Patents

Literature

207results about How to "Small pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Information sensing syringe

InactiveCN105007961AHigh trafficSmall pressing forceAutomatic syringesMedical devicesFluid controlMedicine

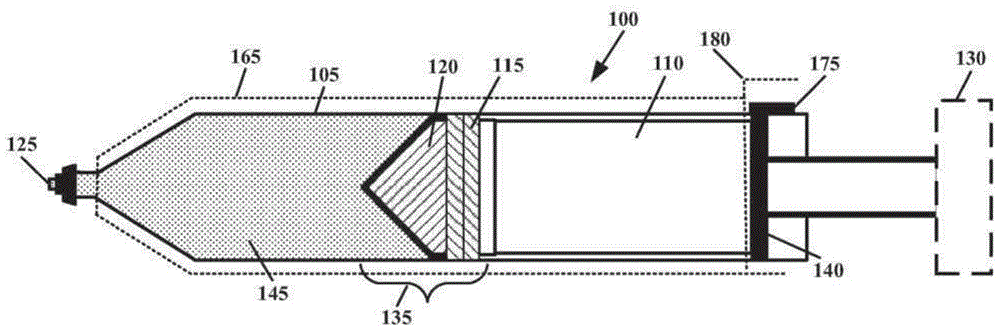

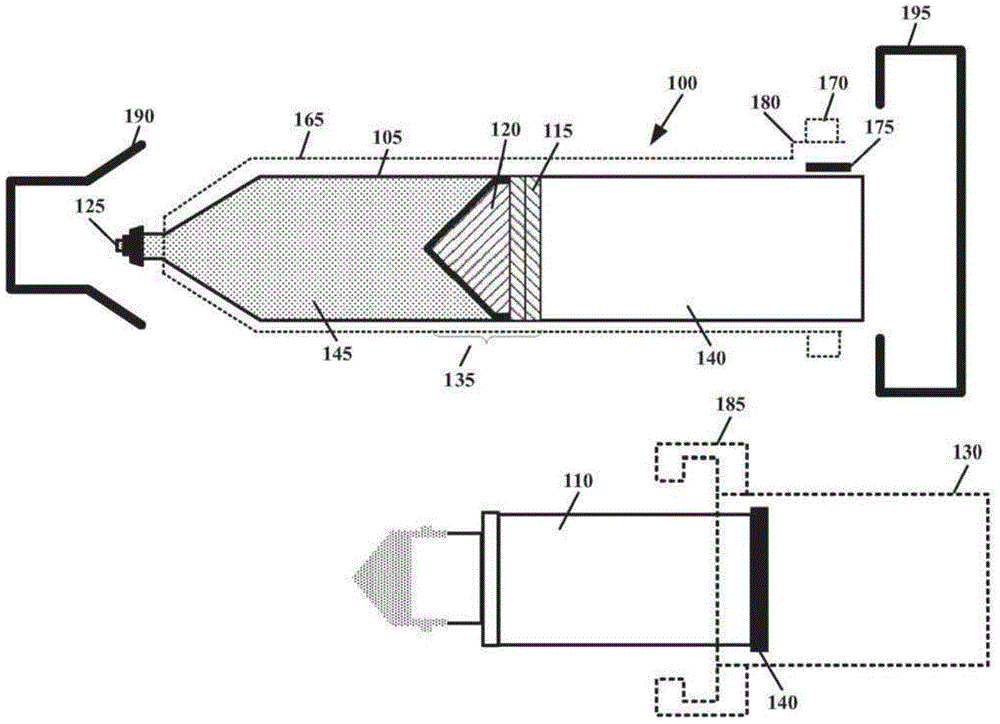

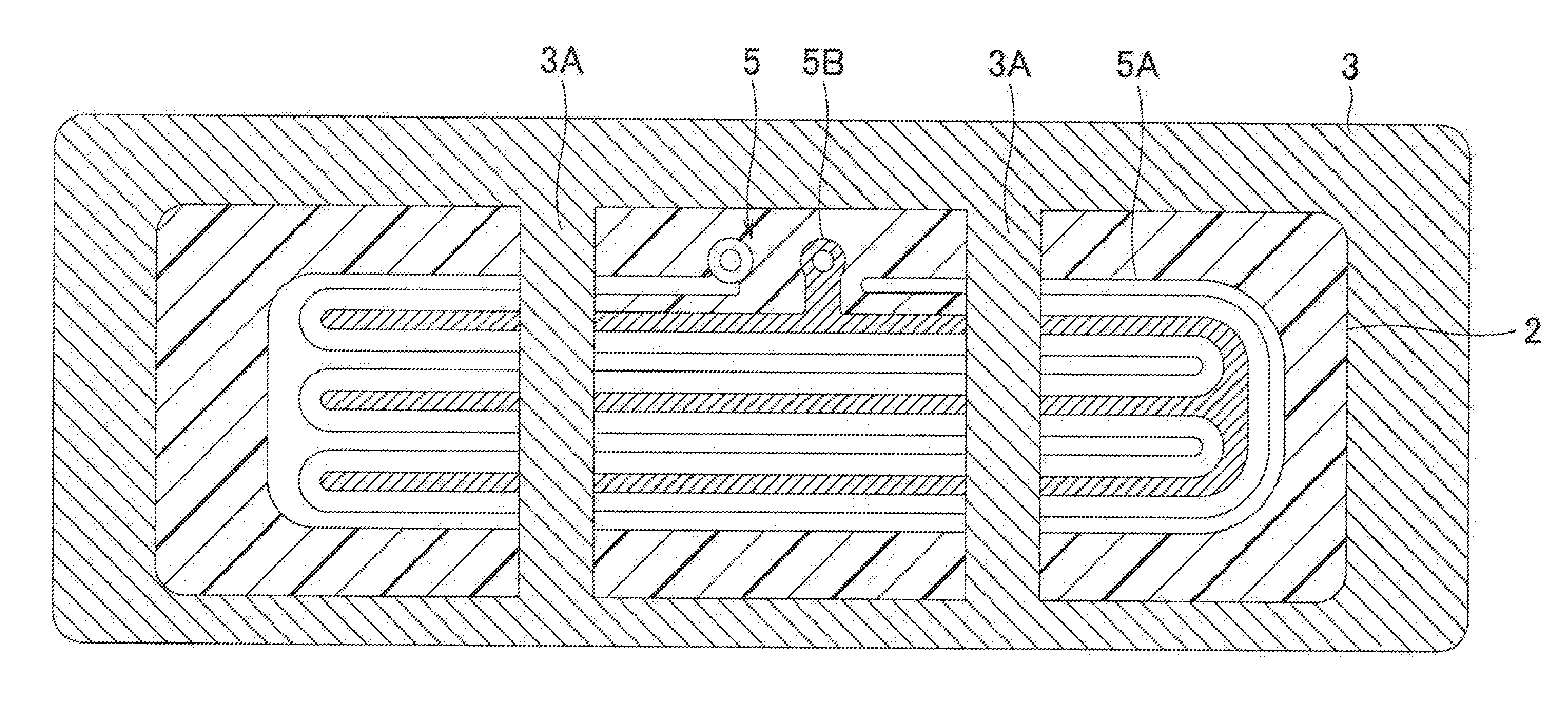

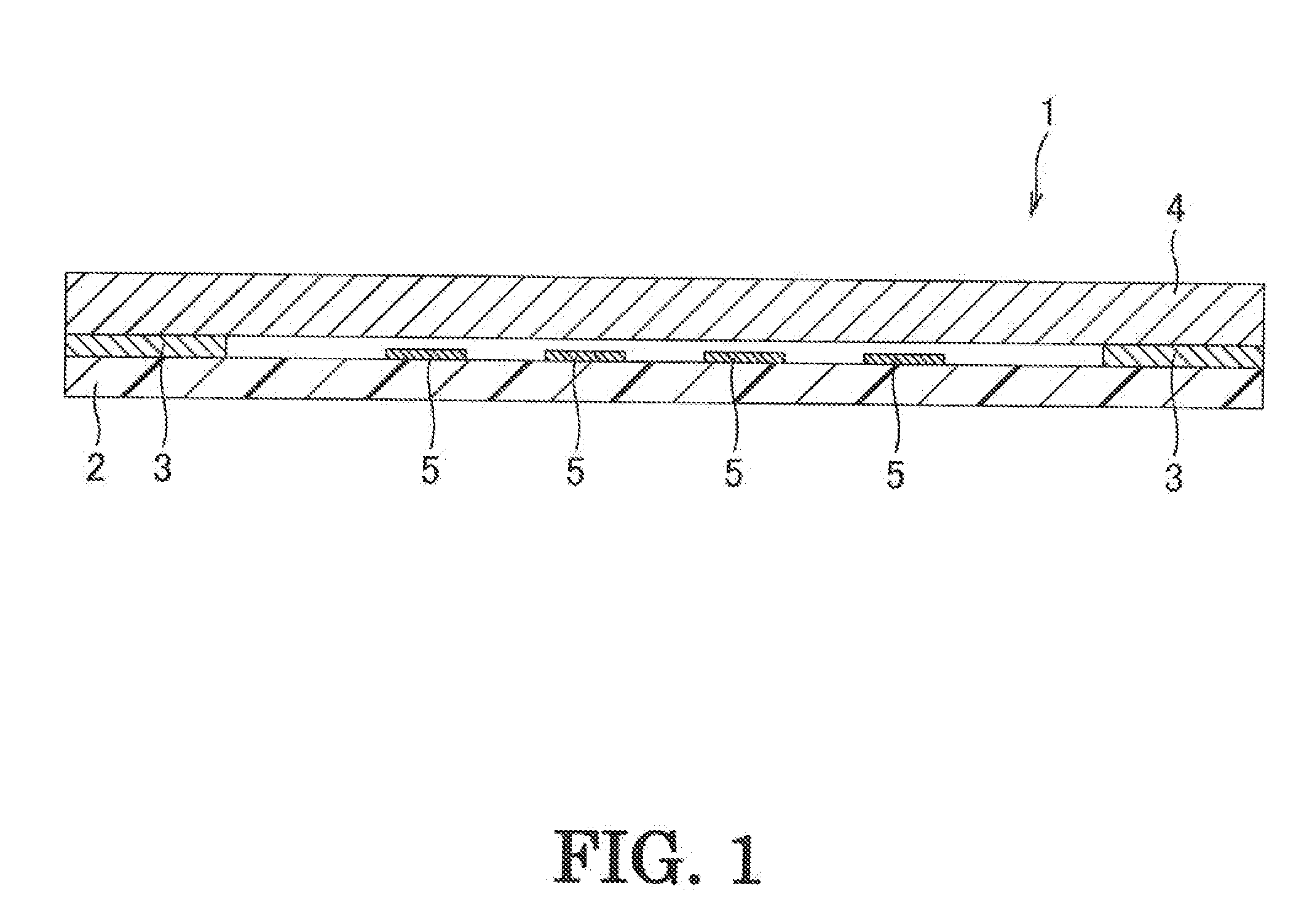

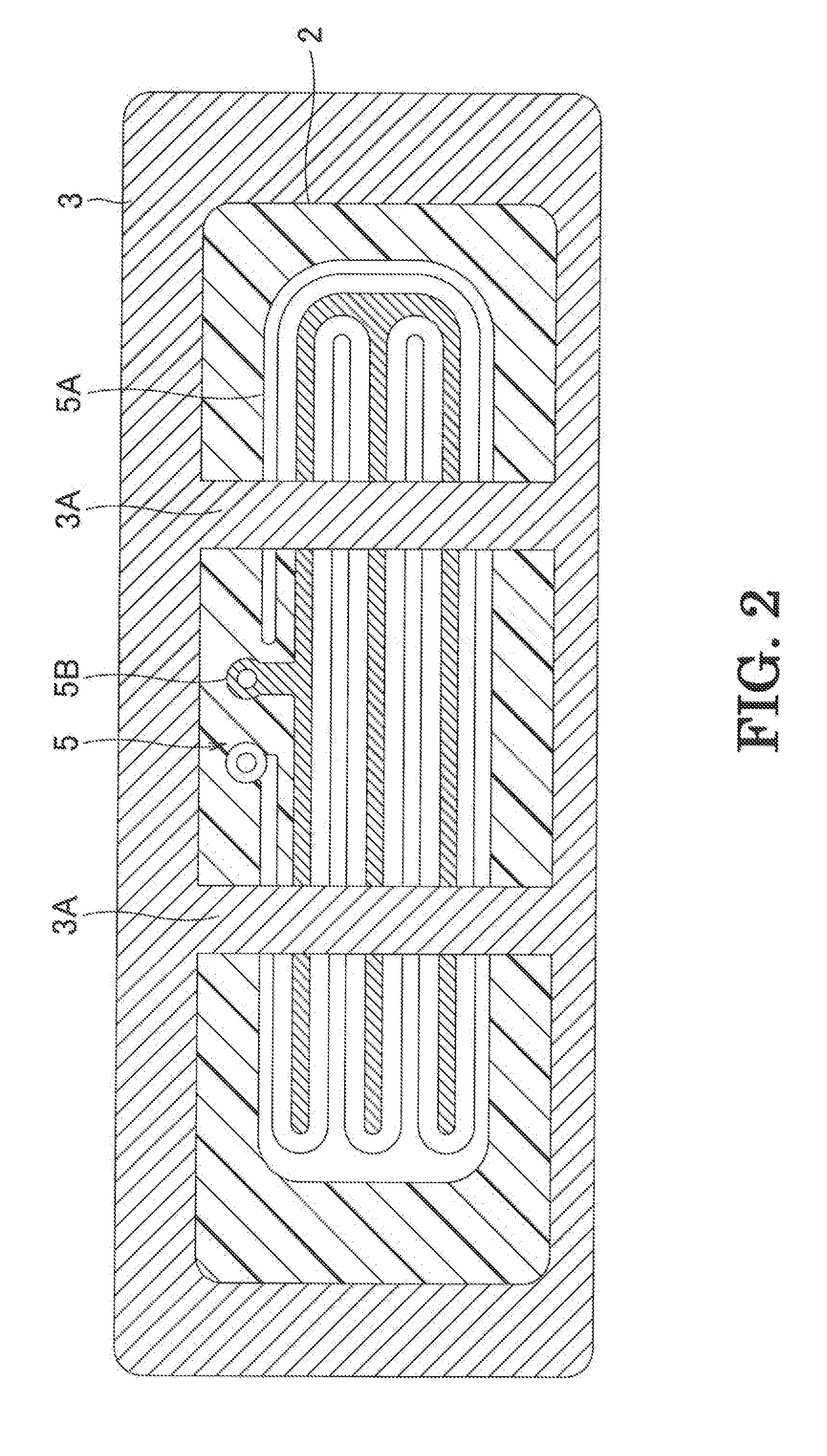

Syringe systems and flow control systems configured to detect information associated with a liquid material are described. The syringe systems may include a syringe body for housing the liquid material and an injector piston for expelling the liquid material out of the syringe through a discharge outlet at a distal end of the syringe body. Components of the syringe, such as an injector piston, may include sensors configured to measure and / or detect a property of the liquid material, such as concentration, pH, or radioactivity. The flow control system may include a pinch valve and a platen arranged about a fluid delivery channel. Flow within the fluid delivery channel may be controlled by increasing (squeezing the fluid delivery channel) or decreasing the distance between the pinch valve and the platen. Components of the flow control system may include detectors configured to detect properties of fluid in the fluid control channel.

Owner:BAYER HEALTHCARE LLC

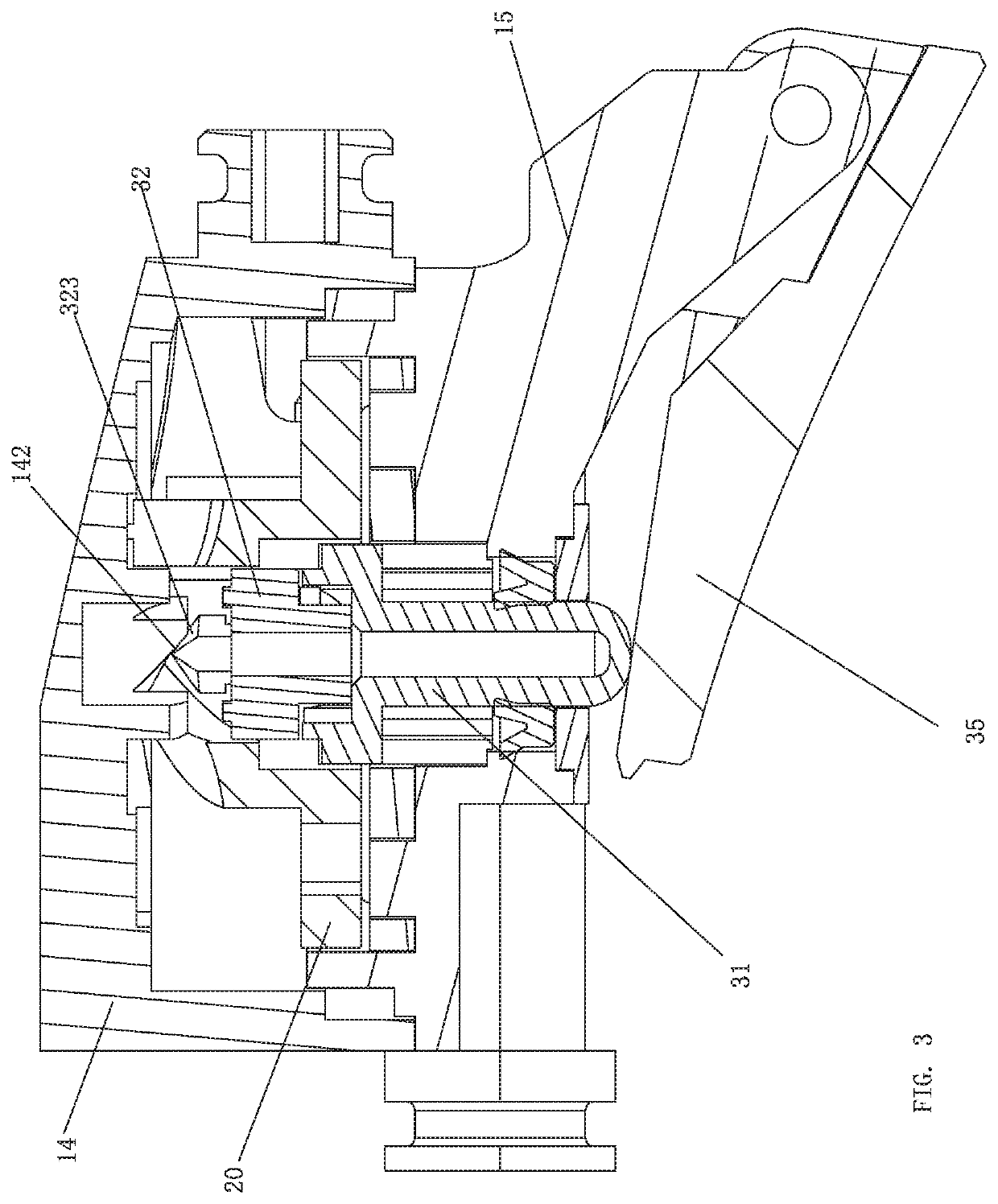

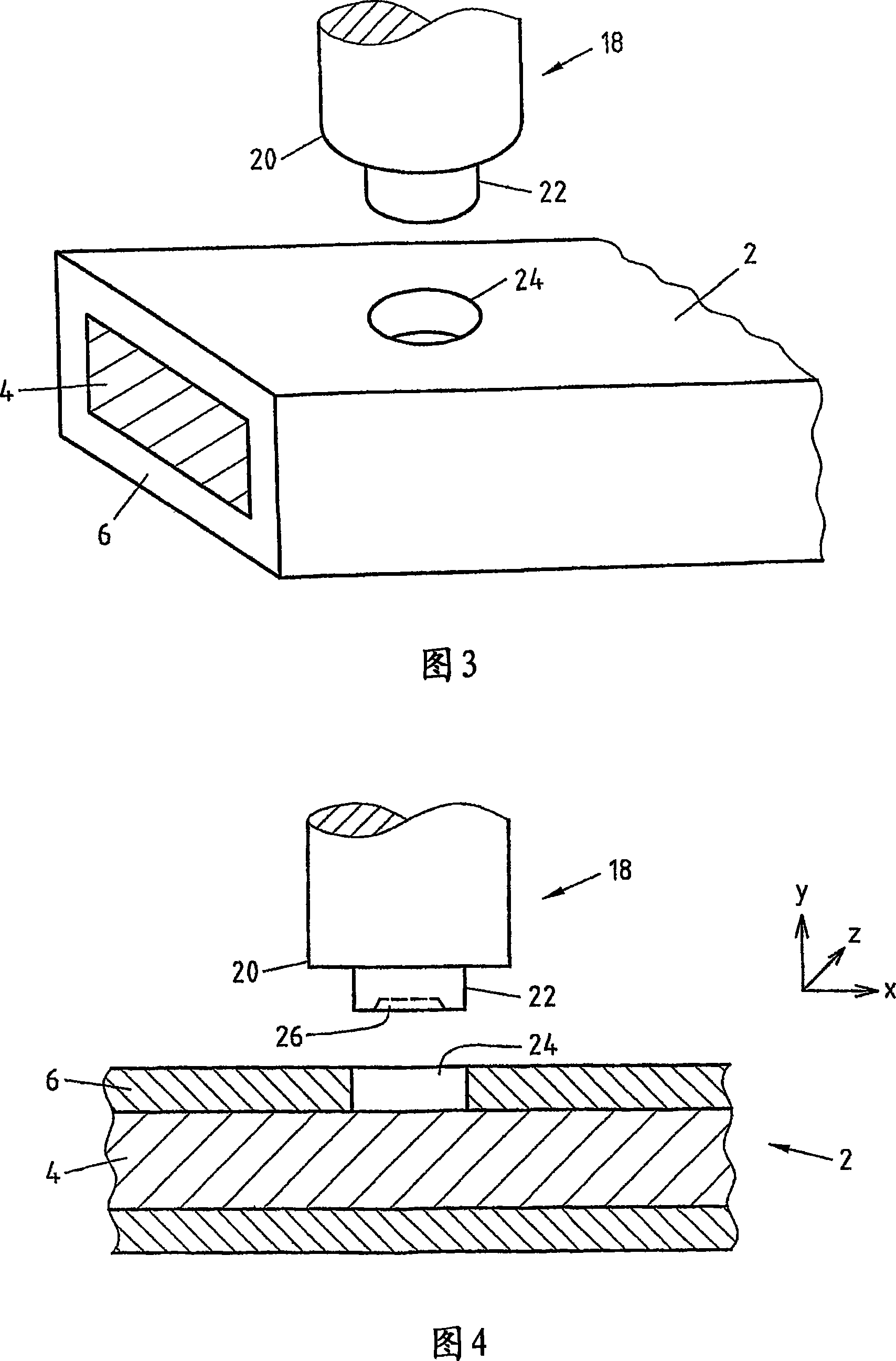

Friction clutch

ActiveCN101952613AIncreased axial heightSmall pressing forceFriction clutchesContact forceEngineering

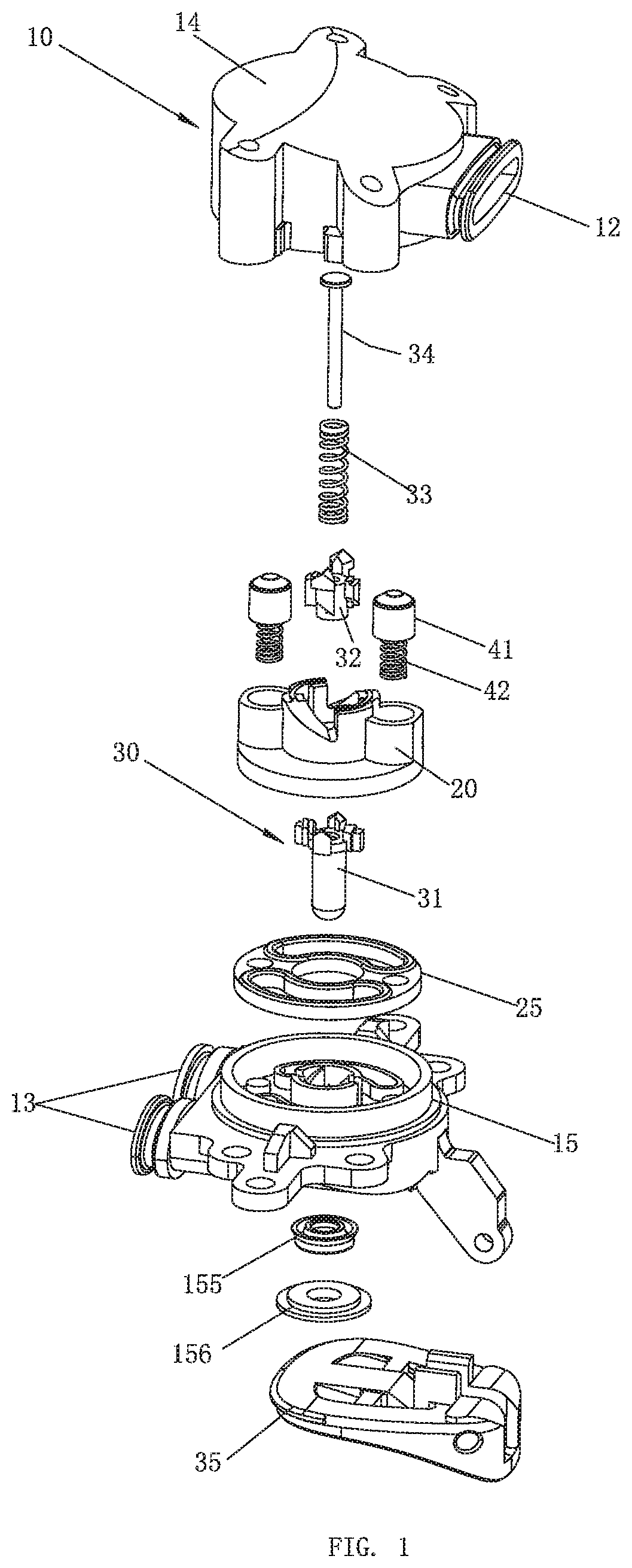

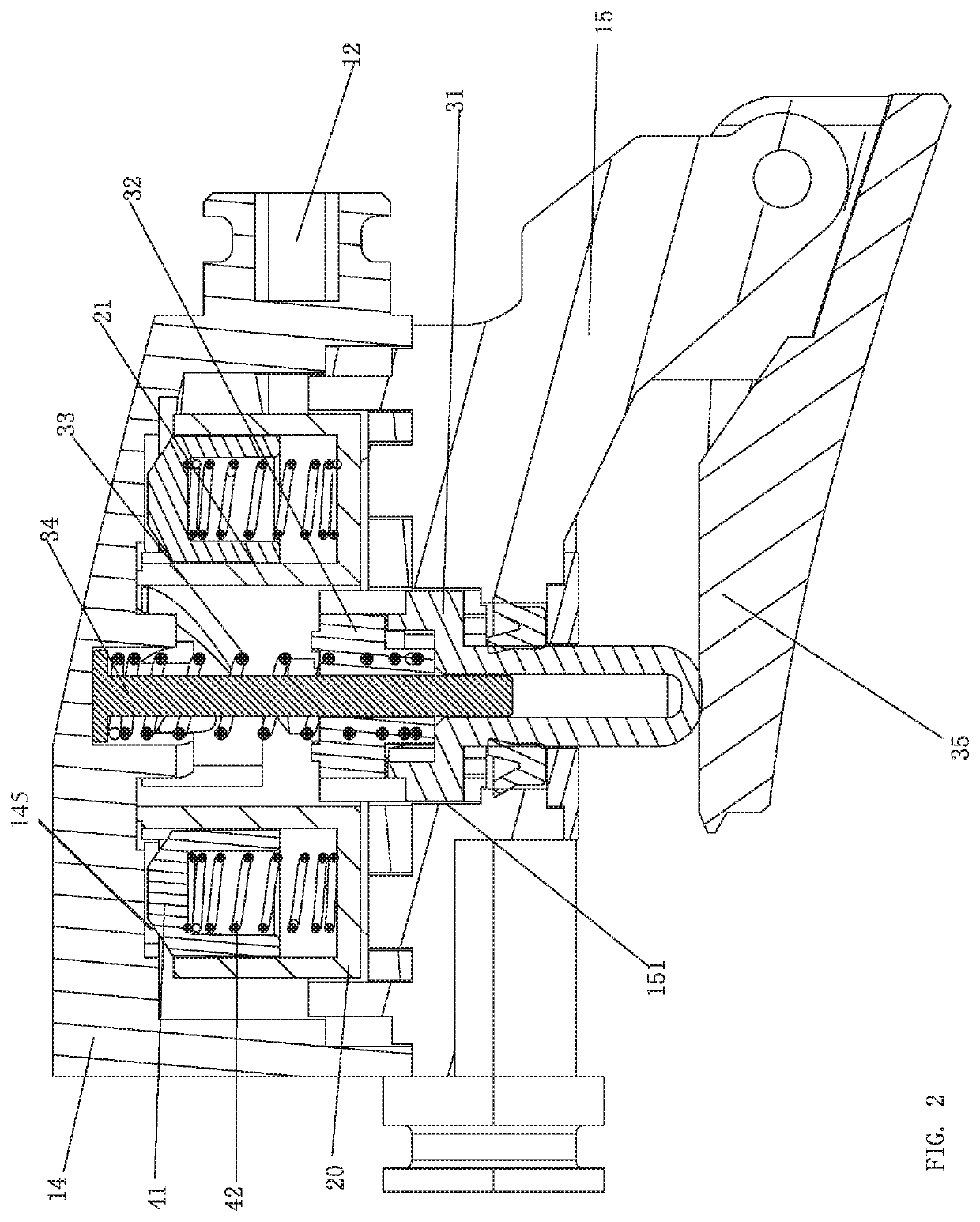

The invention relates to a friction clutch, at least comprising a clutch housing having a pressure plate that can be displaced thereon non-rotatably and axially limited, wherein said pressure plate can be subjected by a lever system supported on the clutch housing to a contact force that is counter to the effect of energy accumulators acting between the clutch housing and the pressure plate with respect to a pressure plate fixed on the cover, while tensioning the friction linings of a clutch plate. To this end, wear of the friction linings is compensated for in that a resulting first distance between the pressure plate and lever system is compensated for by way of a rotation of a ramp system, which is disposed between the pressure plate and lever system, using a rotational device if, while the pressure plate is subjected to a maximum force by the lever system, a second predetermined distance is determined between the pressure plate and clutch housing, said second distance exceeding a predetermined value, and a rotation occurs during an alleviation of the pressure plate by the lever system and a displacement of the pressure plate occurs by means of the energy accumulators active between the pressure plate and the clutch housing.

