A multi-phase link-wheel drive mechanism

A wheel-driven, multi-phase technology, used in motor vehicles, transportation and packaging, etc., can solve the problems of link-type mechanism movement interference, inability to take into account stability, balance obstacle-crossing ability, etc., and achieve efficient and reliable obstacle-crossing process. High barrier effect, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

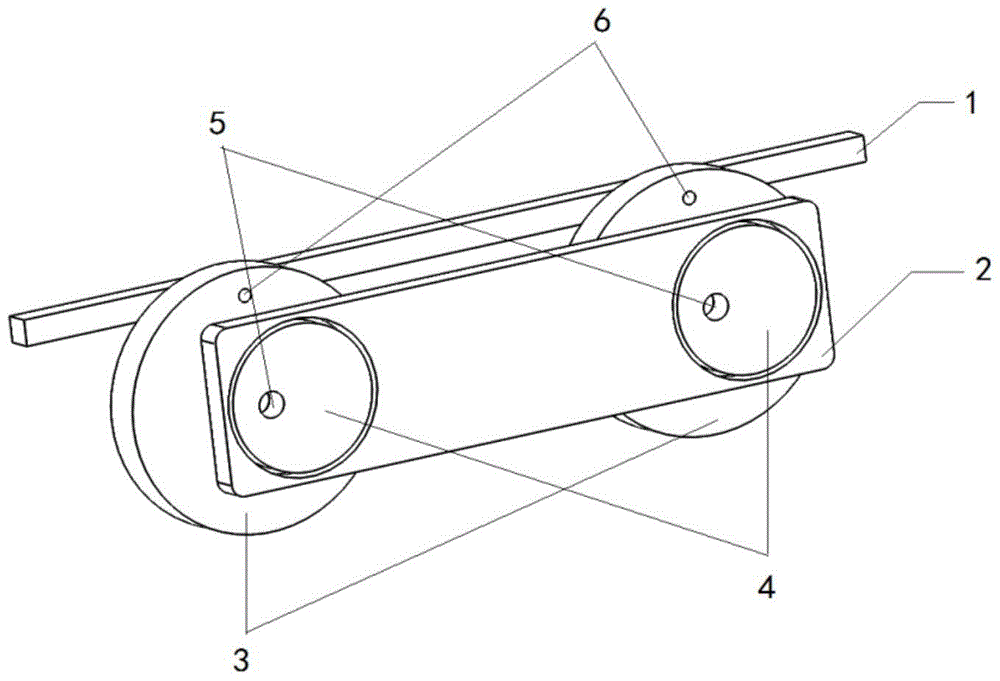

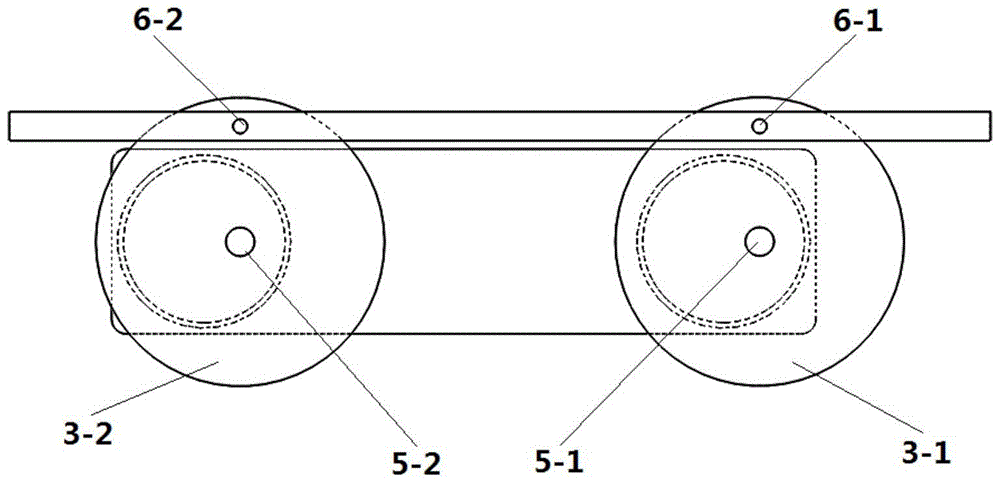

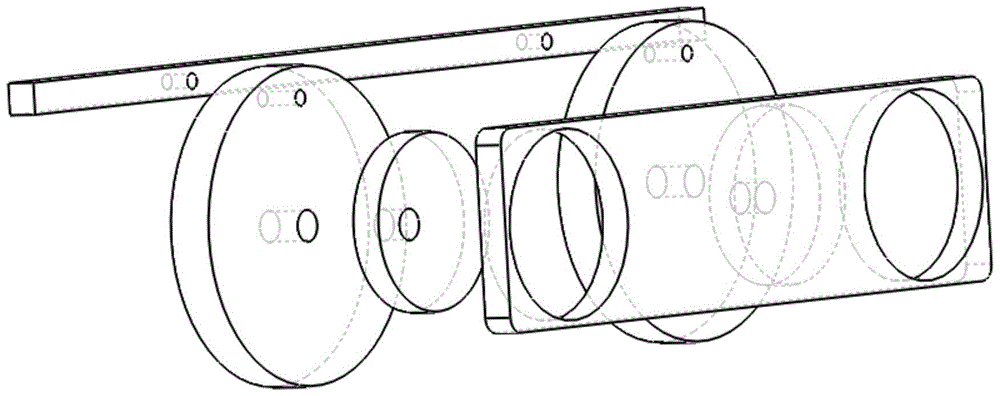

[0024] figure 1 It is a three-dimensional structure diagram of the present invention, and for the convenience of description, only the parts related to the present invention are given.

[0025] A multi-phase linkage wheel drive mechanism, in this embodiment, taking n=2 (two action wheels on each side) as an example, includes action wheels (3-1) and action wheels (3-2) and is connected to The over-obstacle connecting rod (1) on the action wheel (3) is respectively provided with a positioning hole (6-1) and a positioning hole (6-2) on the over-obstacle connecting rod (1), and the movable pin shaft passes through the positioning hole ( 6) The action wheel (3) is connected with the obstacle-crossing connecting rod (1), and the positioning hole (6) on the action wheel (3) is close to the position of the circumference of the wheel. The axle cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com