A combined vehicle and train braking system and method

A combined braking, car-train technology, applied in electric braking systems, brakes, electric vehicles, etc., can solve the problem of limited retarder size and braking torque, limited wheel space, and the influence of trailer braking stability, etc. to improve the braking stability and reduce the braking load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

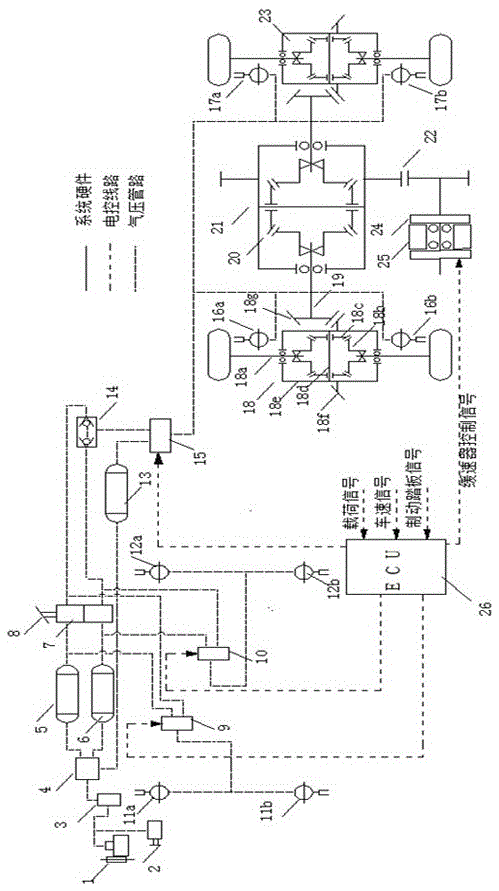

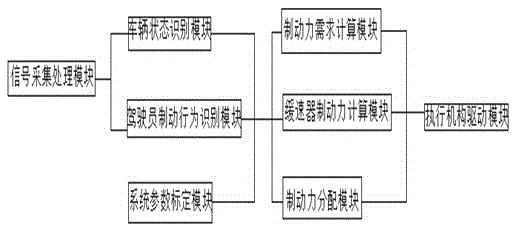

[0024] Such as figure 1 The vehicle-train combined braking system of the present invention is composed of an air pressure braking system, a retarder system and an electronic control unit ECU.

[0025] The pneumatic brake system is the service brake, installed on the tractor, including air compressor 1 and auxiliary air source 2, air compressor 1 and auxiliary air source 2 are connected in parallel, and after parallel connection, it is connected to the input port of pressure regulating valve 3, and the pressure regulating valve The output port of 3 is connected to the input port of the three-circuit distribution valve 4, and the output port of the three-circuit distribution valve 4 is respectively connected to the input ports of the air storage tank 5 in front of the tractor, the rear air storage tank 6 of the tractor and the air storage tank 13 of the trailer. The output port of the front air storage tank 5 of the tractor is respectively connected with the input port of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com