Owner:SCHAEFFLER TECH AG & CO KG

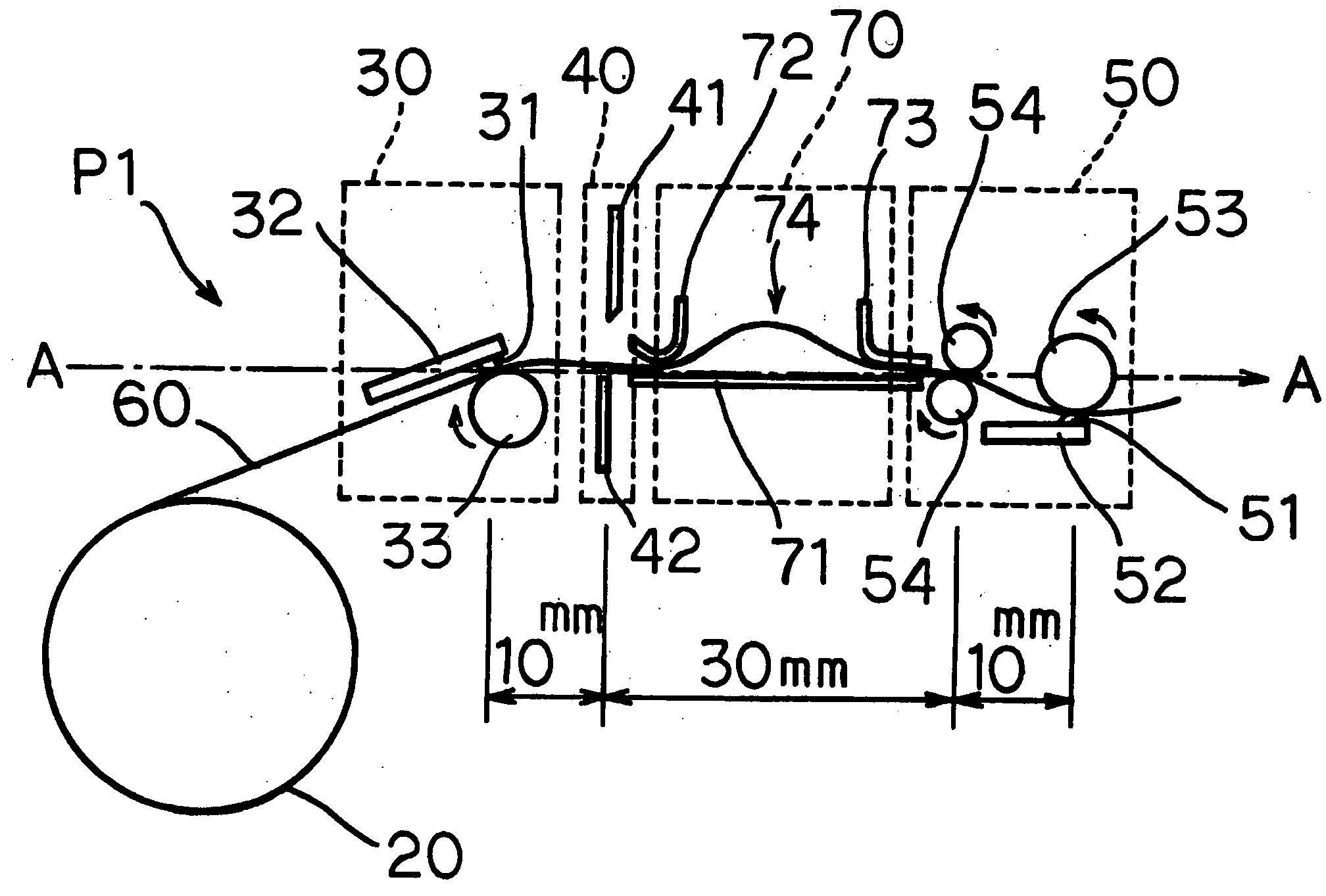

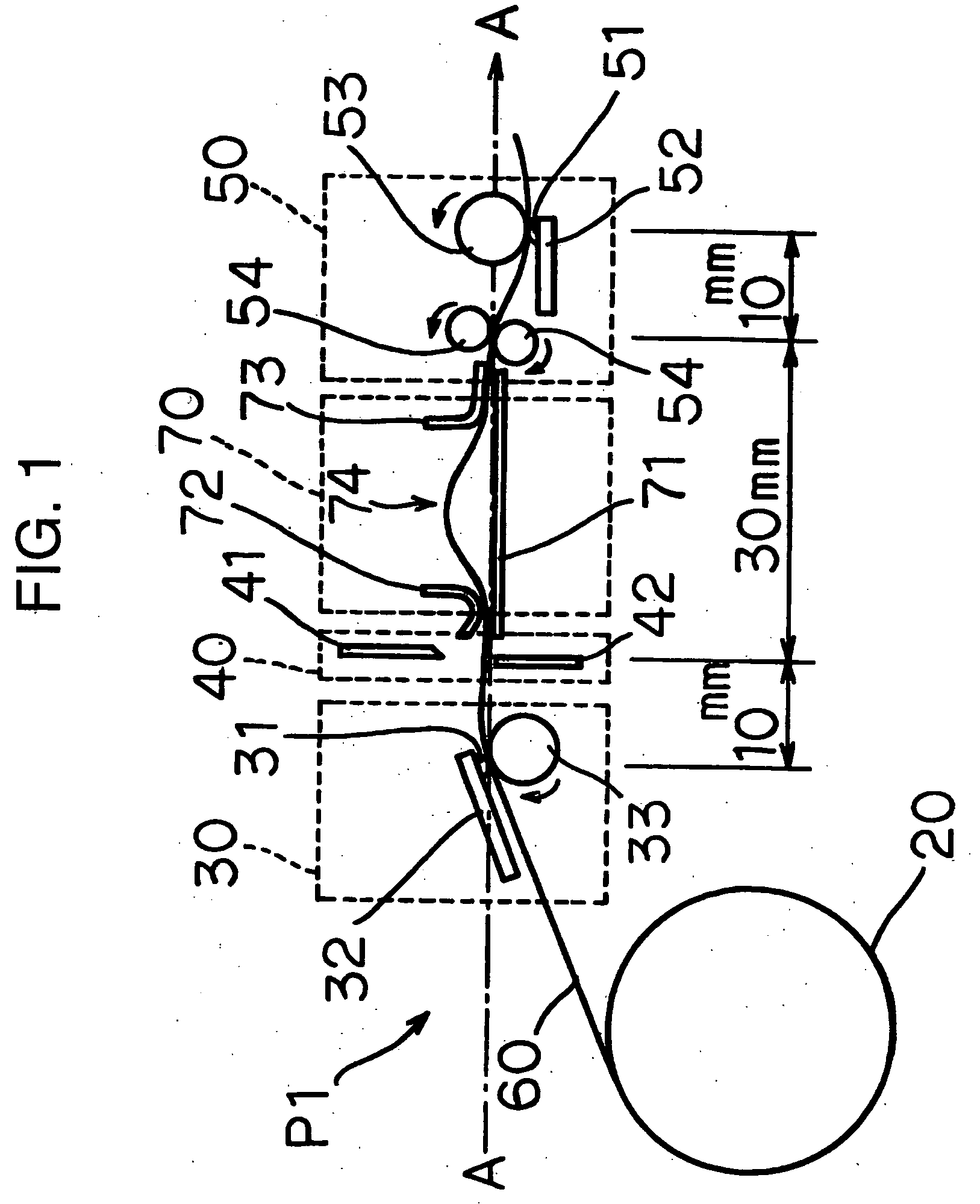

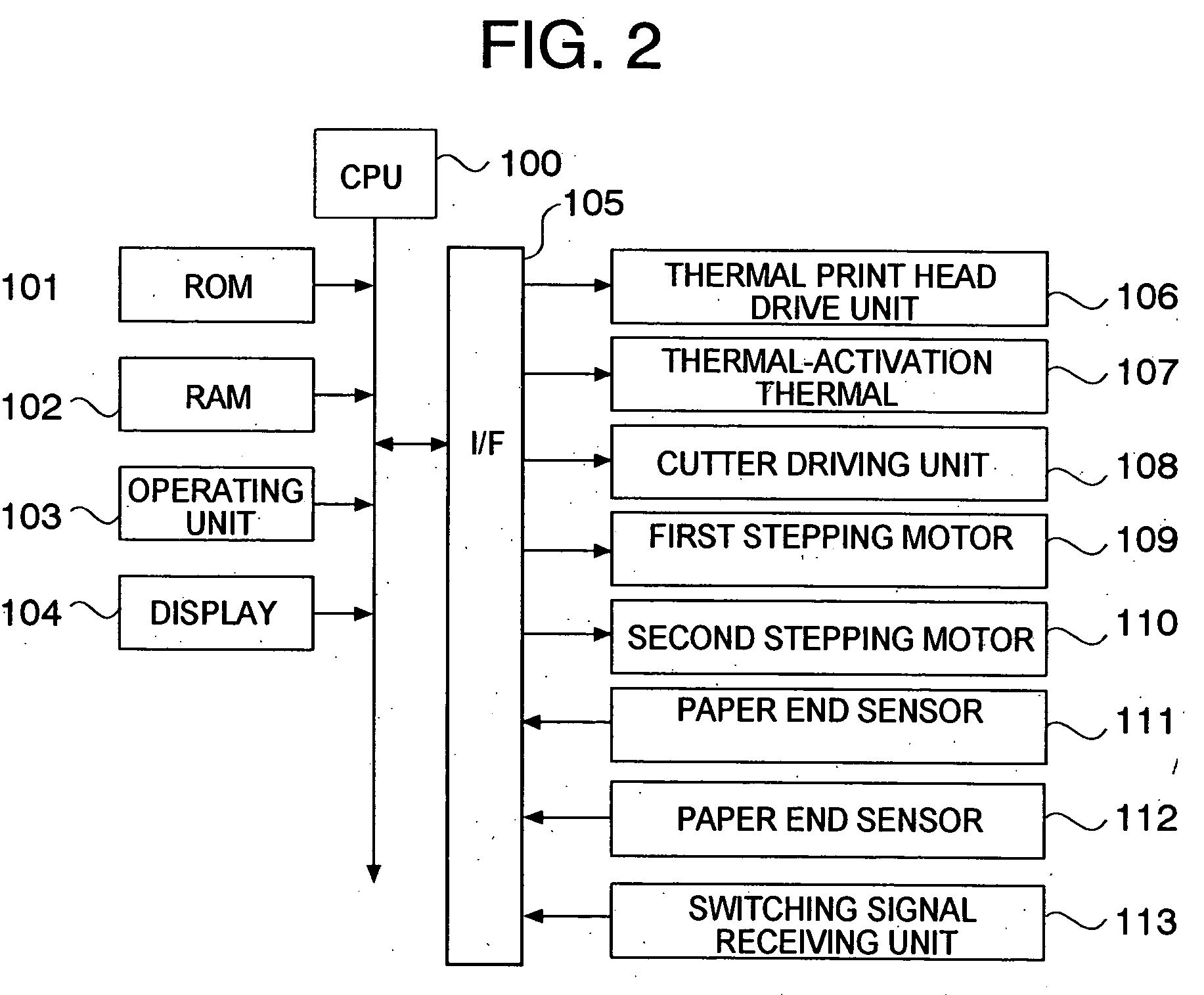

Printer

InactiveUS20060082637A1Small pressing forceImprove sticker efficiencyRecording apparatusInk ribbonsEngineeringAdhesive

Provided is a printer capable of performing printing on both of a heat-sensitive adhesive label and an ordinary label in which release paper is stuck onto an adhesive surface. A thermal printer is composed of a roll housing unit which holds a tape-like heat-sensitive adhesive label and a tape-like ordinary label, each of which is wound in a roll shape, such that those labels are exchangeable, a printing unit which prints on the heat-sensitive adhesive label or the ordinary label which is held in the roll housing unit, a cutter unit which cuts the heat-sensitive adhesive label or the ordinary label into pieces with a predetermined length, a thermal activation unit which functions only in a case where the heat-sensitive adhesive label is held in the roll housing unit and thermally activates a heat-sensitive adhesive layer of the heat-sensitive adhesive label, a guide unit which guides the heat-sensitive adhesive label from the cutter unit to the thermal activation unit, a control unit which controls the above-described respective units to operate differently between a case of using the ordinary label and a case of using the heat-sensitive adhesive label, and the like.

Owner:SEIKO INSTR INC

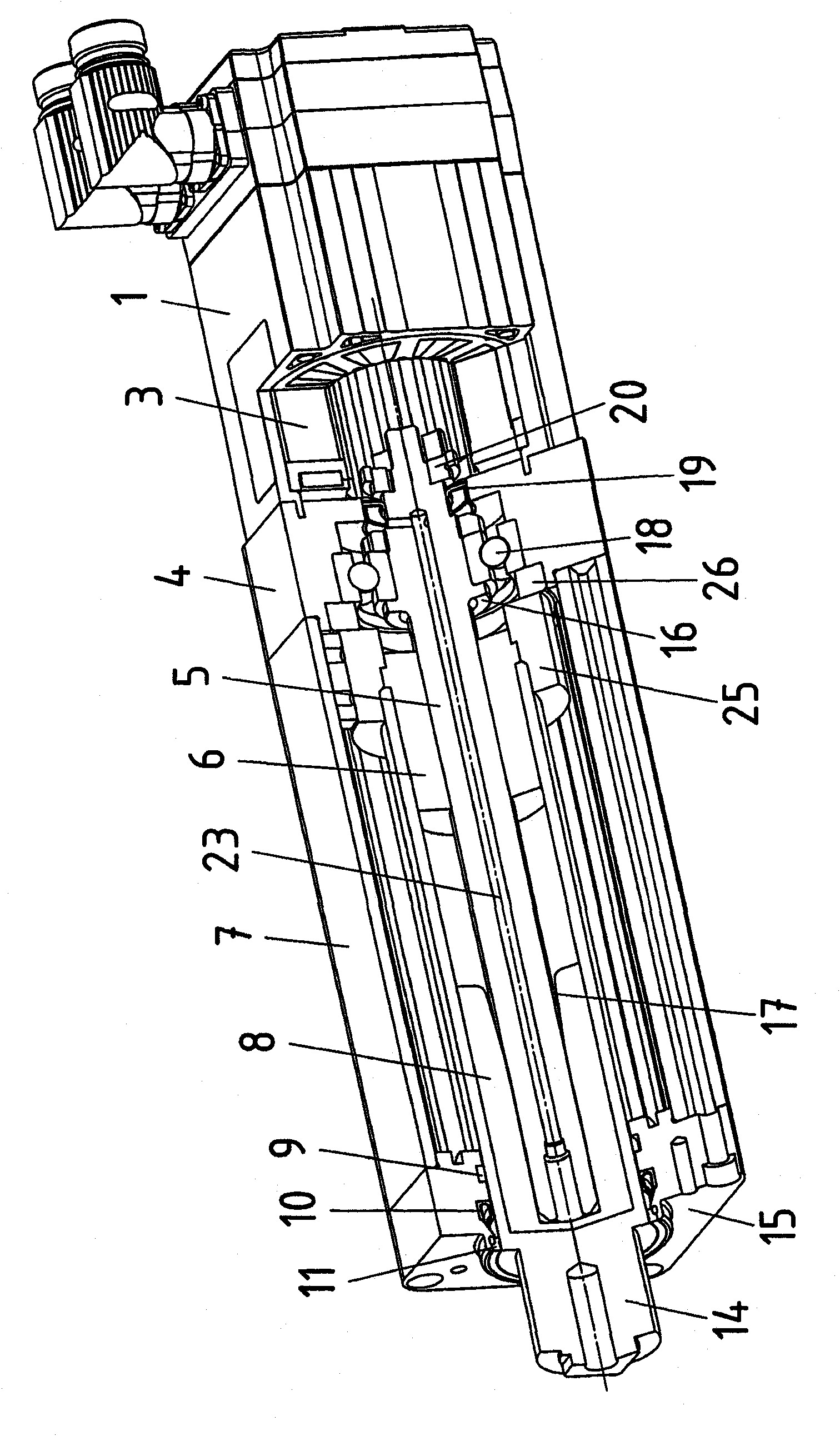

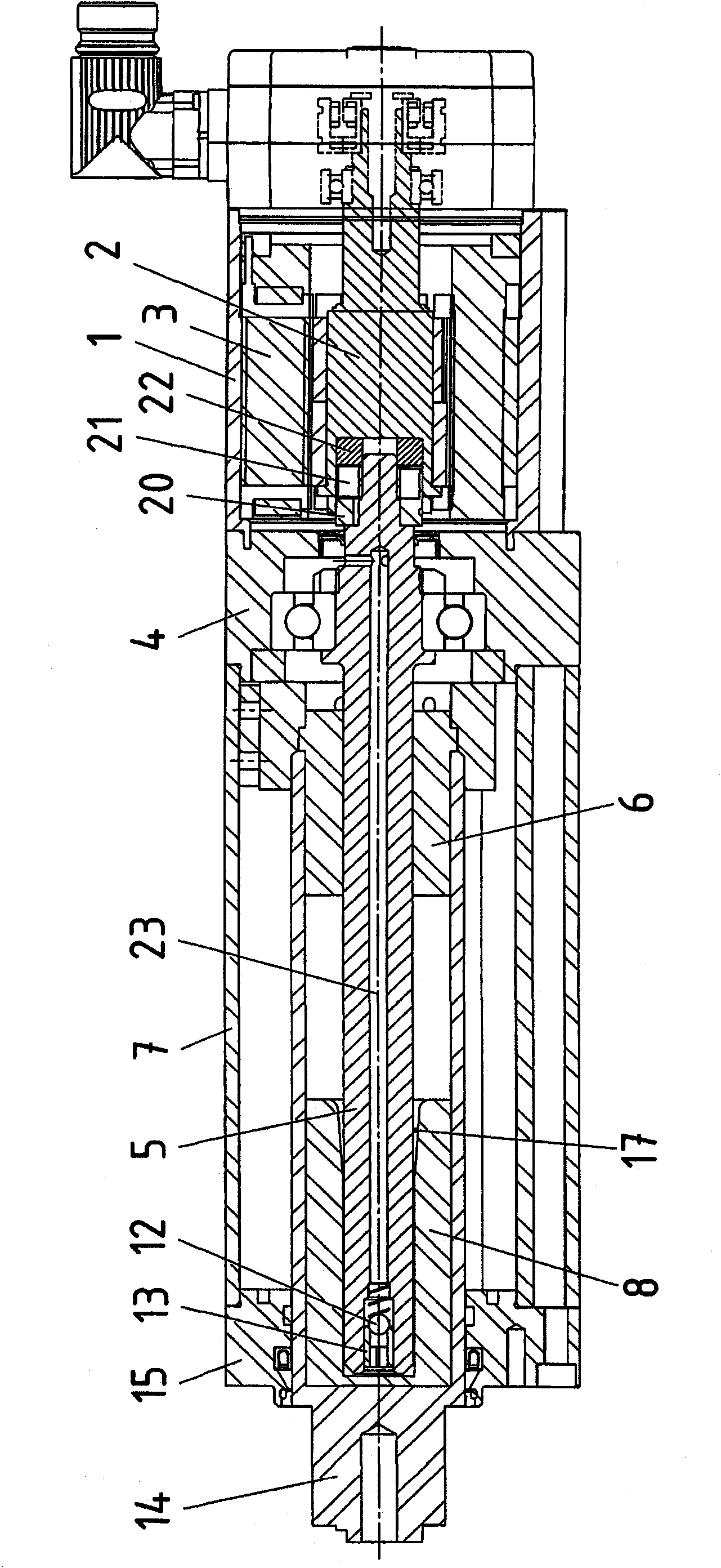

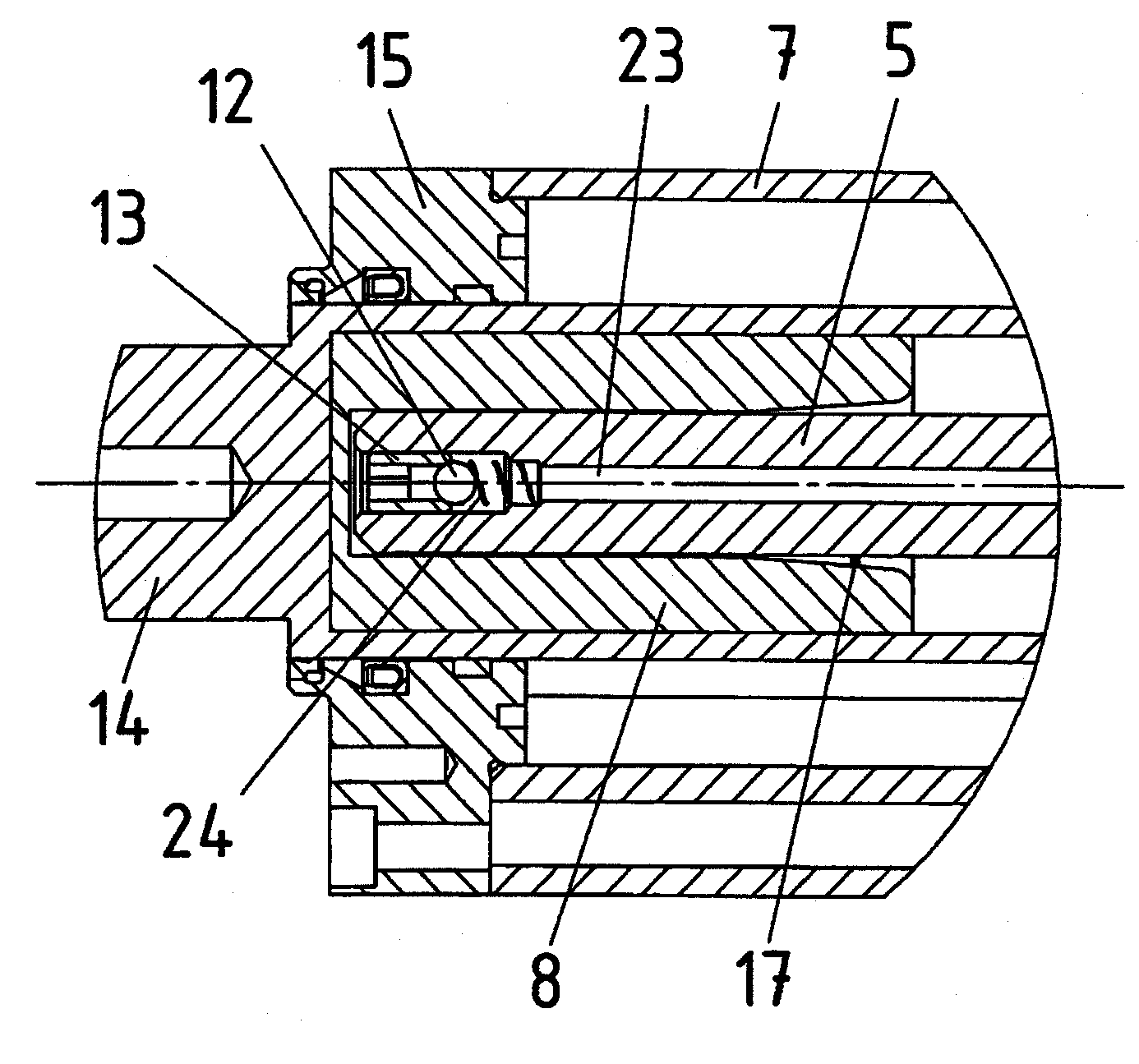

Spindle motor

The invention relates to a spindle motor, comprising an electric motor having a rotor connected to a threaded spindle, the thread of which is engaged with a thread of a spindle nut connected to a piston rod, wherein the spindle nut, along with the piston rod, is axially guided in a housing part, a guide part is connected to the spindle nut and piston rod for axially guiding the same, and wherein the threaded spindle is mounted by means of a bearing in the housing part or in a second housing part connected to the first housing part, a cooling channel being configured in the housing part, in particular a cooling channel which extends in the circumferential direction.

