Patents

Literature

38results about How to "Moderate peel strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based paper and plastic laminating/peelable adhesive and method for manufacturing same

InactiveCN103421461AGood adhesionAdhesivelyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWaxWater based

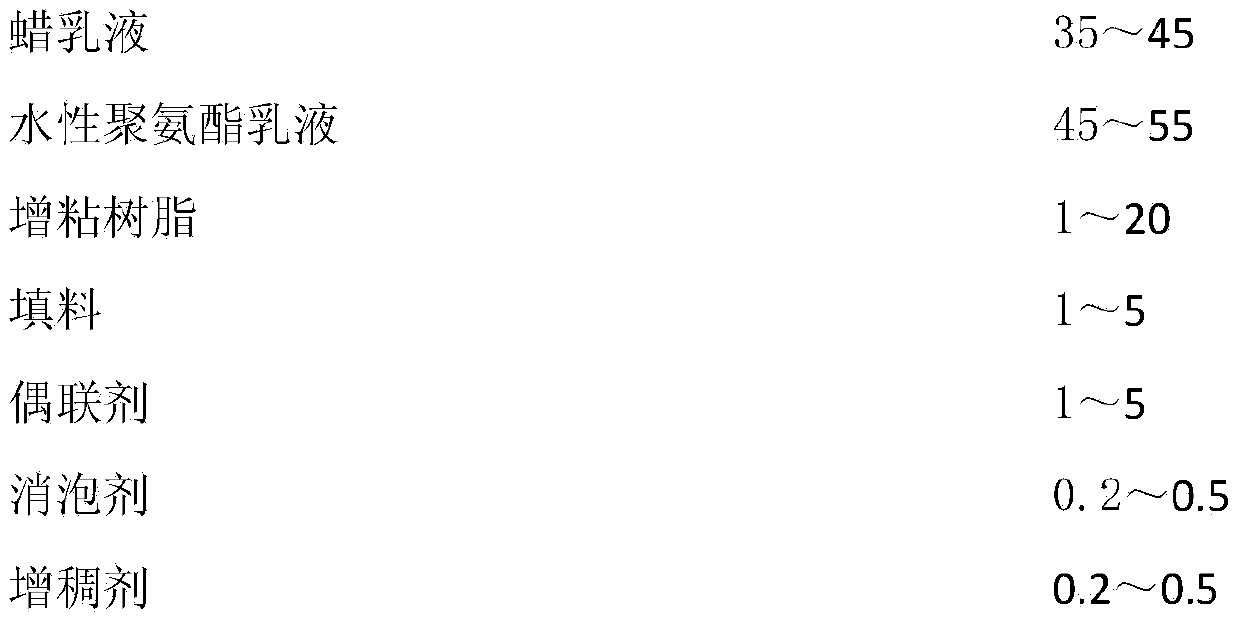

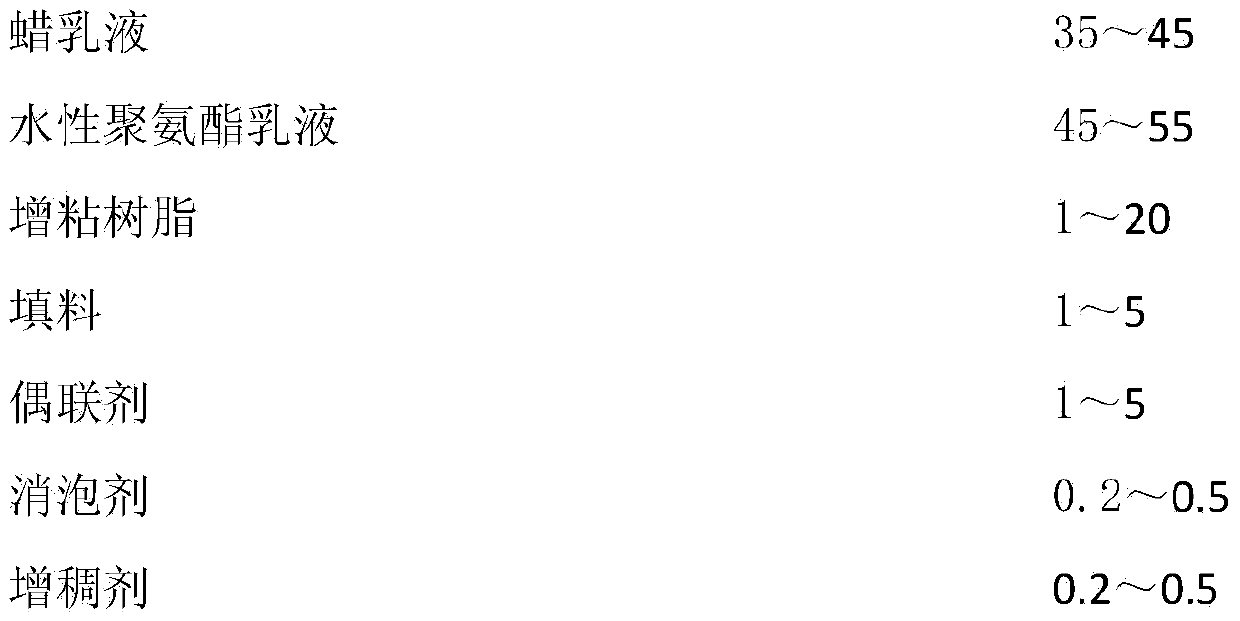

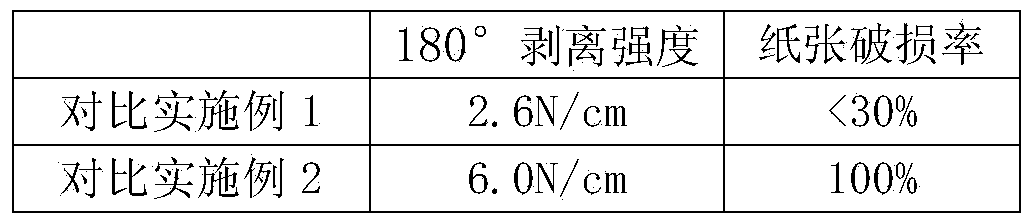

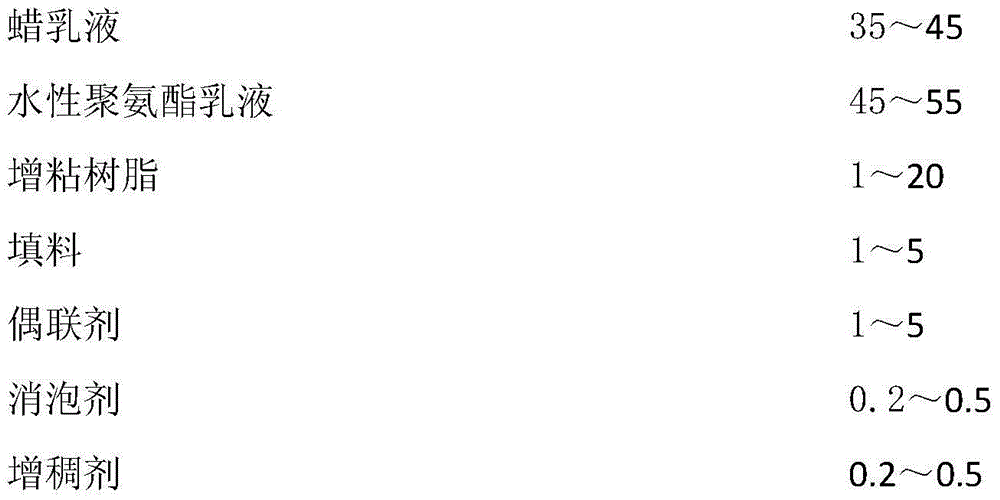

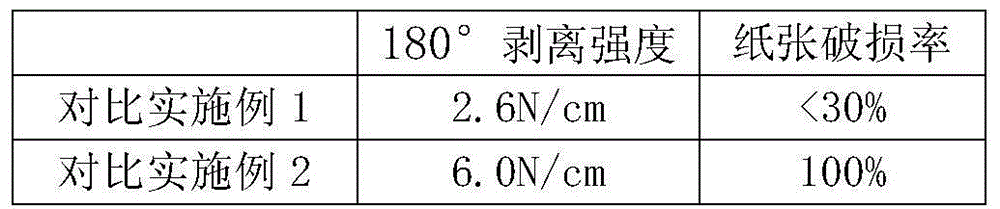

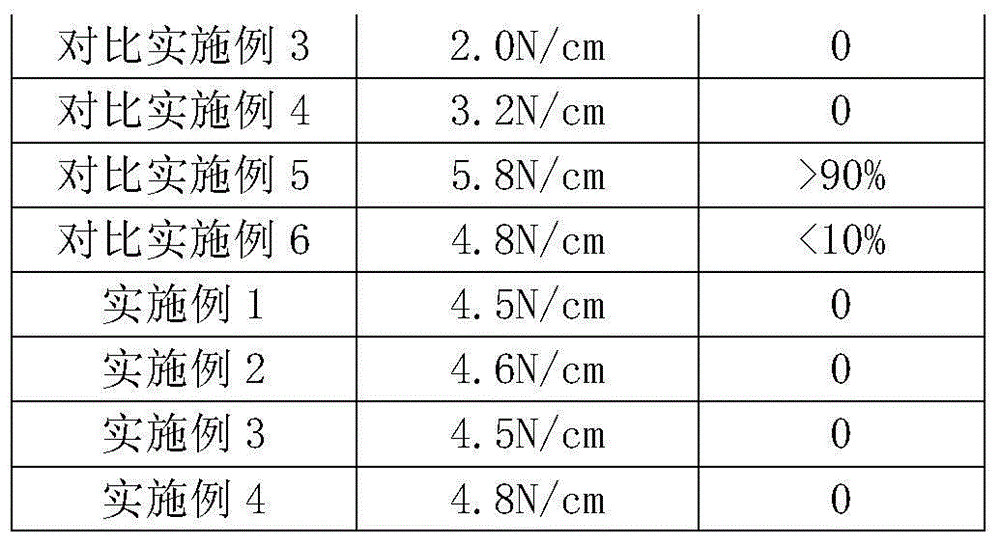

The invention discloses water-based paper and plastic laminating / peelable adhesive and a method for manufacturing the same. The water-based paper and plastic laminating / peelable adhesive comprises, by mass, 35-45 parts of wax emulsion, 45-55 parts of water-based polyurethane emulsion, 1-20 parts of tackifying resin, 1-5 parts of additives, 1-5 parts of coupling agents, 0.2-0.5 part of defoamers and 0.2-0.5 part of thickeners. The water-based paper and plastic laminating / peelable adhesive and the method have the advantages that the wax emulsion, the water-based polyurethane emulsion, the additives, the tackifying resin, the coupling agents, the thickeners and the defoamers are compounded with one another to finally manufacture the water-based paper and plastic laminating / peelable adhesive, the water-based paper and plastic laminating / peelable adhesive is high-temperature-resistant and is high in initial adhesion, permanent adhesion and peel strength when used for laminating paper and plastics, the paper cannot be torn by an adhesion surface of a film when separated from the plastics, and is prevented from being damaged, and the adhesion surface is not sticky after the paper is separated from the plastics.

Owner:SOUTH CHINA UNIV OF TECH

Masking tape containing printing layer and preparation method thereof

ActiveCN103725222AOvercome affinityProduction process is environmentally friendlyNon-fibrous pulp additionFilm/foil adhesivesWater basedEmulsion

The invention discloses a masking tape containing a printing layer and a preparation method thereof. The masking tape comprises a substrate, wherein one side of the substrate is provided with an adhesive layer, and the other side of the substrate is sequentially provided with a printing layer and a release layer; the substrate is masking tape base paper impregnated by a hydroxy butadiene-styrene emulsion; the printing layer is a water-based ink; the adhesive layer is a water-based acrylate pressure-sensitive adhesive; and the release layer is a water-based release agent. All the raw materials are water-based materials, and thus, the production technique is environment-friendly; and the product has the advantages of stable performance, long shelf life, low production cost and high added value.

