Method and device for manufacturing rocking arm with main piston and auxiliary piston

A technology of braking device and main piston, applied in valve device, engine components, engine control and other directions, can solve the problems of poor reliability and durability, increased engine height and weight, inconvenient installation and debugging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

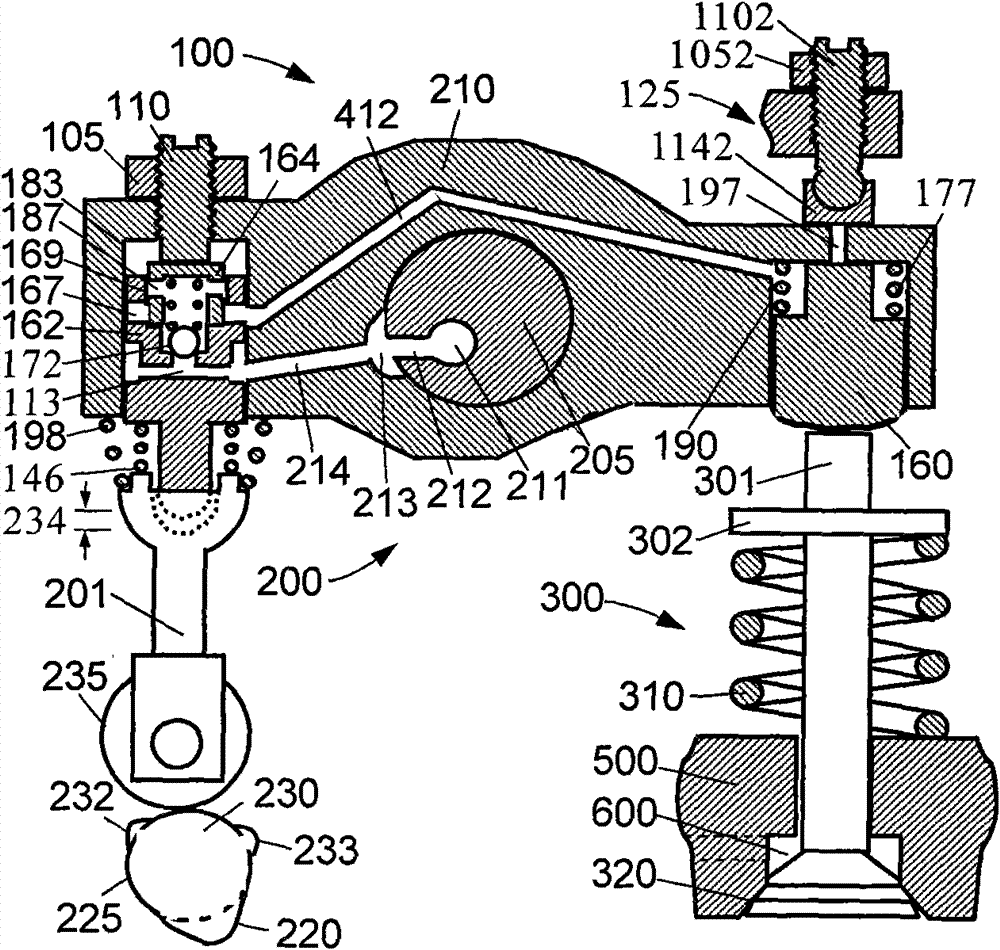

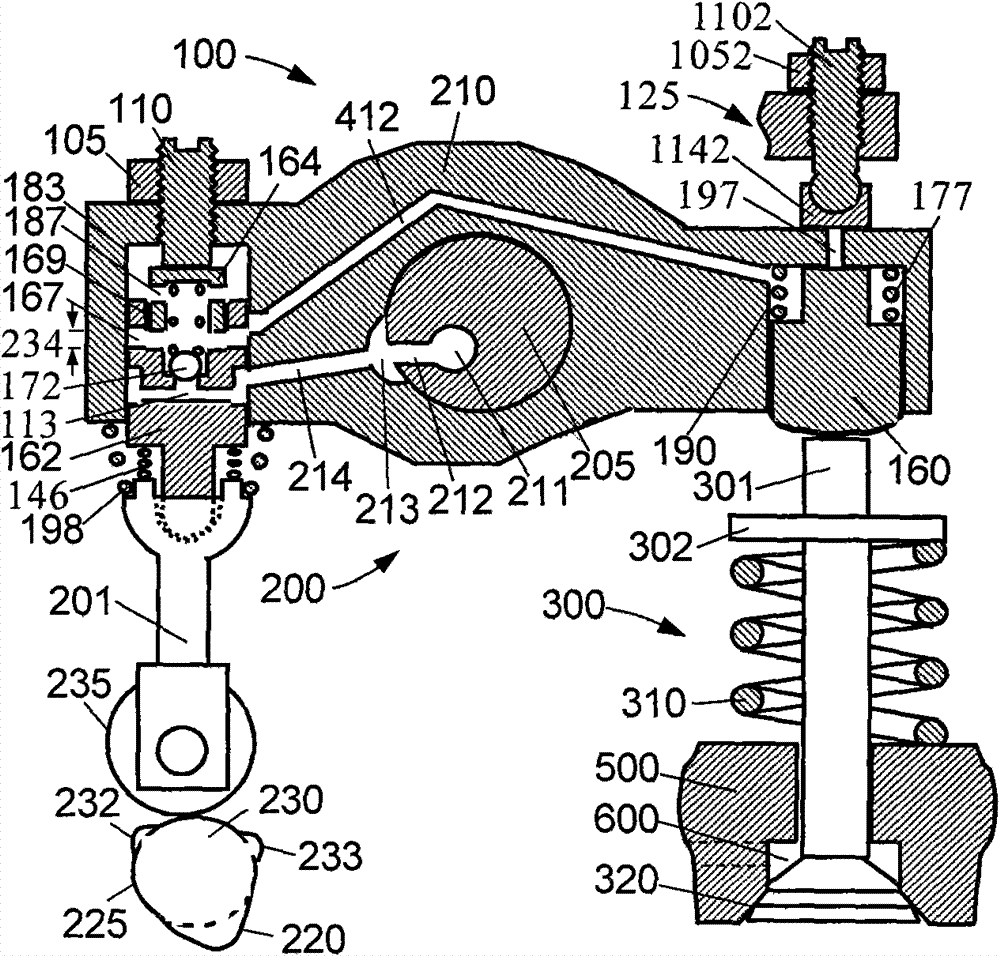

[0066] figure 1 and figure 2 Respectively represent the first embodiment of the rocker arm braking device with primary and secondary pistons of the present invention when the cam 230 is at the position of the inner base circle 225 during non-braking and braking. figure 1 and figure 2 It includes three main components: an exhaust valve actuator 200 , an exhaust valve mechanism 300 and an engine brake drive mechanism 100 .

[0067] The exhaust valve 301 of the exhaust valve mechanism 300 (only one exhaust valve is shown here, which may be multiple valves) is pushed on the valve seat 320 in the engine block 500 by the valve spring 310, preventing the gas (engine braking) air) between the engine cylinders and the exhaust pipe 600.