Owner:SEW-EURODRIVE GMBH & CO KG

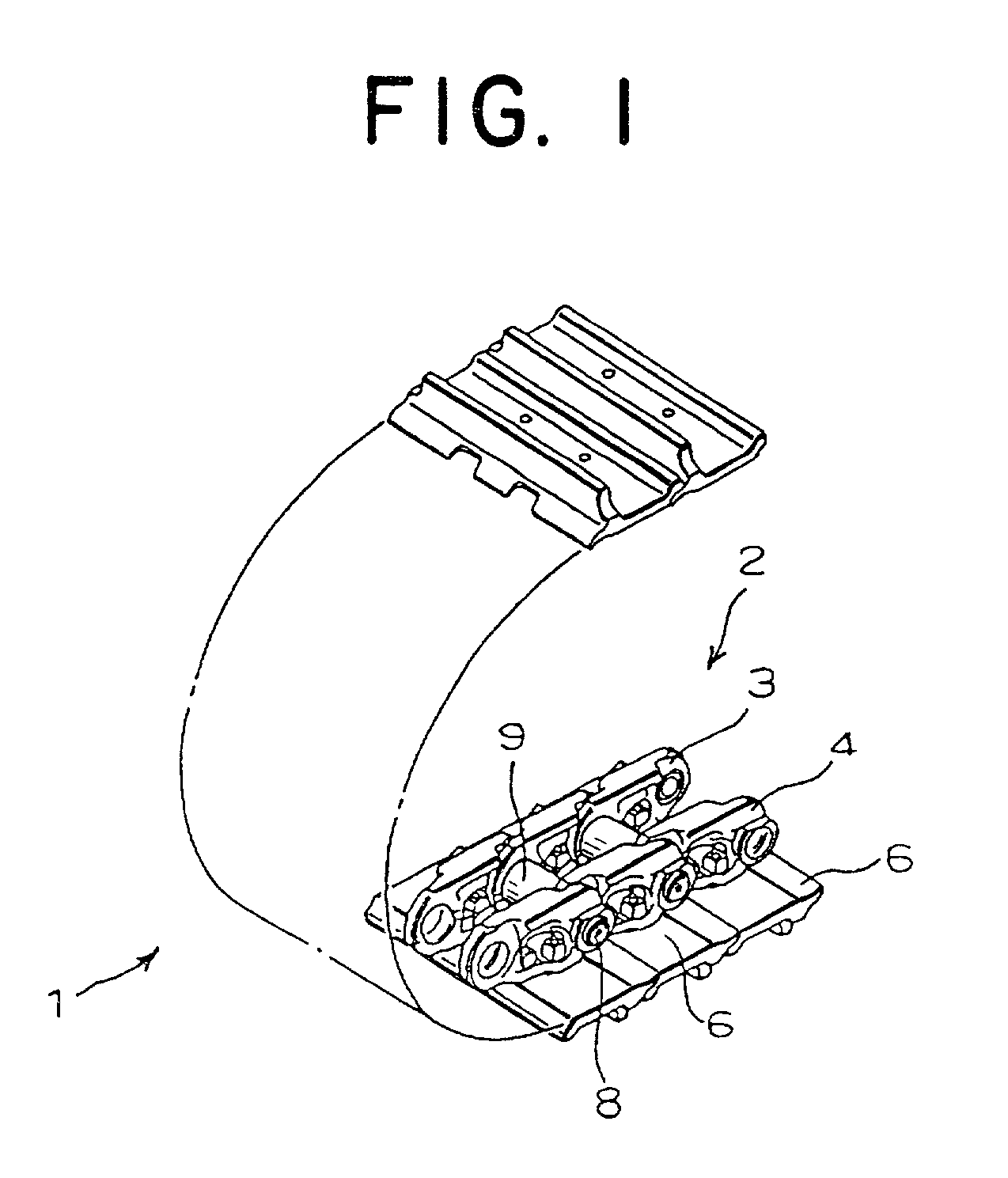

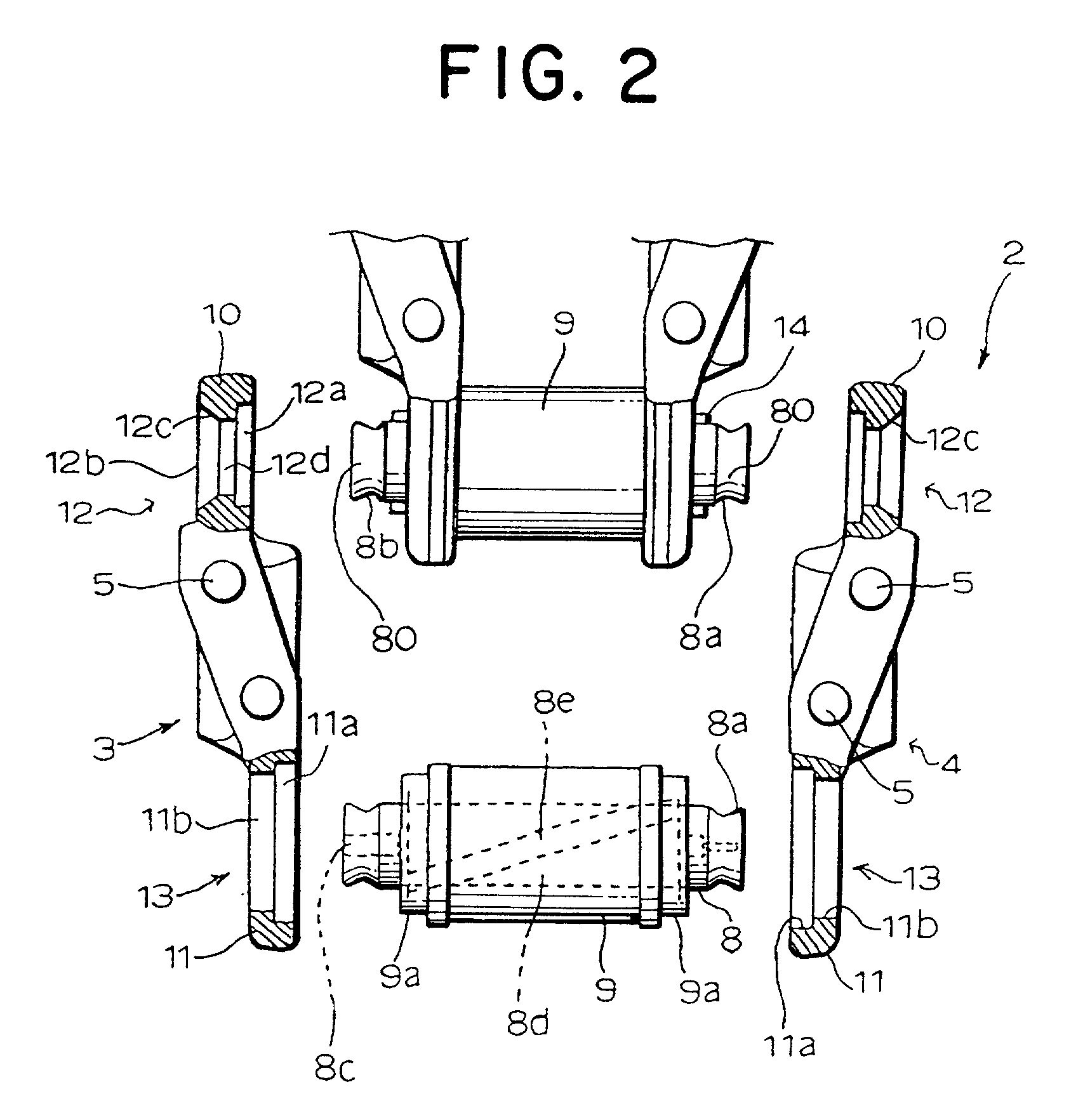

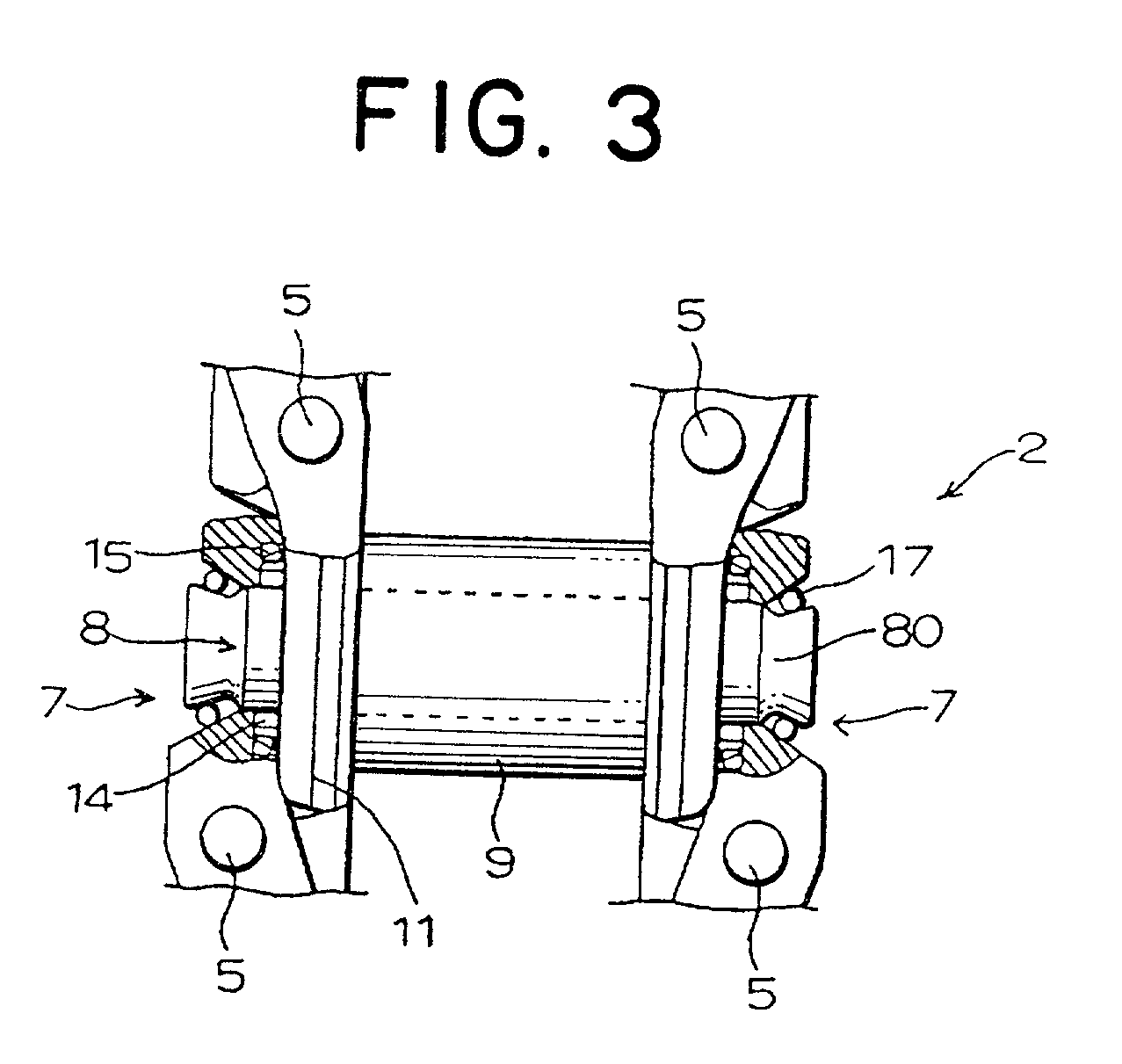

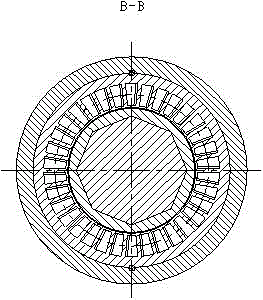

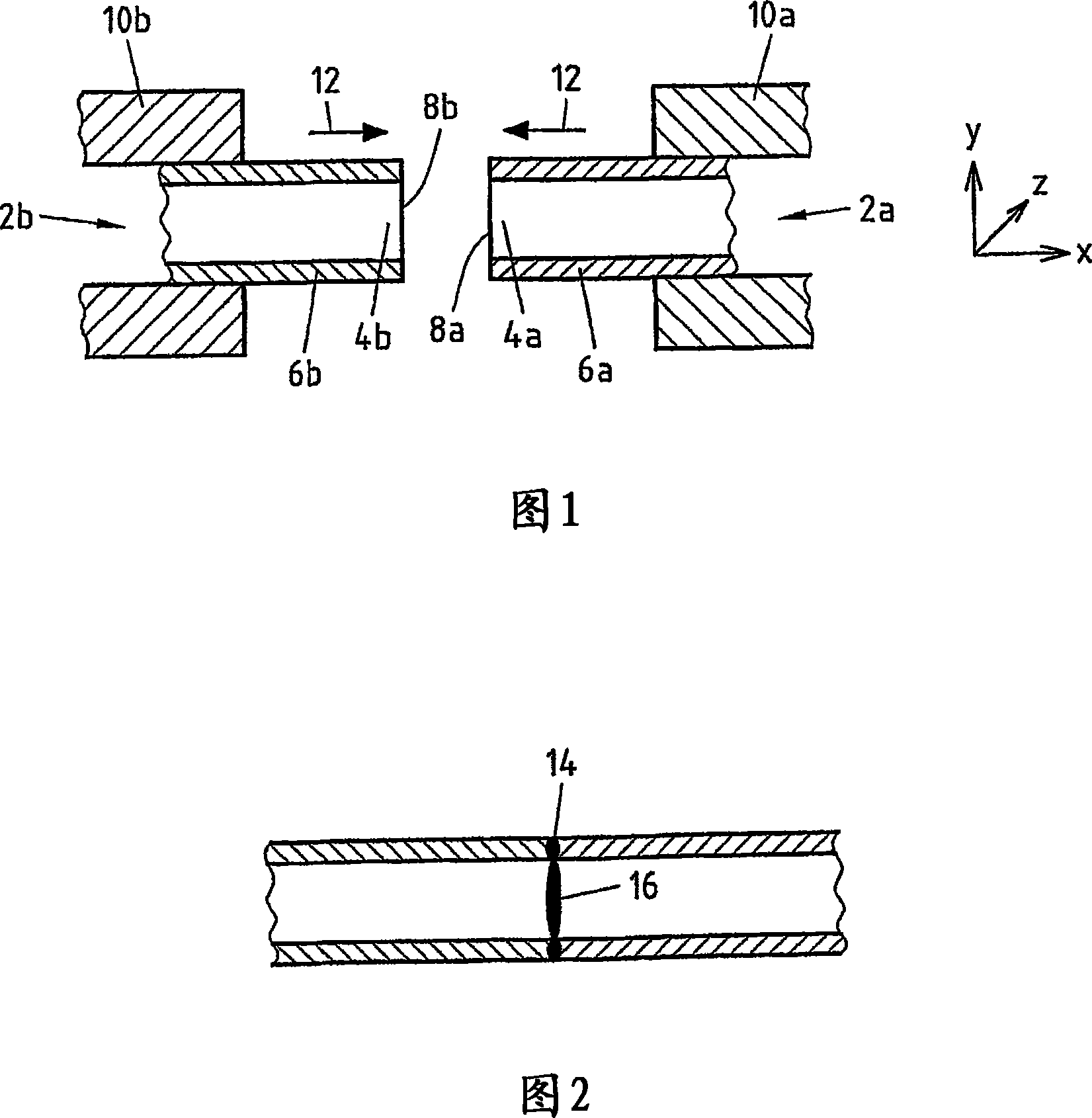

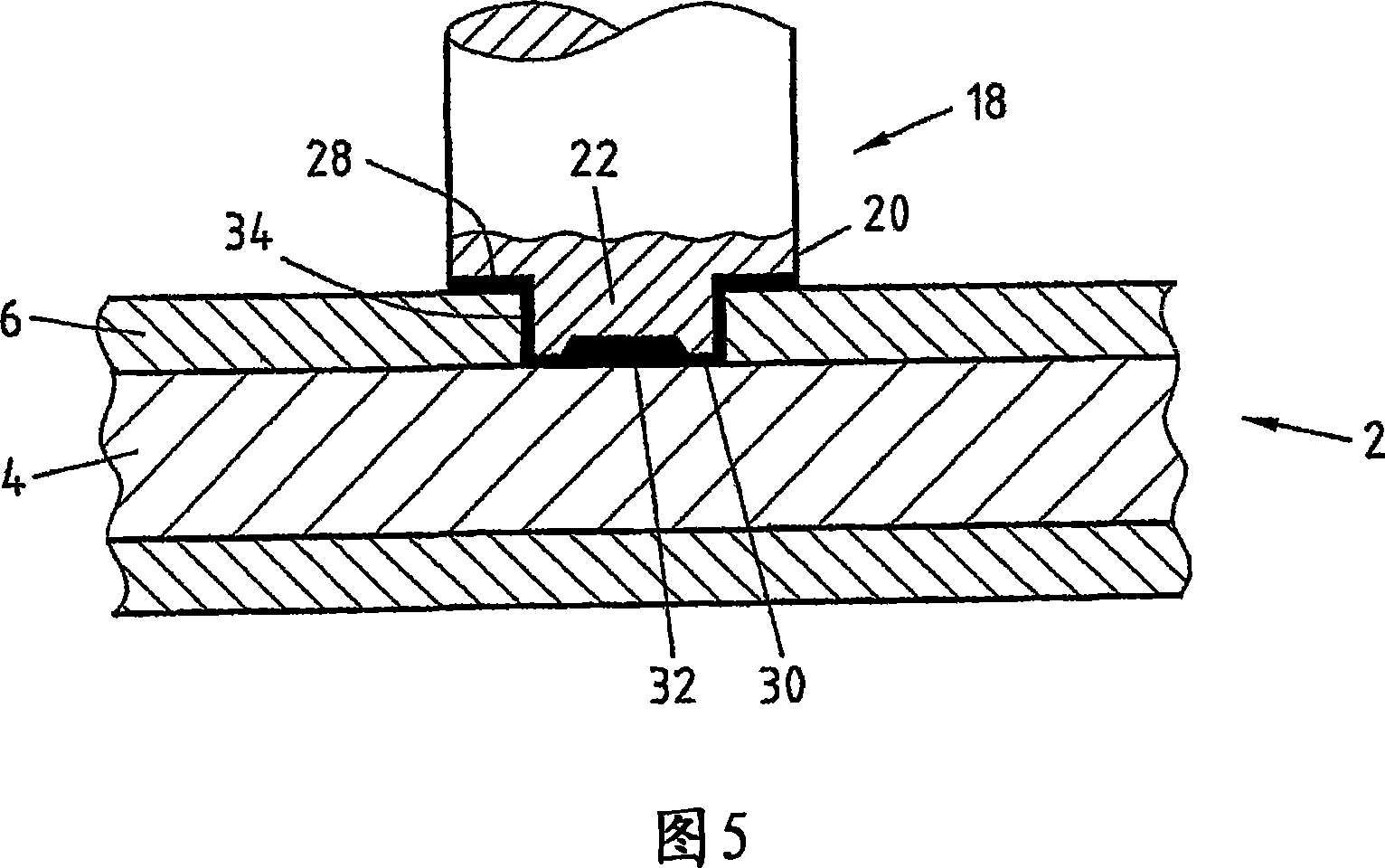

Link-and-pin fixing structure for a crawler chain

InactiveUS6422667B2Reduce tightening forceSmall pressing forceRopes and cables for vehicles/pulleyCouplings for rigid shaftsEngineeringMechanical engineering

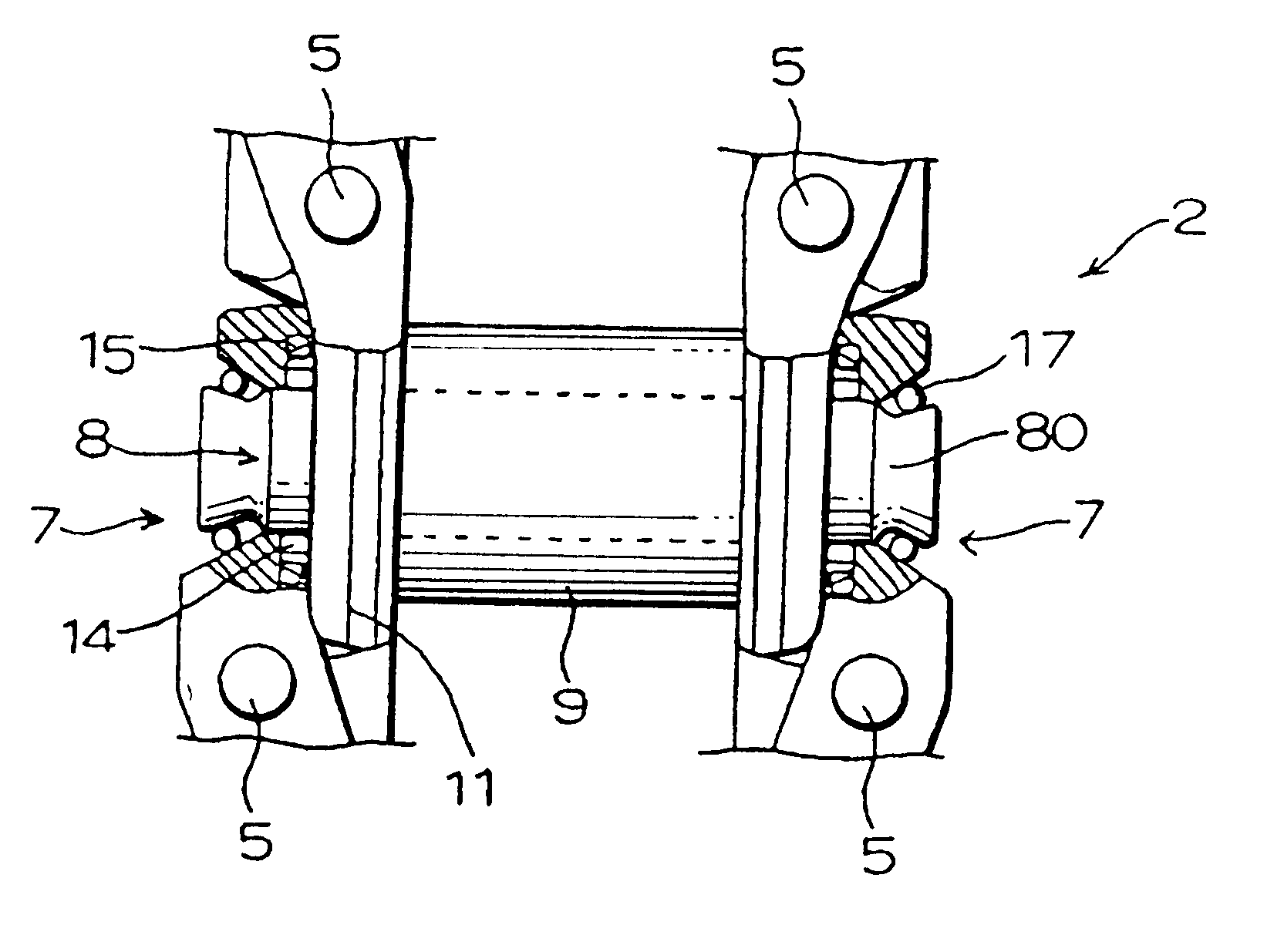

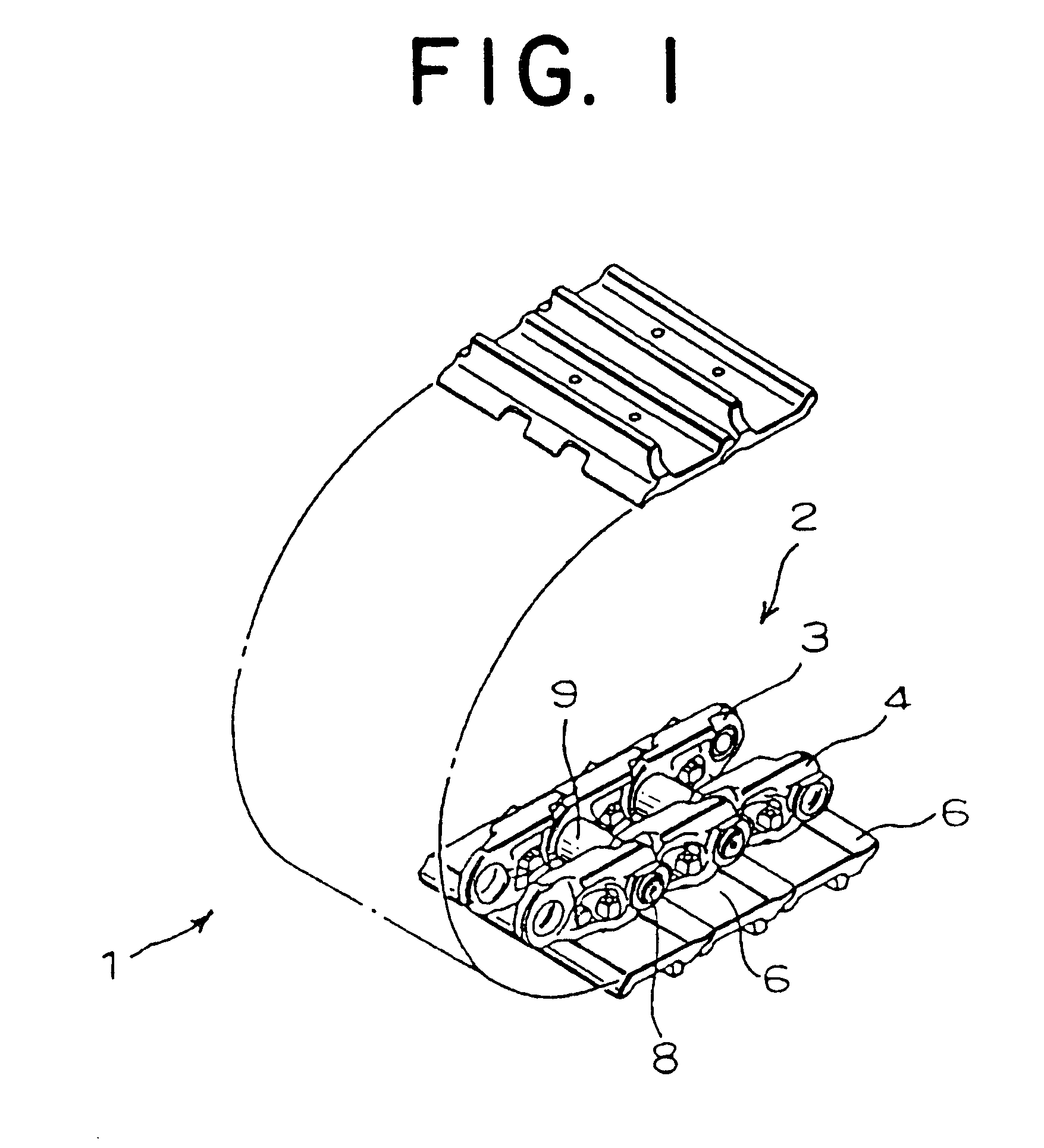

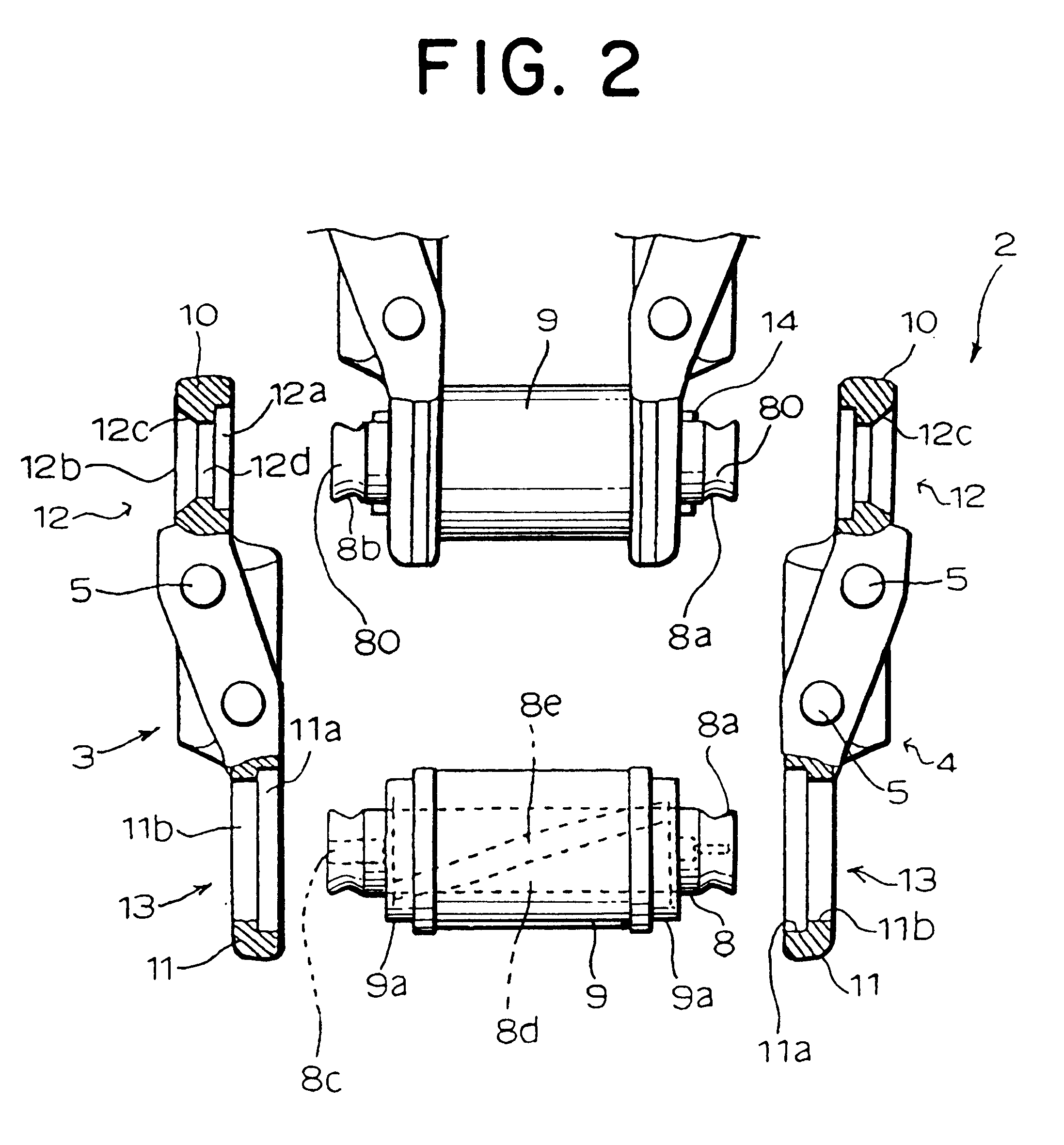

A fitting space having an annular opening, in which an elastic ring whose diameter of a section is D is to be fitted, is formed between a pin-press-fit hole of a link and an exposed end portion of a pin. A link inner wall face and a pin outer peripheral face in the fitting space are formed with tapered faces whose diameters decrease as they go toward an inmost of the fitting space at angles alpha and beta (alpha>beta) with respect to the axial line of the pin, respectively. The elastic ring contacts with the respective tapered faces in the fitting space at the angles alpha and beta with respect to a perpendicular passing a center of its section. Dimensions d1 and d2 between contact points at the respective tapered faces and a horizontal line passing the center of the section of the elastic ring, the diameter D of the section of the elastic ring, and the angles alpha and beta have a relation of alpha>beta, D>d1+d2 (where d1=D / 2.cos alpha, d2=D / 2.cos beta). Therefore, the links and the pin can be connected to each other securely and firmly with a sufficient holding force to the pin in the axial direction. Thus, assembly of the links and the pin can be carried out easily at a low cost.