Owner:广州市白云区麒胜装饰材料厂有限公司

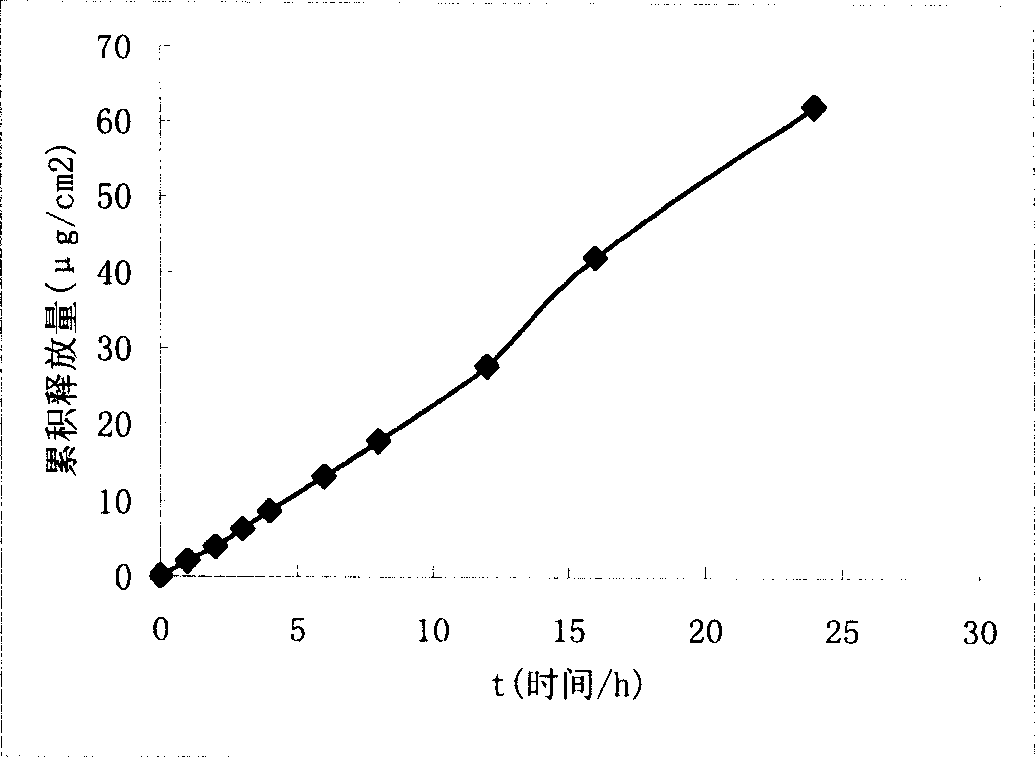

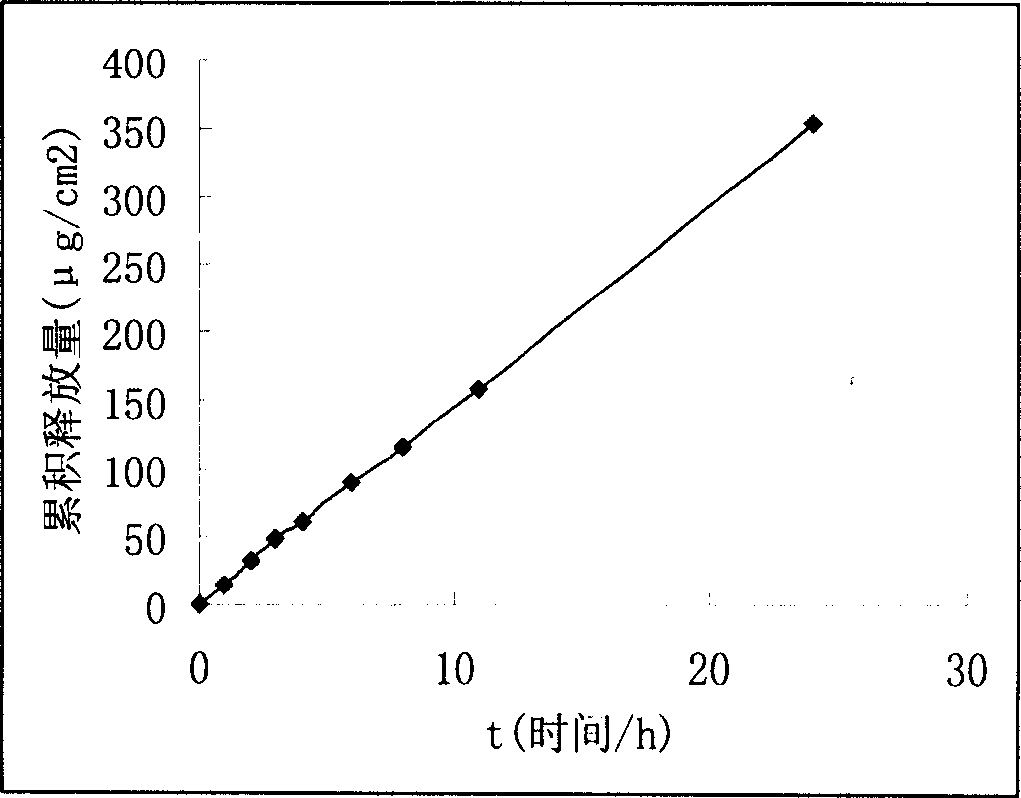

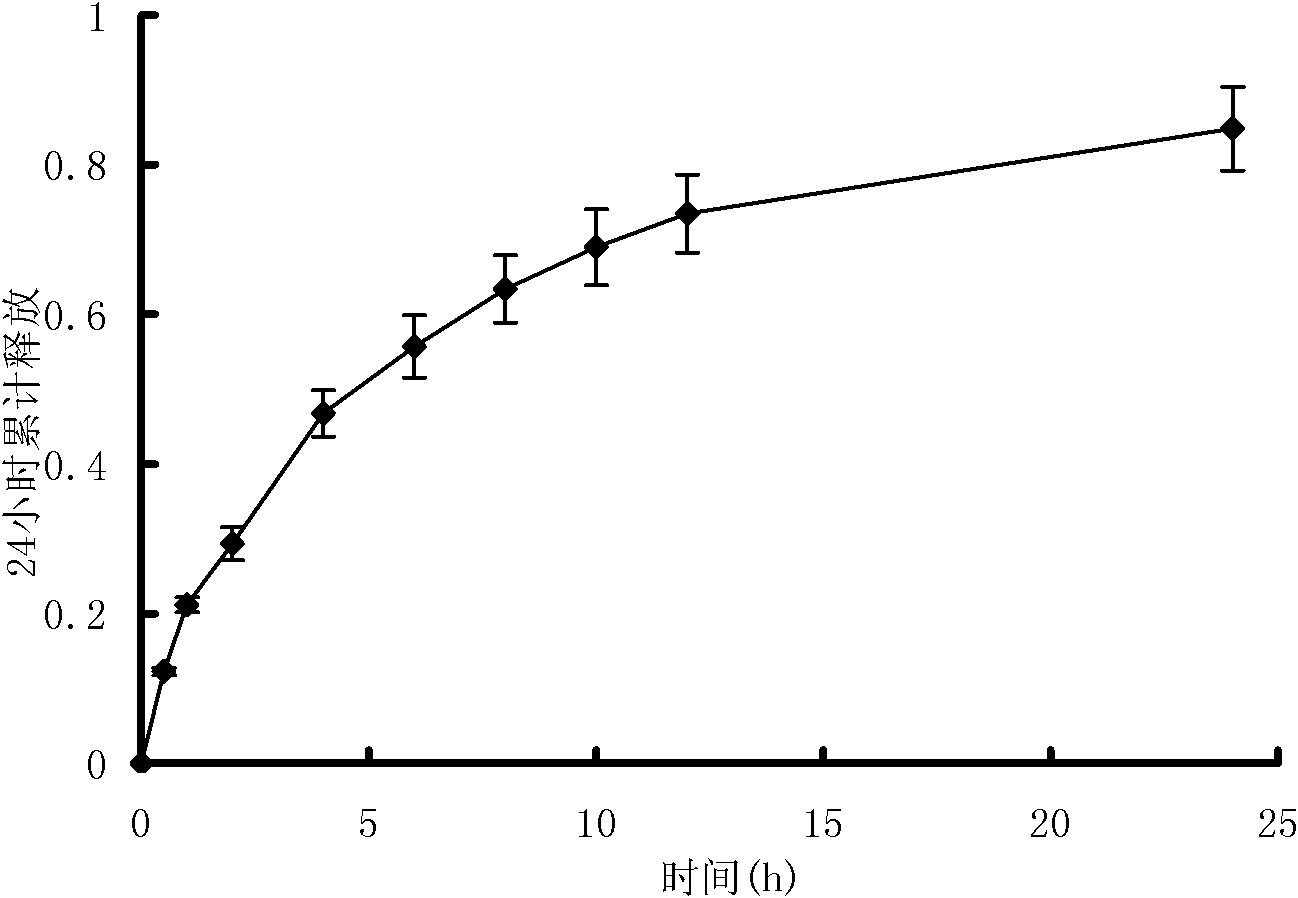

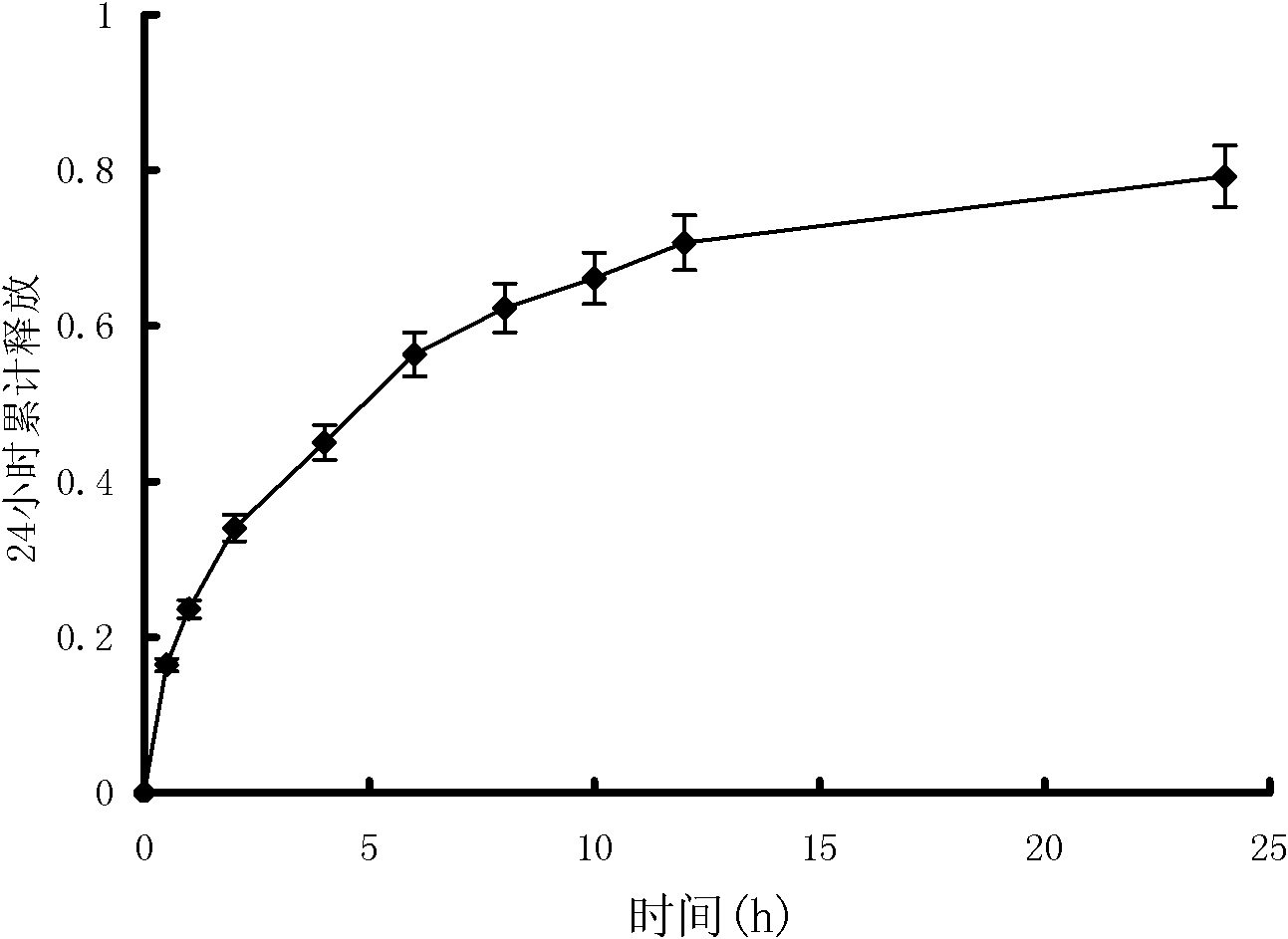

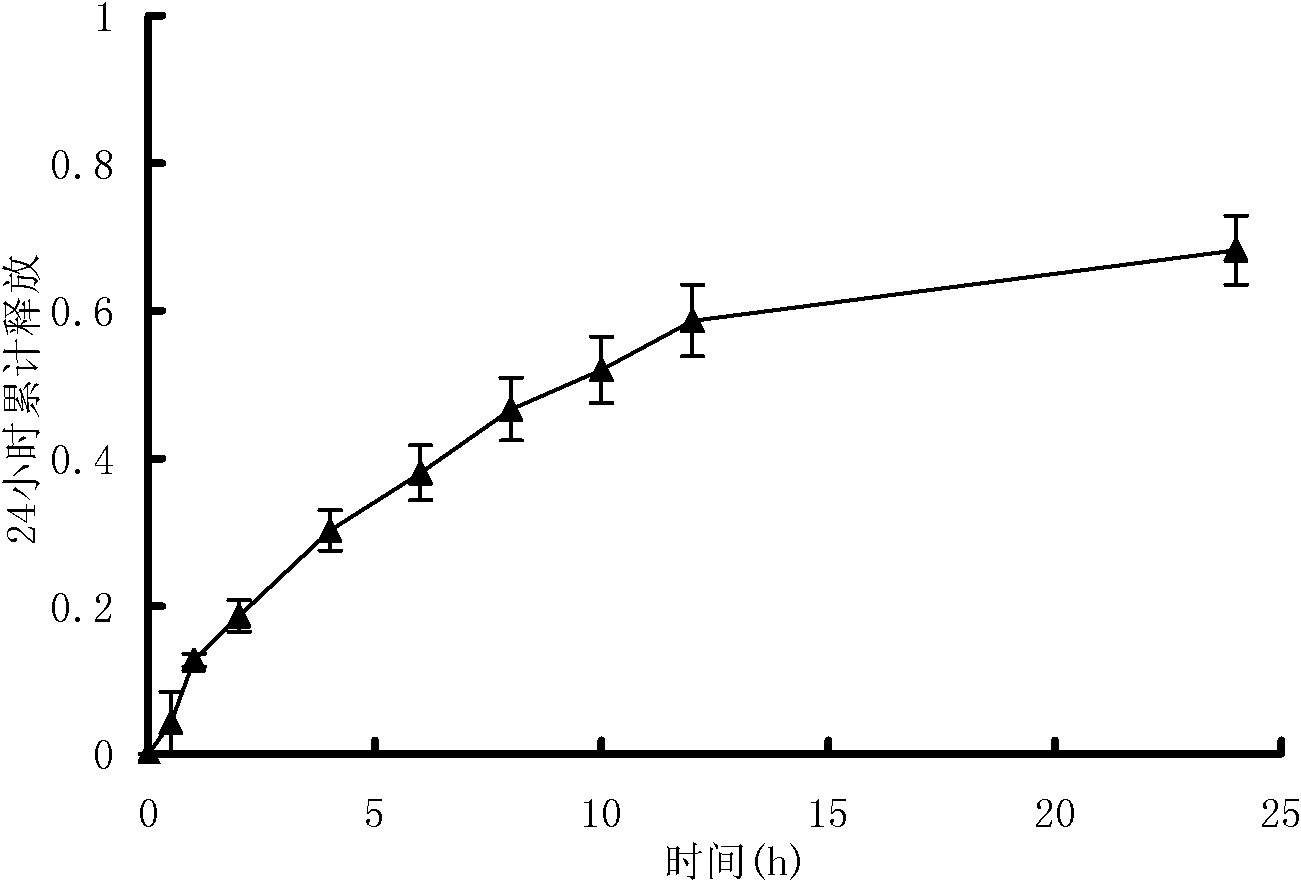

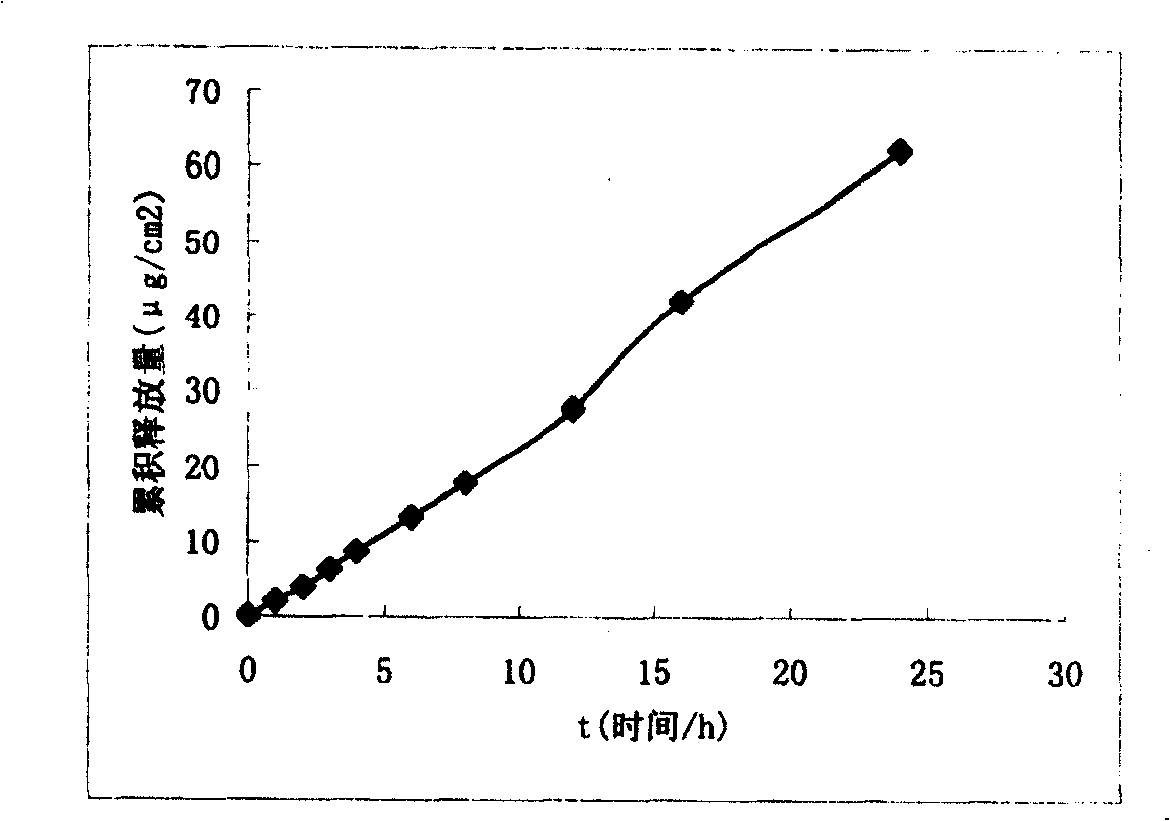

Aquogel type thiamazole plaster preparation

InactiveCN1857261AImprove cohesive strengthGood cross-linking effectOrganic active ingredientsPharmaceutical non-active ingredientsUse medicationSide effect

The aquogel type thiamazole plaster includes a back lining layer, a medicine matrix layer and a protecting film. The medicine matrix layer contains medicine thiamazole in 0.2-20 wt% of the medicine matrix layer, aquogel type contact adhesive material, cross-linking agent, pH regulator, humectant, tackifier medicine, transdermal promoter and water, . The present invention has high transdermal effect of medicine, good skin compatibility, high air and moisture permeability, lowered toxicity and side effect of medicine and other advantages, and is used for treating hyperthyroidism.

