Patents

Literature

174 results about "Compression release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

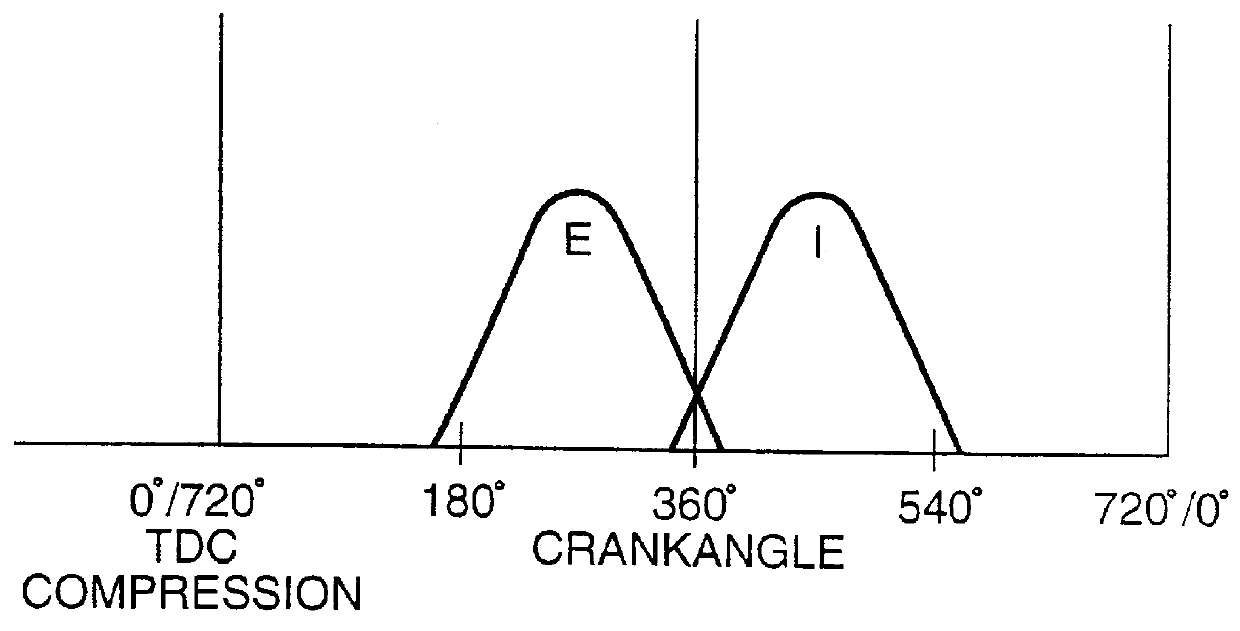

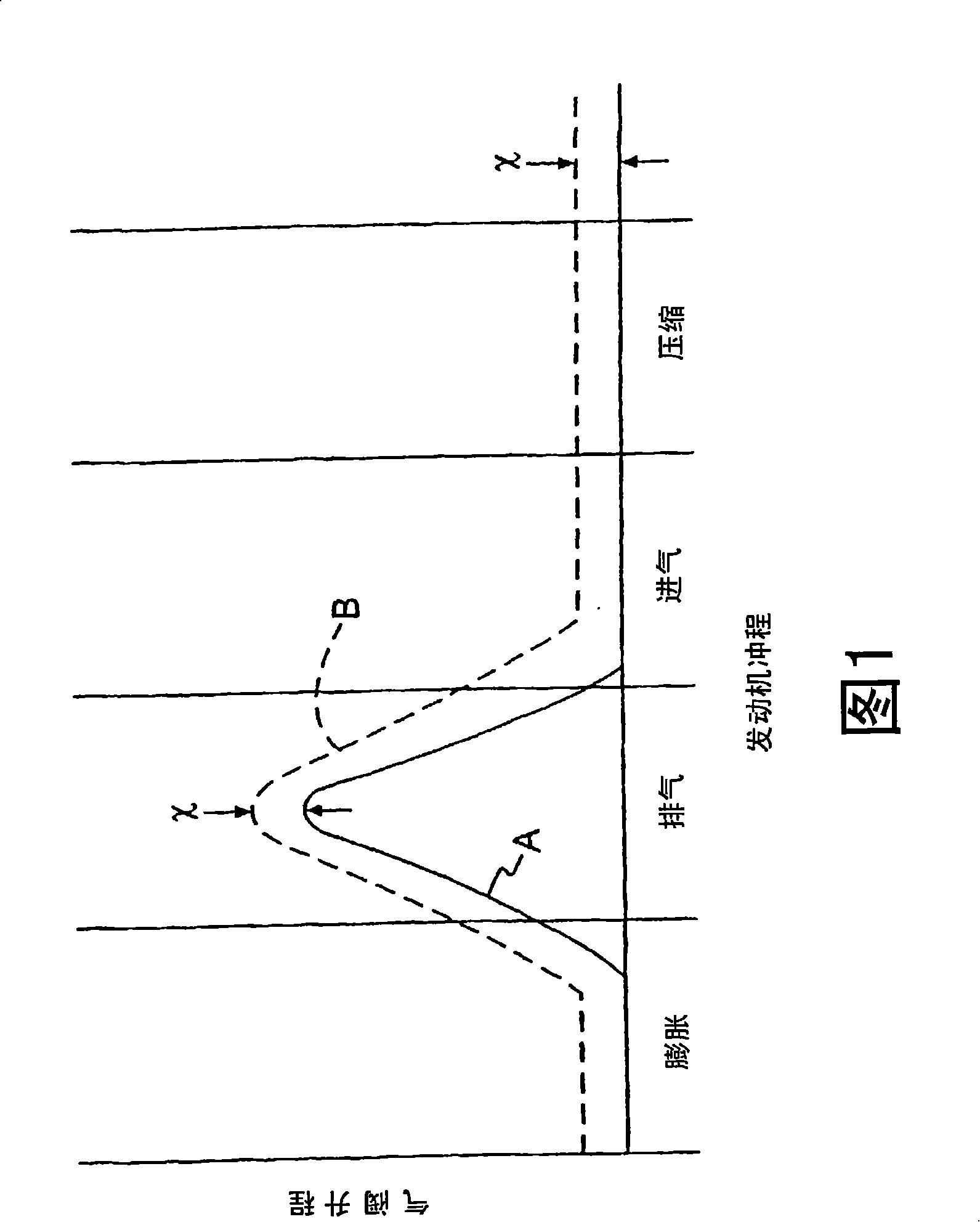

A compression release mechanism works to ease the starting of internal combustion engines by allowing them to spin up to starting speed without having to work against the pumping action of the pistons. It does this through a release valve that is incorporated within the cylinder head that vents the cylinder pressure to the outside atmosphere until the engine has sufficient momentum to overcome it. At that point the valve closes and the ignition is engaged.

Method and apparatus to accomplish exhaust air recirculation during engine braking and/or exhaust gas recirculation during positive power operation of an internal combustion engine

InactiveUS6082328AHigh retarding powerEasy to operateValve arrangementsNon-fuel substance addition to fuelStored energyExternal combustion engine

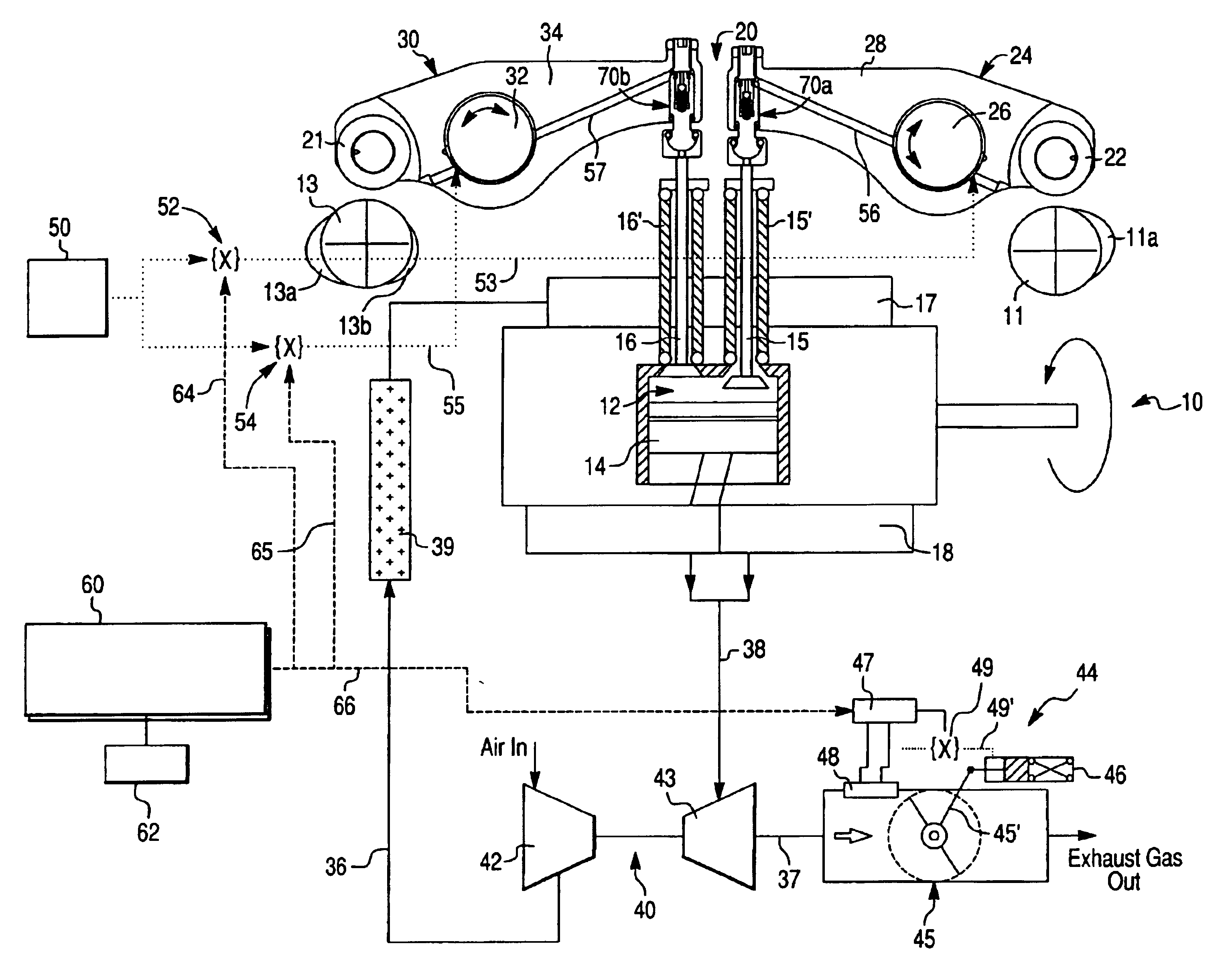

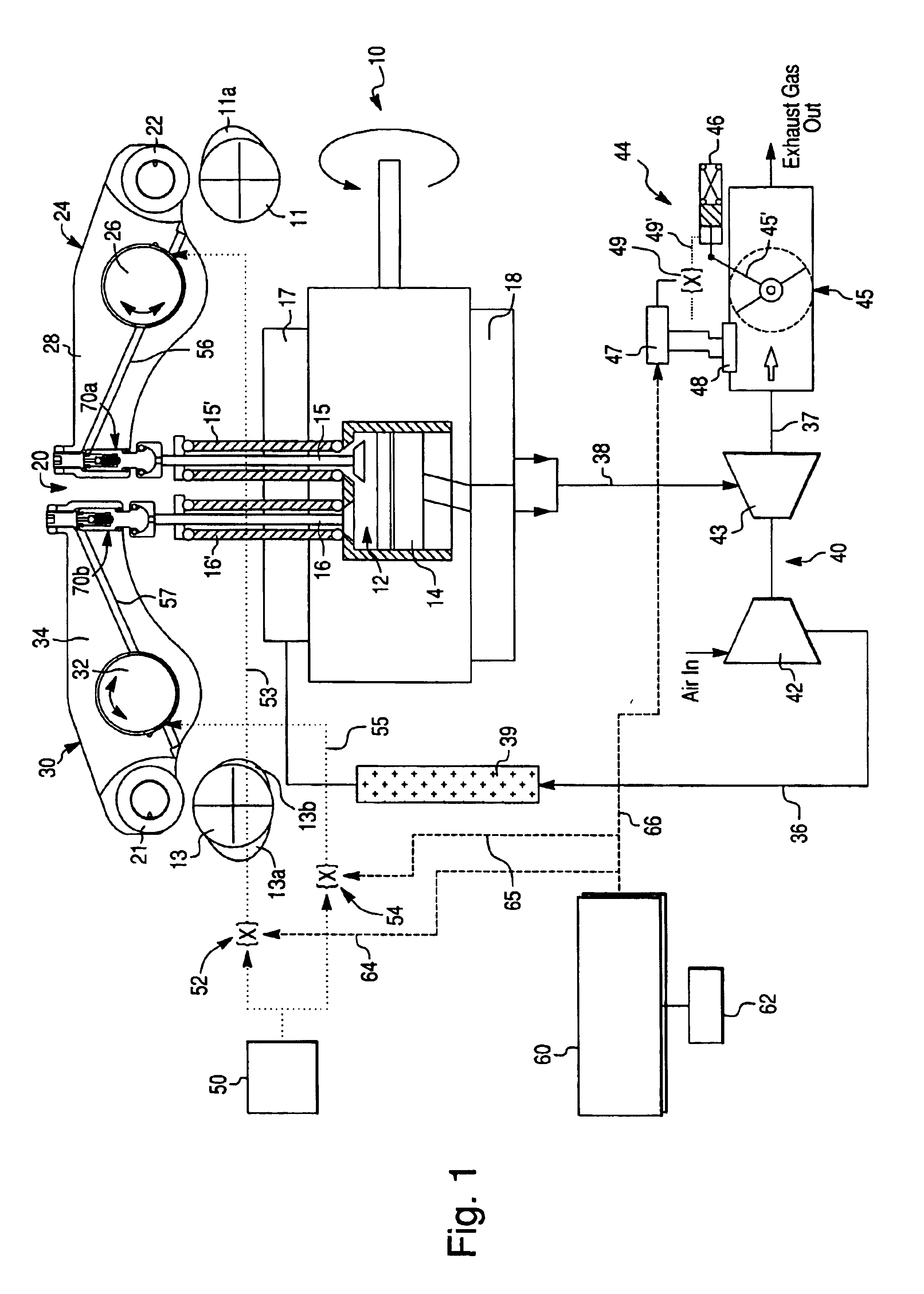

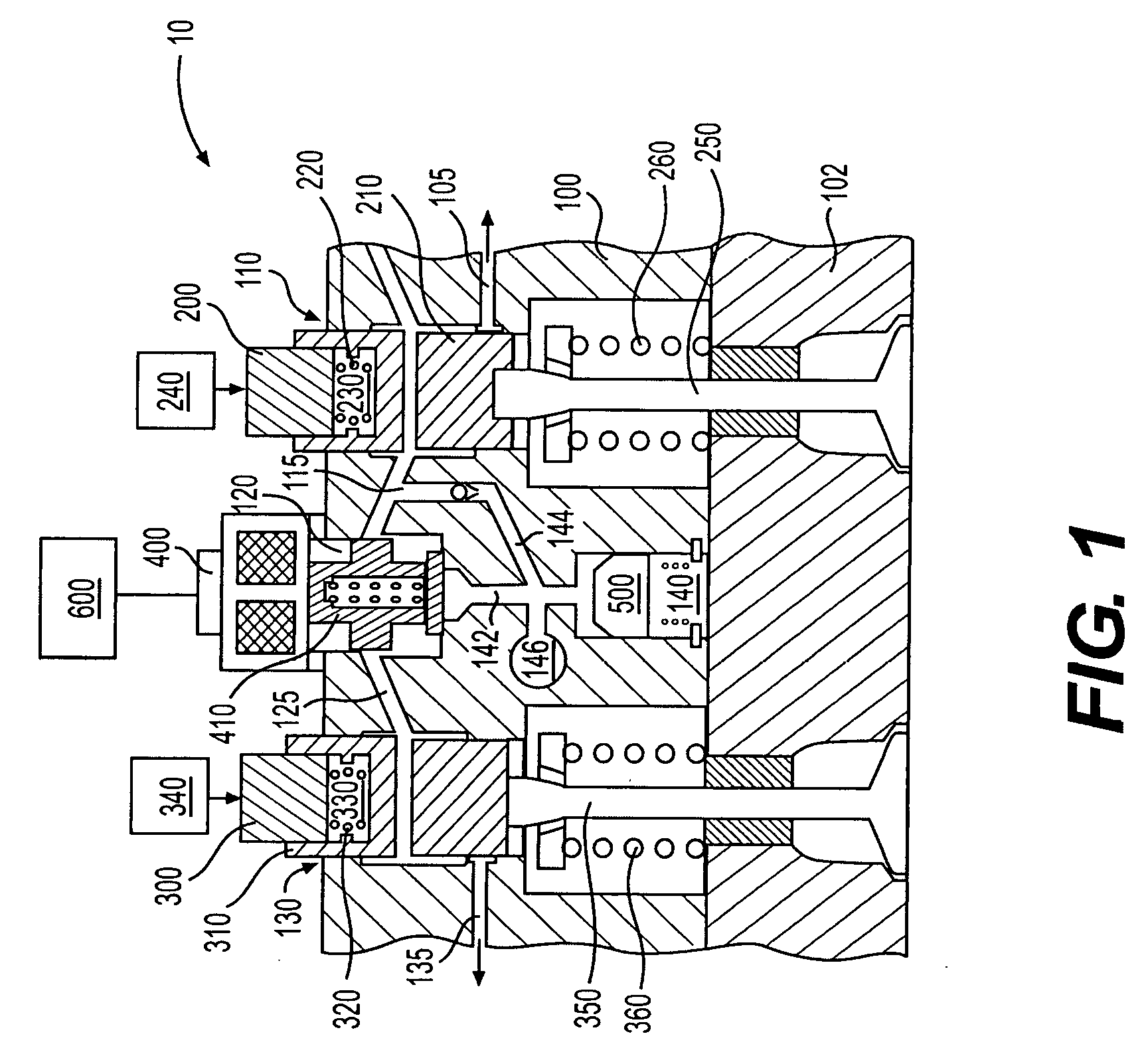

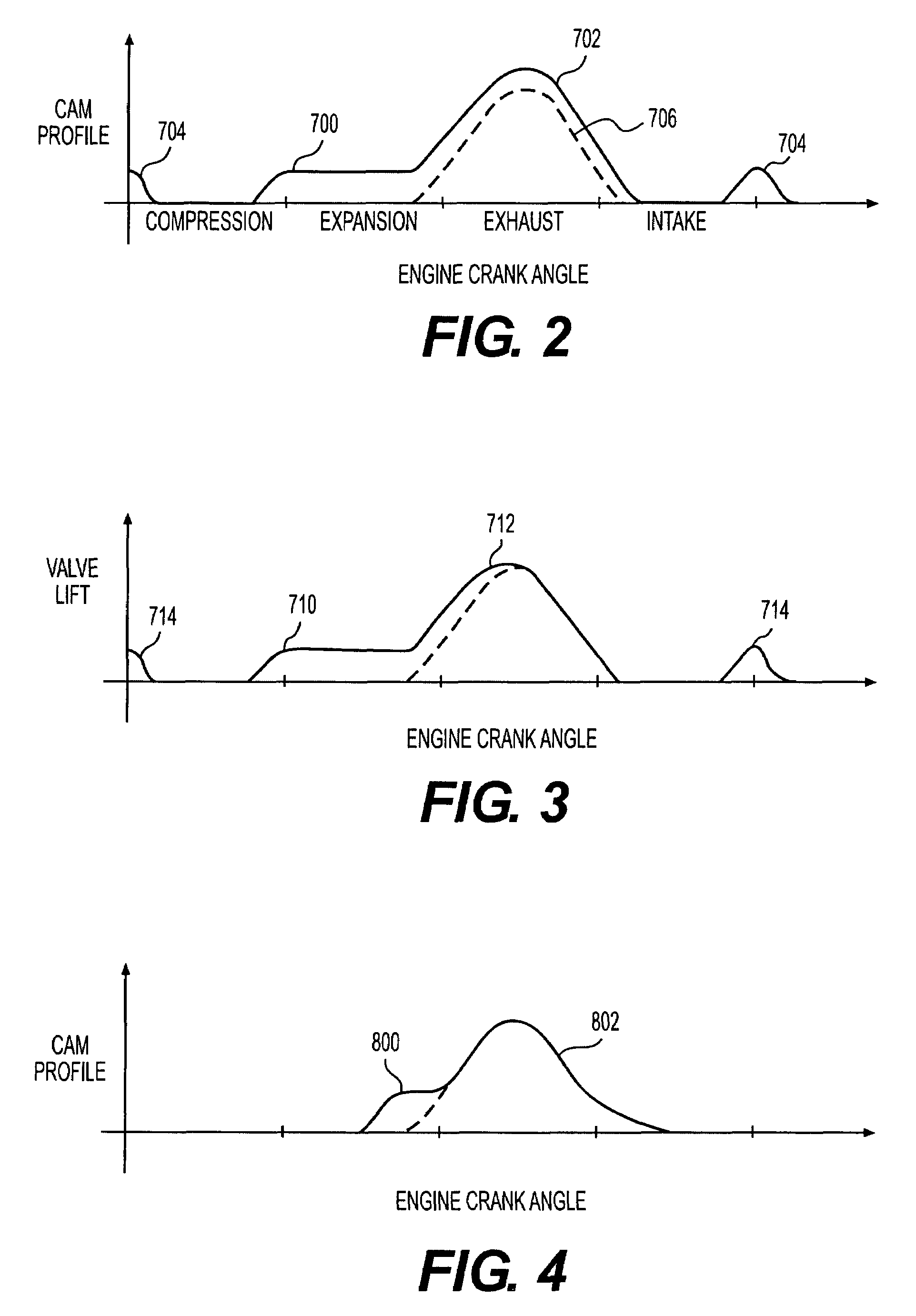

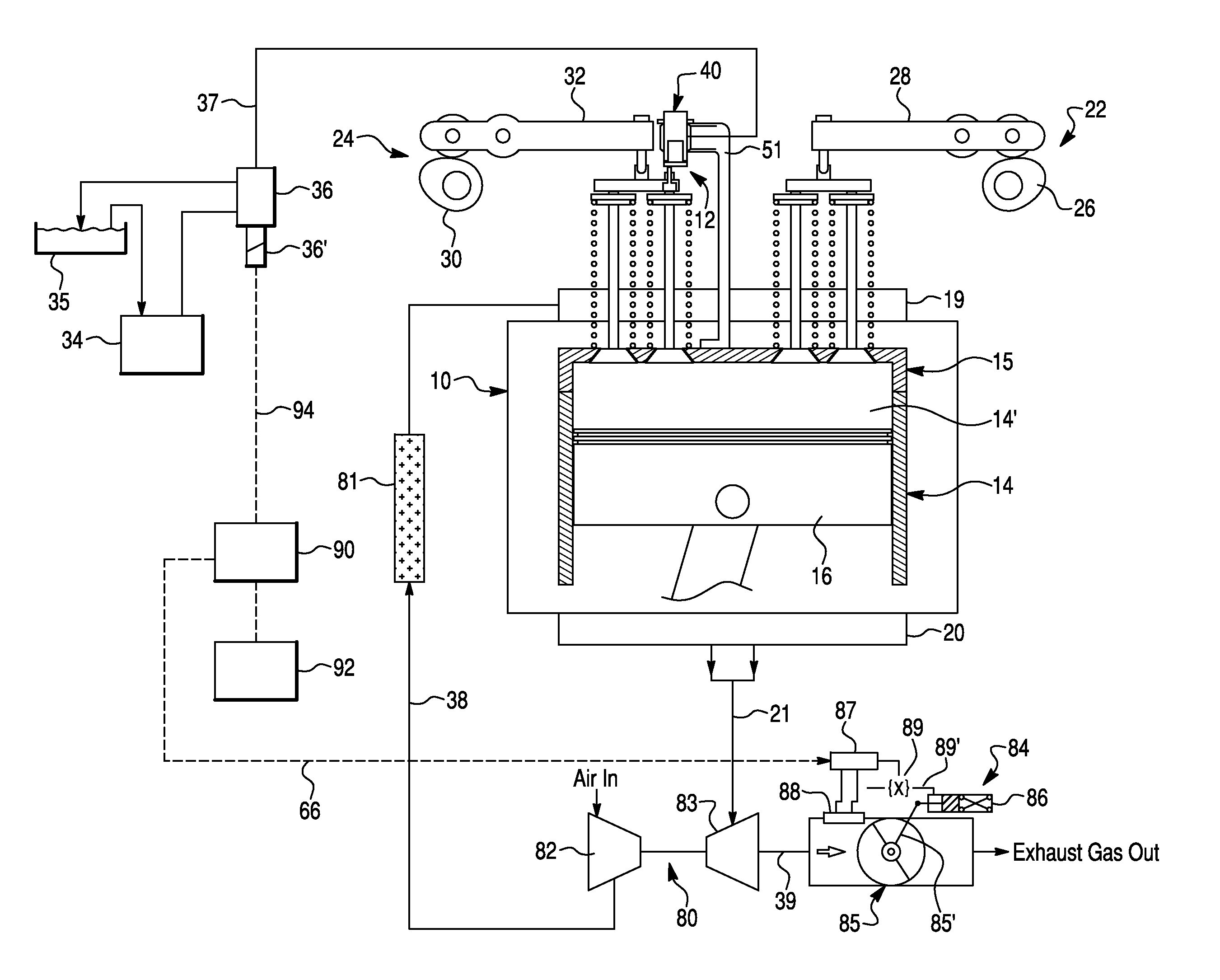

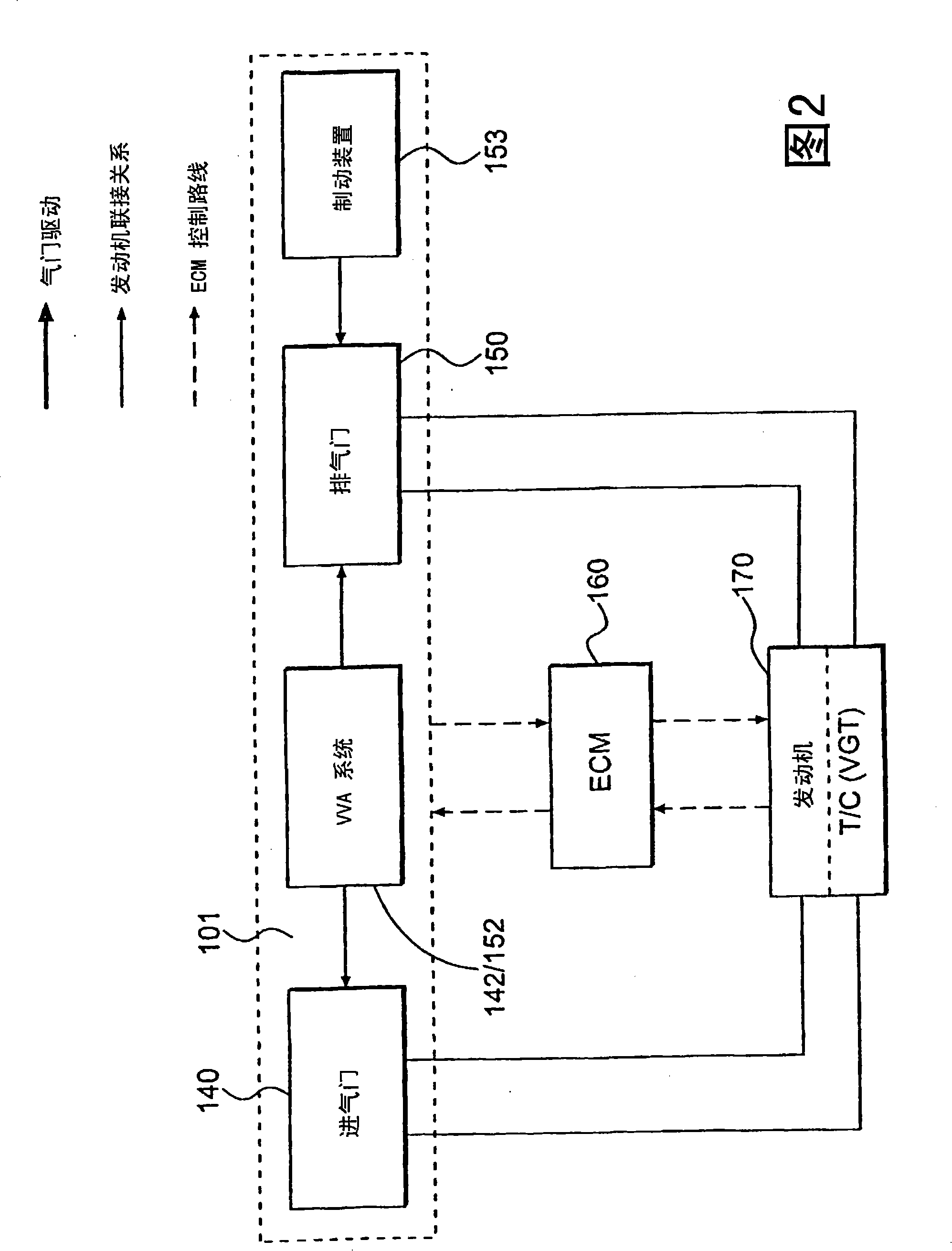

A method and apparatus for carrying out variable timing exhaust gas recirculation is disclosed for use during both positive power and retarding operation of an internal combustion engine. Motion or energy is derived from an engine component and stored as potential energy. The stored energy is selectively applied to a valve actuator to carry out exhaust gas recirculation in an engine cylinder. The energy derived from the engine may be stored and selectively applied to the valve actuator with an electronically controlled trigger valve. The valve actuator may be a slave piston having an inner core and an outer sleeve capable of opening the valve of the cylinder in response to independent exhaust gas recirculation and compression release hydraulic systems.

Owner:DIESEL ENGINE RETARDERS

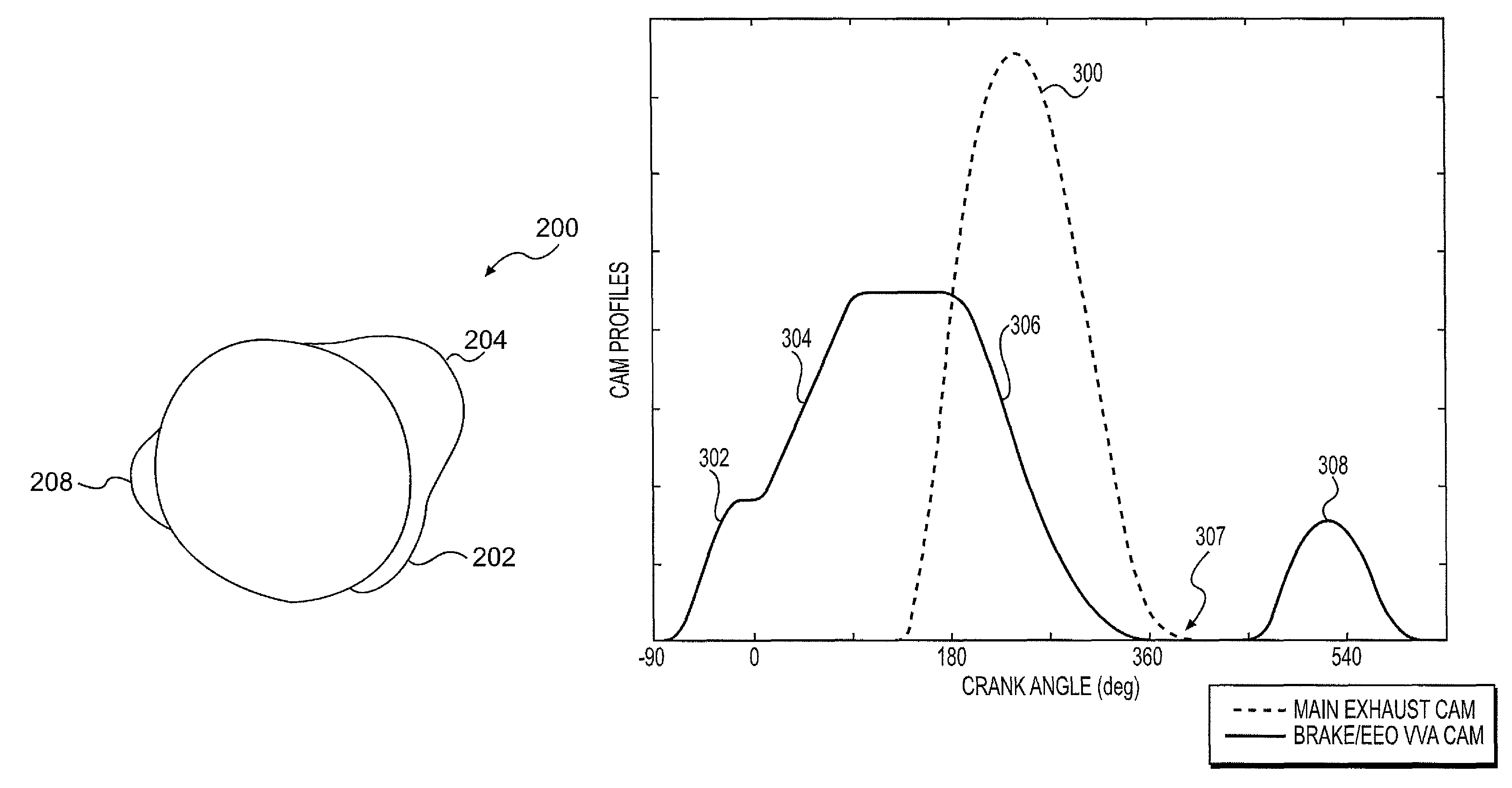

Lost motion variable valve actuation system for engine braking and early exhaust opening

ActiveUS7712449B1Improved transient torqueAvoid impactValve drivesOutput powerEngineeringExhaust gas recirculation