Owner:KOMATSU LTD

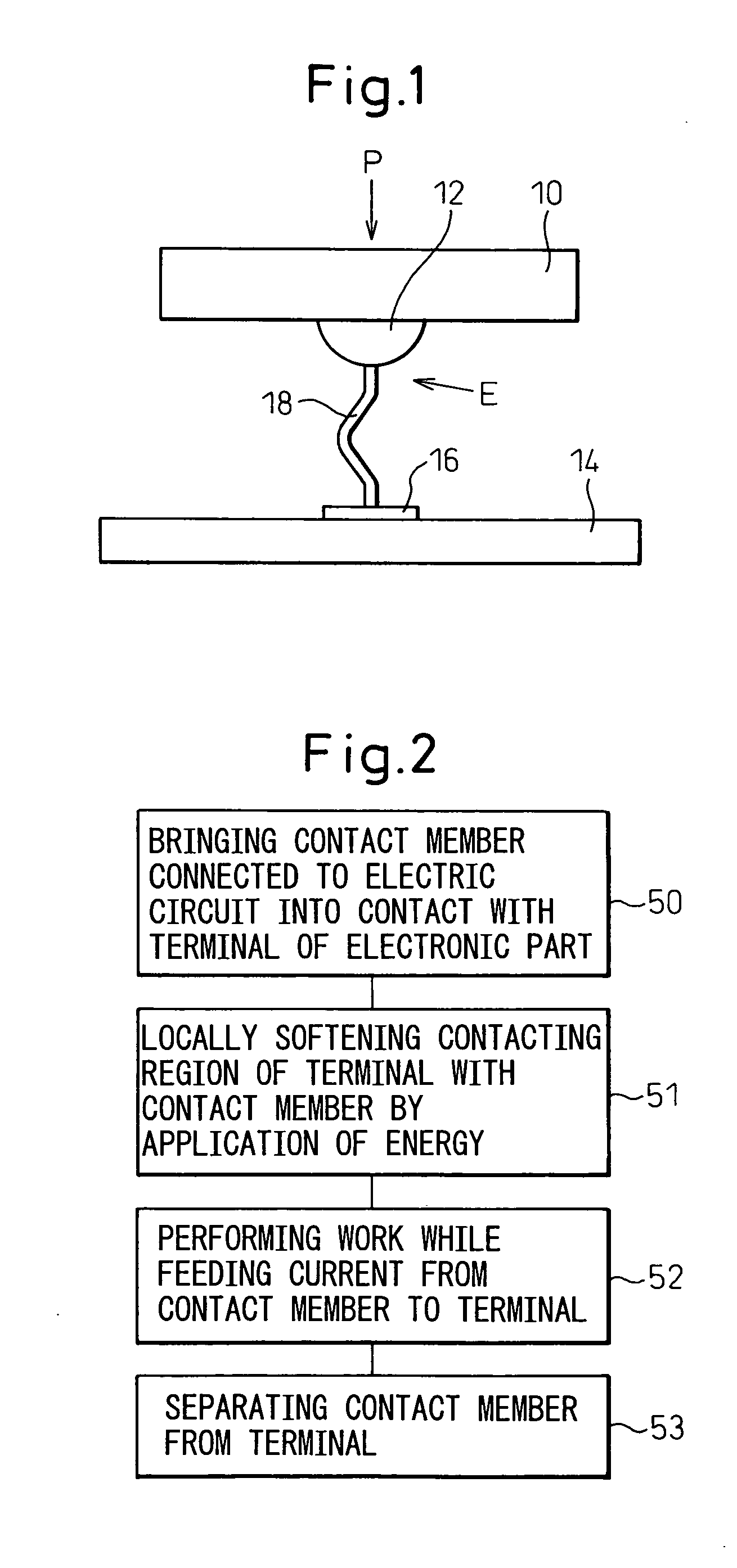

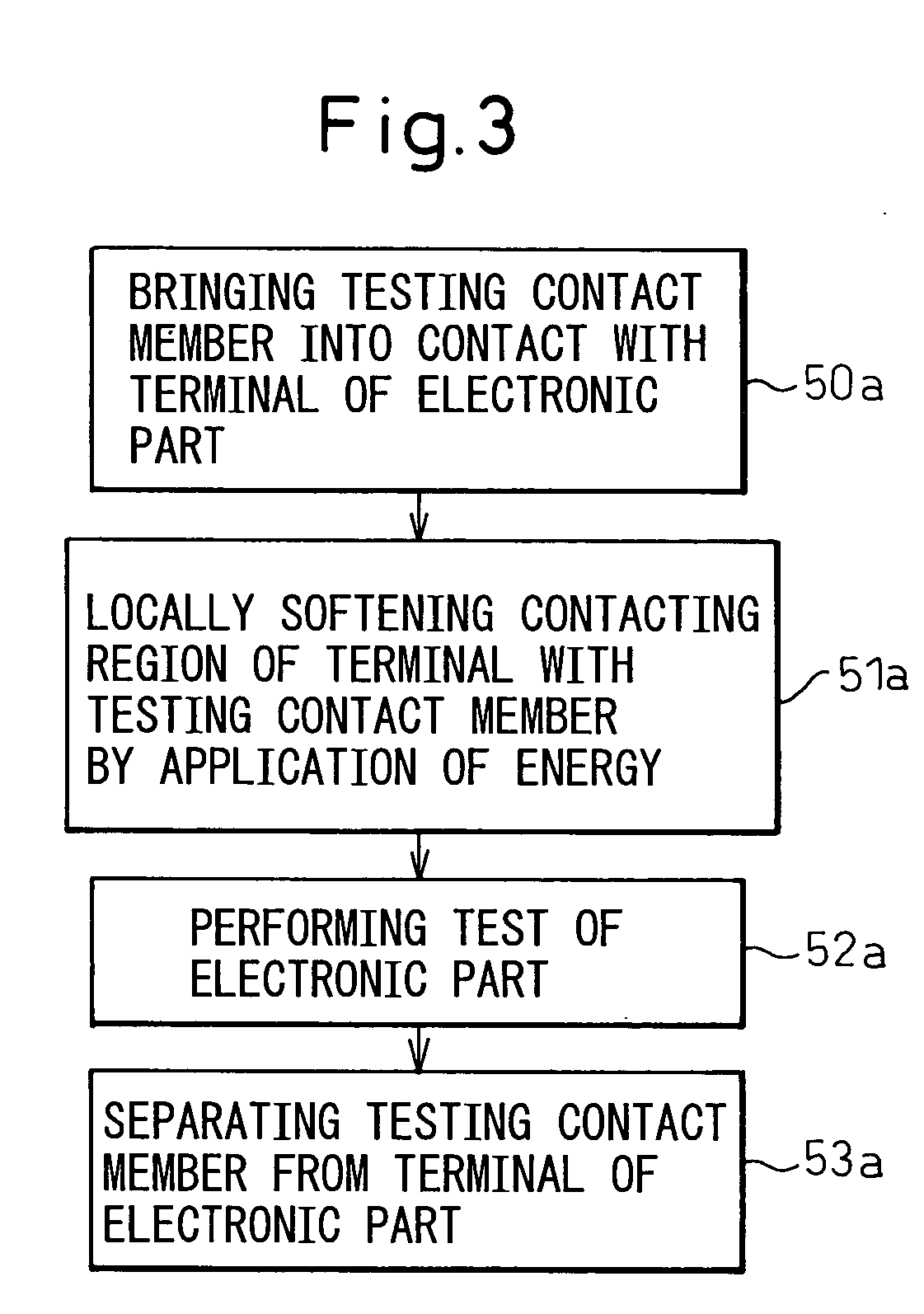

Electrical connecting method

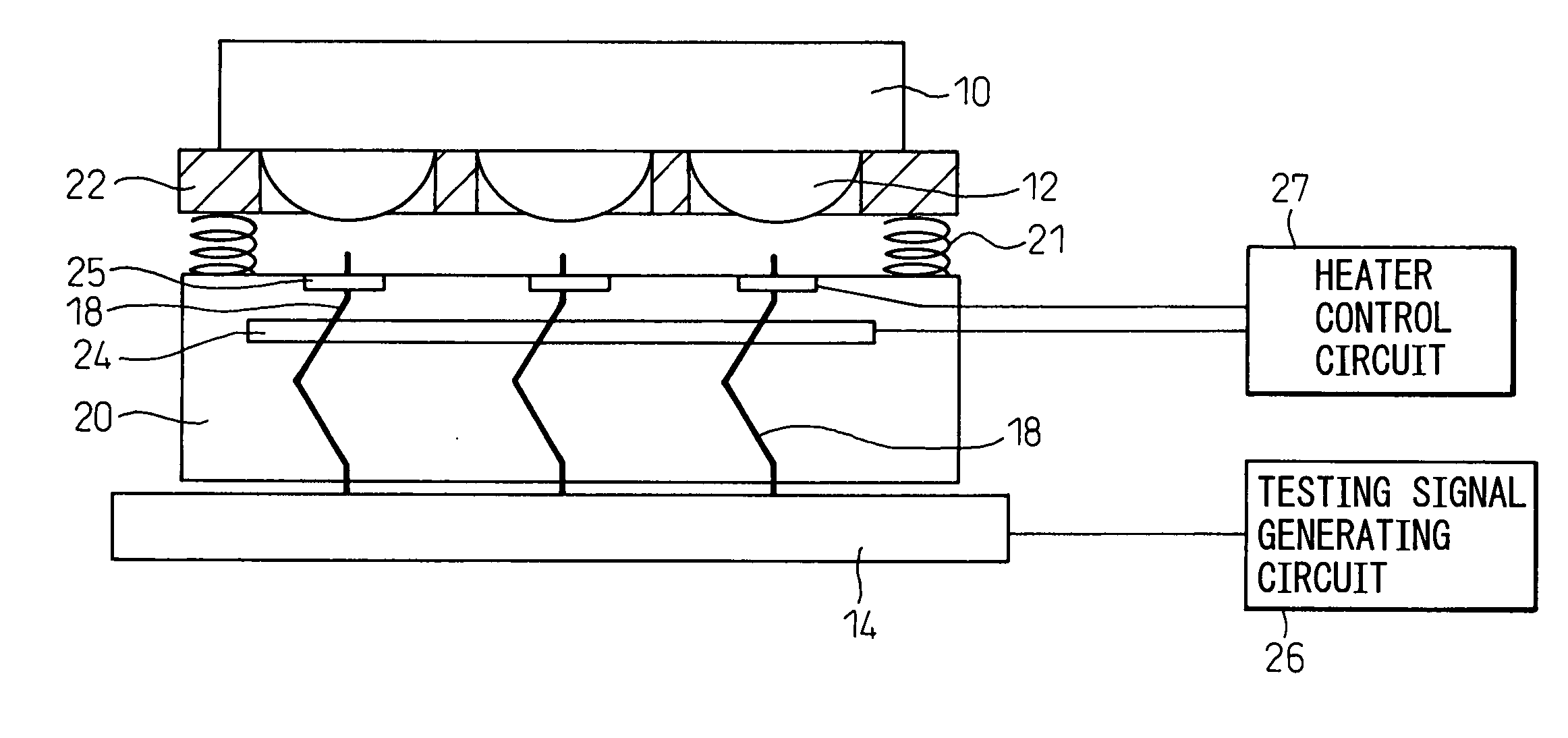

InactiveUS20050253614A1Minimize damageLow-resistance connectionCoupling device connectionsElectric discharge tubesElectricityEngineering

An electrical connecting method has the step of bringing a contact member connected to an electric circuit into contact with a terminal of an electronic part. A desired processing is performed by feeding current to the terminal via the contact member. The contact member is then separated from the terminal. When the contact member is brought into contact with the terminal, energy is applied to the contact member or the terminal in order to locally soften a portion of the terminal contacting the contact member. Thereafter, the desired processing is performed, in the state that the contacting portion of the terminal with the contact member is softened so as to reduce the contact resistance and so as to increase the subsequent separatability of the contact member from the terminal.

Owner:SOCIONEXT INC

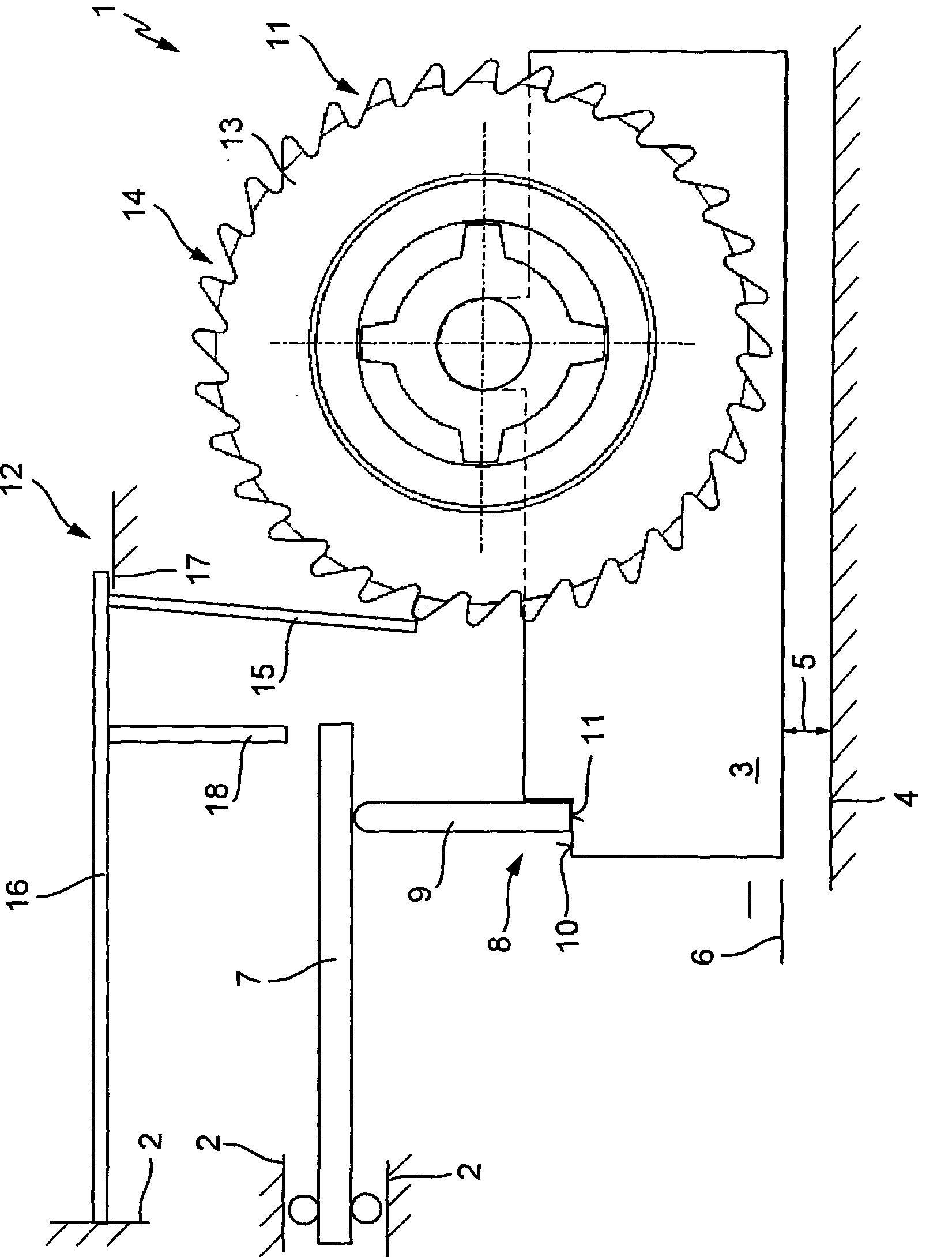

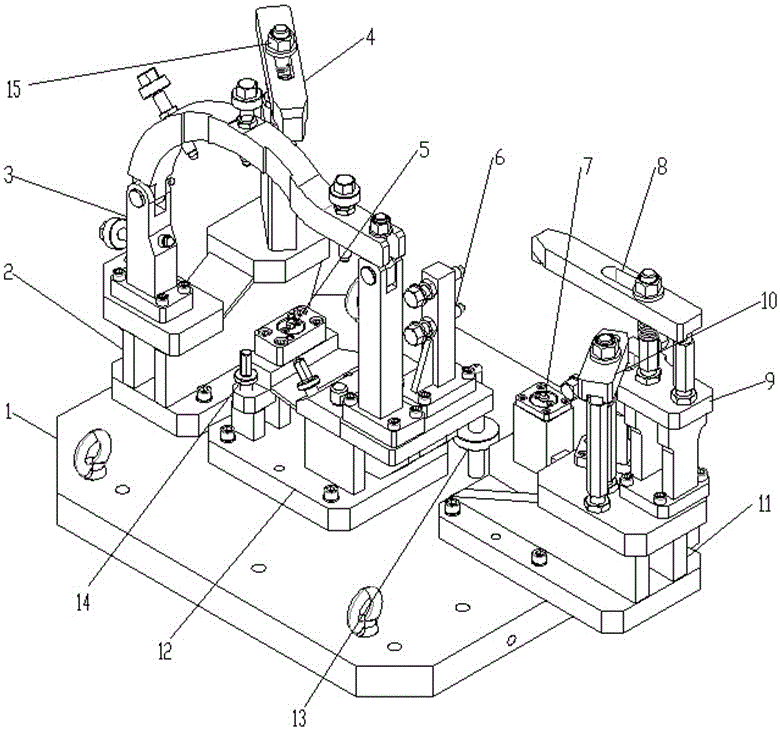

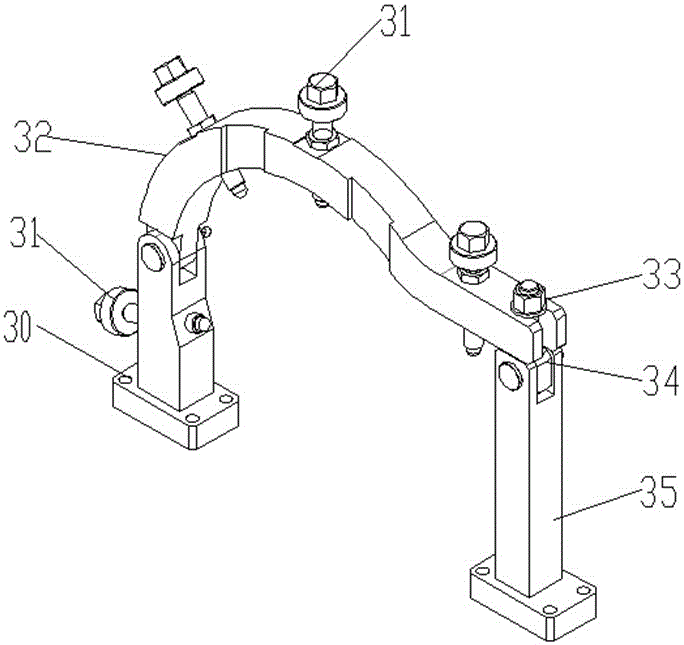

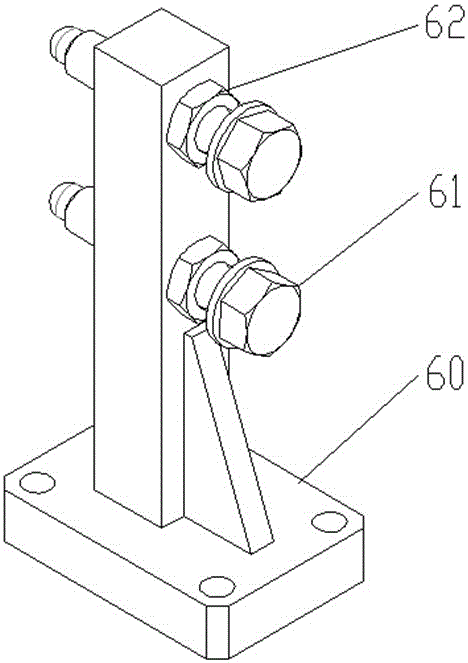

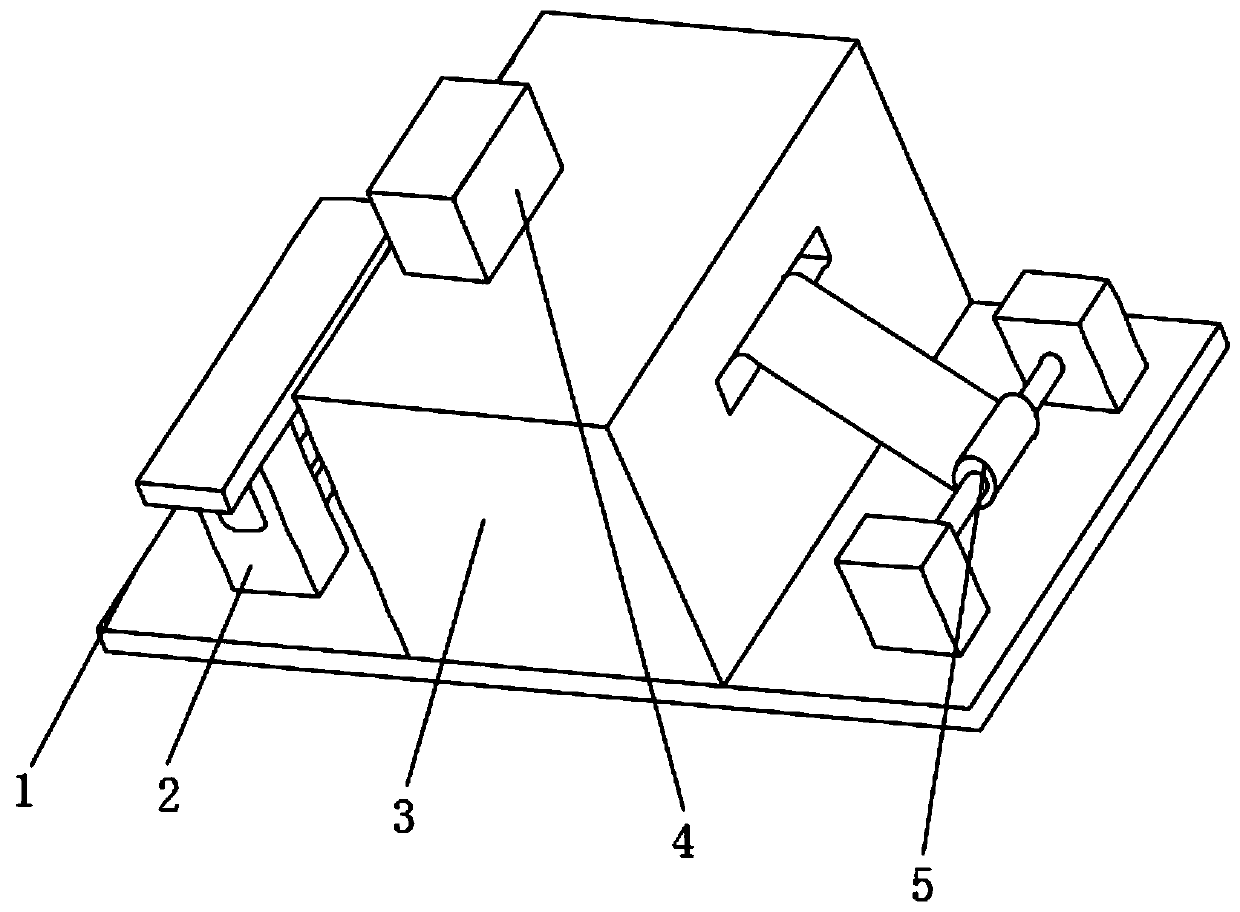

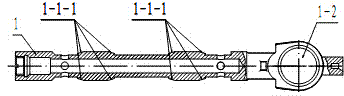

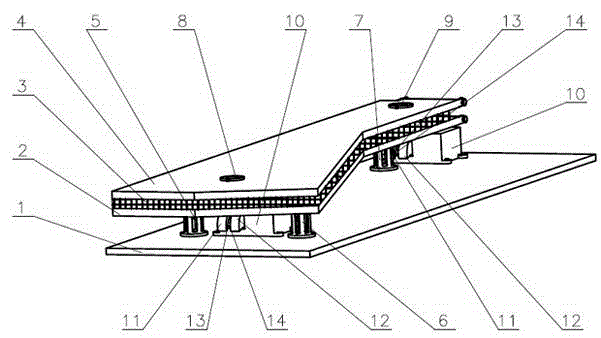

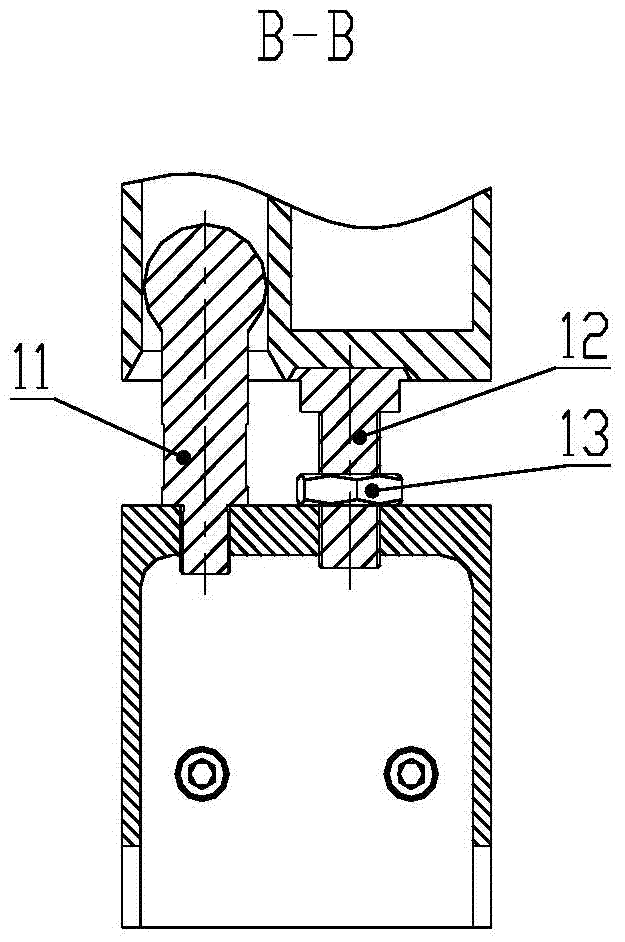

Clamp for processing gearbox body of forklift

ActiveCN105149985ASolve the processing vibration problemReliable compressionPositioning apparatusMetal-working holdersEngineeringMulti point

The invention relates to a clamp for processing a gearbox body of a forklift. The specific structure of the clamp is that a left pressing plate mechanism, an intermediate mechanism and a right pressing plate mechanism are correspondingly arranged on a bottom plate, wherein a first locating pin and a second locating pin are correspondingly arranged on the bottom plate parts at two sides of the intermediate mechanism; the left pressing plate mechanism comprises an arc-shaped pressing plate and a left pressing plate; the right pressing plate mechanism comprises a locating pressing plate and a right pressing plate; one side of the gearbox body to be processed, of the forklift, is a differential housing and the other side of the gearbox body to be processed, of the forklift, is a motor mounting housing; when the clamp is put into use, the gearbox body to be processed, of the forklift, is positioned on the first locating pin and the second locating pin, the arc-shaped pressing plate and the left pressing plate are pressed to the top part of the differential housing, the right pressing plate is pressed to the top part of the motor mounting housing, and the locating pressing plate is pressed onto a lug on the motor mounting housing, so that the gearbox body to be processed, of the forklift, can be positioned and clamped. The clamp is reliable to locate and compress; the problem of vibrating in processing can be solved; the one-point compressing in the prior art is adjusted to be multi-point compressing, thereby removing the influence of human factors on the workpiece clamping effect.

Owner:ANHUI HELI CO LTD

Link-and-pin fixing structure for a crawler chain

InactiveUS20010001223A1Small pressing forceReduce tightening forceRopes and cables for vehicles/pulleyCouplings for rigid shaftsAngle alphaMechanical engineering

A fitting space having an annular opening, in which an elastic ring whose diameter of a section is D is to be fitted, is formed between a pin-press-fit hole of a link and an exposed end portion of a pin. A link inner wall face and a pin outer peripheral face in the fitting space are formed with tapered faces whose diameters decrease as they go toward an inmost of the fitting space at angles alpha and beta (alpha> beta) with respect to the axial line of the pin, respectively. The elastic ring contacts with the respective tapered faces in the fitting space at the angles alpha and beta with respect to a perpendicular passing a center of its section. Dimensions d1 and d2 between contact points at the respective tapered faces and a horizontal line passing the center of the section of the elastic ring, the diameter D of the section of the elastic ring, and the angles alpha and beta have a relation of alpha> beta, D> d1+ d2 (where d1=D / 2. cos alpha, d2= D / 2.cos beta). Therefore, the links and the pin can be connected to each other securely and firmly with a sufficient holding force to the pin in the axial direction. Thus, assembly of the links and the pin can be carried out easily at a low cost.

Owner:KOMATSU LTD

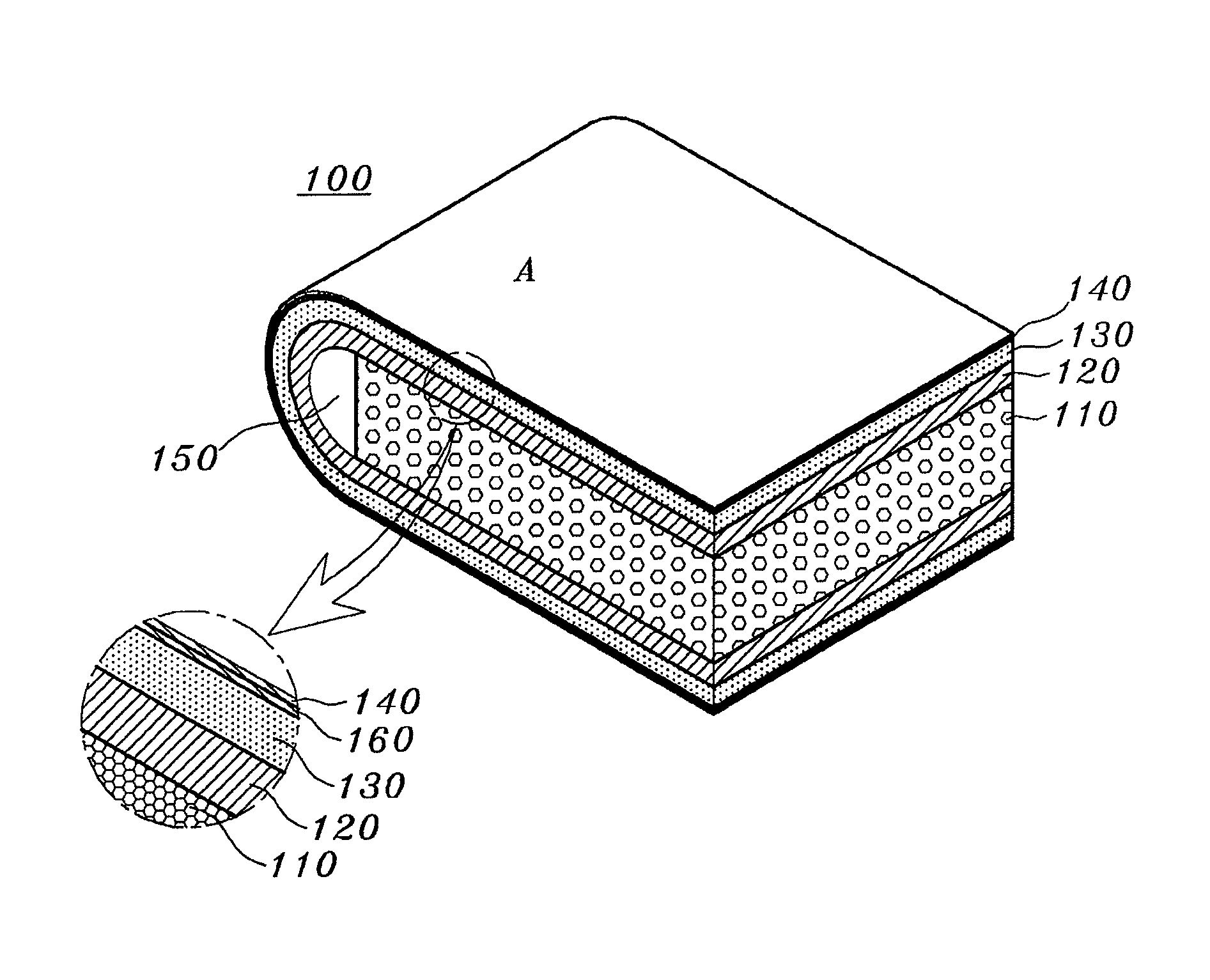

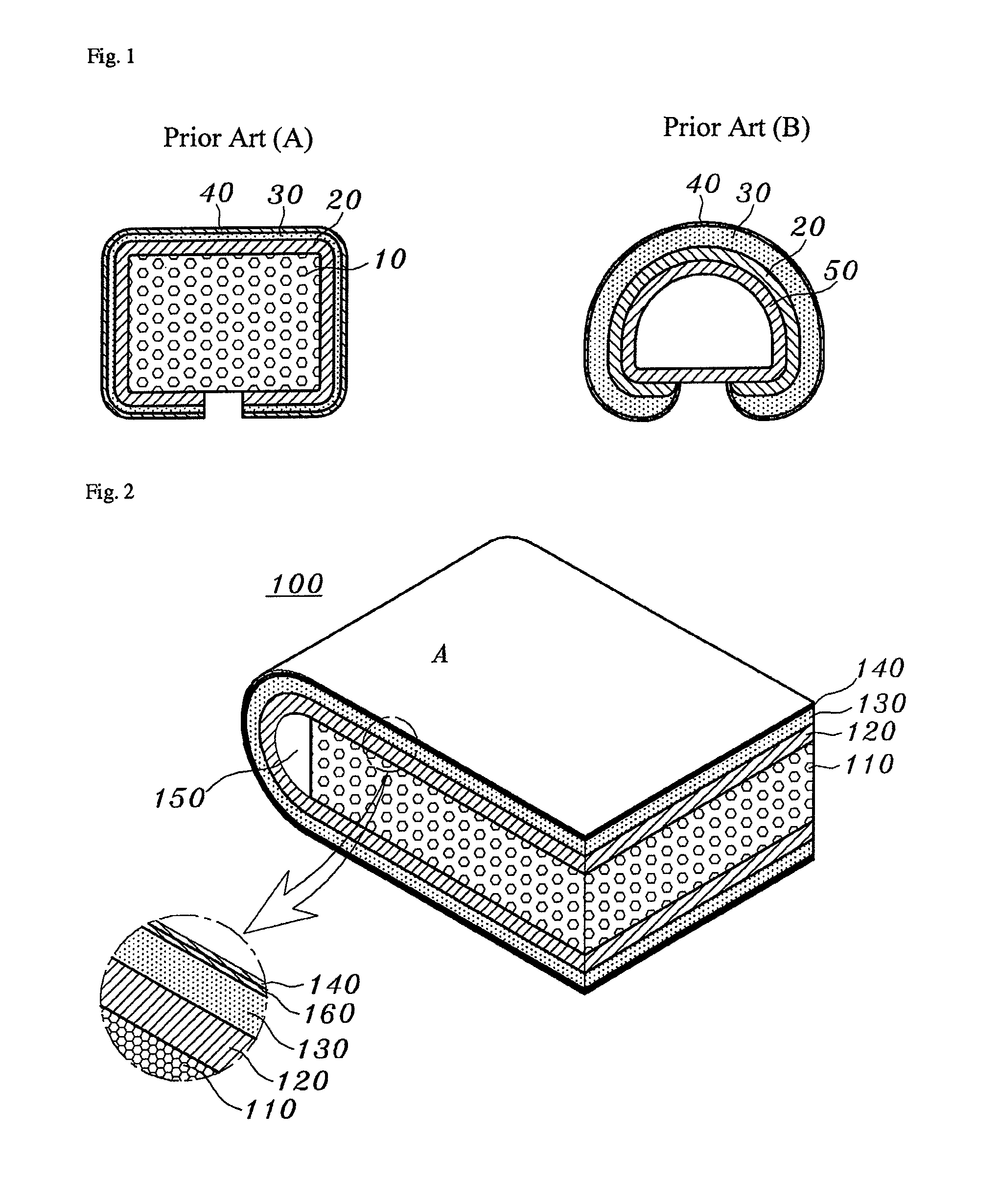

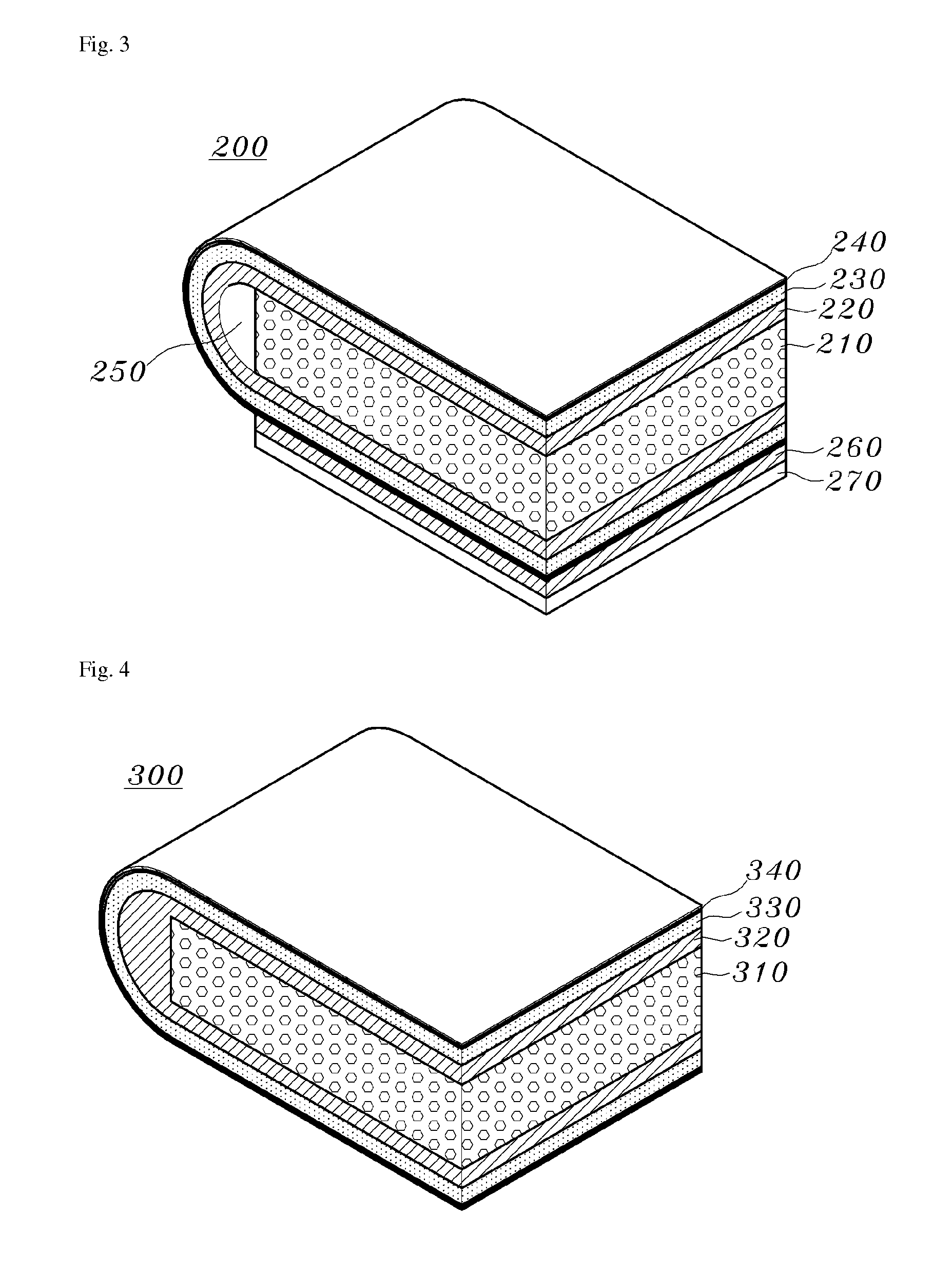

Elastic electric contact terminal

ActiveUS8461455B2Improve conductivityIncrease elasticityNon-insulated conductorsCoupling device detailsFoam rubberEngineering