Owner:HUAZHONG UNIV OF SCI & TECH +1

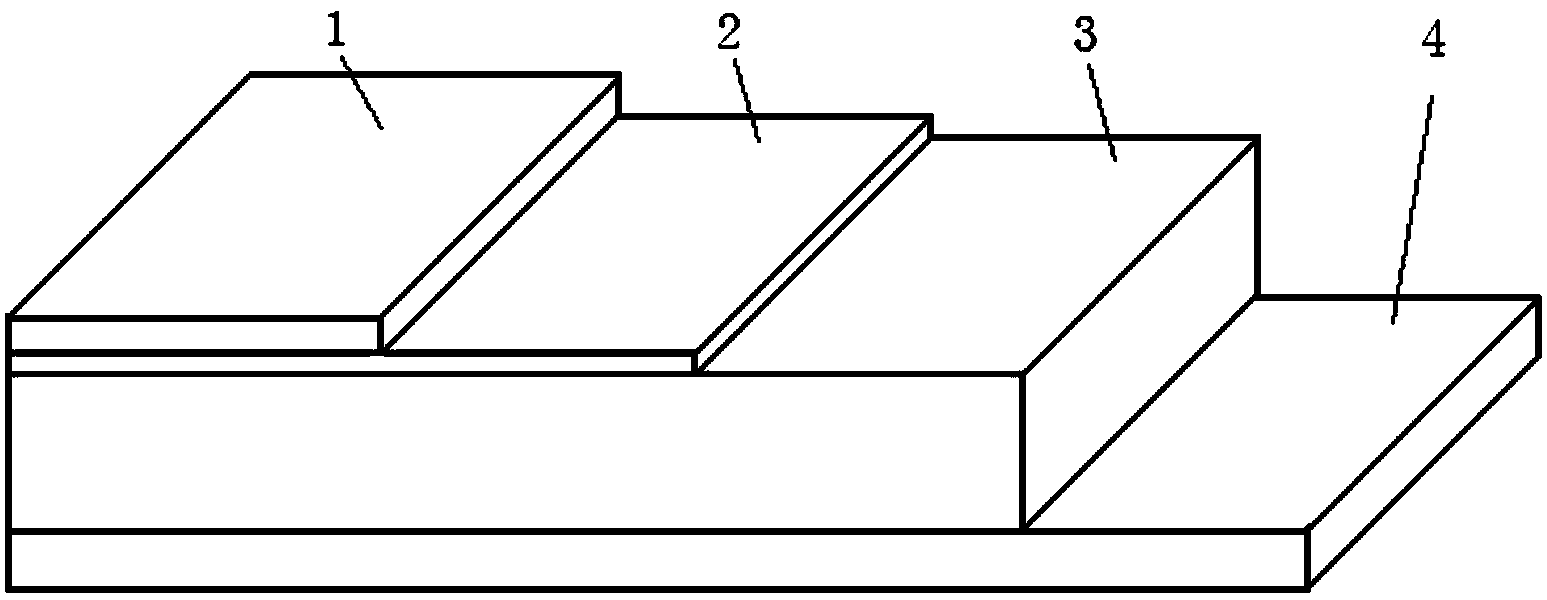

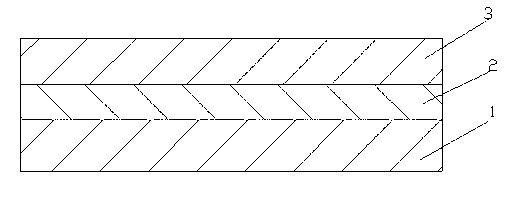

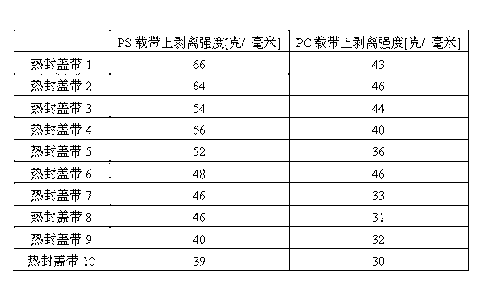

Heat seal cover tape and preparation method of heat seal cover tape

InactiveCN103273714ASimple production processLow requirements for production equipmentSynthetic resin layered productsPolyethylene glycolPolystyrene

The invention discloses a heat seal cover tape and a preparation method of the heat seal cover tape, belonging to the package field of electronic parts and components. A bottom coating is arranged above a base material film layer of the heat seal cover tape; a heat seal layer is arranged above the bottom coating; and the heat seal cover tape is prepared by coating through a coating machine. According to the heat seal cover tape, the production technology is simple and the requirement on production equipment is low. The heat seal cover tape has excellent heat seal property, proper peel strength, even peeling force, high light transmittance, anti-bonding property, high temperature resistance, high humidity resistance, anti-aging performance and enough tensile strength. The heat seal cover tape is suitable for being arranged on a carrier tape made from polystyrene, polycarbonate, polyethylene glycol terephthalate plastic and the like in a way of heat seal. According to the heat seal cover tape and the preparation method of the heat seal cover tape, the problems that the product has dependence on import, high in price and the like can be solved.

Owner:JINGJIANG RUITAI ELECTRIC MATERIAL

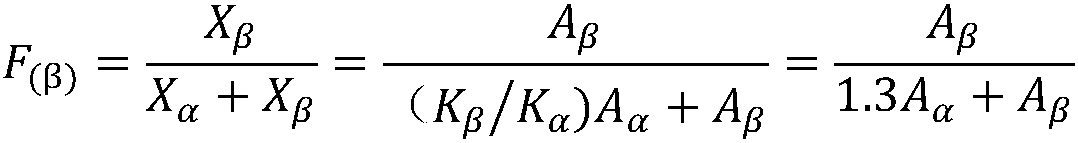

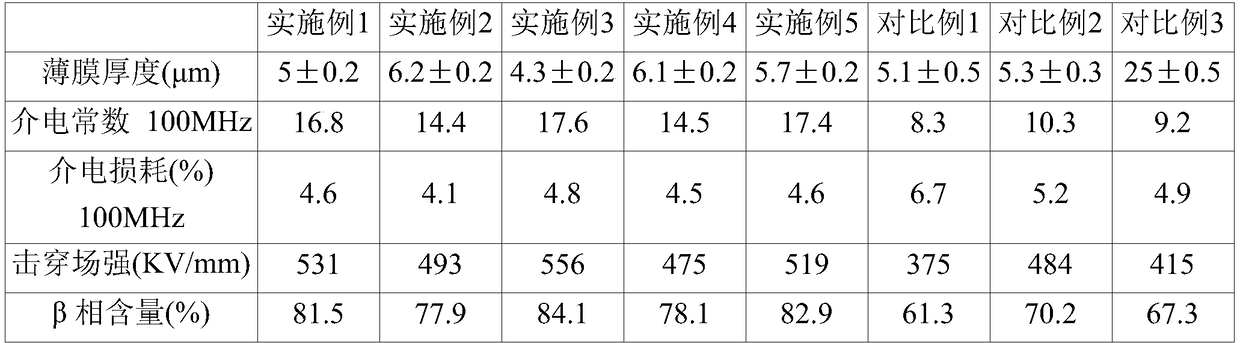

Preparation method for polyvinylidene fluoride dielectric film

The invention discloses a preparation method for a polyvinylidene fluoride dielectric film. The preparation method comprises the following steps: 1) preparation of a film casting solution, adding polyvinylidene fluoride resin into an organic solvent, heating, stirring and dissolving, thereby obtaining the film casting solution; 2) and preparation of the film: coating a base material with the filmcasting solution through a coater, entering a three-section oven to dry, entering a water slot to quench after drying, stripping through stripping stick, annealing after oriented thermal stretching, and rolling, thereby obtaining a film product. The preparation method disclosed by the invention selects flexible high-temperature-resistant materials such as surface-treated aluminum foil and a polyester film as coating base materials, adopts a process treatment method integrating melting-quenching and stretching-annealing, avoids defects caused by a single method, and provides important referencefor industrial production of the polyvinylidene fluoride dielectric film. The obtained polyvinylidene fluoride dielectric film is high in beta-phase content, is thin and uniform in thickness, has excellent properties such as a high dielectric constant and great disruptive strength, and is expected to be applied to manufacturing high-energy-storage electronic apparatuses.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

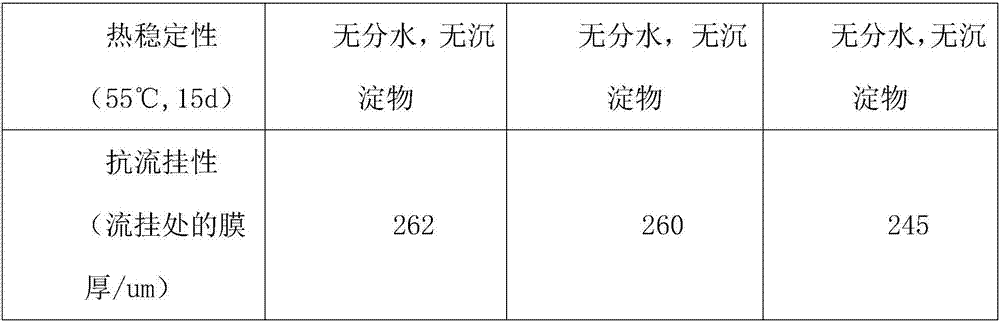

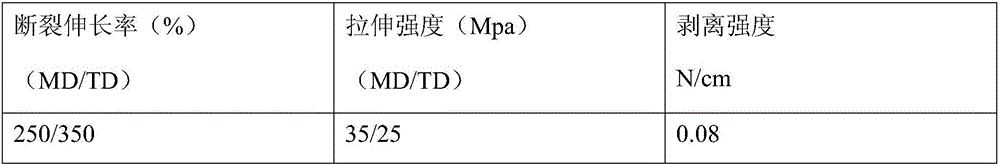

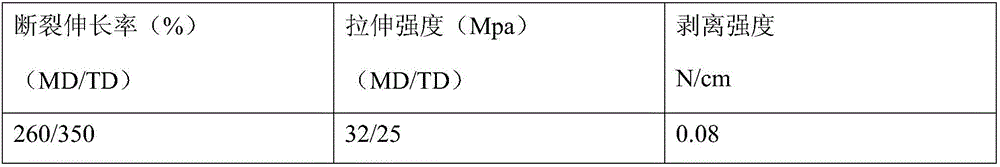

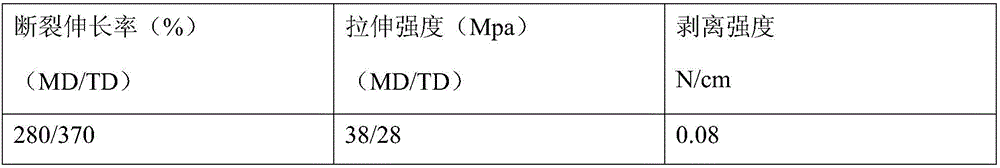

Preparation method of waterborne strippable coating

InactiveCN106833342AGood flexibilityFeel goodAnti-corrosive paintsPolyurea/polyurethane coatingsDrying timeMaterials science

