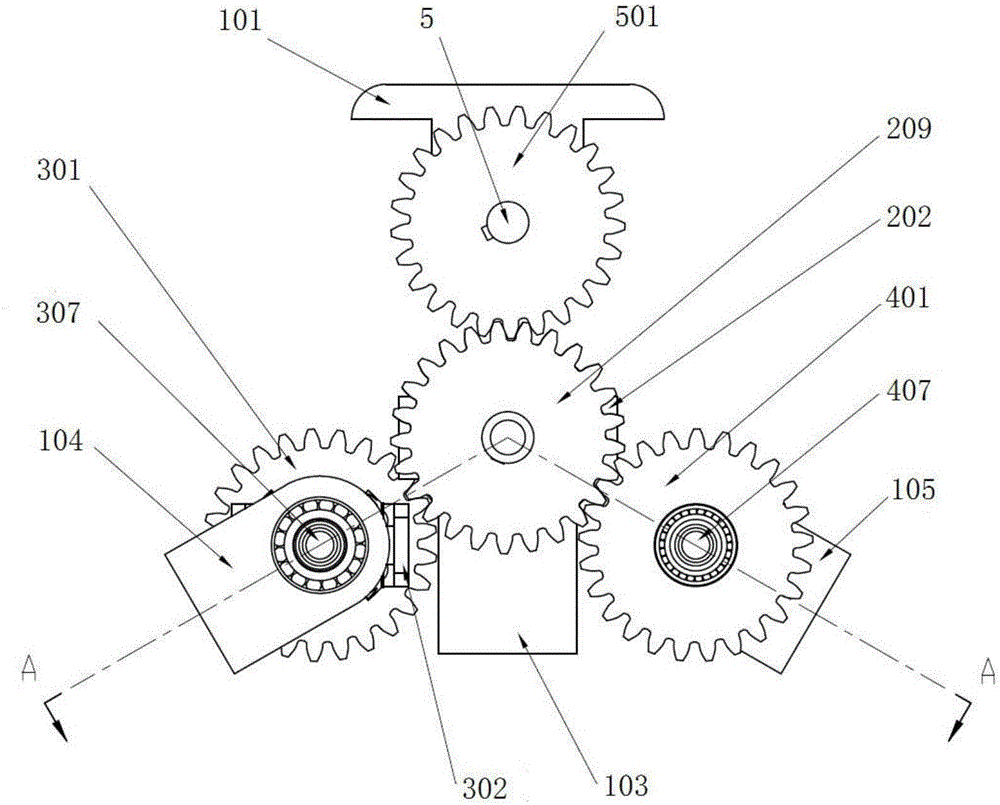

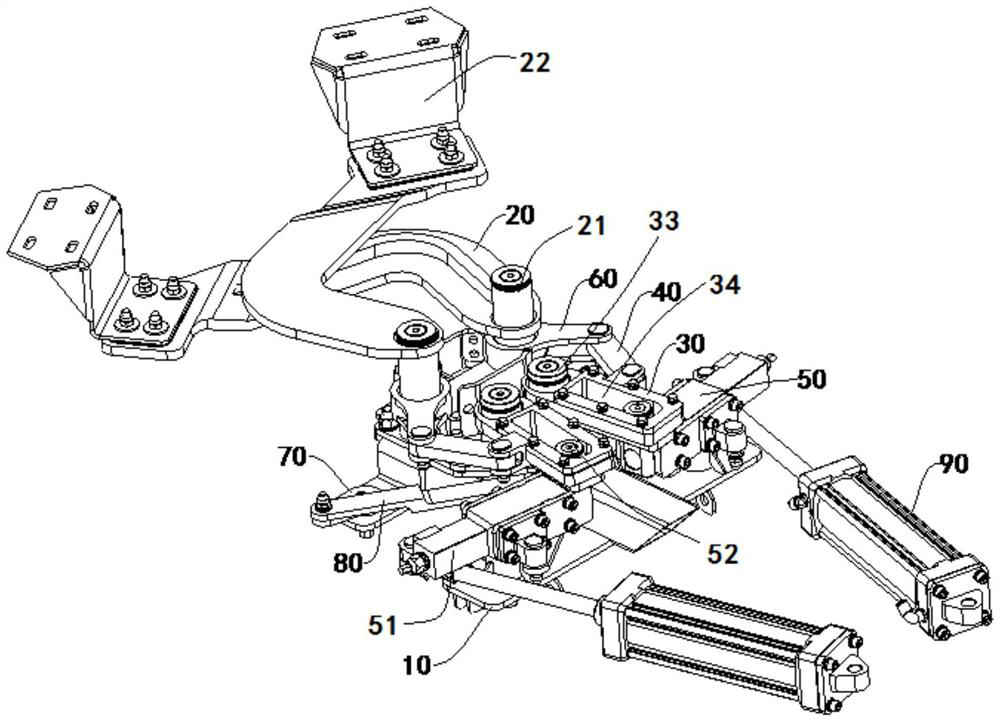

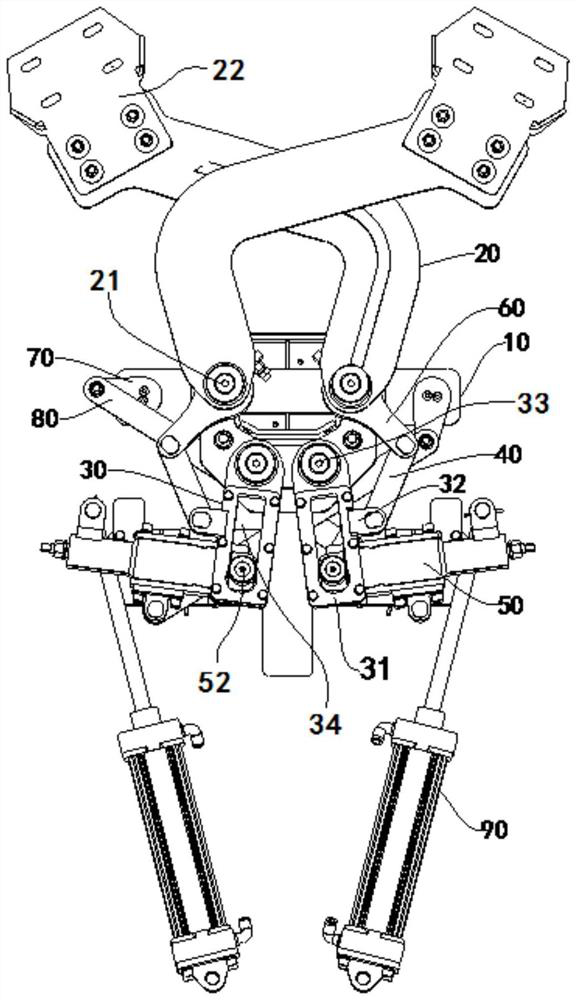

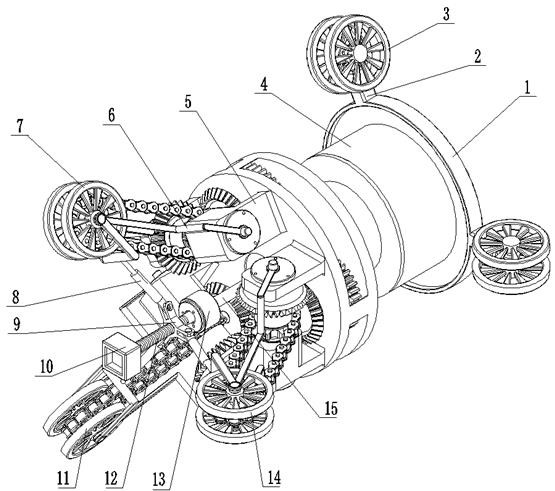

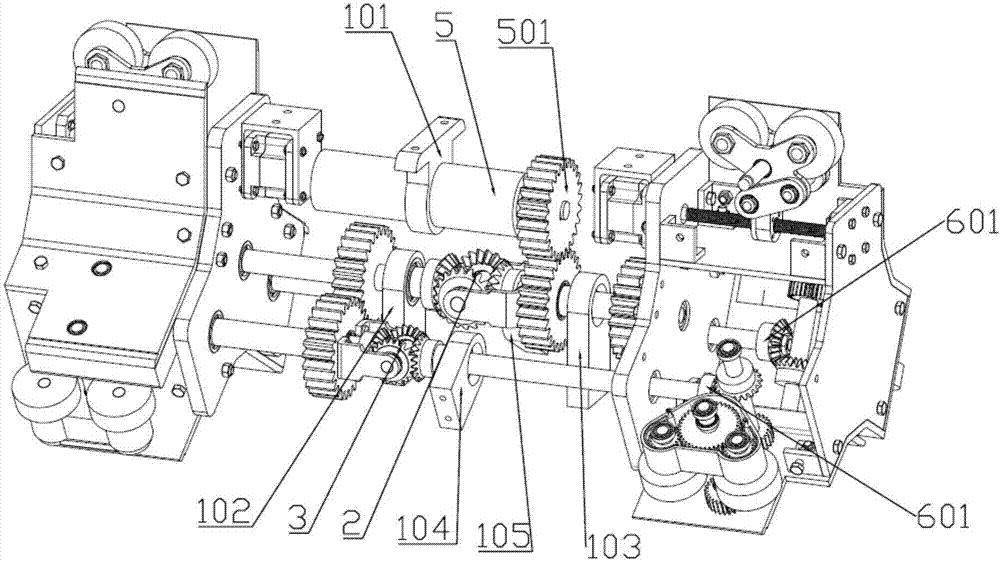

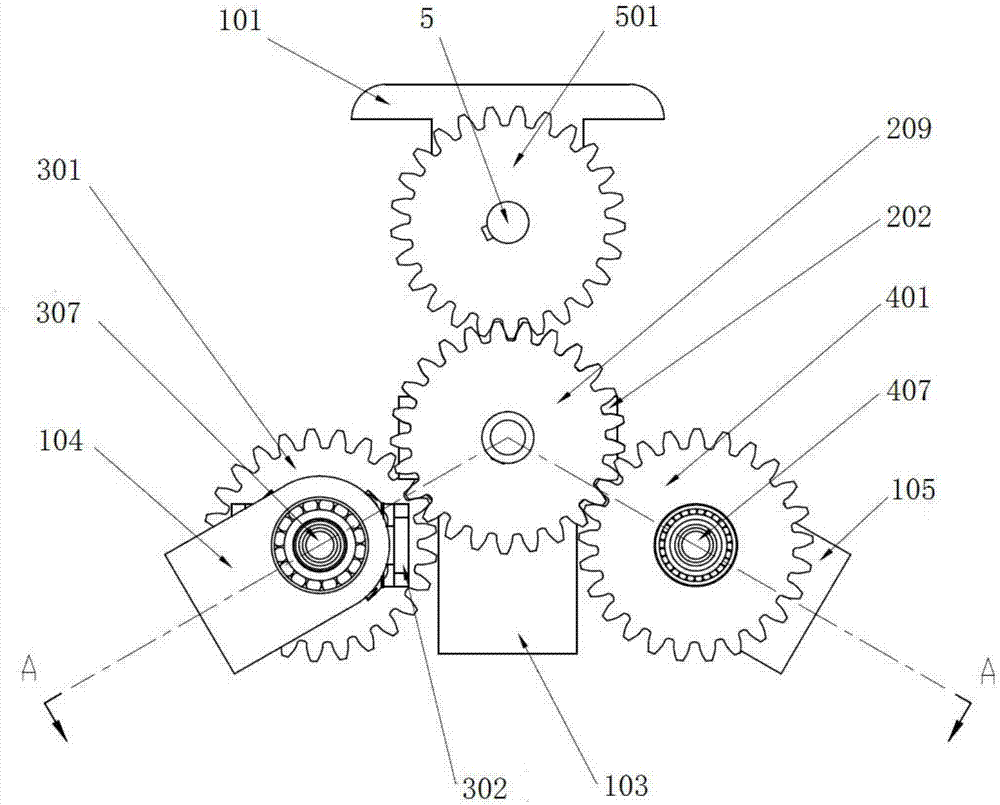

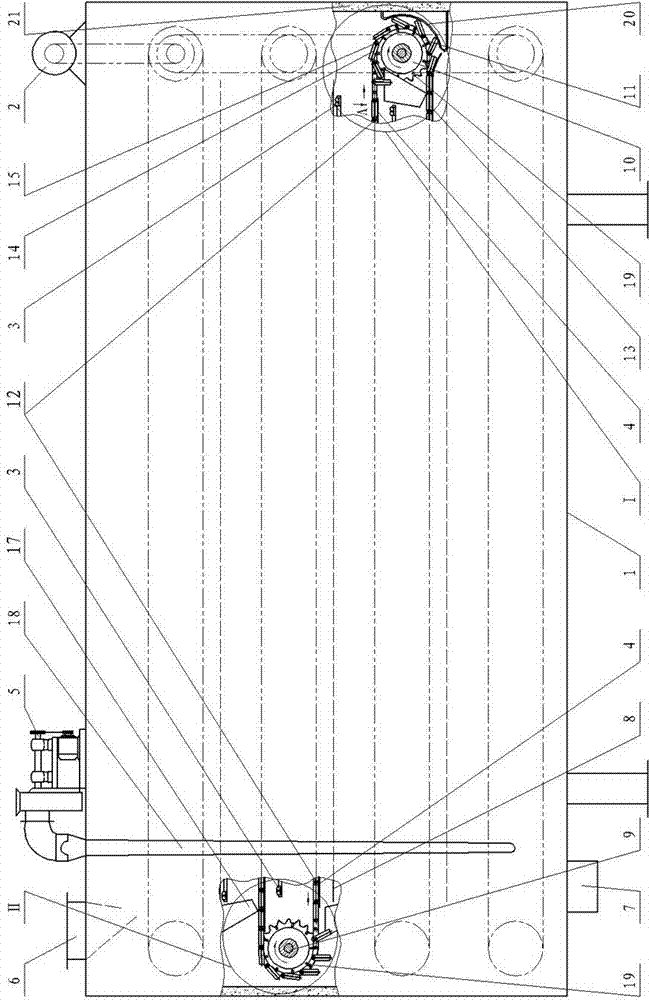

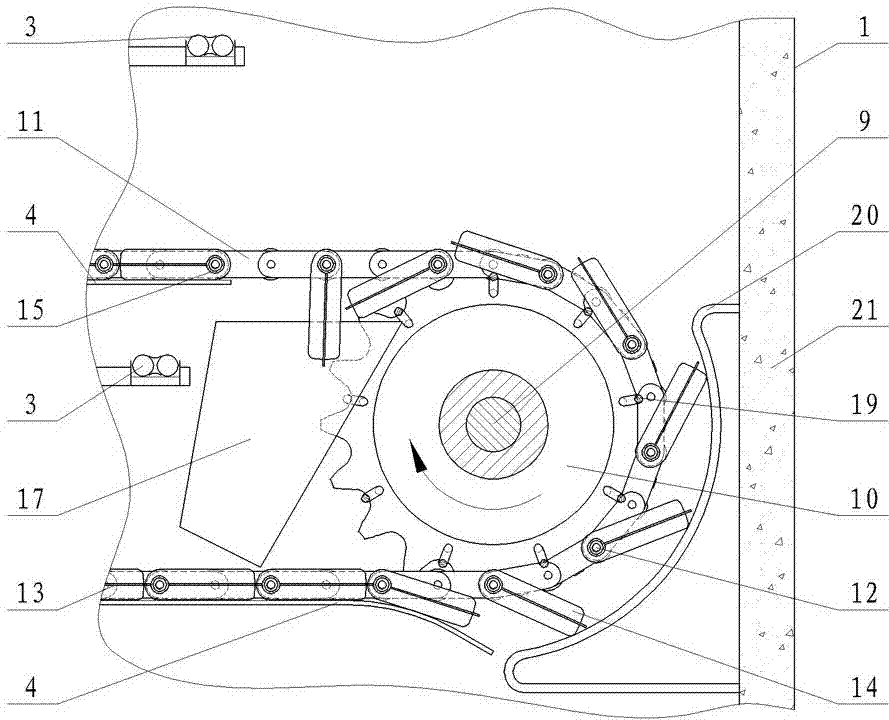

Traction device for wheeled pipeline robot

The invention discloses a traction device for a wheeled pipeline robot. The traction device comprises a housing and a four-axis differential driving device, wherein a power output bevel gear for driving a driving wheel transmission mechanism is arranged on each of four output ends of the four-axis differential driving device; a pipeline diameter adapting mechanism is arranged above the center between two front driving wheel transmission mechanisms, and another pipeline diameter adapting mechanism is arranged above the center between two rear driving wheel transmission mechanisms. According to the traction device for the wheeled pipeline robot, the rotating speed of four axes can be self-adaptively adjusted according to related running conditions in a pipeline; whether in a transition state or a turning state, the four driving wheels can perform differential movement during turning, thus the problem of movement interference on the traction device of a pipeline robot in obstacle crossing or turning can be solved, the driving efficiency can be improved, the abrasion of a driving device can be reduced, and as a result, the service life of the traction device can be prolonged; in addition, the traction device has the advantages of being high in obstacle crossing performance and pipe diameter adapting performance, high in effective driving power, high in structure symmetry, and wide in applicable scope.