Owner:JOINSET +1

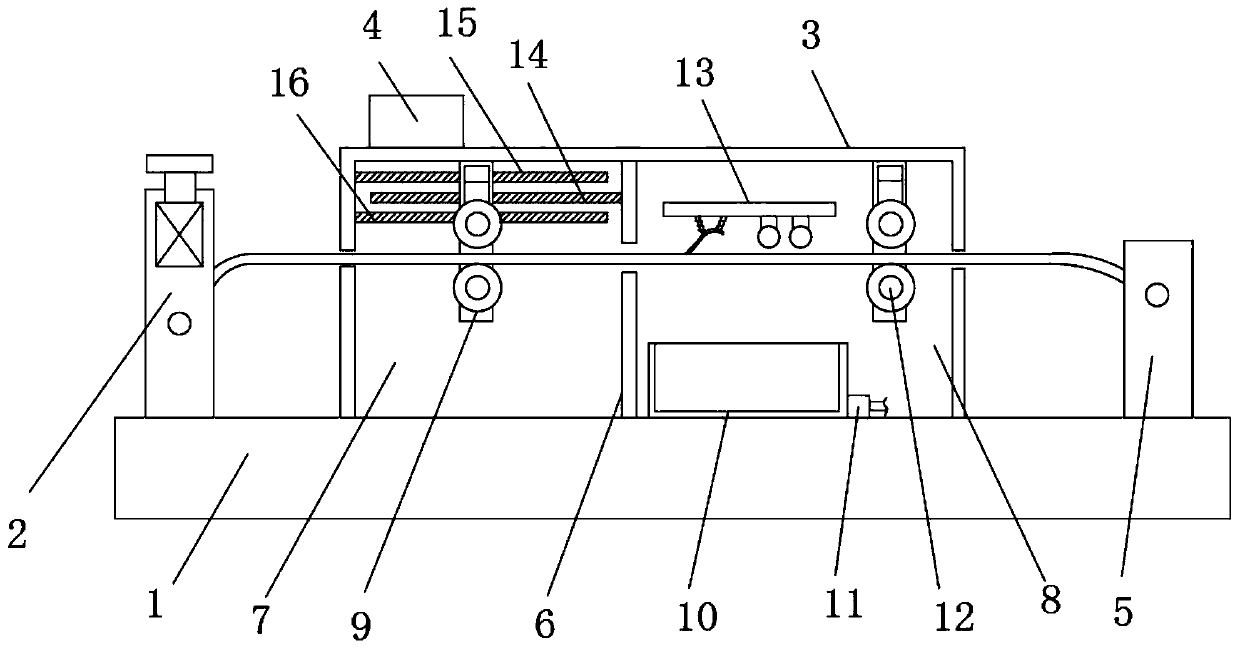

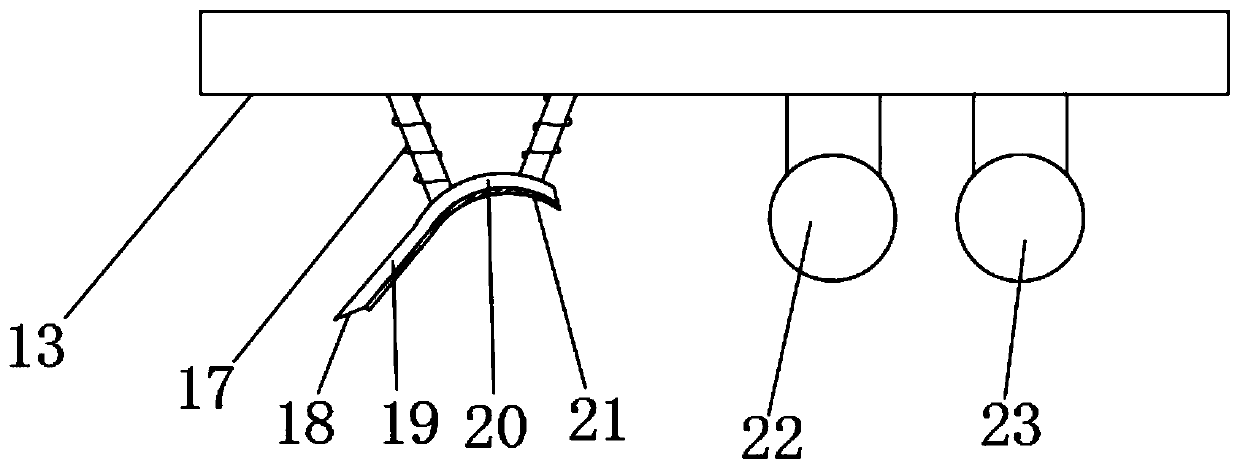

Jet-dyeing device with good cloth spraying uniformity and application method thereof

ActiveCN110424112AEasy to rewindNeatly rolledMechanical cleaningTextile storage in wounded formEngineeringMechanical engineering

The invention discloses a jet-dyeing device with good cloth spraying uniformity and an application method thereof. The jet-dyeing device comprises a base, a rack, a box body, a heating box and an unwinding roller. The unwinding roller is in drive connection with one end of the top of the base; the box body is fixedly mounted at the top center of the base; the inside of the box body is divided intoa drying chamber and a spraying chamber through a partition arranged; a second adjustment is fixedly mounted at the side, close to the unwinding roller, of the interior of the spraying chamber; a mounting plate is fixedly mounted at one side of the second adjustment. Processing and guiding can be performed on cloth different in thickness by adjusting a distance between an adjusting roller and a driving roller through the two adjustments; clamp rings are driven to move back and forth on the unwinding roller by enabling an electric telescopic bar to operate, a distance between the two clamp rings can be adjusted, and therefore, cloth different in width can be wound conveniently; winding evenness is better, operating is simple, and using is facilitated.

Owner:安徽宜民服饰股份有限公司

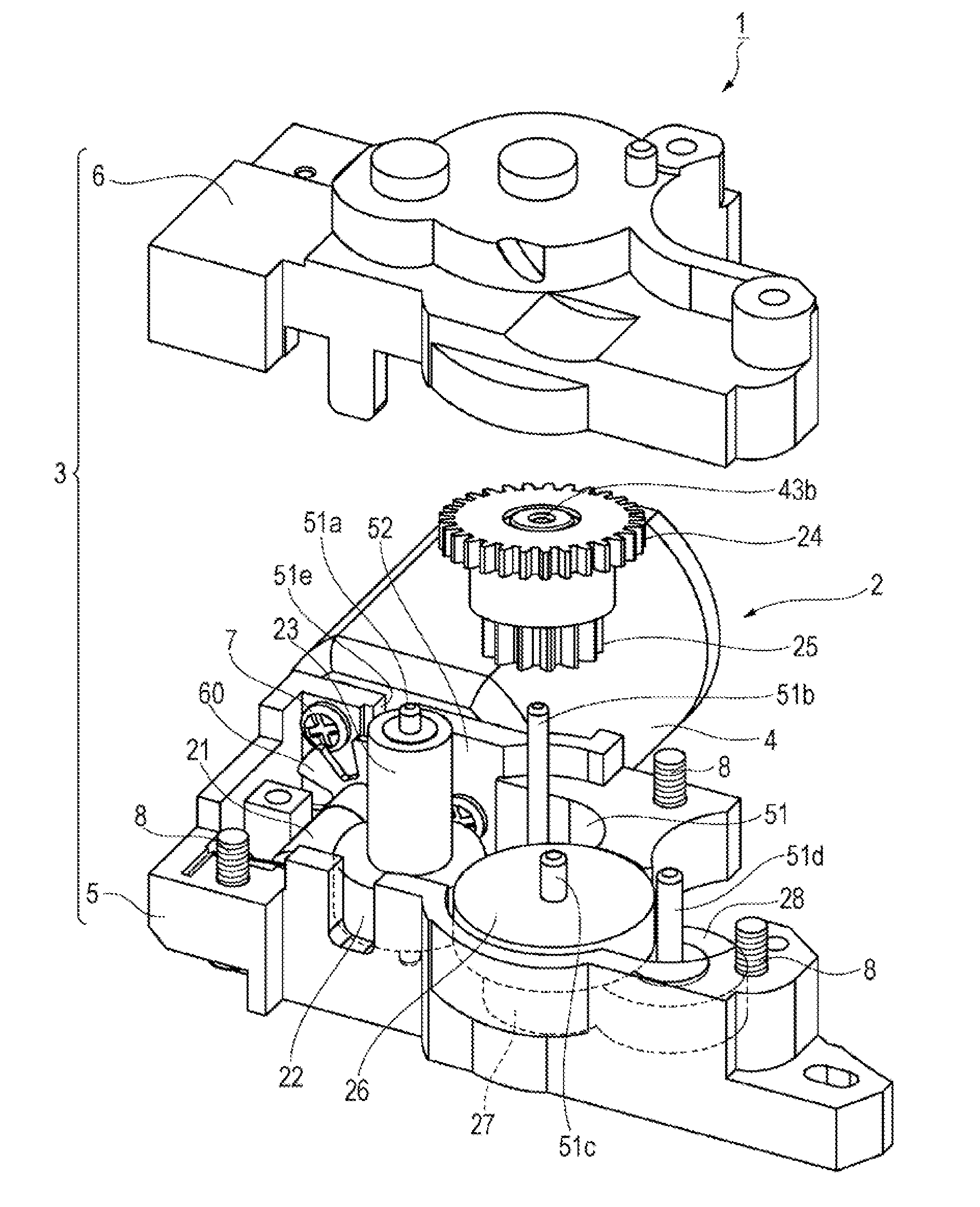

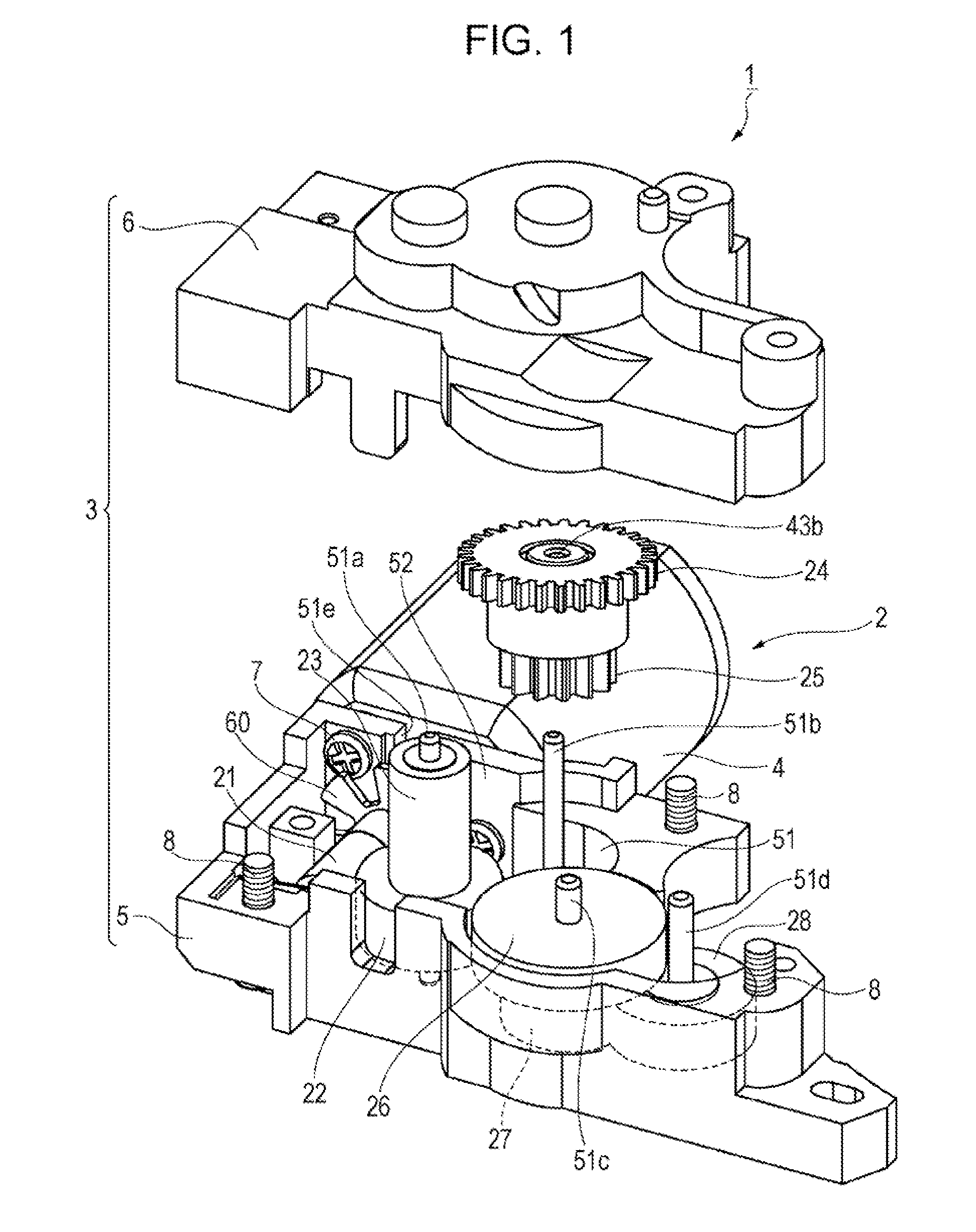

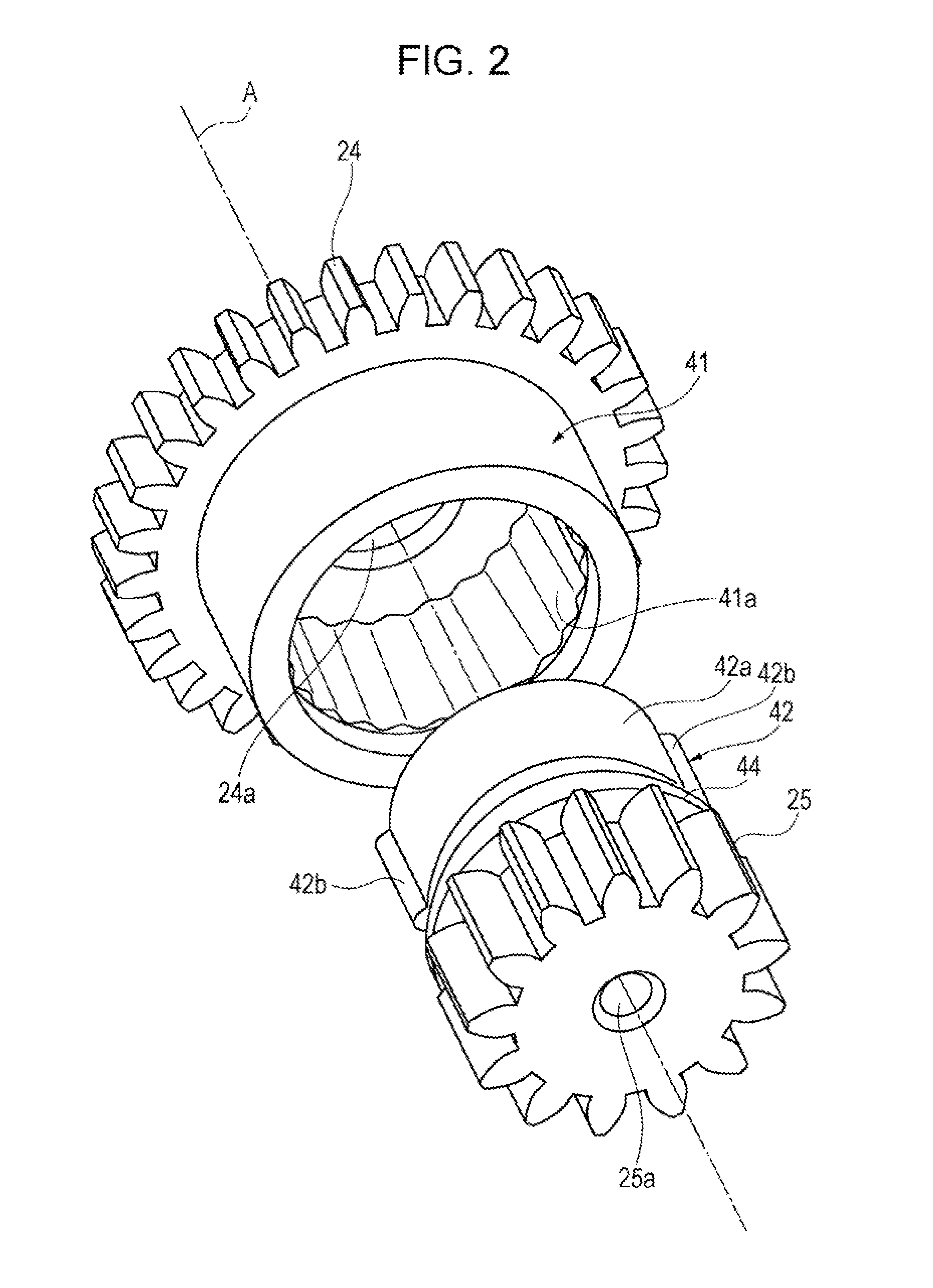

Geared motor

InactiveUS20140157926A1Easy to wearSmall pressing forceSlip couplingToothed gearingsGear driveEngineering

A geared motor reduces a speed of rotation of a DC motor with a gear train and outputs the rotation to the outside. The gear train includes a second gear including a cylindrical portion a third gear a first insertion portion that is inserted in the cylindrical portion the second gear. The second gear and the third gear are made of a resin material. A projecting-and-recessed portion is provided on an inner peripheral surface of the cylindrical portion of the second gear. The projecting-and-recessed portion extends continuously in a circumferential direction over the entire circumference of the inner peripheral surface of the cylindrical portion. Pressing portions are evenly arranged in the circumferential direction on an outer peripheral surface of the first insertion portion of the third gear. The pressing portions are configured enter recesses in the projecting-and-recessed portion and press wall surfaces of the recesses.

