Load controllable engine braking device and engine braking method

A technology of engine braking and engine, applied in the direction of engine control, engine components, machine/engine, etc., can solve the problems of large braking load, etc., and achieve the goals of reducing braking load, compact structure, improving reliability and durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

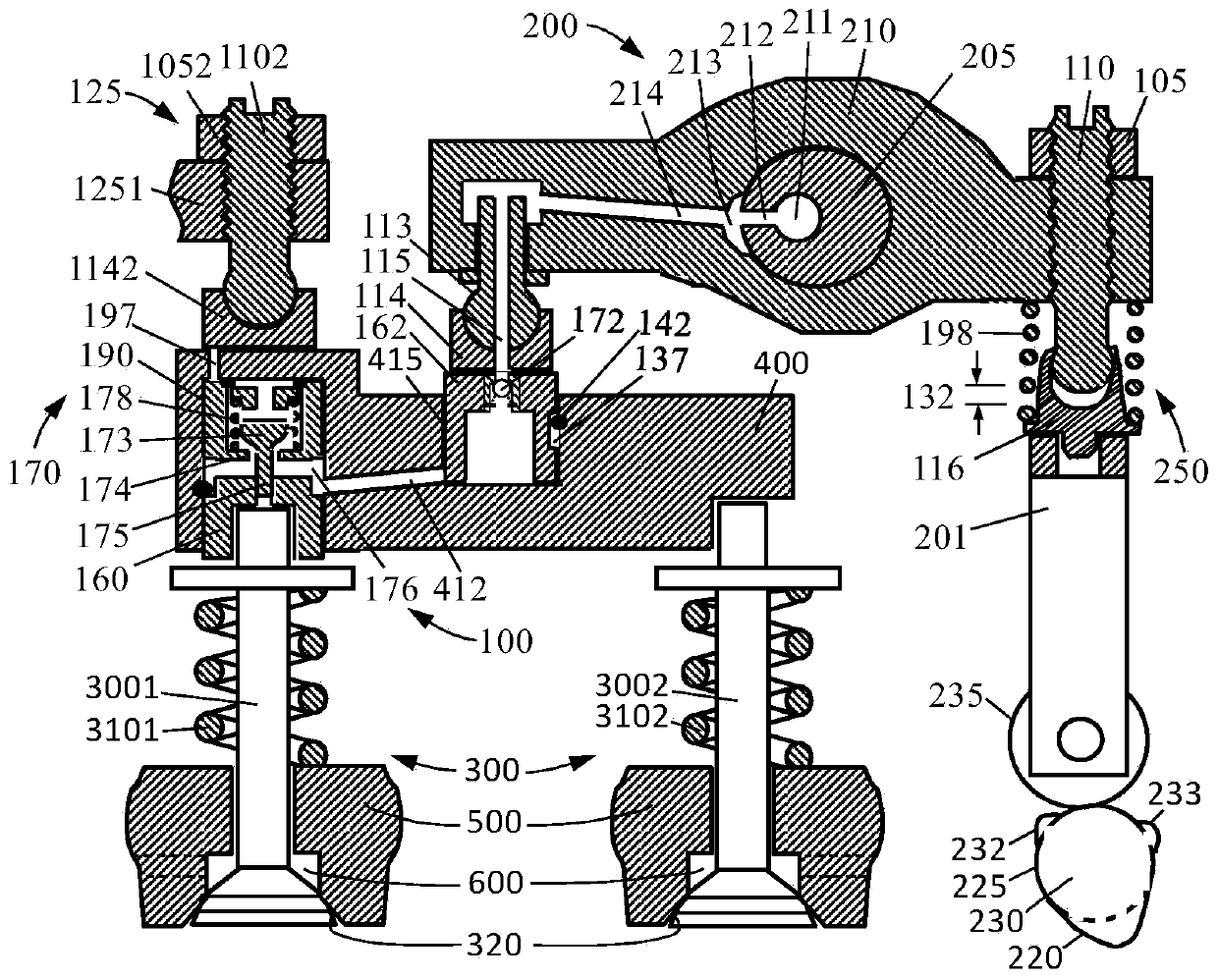

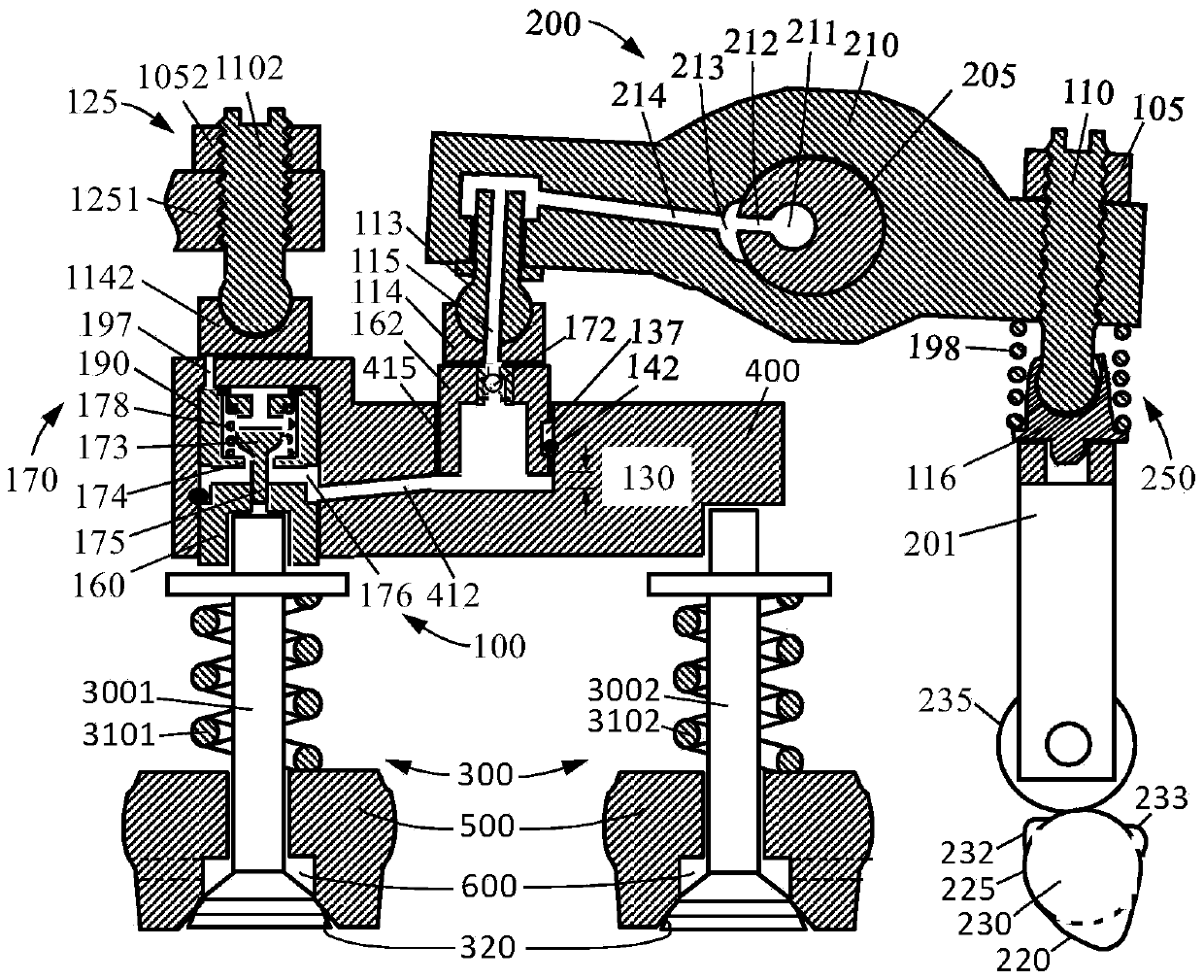

[0020] Such as figure 1 with figure 2 As shown, Embodiment 1 of the load-controllable engine braking device of the present invention is in the positions of "OFF" (the oil supply mechanism cuts off oil) and "ON" (the oil supply mechanism supplies oil). figure 1 with figure 2 It includes three main components: a valve actuator 200 of the engine, a valve 300 (including a first valve 3001 and a second valve 3002 ) and a load-controllable engine brake drive mechanism 100 .