Owner:TIANJIN UNIV

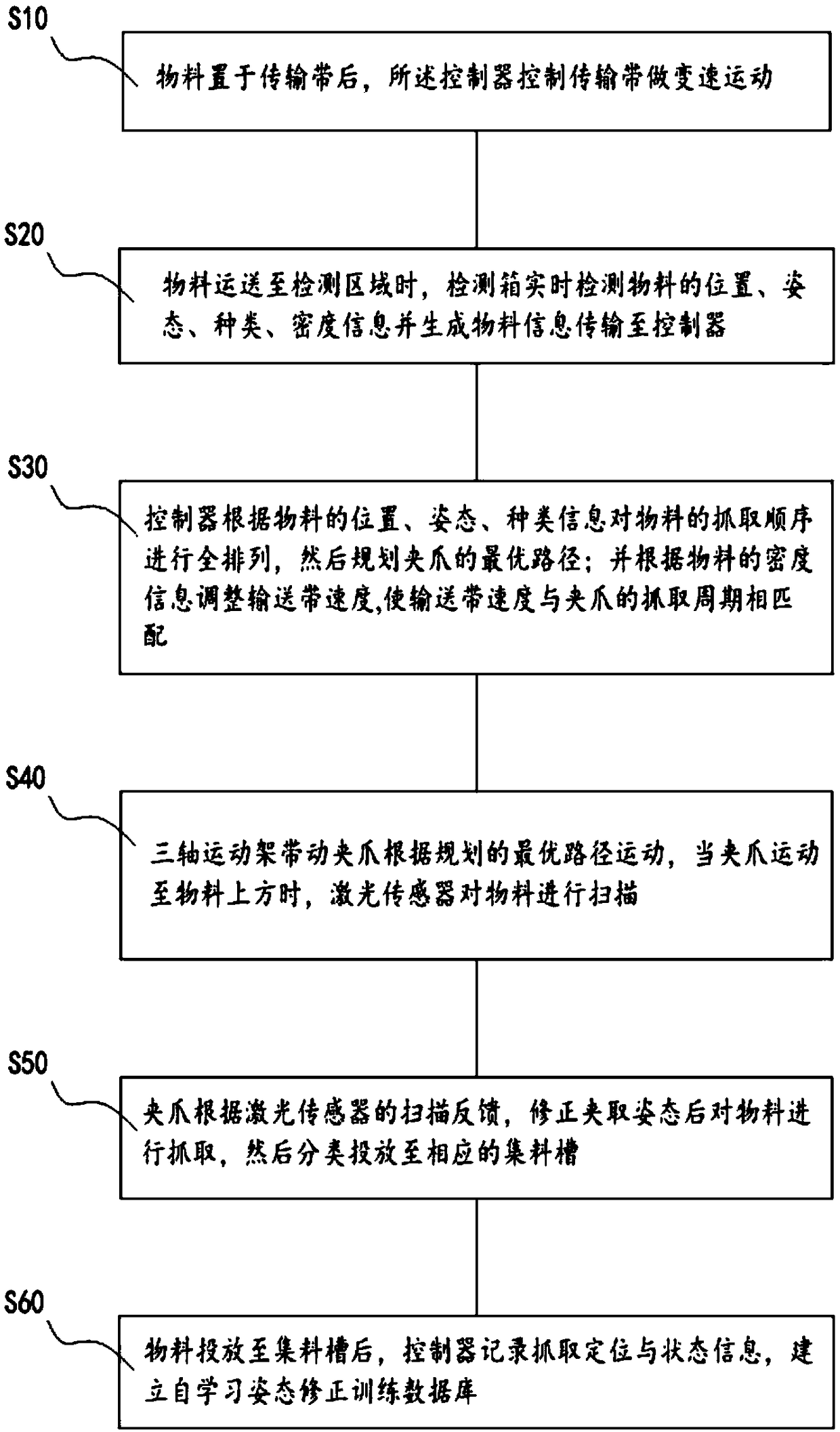

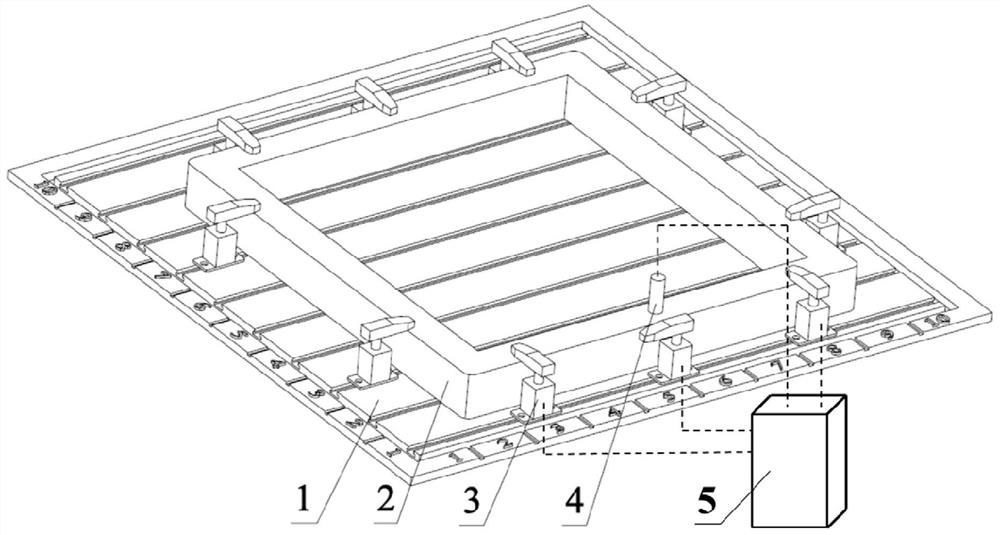

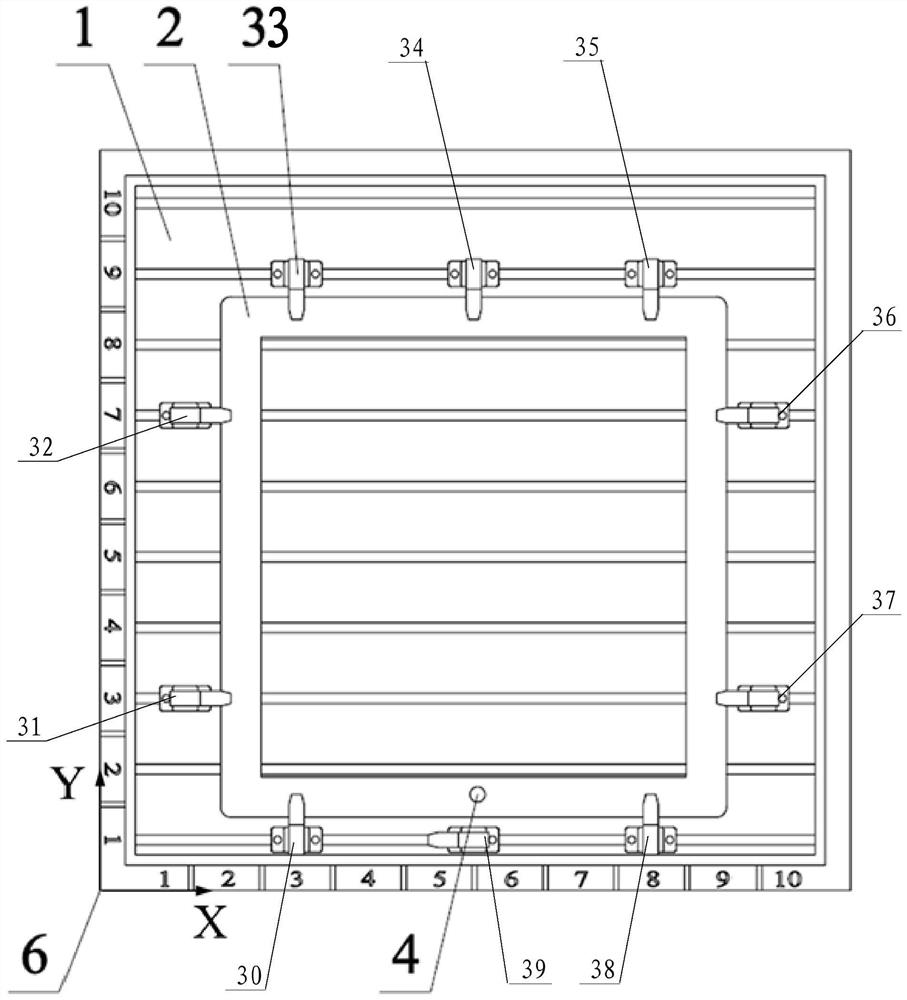

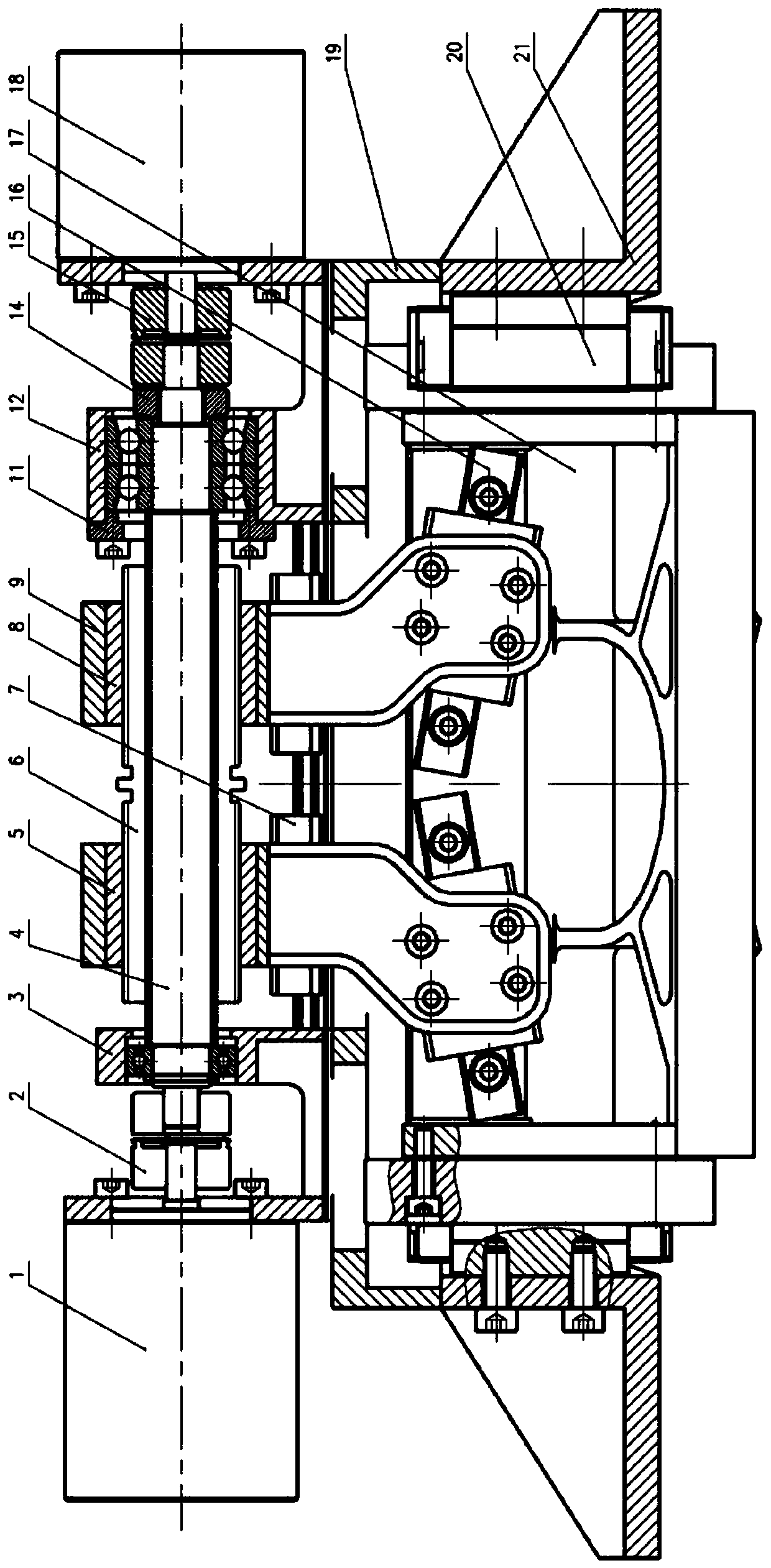

Solid waste sorting robot equipment and motion control method thereof

PendingCN109176522AImprove crawling efficiencyImprove grip stabilityProgramme-controlled manipulatorSimulationLaser sensor

The invention provides solid waste sorting robot equipment and a motion control method thereof. The solid waste sorting robot equipment comprises a detection box, a controller, a triaxial motion rack,a clamping claw, a laser sensor and collection troughs. According to the solid waste sorting robot equipment and the motion control method thereof, the detection box is used for detecting the kinds and pose information of materials, movement of the clamping claw is achieved through the triaxial motion rack, the laser sensor is used for feeding back and grabbing locating information to achieve self-learning pose correction, and the aim of accurate grabbing is achieved. According to the solid waste sorting robot equipment, the materials are grabbed more smoothly, motion interference is small, and the grabbing efficiency is high.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL +1

