Stacked compression release valve

A pressure reducing valve and superimposed technology, applied in the field of hydraulic control valve, can solve the problems of inconvenient use, insufficient compact installation of the pressure reducing valve, and no secondary oil circuit pressure protection, etc., so as to reduce the pressure measuring port and reduce extravasation. The effect of missing links and reducing process holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

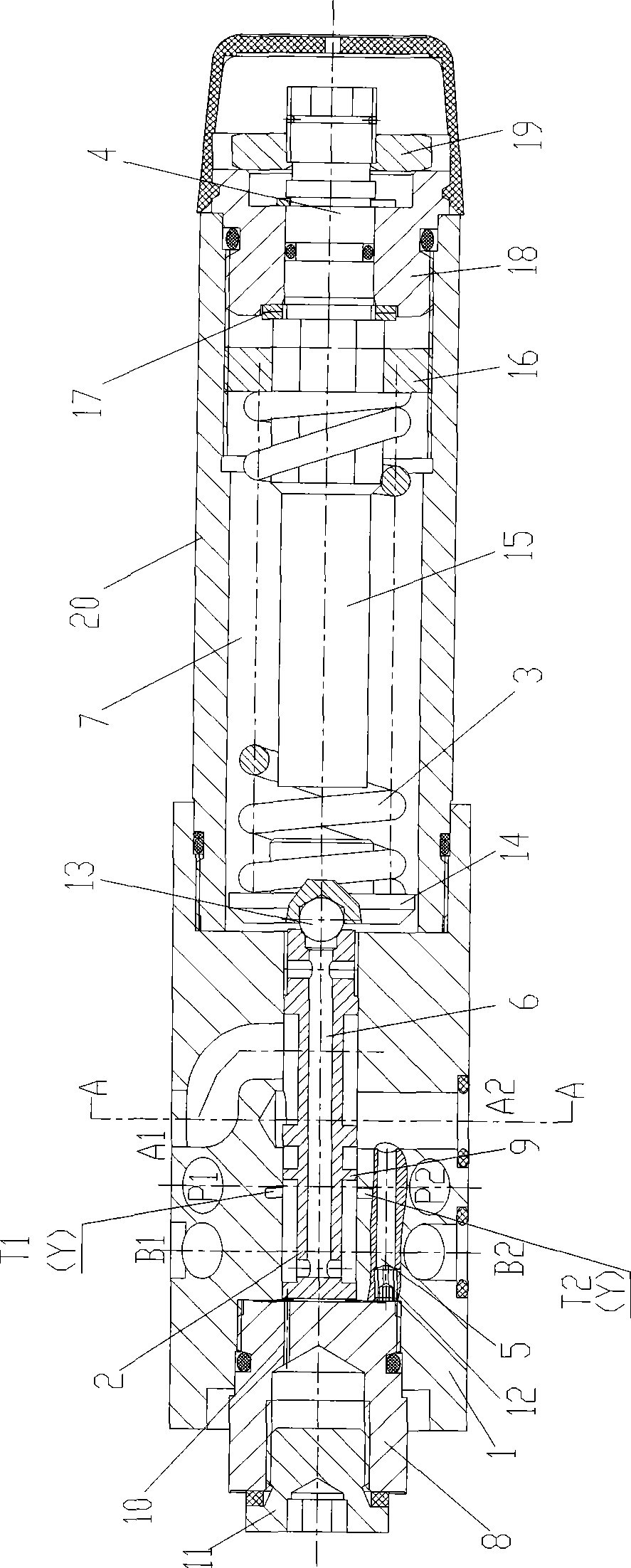

[0027] by figure 1 shown for explanation. In the static position, the valve is normally open and oil can flow freely from A1 to port A2. The pressure of the oil port A2 acts on the piston area opposite to the spring 3 through the control oil circuit 5 at the same time. When the pressure of oil port A2 exceeds the setting value of spring 3, the control spool 2 moves to the control position, and the pressure of oil port A2 remains stable. The signal and control oil are provided from the inside of oil port A2 through the damper 12 and the control oil passage 5. If the pressure of oil port A2 continues to rise due to the external force acting on the actuator, the control spool 2 will continue to move in the direction of the spring 3. In this way, the oil port A2 communicates with the oil tank through the spool shoulder 9 on the control piston 2 . Excess oil flows back to the tank to prevent further pressure build-up. The spring chamber 7 drains oil from the outside to the fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com