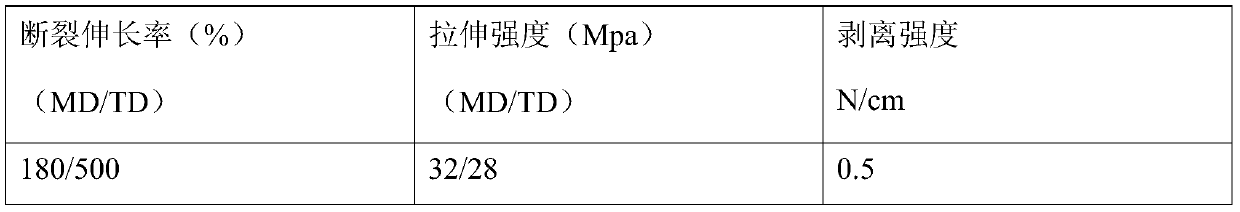

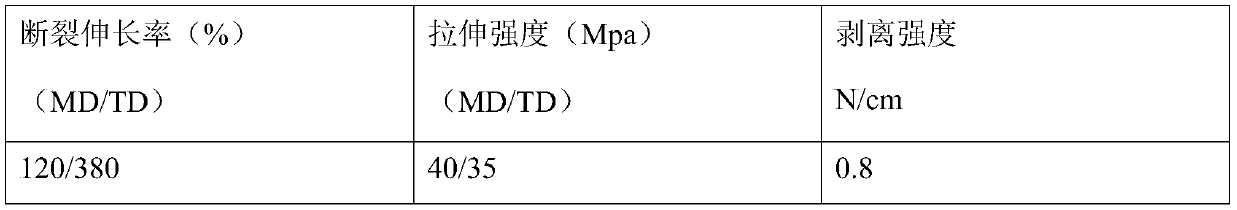

The invention discloses a preparation method of a waterbornestrippable coating and belongs to the field of coatings. The preparation method comprises following operation steps: deionized water is added to a container, a wetting agent, a dispersing agent and a thickening agent are added sequentially under stirring at a rotating speed of 200-600 r / min, and the materials are stirred for 5-10 min; inorganic filler is added, and dispersion is performed for 20-40 min at a rotating speed of 1,500-2,500 r / min; the rotating speed is regulated to be 700-1,300 r / min, a polyurethane emulsion and a styrene-acrylic emulsion are added, and stirring is performed for 15-20 min; the rotating speed is regulated to be 200-600 r / min, a flatting agent, a coalescing agent, an organic silicon stripping agent and a waterborne corrosion inhibitor are added sequentially, and pH is regulated to be 8-9. According to the preparation method of the waterbornestrippable coating, tensile strength, breaking elongation and 180-degree stripping strength are greatly improved, drying time is short, and resistance to water and a 3% NaCl solution exceeds 24 h.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

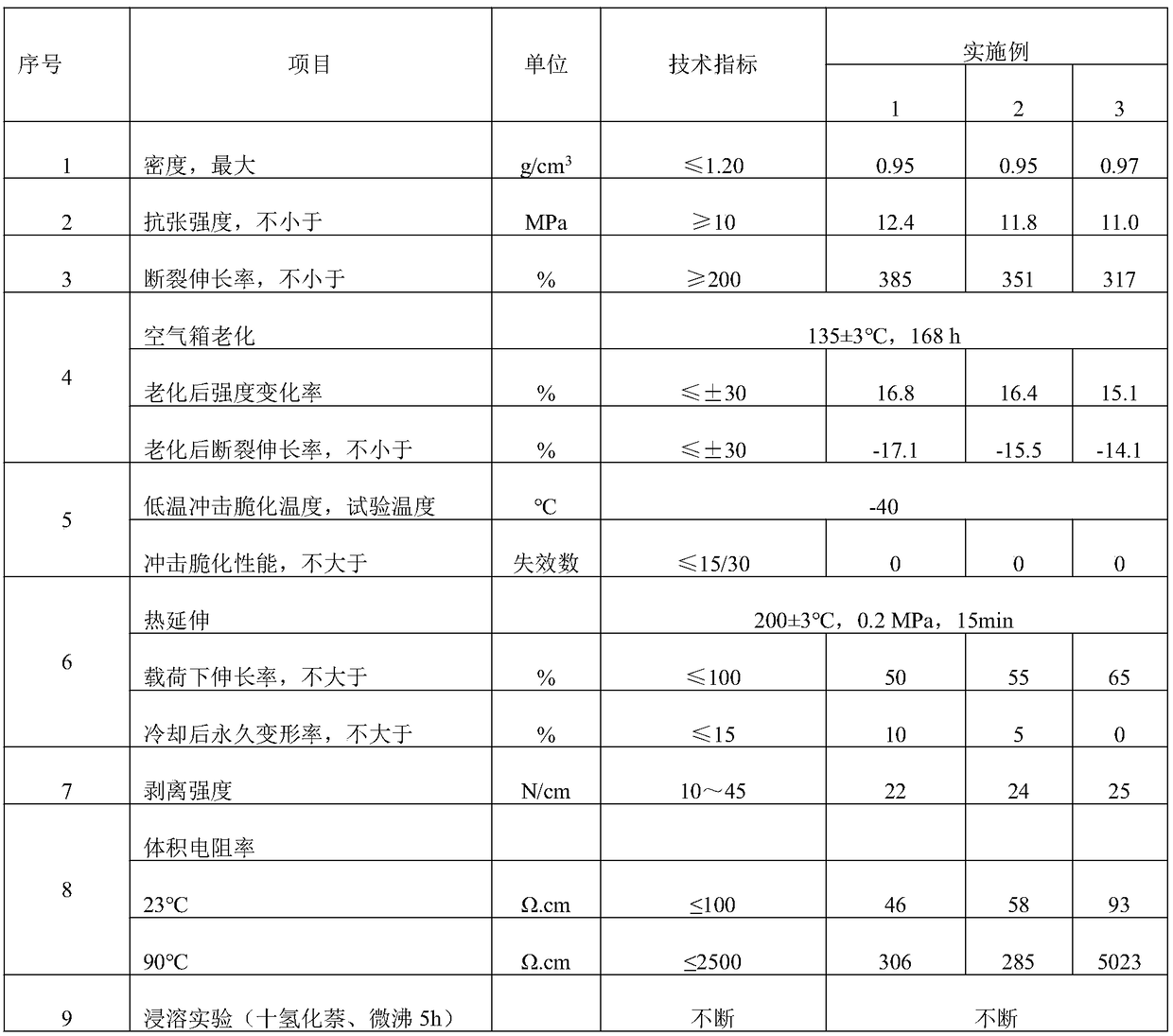

Silane cross-linked peelable semi-conductive external shielding material and preparation method thereof

The invention discloses a silane cross-linked peelable semi-conductive external shielding material and a preparation method thereof. The silane cross-linked peelable semi-conductive external shieldingmaterial is prepared by mixing a grafted material A and a catalytic material B with a mass ratio of (5 to 9) to 1 and then cross-linking in warm water, wherein the grafted material A comprises the following components in parts by weight: 100 parts of ethylene-vinyl acetate copolymer, 1 to 4 parts of silane, 0.2 to 1 part of an initiator, 0.1 to 1 part of an antioxidant, and 5 to 10 parts of a lubricant; the catalytic material B comprises the following components in parts by weight: 100 parts of ethylene-vinyl acetate copolymer, 100 to 150 parts of conductive filler, 10 to 20 parts of a lubricant, 5 to 10 parts of a stripping agent, 1 to 5 parts of a dispersant, 0.5 to 3 parts of a catalyst, and 0.5 to 2 parts of an antioxidant; the ethylene-vinyl acetate copolymer has a VA content of 25%to 30%, a melt flow rate of 2.3 to 7.5 g / 10min (the test conditions are 190 DEG C and 2.16 kg, the same below). The silane cross-linked peelable semi-conductive external shielding material disclosed by the invention has good electrical conductivity, and in particular, can ensure effective cross-linking of the product.

Owner:FAR EAST CABLE +2

High-performance waterborne pressure-sensitive adhesive and preparation method thereof and PE protective film

InactiveCN105969265AHigh solid contentMatching scienceFilm/foil adhesivesEster polymer adhesivesPressure sensitiveChemistry

The invention discloses a high-performance waterborne pressure-sensitive adhesive for a polyethylene protective film. A mode of seed emulsion polymerization is adopted, a seed emulsion is prepared, a pre-emulsion is dropwise added to the seed emulsion, reaction is conducted completely in a mode of replenishing an initiator, cooling, pH value adjusting and filtering are conducted, and the high-performance waterborne pressure-sensitive adhesive is obtained. The invention further provides the polyethylene protective film of the waterborne pressure-sensitive adhesive. The prepared emulsion pressure-sensitive adhesive can obtain the protective film with proper peel strength by adjusting the dosage of a cross-linking agent and coated adhesive quantity and is widely used for door window framework profiles, window frame profiles, solar frame profiles, decorative panels such as aluminum-plastic panels and plastic gusset plates, curtain wall profiles and decoration strip profiles.