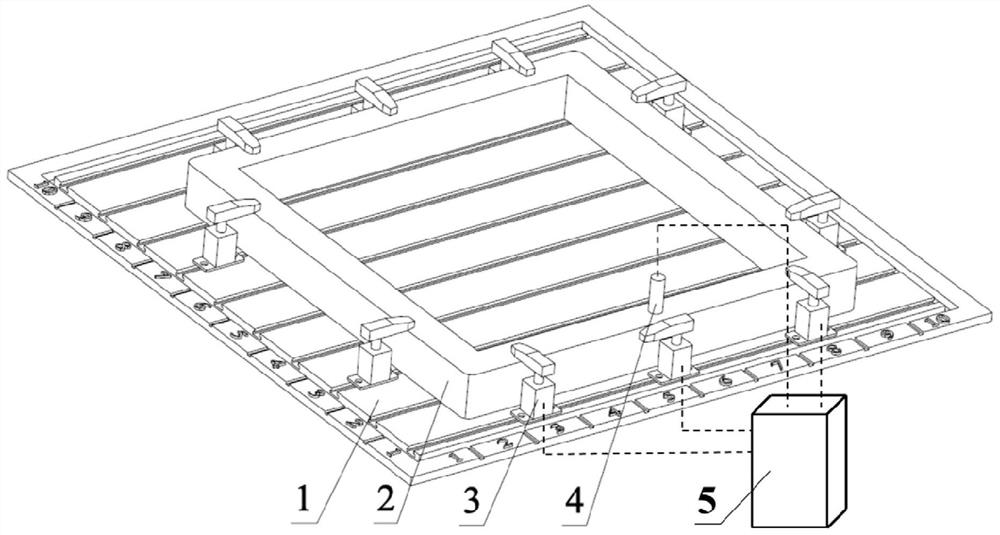

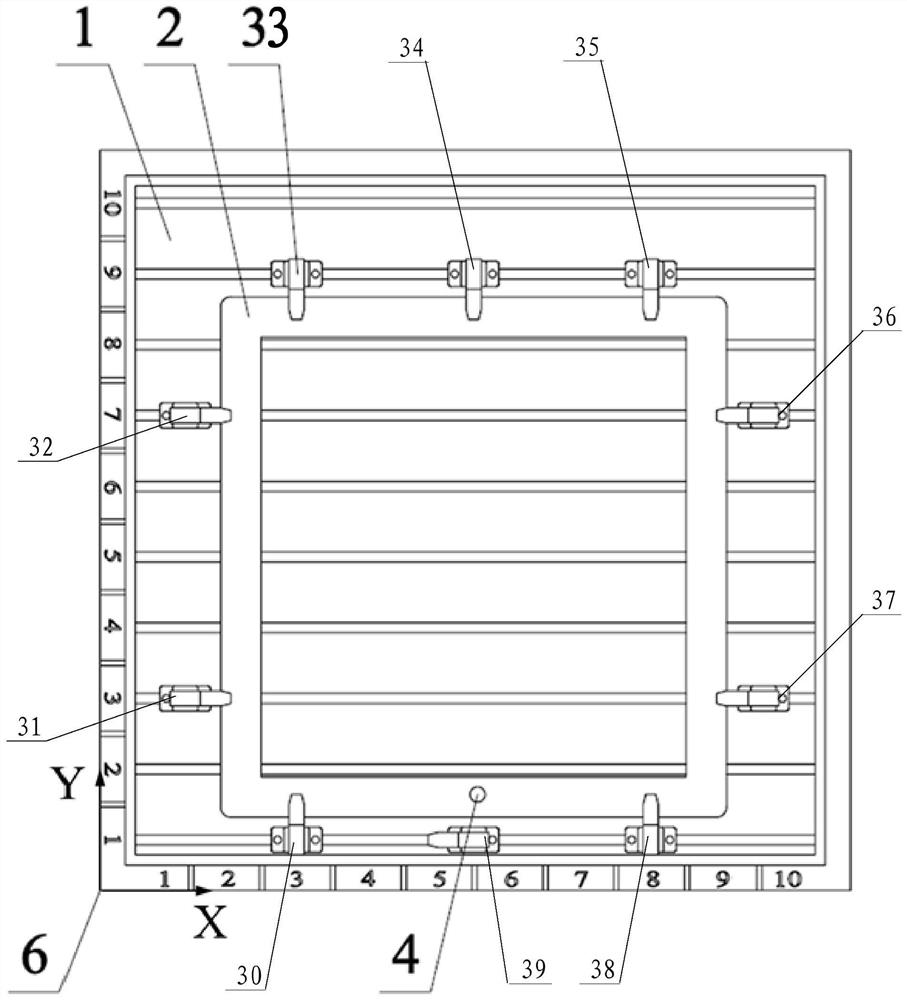

Automatic tool avoiding method of clamping mechanism

ActiveCN111761388AImprove reliabilityResolve Motion InterferencePositioning apparatusMetal-working holdersControl engineeringProcess engineering

The invention discloses an automatic tool avoiding method of a clamping mechanism. The method is characterized in that a flexible tool system with an automatic avoiding function is built by taking anexisting machine tool and numerical control system as a platform; then an existing mounting platform is subjected to area division, coordinates of the clamping mechanism under the current mounting platform are calibrated and input into the system, and a workpiece is clamped through air pressure; in the machining process, the numerical control system reads the coordinate position of a tool, and when the tool reaches the coordinate position of the clamping mechanism, the clamping mechanism automatically releases the workpiece and avoids the tool; and after the tool leaves the coordinate positionof the clamping mechanism, the clamping mechanism returns to the original position and clamps the workpiece again. The method solves the problem of motion interference generated by the tool and the clamping mechanism, is high in reliability and easy to operate, and improves the machining efficiency.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

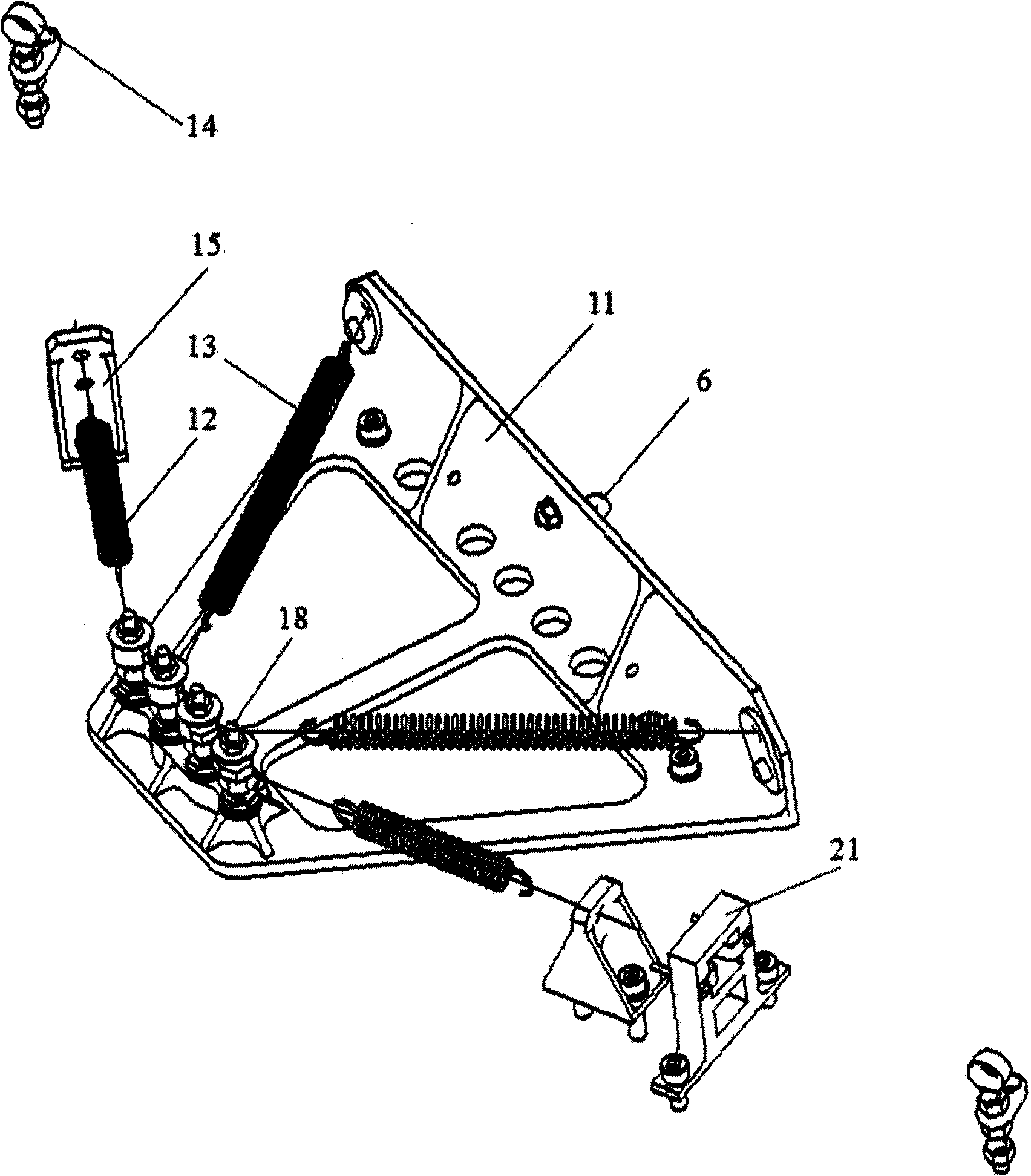

Uniform force focusing mechanism driven by inclined guide rail

ActiveCN111474661AGuaranteed support rigidityResolve Motion InterferenceMountingsEngineeringSupport point

The invention discloses a uniform force focusing mechanism driven by an inclined guide rail. The uniform force focusing mechanism comprises a focusing mounting base, supports slidably connected to thetwo sides of the focusing mounting base through vertical linear guide rails, and bases assembled and fixed to the upper ends of the supports. A horizontal focusing assembly is mounted at the upper part of the bases; the horizontal focusing assembly is provided with a spline shaft and a hollow lead screw which are matched through a sliding pair. The hollow lead screw is matched with the spline shaft through a sliding pair so as to move in the axial direction of the spline shaft, and the hollow lead screw is in transmission connection with a wedge angle sliding block mechanism so as to drive the wedge angle sliding block to slide along the inclined guide rail and drive the focusing mounting base to move along the vertical linear guide rail to adjust the vertical position of an optical element. The hollow lead screw can horizontally move on the spline shaft so that motion interference caused by manufacturing and mounting errors of the left wedge angle sliding block and the right wedge angle sliding block can be compensated, the problem of multi-supporting-point motion interference is solved on the premise that the supporting rigidity is guaranteed and the part machining and assembling difficulty is lowered.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

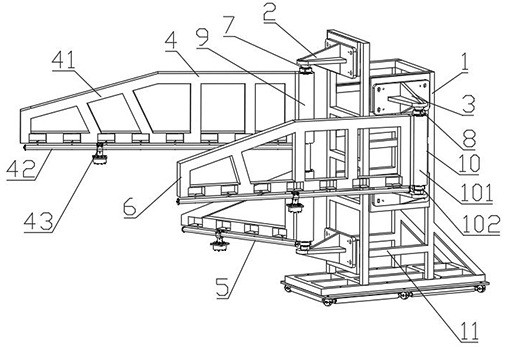

Opening and closing mechanism and railway vehicle

ActiveCN111976761ALarge working spaceResolve Motion InterferenceRailway transportAxle-box lubricationControl theoryMechanical engineering

The invention provides an opening and closing mechanism and a railway vehicle. The opening and closing mechanism comprises a first side opening and closing assembly. The first side opening and closingassembly comprises a supporting base body, a rotating arm and a driving arm; the rotating arm is rotationally connected with the supporting base body; the driving arm is rotationally connected with the supporting base body; the rotation axis, relative to the supporting base body, of the rotating arm and the rotation axis, relative to the supporting base body, of the driving arm are arranged at intervals; and the driving arm is connected with the rotating arm through a motion transmission mechanism, so that the driving arm can rotate to drive the rotating arm to rotate. The opening and closingmechanism can be used for a railway vehicle to control opening and closing of a vehicle fairing. According to the opening and closing mechanism, a motion driving structure of a rotating shaft openingand closing mechanism is improved, the rotation axis, relative to the supporting base body, of the rotating arm and the rotation axis, relative to the supporting base body, of a rotating arm drivingstructure are designed to be of a non-coaxial structure, rotating arm driving action components are separated from the rotating arm, the action space of the rotating arm driving structure is increased, and the problem of motion interference among components in the opening and closing process of the fairing can be effectively solved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

An assembly device for an aeroengine low-pressure turbine shaft-disk assembly

The invention discloses an assembly device for a low-pressure turbine shaft-disc assembly of an aero-engine. The assembly device comprises a turbine clamp, a turbine shaft posture adjustment and buttjoint system, a transposition type tightening system and a lathe bed. According to the assembly device, the turbine clamp realizes horizontal installation of the axis of a turbine unit body; the turbine shaft attitude adjustment and butt joint system realizes parallel calibration movement and concentric calibration motion of the contact end surface of a turbine shaft relative to a connecting discand realizes feeding butt joint motion of the turbine shaft relative to the connecting disc; the transposition type tightening system realizes transposition of a tightening shaft to a tightening station corresponding to bolts distributed circumferentially. The assembly device has the advantages that a horizontal installation mode of the axis of a low-pressure turbine shaft-disc is adopted, so thatcentering positioning calibration of the turbine shaft relative to the connecting disc can be realized, the end surfaces can be accurately and tightly attached, and therefore the butt joint assembling precision can be improved; and the transposition type tightening system is adopted, the bolt pre-tightening force deviation can be effectively controlled by using the tightening shaft, and thereforethe tightening quality can be ensured; and a gantry type mobile station is adopted, and therefore the problem of motion interference in the feeding process of the tightening system can be solved.