Owner:COPAL CO LTD

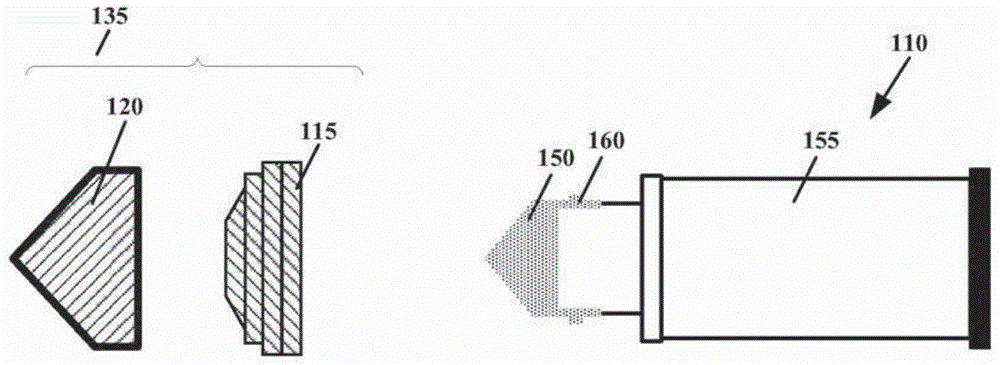

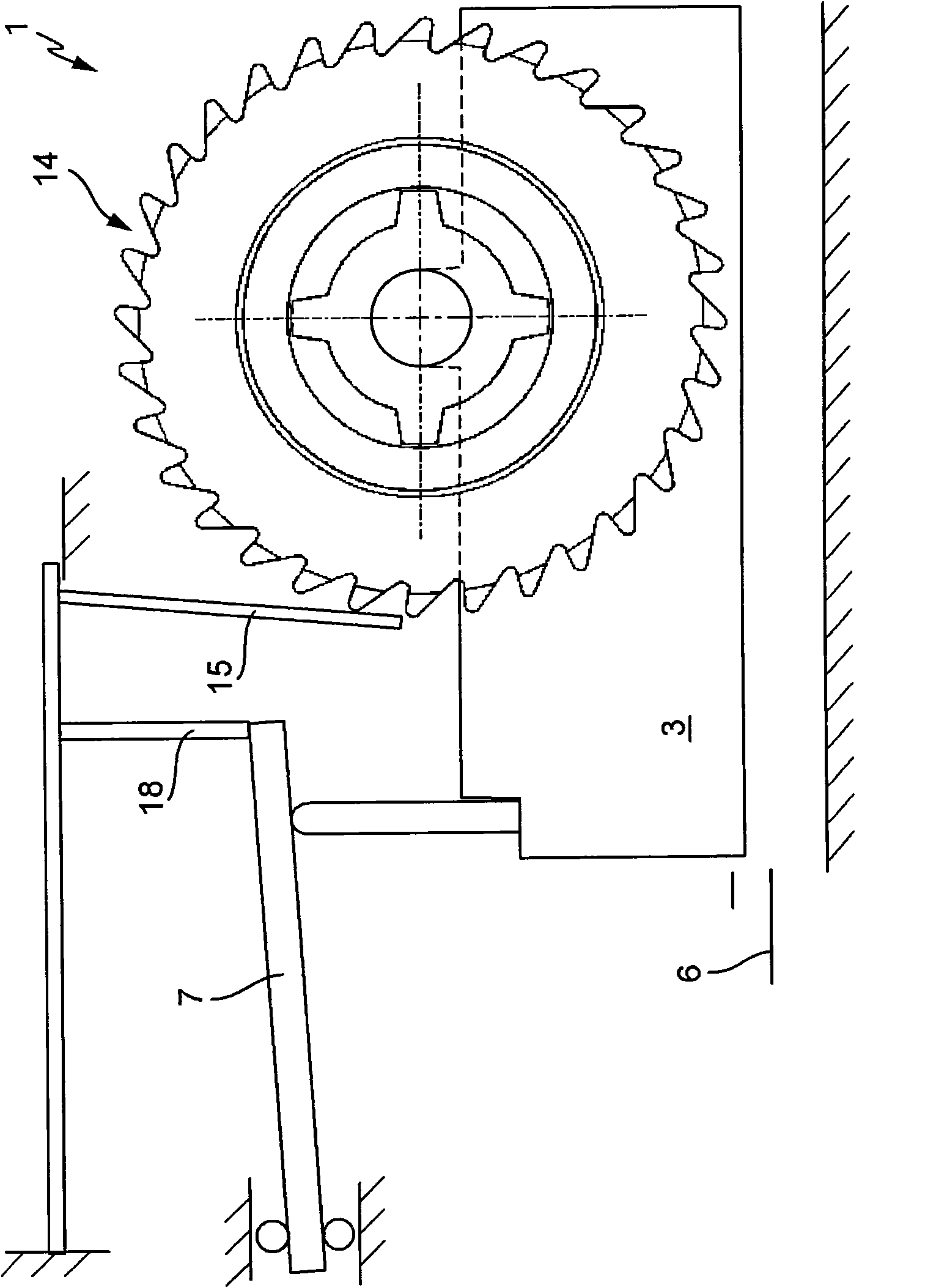

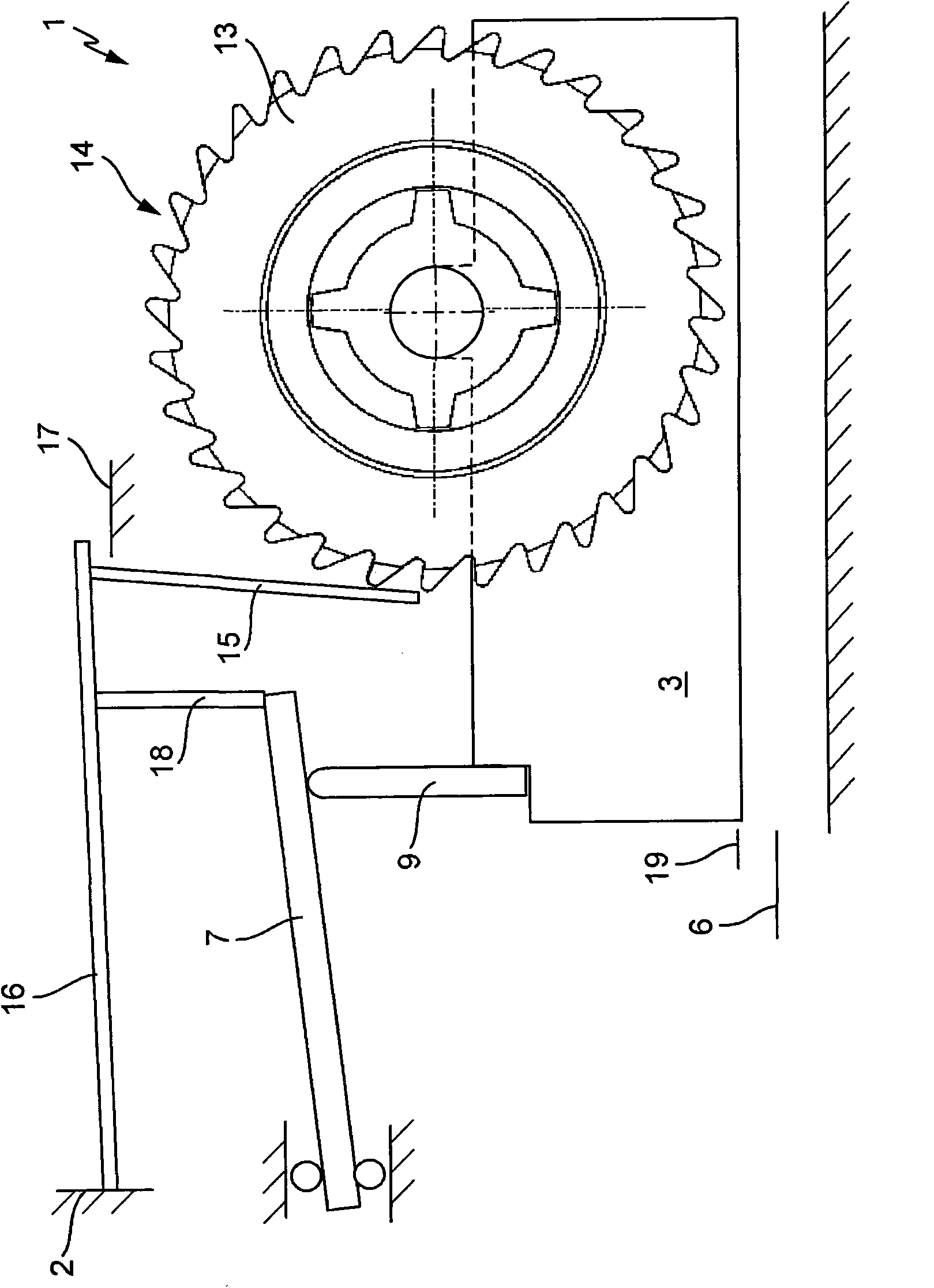

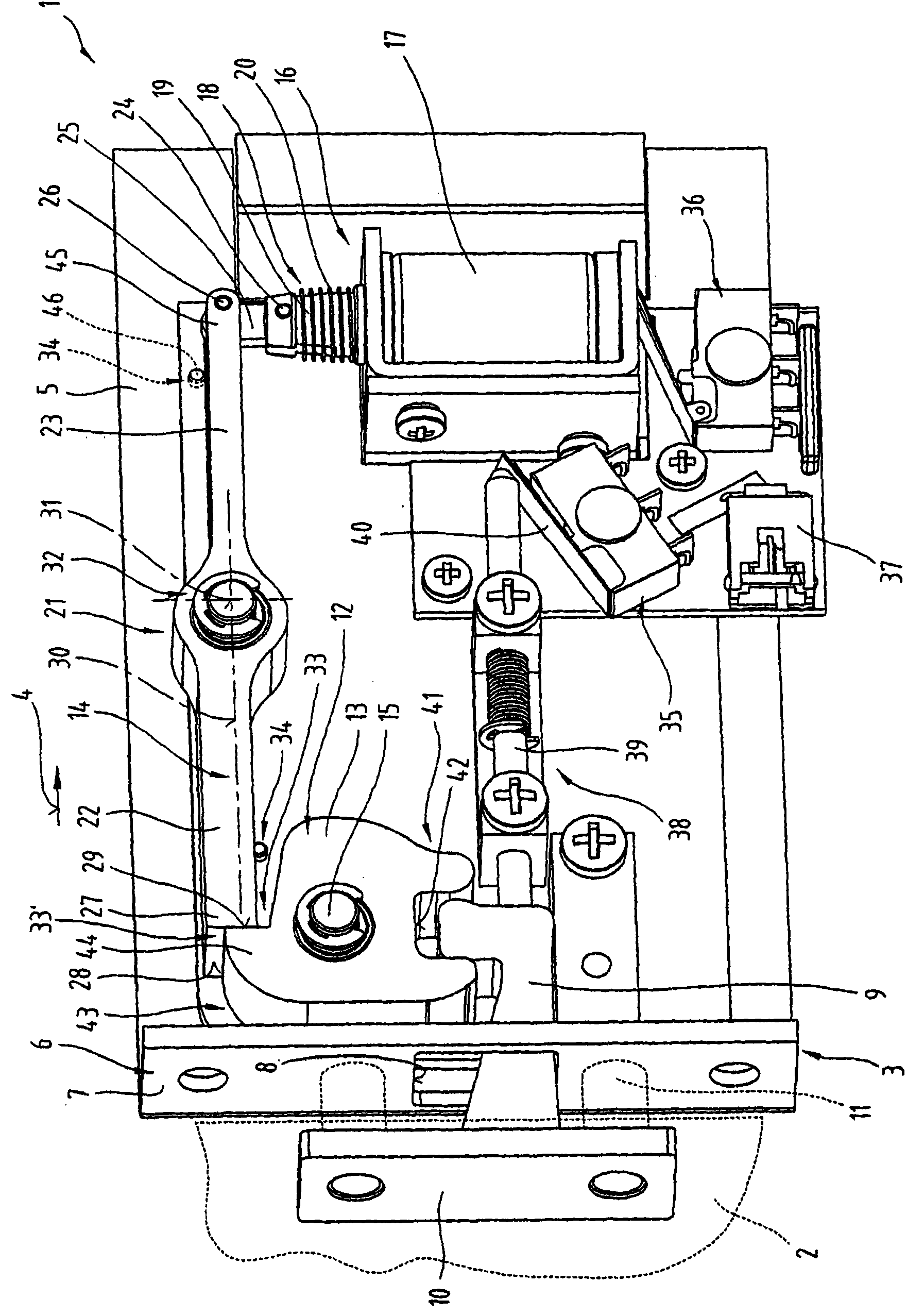

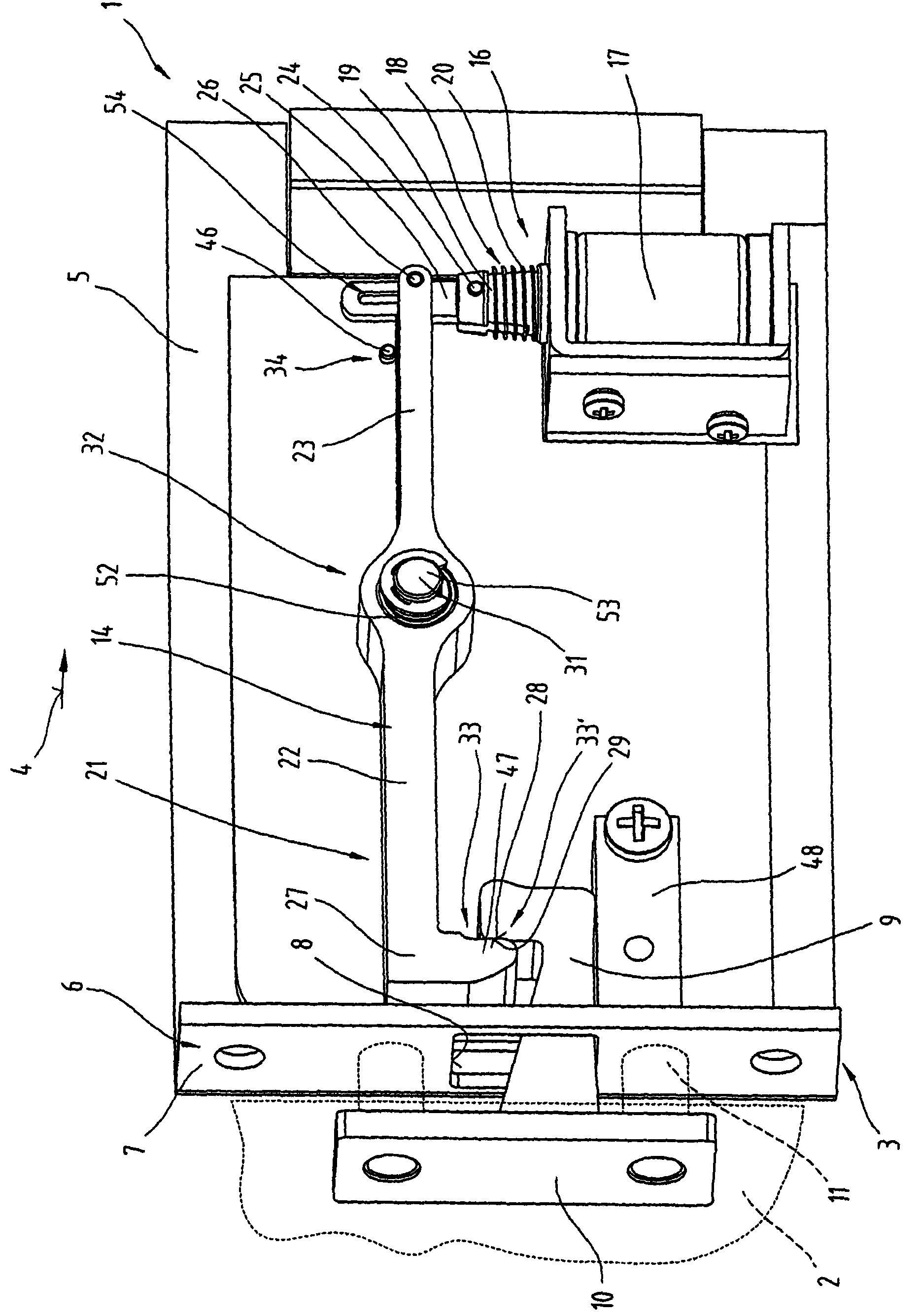

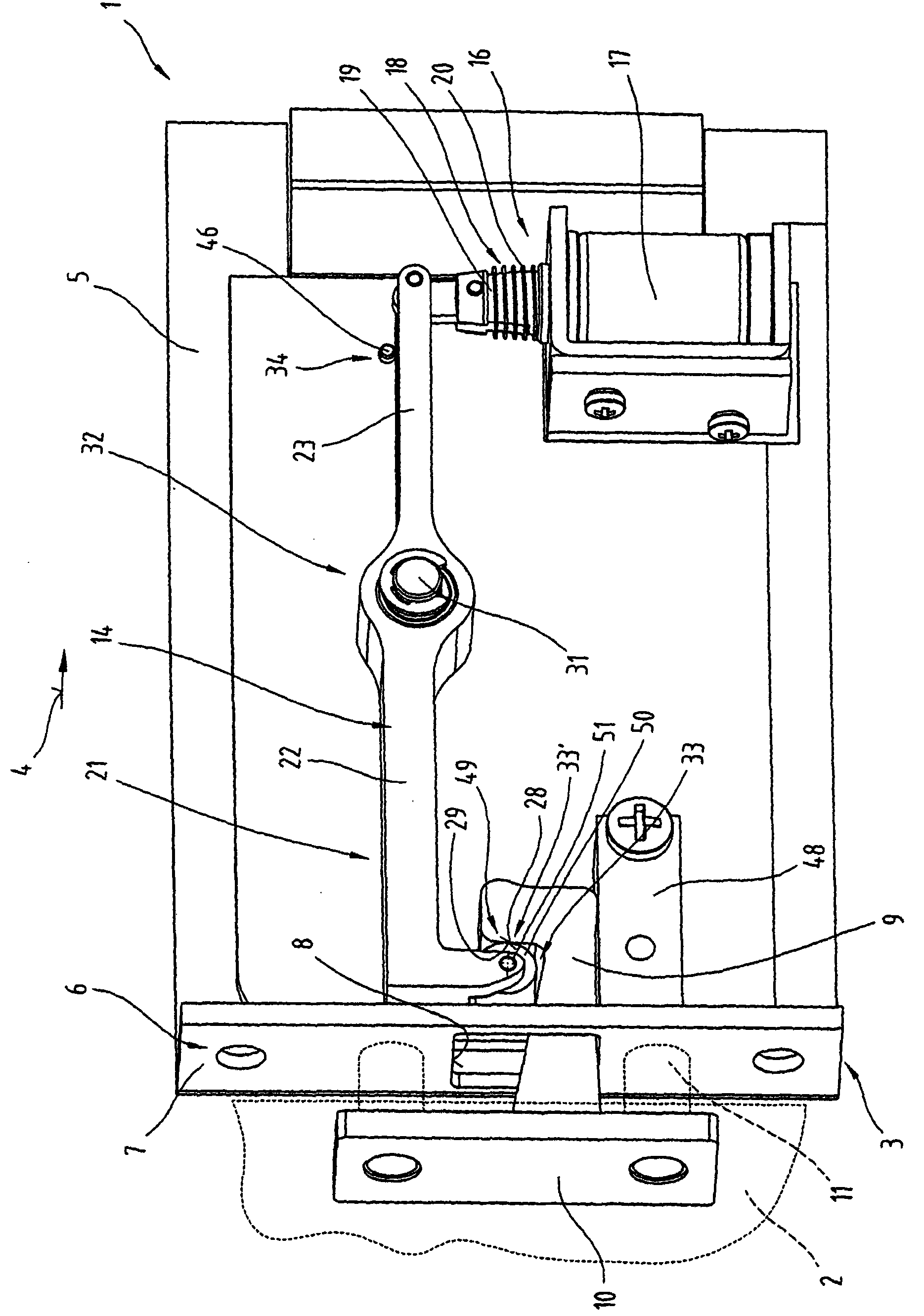

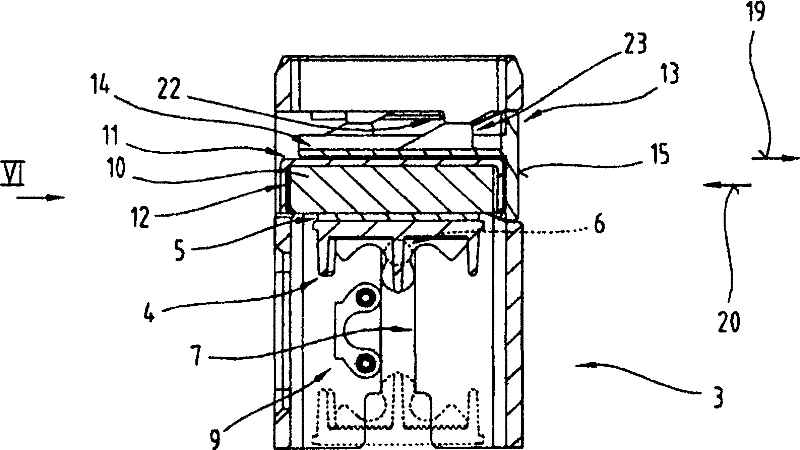

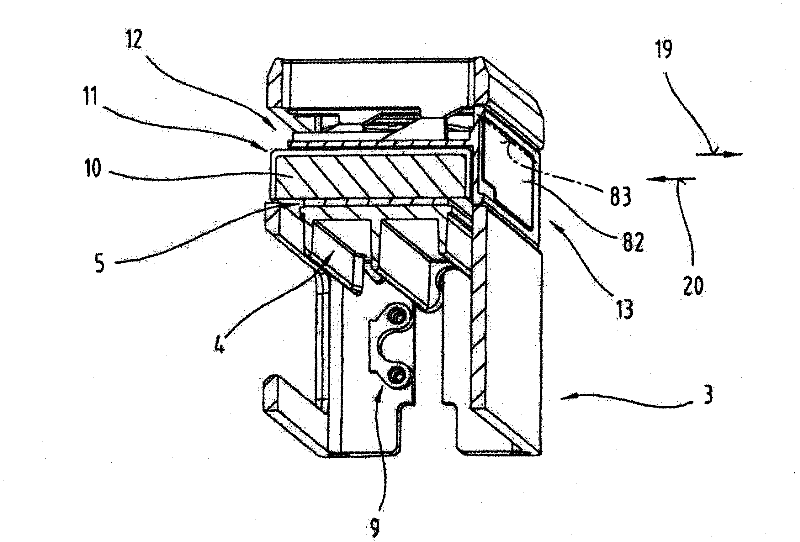

Lock which can be unlocked in an electrically automated manner, in particular for storage systems like lockers

ActiveCN101802328AReduce torsionImprove automationNon-mechanical controlsElectrical locking actuatorsElectricityCoupling

The invention relates to a lock (1) which can be unlocked in an electrically automated manner, in particular for use for storage systems like lockers. In this case, a blocking element (9) is provided which can be inserted into the lock (1), can be blocked in the lock (1) and in this case holds a locker door (2), which is firmly connected to the blocking element (9), in the closed position. Furthermore, a blocking catch (14) is provided which can be moved rotationally in a limited manner and which, on assuming its blocking position, engages either directly or indirectly via at least one coupling element (12), which is mounted such that it can move, with the blocking element (9). The essential feature in this case is that the section of a force introduction point (33') for the blocking force into the blocking catch (14) is designed such that force and impulse introduction, which are dependent on an interlock on the installation, from the blocking element (9) or from an intermediate coupling element (12), which may be provided, to the blocking catch (14) occurs directed virtually exclusively radially with respect to the pivoting axis (31) thereof, and any tangential force or impulse components which may occur can be transmitted virtually exclusively by friction forces to the force introduction point (33'). This achieves increased security against external manipulatory actions.

Owner:KEBA HANDOVER AUTOMATION GMBH

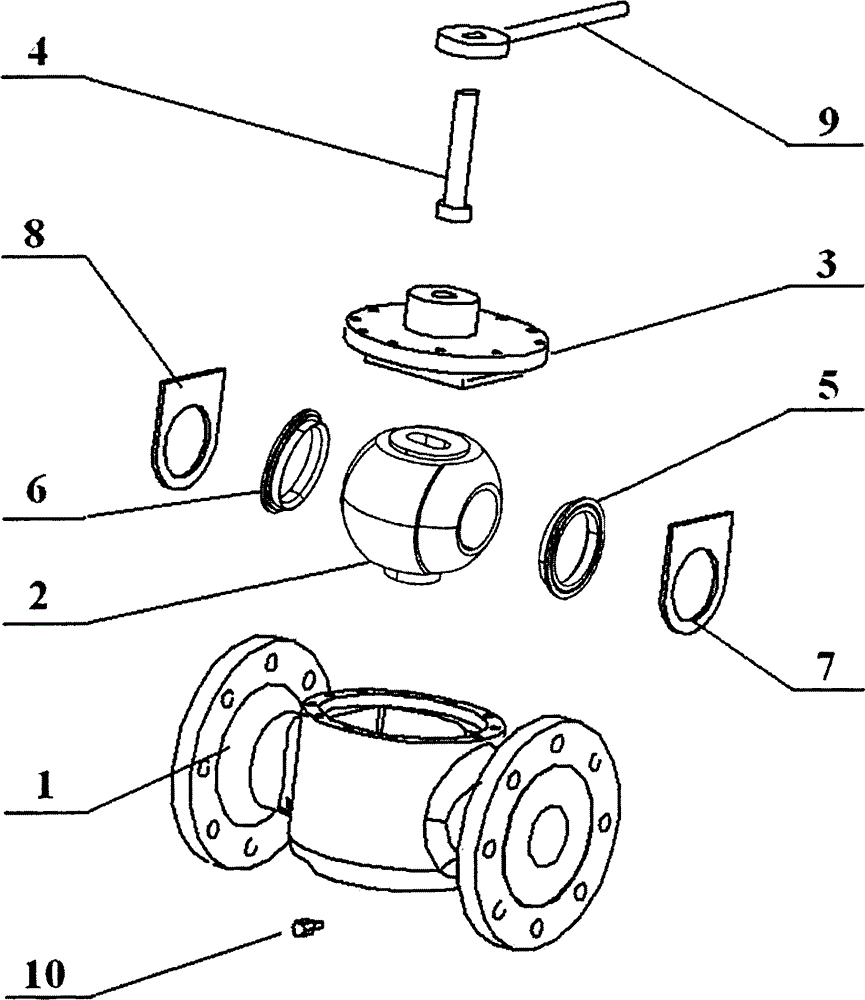

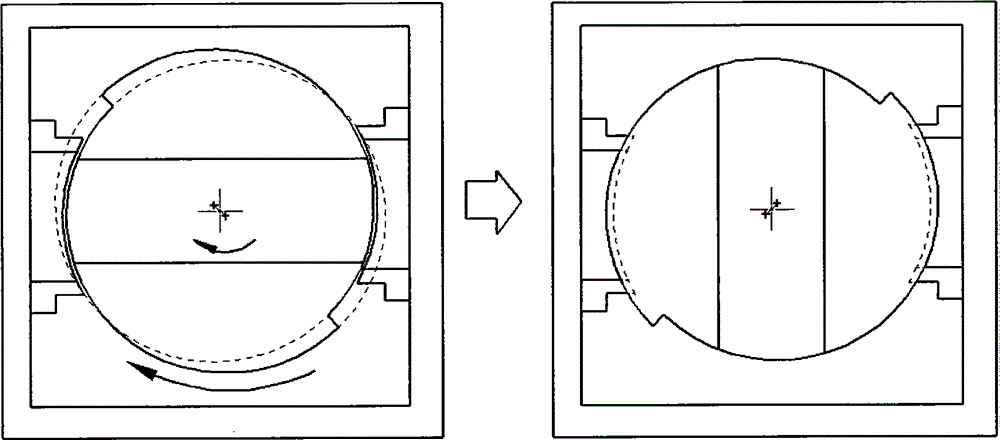

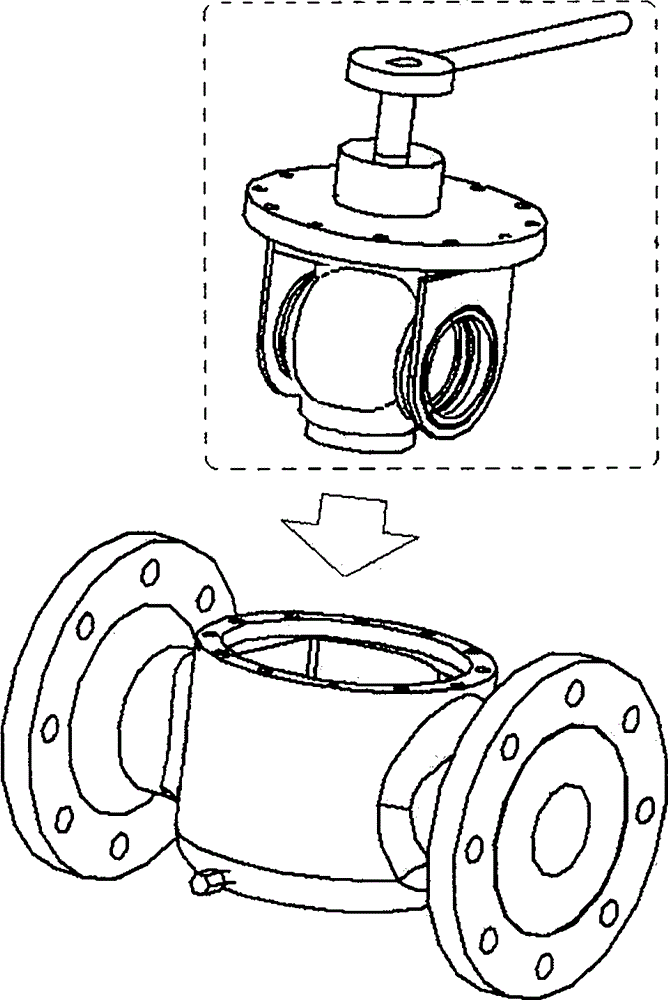

Forced seal valve capable of conducting eccentric double-spherical-angle stroke operation

InactiveCN105370909AIncrease the sealing specific pressureGuaranteed tightnessPlug valvesSpherical angleEngineering

The invention relates to a forced seal valve capable of conducting eccentric double-spherical-angle stroke operation. The forced seal valve mainly comprises a valve body, an opening and closing piece, a valve deck, a valve rod, valve bases, a valve base supporting plate, an operation mechanism, a blowdown valve and the like. The opening and closing piece comprises two eccentric spherical structures. By means of the eccentric structures, when the valve rod drives the opening and closing piece to rotate, two eccentric spherical faces can both move in the axis directions of the downstream valve base and the upstream valve base, and therefore the effect of pressing or releasing the valve bases is achieved, and forced sealing of the opening and closing piece, the downstream valve base and the upstream valve base under the specific valve position is achieved. In addition, a module can be formed by the opening and closing piece, the valve rod, the valve bases, the valve base supporting plate and the valve deck, the whole module can be pulled out of the valve as a whole after fastening pieces through which the valve deck and the valve body are connected are detached, and therefore easily-damaged parts of the valve can be replaced in a modularized manner.

Owner:JIANGSU RELIABLE MECHANICAL EQUIP CO LTD

Boundary Microphone

InactiveUS20110182456A1Feel goodSmall pressing forcePiezoelectric/electrostrictive microphonesTransducer detailsPressure sensitiveMicrophone

A boundary microphone includes a base, a microphone unit that is mounted on the base and converts sound into electrical signals, and a pressure-sensitive switch that switches on / off the output signals from the microphone unit. The pressure-sensitive switch includes a membrane covering a circuit board having an electrode pattern on its upper surface, a spacer disposed between the membrane and the circuit board. The electrode pattern is turned on the pressure-sensitive switch upon contact with the membrane. The membrane is composed of a conductive cloth having flexibility in the thickness direction.

Owner:AUDIO-TECHNICA

Waterway switching mechanism and method for switching the waterway switching mechanism

ActiveUS20200353486A1Simple structureEasy to switchSpray nozzlesDomestic plumbingStructural engineeringControl theory

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

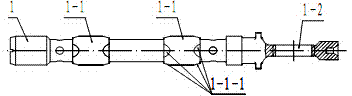

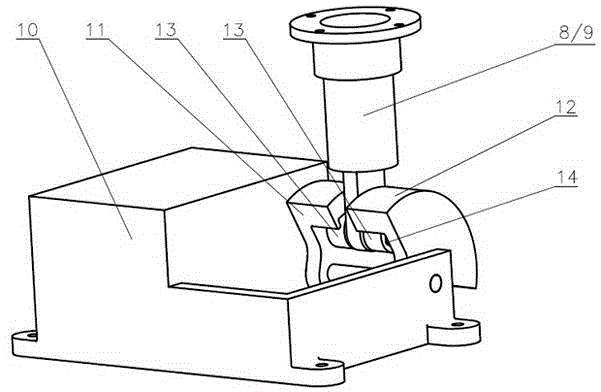

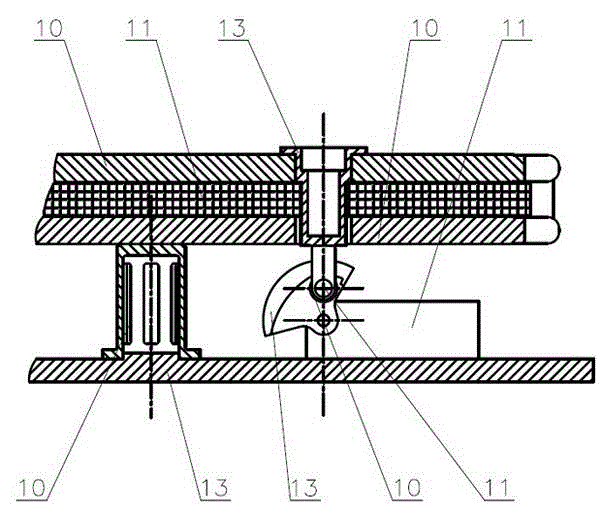

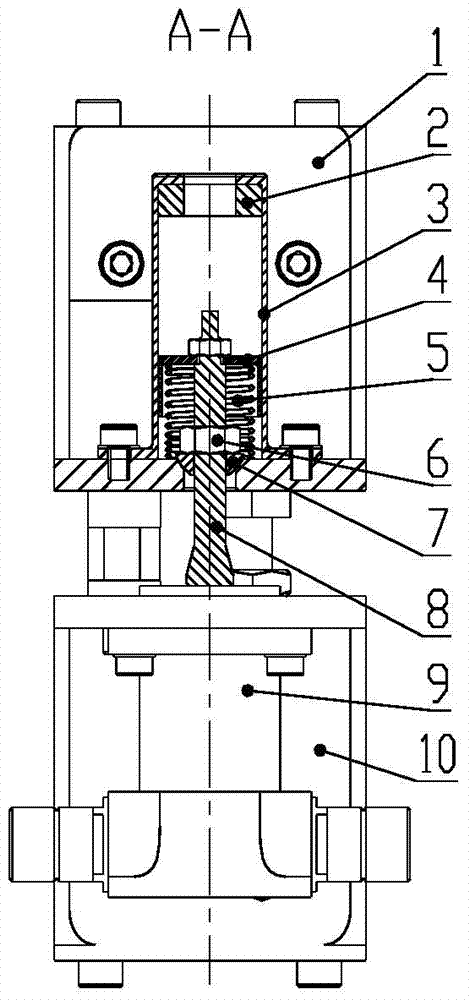

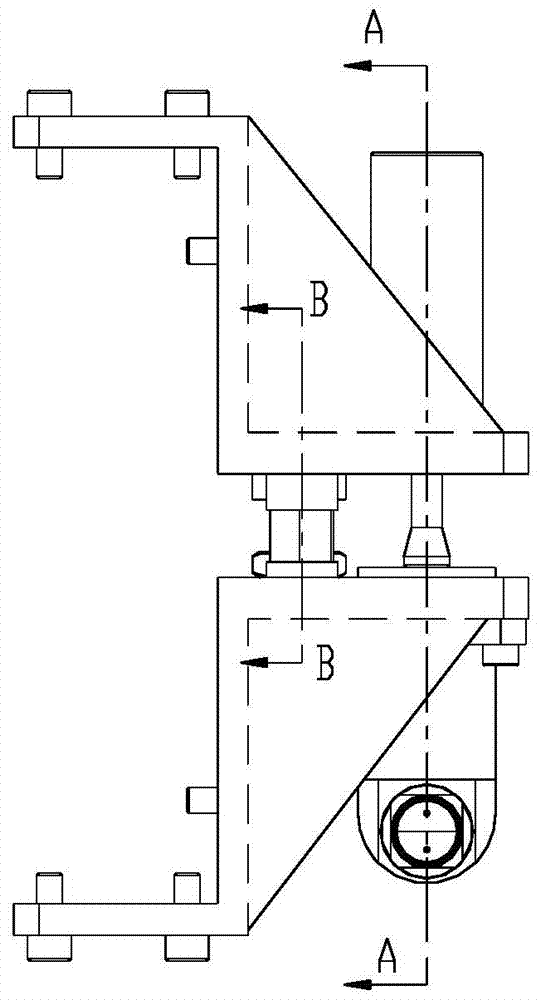

Hydraulic valve plunger abrasive machining positioning fixture

ActiveCN104842270ARealize automatic correction functionGuaranteed machining accuracyRevolution surface grinding machinesGrinding work supportsMechanical engineeringPlunger

The invention discloses a hydraulic valve plunger abrasive machining positioning fixture, and belongs to the technical field of abrasive machining devices. The hydraulic valve plunger abrasive machining positioning fixture comprises a fixture base, a left tip, a workpiece positioning sleeve, a right tip, an indexing plate and an indexing plate positioning mechanism. The fixture base is of a U-shaped structure. The left tip is fixedly installed on the left side wall of the opening end of the fixture base, and the right tip capable of moving leftwards and rightwards is installed on the right side wall of the opening end of the fixture base. The left tip and the right tip are located on the same central axis. The workpiece positioning sleeve is installed at the left end of the plunger workpiece and matched with the left tip. The indexing plate is sleeved with a large circular hole of the plunger workpiece. The indexing plate positioning mechanism is installed on a base body of the fixture base of the U-shaped structure and matched with the indexing plate. By means of the hydraulic valve plunger abrasive machining positioning fixture, the plunger workpiece is accurately positioned, the machining quality of the plunger workpiece is ensured, the switching of grinding positions of the plunger workpiece can be rapidly completed, and the work efficiency is improved.