Owner:JIANGYIN JIANGTAI HIGH POLYMER NEW MATERIAL CO LTD

Special sweat-resistant waterproof hot-melt pressure-sensitive adhesive for adhesive bandage and preparation method thereof

InactiveCN110724480AImprove performanceImprove experienceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer sciencePetroleum resin

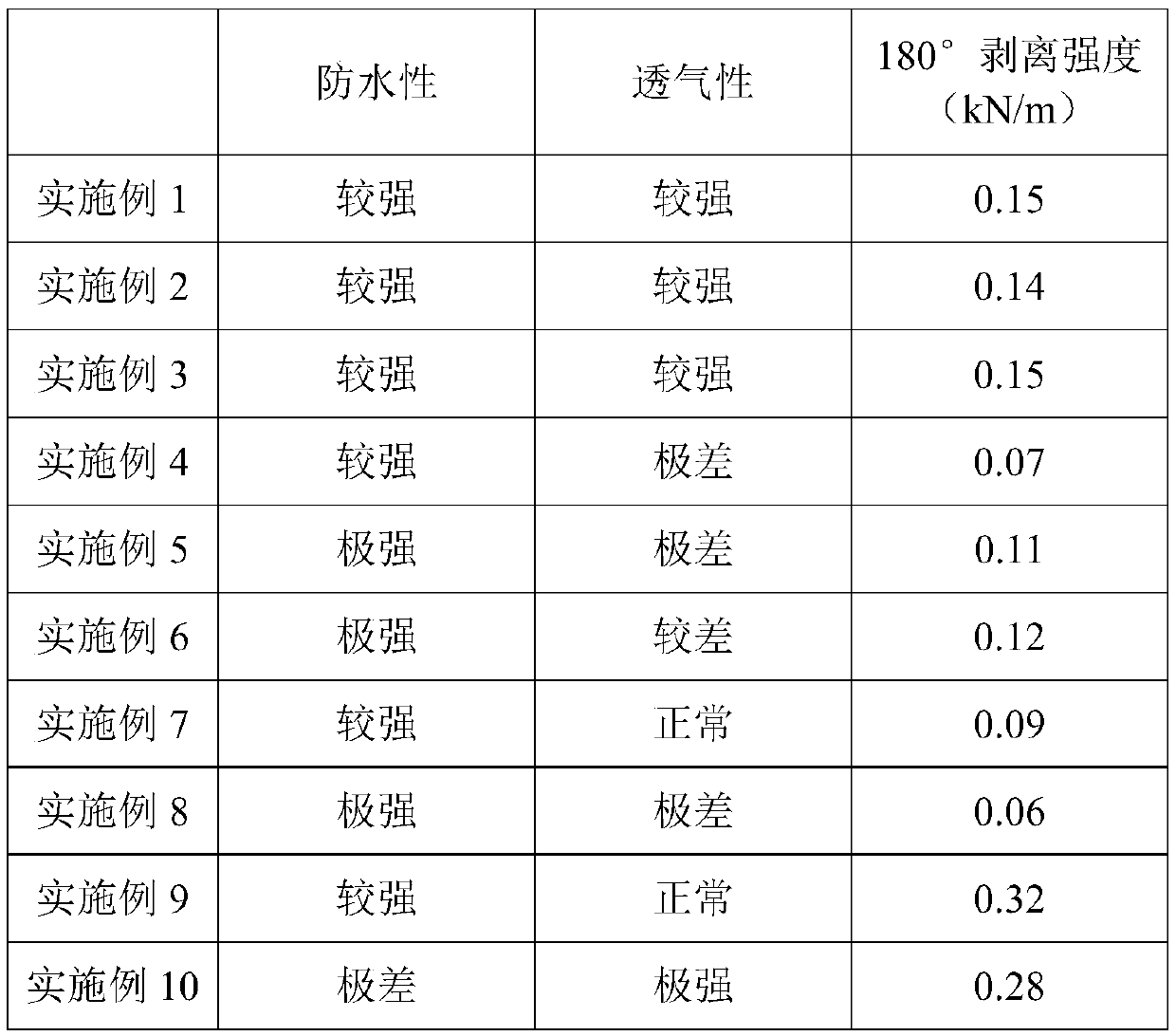

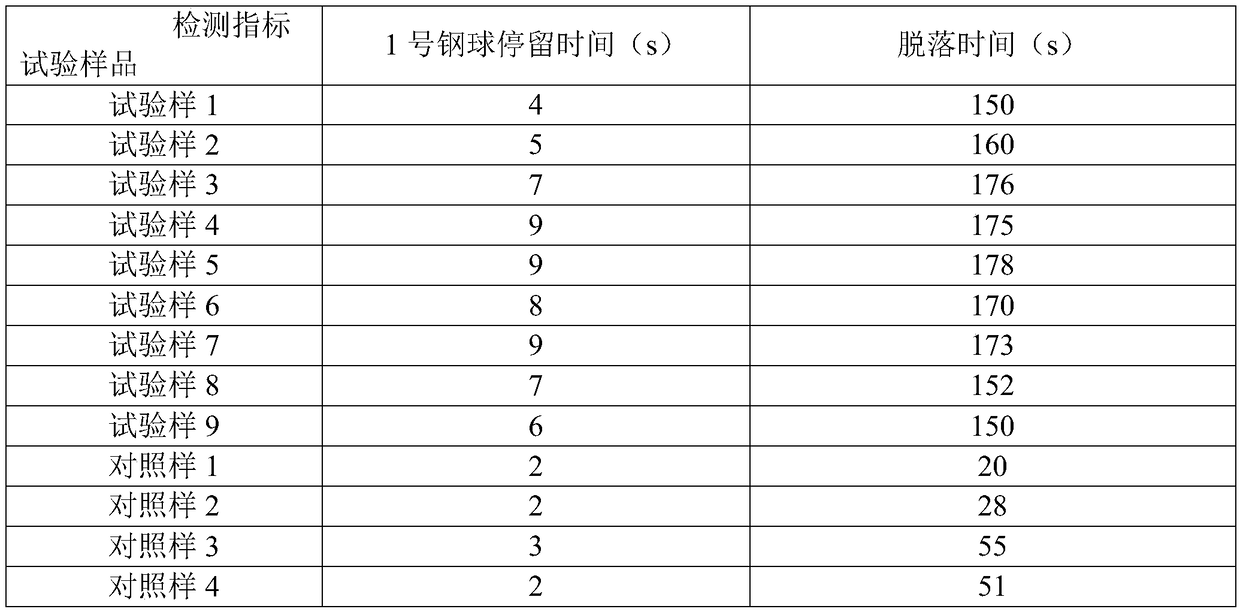

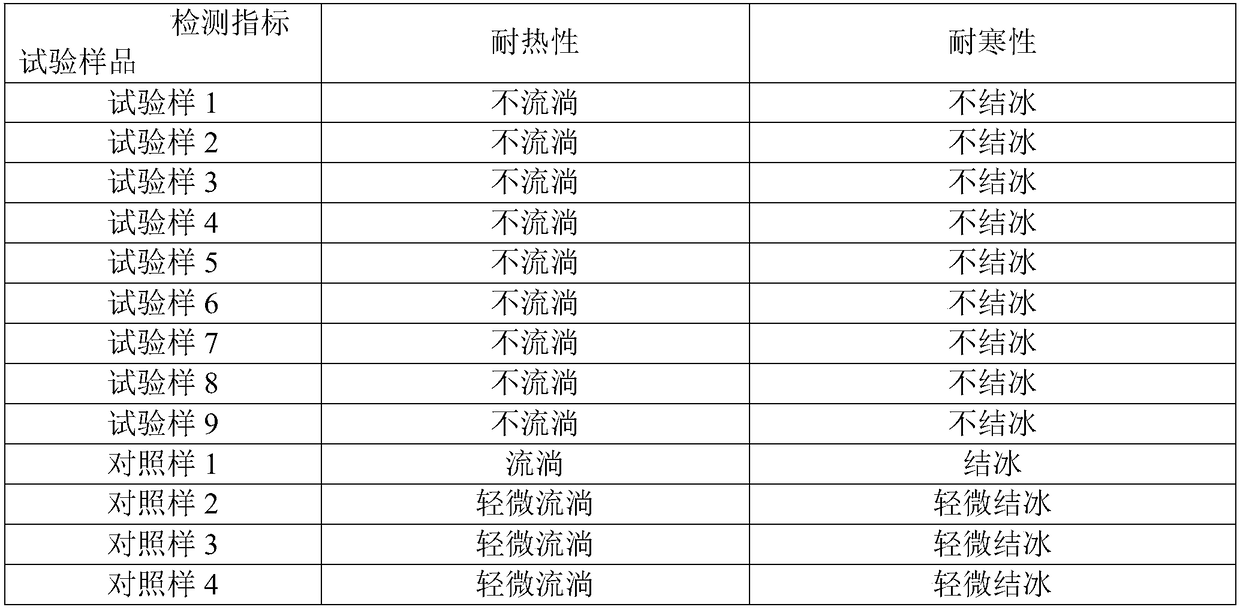

The invention discloses a special sweat-resistant waterproof hot-melt pressure-sensitive adhesive for an adhesive bandage. The special sweat-resistant waterproof hot-melt pressure-sensitive adhesive comprises the following raw materials, by mass, 30-40 parts of styrene resin, 14-18 parts of a filler, 18-22 parts of petroleum resin, 5-7 parts of a dispersing agent and 1-3 parts of an anti-aging agent. Experimental test results prove that the hot-melt pressure-sensitive adhesive prepared in the invention shows good water resistance and air permeability in water resistance and air permeability tests; meanwhile, the adhesive shows moderate peel strength in 180-degree peel strength tests, so the adhesive is firm in adhesion and does not cause pain when being peeled off from skin. Besides, the hot-melt pressure-sensitive adhesive prepared in the invention is safe and non-irritant, has no residue when being peeled from skin, allows the use experience of the adhesive bandage to be good, and has very high practical application value and development prospects.