Owner:DALIAN UNIV OF TECH

An automatic welding device for anchor chain crosspieces

InactiveCN106624574BResolve positional swapsAchieve 90 degree flipWelding/cutting auxillary devicesAuxillary welding devicesTransfer procedureInterference problem

The invention relates to an automatic welding device for anchor chain crosspieces and is used for solving the automatic welding problem of the anchor chain crosspieces. The automatic welding device comprises traction devices, fixed platforms, movable welding platforms, clamping mechanisms, welding robots and supports, wherein the traction devices are respectively symmetrically arranged at two ends of the automatic welding device and located on two sides of the fixed platforms, the fixed platforms are respectively located on two sides of the movable welding platforms, the opposites sides of the movable welding platforms are provided with the clamping mechanism, the middles of the clamping mechanisms are provided with anchor chain crosspiece welding stations, vertical chain links connected with horizontal chain links in the middle are to-be-welded chain links, and the welding robots are respectively arranged on two sides of the welding stations and used for welding the vertical chain links on the welding stations. The automatic welding device has the advantages that anchor chain conveying stability can be guaranteed, precise anchor chain positioning is guaranteed, the universality of the device is increased, the reverse moving problem of anchor chains and the interference problem of a welding gun and the anchor chains during welding are solved, and the device is applicable to anchor chain conveying and clamping and automatic welding of the anchor chain crosspieces.

Owner:QINGDAO UNIV OF SCI & TECH

Self-adaptive intelligent pipeline robot and intermittent circulation driving method

ActiveCN114576464AResolve Motion InterferenceSimplify complexityElectric energy managementPigs/molesSelf adaptiveAuto regulation

According to the self-adaptive intelligent pipeline robot and the intermittent circulation driving method, rear walking wheels are arranged on the outer side wall of a base, a mounting frame and a driving mechanism are arranged on the base, the driving mechanism is located in the mounting frame, a main transmission shaft is arranged on a power output shaft of the driving mechanism, and an intelligent detection sensing unit is arranged at the end of the main transmission shaft; three supports which are distributed at 120 degrees are arranged on the front side of the mounting frame, driving wheel carriers are arranged on the three supports, driving wheels are arranged at the ends of the driving wheel carriers, and the main transmission shaft is connected with the three driving wheels through a transmission mechanism; and the intelligent detection sensing unit controls the driving mechanism to decelerate according to a detection signal, and meanwhile, the three driving wheels generate differential speed to pass through the curve by applying an intermittent circulation driving method. The working radius can be automatically adjusted, motion interference does not exist when the device passes through a curve, and the device has the advantages of being small in size, light in weight and high in working efficiency.

Owner:XI'AN PETROLEUM UNIVERSITY

Double-sided mode disc air conditioner control mechanism

PendingCN111993859AResolve Motion InterferenceSolve the problem of too many transmission times and reduced accuracyAir-treating devicesVehicle heating/cooling devicesPhysicsAutomotive air conditioning

The invention relates to the technical field of automobile air conditioners and discloses a double-sided mode disc air conditioner control mechanism. An air distribution shell assembly is included. Three air doors are rotatably mounted in the air distribution shell assembly through air door shafts; a mode disc is mounted on one side of a shell of the air distribution shell assembly; a face blowingmode track groove and a defrosting mode track groove are formed in the outward side of the mode disc; a foot blowing mode track groove is formed in the inward side of the mode disc; and a swing arm is connected to the air door shafts, the end of the other end of the swing arm extends into the track groove, a foot blowing air door transition swing arm driving the foot blowing air door swing arm torotate around the air door shaft of the foot blowing air door is arranged at the other end of the foot blowing air door swing arm, and the other end of the foot blowing air door transition swing armextends into the foot blowing mode track groove. According to the double-sided mode disc air conditioner control mechanism, problems that three track lines of face blowing, foot blowing and defrostingcannot be arranged on the same side of one mode disc due to space limitation is effectively solved, accurate switching control over all modes can be achieved, and a requirement for comfort of a wholevehicle is met.

Owner:DONGFENG BEHR THERMAL SYST

Vegetable dehydrator with fixed material clearers below

The invention provides a vegetable dehydrator with fixed material clearers below. The vegetable dehydrator is characterized in that each layer of box body is provided a set of conveying devices driven by a transmission device, each chain the each conveying device is provided with a pin extending to the inner side, the pins are disposed at intervals, two ends of a chain plate are hung on the pins, a retaining plate is supported on a guide rail to form groove-shaped material passages, an infrared radiating device is disposed above each passage, a guide groove is formed below the tail end of each passage, each layer of box body is provided with an air guide port and connected with a fan through an air guide pipe, a shifting rod is fixed on the end face of each sprocket, located below the transmission device, of each conveying device, a limit rod is disposed between each sprocket and the inner wall of each box body, each sprocket, below a feed inlet, of each conveying device is provided with an elastic shifting board mechanism, the fixed material clearer is disposed below each of the upper groove-shaped material passage and the lower groove-shaped material passage, located below the feed inlet, of each conveying device, the feed inlet is formed at the top of each box body, and a discharge outlet is formed at the bottom of each box body. The vegetable dehydrator is simple in structure and thorough in material clearing.

