A wheeled pipeline robot traction device

A pipeline robot and traction device technology, applied in special pipes, pipe components, mechanical equipment, etc., can solve the problem of affecting the working efficiency and service life of the traction device, reducing the motion stability of the traction device, and unable to effectively control the attitude of the driven end, etc. problems, to achieve the effect of convenient structural design and layout, structural symmetry, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

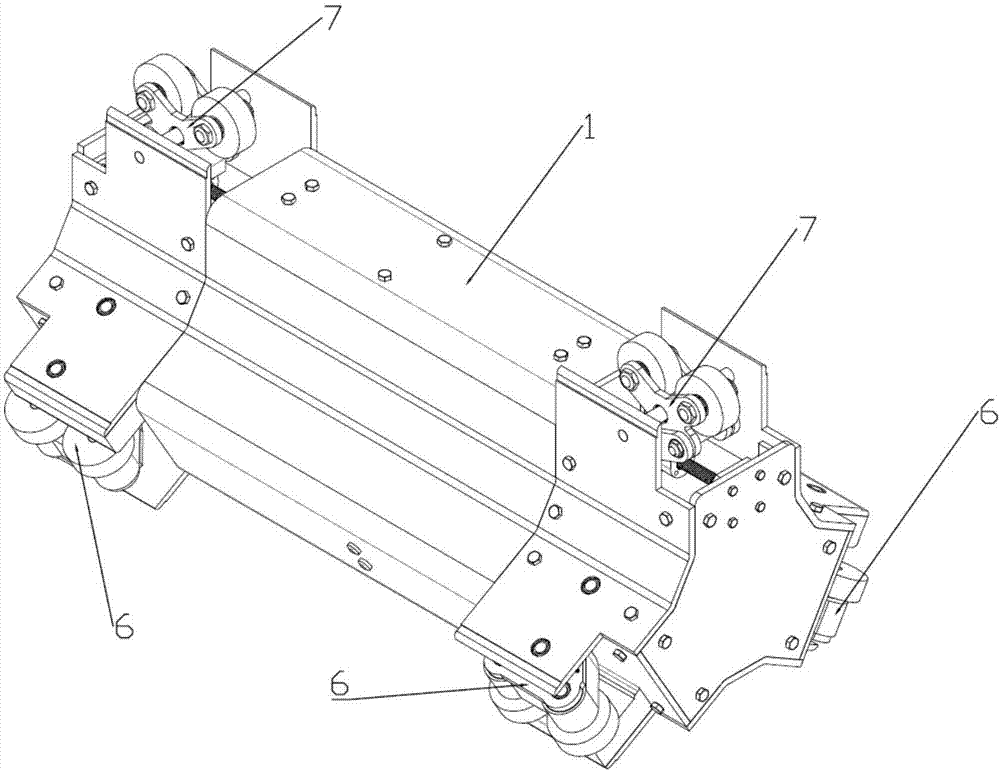

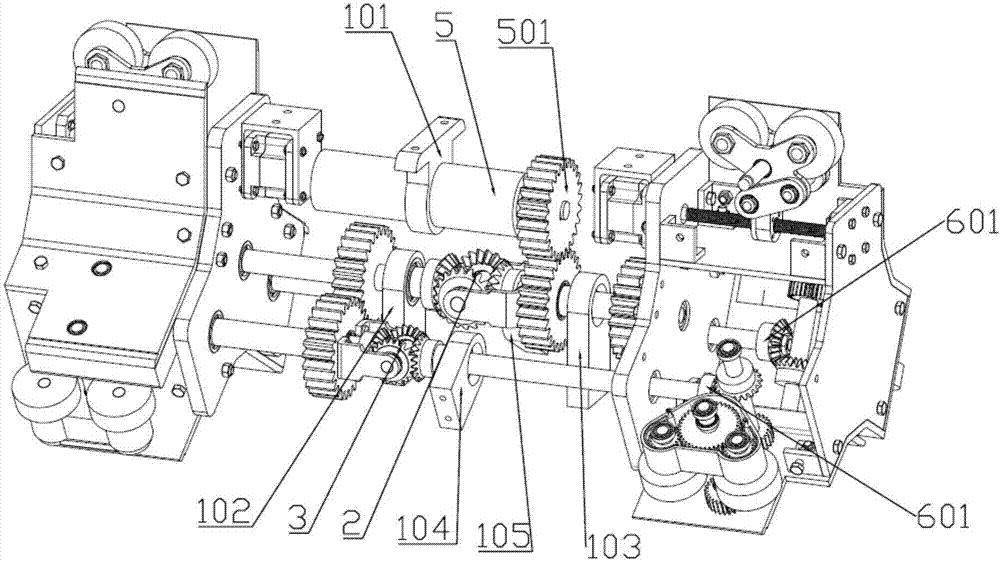

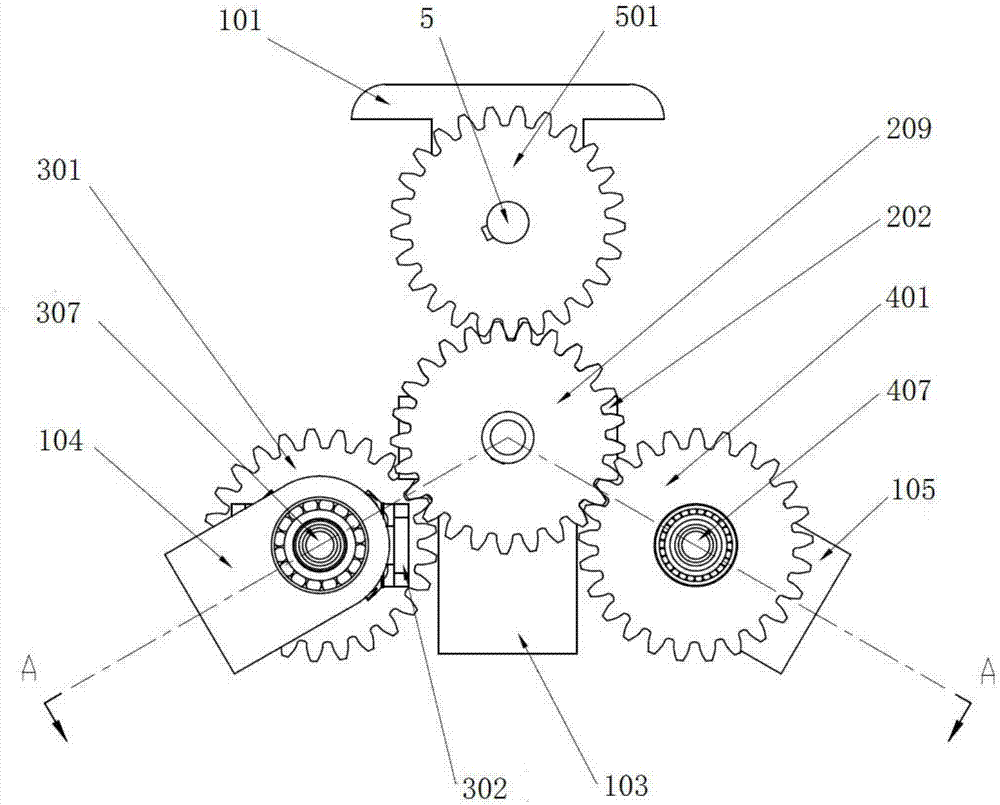

[0029] see Figure 1 to Figure 8 , a wheeled pipe robot traction device, including a housing 1 and a four-axis differential drive device, the four-axis differential drive device includes a transfer case 2 installed in the housing 1, a differential I3, The differential gear II and the drive motor 5, the drive motor 5 is fixed in the housing 1, and a power output gear 501 is installed on the output shaft of the drive motor 5.

[0030] The transfer case 2 is provided with a front transfer shaft 206 and a rear transfer shaft 207, and a transfer input gear 201 and a transfer output gear meshed with the power output gear 501 are arranged on the rear transfer shaft 207 II209, the transfer input gear 201 is rotatably connected to the rear transfer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com