Owner:FACTORY 5721 OF PLA

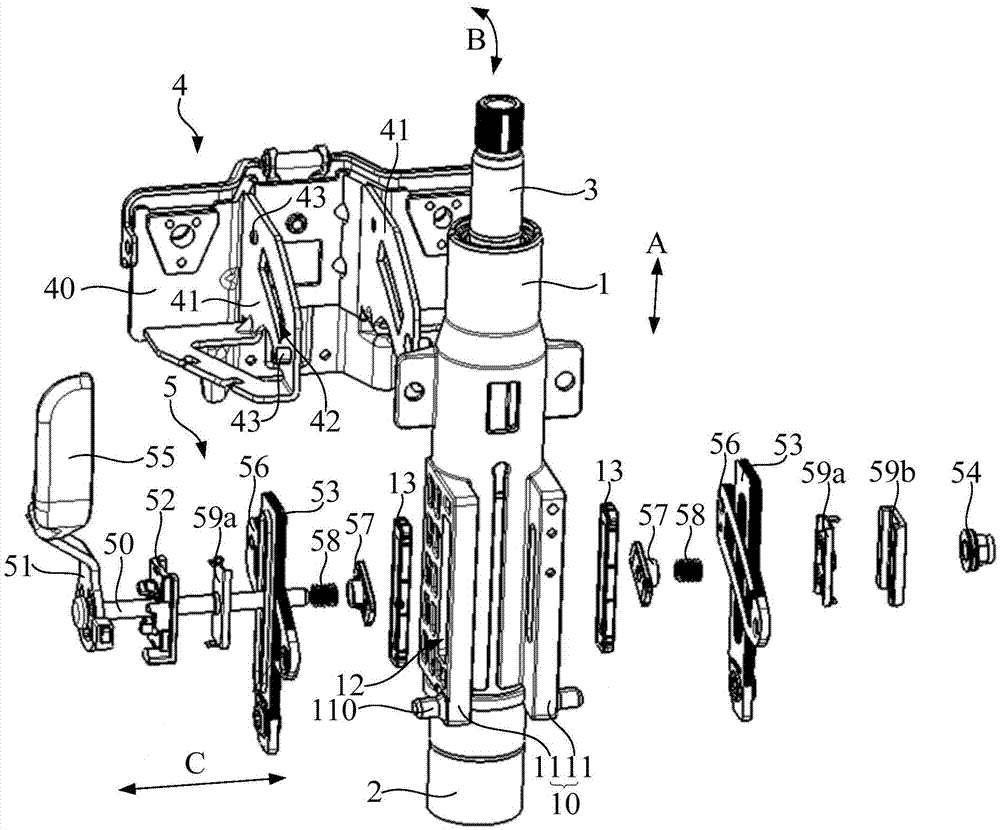

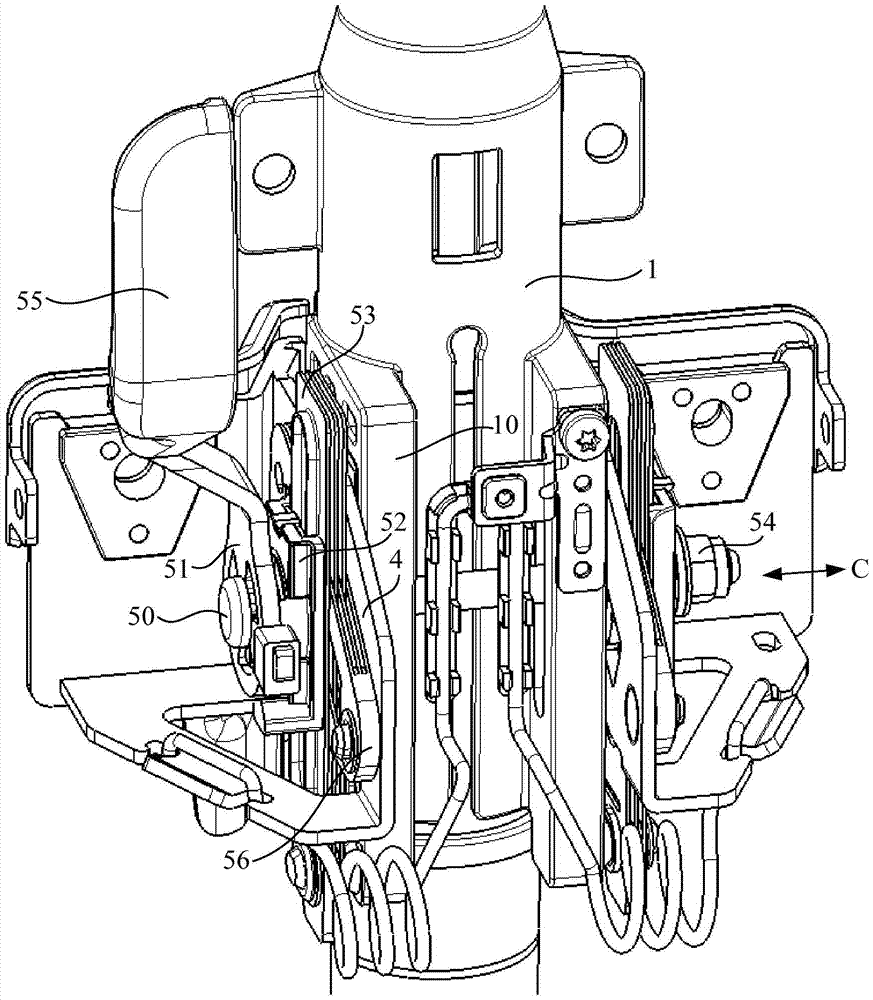

Flexible solar wing compaction and release device

ActiveCN104908979ANot destroyedLift fixed constraintsCosmonautic power supply systemsEngineeringHeight difference

The invention provides a flexible solar wing compaction and release device. The compaction and release device mainly consists of a driving end, a driven end and a support piece, wherein a driven piece is fixed with a movable plate; a roller on the driven piece rolls in a wedged compaction wheel of the driving end; and the movement of the movable plate to a fixed plate is realized through the height difference of the wedged compaction wheel to press a buffer material of a flexible wing to generate compaction force. After the compaction is in place, the movement trajectory of the wedged compaction wheel is an arc trajectory; and the roller of the driven end cannot automatically slide to reduce the compaction force. Before a solar wing is unfolded in orbit, the compaction and release device actively moves to release the fixed restraint between the movable plate and the fixed plate, so that the movable plate is smoothly unfolded under the driving of an unfolding mechanism. The device can repeatedly press and release the flexible solar wing, and is simple in structure and reliable in compaction. In addition, the support force is provided between the flexible solar wing and a cabin body by multiple support points, and the compaction force is provided by multiple locking points, so that the compaction and release device is high in bearing capacity.

Owner:SHANGHAI AEROSPACE SYST ENG INST

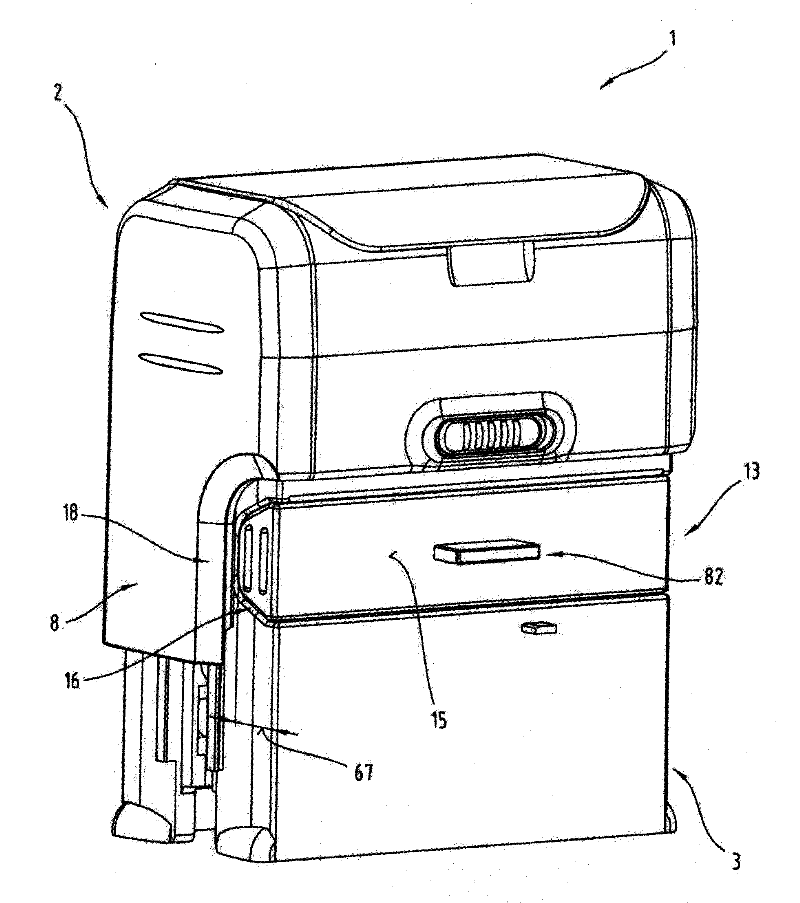

Stamps and ink pads for self-inking stamps

Owner:TRODAT GMBH

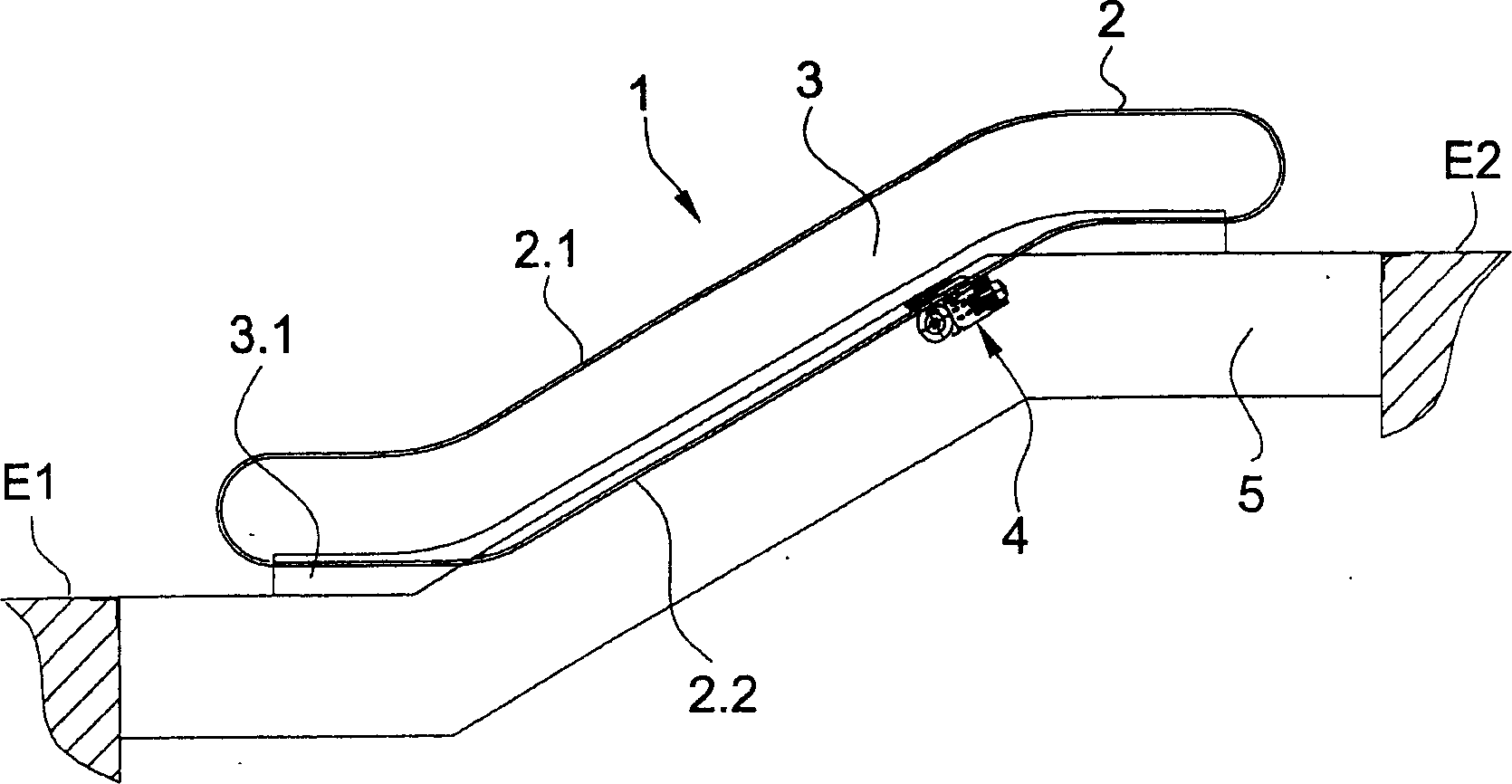

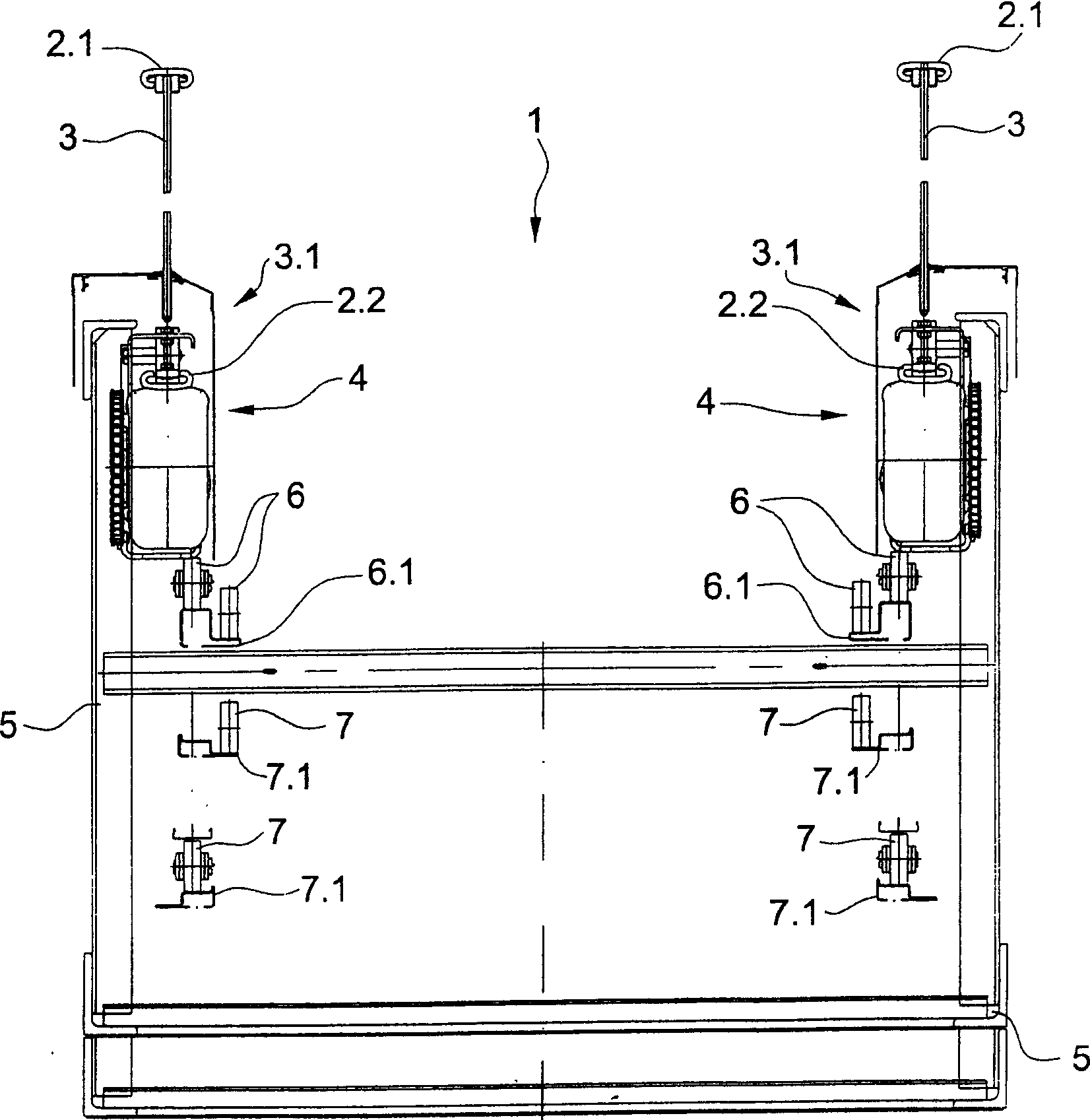

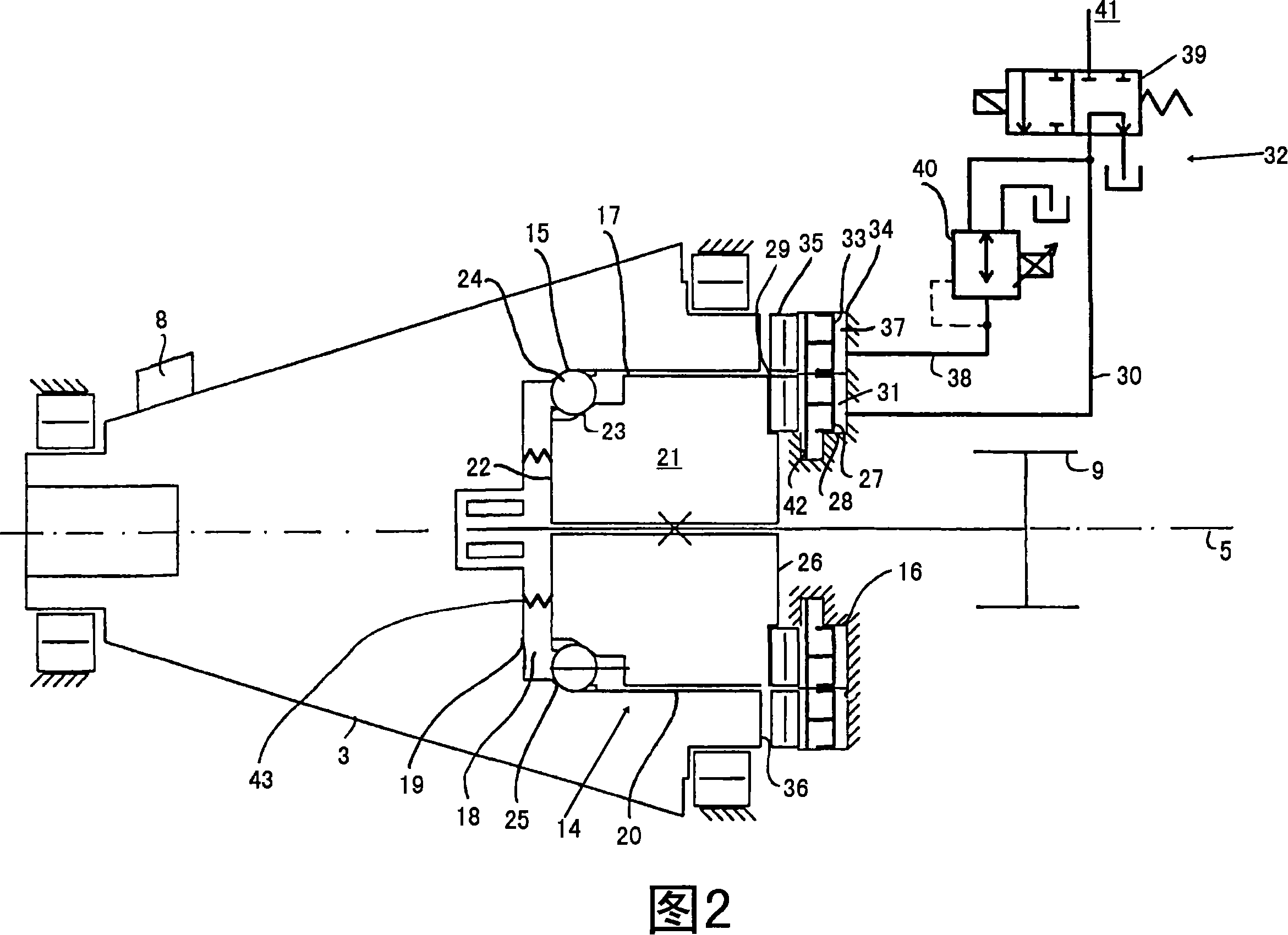

Handrail-drive for an escalator or a moving walk

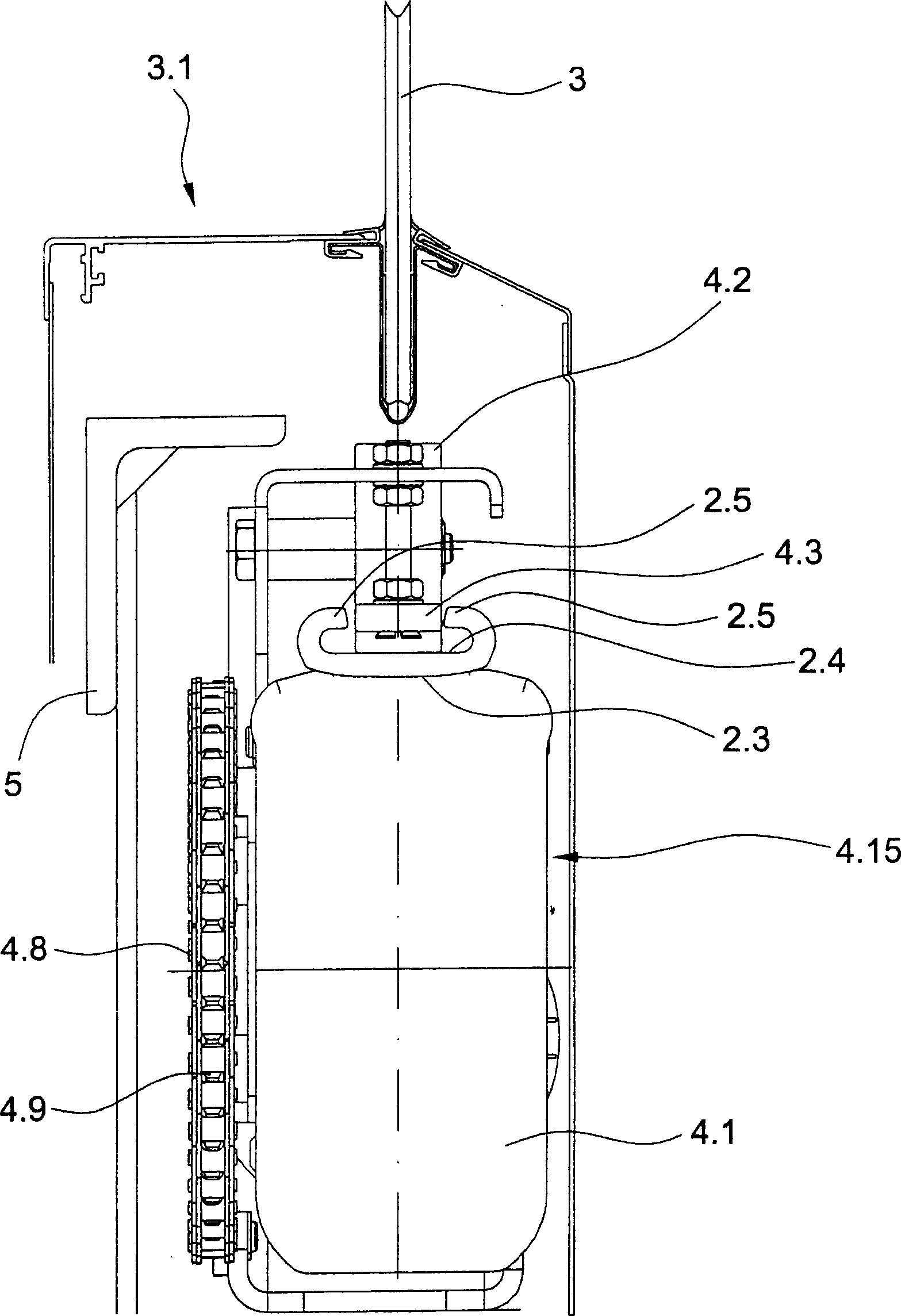

In this handrail-drive, a chain wheel 4.9 of the driving wheel is connected with the driving wheel 4.15 holding a driving wheel tire 4.1 by an axle 4.16, and the axle 4.16 is rotatably held by a bearings 4.17. The driving wheel tire 4.1 filled with gas, for example, compressed air is applied on a removable wheel rim 4.18 arranged on the axle 4.16 to cover it. The driving wheel tire 4.1 is adapted to a shape of the handrail. The handrail is only slightly or negligibly deformed owing to spring characteristic and air cushion characteristic of the driving wheel tire 4.1 and large contact surface obtained from it.

Owner:INVENTIO AG

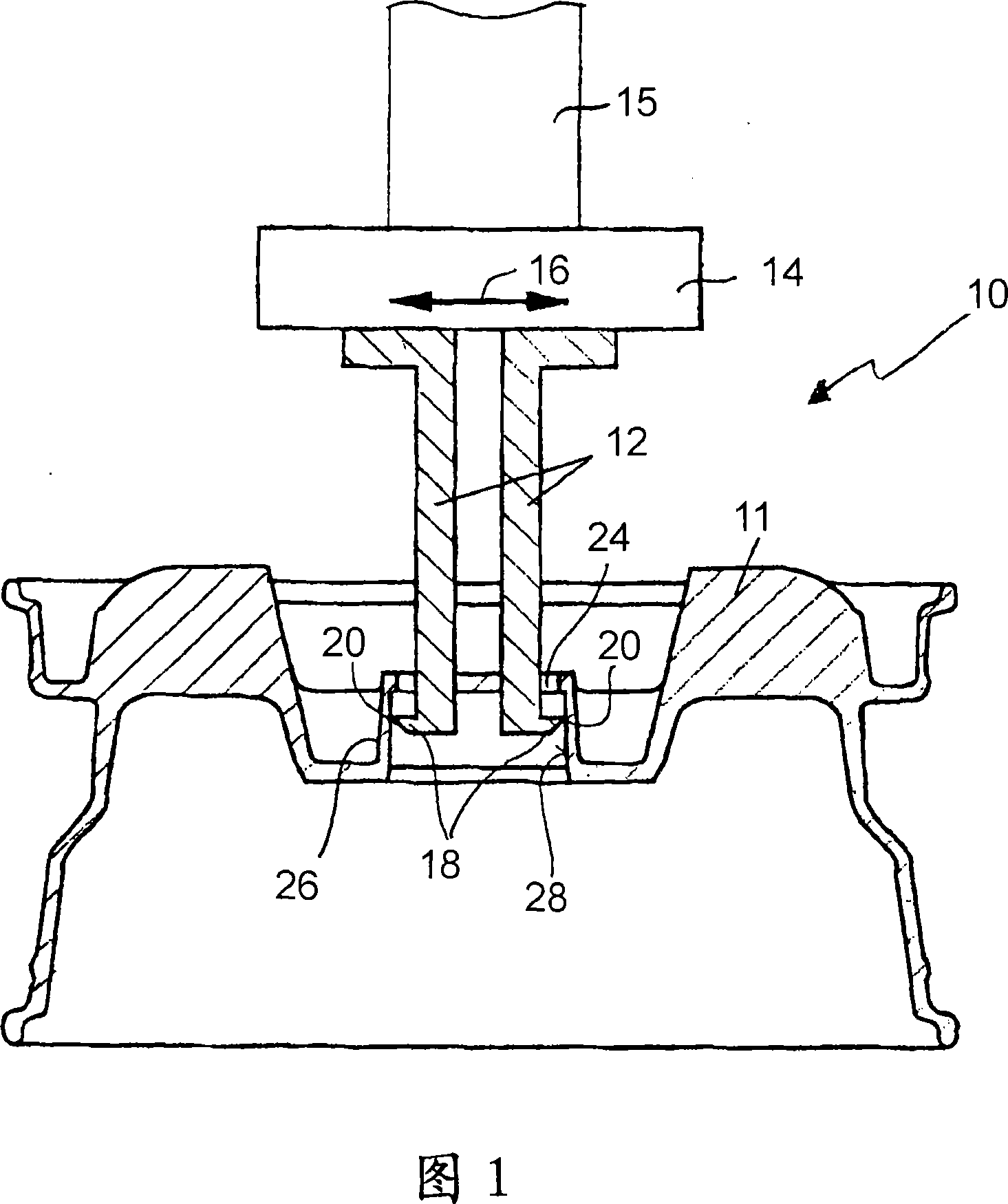

Battery module having a plurality of battery cells, method for the production thereof, and battery

ActiveUS20190044113A1Influence rate of agingDifferent rate of agingFinal product manufactureSecondary cells manufactureEngineeringLithium-ion battery

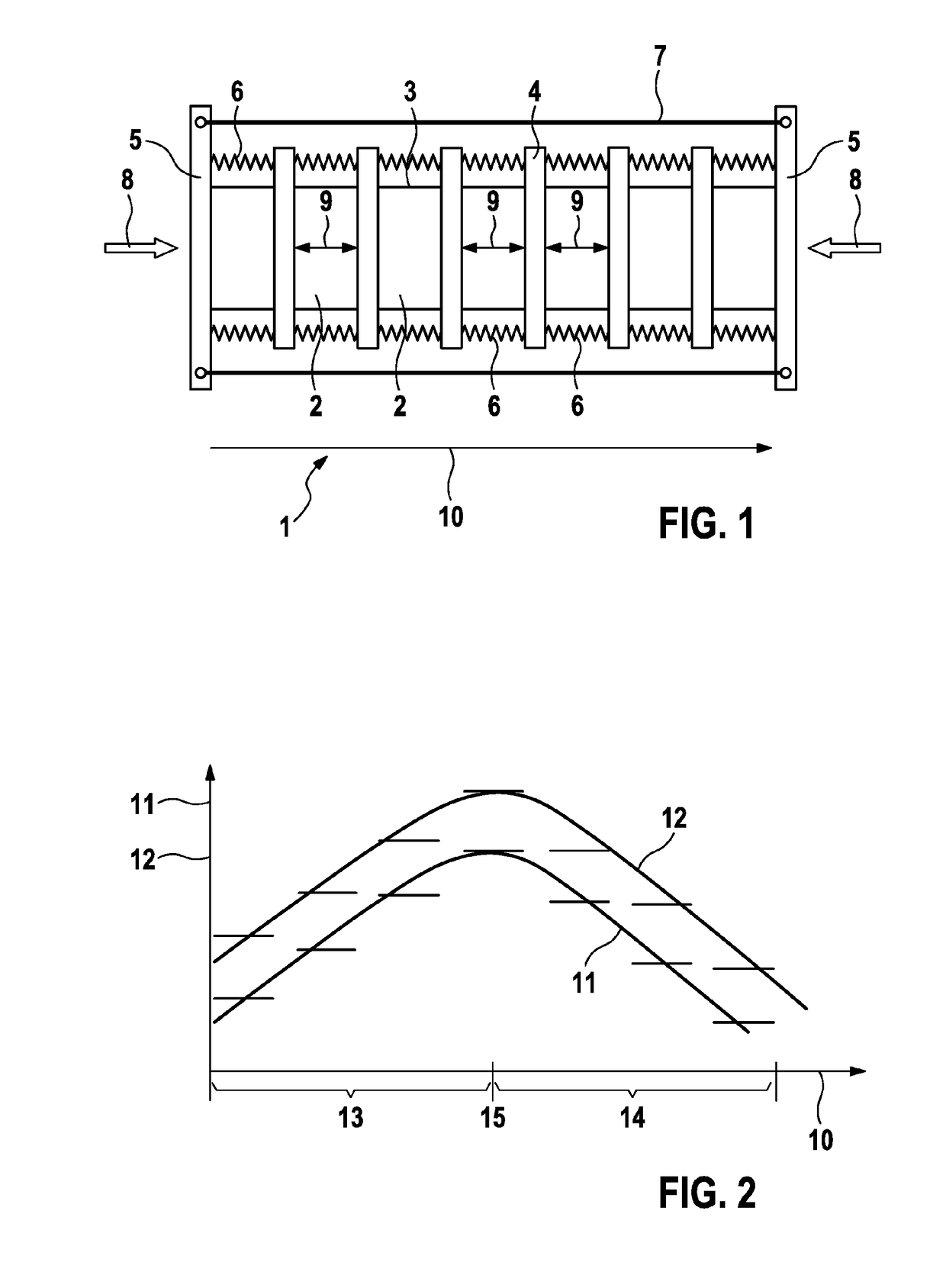

The invention relates to a battery module having a plurality of battery cells, in particular lithium-ion battery cells, having a plurality of partitions (4), wherein a battery cell (2) is arranged between two partitions (4), and a spring element (6) is furthermore arranged between two partitions (4) adjacent to a battery cell (2), in particular a tension and / or compression spring element, which is arranged in a manner contacting and / or connected to the two partitions (4) such that a value of a deformation constant (12) of the spring element (6) determines a force transmitted by the two partitions (4) to the battery cell (2).