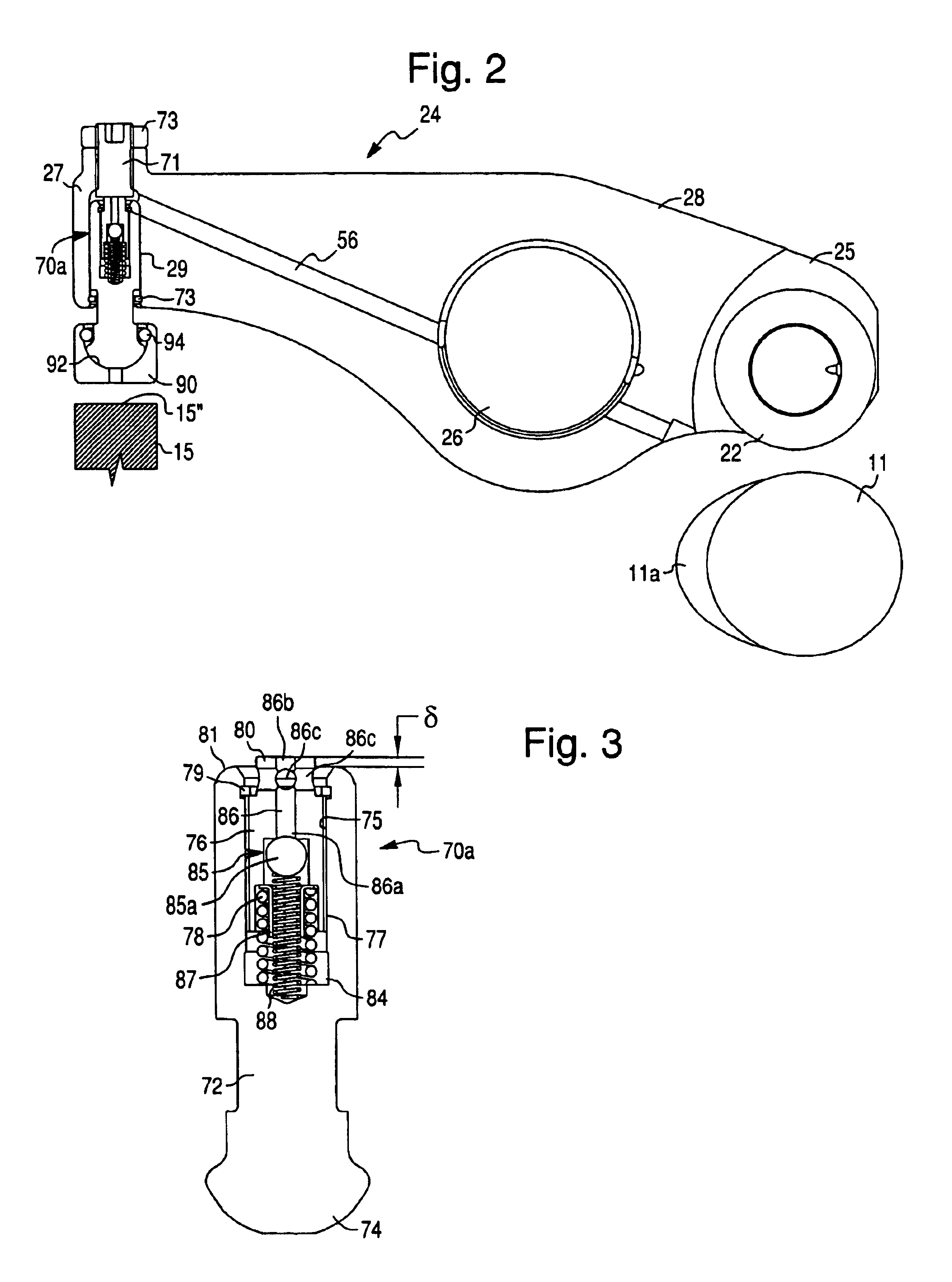

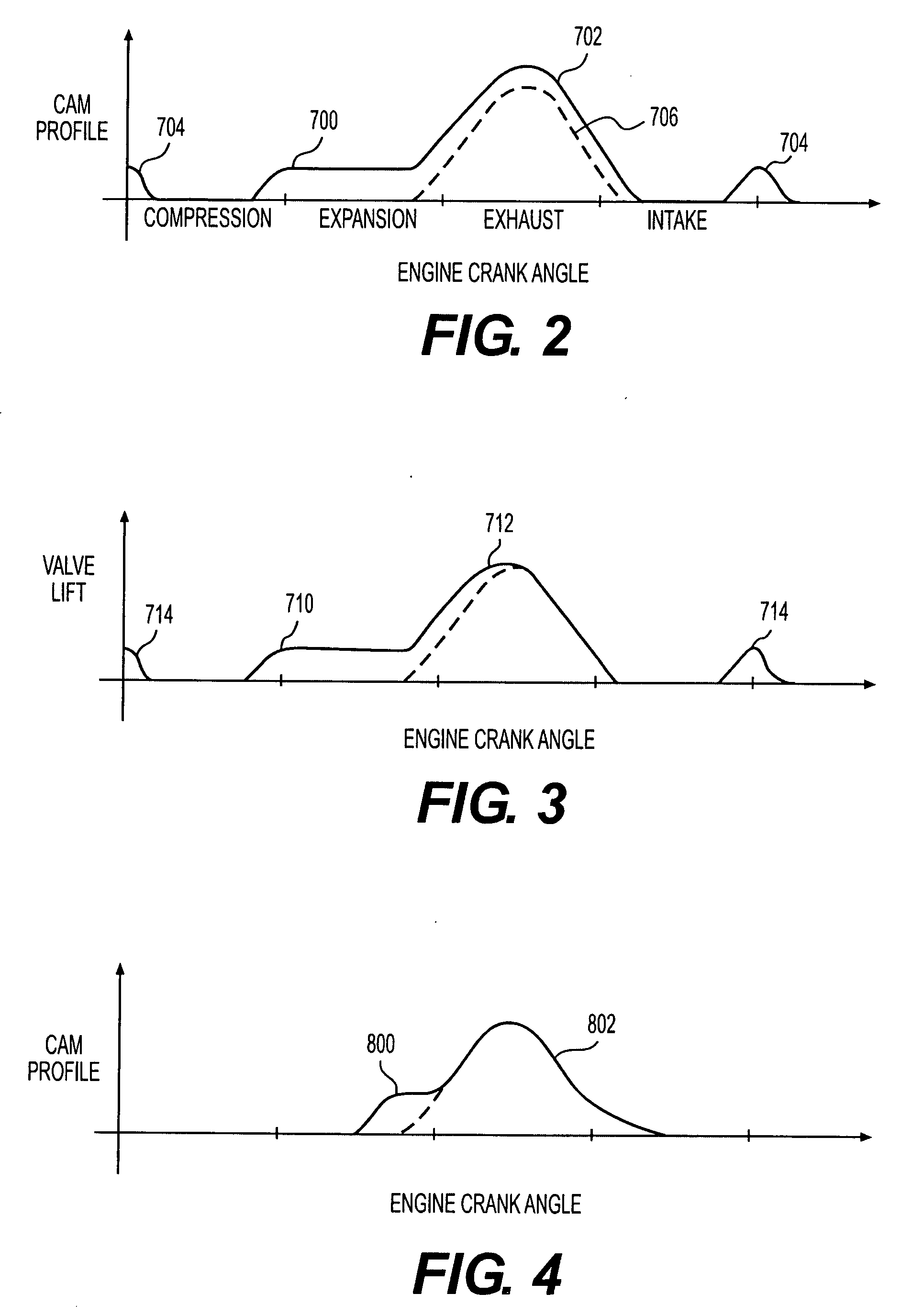

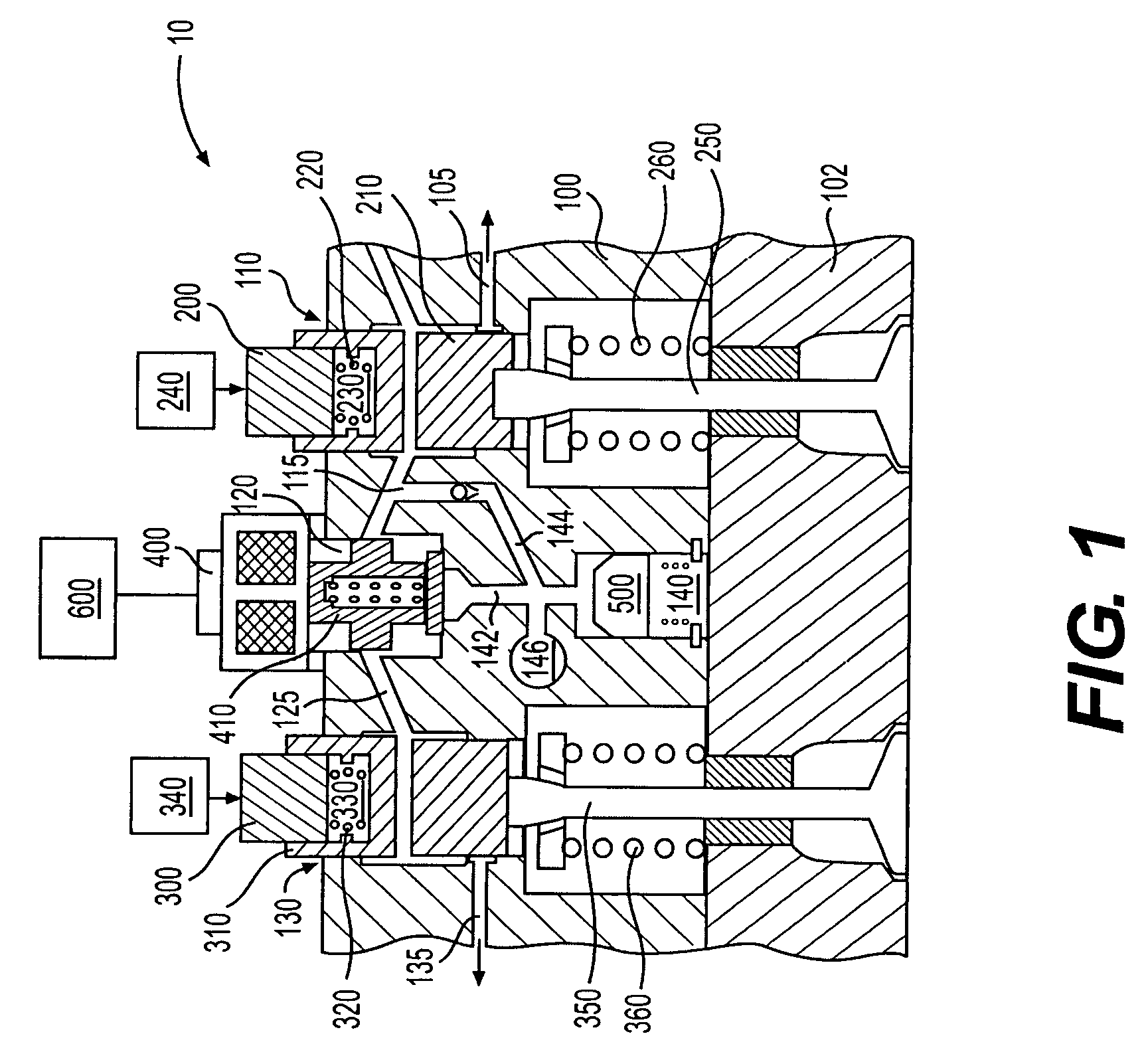

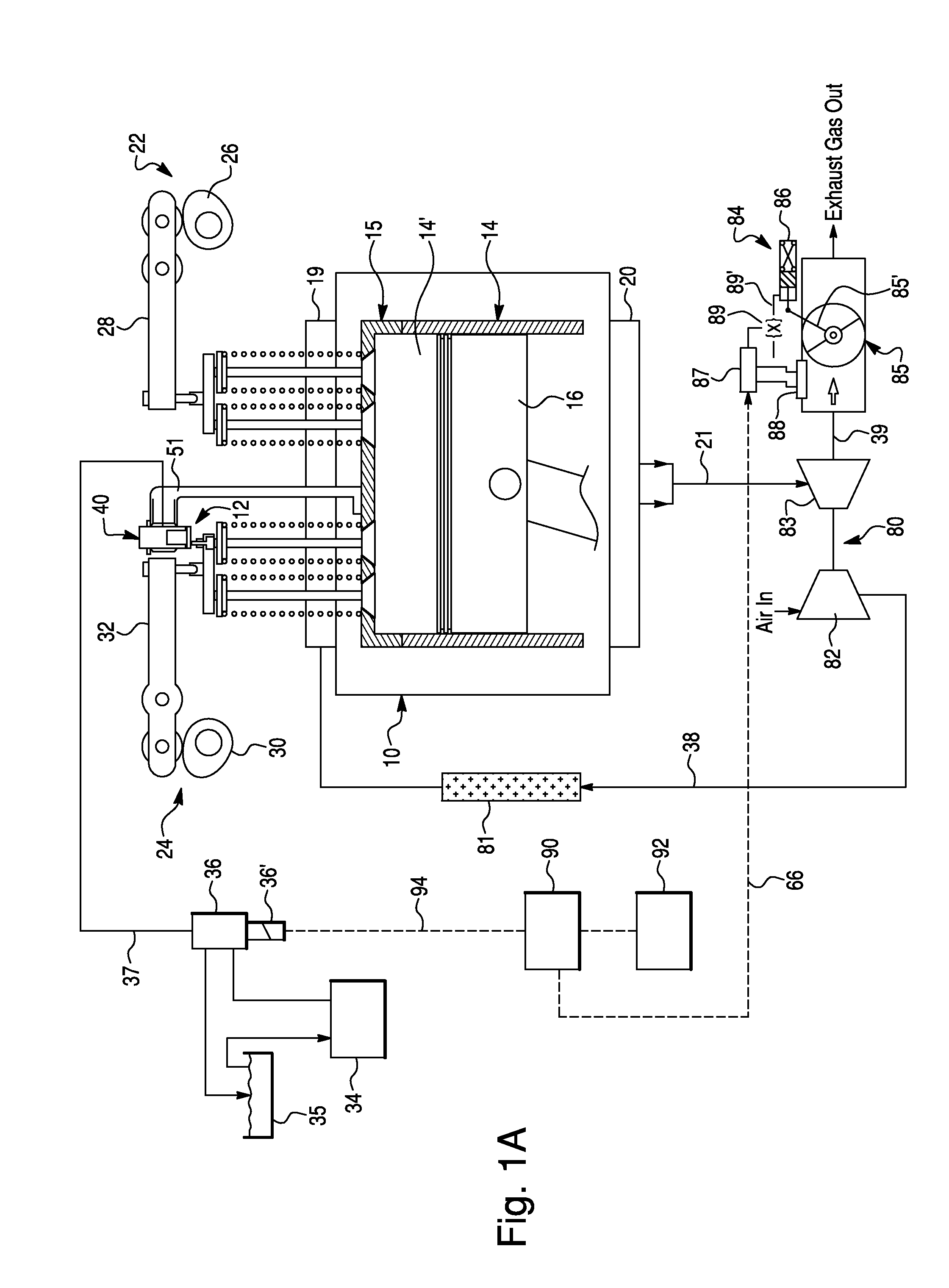

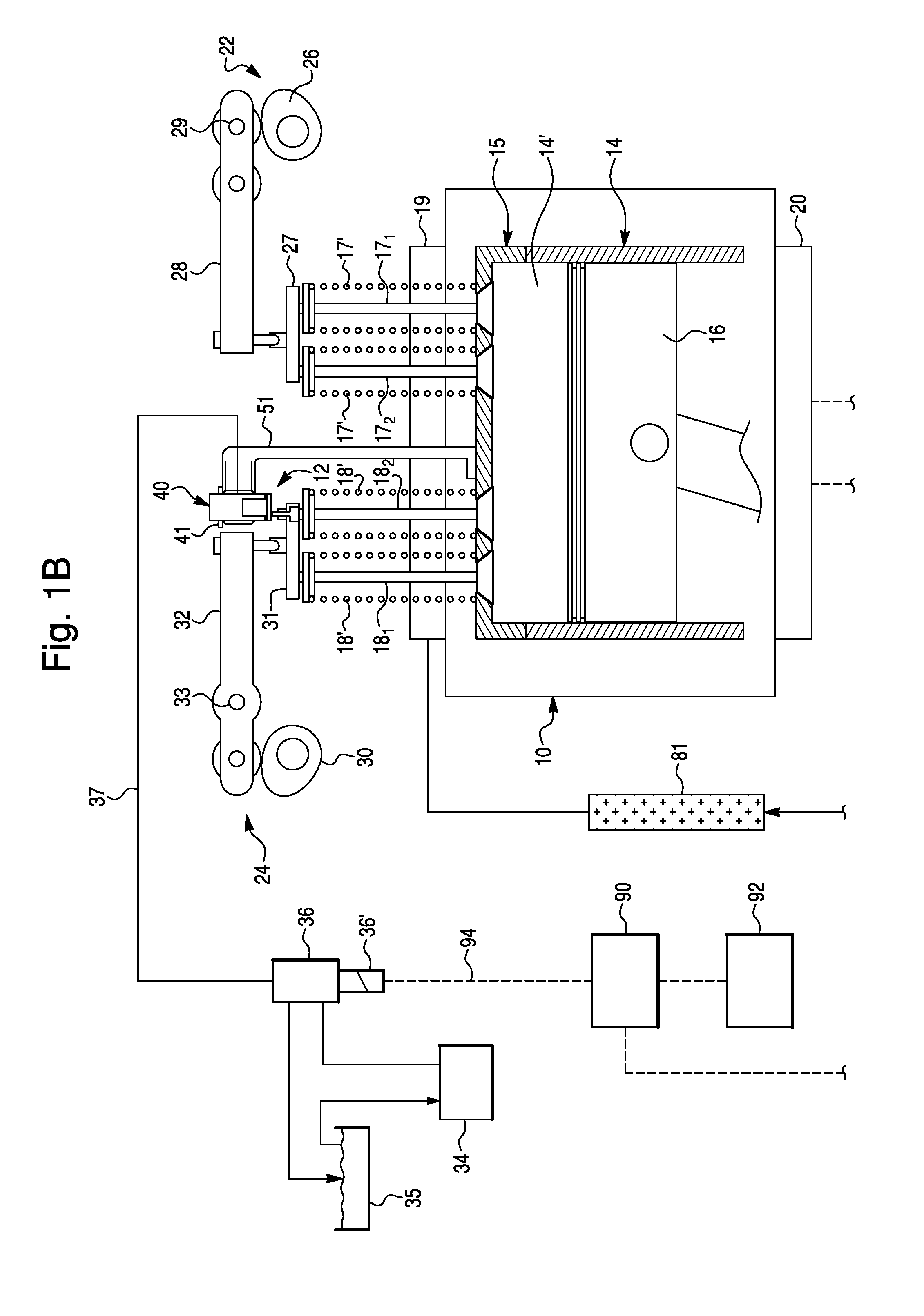

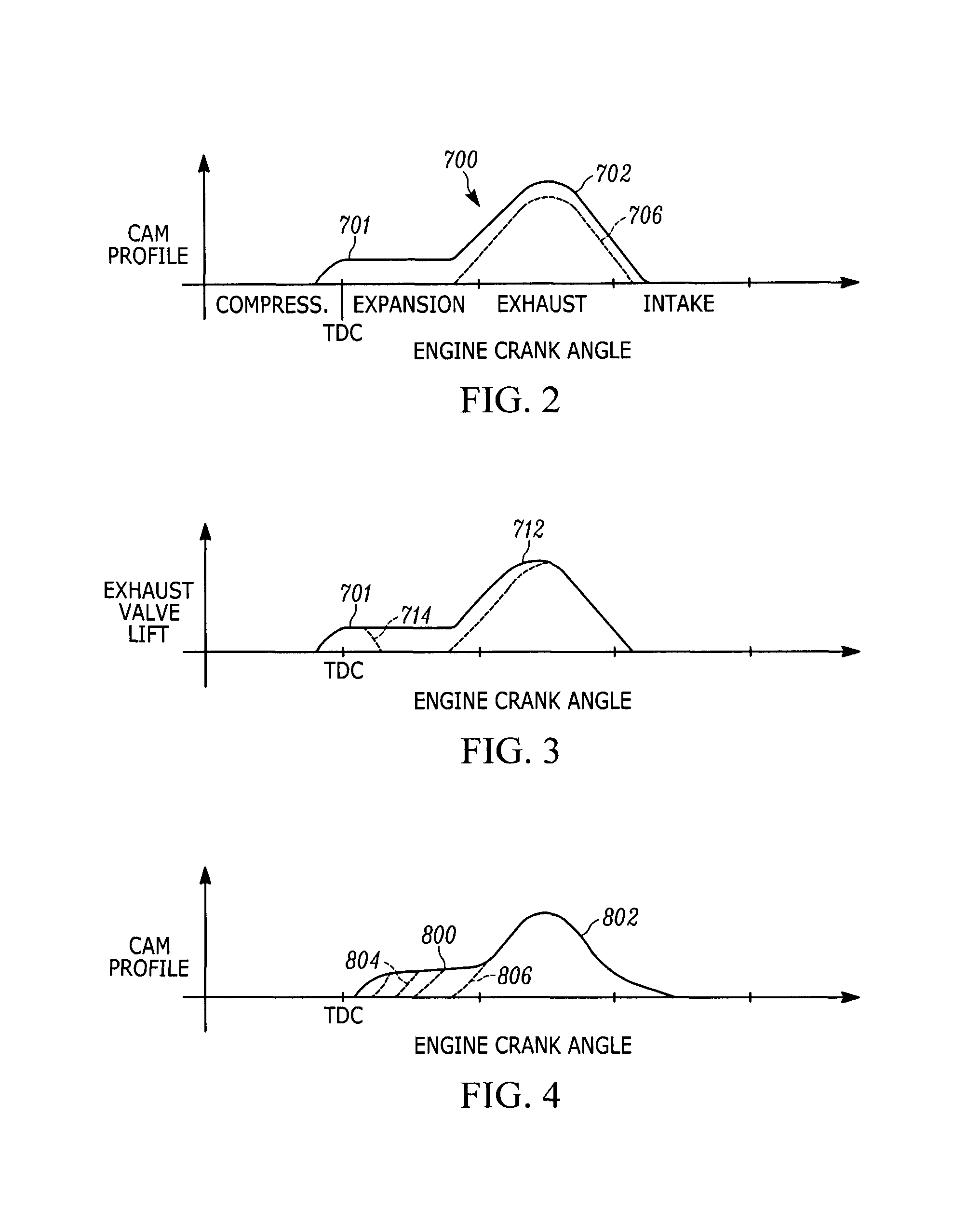

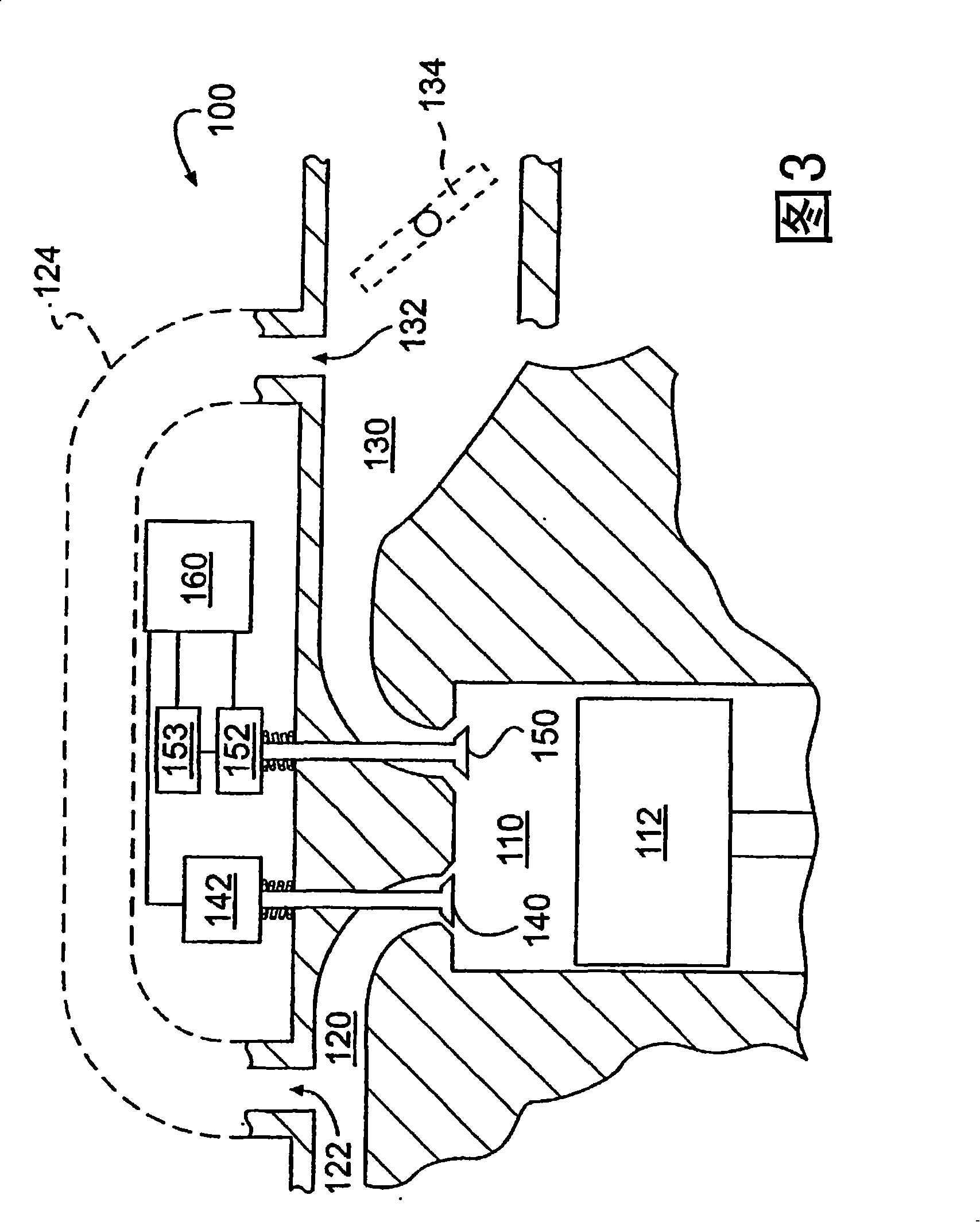

A method and system for actuating an internal combustion engine exhaust valve to provide compression release actuation during an engine braking mode of engine operation and early exhaust valve opening actuation during a positive power mode of engine operation is disclosed. The system may include a first cam having a compression release lobe and an early exhaust valve opening lobe connected to a hydraulic lost motion system including a first rocker arm. A hydraulically actuated piston may be selectively extended from the hydraulic lost motion system to provide the exhaust valve with compression release actuation or early exhaust valve opening actuation. The hydraulically actuated piston may be provided as a slave piston in a master-slave piston circuit in a fixed housing, or alternatively, as a hydraulic piston slidably disposed in a rocker arm. The method and system may further provide exhaust gas recirculation and / or brake gas recirculation in combination with compression release actuation and early exhaust valve opening actuation.

Owner:JACOBS VEHICLE SYST

Lost motion variable valve actuation system for engine braking and early exhaust opening

ActiveCN102414424AMeet the seating speed limitAvoid shockValve drivesOutput powerEngineeringExhaust gas recirculation

A method and system for actuating an internal combustion engine exhaust vaive to provide compression release actuation during an engine braking mode of engine operation and early exhaust valve opening actuation during a positive power mode of engine operation is disclosed. The system may include a first cam having a compression release lobe and an early exhaust valve opening lobe connected to a hydraulic lost motion system including a first rocker arm. A hydraulically actuated piston may be selectively extended from the hydraulic lost motion system to provide the exhaust valve with compression release actuation or early exhaust valve opening actuation. The hydraulicaily actuated piston may be provided as a slave piston in a master-slave piston circuit in a fixed housing, or alternatively, as a hydraulic piston slidably disposed in a rocker arm. The method and system may further provide exhaust gas recirculation and / or brake gas recirculation in combination with compression release actuation and early exhaust valve opening actuation.

Owner:JACOBS VEHICLE SYST

Fuel injector with non-metallic tip insulator

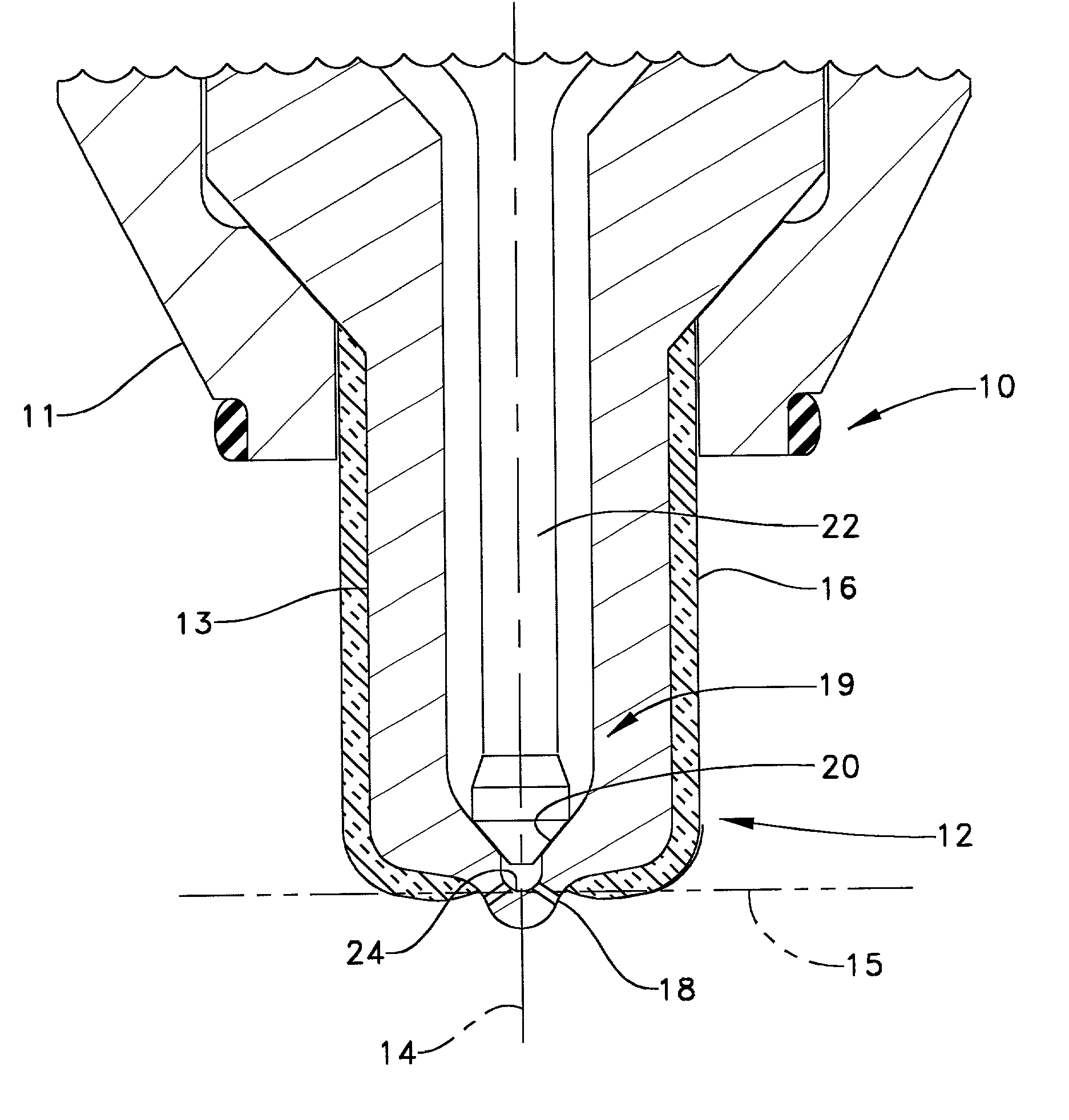

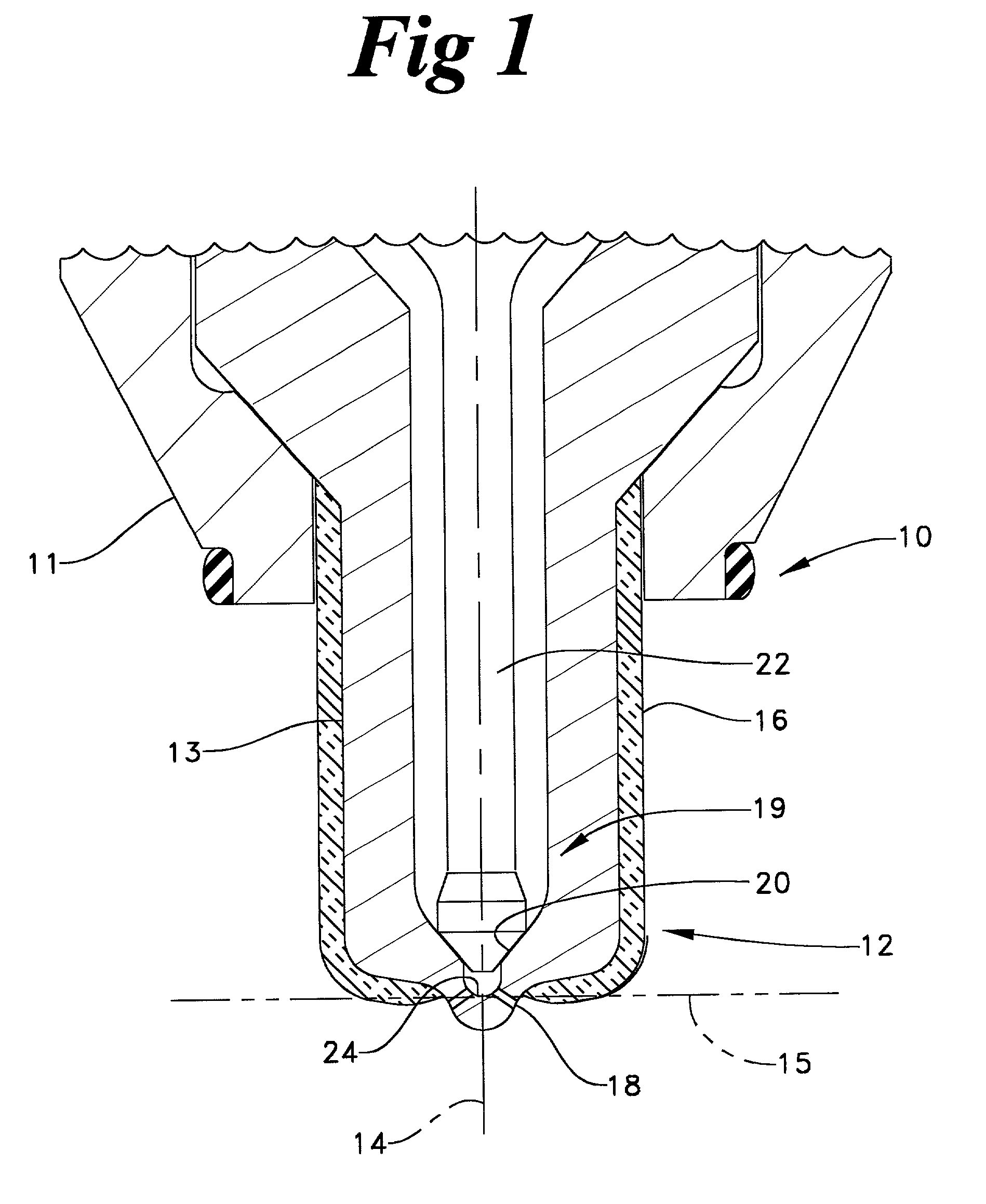

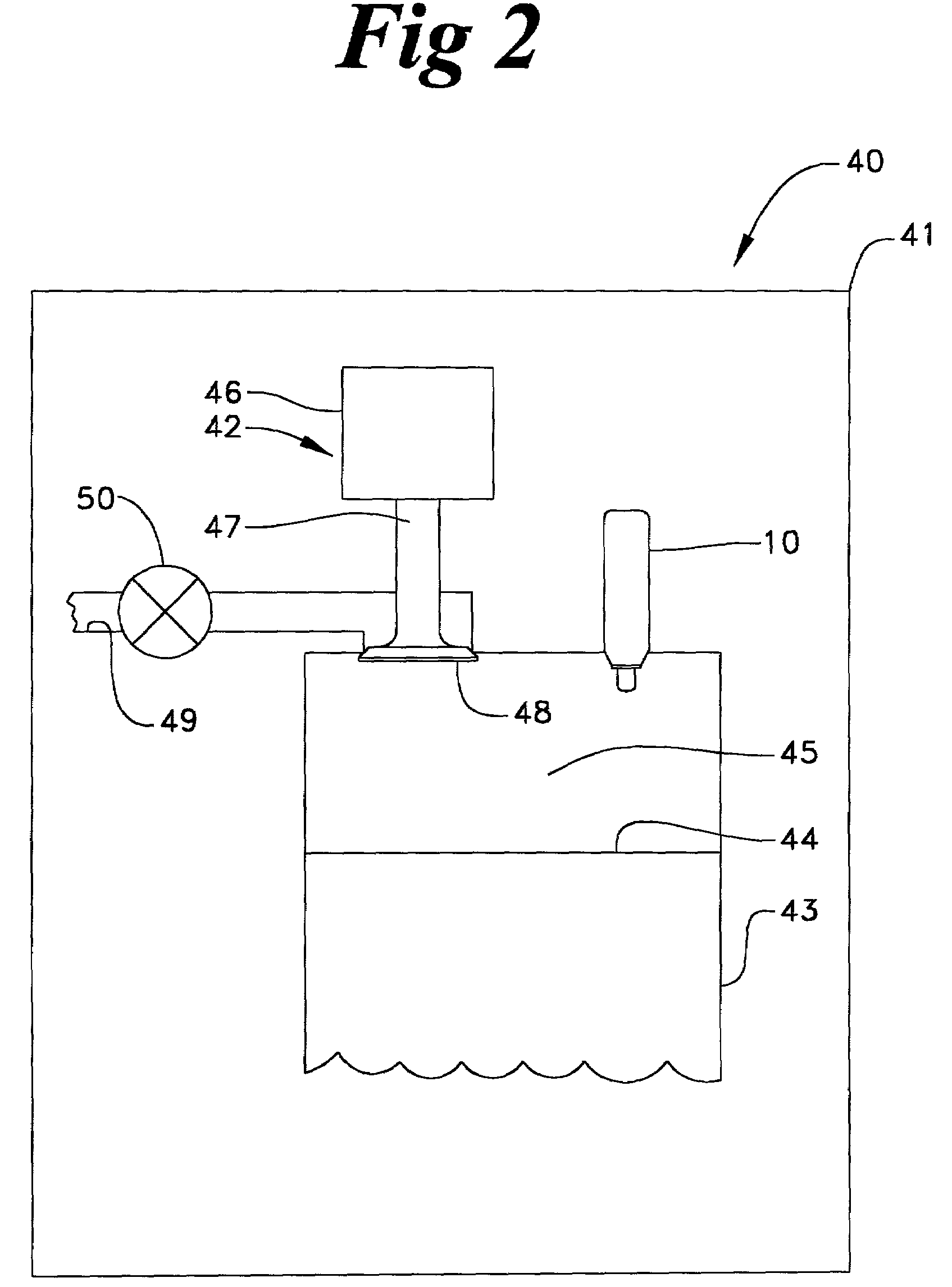

InactiveUS7070126B2Reducing injector tipReducing injector tip overheatingValve arrangementsCasingsEngineeringCeramic

A fuel injector is provided which has an injector body with a metallic tip having an outer surface. A non-metallic insulator, such as a ceramic, is attached to the tip and covers a portion of the outer surface. Injector tip overheating can be a problem, especially during sustained two-cycle boosted engine compression release braking. In addition, injector tip overheating can be a problem when an engine is experiencing simultaneous engine compression release braking and exhaust braking.

Owner:CATERPILLAR INC

Modal variable valve actuation system for internal combustion engine and method for operating the same

ActiveUS6925976B2Improve fuel economyImprove power densityValve drivesOutput powerExhaust brakeInlet valve

A variable valve actuation system for providing discrete exhaust and intake valve lift profiles for various operating modes of an internal combustion engine. The variable valve actuation system includes exhaust and intake rocker assemblies, exhaust and intake hydraulic extension devices operatively coupling corresponding rocker assemblies with respective engine valves and exhaust and intake control valves for selectively supplying the pressurized hydraulic fluid to the extension devices so as to independently switch them between a pressurized condition and a depressurized condition. The engine further includes an exhaust brake provided to initiate a small lift of the exhaust valve during the engine braking operation while the exhaust extension device maintains the exhaust valve open during a compression stroke for bleeder-compression release braking. The exhaust and intake valves can be adjusted independently to provide combinations of valve lift modes.

