Shifting rod type infrared vegetable dehydrator

A vegetable dehydration and infrared technology, applied in applications, food processing, food science, etc., can solve the problems of easy material leakage at the joints of double-layer chain plates, large inclination angle, and inability to replace the replacement of the rod chain plate, etc., to achieve Solve the problem of motion interference and the effect of reliable equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

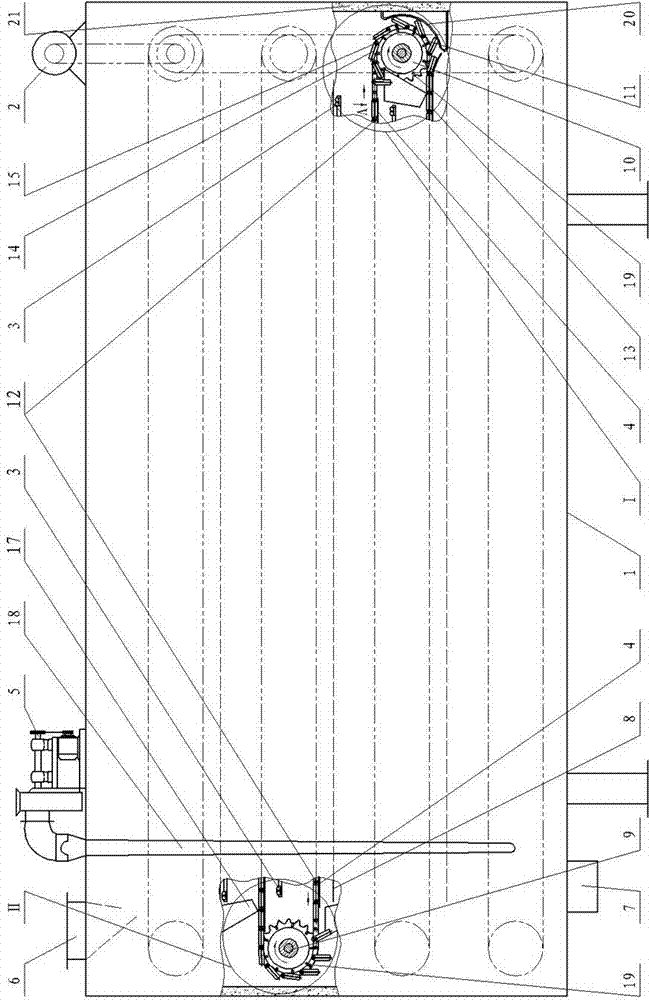

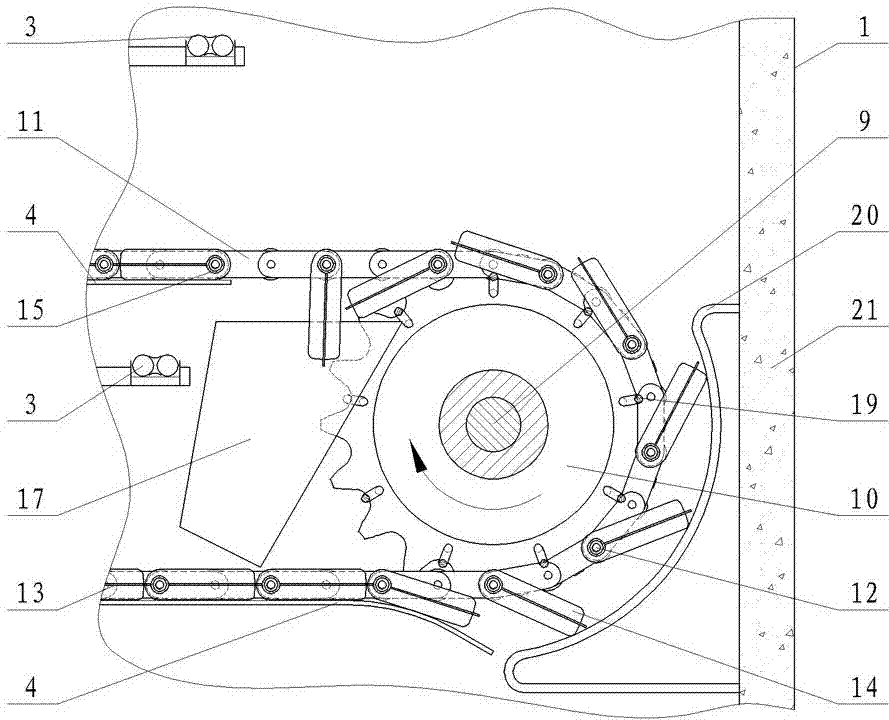

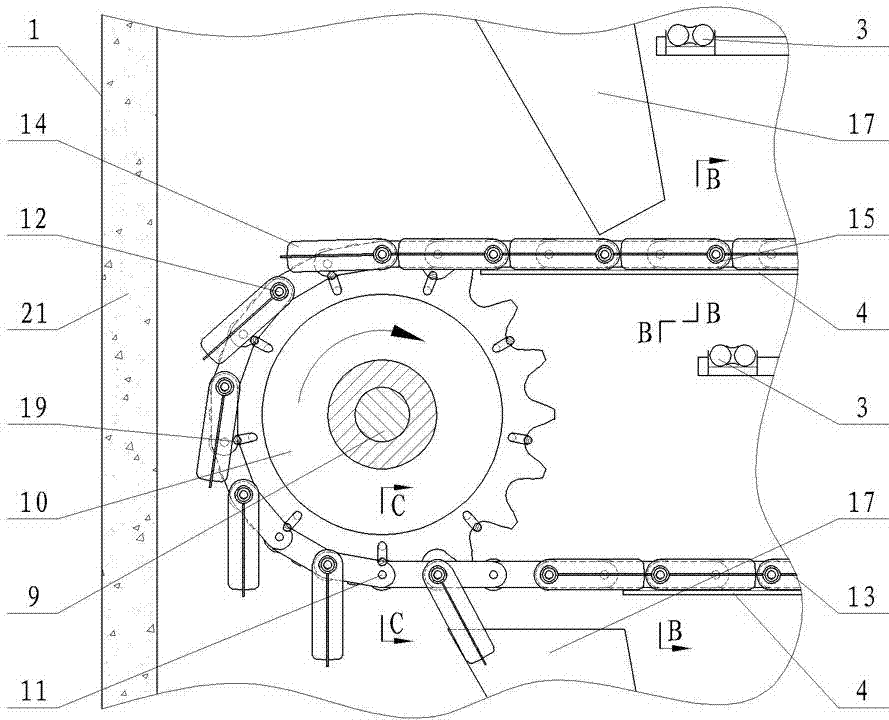

[0021] 1. Box 2, transmission device 3, infrared radiation device 4, guide rail 5, fan 6, feed inlet 7, discharge outlet 8, partition 9, shaft 10, sprocket 11, chain 12, pin shaft 13, panel 14. Baffle plate 15, reinforcing pipe 16, hanging hole 17, material guide trough 18, air induction pipe 19, driving rod 20, limit rod 21, insulation layer.

[0022] exist Figure 1~8 In the shown embodiment: the transmission device 2 of the lever-type infrared vegetable dehydrator is installed on the left end of the top of the box body 1, and the right end is provided with a material inlet 6, and the same end is provided with a material outlet 7 at the bottom of the box body 1. The inner space of the box body 1 is horizontally divided into 4 layers by partitions 8, and a group of conveying devices installed on the top of the box body 1 away from the end of the feed port 6 are arranged in each layer, and the transmission device 2 is driven step by step. The same conveying device The chain p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com