Handling device for handling a motor vehicle rim in a surface treatment installation

An operating device and surface treatment technology, which can be applied to devices for applying liquid to surfaces, spray devices, coatings, etc., which can solve the problems of rim waste and expensive post-processing of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

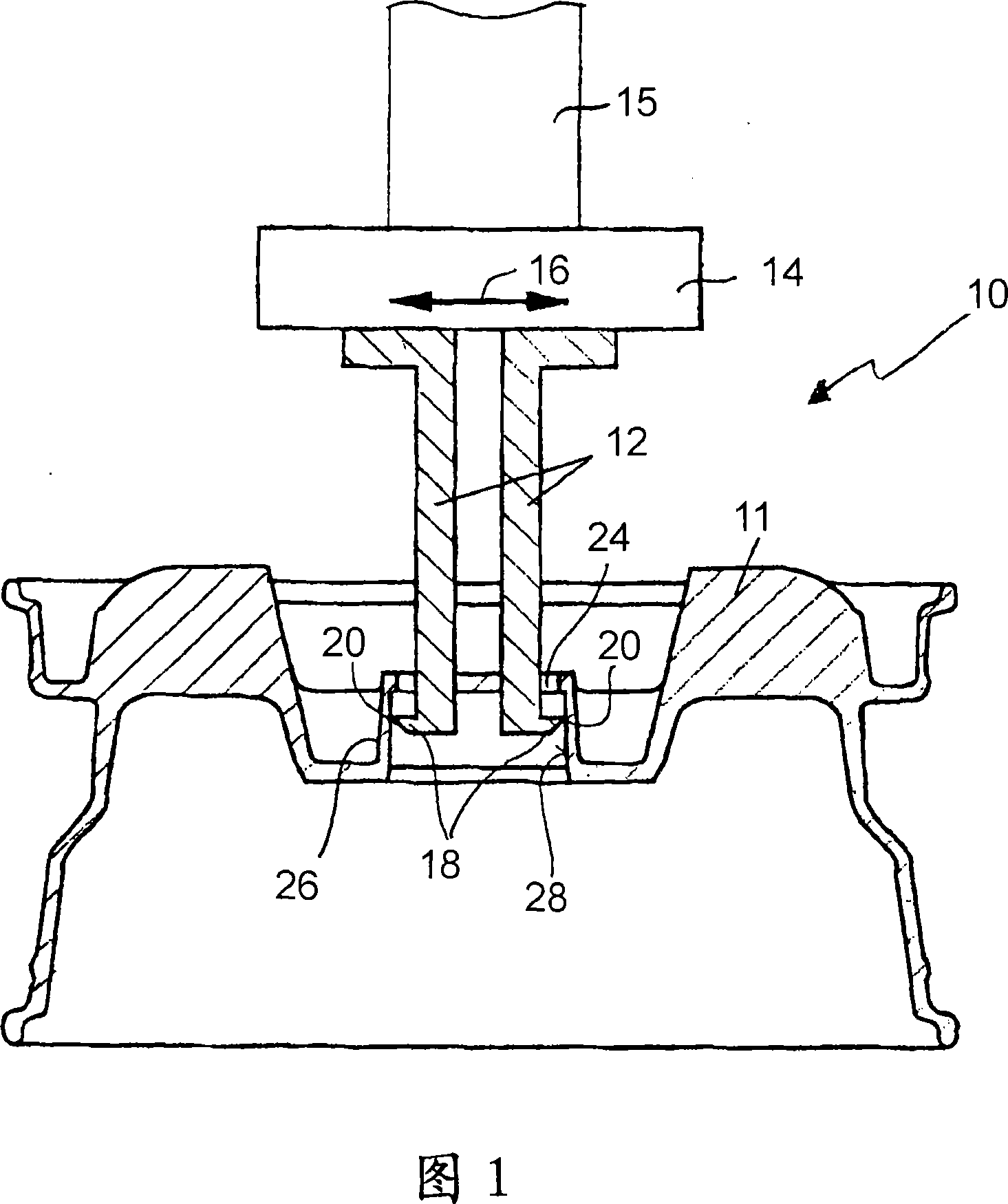

[0016] An exemplary embodiment of the invention will be described below with reference to the single drawing, which shows the main components of an operating device 10 according to the invention for operating a light metal rim 11 in an axial section. The handling device 10 is part of a device for processing the surface of a light metal rim. The task of the handling device 10 here is, for example, to transfer the light metal rim 11 from the coating conveyor to the baking conveyor.

[0017] The handling device 10 has two gripping arms 12 which can be moved relative to each other in the direction indicated by the arrow 16 by means of a drive shown at 14 . The drive device 14 is connected to the manipulator of the handling device 10 , shown at 15 in the figure.

[0018] A knife-edge-shaped pressing element 18 is arranged on the gripping arm 12 at the opposite end of the drive device 14 . The pressing element 18 has a circular arc-shaped outer circumference in a plane perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com