Owner:JENARA ENTERPRISES

Variable valve actuation and engine braking

Systems and methods of actuating two engine valves associated with a common engine cylinder using one or more lost motion systems and one or more control valves are disclosed. The control valves are capable of selectively trapping hydraulic fluid in the lost motion systems for auxiliary engine valve actuations and selectively releasing the hydraulic fluid to default to cam controlled valve seating of the engine valves. The systems may provide a combination of main exhaust, compression release, exhaust gas recirculation and early exhaust valve opening in preferred embodiments.

Owner:JACOBS VEHICLE SYST

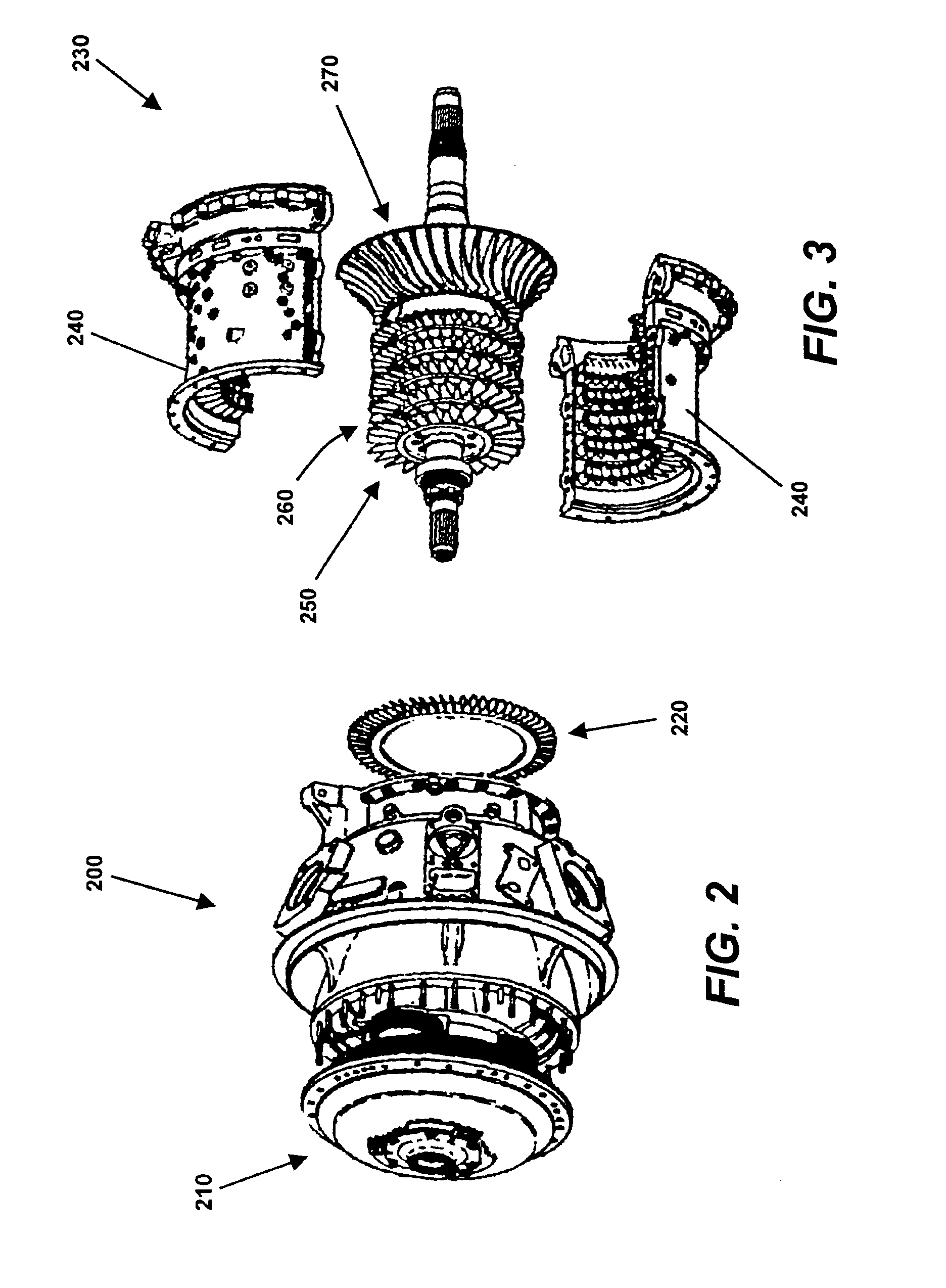

Overspeed control system for gas turbine electric powerplant

InactiveUS6895325B1Operational securityAnalogue computers for vehiclesError detection/correctionCombustorPower station

A turbine overspeed control system for a gas turbine electrical powerplant. The powerplant may employ an aeroderivative gas turbine engine for producing electrical power. The overspeed control system preferably comprises a compression relief system and an air directing system. When an overspeed condition of the gas turbine engine is detected, the compression relief system acts to remove air from a combustion section of the engine. Preferably, the air is removed to the atmosphere. The air directing system operates to ensure that air entering a compressor section of the gas turbine engine does not impinge on the blades of a compressor turbine located therein at the optimum angle. The result of operating the compression relief and air directing systems is a reduced combustor efficiency. Consequently, a reduced amount of hot gases are available to drive the turbines of the gas turbine engine, and the rotational speed thereof decreases.

Owner:ALTEK POWER CORP

Method and device for manufacturing rocking arm with main piston and auxiliary piston

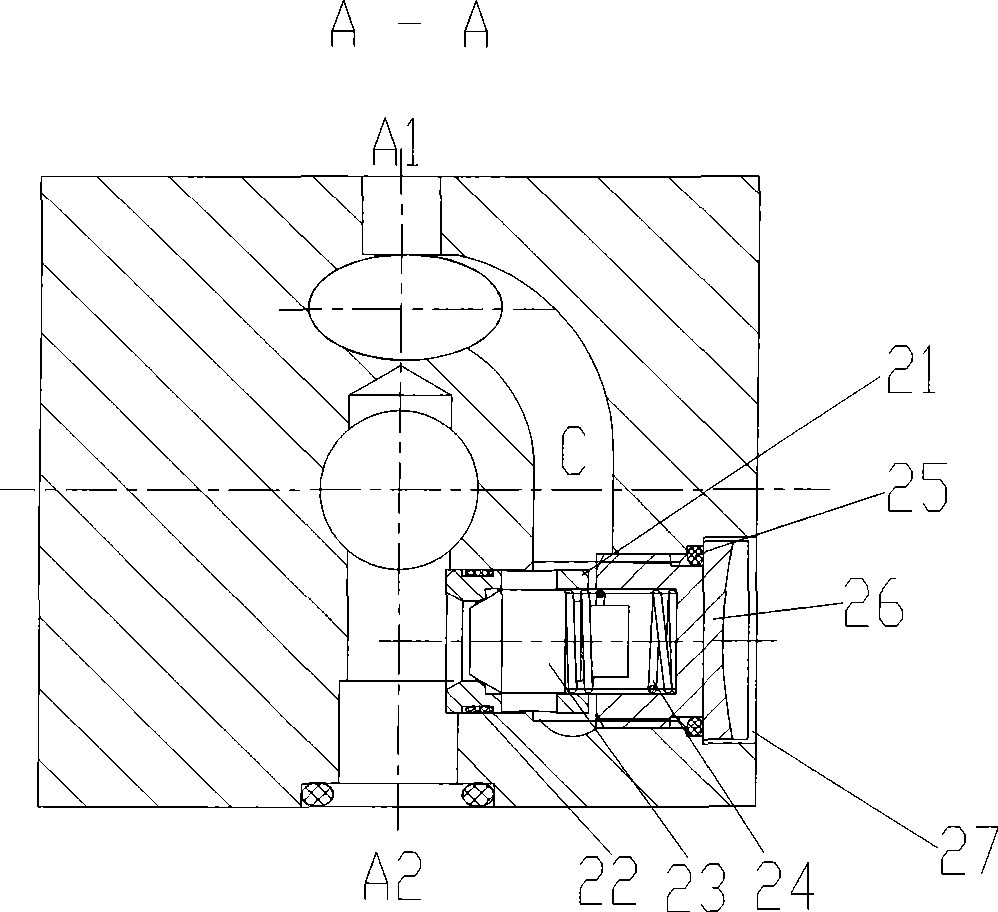

InactiveCN102787880AReduce braking loadIncrease braking powerValve arrangementsOutput powerEngineeringCam

Provided are a method and a device for manufacturing a rocking arm with a main piston and an auxiliary piston. A main piston hole and an auxiliary piston hole which are connected through a hydraulic channel are arranged in the rocking arm, the main piston is driven by using a braking boss on a cam, and the auxiliary piston is driven through hydraulic transmission to open at least one exhaust valve to achieve braking. During a braking process, an isometry section of a maximum braking lift of the braking cam is used, a retraction position of the main piston is kept, a hydraulic channel between the main piston hole and the auxiliary piston hole is closed, and a braking load on the auxiliary piston is transmitted to a braking support above the rocking arm. The main piston is further driven by an integrated exhaust boss on the cam, the main piston drives the rocking arm to move and be separated from the braking support, an oil discharging channel in the rocking arm is opened to discharge oil, the auxiliary piston is returned to the retraction position, and the exhaust valve is braked to move to a closed position. A compression releasing braking mechanism is integrated with the existing valve driving chain, braking load is borne by using the braking support, braking valve rise is reset, the braking load is reduced, and braking power is increased.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

Space linkage compression release mechanism

InactiveCN105659882BReduce in quantityLow costMechanical control devicesCosmonautic component separationEngineeringMechanical engineering

Space linkage pressing the release mechanism, through a rope linkage link mechanism to achieve locking and unlocking the tightening rod.Under the premise of maintaining the unchanged mechanical interface of the original rod type, the lock -up and unlocking the original firework cutter with the rope link mechanism to achieve the unlocking function.The agency overcomes the traditional pressure release agency at each pressure point to use a firework cutter (or other release power sources) to achieve the unlocking function, so it can reduce a large number of spacecraft firework cutters (or other power source unlocking unlockingThe number of devices) reduces costs. At the same time, the agency has a low impact load when unlocked, does not generate excess objects, and can achieve multiple tightening points and unlocking function.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

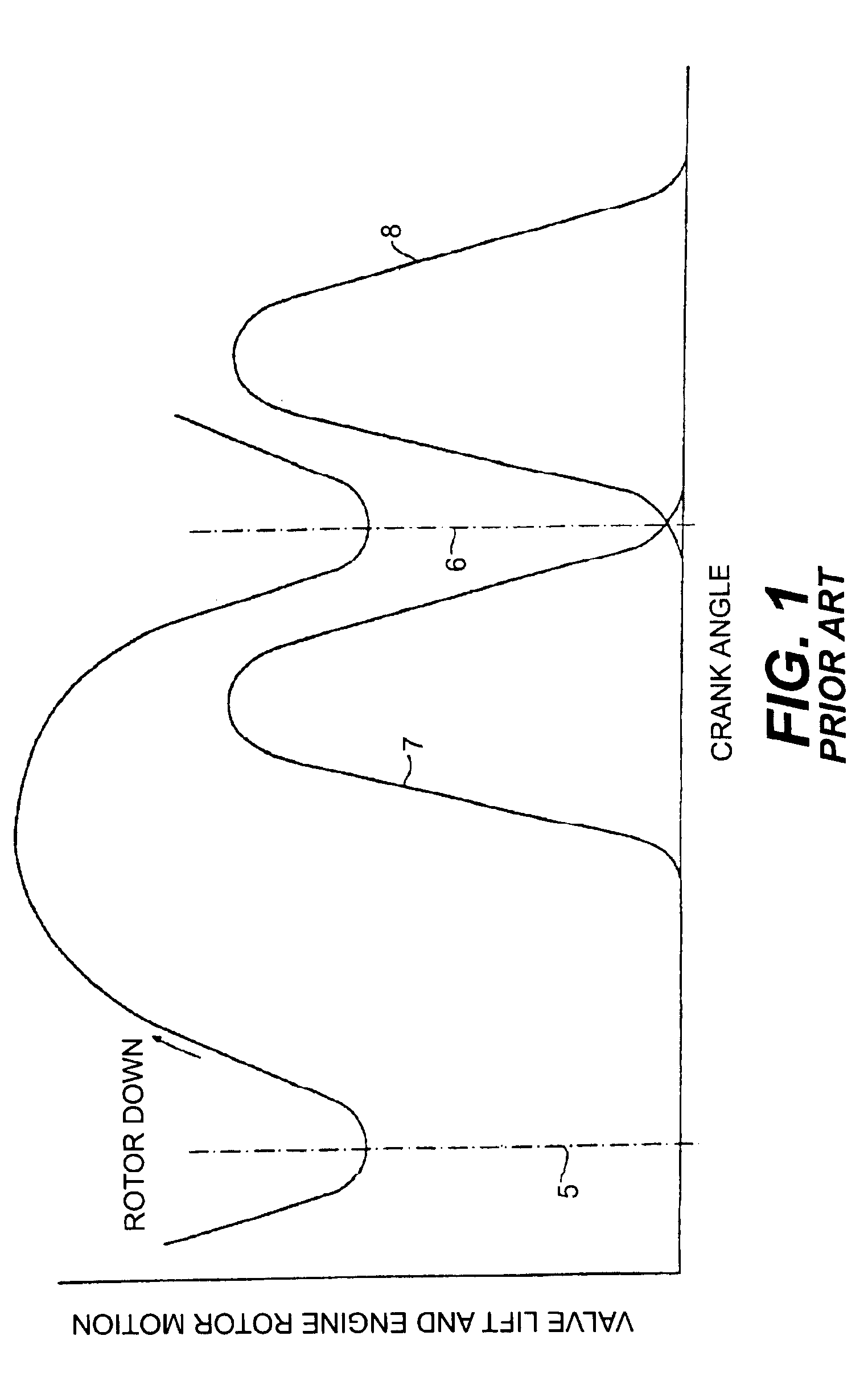

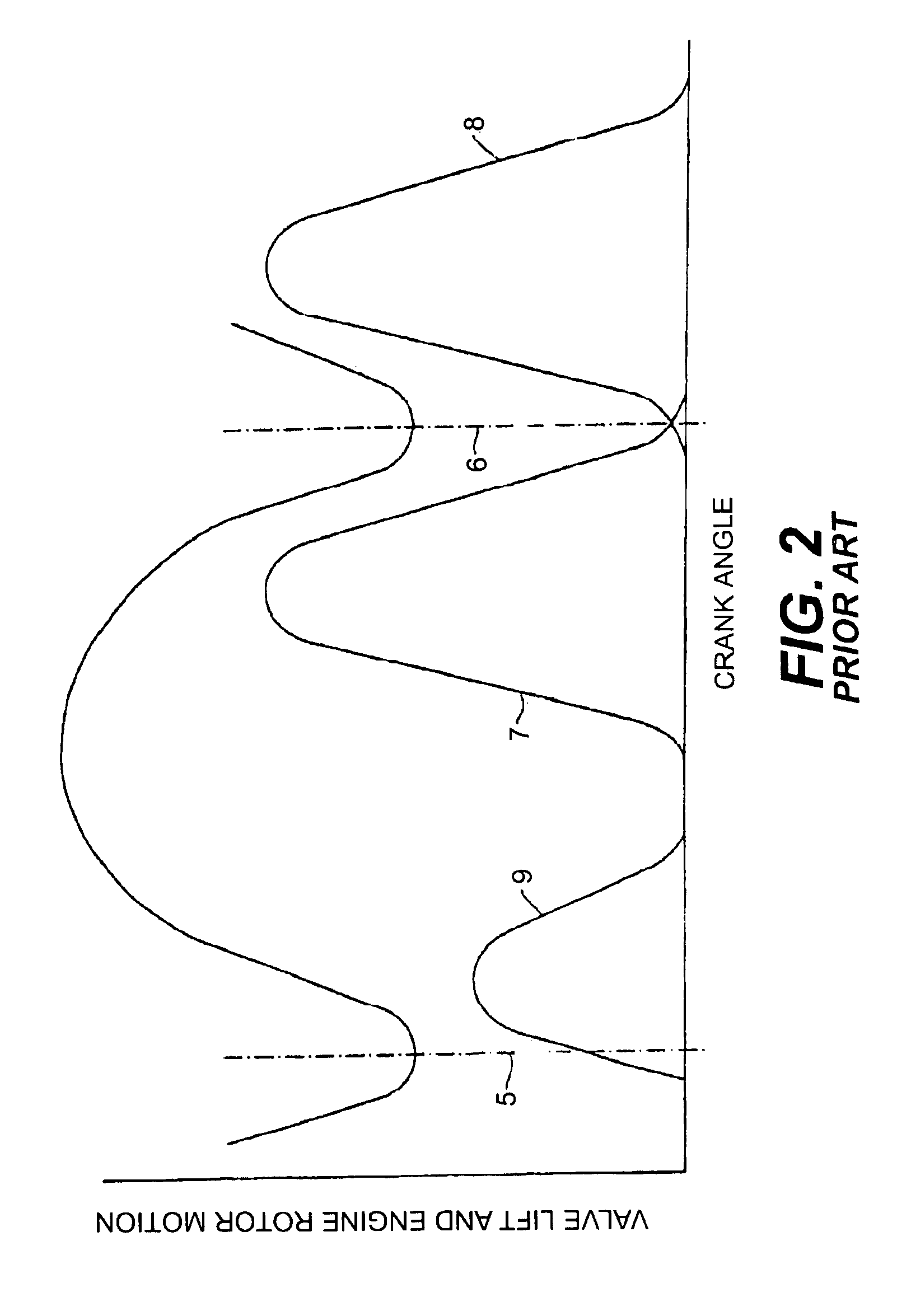

Multi-cycle, engine braking with positive power valve actuation control system and process for using the same

InactiveUSRE39258E1Stable and reliableEasy to controlValve arrangementsExhaust gas recirculationControl systemInlet valve

An apparatus and method for effectuating multi-cycle engine braking is disclosed. The present invention controls the operation of the engine valves to permit more than one compression release event during a single engine operating cycle. The apparatus includes an assembly for operating at least one exhaust valve of an engine cylinder during a positive power operation. The apparatus further includes an assembly for operating at least one intake valve of the engine cylinder. The apparatus further including an assembly for operating the at least one exhaust valve during an engine braking operation.

Owner:JACOBS VEHICLE SYST

Fusing type compression release mechanism and release method thereof

ActiveCN104890902ASimple structureReduce weightCosmonautic vehiclesCosmonautic power supply systemsBiomedical engineeringCompression release

The invention discloses a fusing type compression release mechanism and a release method thereof, wherein the release mechanism comprises a bearing rope, a heater, a fixed section, a separate spring and a separate section; the fixed section, the separate spring and the separate section are sequentially connected to the bearing rope; the separate spring is in compression state; the heater is placed on the bearing rope; two ends of the bearing rope defines the prolapse of the fixed section and the separate section; the release method comprises following steps: S91: connecting a main body structure to the fixed section and connecting a separate body to the separate section; S92: powering the heater and fusing the bearing rope; and S93: ejecting the separate body to the outside with the separate section under the effect of the separate spring. The fusing type compression release mechanism and the release method thereof has the advantages of light weight, simple structure, low cost and high reliability of releasing.

Owner:SHANGHAI AEROSPACE SYST ENG INST

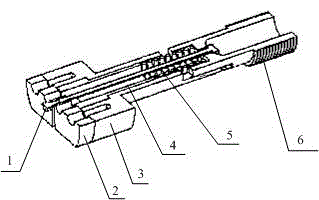

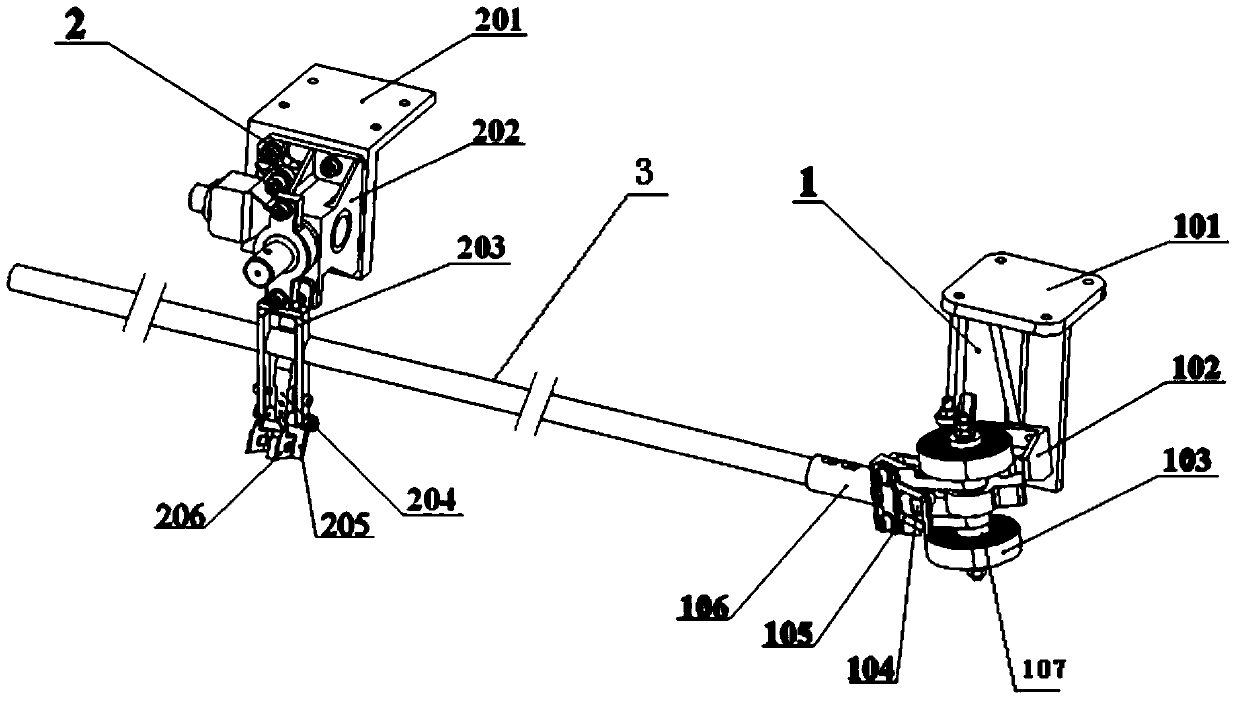

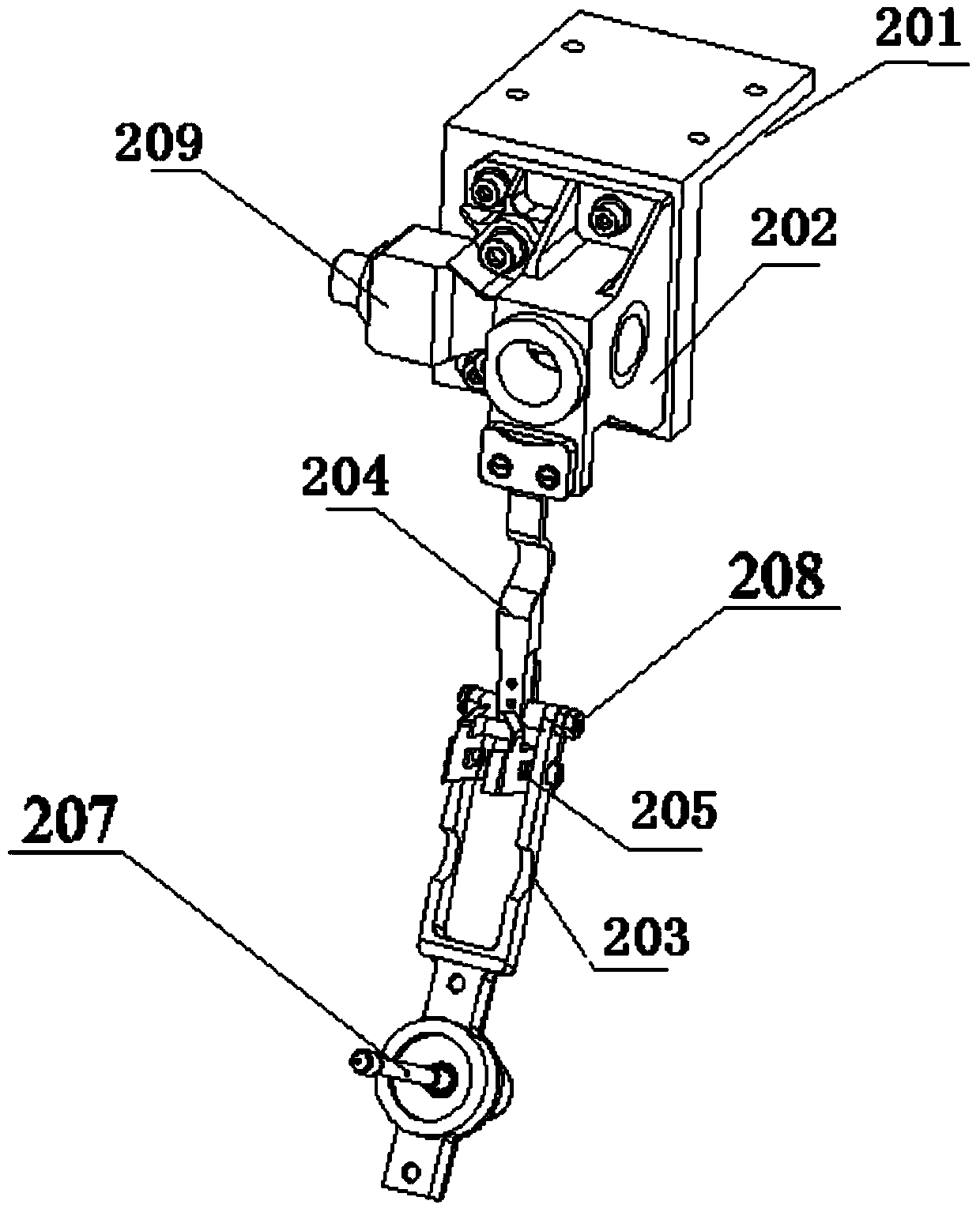

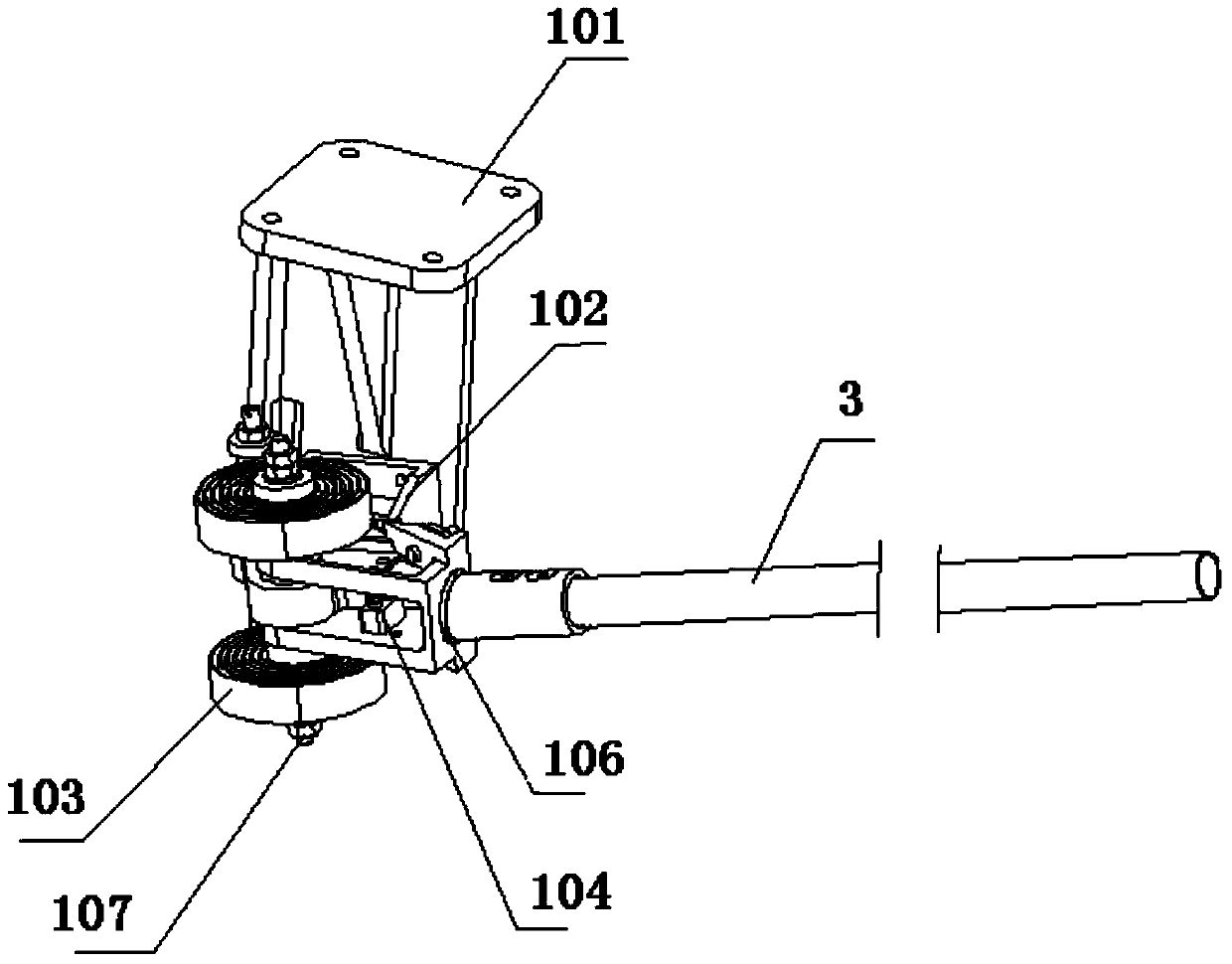

Unfolding release device of rod antenna

ActiveCN104201455AEffective lockingImprove reliabilityCollapsable antennas meansLocking mechanismEngineering

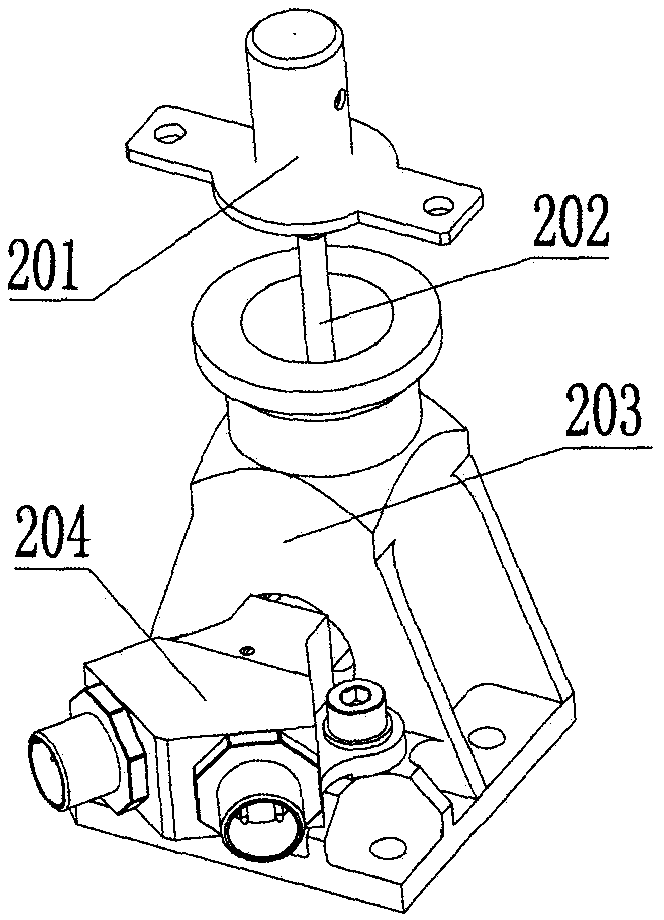

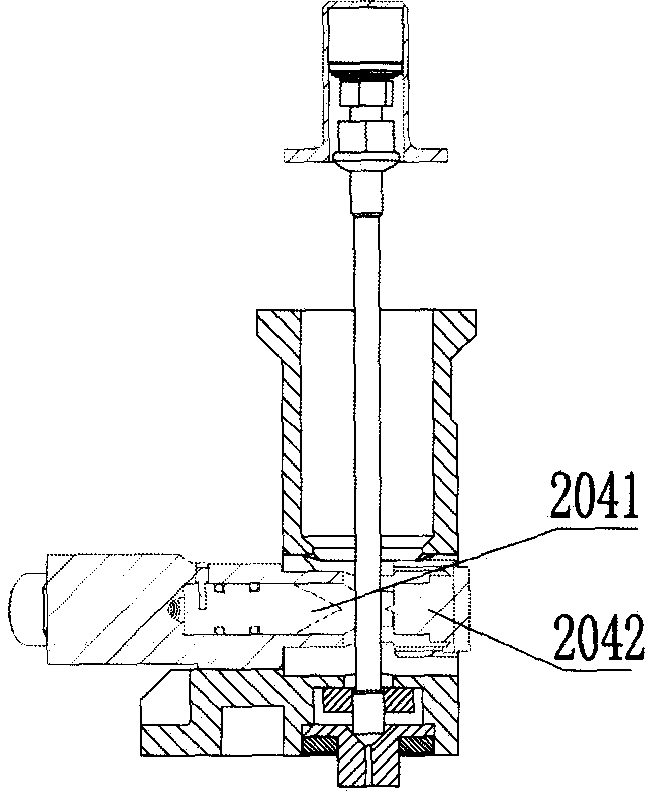

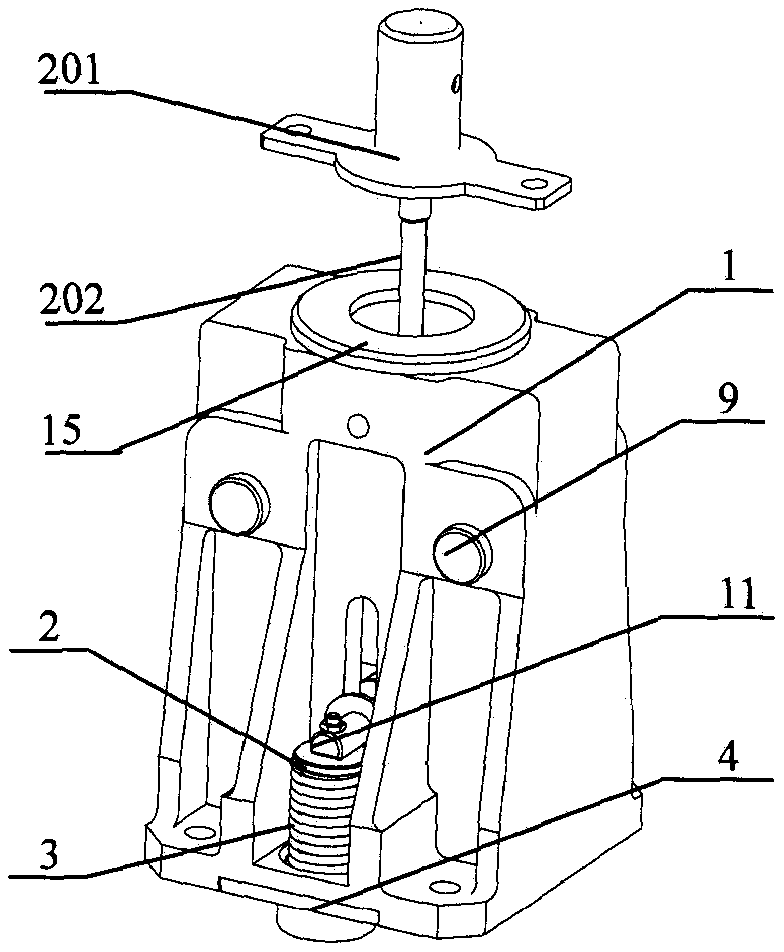

The invention belongs to the technical field of aerospace spaceborne antennas and particularly relates to an unfolding release device of a rod antenna. According to the technical scheme, the unfolding release device comprises the rod antenna (3), a compression release mechanism (2) and an unfolding locking mechanism (1); the compression release mechanism (2) comprises an installation base (201), a compression base assembly (202), a swing frame (203), an installation frame (204), a limiting supporting plate (205), a locking reed (206), a compression screw (207) and a pyrotechnic cutter (209); the unfolding locking mechanism (1) comprises an installation frame (101), a fixed hinge support (102), a volute spring (103), a limiting block (104), a locking leaf spring (105) and a rotating hinged head (106). According to the unfolding release device of the rod antenna, the rod antenna (3) can be unfolded to a fixed angle and can be effectively locked before and after the release.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI +1

