Lost motion variable valve actuation system for engine braking and early exhaust opening

A technology of engine braking and exhaust valves, applied in engine control, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

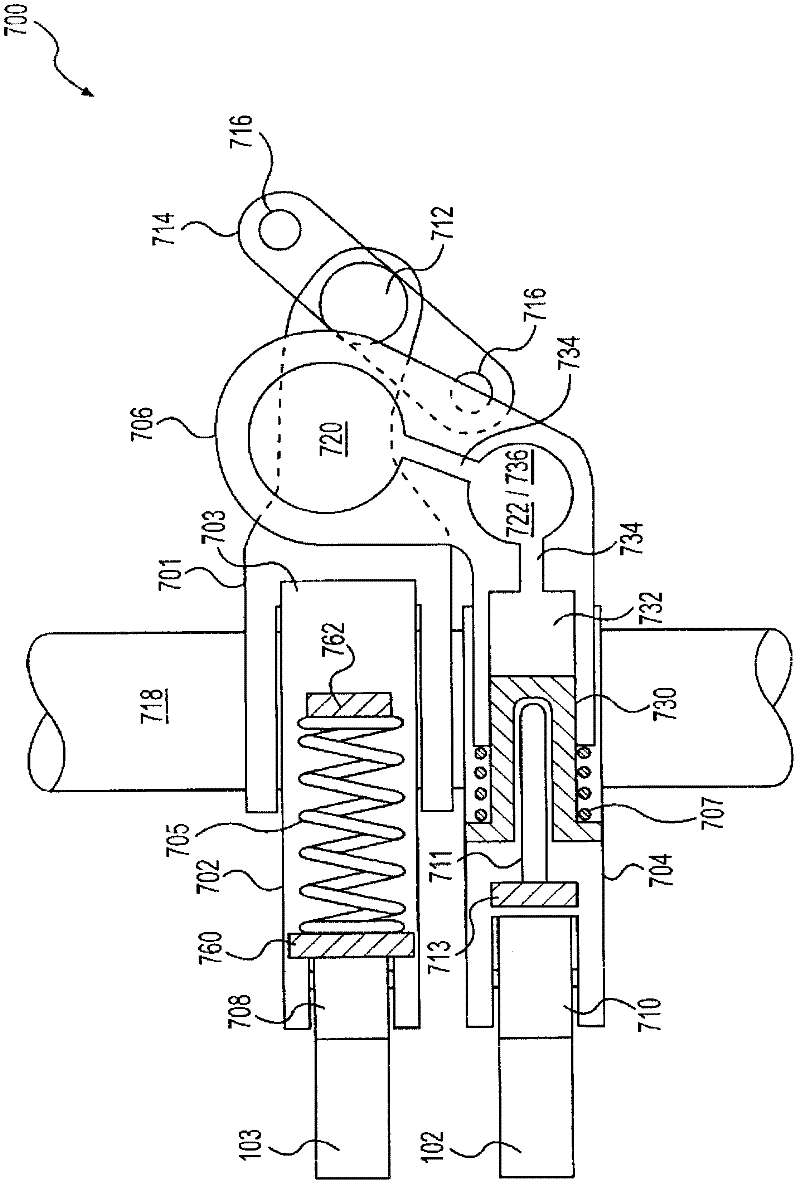

[0038] Reference will now be made in detail to the embodiments of the invention, examples of which are illustrated in the accompanying drawings. Embodiments of the present invention may be used to provide variable valve actuation for compression-release engine braking and brake gas recirculation during engine braking mode of engine operation, as well as early exhaust during positive power mode of engine operation The door opens.

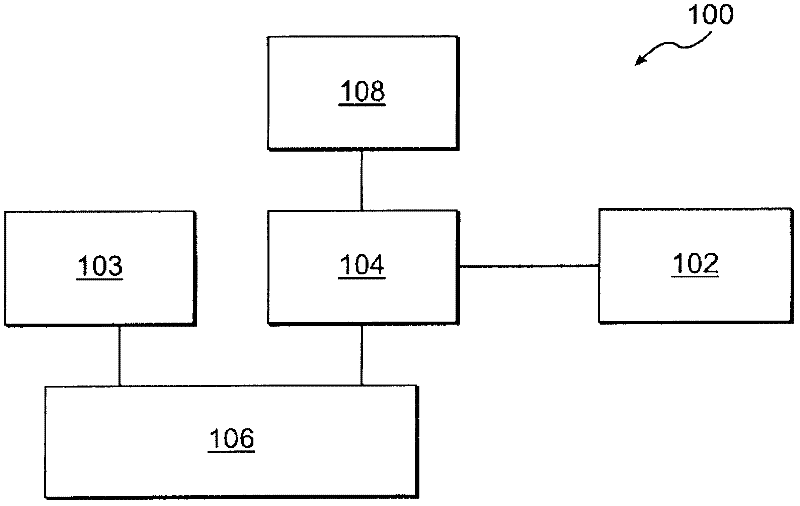

[0039] figure 1 is a block diagram showing the valve actuation system 100 according to the first embodiment of the present invention. The valve actuation system 100 may include a first motion imparting device 102, such as a cam having one or more raised portions or protrusions, which operably contacts a lost motion system 104, which in turn may be operably connected to One or more engine valves 106 . The valve actuation system may also include a second motion imparting device 103 operatively connected to the one or more engine valves 106 . It sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com