Engine braking methods and apparatus

A technology of engine braking and engine, which is applied in the direction of engine control, mechanical equipment, engine components, etc., and can solve the problems of engine positive power output and adverse effects of emissions, reducing the braking efficiency of the blower, reducing the engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

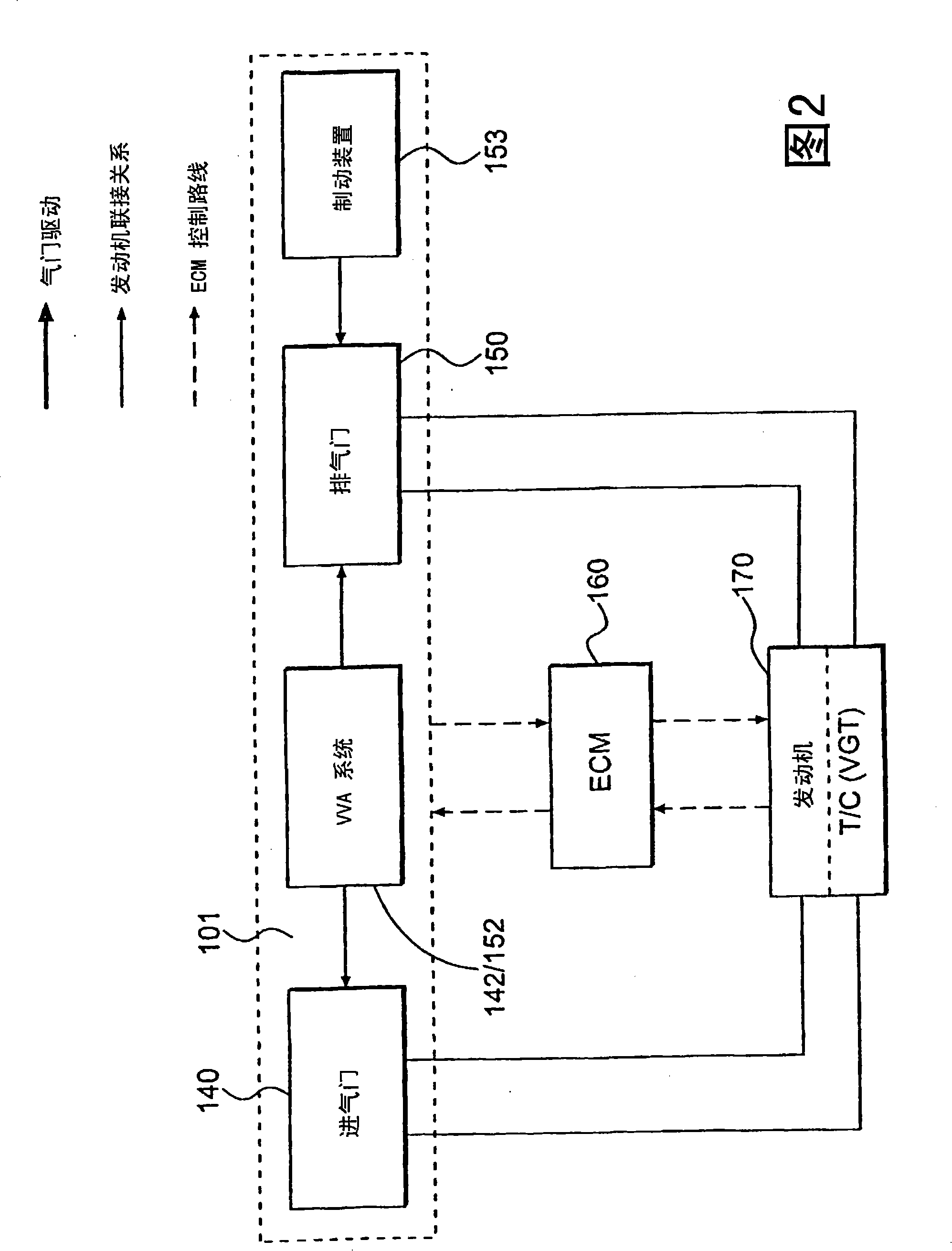

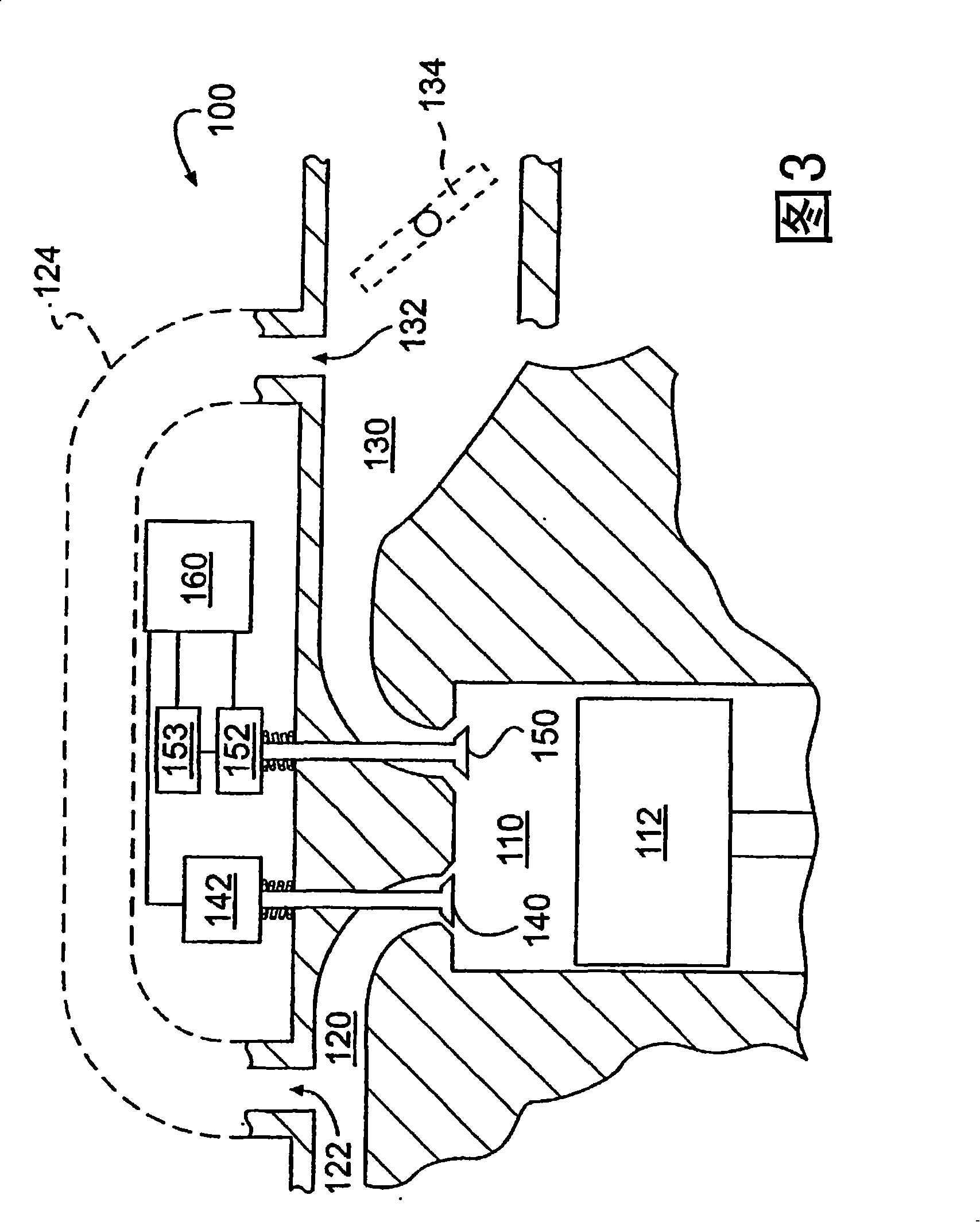

[0038] Reference will now be made in detail to a first embodiment of the system of the present invention, an example of which is represented in FIG. 2 . Valve actuation system 101 may include a VVA system 152 / 142 in operative communication with one or more intake valves 140 and one or more exhaust valves 150 . The VVA system may include two separate components 142, 152 dedicated to actuating the intake and exhaust valves, respectively, or the system may be a combined system. An engine braking device 153 may also be in operative connection with the exhaust valve 150 . In certain embodiments of the invention, particularly compression-release embodiments, the separate engine braking device 153 may be eliminated by integrating the engine braking function into the VVA system 152 / 142.

[0039] The valve actuation system 101 , particularly the VVA system 152 / 142 and the engine braking device 153 may be in operative connection with an ECM 160 . ECM 160 may send control signals t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com