Fusing type compression release mechanism and release method thereof

A release mechanism and fuse-type technology, applied in motor vehicles, aerospace equipment, space navigation equipment, etc., can solve the problems of high cost, large pressing force, and heavy weight of the pressing and releasing mechanism, and achieve low cost and high pressure. Small tightening force and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

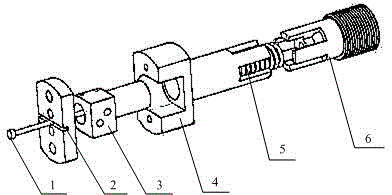

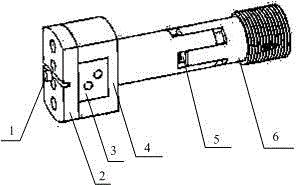

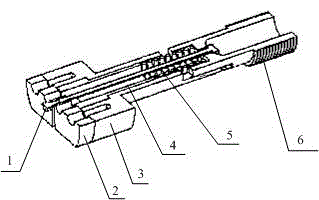

[0029] like figure 1 Shown is an exploded view of the fuse-type compression release mechanism of the present invention, which includes: an end cap 2 connected to a load-bearing rope 1 in sequence, a heater 3 , a fixing section 4 , a separating spring 5 and a separating section 6 . like figure 2 Shown is a schematic diagram of the compression state of the fuse type compression release mechanism of the present invention, as image 3 As shown in its cross-sectional view, the fixed section 4 is provided with a heater groove and a separation spring groove, which are respectively used to accommodate the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com