Owner:SHANDONG UNIV OF TECH

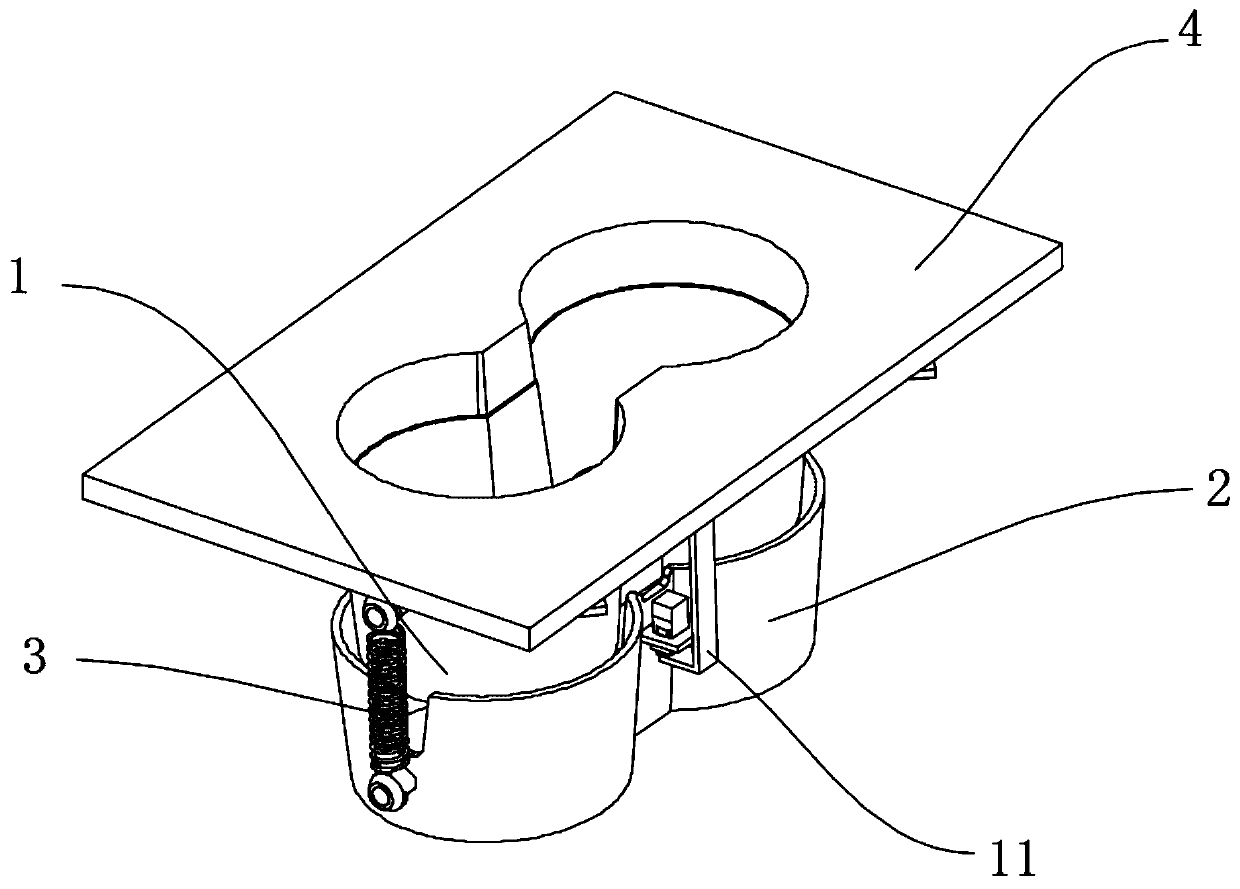

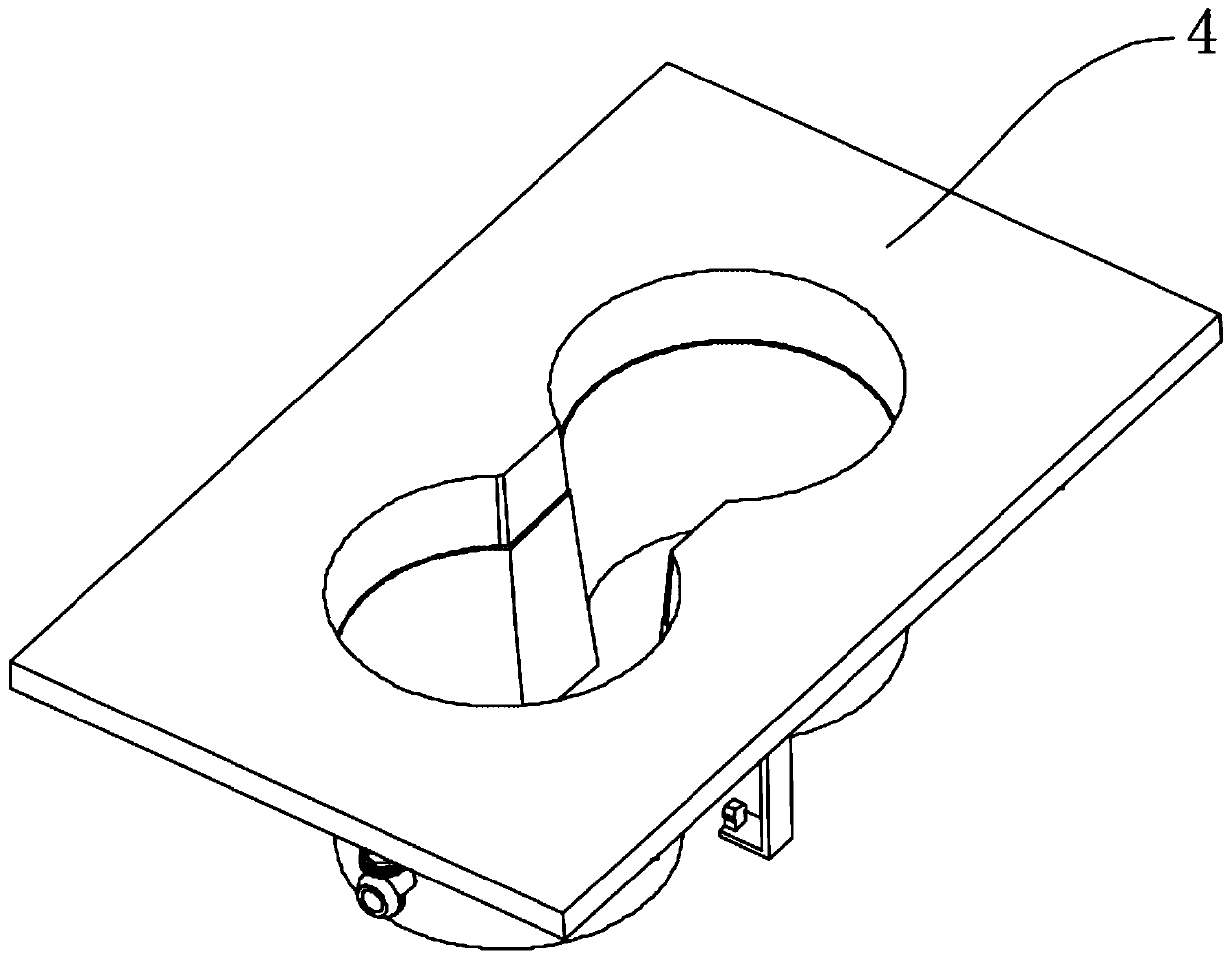

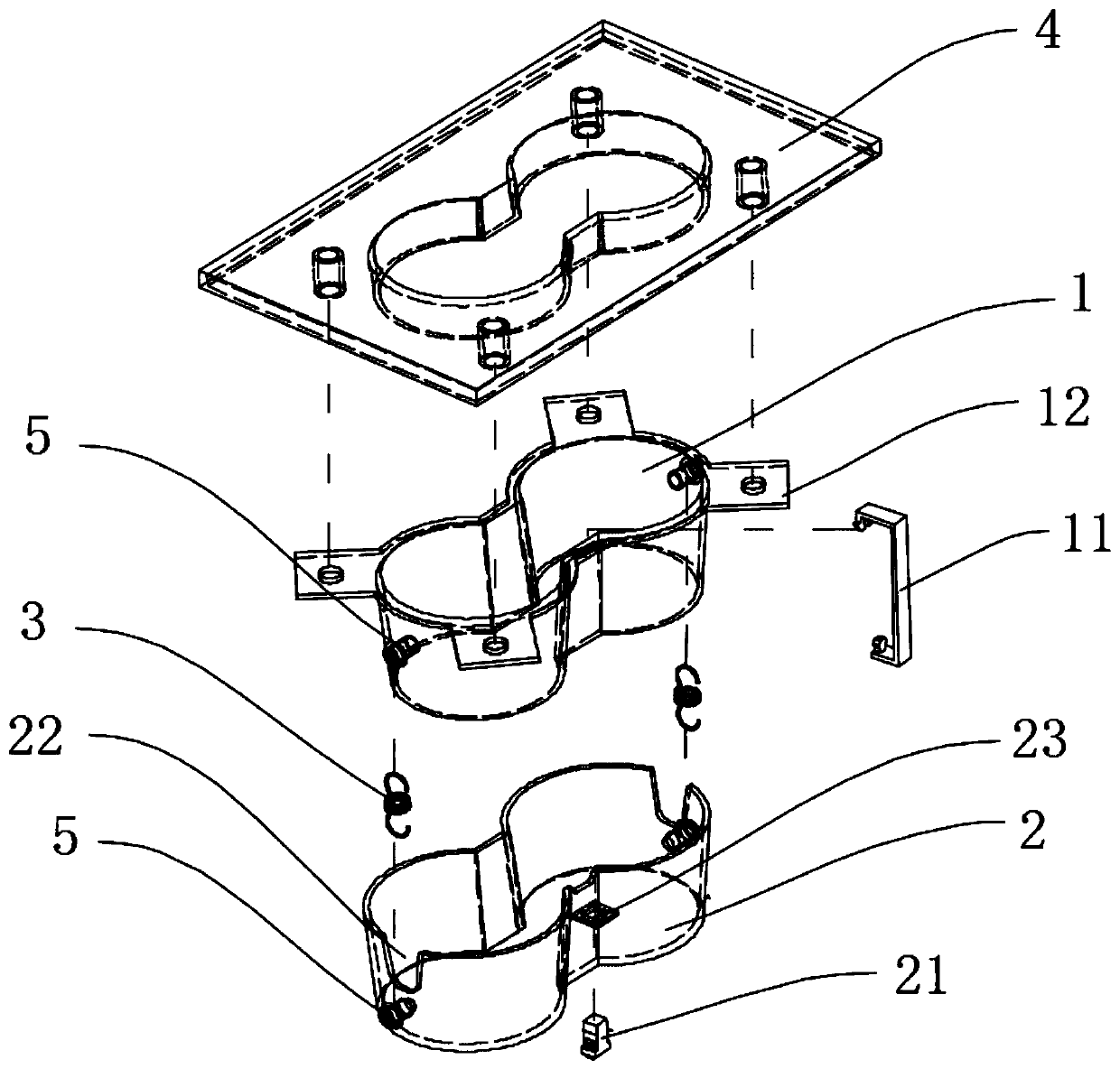

Cup holder structure

InactiveCN109835237AControl placement heightResolve Motion InterferenceVehicle arrangementsEngineeringMechanical engineering

The invention provides a cup holder structure, and relates to the technical field of automobiles. The cup holder structure comprises an upper cup holder body and a lower cup holder body, and the sizeof the lower cup holder body is larger than that of the upper cup holder body, so that the lower cup holder body is arranged on the outer side of the upper cup holder body in a sleeving mode; the upper cup holder body is provided with a cup holder spring bolt, the lower cup holder body is provided with a corresponding cup holder lock catch, and elastic pieces are arranged on the outer walls of theupper cup holder body and the lower cup holder body, so that the lower cup holder body moves up and down or is locked relative to the upper cup holder body. According to the cup holder structure, theheight of the bottom of the cup holder can be adjusted so as to solve the problem of movement interference between a gear shifting arm and the water cup, and the cup holder structure has the advantages of being simple in structure, low in cost and easy to achieve mass production.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