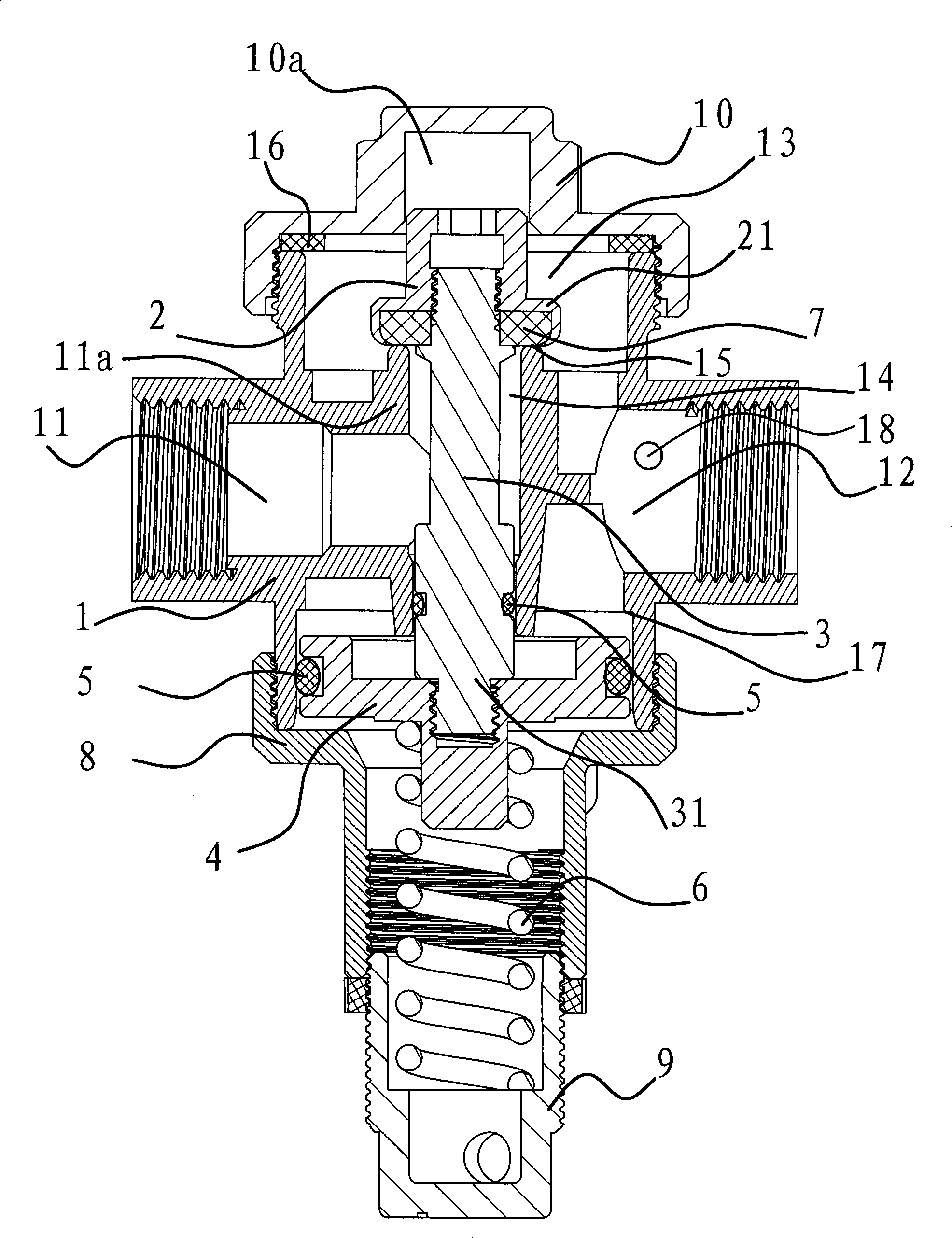

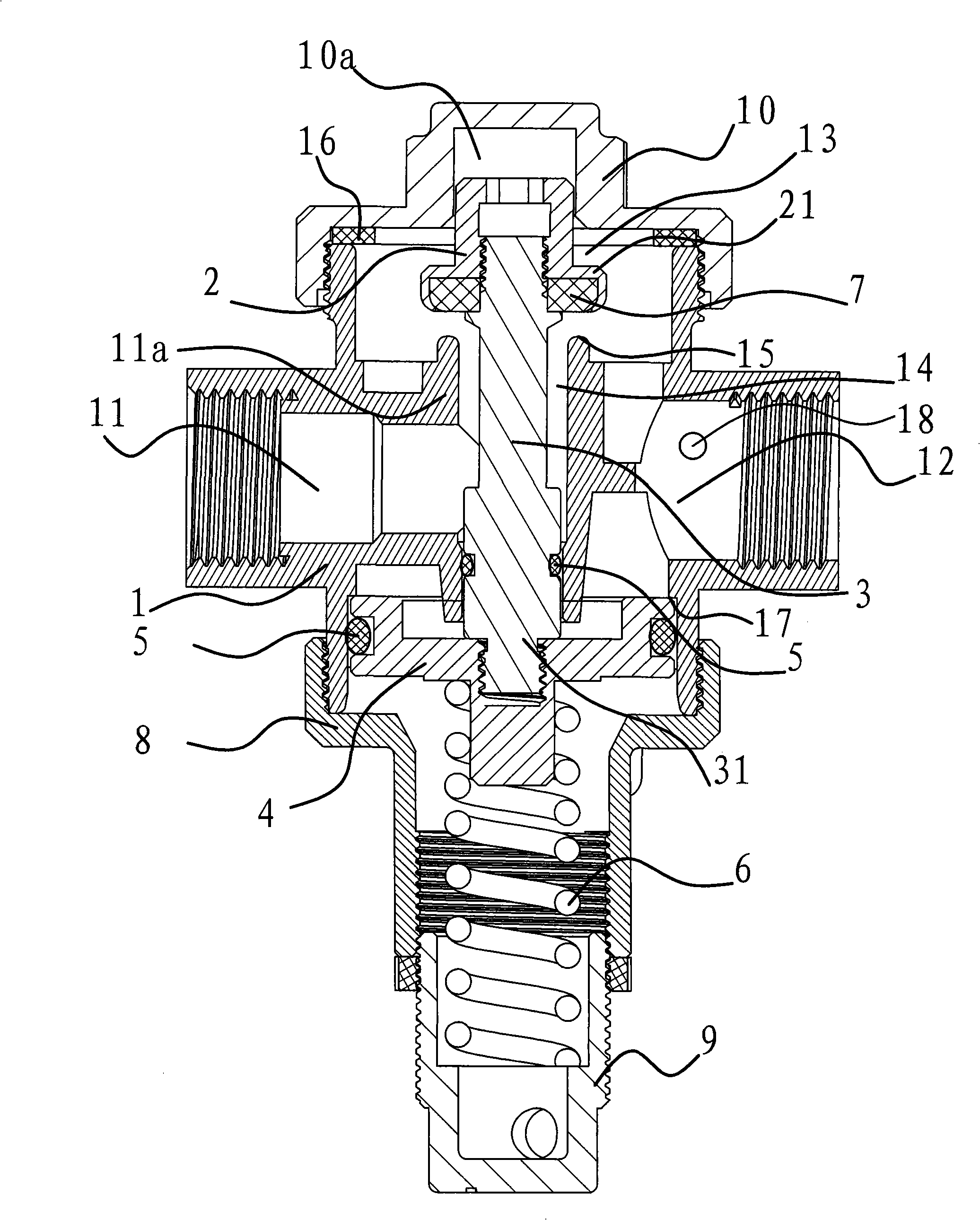

Adjustable compression release valve

InactiveCN101298890AHigh sensitivitySimple structureOperating means/releasing devices for valvesEqualizing valvesAuto regulationEngineering

The invention provides an adjustable pressure reducing valve, belonging to the valve technical field, which solves the problems of small adjustable range of the pressure reducing valve, lower sensitivity in the traditional pressure reducing valve, which includes a valve body with an inlet chamber and an outlet chamber and a valve handle arranged in the valve body, wherein a middle chamber is arranged in the valve body between the inlet chamber and the outlet chamber, and the inlet chamber communicates with the outlet chamber through the middle chamber. A sealing surface and a valve core sealed with the sealing surface are arranged in the middle chamber. The valve handle is movably arranged in the inlet chamber, one end of which passes through the inlet chamber and is fixed with the valve core. A lower piston is arranged in the outlet chamber, the other end of valve handle passes through the inlet chamber backwards and is fixed with the lower piston. A spring is arranged at the lower part of the lower piston, and one end of the spring abuts against the lower piston, and the other end abuts against the adjusting mechanism which can adjust the blenometer. The adjustable pressure reducing valve has the characteristics of simple structure, high sensitivity and wide application range.

Owner:ZHEJIANG WORLD BRASS

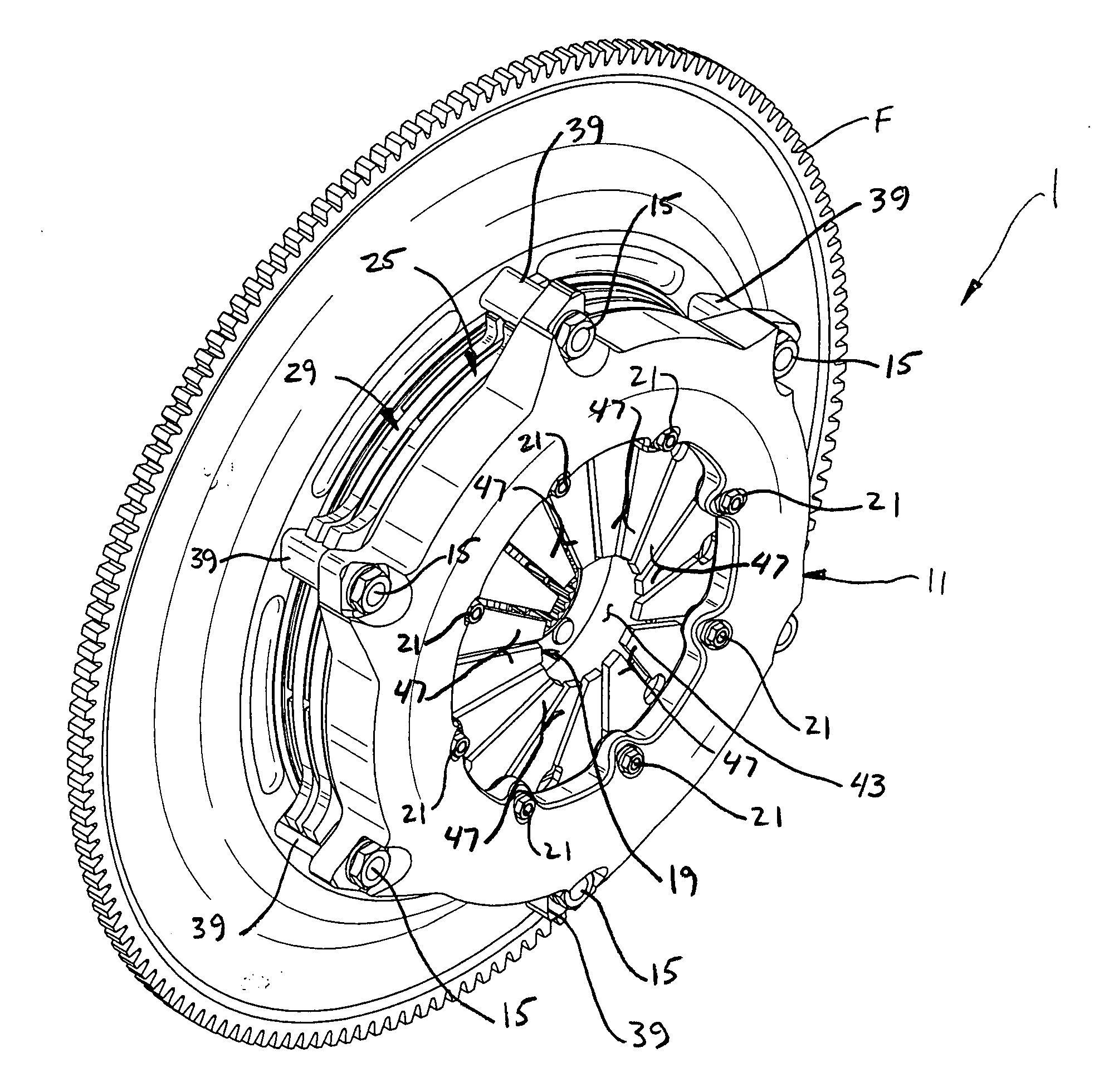

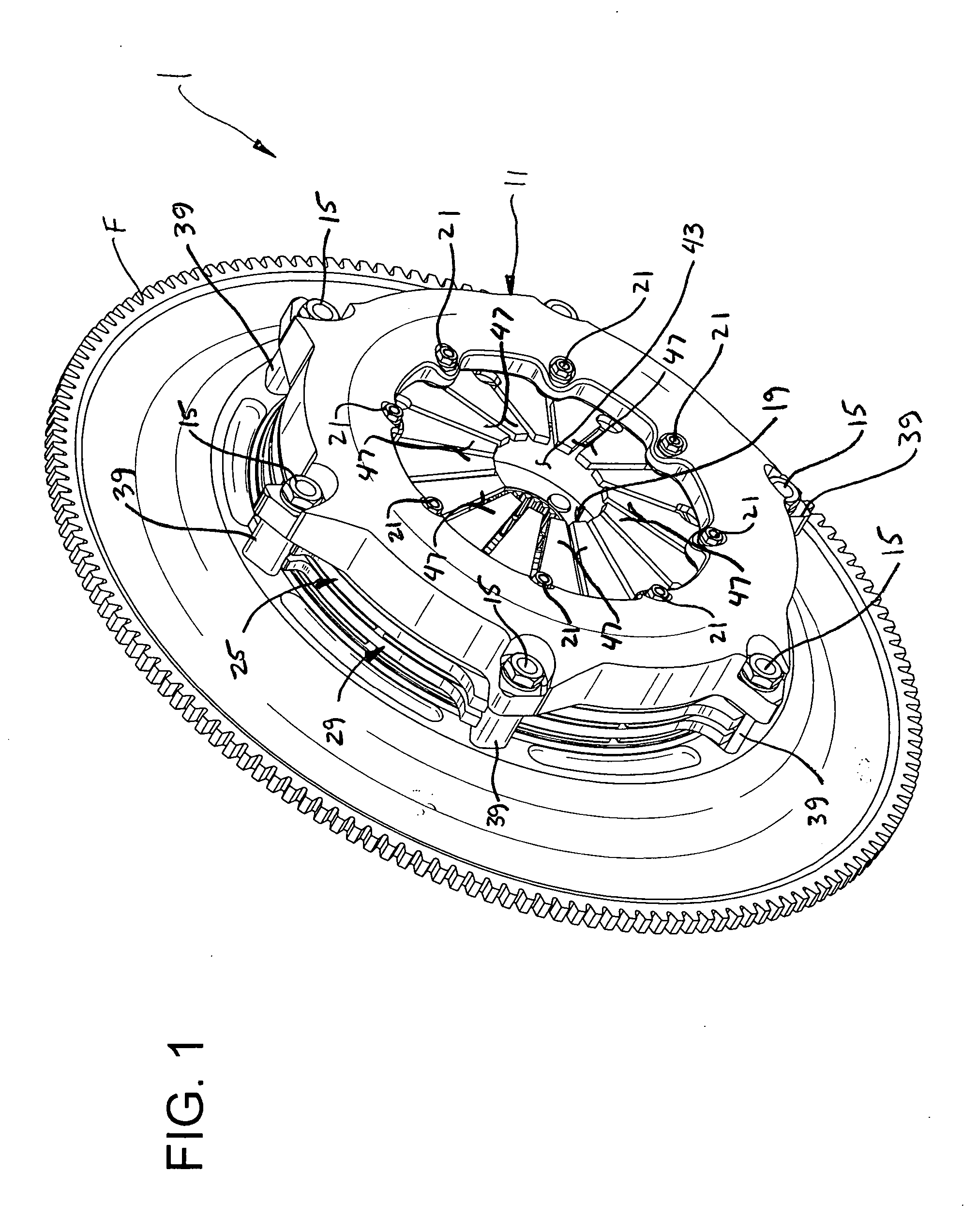

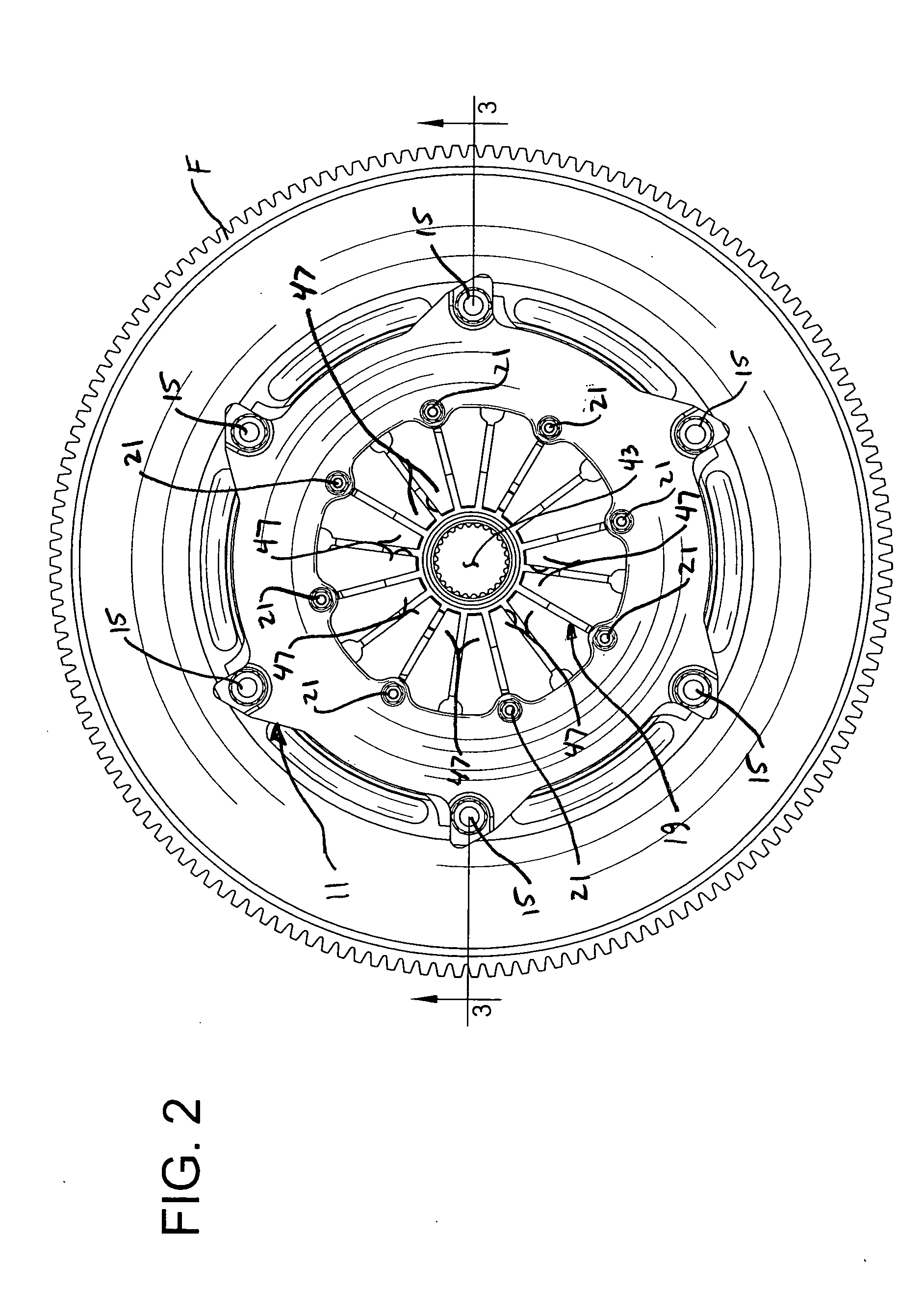

Friction clutch assembly

InactiveUS20050121282A1Reduce deflectionReduce inertiaFriction clutchesInterengaging clutchesDrive shaftEngineering

A friction clutch assembly comprises a cover mounted on a flywheel of a driving shaft. A pressure plate has a contact surface for receiving a driving force from the driving shaft that is axially moveable between an engaged position and a disengaged position. A spring supported by the cover urges the pressure plate into the engaged position. Compression of the spring releases pressure on the pressure plate to permit movement of the pressure plate to the disengaged position. At least one spacer attached to the cover and flywheel has an external surface that engages the pressure plate upon rotation of the flywheel. The external surface of the spacer conforms to the contact surface of the pressure plate so that torque is transmitted between the flywheel and the pressure plate over at least a line of engagement of the spacer external surface and the pressure plate contact surface upon rotation of the flywheel. The cover may have a continuous curved surface with a varying radius of curvature over a length of the curve to resist deflection and prevent premature failure of the cover.

Owner:ACE MFG & PARTS

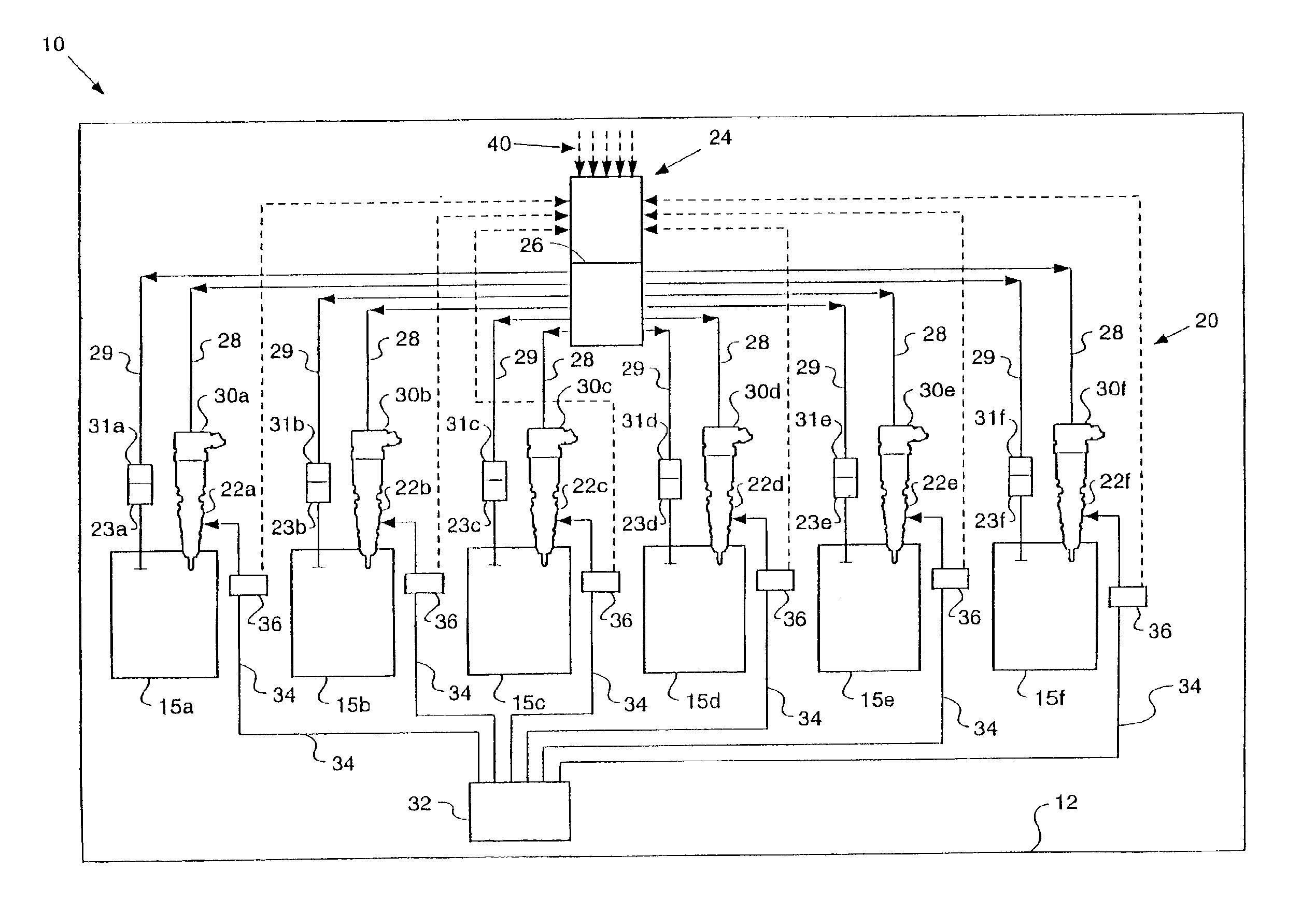

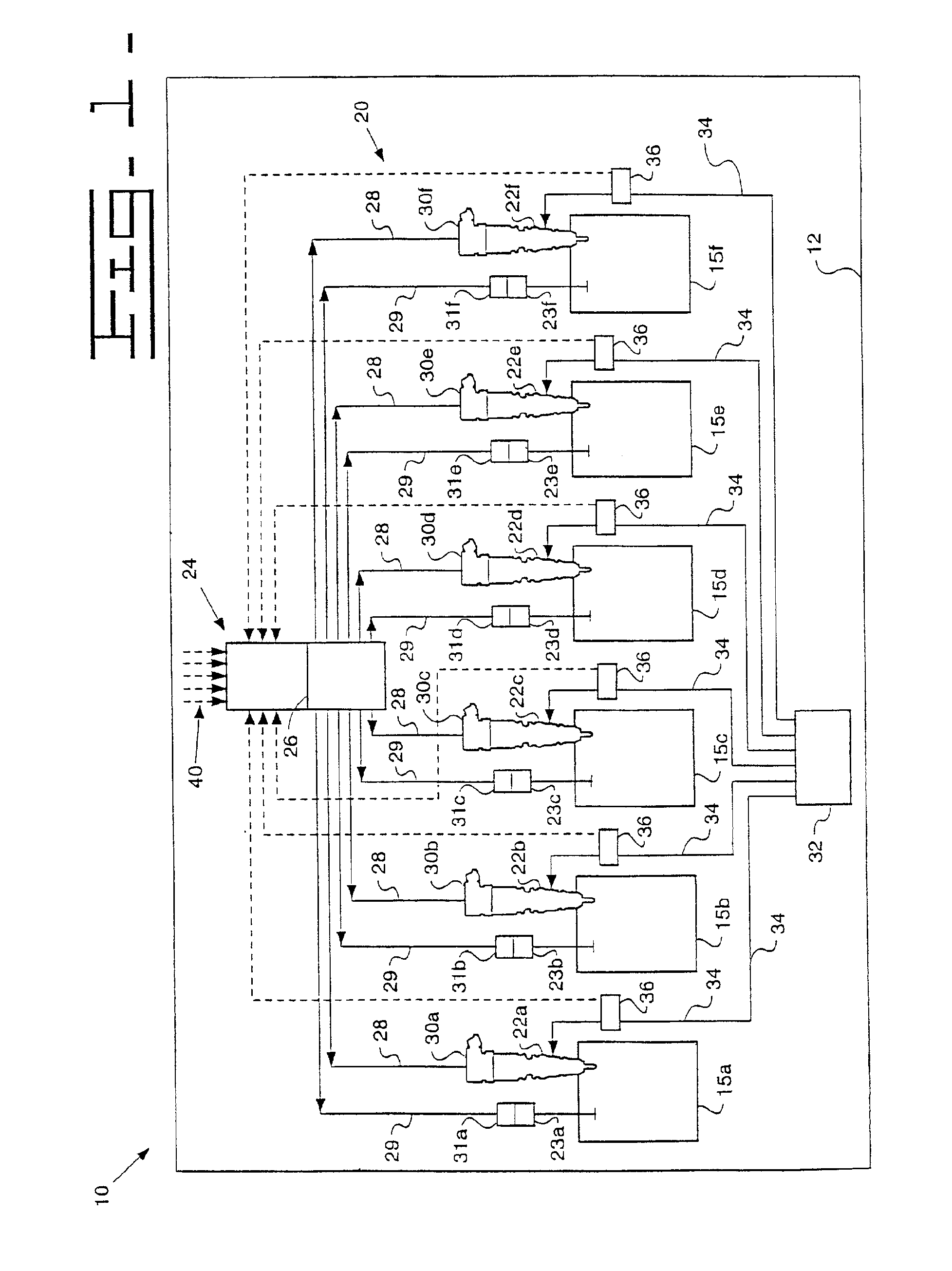

In-chassis engine compression release brake diagnostic test and electronic control module using the same

It is becoming more common for diesel engine cylinders to include an engine compression release brake that can utilize energy built up in the cylinder to provide additional braking for the vehicle. The present invention utilizes a software diagnostic test that is stored in an electronic control module to detect defects in the engine compression release brakes. In particular, the present invention operates a first portion of the engine cylinders in a power mode and a second portion of the engine cylinders in a braking mode and compares a resulting fuel injector response or engine response to an expected value to determine if one or more of the engine compression release brakes are performing as expected.