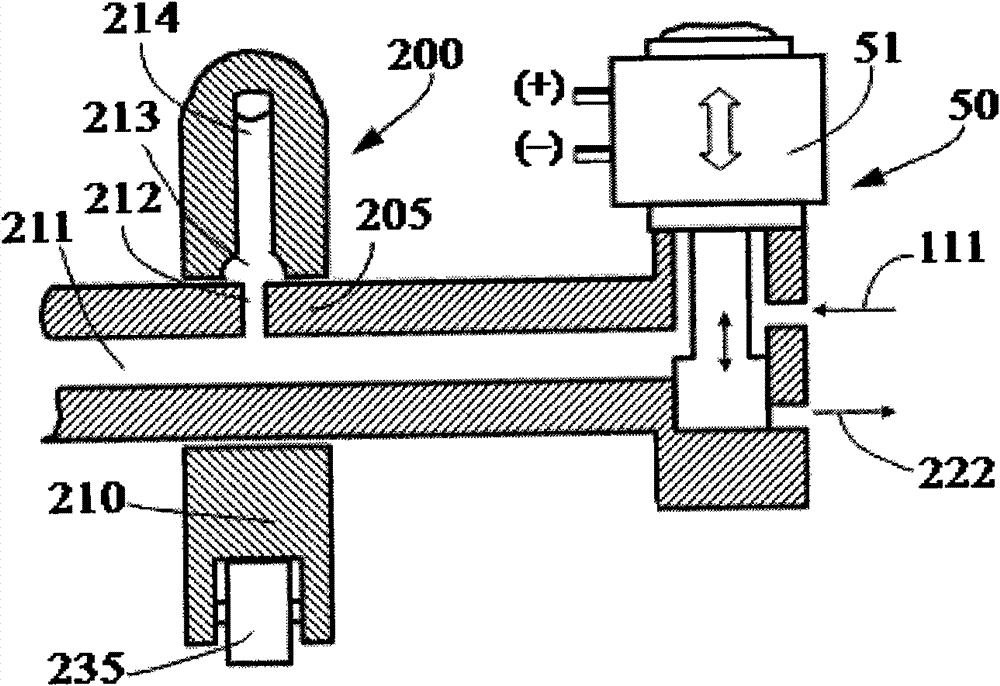

[0068] Exhaust valve actuator 200 includes cam 230 , cam follower 235 , pushrod 201 and rocker arm 210 . The exhaust valve actuator 200 and the exhaust valve 300 mechanism are collectively referred to as an exhaust valve drive chain. The end of ...

Embodiment 2

[0089] Figure 9 and Figure 10 Respectively represent the second embodiment of the rocker arm braking device with primary and secondary pistons of the present invention when the cam is in the position of the inner base circle during non-braking and braking. The difference between this embodiment and the first embodiment is that there is no switching piston installed above the primary piston 162 in this embodiment, and the hydraulic transmission between the primary piston hole 183 and the secondary piston hole 190 is always kept open. Therefore, during engine braking, most of the braking load on the secondary piston 160 is transmitted to the primary piston 162 , and only a small portion is transmitted to the brake bracket 125 above the rocker arm 210 .

[0090] The working principle and process of this embodiment are similar to those of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com