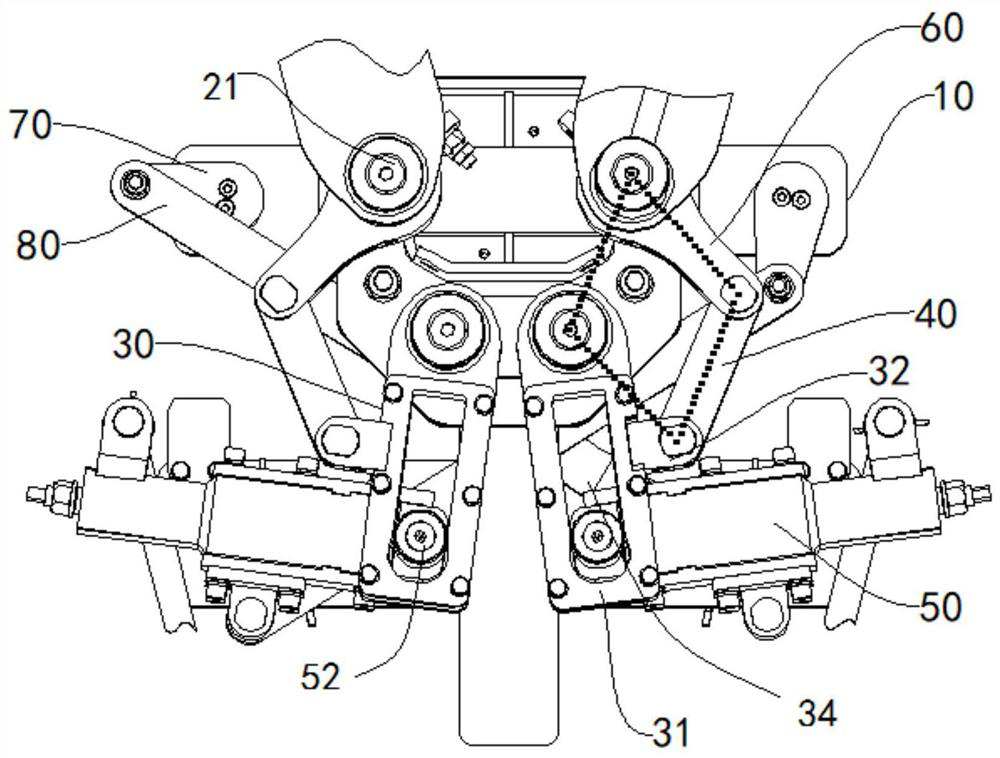

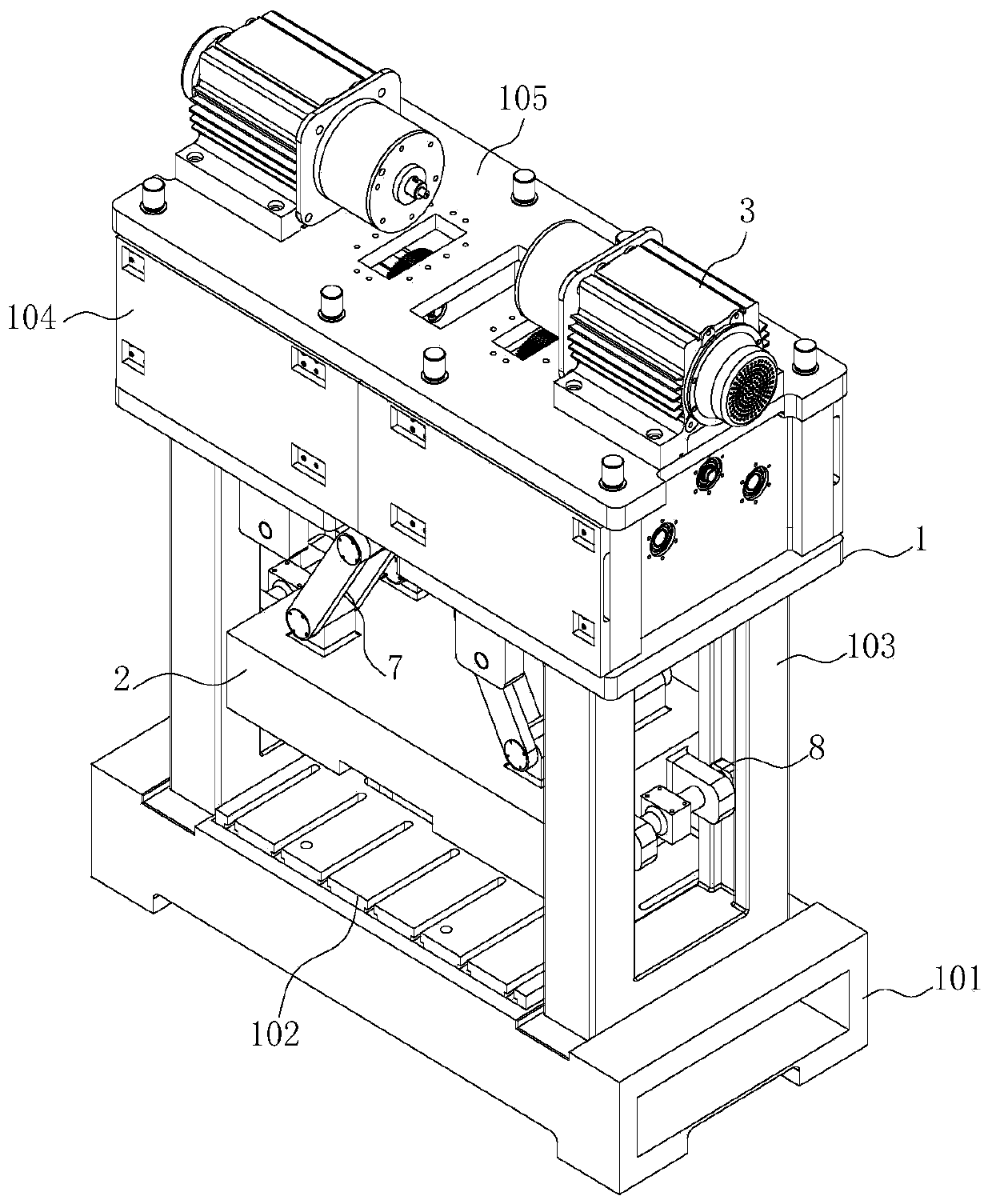

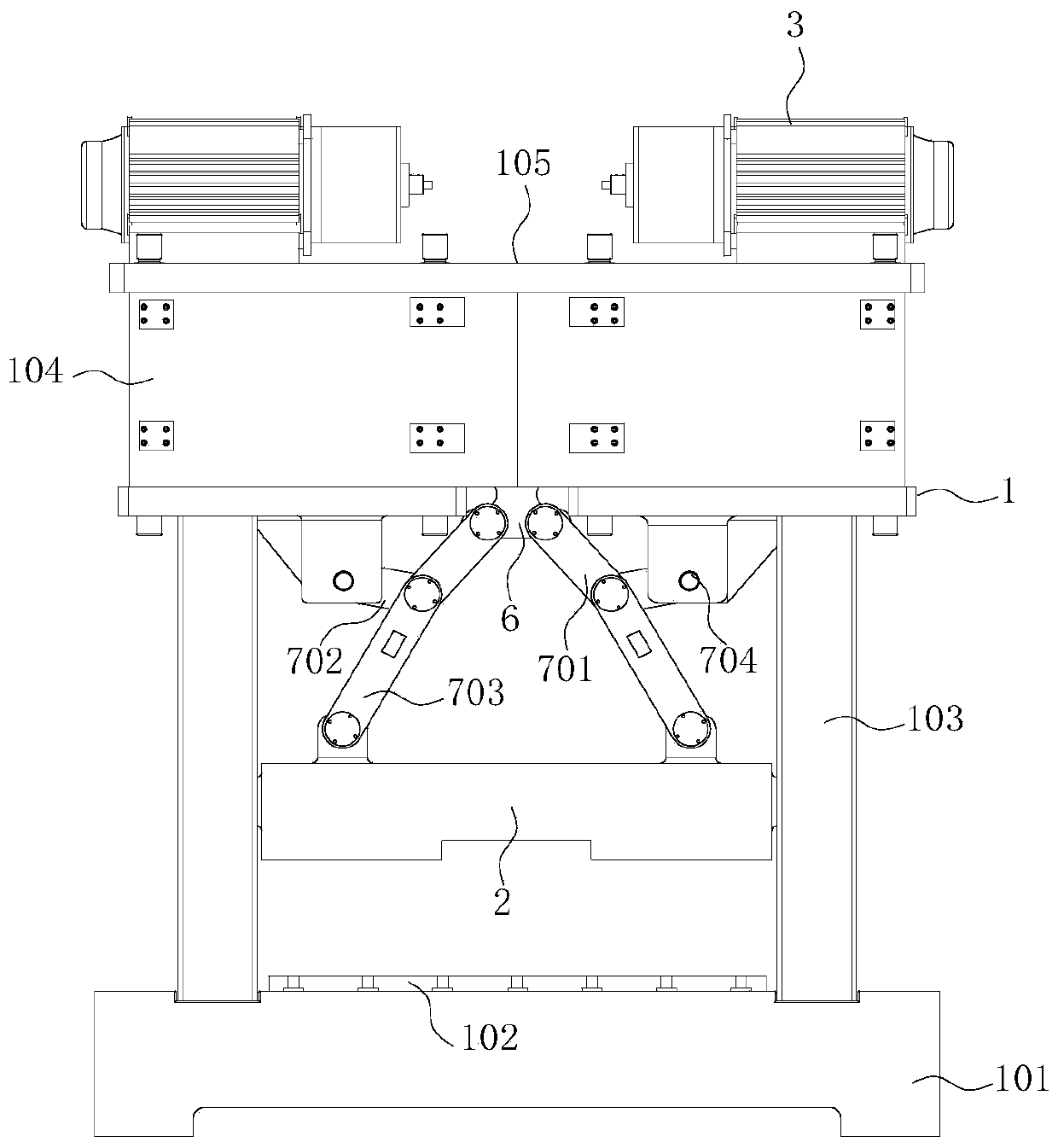

Four-point multi-link pressing machine adopting double-servo drive

InactiveCN109719242AEliminate backlashResolve Motion InterferenceForging press drivesSynchronous controlGear wheel

The invention discloses a four-point multi-link pressing machine adopting double-servo drive, belongs to the technical field of forging and pressing machinery, and aims at solving the problems that the needs of high power and high torque are difficultly met by a servo motor, a synchronous control error exists in the servo motor, and the effective output capacity of a servo pressing machine is reduced due to a backlash of an engagement gear in a speed reduction system, in the prior art. The four-point multi-link pressing machine adopting double-servo drive comprises a machine body, a downwards-moving slide block located in the machine body and sliding up and down, a planetary gear speed reduction device fixed to the upper end of the machine body, an auxiliary speed reduction unit connectedwith the planetary gear speed reduction device, a power input unit connected with the auxiliary speed reduction unit, two floating lead slide blocks connected with the power input unit and symmetrically arranged in the front-rear direction, and a double-symmetrical elbow lining mechanism, wherein the power input unit is of a double-symmetrical input structure; the upper parts of the sidewalls of the floating lead slide blocks are connected with the power input unit; and a power input end of the double-symmetrical elbow lining mechanism is connected with the lower parts of the sidewalls of thefloating lead slide blocks, and a power output end is connected with the downwards-moving slide block, and drives the downwards-moving slide block to relatively move or reversely move relative to a workbench.

Owner:JILIN UNIV

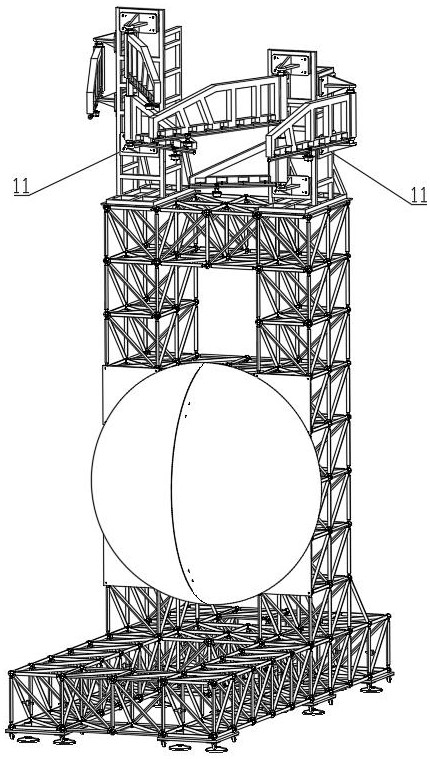

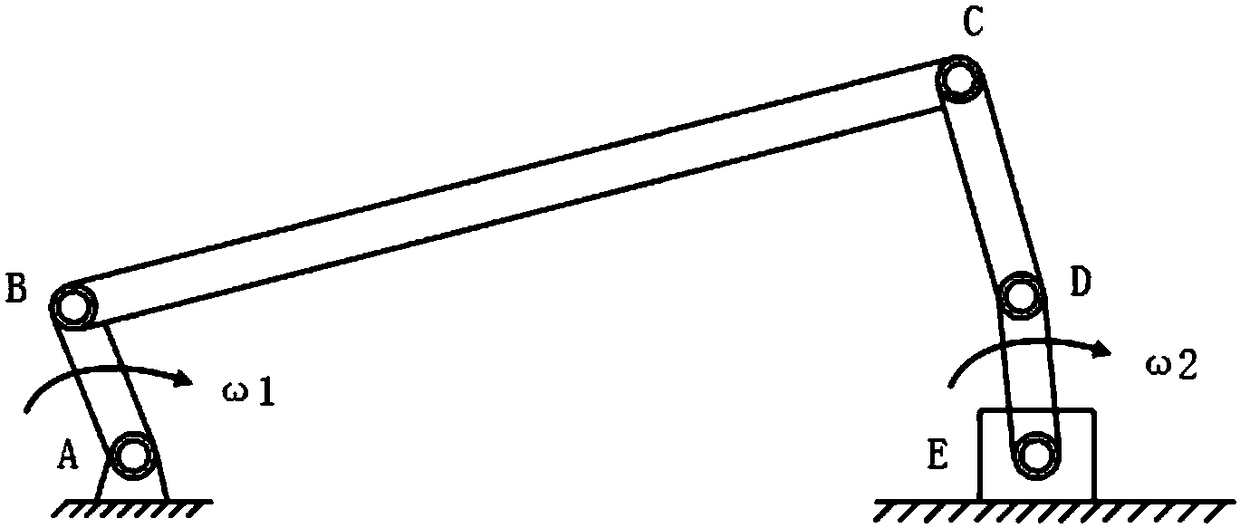

Three-rocker-arm test device for spatial mechanism compound motion microgravity expansion