Owner:CATERPILLAR INC

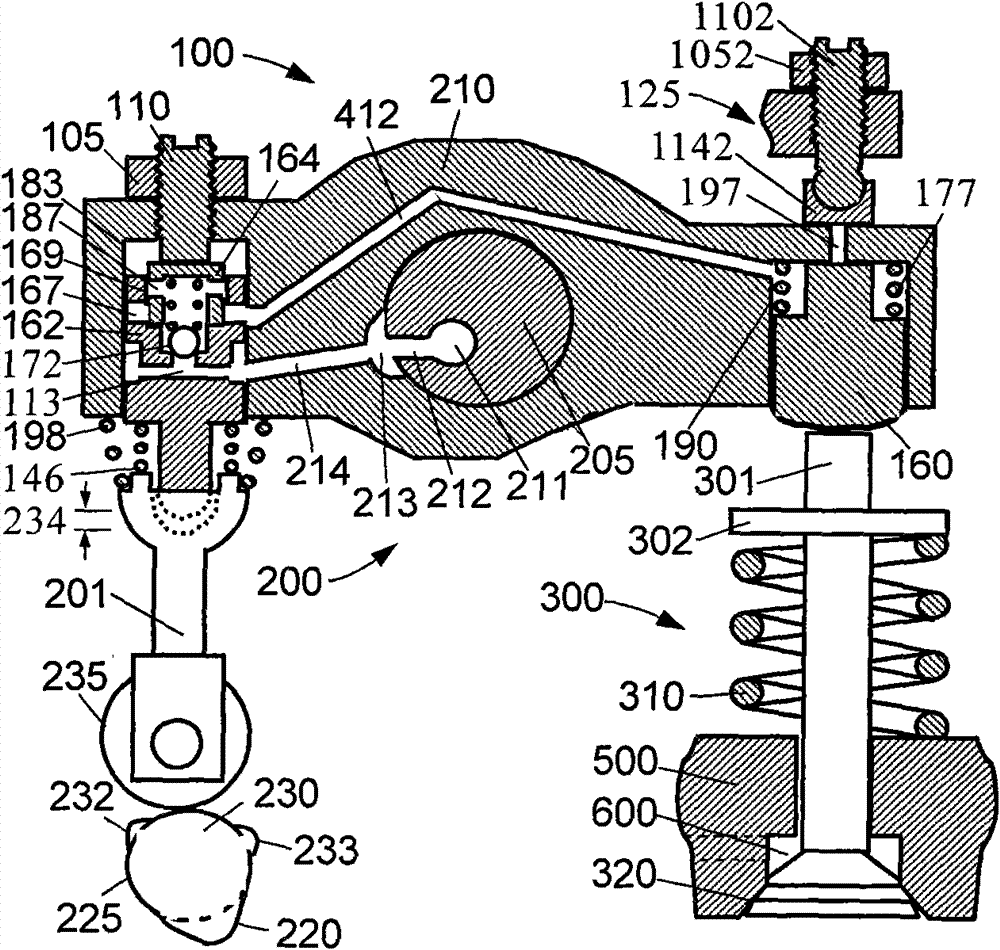

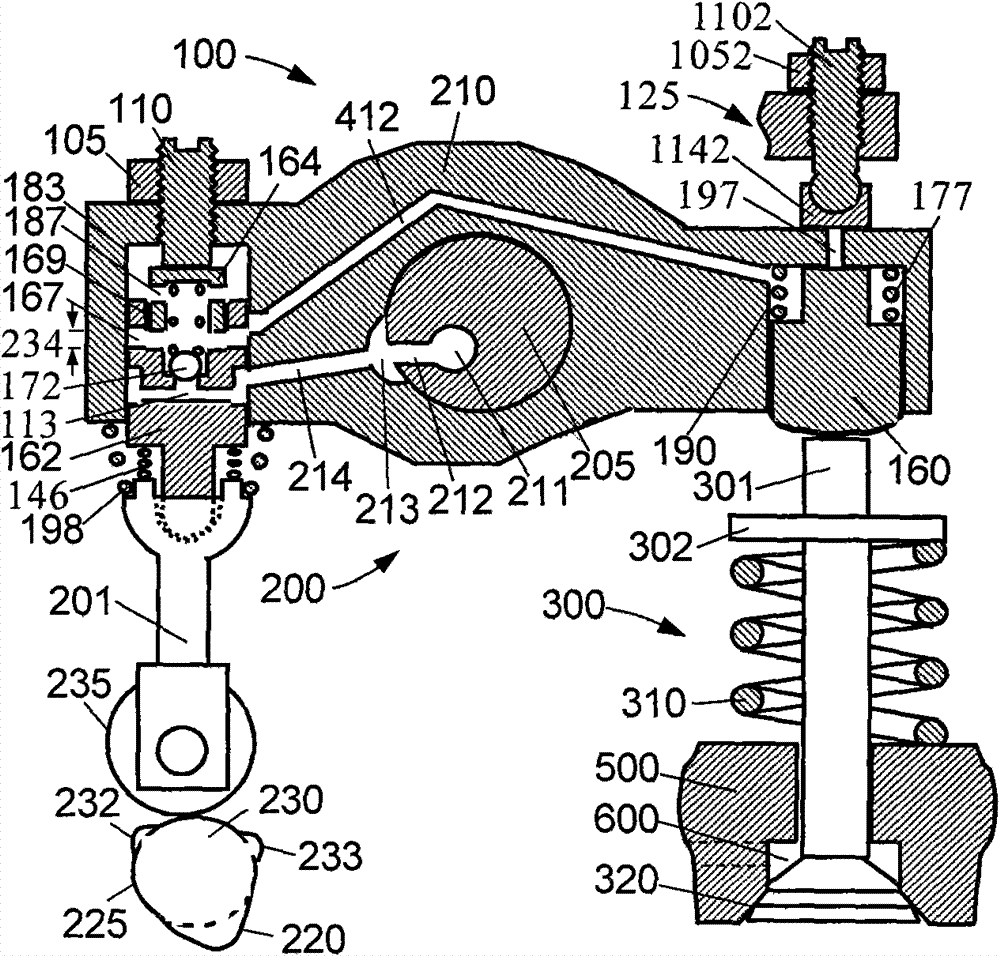

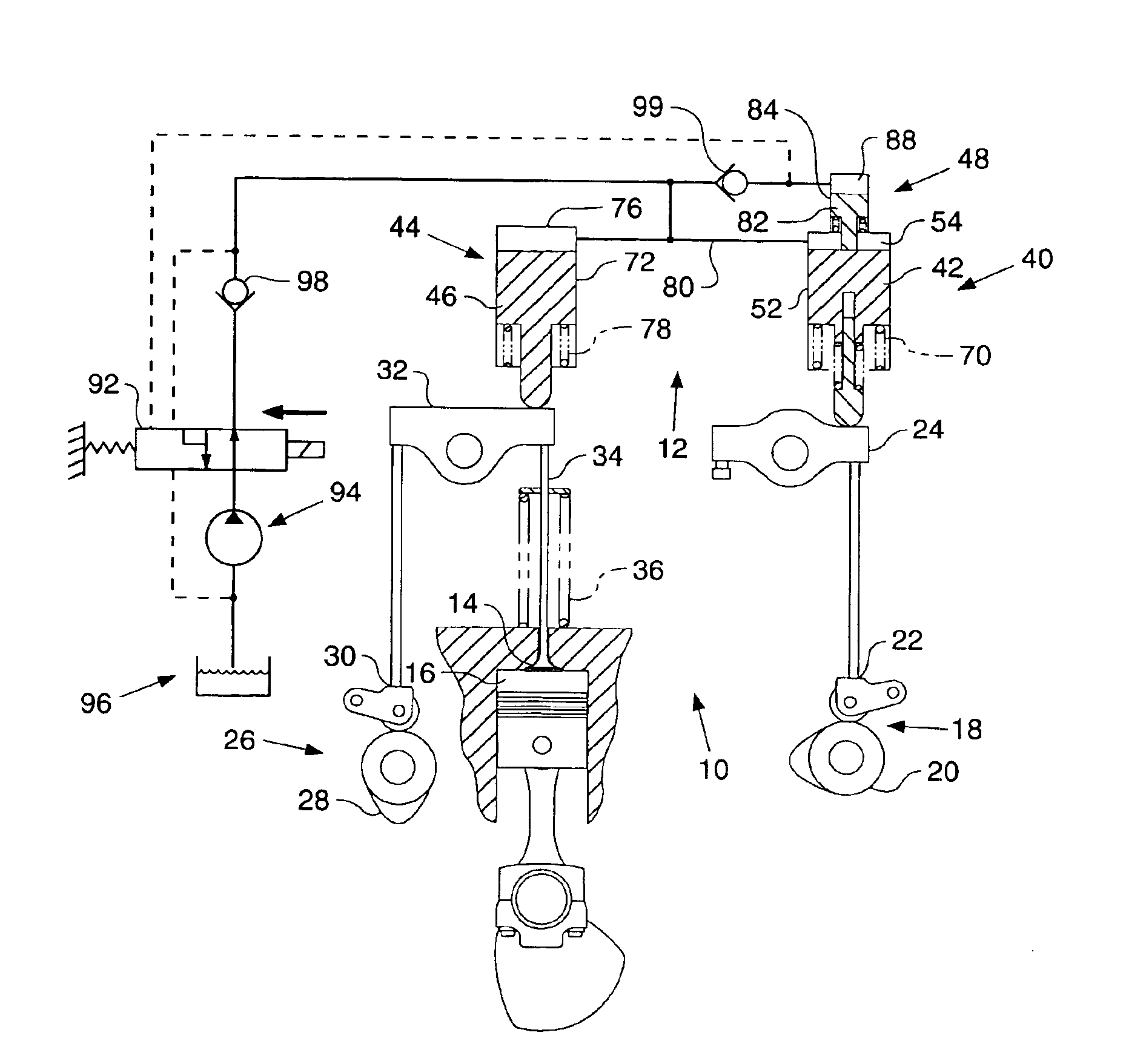

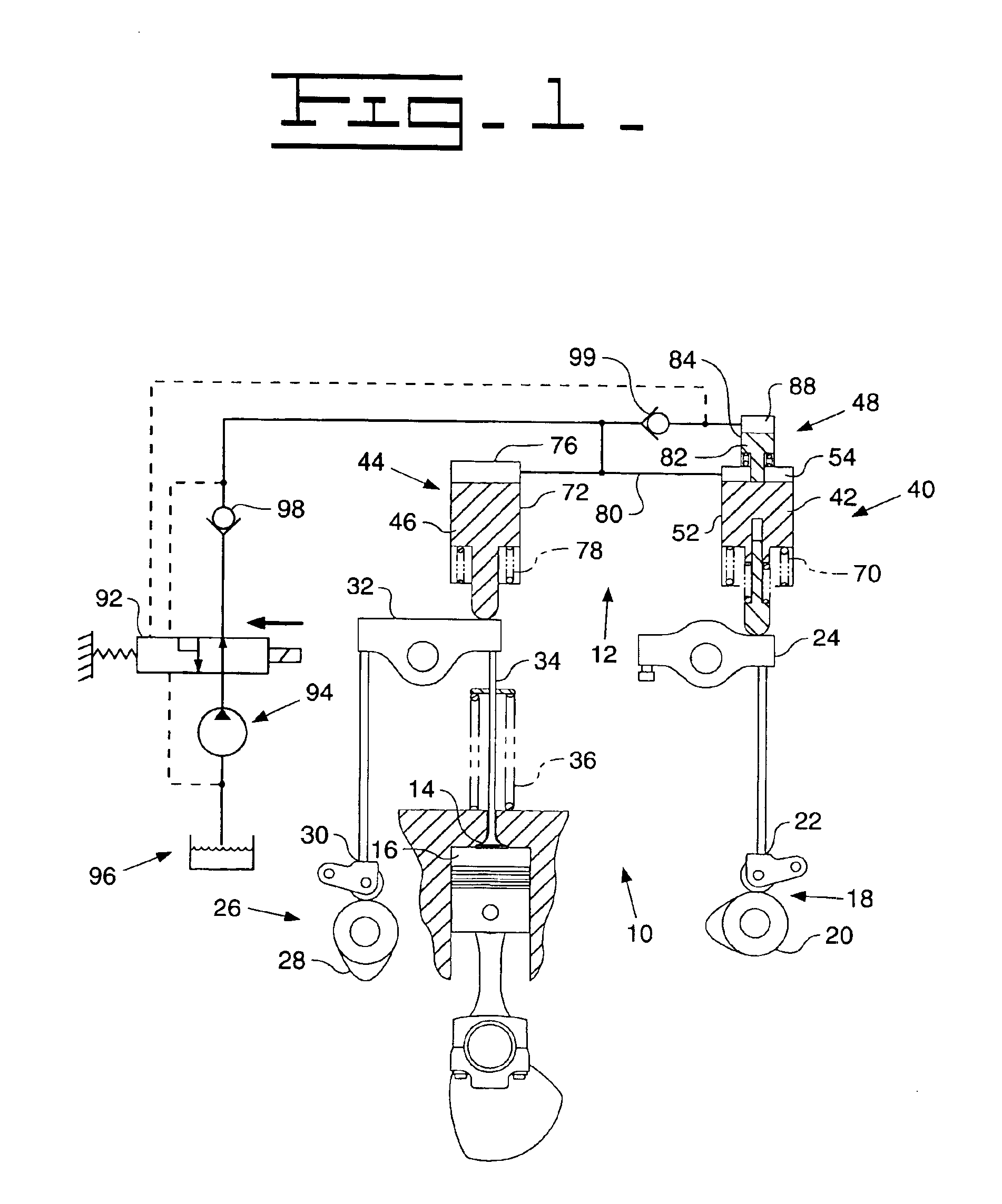

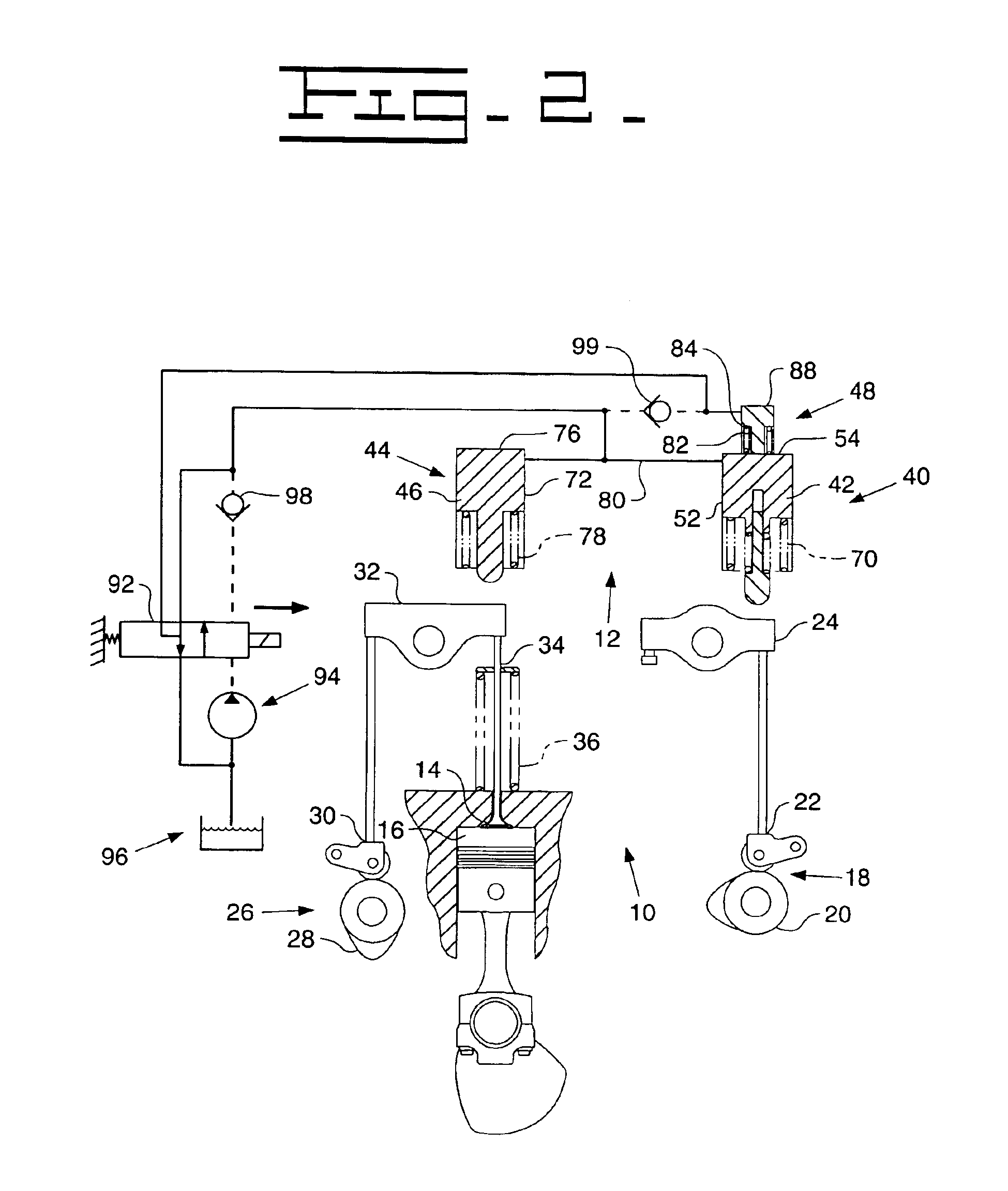

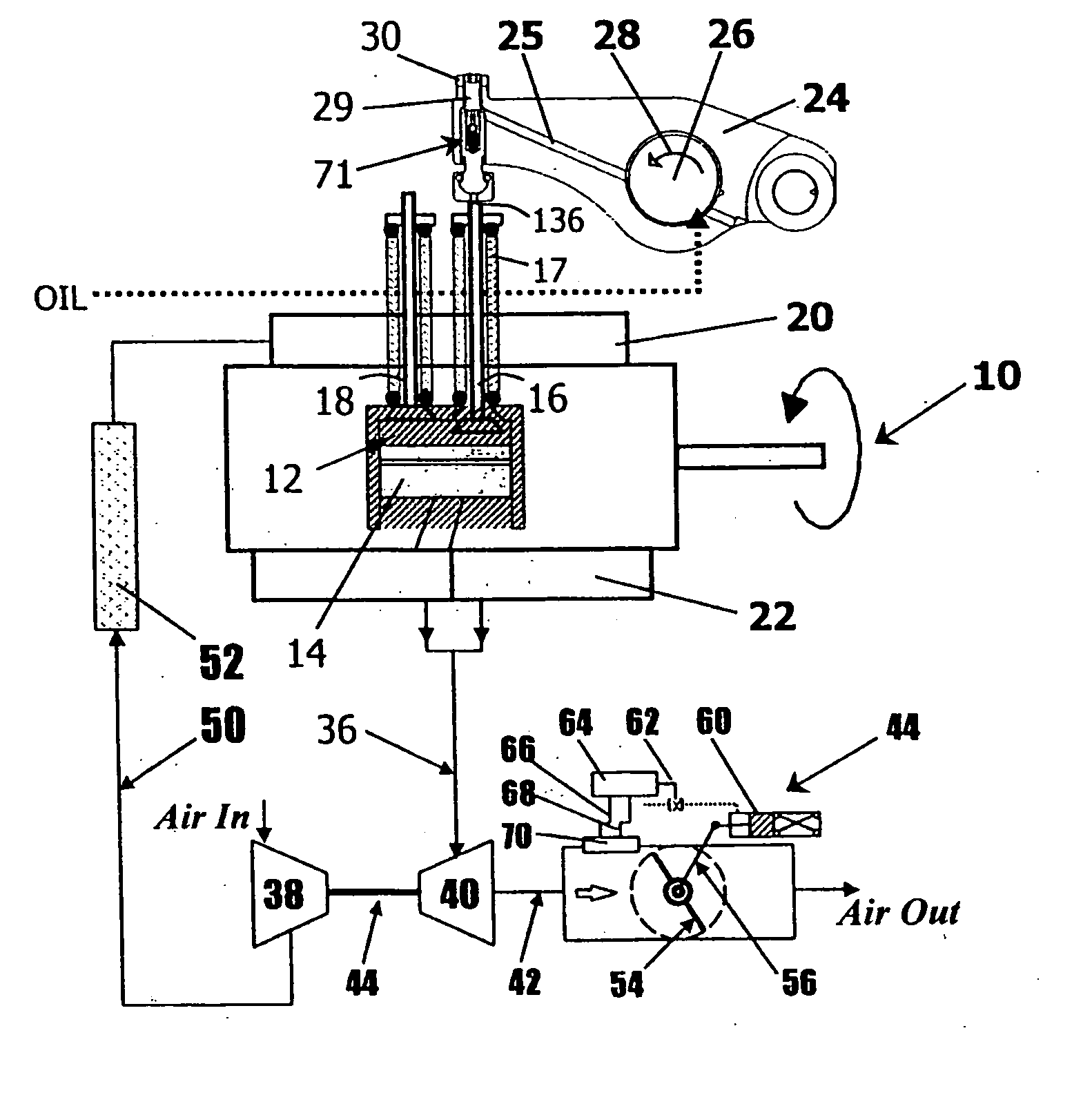

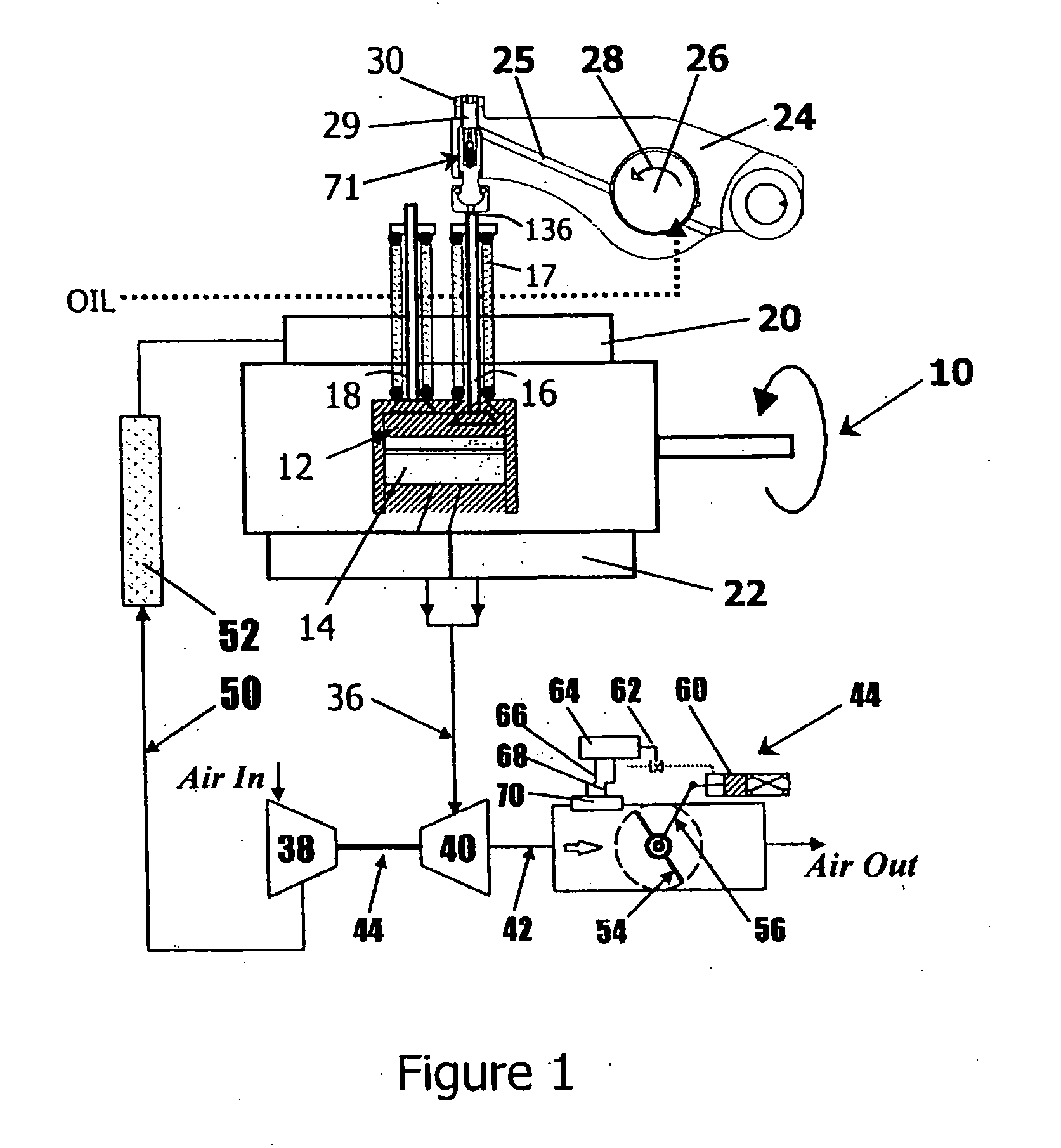

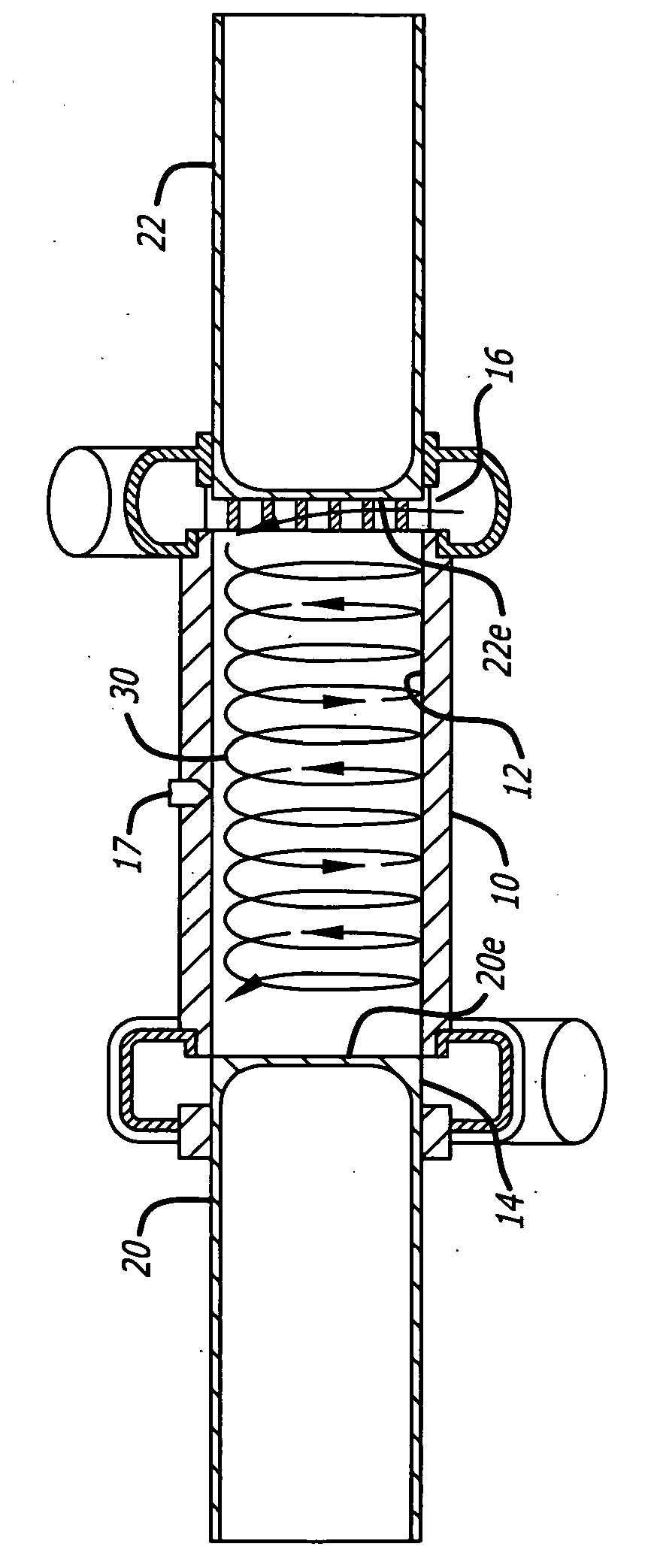

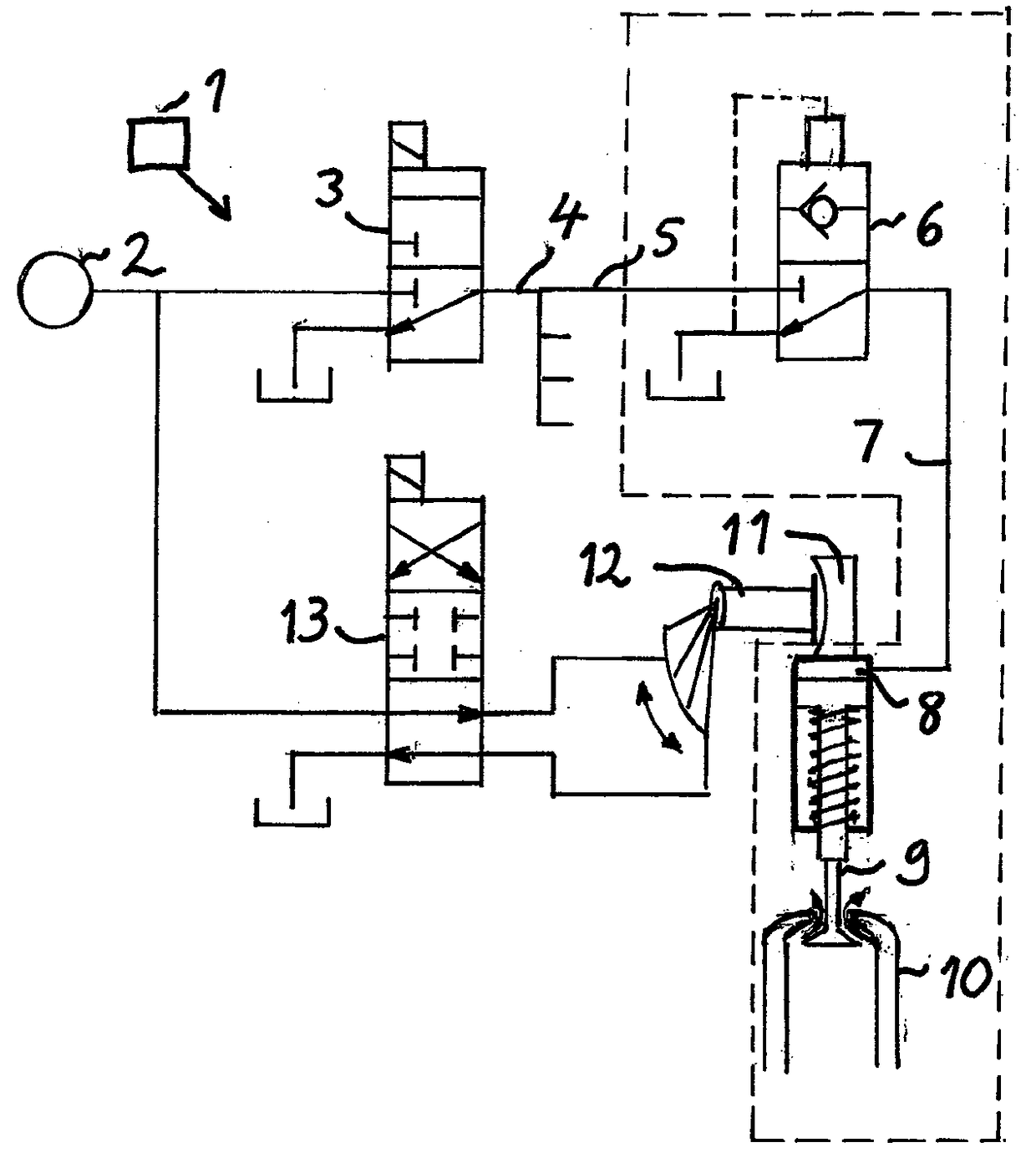

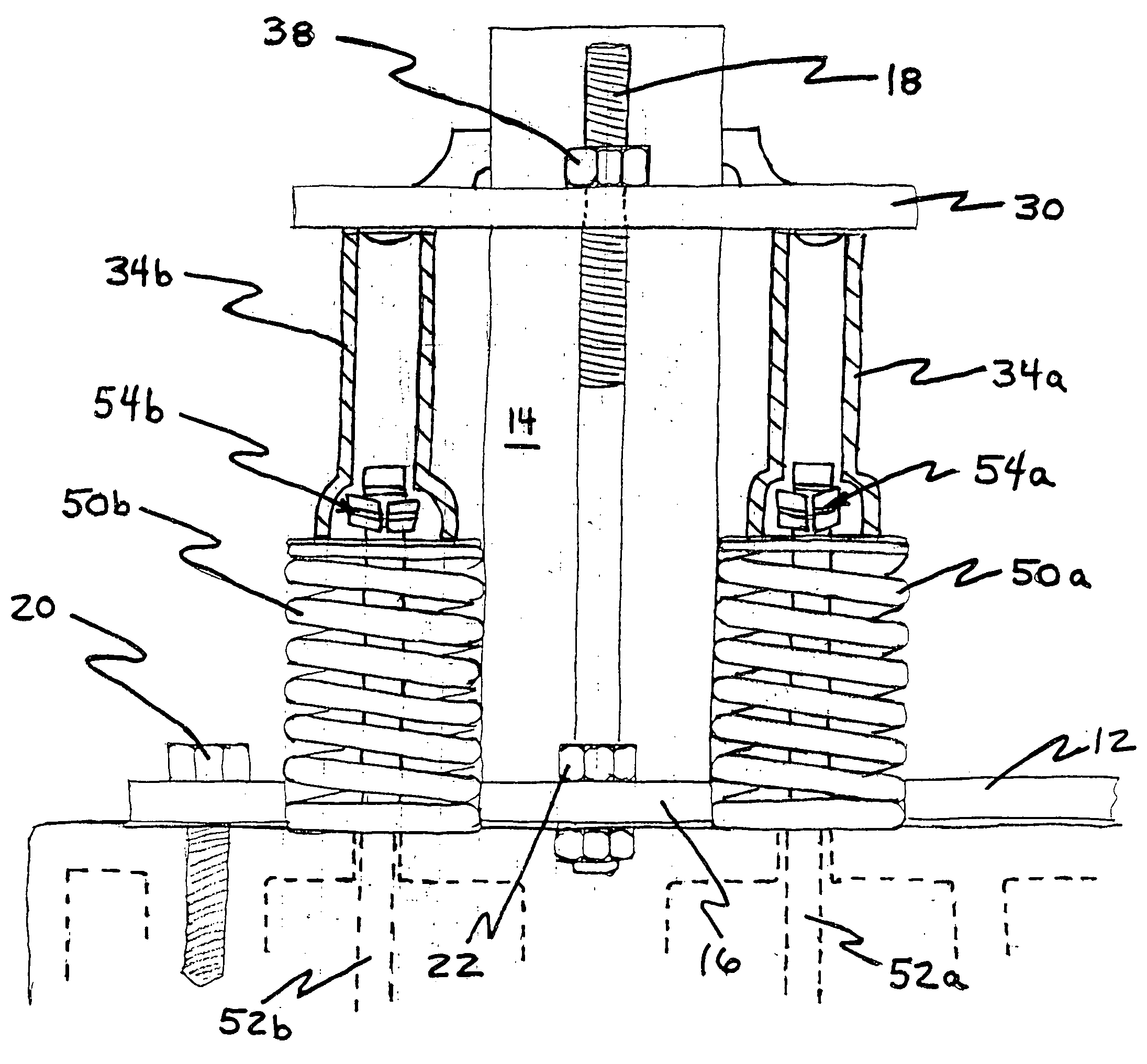

Compression release brake system

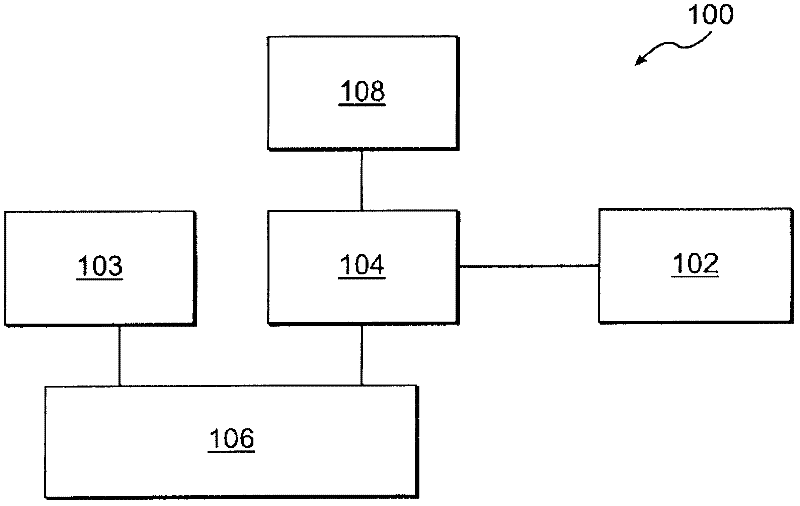

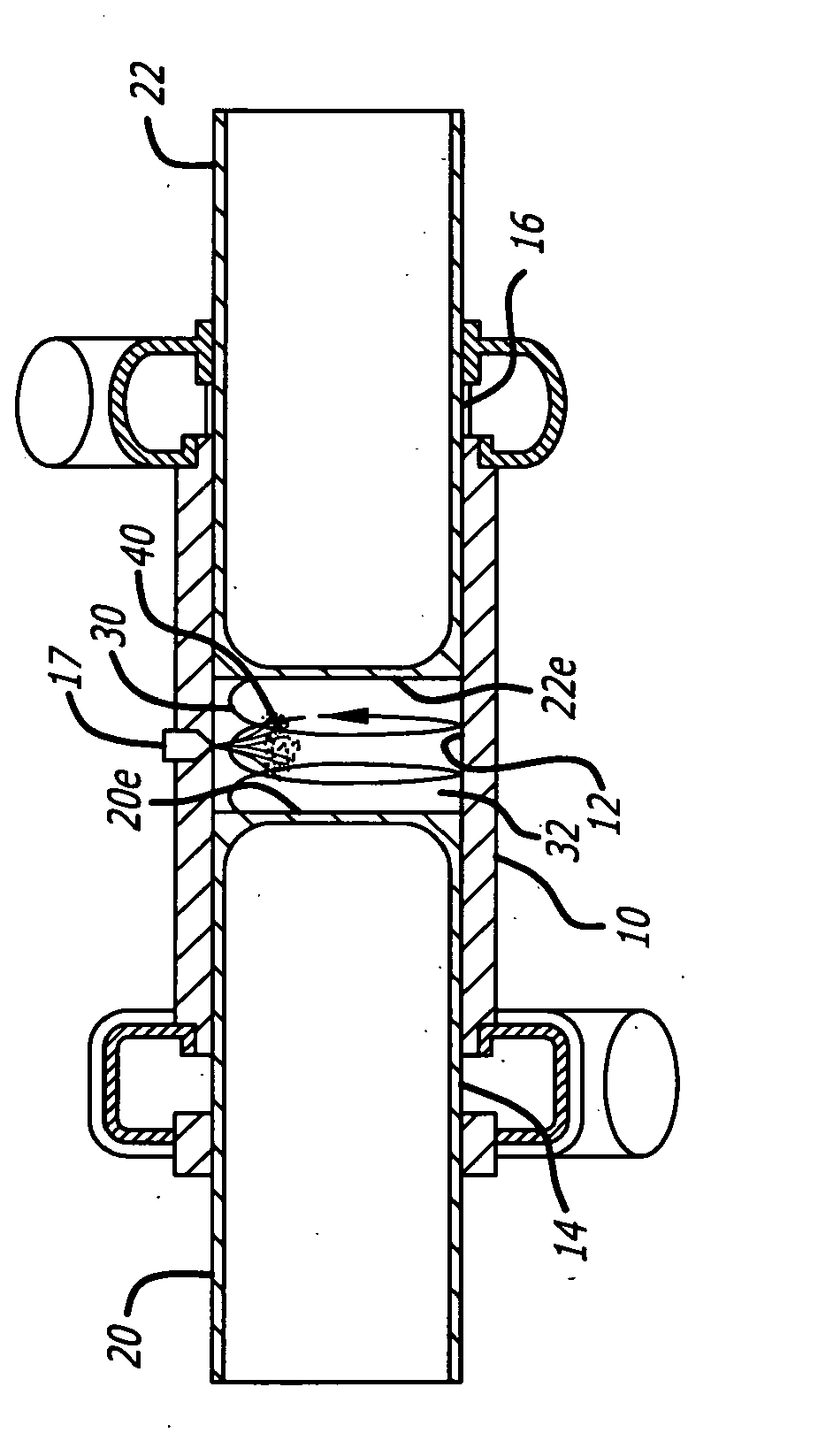

A compression release brake system 10 includes a hydraulic apparatus 12 for controllably opening at least one exhaust valve 14 of at least one cylinder 16 of an engine in response to motion of a cam actuator 12. The system 10 includes a master piston assembly 40 having a master piston 42 engageable with the cam actuator 12. The master piston 42 includes a compressible piston pin 56. A slave piston assembly 44 is hydraulically linked to the master piston assembly 40 and includes a slave piston 46 engageable with the at least one exhaust valve 14.

Owner:CATERPILLAR INC

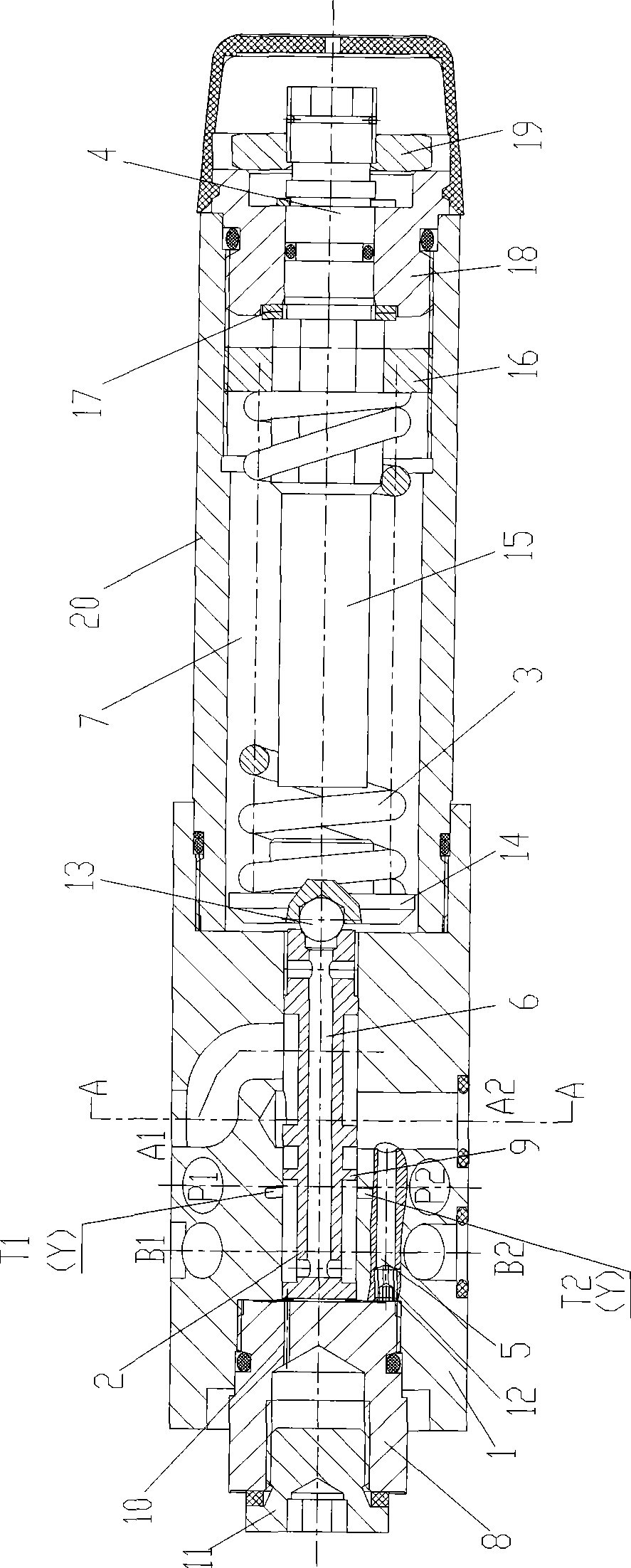

Stacked compression release valve

InactiveCN101469726AWill not cause stuck phenomenonSimple structureServomotor componentsCheck valvesCompression releaseHydraulic control

The present invention discloses a overlaid compression release valve hydraulic controlling valve field, which includes a valve body, an adjust element that mounted on the right end of the valve body, and a threaded sleeve mounted on the left end of the valve body; a valve body main hole is made by casting inside the valve body; P1, P2, A1, A2, B1, B2, T1, T2 flow passage, wherein P1 communicates with P2, A1 and A2 communicated through the main hole, B1 communicates with B2, T1 communicates with T2 and passes through the main hole; a C flow passage is set bypass the lateral surface of the main hole between the valve body A1 and the flow passage A2; a one-way valve hole is set on the lateral surface of the valve body; a one-way valve is mounted inside the one-way valve; one end of the one-way valve communicates with the flow passage A2 and the other end communicates with the outer wall of the valve body, the top end communicates with the flow passage C, and the one-way valve allows oil can only flow from oil port A2 to oil port A1. The beneficial effect of the invention is that inside of the overlaid one-way valve adopts pouring flow passage which simplifies structure and reduces fabrication holes; a selectable one-way valve is added to become a one-way compression release valve so as to make oil flows freely in opposite direction.