[0021] The valve actuator 200 includes a cam 230 , a cam follower 235 , a push rod 201 , a rocker arm 210 and a valve bridge 400 . Together, the valve actuator 200 and the valve 300 may be referred to as a valve drive chain. Usually, one end of the rocker arm 210 (close to the valve bridge 400 or close to the cam 230 ) is provided with a valve clearance adjusting mechanism. The valve gap adjusting mechanism in this embodiment includes a valve gap adjusting screw 110 arranged in a rocker arm 210 on one sid...

Embodiment 2

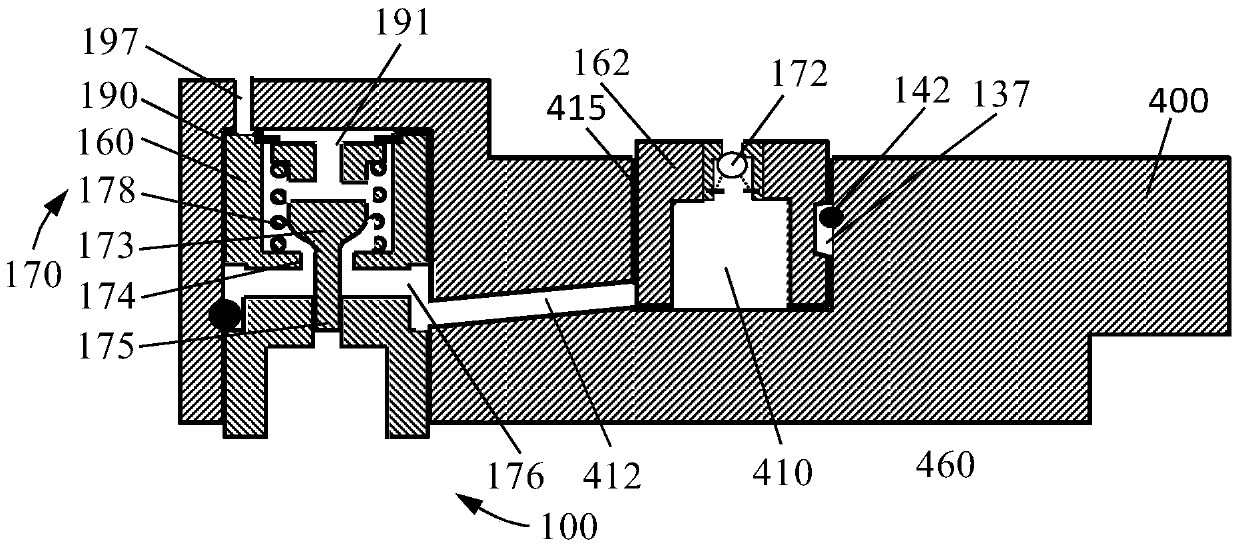

[0037] Such as Figure 5 with Image 6 As shown, Embodiment 2 of the load-controllable engine braking device of the present invention is in the positions of "off" (the oil supply mechanism cuts off oil) and "on" (the oil supply mechanism supplies oil) respectively. The difference between this embodiment and the first embodiment above is that the box body in this embodiment adopts the rocker arm 210 of the engine. That is to say, the engine brake drive mechanism 100 is mainly integrated in the rocker arm 210 . The main piston hole 415 is arranged at one end of the rocker arm 210 and opens downward, and the auxiliary piston hole 190 is arranged at the other end of the rocker arm 210 and also opens downward. The outer end (lower side) of the main piston 162 in the main piston hole 415 is connected with the cam, and the outer end (lower side) of the auxiliary piston 160 in the auxiliary piston hole 190 is connected with the valve 3001 of the engine. An oil hole 197 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com