ActiveCN114590422ASolve the problem of launching simulation experiments in ground microgravityResolve Motion InterferenceMachine part testingCosmonautic condition simulationsStructural engineeringMicro gravity

The invention provides a three-rocker-arm test device for composite motion microgravity expansion of a spatial mechanism. The three-rocker-arm test device comprises a rocker arm support, a first main shaft support, a second main shaft support, a first rocker arm assembly, a second rocker arm assembly, a third rocker arm assembly, a first main shaft body, a second main shaft body, a double-rotating-shaft assembly and a single-rotating-shaft assembly. The rocker arm support is installed on the truss, the first main shaft supports are installed at the top end and the bottom end of one side of the rocker arm support respectively, the first main shaft body is installed between the two first main shaft supports, the second main shaft supports are installed at the top end and the middle of the other side of the rocker arm support respectively, and the second main shaft body is installed between the two second main shaft supports. The first rocker arm assembly and the second rocker arm assembly are connected to the first spindle body through the double-rotating-shaft assembly, and the third rocker arm assembly is connected to the second spindle body through the single-rotating-shaft assembly. The invention always provides a device which is unfolded in a microgravity environment, and reliably verifies the feasibility of the ground unfolding test of the unfolding mechanism.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

A Harmonic Component Focusing Mechanism

The invention discloses a harmonic component force focusing mechanism, which belongs to the field of space load technology and is used to solve the technical problem that the support rigidity and stability of the focusing mechanism in the prior art are difficult to guarantee. The invention is provided with a base for focusing The mounting base is installed inside the base, and both ends are slidingly connected to the base through linear guide rails, and the inside of the focusing mounting base is symmetrically rotated and connected with connecting rods; the eccentric force component part is provided with a force component base fixedly connected to the base; Both sides of the force base are rotatably connected with rotating shafts; the rotating shafts are fixedly connected with eccentric wheels that are rotatably connected with the connecting rod, and the connecting rod drives the focusing mounting seat to move linearly along the linear guide rail from both sides of the focusing mounting seat through the eccentric wheel; the driving part A drive shaft that can extend into the interior of the rotating shaft is provided; a flexspline is installed on the harmonic generator fixed at the end of the drive shaft, and the harmonic transmission of the flexspline meshes with the gear of the rotating shaft. The present invention has large support rigidity and high first-order mode , compact structure, lower requirements for parts processing and assembly precision.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

A method for automatic tool avoidance of clamping mechanism

ActiveCN111761388BImprove reliabilityResolve Motion InterferencePositioning apparatusMetal-working holdersControl engineeringProcess engineering

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

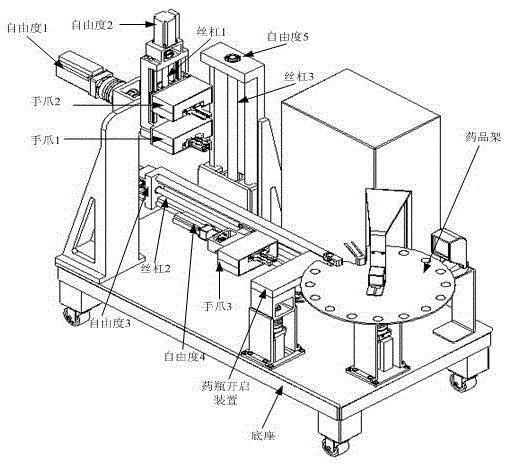

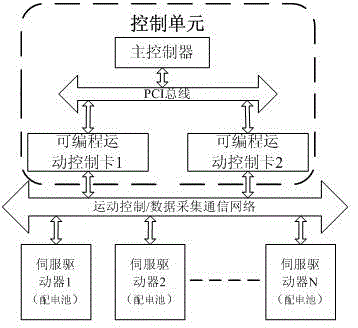

Implementation method of a zero-return control system for a dispensing robot

ActiveCN103543677BResolve Motion InterferenceShorten return to zero timeProgramme controlComputer controlProgrammable read-only memoryControl system

The invention discloses a dosage robot resetting control system and an implementation method thereof. A main controller sets each freedom degree control mode as an absolute position control mode according to a user command; in the absolute position control mode, a servo driver stores current position data of freedom degree in an EEP-ROM (electrically-erasable programmable read-only memory) of the servo driver through zero setting to serve as a zero position; experiments show that a dosage robot can be automatically reset under various working conditions and collision is avoided, the problem of motion interference of the dosage robot during resetting is solved well, resetting time of the robot is shortened, working efficiency of the robot is improved, and needs for cooperative work of robot arms are met well.

Owner:深圳市博为医疗机器人有限公司

A multi-phase link-wheel drive mechanism

The invention relates to a multiphase connecting rod wheel driving mechanism comprising travelling wheels, an obstacle-crossing connecting rod, small wheels and a sheet connecting rod connected to the small wheels. Positioning holes are formed in the travelling wheels and the obstacle-crossing connecting rod. Movable pins pass through the positioning holes to connect the travelling wheels with the obstacle-crossing connecting rod. One small wheel is mounted on each travelling wheel and is completely fixed relative to the corresponding travelling wheel. Each small wheel is not concentric with the corresponding travelling wheel and covers the circle center of the corresponding travelling wheel. Power shafts are positioned on the circle centers of the travelling wheels. An included angle is formed by a connecting line between the circle center of each small wheel and the axis of the corresponding travelling wheel and a connecting line between the corresponding connecting rod positioning hole and the axis of the travelling wheel, in other words, the two connecting lines do not coincide. A plurality of round grooves are formed in the sheet connecting rod. The sheet connecting rod is embedded on the small wheels through the round grooves externally. The diameter of each round groove is slightly larger than that of each small wheel. The small wheels are embedded in the round grooves internally and can rotate freely in the round grooves. The sheet connecting rod rotates around the power shafts along with the small wheels. The mechanism is simple to control and has a concise travelling mechanism, can solve the problem of 'singular points' effectively and has remarkable advantages as compared with other travelling mechanisms.

Owner:SOUTHWEST UNIV

An assembly method of an aeroengine low-pressure turbine shaft-disk assembly

The invention discloses an assembling method for a low-pressure turbine shaft-disc assembly of an aero-engine. The assembling method comprises the following steps that workpieces are installed, the position and the posture of a turbine shaft are adjusted; the turbine shaft butts joint and is pre-installed; an indexable tightening system is fed to a front end operation area; a tightening shaft is tightened; and the indexable tightening system returns back. According to the assembling method for the low-pressure turbine shaft-disc assembly of the aero-engine, an assembly mode that an axis of a low-pressure turbine shaft-disc is horizontal is adopted, the position and the posture of the low-pressure turbine shaft with the large length are adjusted precisely and advantageously in the butt-joint process, centering positioning alignment and end face correct close fitting of the turbine shaft relative to a connecting disc are achieved, and the butt-joint and assembling precision is improved;a turbine shaft position and posture adjusting table is applied, quantitative position and posture adjusting is conducted on the low-pressure turbine shaft through a mechanical way, experiential methods such as traditional manual hanger operating are replaced, manual repeated trial assembly and correction are avoided, the butt-joint efficiency is improved, and assembly consistency requirements ofassemblies are met; and the indexable tightening system is adopted, worker skill requirements and the labor intensity are reduced, and the tightening efficiency is improved.

Owner:DALIAN UNIV OF TECH

A wheeled pipeline robot traction device

The invention discloses a traction device for a wheeled pipeline robot. The traction device comprises a housing and a four-axis differential driving device, wherein a power output bevel gear for driving a driving wheel transmission mechanism is arranged on each of four output ends of the four-axis differential driving device; a pipeline diameter adapting mechanism is arranged above the center between two front driving wheel transmission mechanisms, and another pipeline diameter adapting mechanism is arranged above the center between two rear driving wheel transmission mechanisms. According to the traction device for the wheeled pipeline robot, the rotating speed of four axes can be self-adaptively adjusted according to related running conditions in a pipeline; whether in a transition state or a turning state, the four driving wheels can perform differential movement during turning, thus the problem of movement interference on the traction device of a pipeline robot in obstacle crossing or turning can be solved, the driving efficiency can be improved, the abrasion of a driving device can be reduced, and as a result, the service life of the traction device can be prolonged; in addition, the traction device has the advantages of being high in obstacle crossing performance and pipe diameter adapting performance, high in effective driving power, high in structure symmetry, and wide in applicable scope.

Owner:TIANJIN UNIV

Shifting rod type infrared vegetable dehydrator

Owner:SHANDONG UNIV OF TECH

Six-rod three-input connecting rod mechanism teaching aid

InactiveCN108932891AResolve Motion InterferenceImprove controllabilityEducational modelsHinge angleEngineering

A six-rod three-input connecting rod mechanism teaching aid is composed of a bottom plate, a first stepping motor, a second stepping motor, a third stepping motor, a bearing seat, a coupling, a shaft,a bearing, a bearing cover, a first connecting rod, a second connecting rod, a third connecting rod, a fourth connecting rod, a guide rail, a screw nut, a screw rod, gears, a snap ring, a double cross telescopic coupling, a vibration sliding block and bolts; and the first connecting rod, the second connecting rod, the third connecting rod, the fourth connecting rod and the guide rail are sequentially connected through hinges, and the screw nut and the vibration sliding block are connected through the bolts. Rotating speeds of the three stepping motor are respectively controlled by utilizing acontrol program, and then motion controllability is achieved; and the problem of motion interference between the second stepping motor and the fourth connecting rod while rotation is performed is solved well through adoption of the double cross telescopic coupling, continuous adjustment in an online non-stop motion manner is achieved, and the six-rod three-input connecting rod mechanism teachingaid has the advantages of multiple functions, compact structure, beautiful appearance, convenient assembly, low manufacturing cost and the like.

Owner:广西合臻泰商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com