Owner:SHANGHAI LIXIN HYDRAULIC

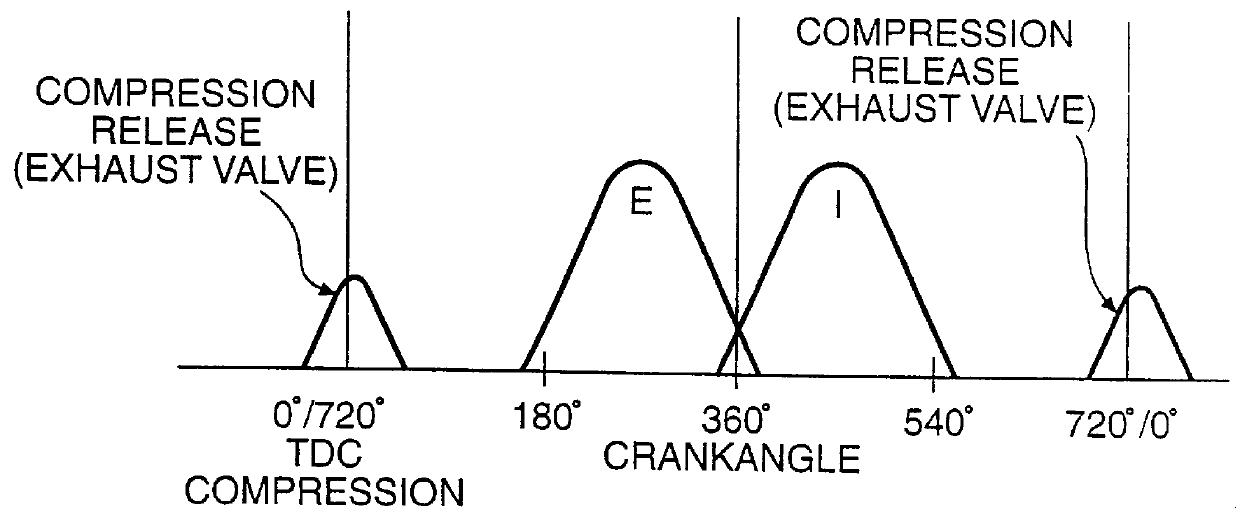

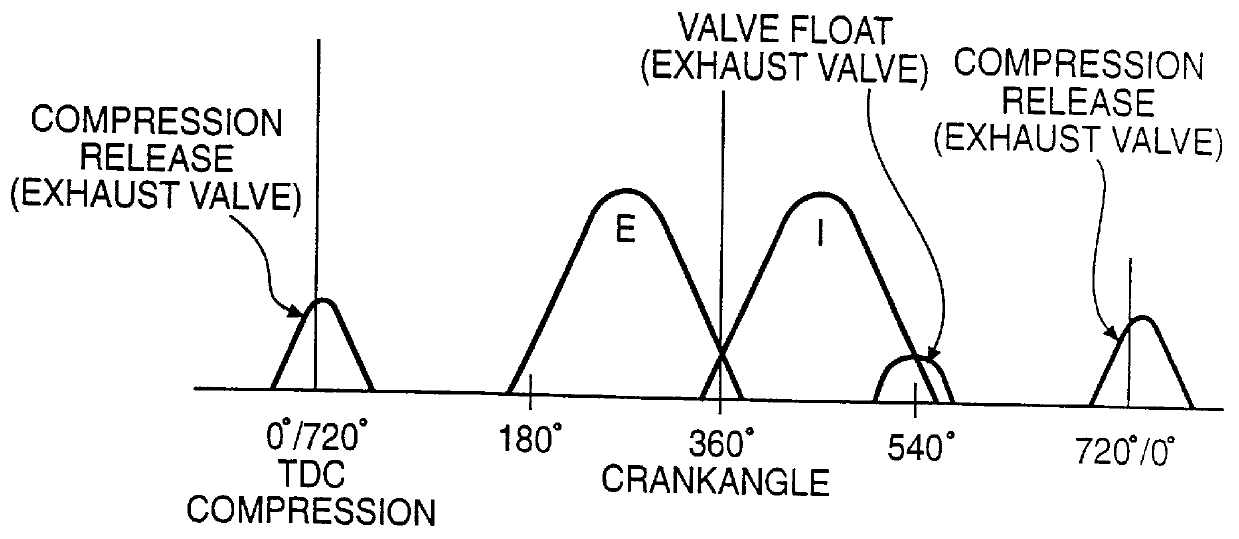

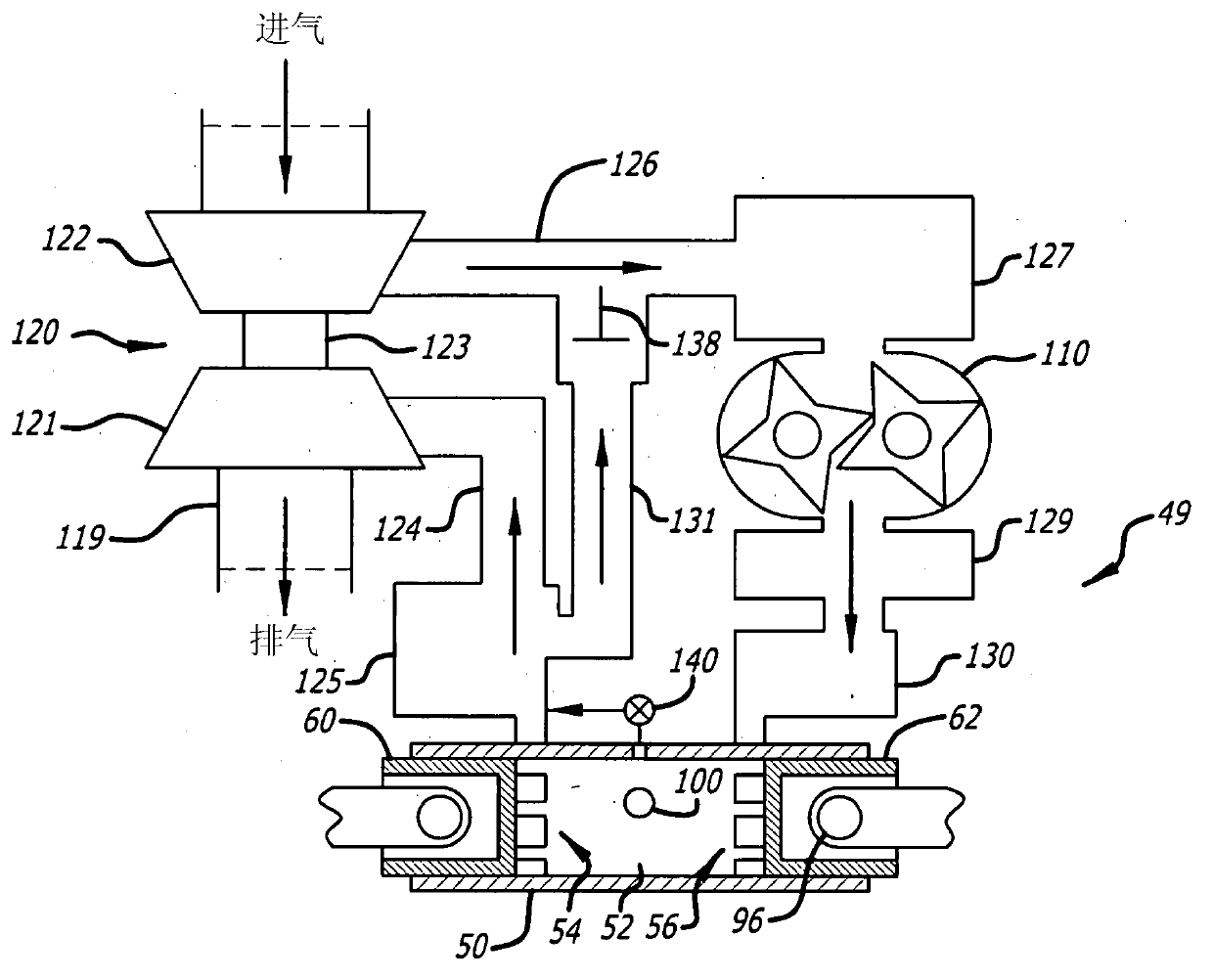

Apparatus and method for retarding an engine with an exhaust brake and a compression release brake

An apparatus and method for retarding an engine having a cylinder with an exhaust valve, an intake valve, an intake stroke, an exhaust stroke, a compression stroke and an expansion stroke. The apparatus includes an exhaust brake and a compression release brake. The exhaust brake includes a variable exhaust restrictor, a pressure sensor for sensing pressure of exhaust gases and a controller operatively connected to the pressure sensor and to the exhaust restrictor. Opening of the exhaust restrictor is adjusted during operation of the apparatus so exhaust pressure is sufficient to cause exhaust valve float prior to bottom dead center of intake strokes of the cylinder, thereby enhancing operation of the compression release brake.

Owner:JENARA ENTERPRISES

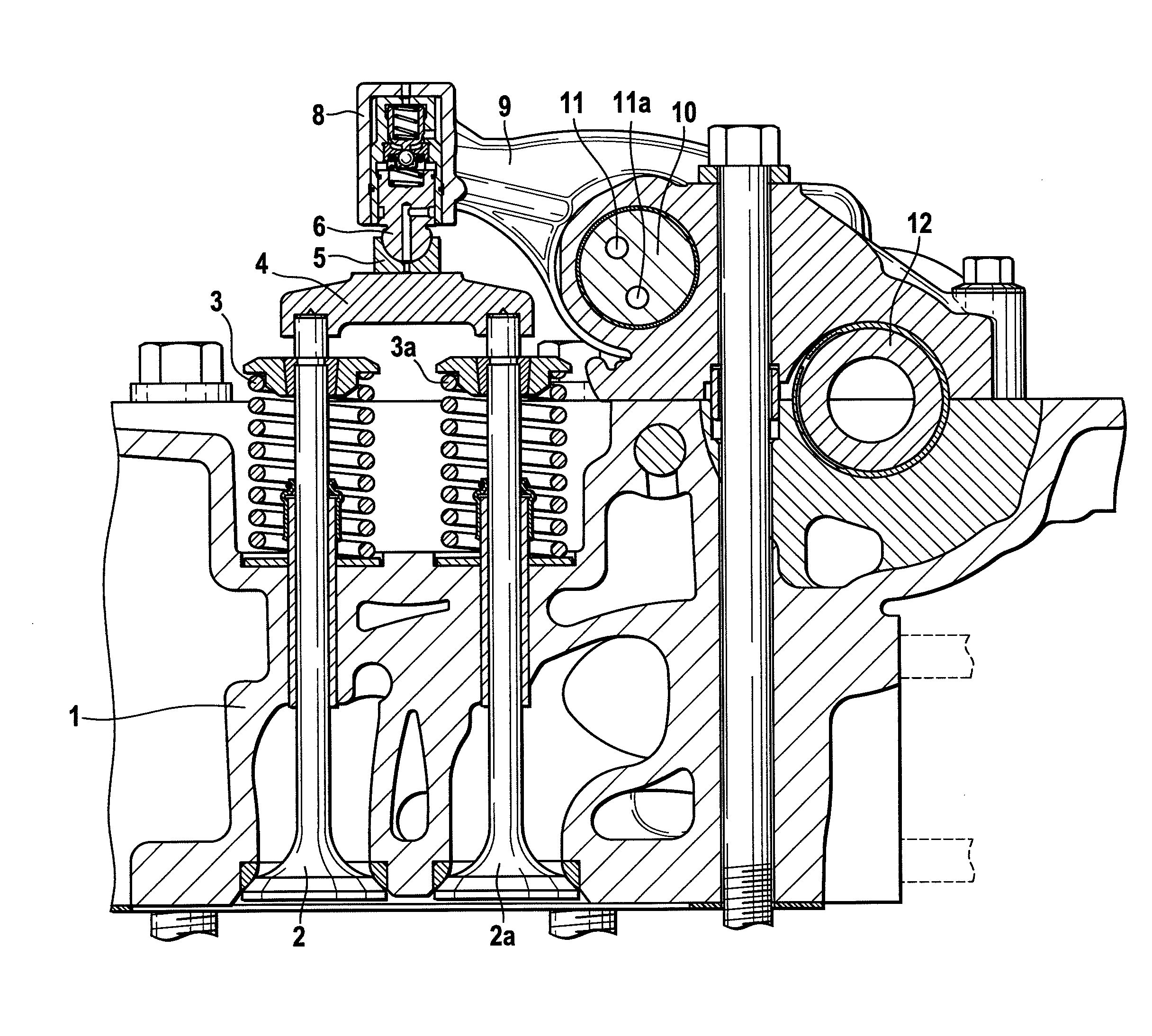

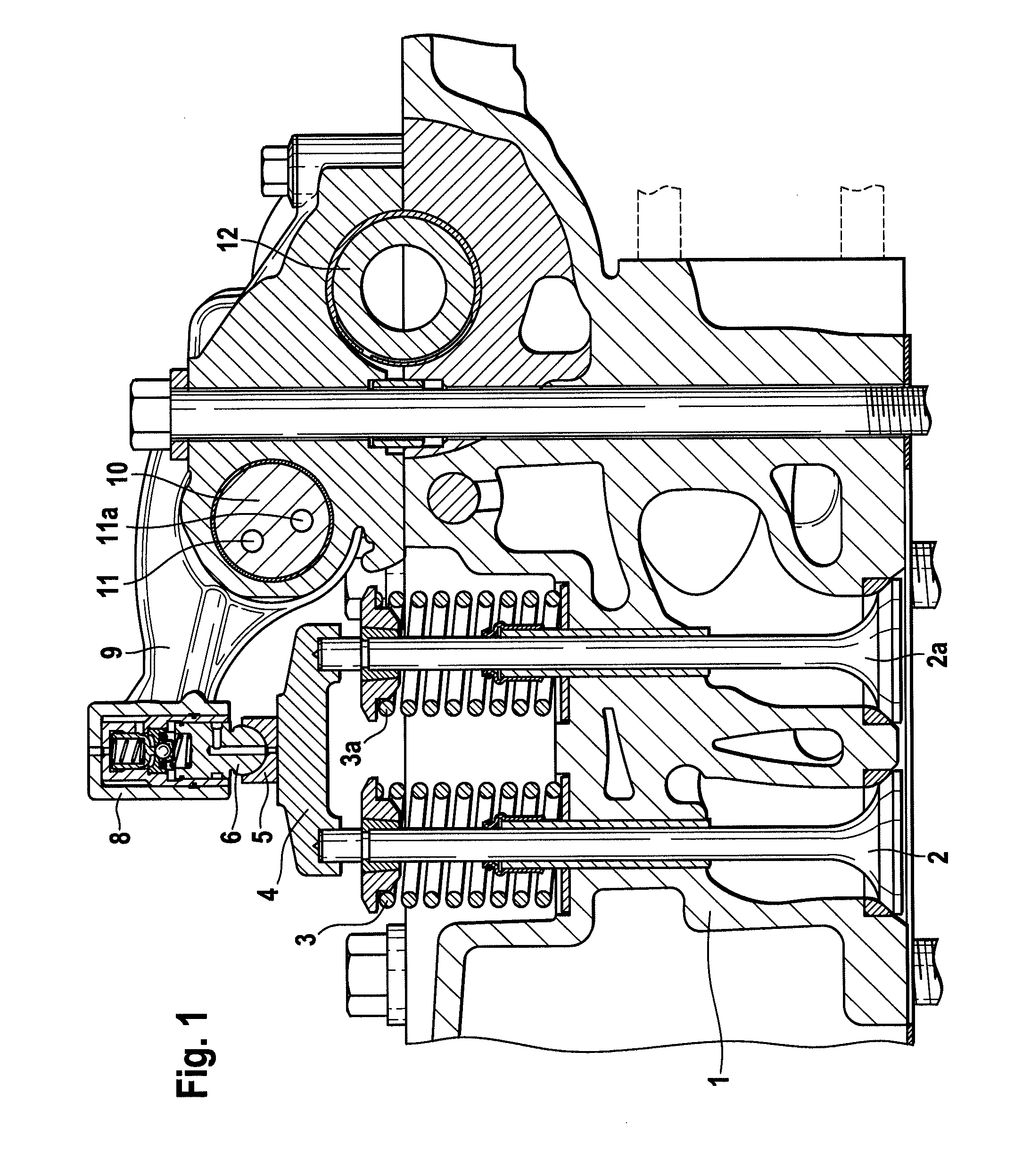

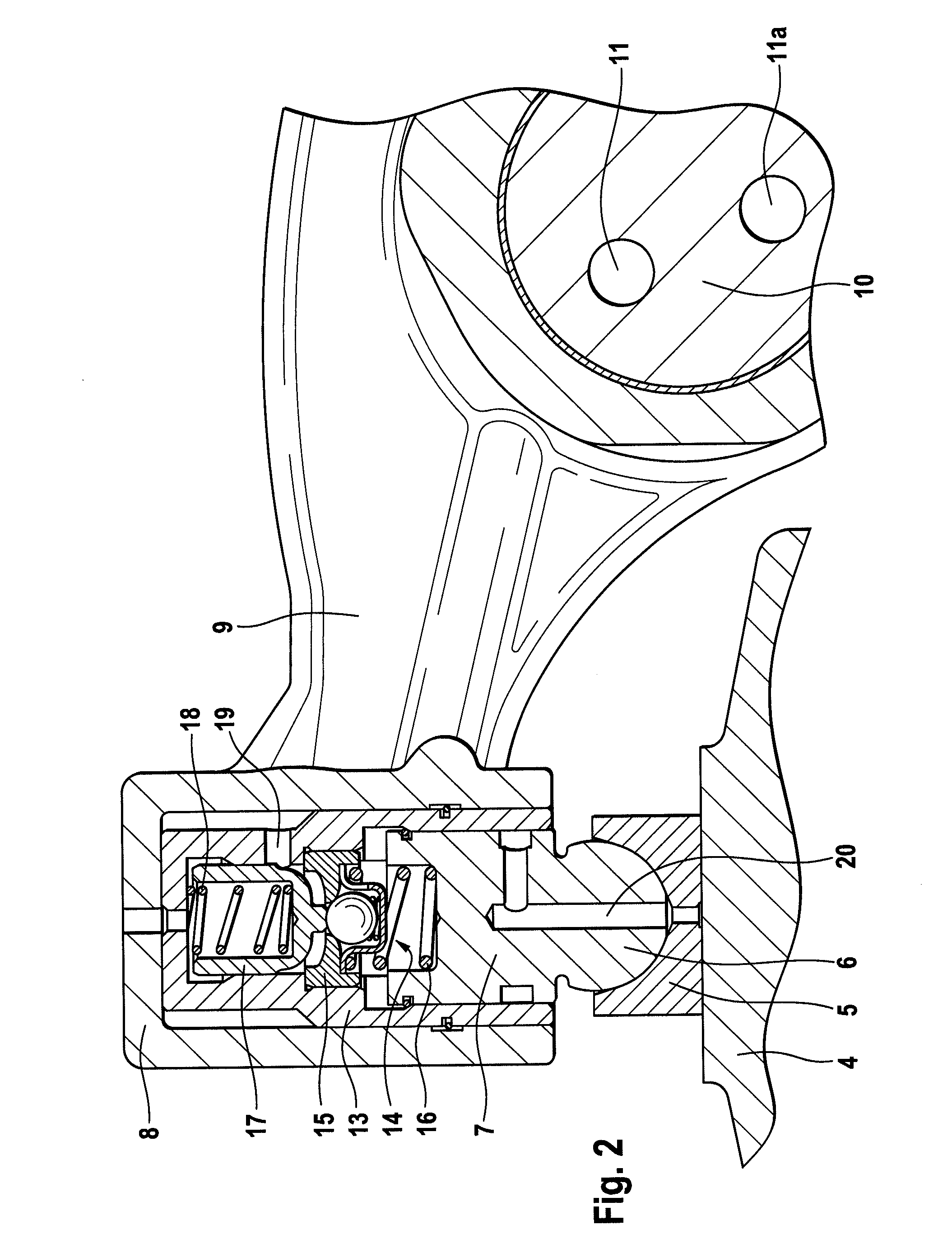

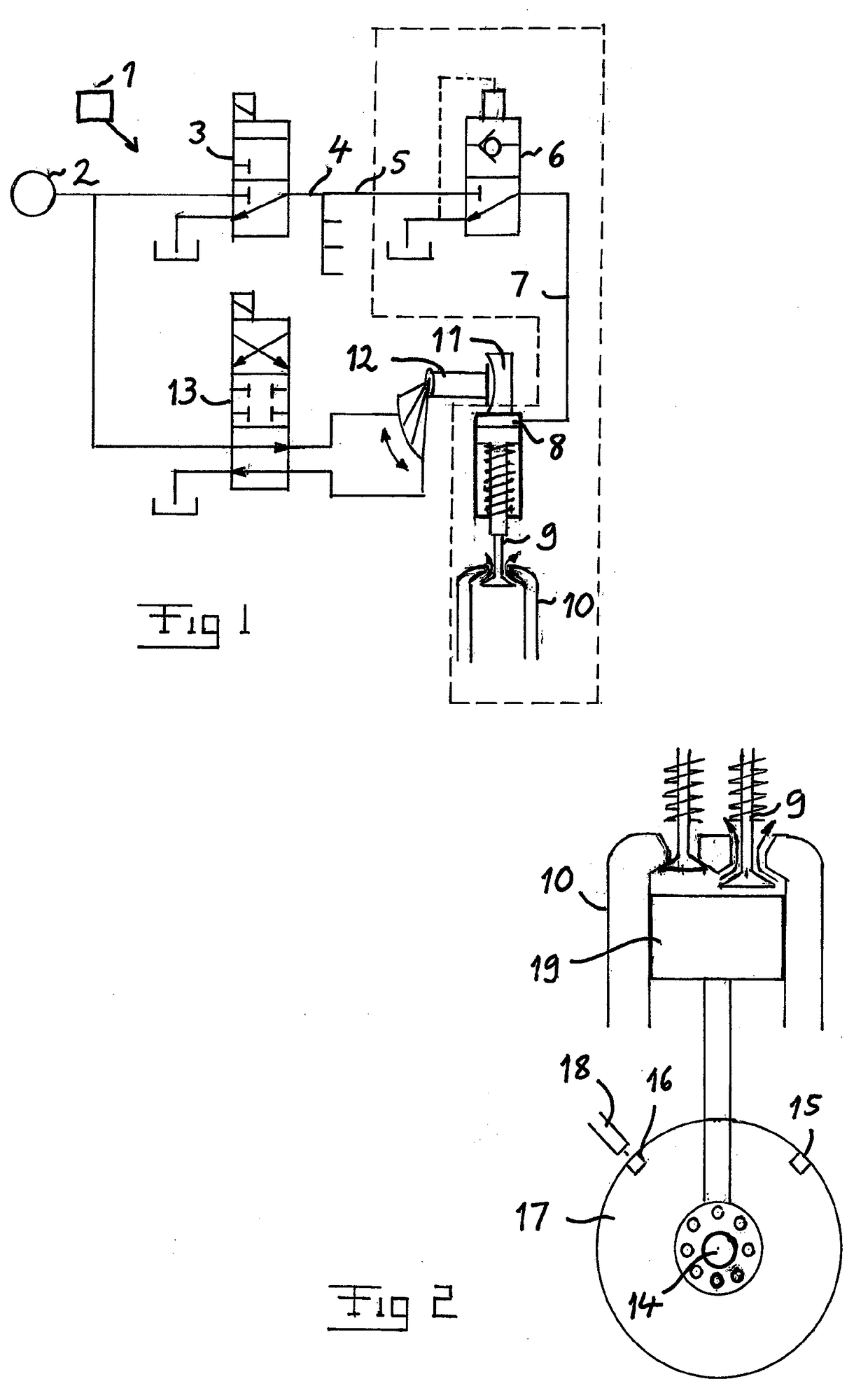

Internal combustion piston engine with an adjustable inflating element

InactiveUS20110220052A1Easy to measureLow costNon-fuel substance addition to fuelValve drivesExternal combustion engineInlet valve

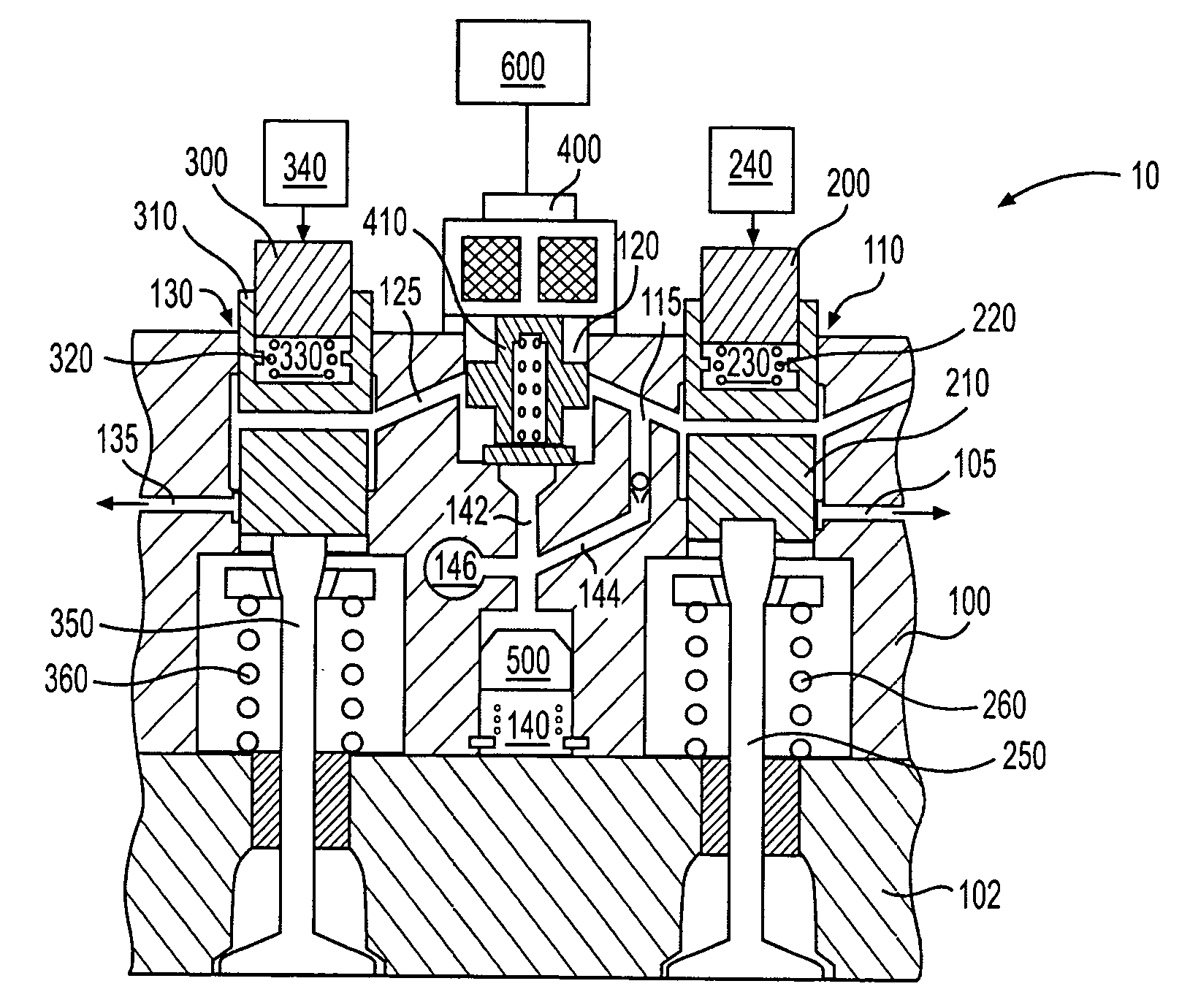

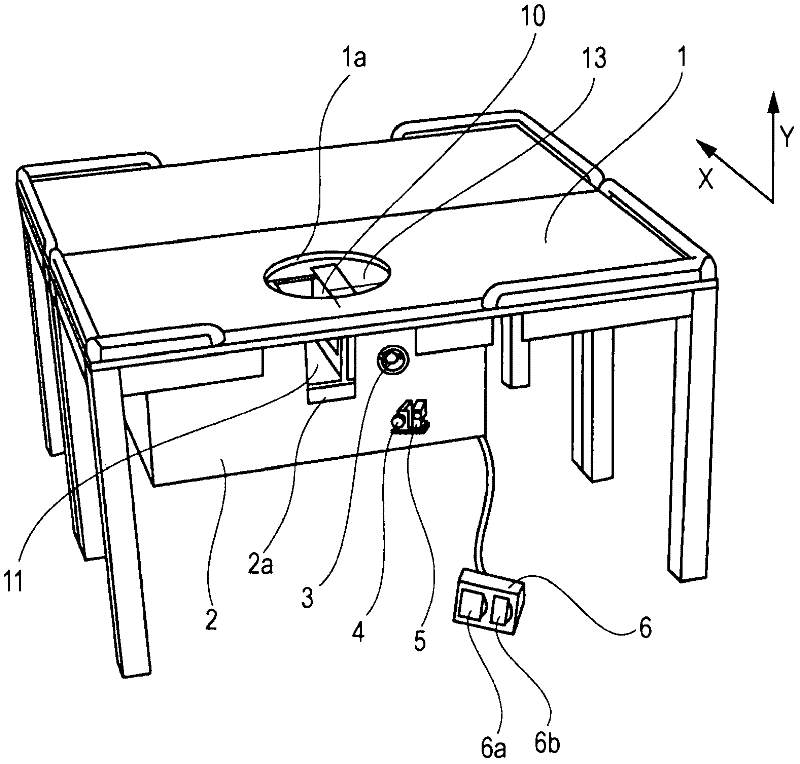

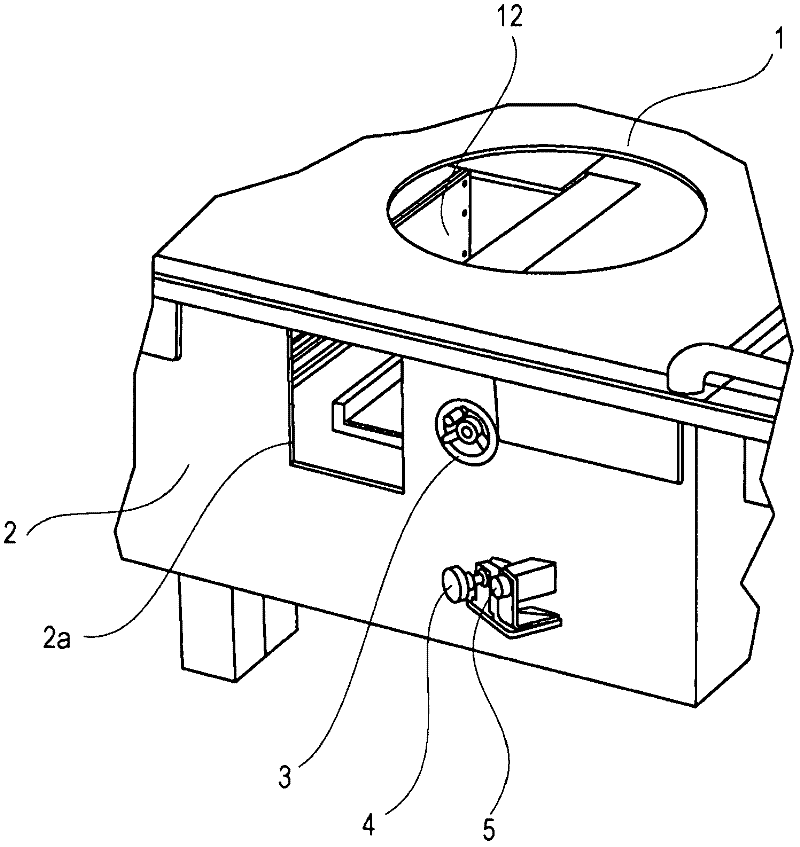

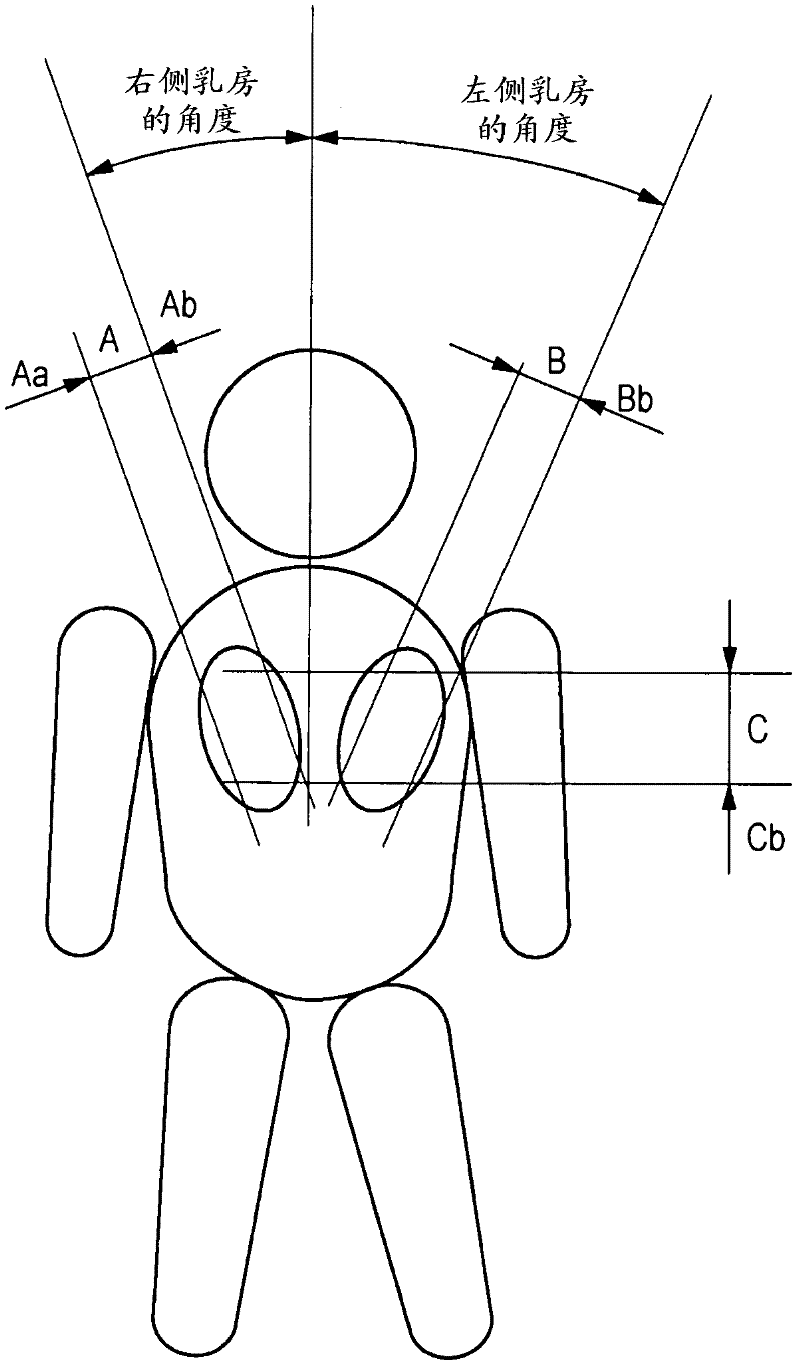

An internal combustion piston engine based on a four-stroke process, having a crankcase in which at least one cylinder / piston assembly is arranged, the piston being guided by a connecting rod connected to a crankshaft. At least one cylinder head (1) closes the cylinder, each of whose intake and exhaust channels are controlled by at least one intake valve and at least one exhaust valve (2, 2a). The intake and exhaust valves are actuable by a finger lever or a rocker arm driven by a camshaft (12) through intake and exhaust cams. The finger levers or rocker arms are guided on at least one axle (10). At least one additional cam is provided in the region of the base circle of the outlet cam for an additional opening of the at least one exhaust valve (2, 2a), and a control element is installed between the finger lever or rocker arm and the exhaust valve or valves (2, 2a), which control element can be connected to a pressure oil source and has a variable length, so that the additional cam is active during a compression relief operation and inactive during a pure engine operation. The control element is configured as an inflating element (8) and is operatively connected through a working piston (7), with interposition of a spacer, to a bridge (4) associated to a plurality of exhaust valves (2, 2a), or is operatively connected to a valve stem of an exhaust valve.

Owner:SCHAEFFLER TECH AG & CO KG

Two stroke opposed-piston engines with compression release for engine braking

ActiveCN103314184AAchieve brakingValve arrangementsExhaust gas recirculationTop dead centerControl theory

In a two-stroke opposed-piston engine, a ported cylinder with a pair of opposed pistons is equipped with a decompression port including a valve and a passage with an opening through the cylinder wall that is located between the cylinder's intake and exhaust ports. The decompression port enables the release of compressed air from the cylinder after the intake and exhaust ports are closed. The valve controls airflow through the passage, and is opened to permit compressed air to be released from the cylinder through the passage, and closed to retain compressed air in the cylinder. Engine braking is supported by release of compressed air through the decompression port into an exhaust channel when the pistons are at or near top dead center positions as the cycle transitions from the intake / compression stroke to the power / exhaust stroke. Compression release from the cylinder via the decompression port after intake and exhaust, port closure can also support other engine operations.

Owner:ACHATES POWERS INC

Variable valve actuation and engine braking

Systems and methods of actuating two engine valves associated with a common engine cylinder using one or more lost motion systems and one or more control valves are disclosed. The control valves are capable of selectively trapping hydraulic fluid in the lost motion systems for auxiliary engine valve actuations and selectively releasing the hydraulic fluid to default to cam controlled valve seating of the engine valves. The systems may provide a combination of main exhaust, compression release, exhaust gas recirculation and early exhaust valve opening in preferred embodiments.