Owner:ROBERT BOSCH GMBH

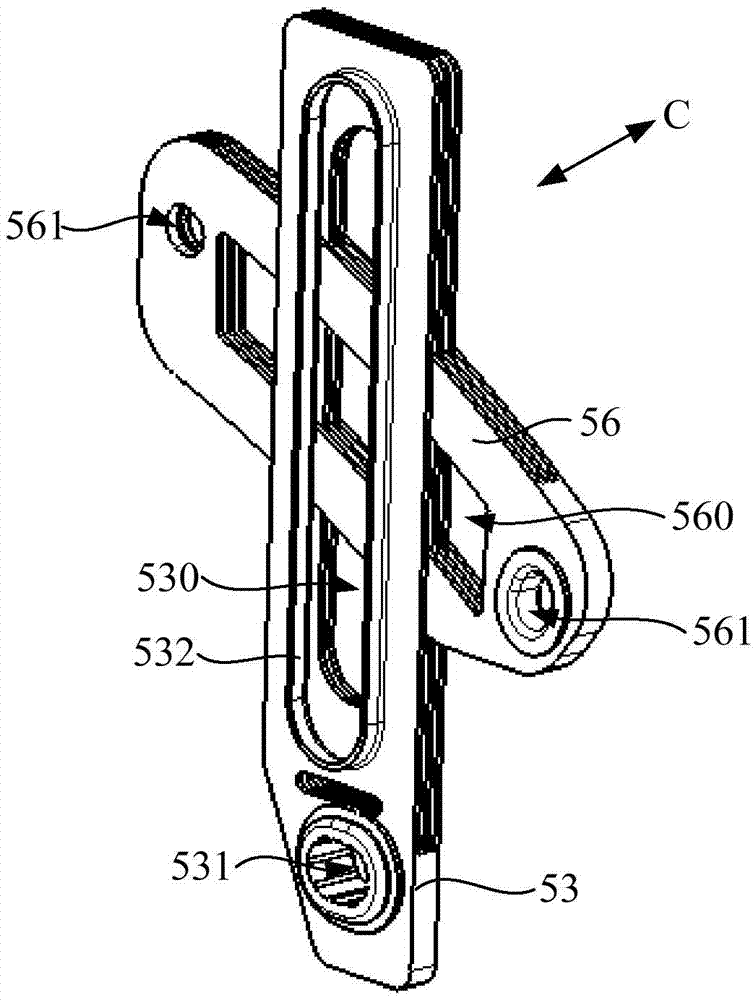

A Force-Limited Compression-Release Mechanism

ActiveCN105253331BSmall pressing forceIncrease the pressing forceCosmonautic power supply systemsEngineeringMechanical engineering

The invention discloses a force-limited compression release mechanism. The invention can realize segmental compression of large flexible solar wing sun blankets, and meet the requirements of different compression forces inside the solar blanket and solar blanket box boards. The present invention includes a pressing assembly and a base assembly, wherein the pressing assembly includes a pressing rod, a lock nut, a separation spring, a spring sheath, an escape cap and a mounting seat for the pressing rod, and the base assembly includes a pyrotechnic separation nut , Positioning guide column, force limiting screw, lock nut and separation nut mounting seat. When compressing the solar blanket, the compression rod is connected with the pyrotechnic separation nut, and the compression force is loaded through the lock nut to realize the connection between the upper and lower box plates and apply the compression load; when the internal compression load of the solar blanket reaches the required value , through the force limiting screw to prevent the compression force from being further transmitted to the sun blanket; the lock nut continues to load, and the compression force of the secondary load is transmitted to the force limiting screw to achieve a higher pre-set between the upper and lower box panels of the sun blanket Tight load requirements.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Vehicle, steering system of vehicle, and adjustable steering column of vehicle

ActiveCN106976475ALarge locking forceHigh locking reliabilitySteering columnsSteering columnSteering system

The invention relates to a vehicle, a steering system of the vehicle, and an adjustable steering column of the vehicle. The adjustable steering column comprises a mounting support, an upper column tube and a locking and releasing control assembly, wherein the mounting support is used for being fixed to a vehicle body and is provided with clamping arms which are provided with first through holes; a fixing support is fixedly arranged on the outer wall of the upper column tube, used for being fixed to the clamping arms and provided with second through holes; the locking and releasing control assembly comprises a supporting rod penetrating through the first through holes and the second through holes, first adjusting pieces, second adjusting pieces, first friction pieces and limiting pieces, and the supporting rod is sequentially sleeved with the first adjusting pieces, the second adjusting pieces, the first friction pieces and the limiting pieces in the axial direction; the first adjusting pieces are fixed to the supporting rod, the supporting rod is sleeved with the second adjusting pieces and the first friction pieces in a spaced mode, the first friction pieces are provided with third through holes where the supporting rod can penetrate, and the limiting pieces are static relative to the supporting rod in the axial direction; and the clamping arms and the fixing support are oppositely arranged in the axial direction and located between the first friction pieces and the limiting pieces in the axial direction. Locking force of the adjustable steering column in the locked state is increased, and locking reliability of the steering column is improved.

Owner:SAIC MOTOR

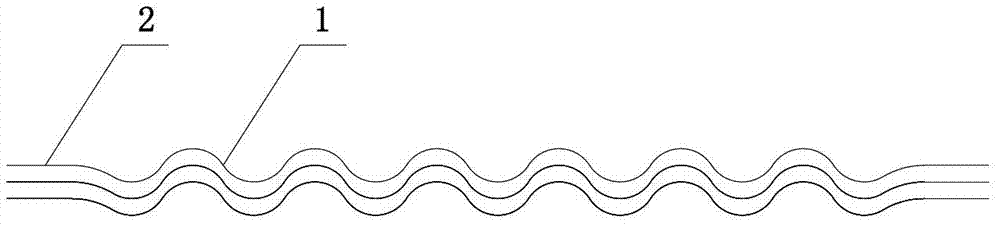

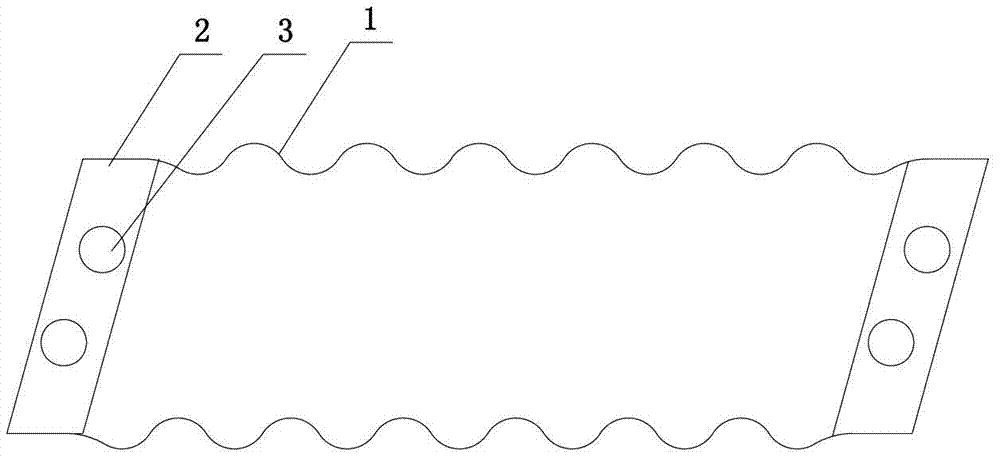

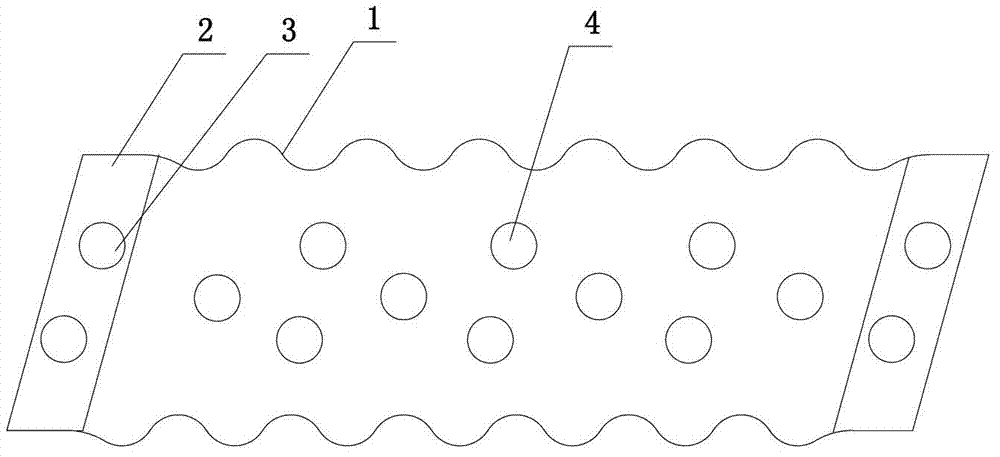

Structure and method for conductive connection between copper materials or between copper material and other components

InactiveCN102738600AFully contactedClosely connectedLine/current collector detailsClamped/spring connectionsState of artWave shape

The invention relates to a connection technology between copper materials or between a copper material and other components, in particular to a structure and method for conductive connection between copper materials or between a copper material and other components. A multi-layer copper foil flexible connection structure is connected between the copper materials or between the copper material and other components, the copper foil flexible connection structure is a multi-layer structure formed by superposing wave-shaped or snake-shaped or unfolded spiral copper foil strips, the middle wave-shaped or snake-shaped or unfolded spiral copper foil strips are in a free layering state, and two ends of the wave-shaped or snake-shaped or unfolded spiral copper foil strips of the multi-layer structure are directly connected to the copper materials or other components. The structure and method for conductive connection disclosed by the invention solve the problems of unsatisfactory conductive performance, low reliability and the like of the prior art, the copper foil flexible connection which has a simple structure and high reliability and is convenient to maintain is adopted, and the conductive connection structure not only has a good conductive performance, but also has good heat compensation ability and a vibration isolation effect.

Owner:江西九星铜业有限公司

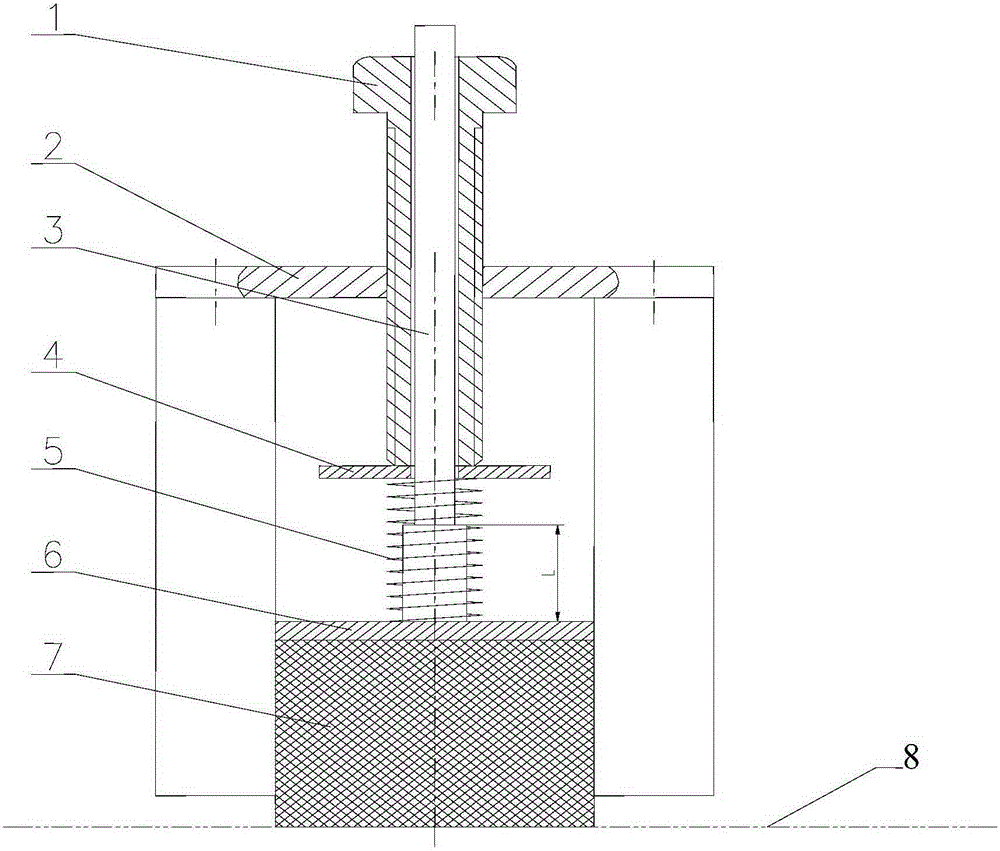

Sealing device capable of automatically compensating abrasion loss

ActiveCN106594282APrevent overcompressionPlay a protective effectEngine sealsEngineeringSelf locking

The invention relates to a sealing device, in particular to a sealing device capable of automatically compensating the abrasion loss. According to the sealing device capable of automatically compensating the abrasion loss, an adjusting screw rod and a sealing box of the sealing device are in screw-thread fit connection, the lower end of the adjusting screw rod abuts against the upper surface of a gasket, the lower surface of the gasket compresses an elastic medium, the lower end of an indicator rod and the upper surface of a pressing plate are fixedly connected, meanwhile, the indicator rod sequentially penetrates the elastic medium, the gasket and a through hole in the middle of the adjusting screw rod, the upper end of the indicator rod is arranged outside the upper end of the adjusting screw rod in a protruding manner, the lower end of the elastic medium compresses the upper surface of the pressing plate, the lower surface of the pressing plate compresses sealing stuffing, and the sealing stuffing and the equipment surface are in close fit connection. According to the technical scheme, the self-locking screw rod and a creative structure with the indicator rod and a spring matched are adopted, and the sealing device is a novel sealing device which is simple in structure, reliable to use, low in machining cost, small in maintenance workload, long in sealing stuffing replacement period and high in utilization rate.

Owner:NANJING KISEN INT ENG

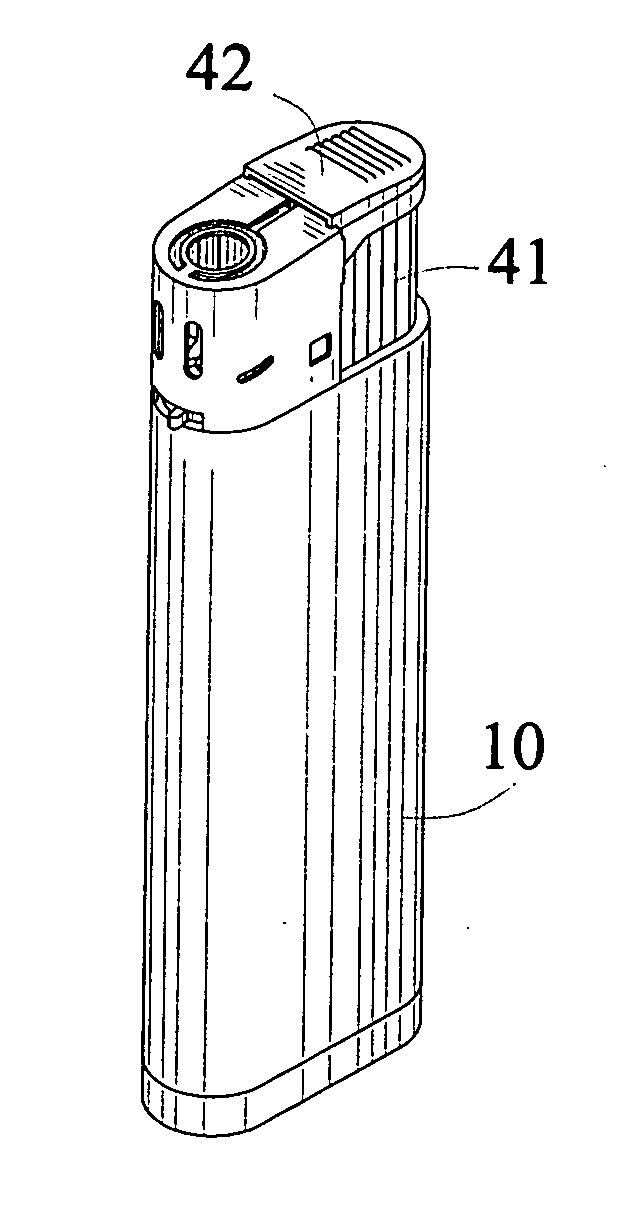

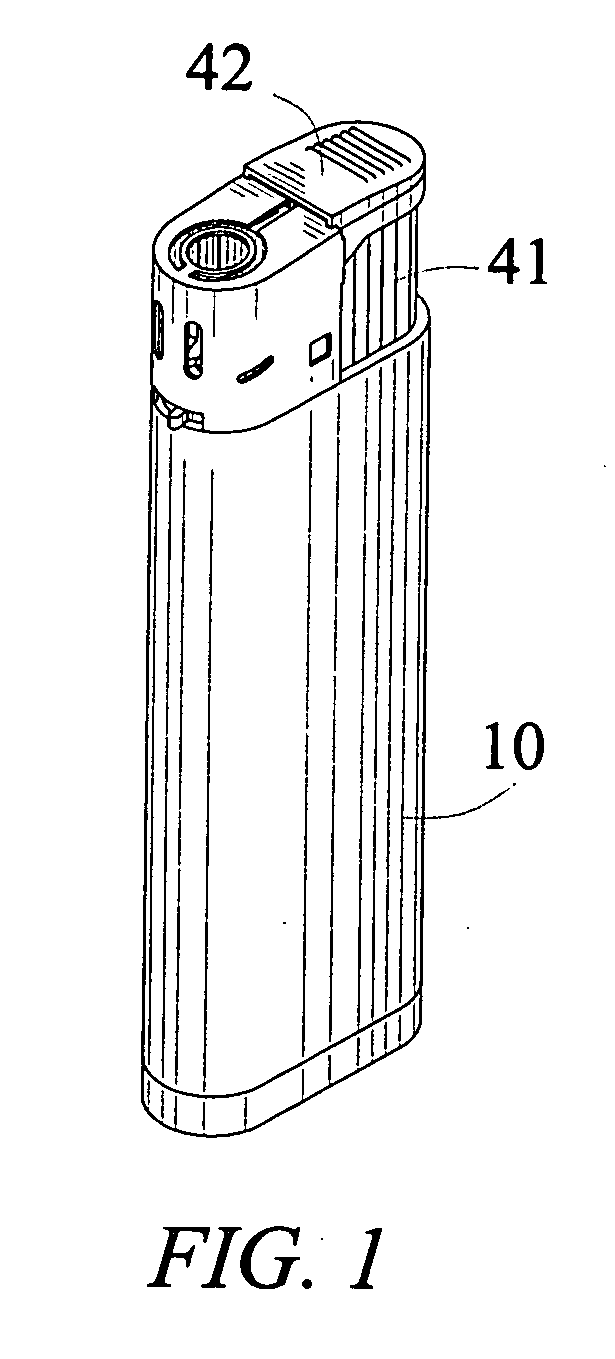

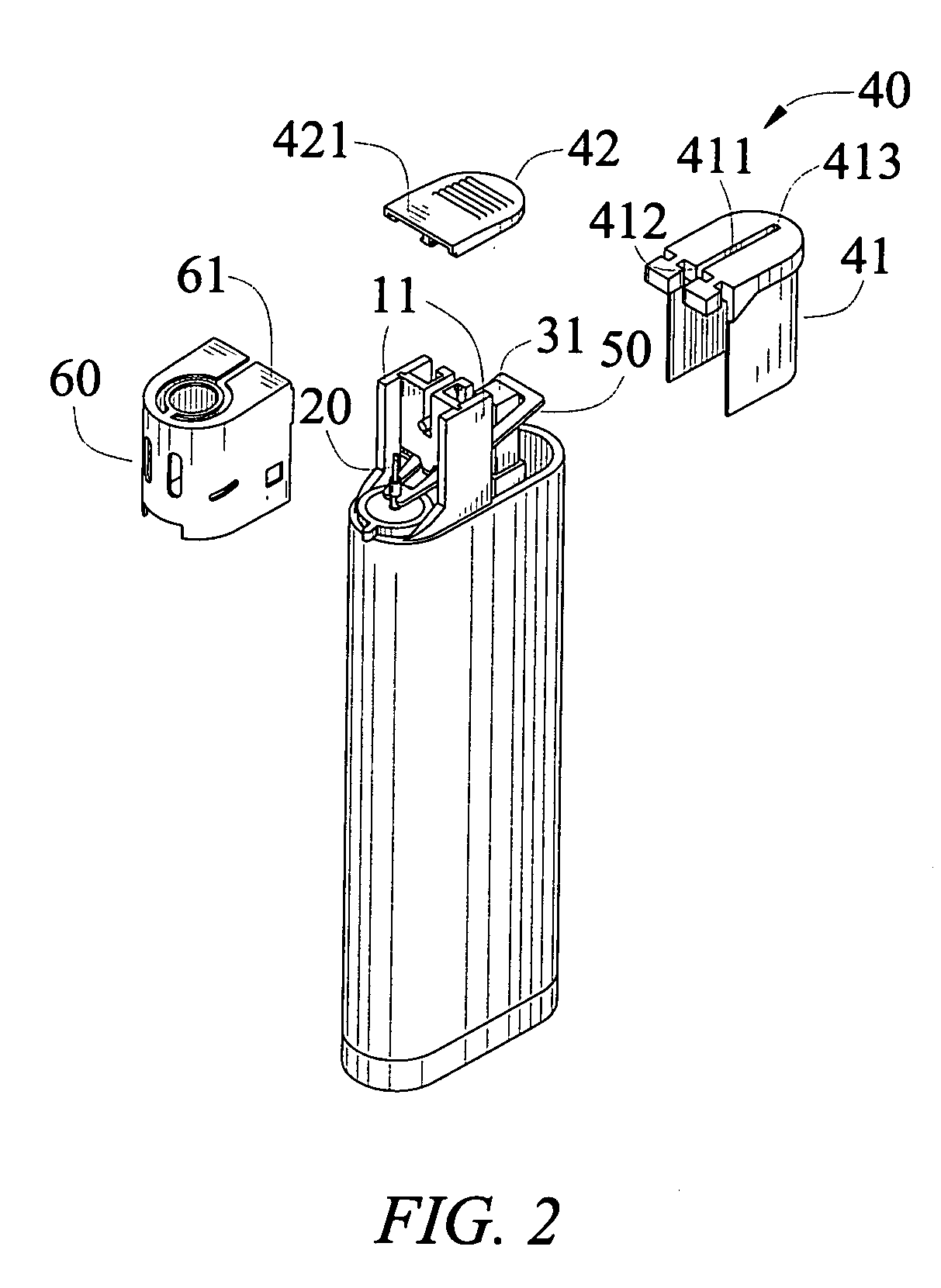

Child resistant gas lighter

InactiveUS20110091825A1Safer for childDifficult to understandIncandescent ignitionFuel lightersEngineeringMechanical engineering

The child resistant gas lighter of the invention has an ignition sleeve having a slit defined therein and an integrated safety cap having a press surface, an opposite slide surface, a direction bar formed on the slide surface which is inserted in the slit and is able to make the safety cap slidable in the slit. In use, a user has to move the safety cap against a bias spring by his thumb until the safety cap is no longer blocked by a top surface of a flame cover and then press down the safety cap. The invention is hard for children to get understand how to ignition thus making it safer for children, and needs a smaller pressing force thus making the gas lighter more adult user friendly without sacrificing child resistance.

Owner:HUANG XINHUA

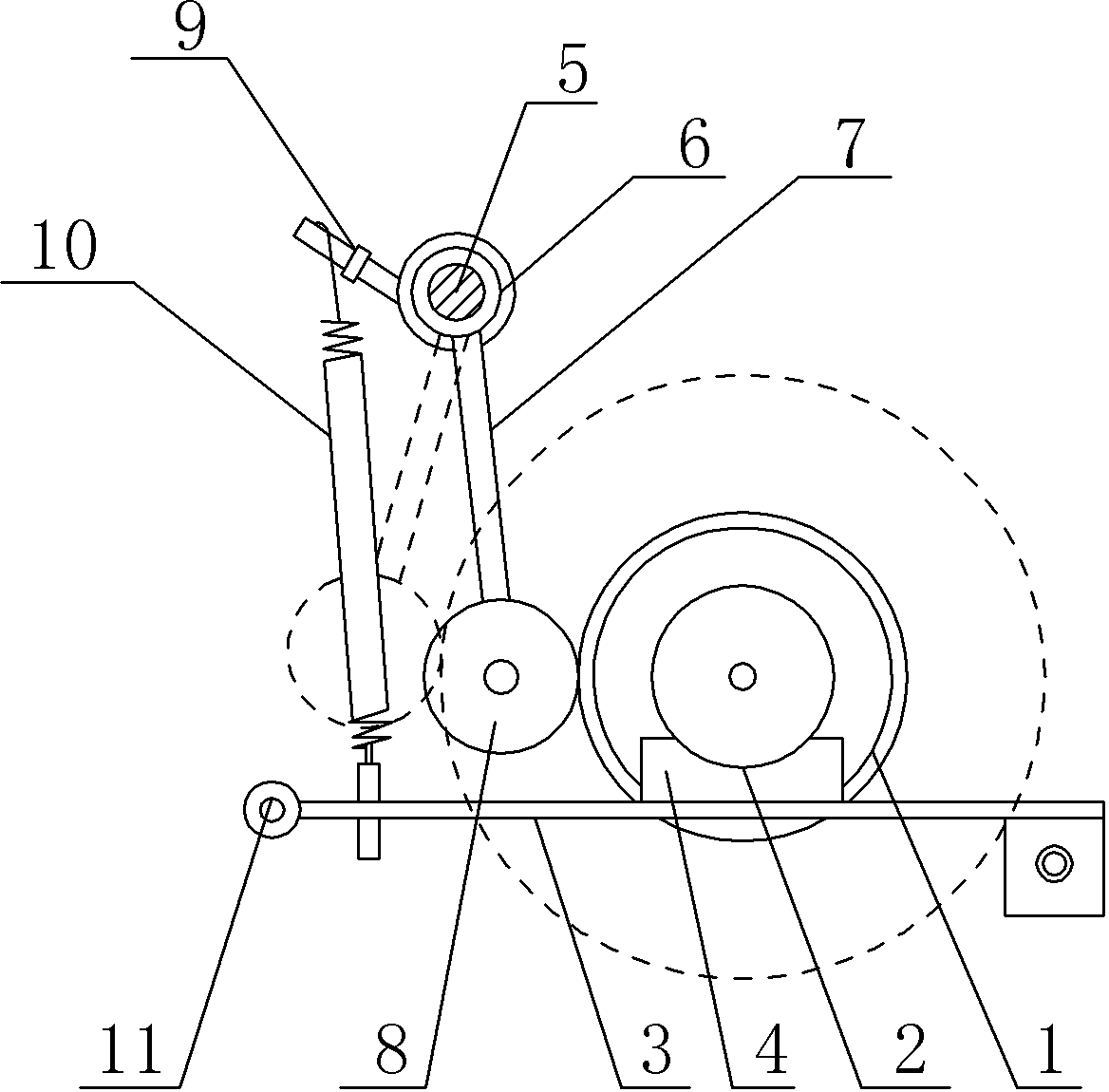

Self-adjusting type thin film rolling mechanism

The invention belongs to the technical field of packaging machines, and relates to a self-adjusting type thin film rolling mechanism. The self-adjusting type thin film rolling mechanism comprises a machine frame provided with a discharging roller and a storage roller, wherein the discharging roller provided with a thin film in a rolling mode, and the discharging roller and the storage roller are tightened through the thin film. The self-adjusting type thin film rolling mechanism is characterized in that the discharging roller is coaxially provided with a friction wheel, a flat plate is hinged to the part, below the friction wheel, of the machine frame, a wheel yoke is installed at the position, opposite to the friction wheel, of the flat plate, and a balance weight is fixed to the free end of the flat plate. A supporting axle is arranged at the position, above the discharging roller, of the machine frame, the supporting axle is provided with a rotary table in a sliding fit mode, the rotary table is connected with a wheel pressing rod, and a pressing wheel connected with the tail end of the wheel pressing rod presses a thin film face of the discharging roller. A threaded rod is connected to the rotary table, a spring rod is hung on the threaded rod, and the lower end of the spring rod is connected with the free end of the flat plate. The speed for unrolling the thin film can be adjusted according to thin film faces with different thicknesses.

Owner:CHONGQING RUITING PLASTIC

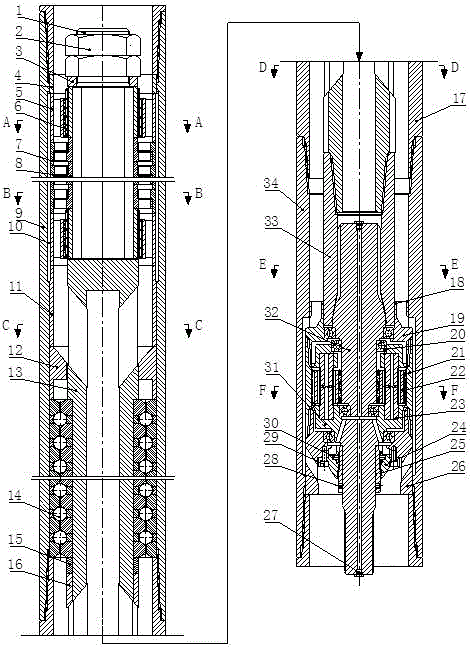

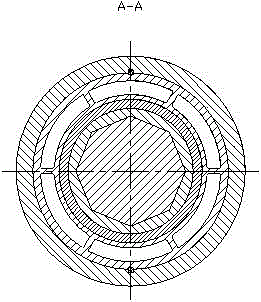

Novel turbodrill capable of achieving accurate positioning of stator and rotor

ActiveCN105257210AStable structurePrevent circular motionHydro energy generationBorehole drivesThrust bearingReducer

The invention discloses a novel turbodrill capable of achieving accurate positioning of a stator and a rotor. The novel turbodrill is applied to the fields of petroleum drilling, mining, geological drilling and the like and solves the problem that the hydraulic performance of turbine sections is low when the turbodrill works. According to the technical scheme, the turbine stator is fixedly installed on a turbine shaft through a screw and a fastening nut, and the inner wall of a shell and the outer wall of each stage of a stator sleeve are provided with two symmetric key grooves to position the turbine stator in a flat key mode; the turbine shaft and a rotor sleeve are both machined to be regular octagon structures which are mutually matched; a thrust bearing set is installed on the middle-back section of the turbine shaft; a planetary gear reducer is arranged in a lower shell. According to the novel turbodrill, by means of the two methods that the turbine rotor and the turbine stator are fixed in the circumferential direction, it is guaranteed that the stator and the rotor cannot relatively rotate separately and precise circumferential positioning of the stator and the rotor can be achieved, therefore, the hydraulic performance of the turbodrill is improved, and meanwhile the cost is lowered.

Owner:泰州市海通资产管理有限公司

Contact device for cone ring transmission

InactiveCN101131200ASmall pressing forceConvenient oil supplyGearing controlFriction gearingsEngineeringMechanical press

Owner:GETRAG FORD TRANSMISSIONS GMBH

Handling device for handling a motor vehicle rim in a surface treatment installation

ActiveCN101189072AWon't causeSmall pressing forceLiquid surface applicatorsSpraying apparatusMechanical engineeringAutomotive engineering

A handling device for handling a motor vehicle rim in an installation for its surface treatment has at least one gripping arm which can be inserted into a hub of the rim and carries at least one pressure element which can be pressed against an inner surface of the hub. According to the invention, the at least one pressure element is designed as a cutting edge or as a pointed peg.

Owner:艾森曼机械设备上海有限公司

Multilayered electrical flat conductor

InactiveCN101111980AEasy to fixSmall pressing forceLine/current collector detailsCable fittings in presence of gas/oilElectricityEngineering

Owner:AUTO KABEL MANAGEMENTGMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com