Owner:JACOBS VEHICLE SYST

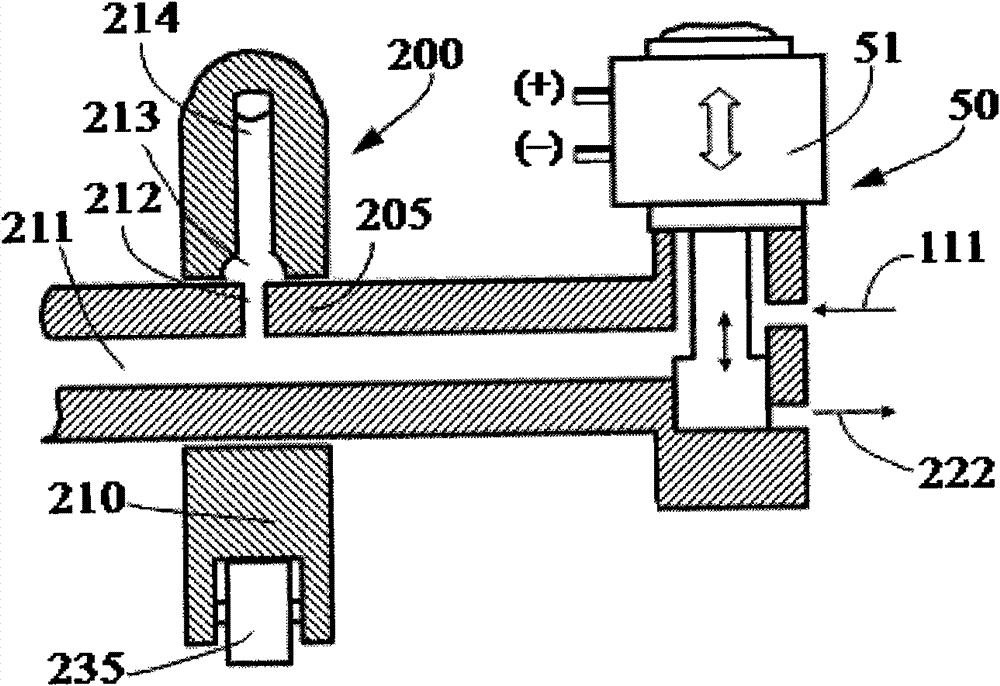

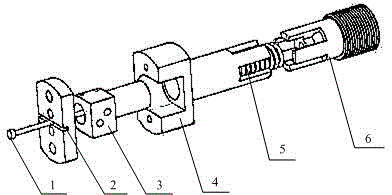

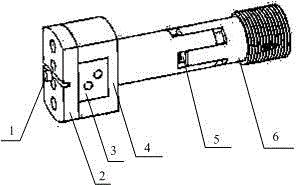

Self-contained compression brakecontrol module for compression-release brakesystem of internal combustion engine

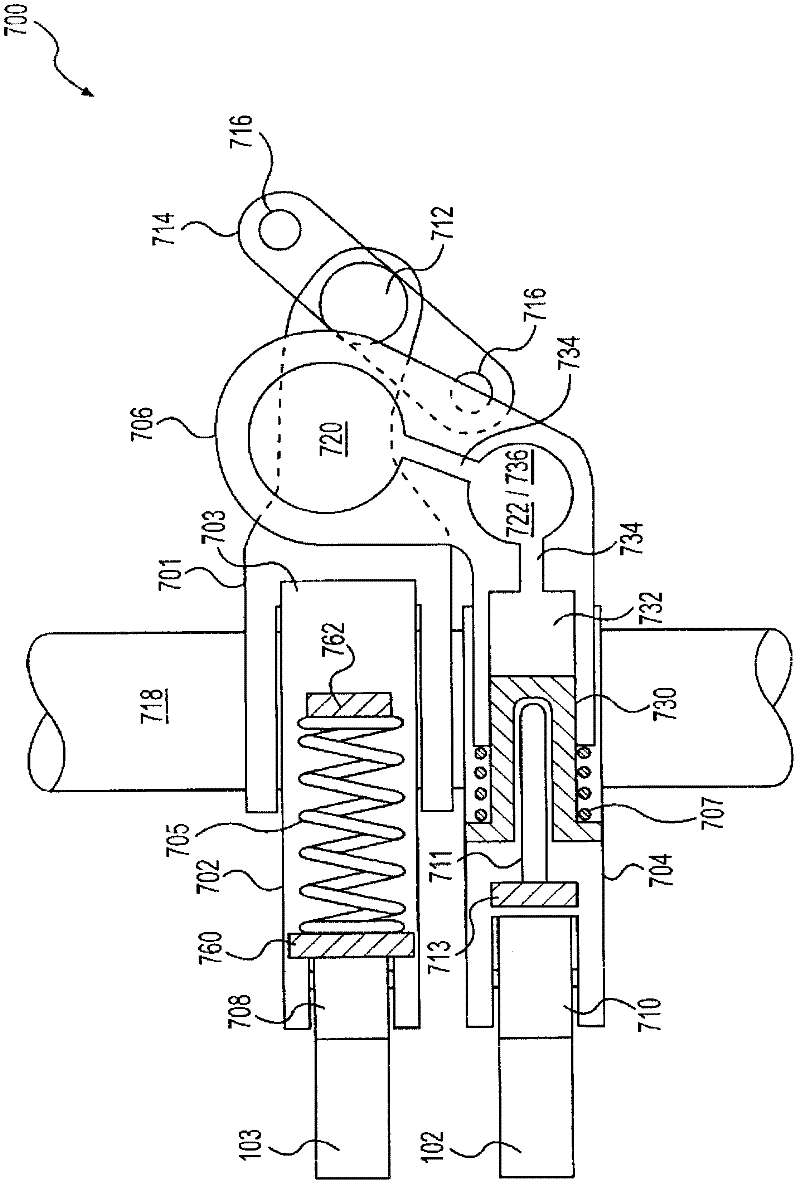

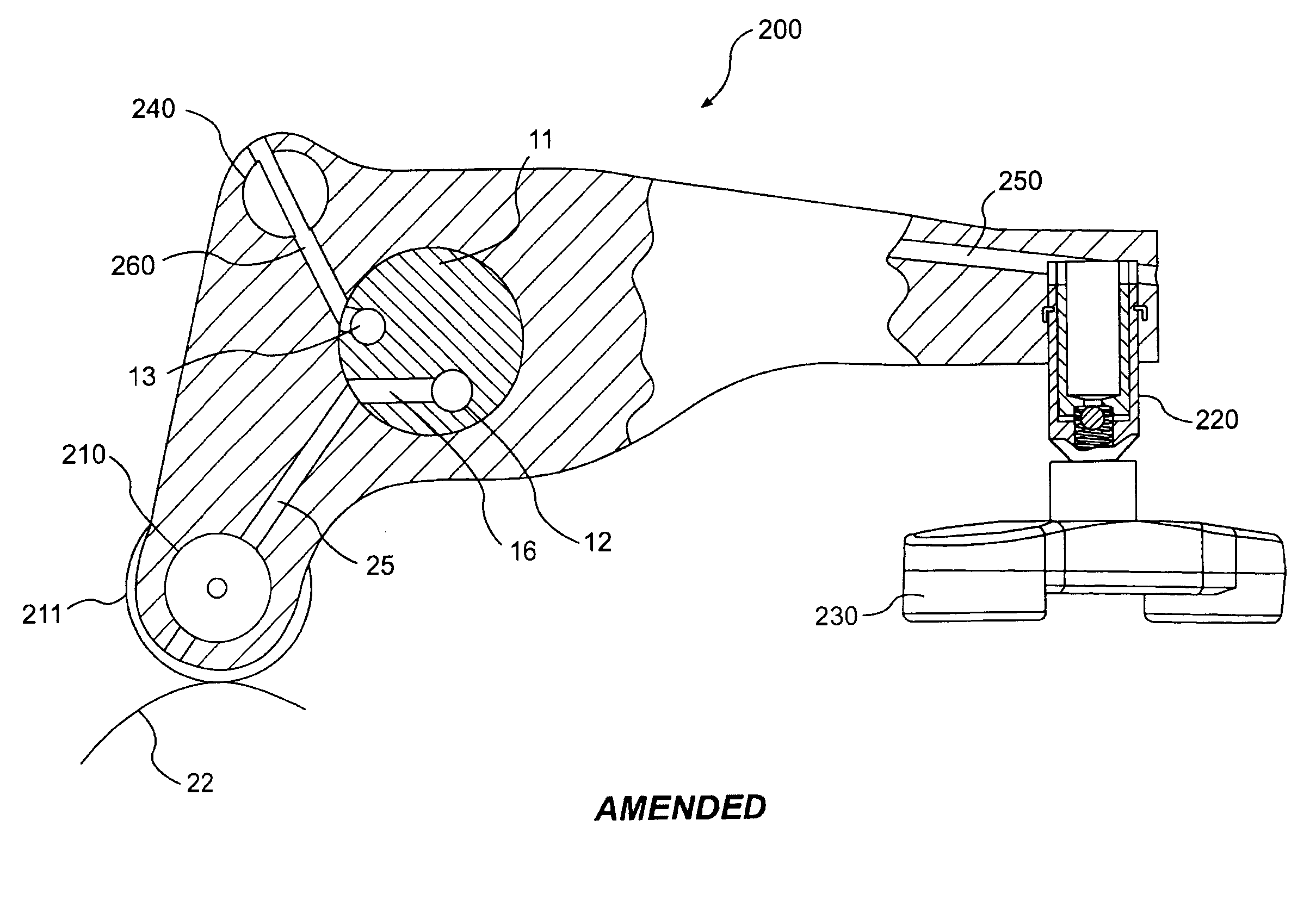

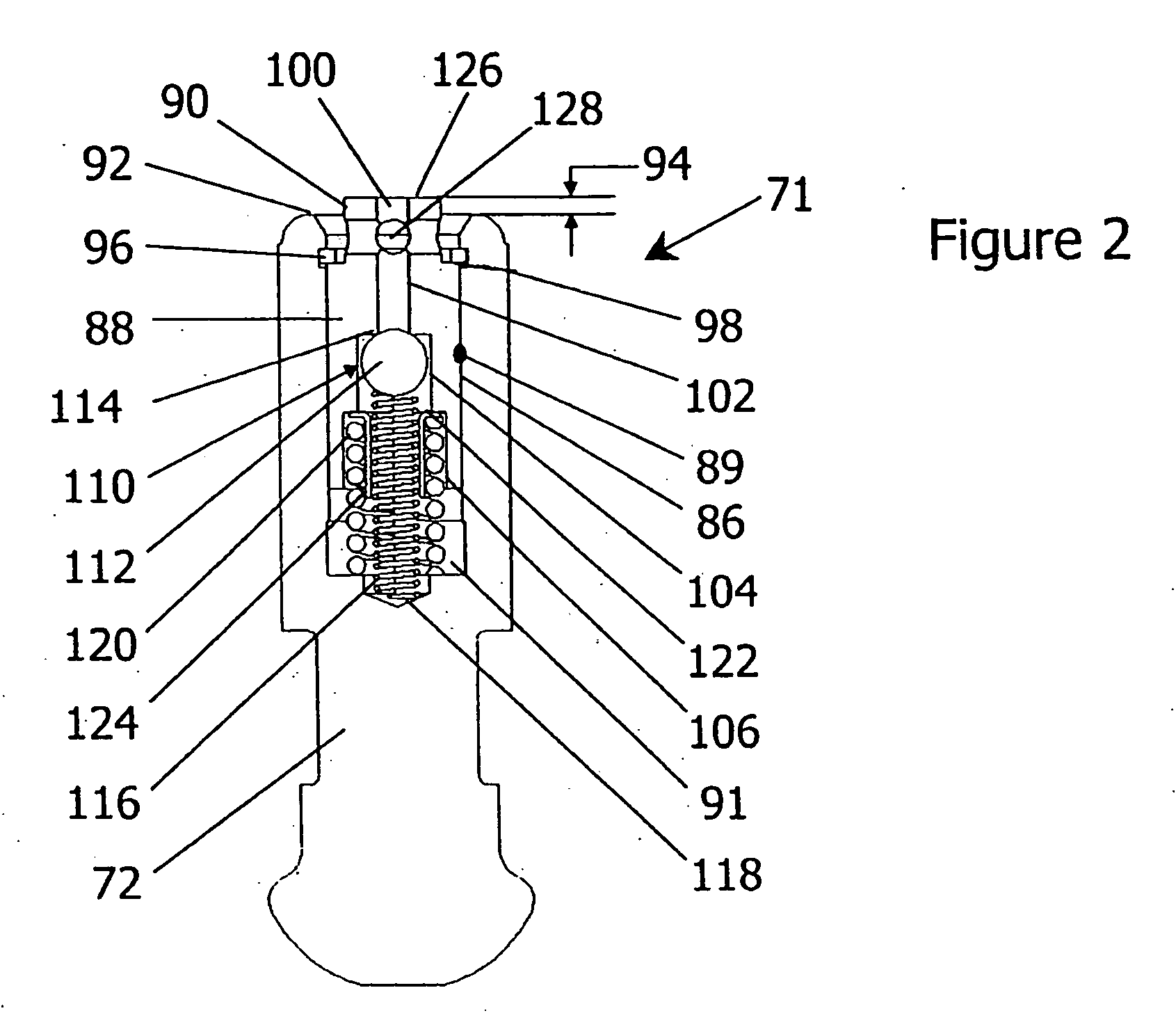

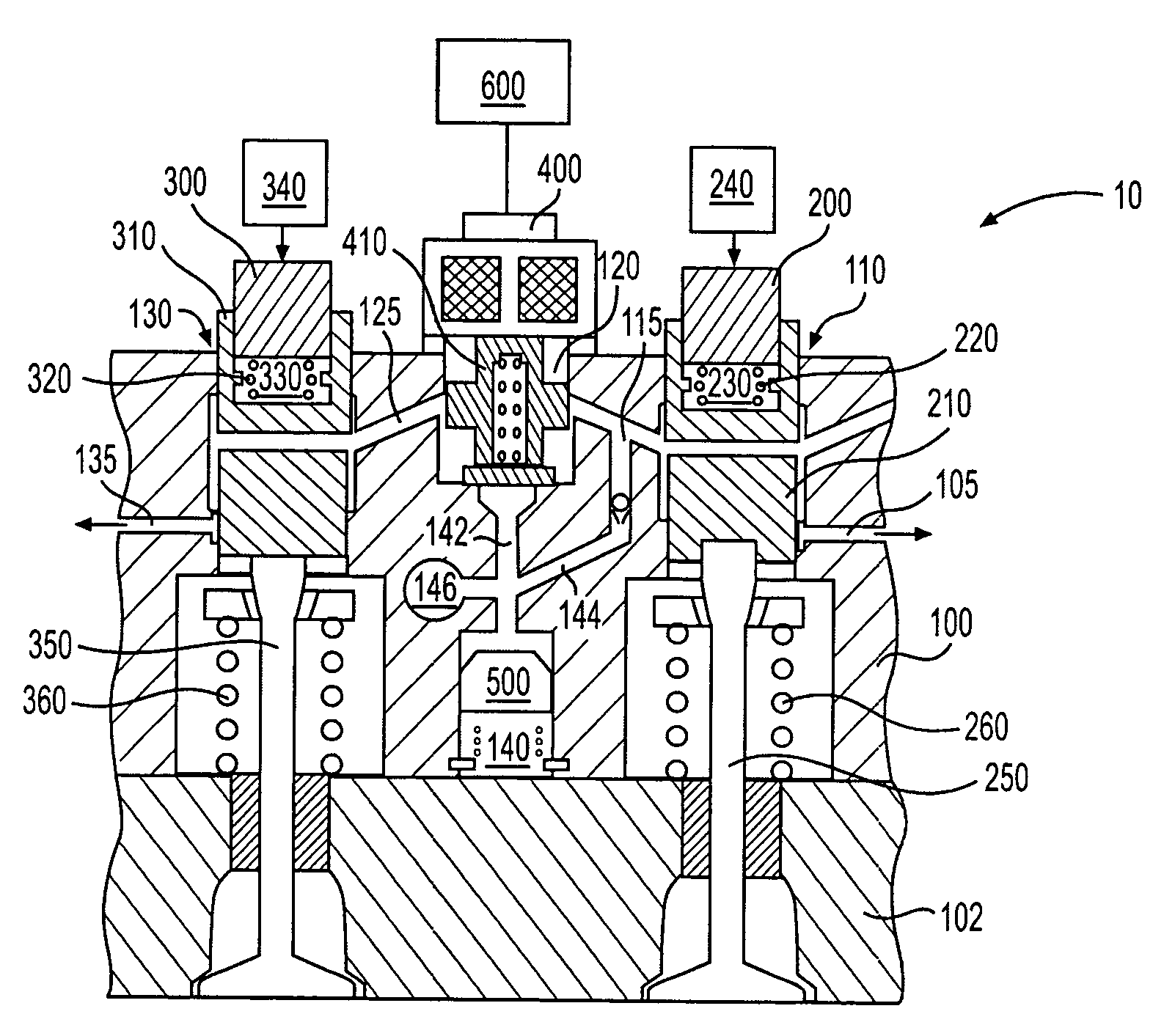

InactiveUS7900597B2Improve running characteristicsSmall and compactNon-fuel substance addition to fuelOutput powerHydraulic fluidActuator

A compression-release brake system for operating an exhaust valve of an engine during an engine braking operation. The compression-release brake system comprises a self-contained compression brake control module (CBCM) operatively coupled to the exhaust valve for controlling a lift and a phase angle thereof and a source of a pressurized hydraulic fluid. The CBCM includes a casing defining piston and actuator cavities, a slave piston mounted within the piston cavity, a check valve provided between a supply conduit and a slave piston chamber and a compression brake actuator disposed in the actuator cavity. The compression brake actuator includes an actuator element and a biasing spring. The actuator element selectively engages the check valve when deactivated so as to unlock the slave piston chamber, and disengages from the check valve when activated so as to lock the slave piston chamber. The actuator element is exposed to atmospheric pressure.

Owner:PACBRAKE

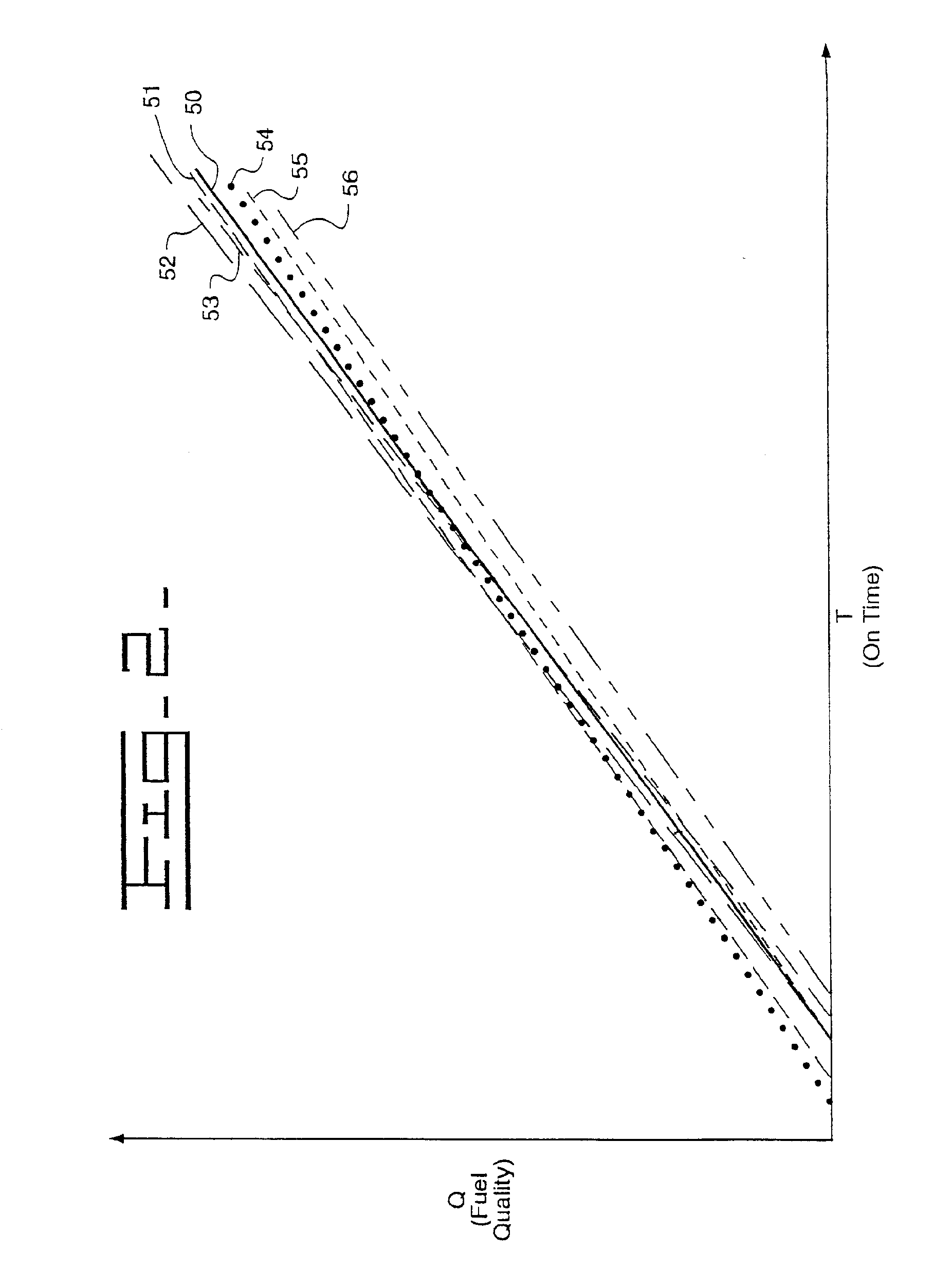

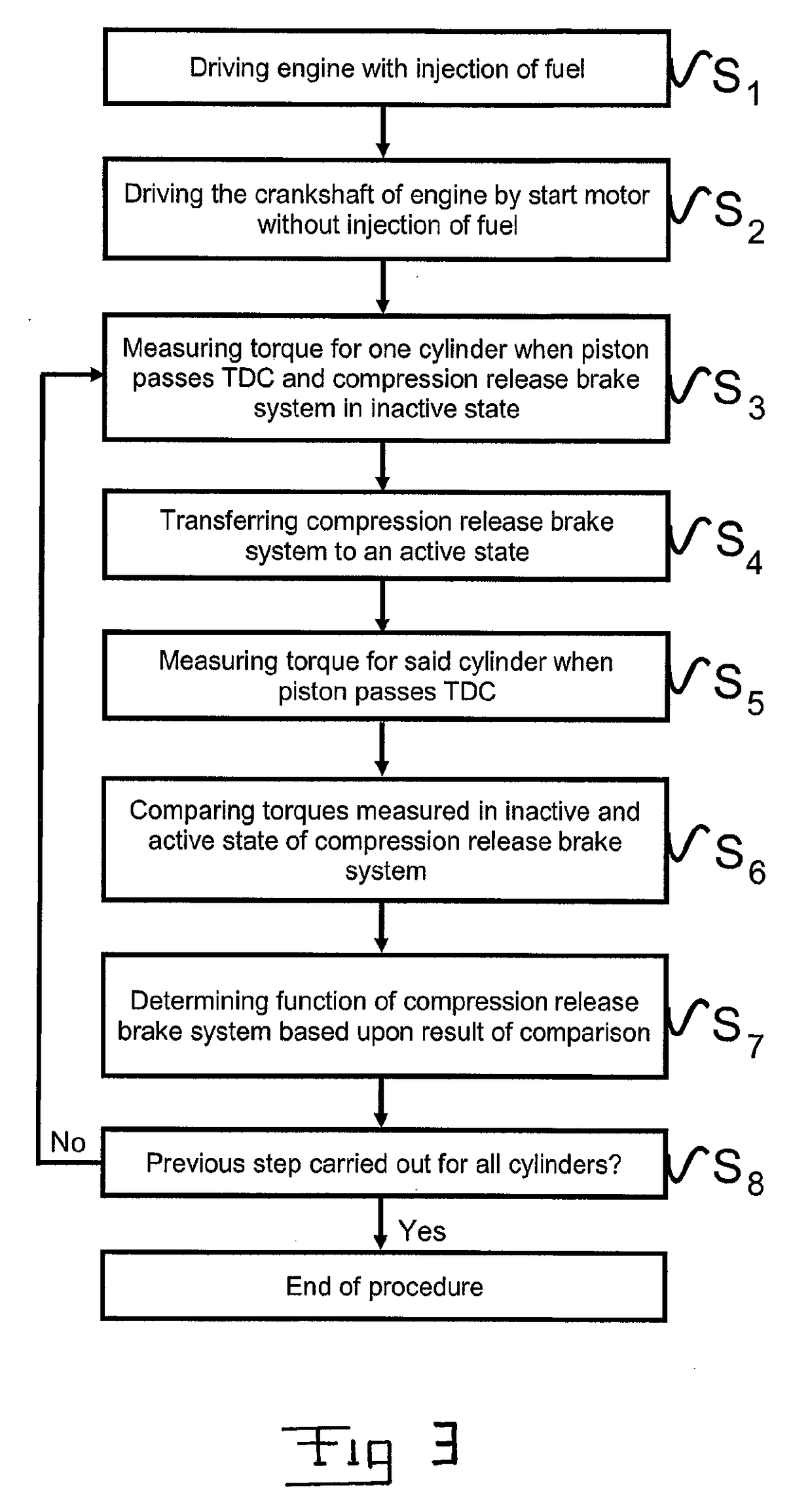

Method for checking the function of a compression release brake system

ActiveUS20170175652A1Easy to carryLow costValve arrangementsElectrical controlControl theoryActive state

Function of a compression release brake system of a compression ignited engine with a plurality of cylinders in a motor vehicle is checked by driving a crank shaft of the engine to rotate at a constant speed without injection of fuel into the cylinders while for each cylinder, for the compression release brake system in an inactive state and then in an active state, measuring the torque to be applied for maintaining said speed in a position of said crank shaft where the torque would be influenced by the behavior of that cylinder by a correctly functioning action of said compression release brake system in an active state. The torque values obtained for each cylinder for the compression release brake system in inactive and active state are compared, and the function of the compression release brake system for each individual cylinder of the engine is determined based on the comparison.

Owner:SCANIA CV AB

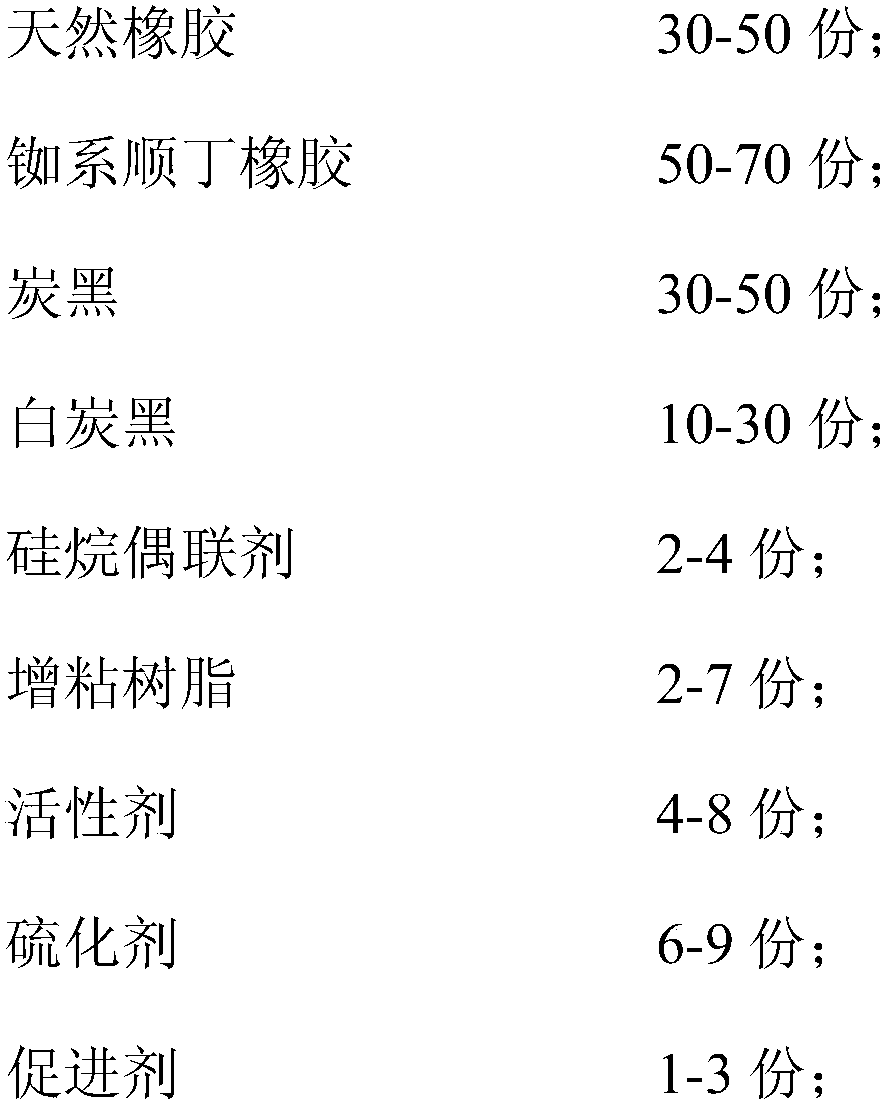

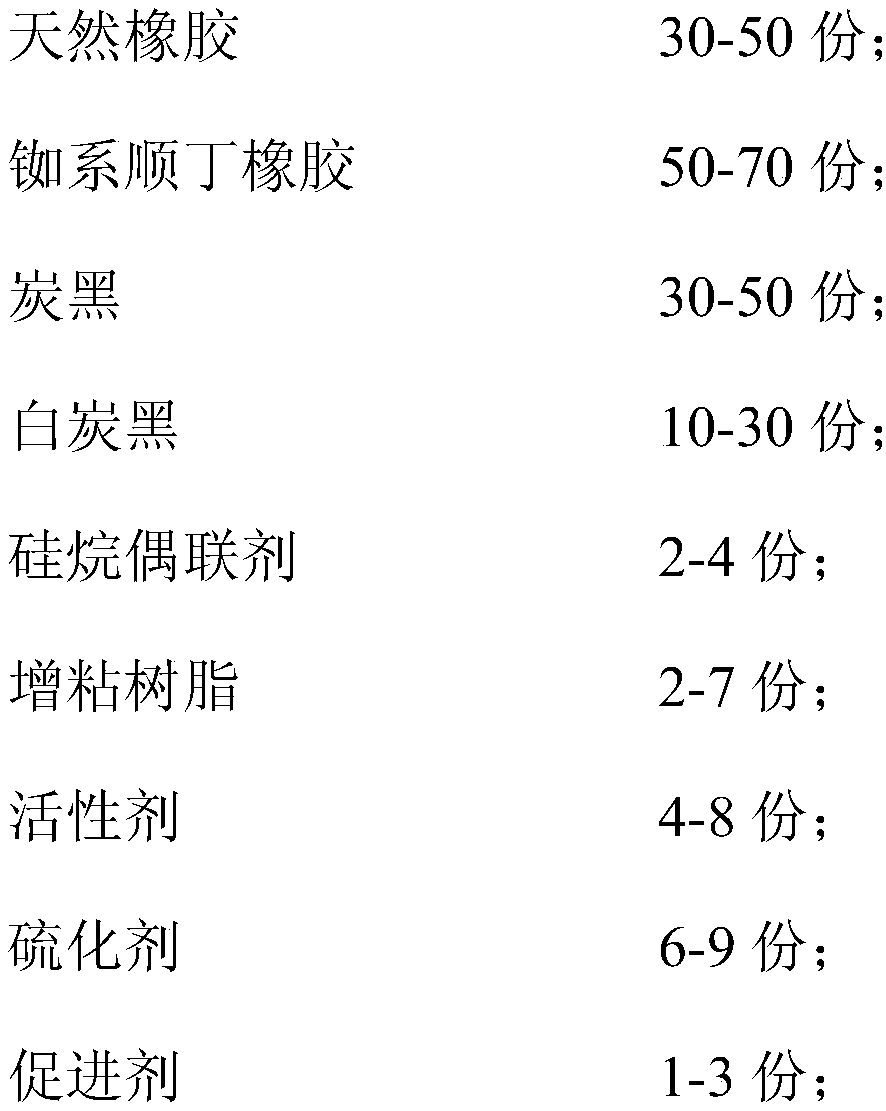

Glue material for run-flat tire supporting glue, preparation method of glue material and run-flat tire

The invention provides a glue material for run-flat tire supporting glue, a preparation method of the glue material and a run-flat tire. The glue material comprises, by weight, 30-50 parts of naturalrubber, 50-70 parts of rubidium butadiene rubber, 30-50 parts of carbon black, 10-30 parts of white carbon black, 2-4 parts of silane coupling agents, 2-7 parts of tackifying resin, 4-8 parts of active agents, 6-9 parts of vulcanizing agents or 1-3 parts of accelerants. The glue material is prepared by mixing the components except for the vulcanizing agents and the accelerants, performing short-time secondary mixing and finally performing final mixing. The supporting glue formed after vulcanizing the glue material for the run-flat tire supporting glue has good rigidity, a rim of the tire cannot touch the earth in deflation, the tire stably runs, has high flexing resistance and tearing resistance and cannot break in high-frequency compression release process, and the buffer performance of the tire is ensured.

Owner:QINGDAO FULUN TECH

Engine system and operation method using engine braking mechanisms for early exhaust valve opening

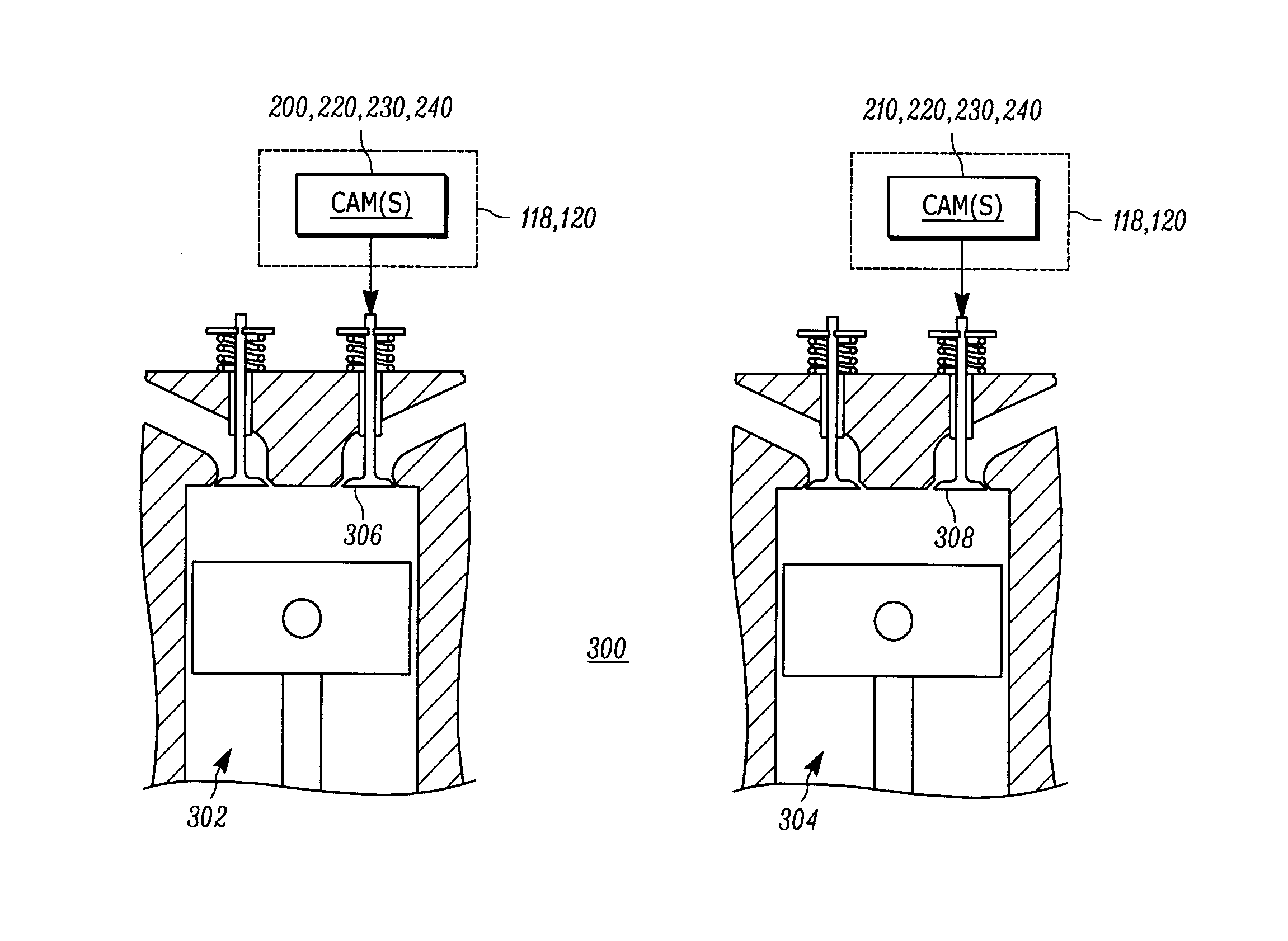

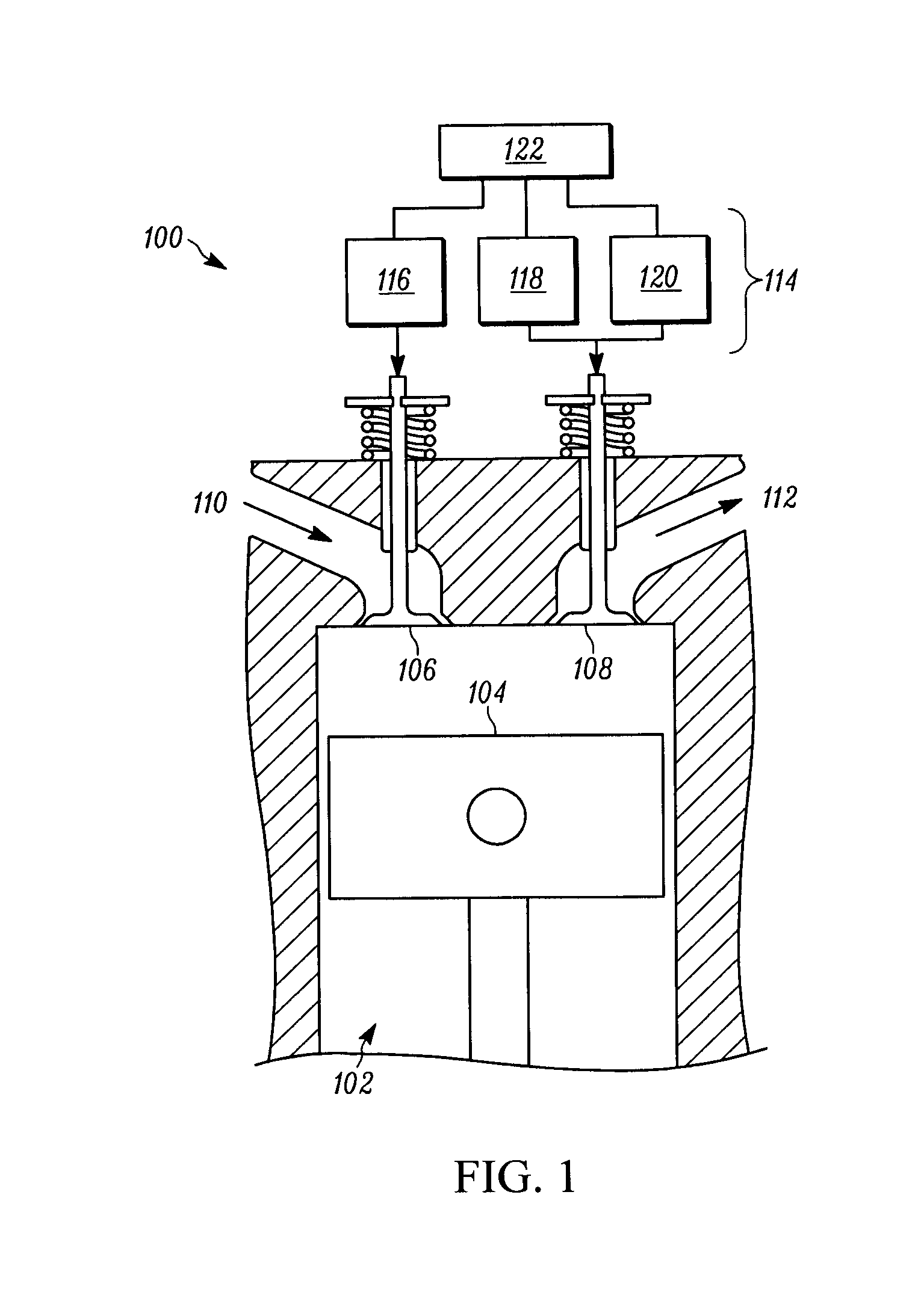

ActiveUS9234467B2Electrical controlInternal combustion piston enginesEngineeringInternal combustion engine

A valve actuation system for an internal combustion engine is disclosed. The engine has a first set of cylinders having a first set of exhaust valves and a second set of cylinders having a second set of exhaust valves. The valve actuation system for the exhaust valves includes one or more first cams having a compression-release lobe and a main exhaust lobe adapted to transfer valve actuation motion to the first set of exhaust valves, and one or more second cams having an early exhaust valve opening (EEVO) lobe and a main exhaust lobe adapted to transfer valve actuation motion to the second set of exhaust valves. The valve actuation system may provide any combination of (i) main exhaust valve actuation with or without compression release actuation with (ii) main exhaust valve actuation with or without EEVO for the two sets of cylinders.

Owner:JACOBS VEHICLE SYST

Engine braking methods and apparatus

InactiveCN101180459ANon-fuel substance addition to fuelInternal combustion piston enginesWork cycleVariable geometry

The present invention discloses a method and apparatus for implementing blower type engine braking and compression-release type engine braking on an internal combustion engine. With blower-type engine braking, the exhaust valve is held at a relatively constant low lift during all or most of the engine's operating cycle. Engine braking may be combined with operation of exhaust gas recirculation, variable exhaust brake operation, and / or operation of a variable geometry turbocharger.

Owner:JACOBS VEHICLE SYST

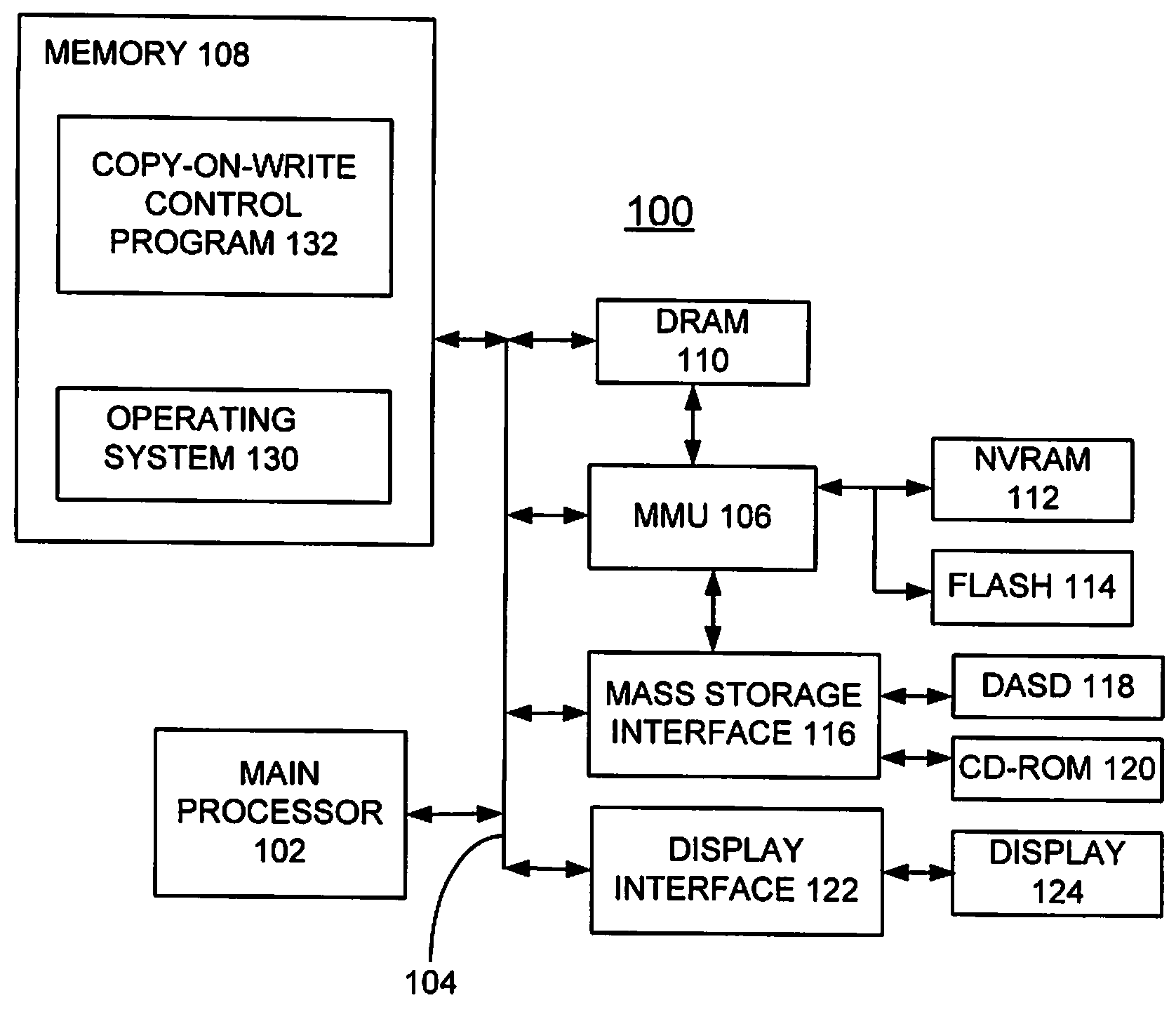

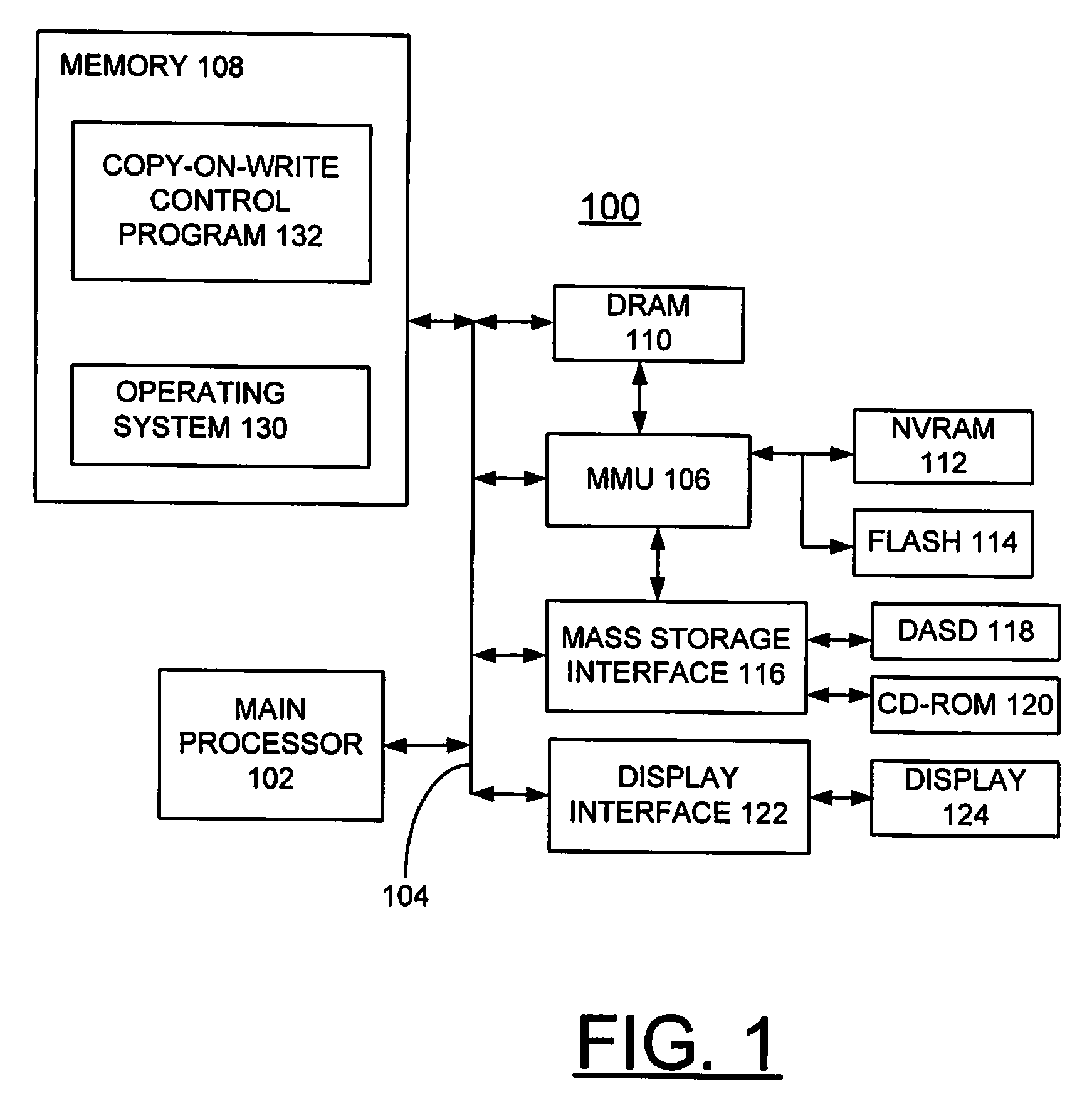

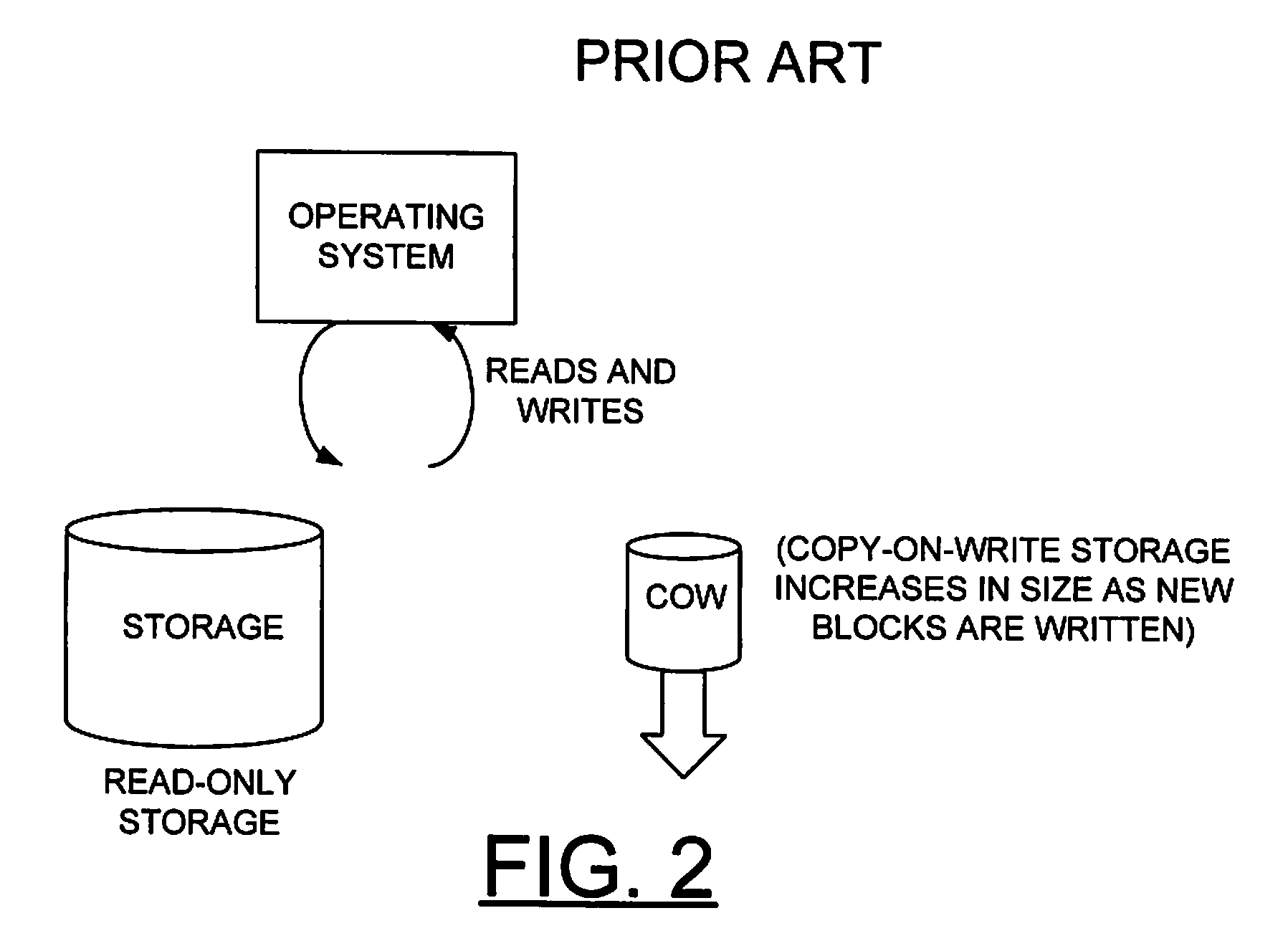

Method and apparatus for implementing dynamic copy-on-write (COW) storage compression through purge function

InactiveUS20080162842A1Memory loss protectionDigital data processing detailsFunction methodCompression release

Methods, apparatus and computer program product implement enhanced dynamic copy-on-write storage compression. For a write operation, a purge function for a block being written is detected by the COW storage for compressing freed blocks from the COW storage. Responsive to the detected purge function and the block being a previously written block in the COW storage, the previously written block in the COW storage is deleted from the COW storage. Responsive to the detected purge function and the block not being a previously written block in the COW storage, the block is marked as zero in the COW storage.

Owner:IBM CORP

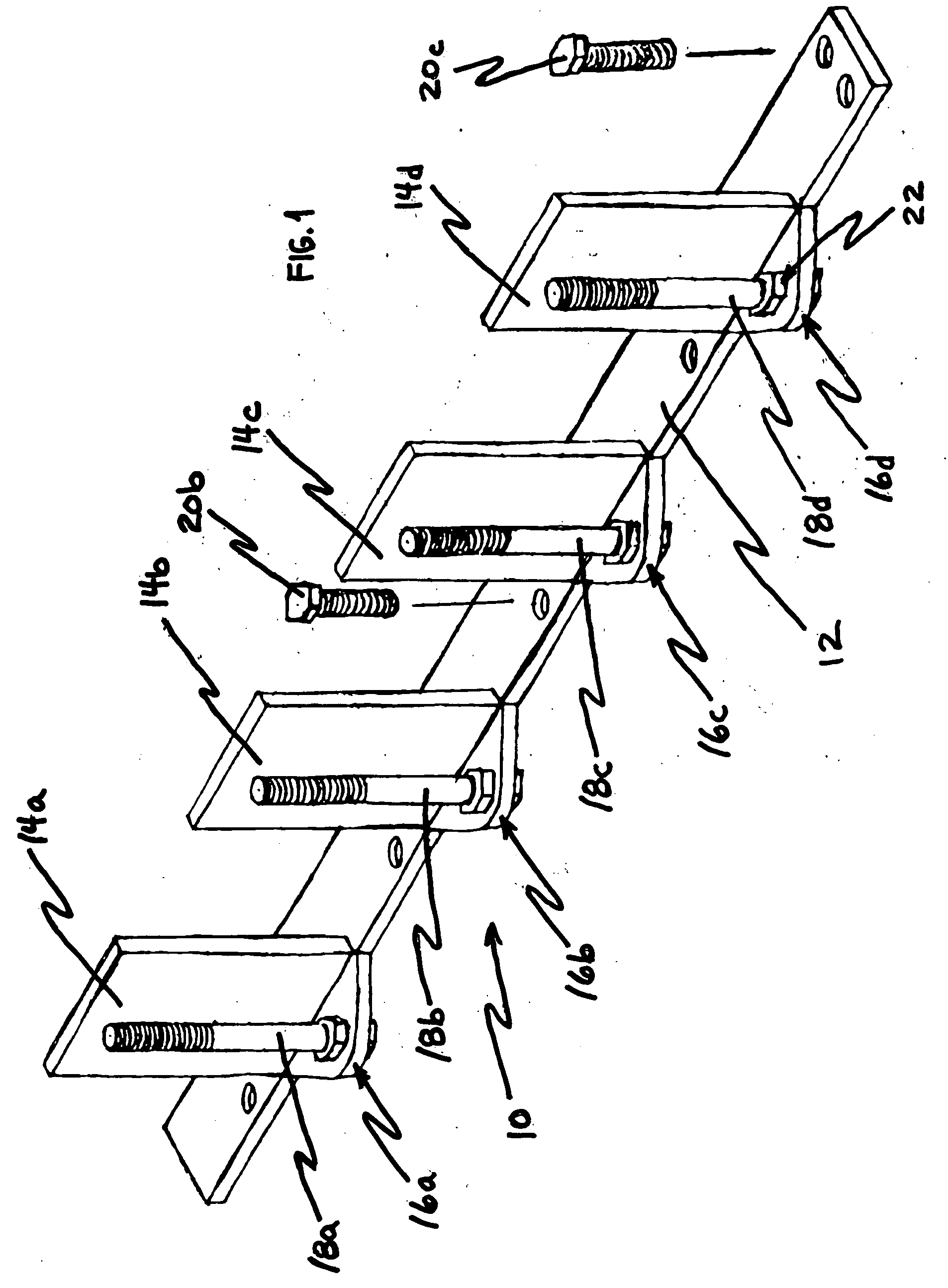

Tool for facilitating the removal and replacement of engine valve stem springs and seals

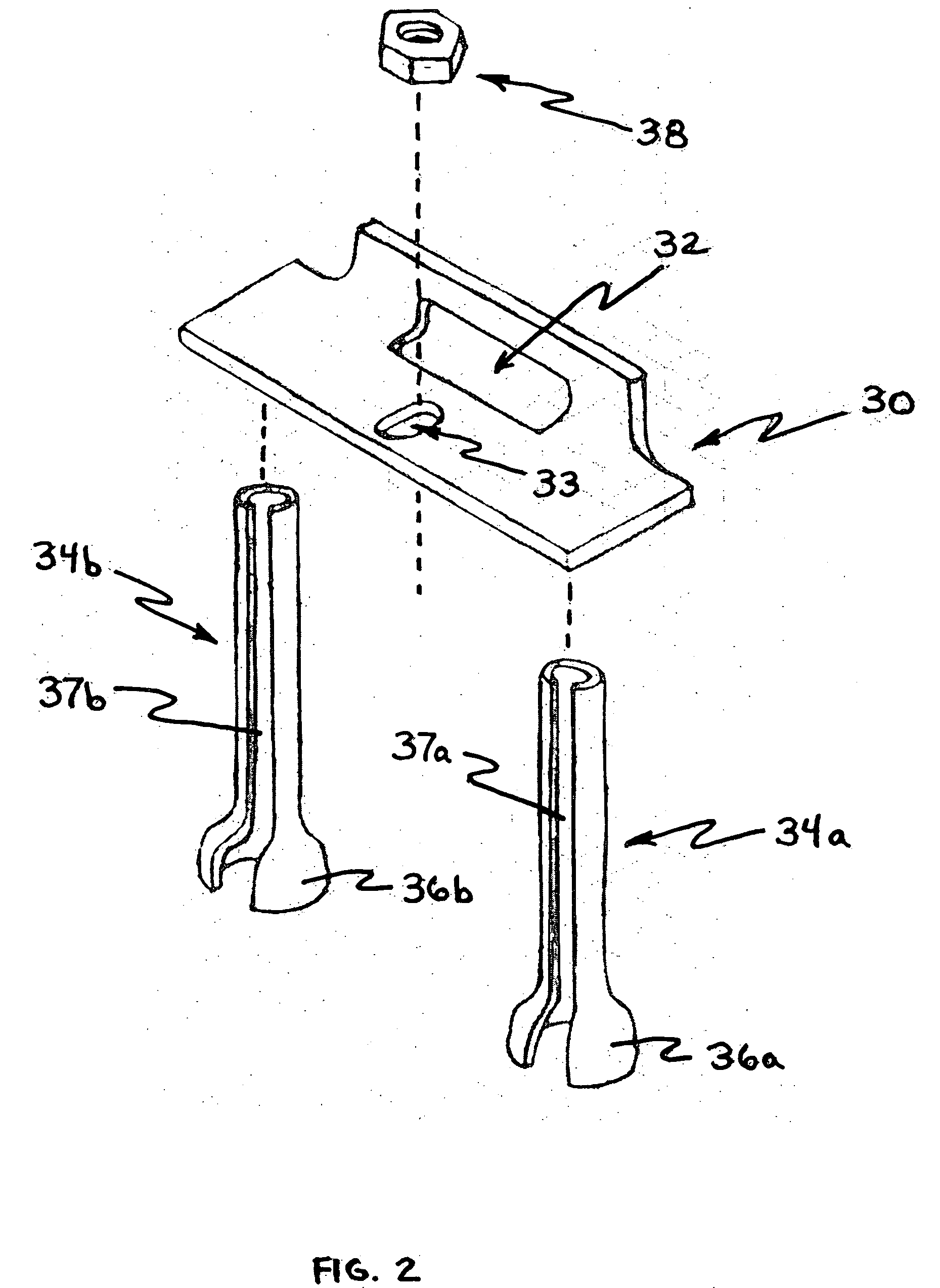

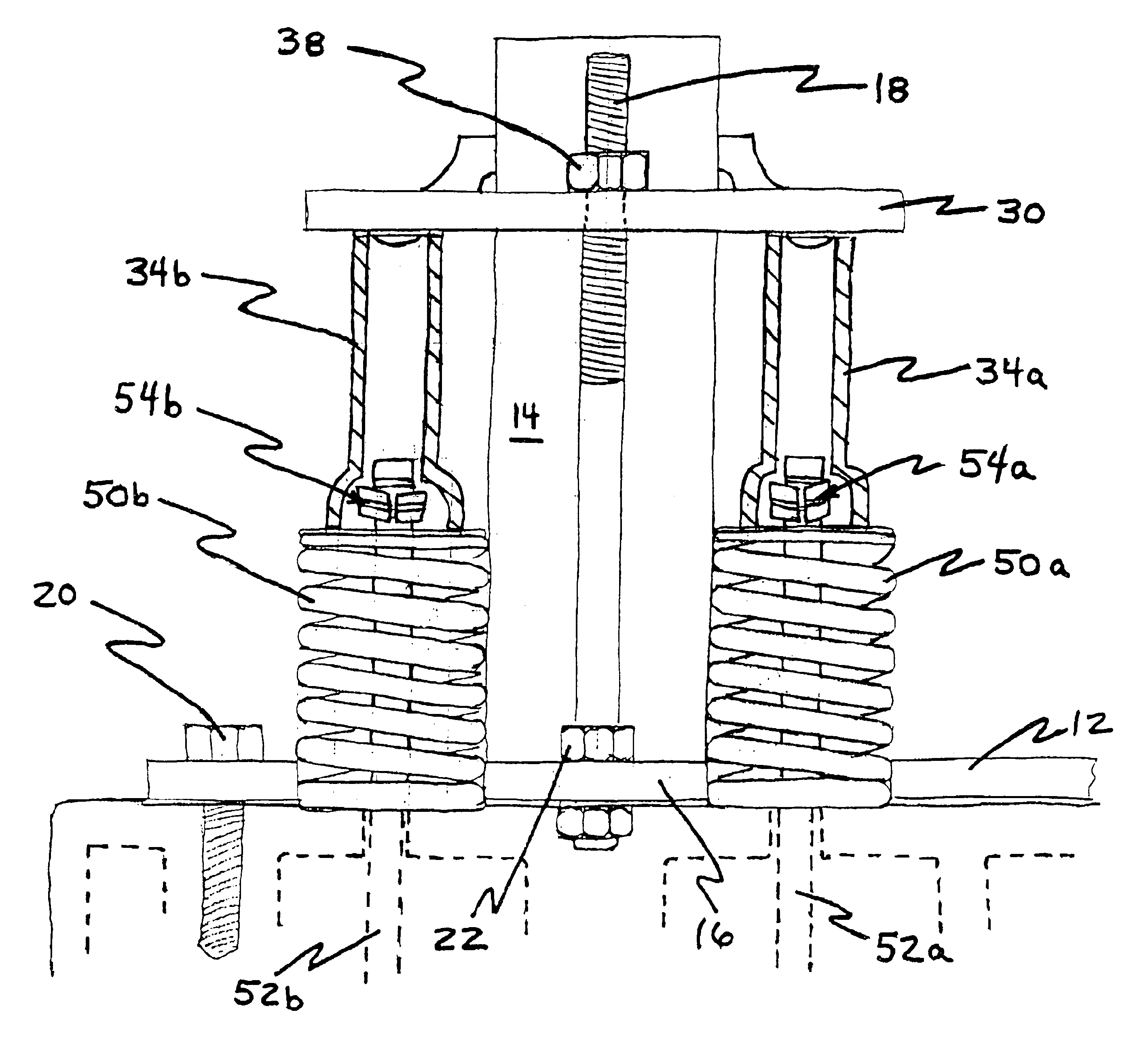

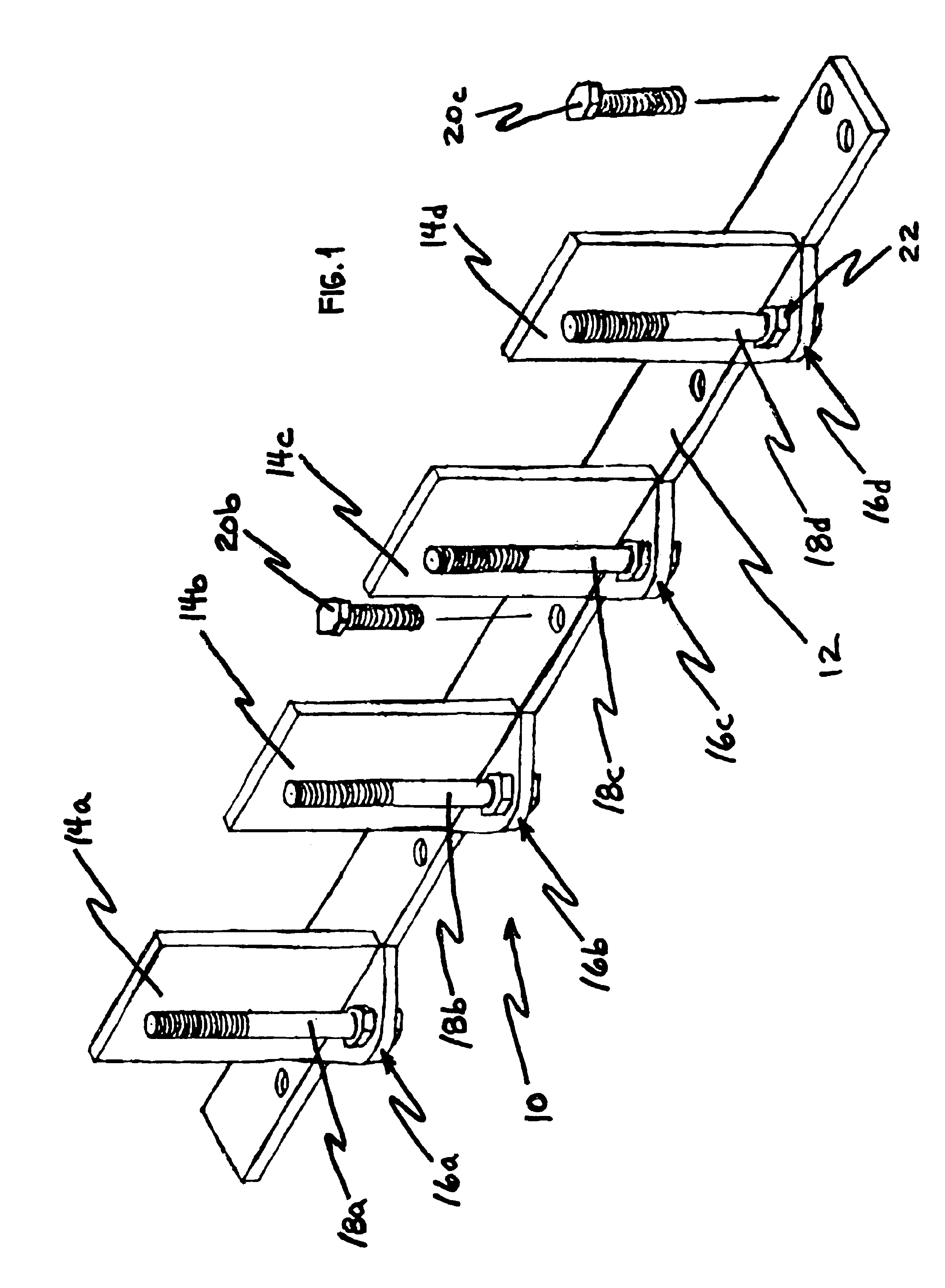

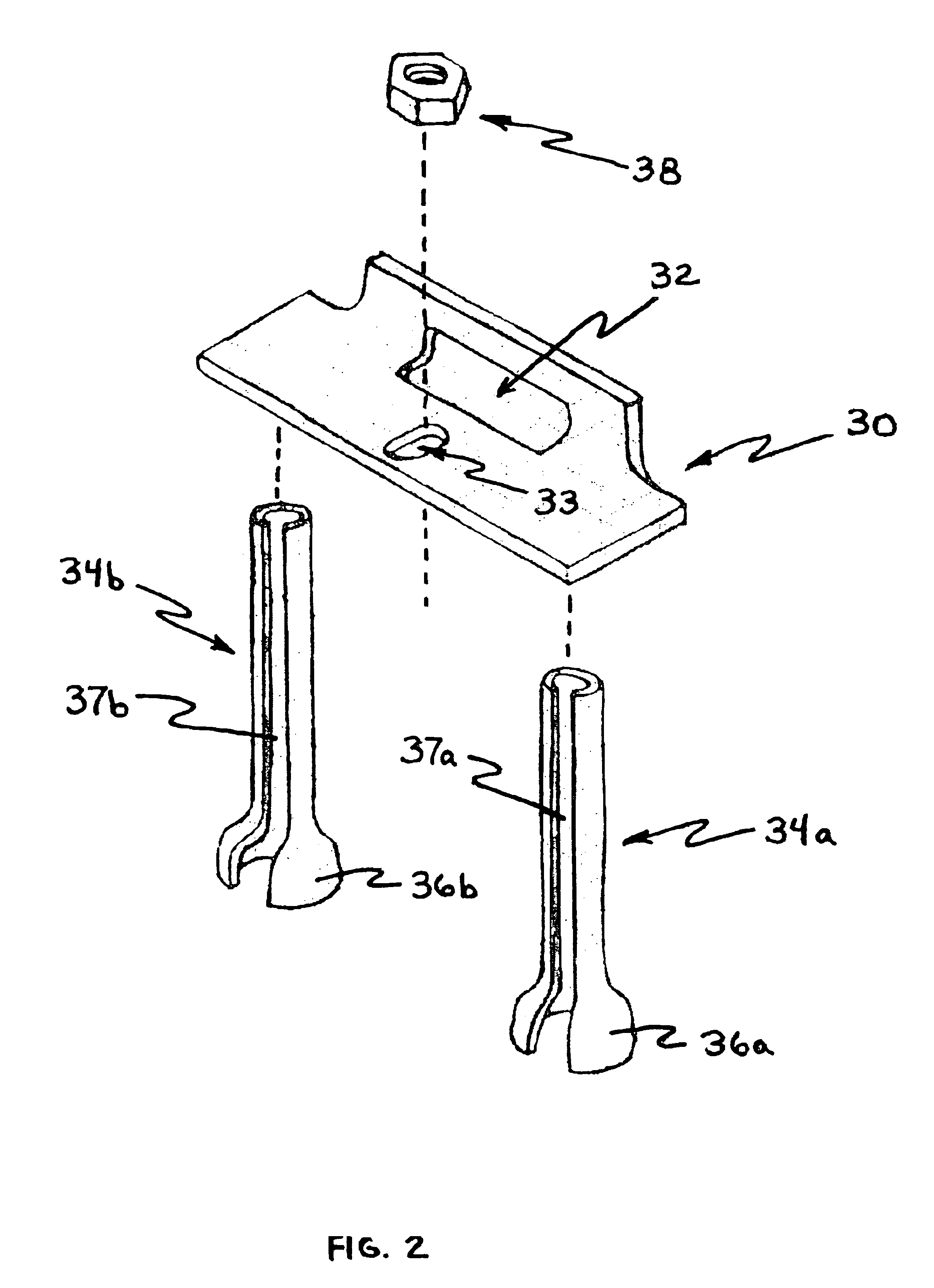

InactiveUS20050076486A1Facilitates removal and replacementEfficient use ofMetal working apparatusMetal-working hand toolsCylinder headSplit ring

A tool for the removal and replacement of valve springs on the cylinder head of an internal combustion engine while the cylinder head is either mounted to the engine block within the vehicle or is positioned on a work bench apart from the engine. The tool comprises a bracket component that is mounted by a number of bolts to the cylinder head to be worked on. The bracket includes a number of upright threaded bolts each associated with an adjacent upright guide. A pressure plate is progressively positioned on each set of the upright bolts and upright guides. Beneath the pressure plate are positioned two (or more) valve guides that engage the outer upper perimeter of two or more valve springs. A nut is threaded on to the upright bolt in a manner that forces the pressure plate and the valve guides downward onto the valve springs. Compression of the springs releases the split rings or collars that hold the valve springs to the valve stems. The end of the valve stems that incorporate the split ring attachment mechanisms are allowed to move upward into the valve guides while the perimeter of the spring is compressed. In this manner the split ring can be removed and the springs released upon removal of the nut from the threaded upright bolt. The pressure plate may then be moved to the next upright bolt on the bracket to effect removal of the adjacent set of valve springs.

Owner:ALANIS FRANSISCO

Tool for facilitating the removal and replacement of engine valve stem springs and seals

InactiveUS6938315B2Facilitates removal and replacementEfficient use ofMetal working apparatusMetal-working hand toolsSplit ringCylinder head

Owner:ALANIS FRANSISCO

Compression apparatus

InactiveCN102525554AReduce the burden of discomfortImprove convenienceUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsEngineeringCompression release

An apparatus includes two compression plates arranged to compress a subject portion, and a compression release means arranged to move at least one of the two compression plates in a direction opposite to a direction in which the subject portion is compressed in a state in which the subject portion is compressed and power is not supplied.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com