Owner:RUGAO JIAHAO HOT MELT ADHESIVE

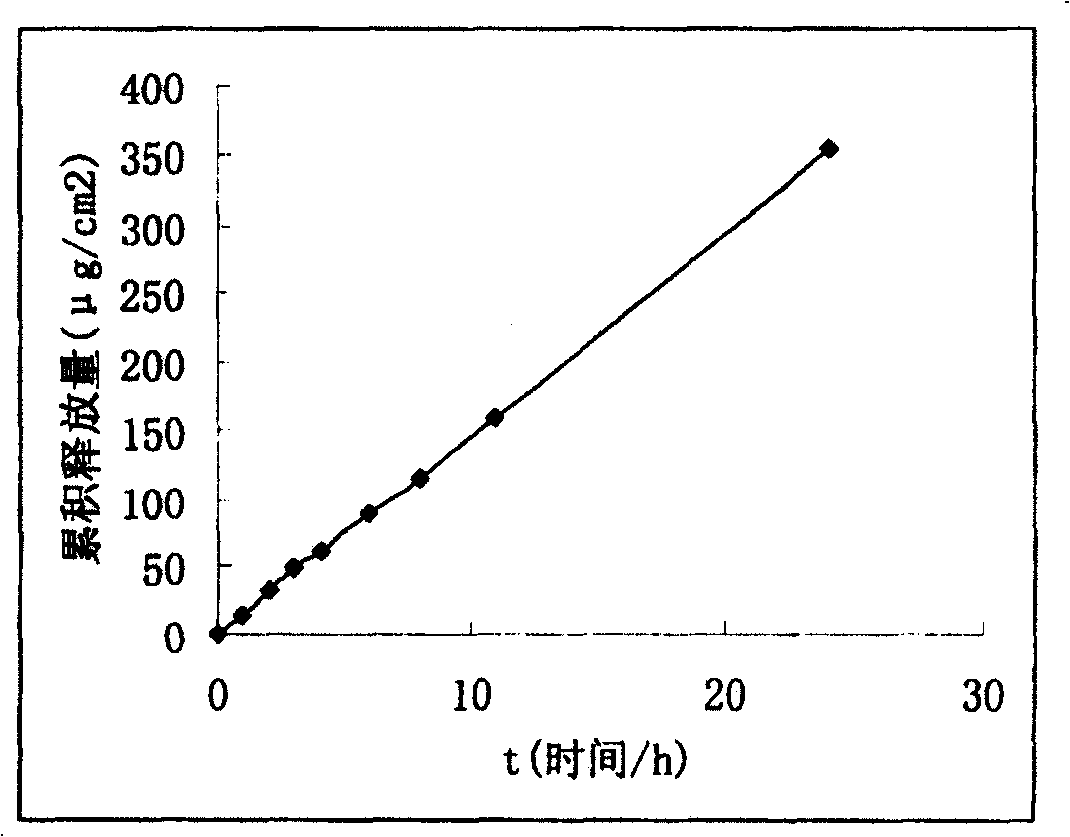

Hydrogel and process using hydrogel to produce cooling plaster

ActiveCN108403622ANot prone to precipitationModerate adhesivenessHydroxy compound active ingredientsAntipyreticDihydroxyaluminum aminoacetateAcetic acid

The invention discloses hydrogel and a process using the hydrogel to produce a cooling plaster and belongs to the technical field of cooling plaster production. The hydrogel comprises 70-81 parts of glycerin, 11-18 parts of resin powder, 3.9-4.9 parts of thickening agent, 0.35-0.45 part of dihydroxyaluminum aminoacetate, 0.25-0.33 part of ethylenediamine tetraacetic acid disodium, 16-18 parts of polyvinyl pyrrolidone, 7.5-8.8 parts of 10wt% tartaric acid aqueous solution, 0.85-1 part of waterborne preservative, 1.0-1.25 parts of cooling agent, 1.6-1.9 parts of anhydrous alcohol and 170-200 parts of deionized water, wherein the resin powder comprises at least one of H106 and HQ841. The hydrogel is good in adhesiveness and stripping strength, is mild and non-irritant, and cannot easily damage the skin.

Owner:杭州求是医学科技有限公司

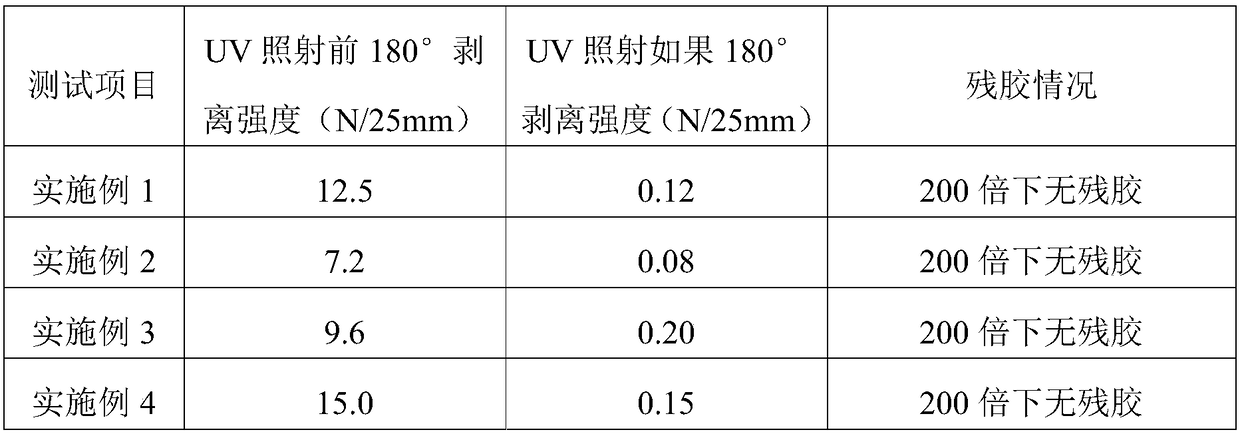

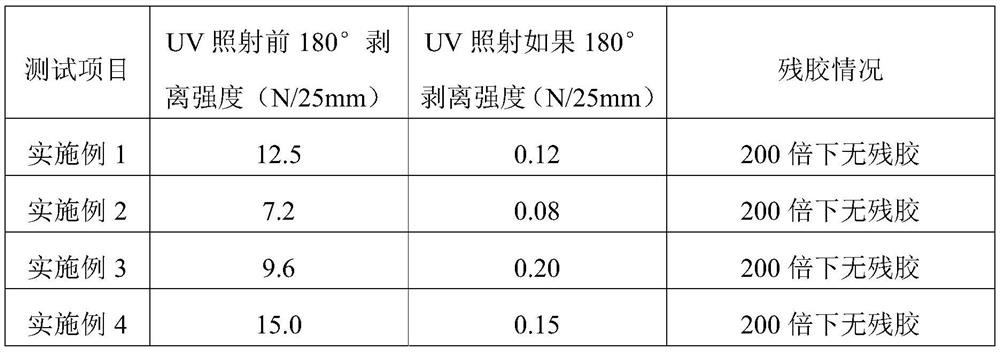

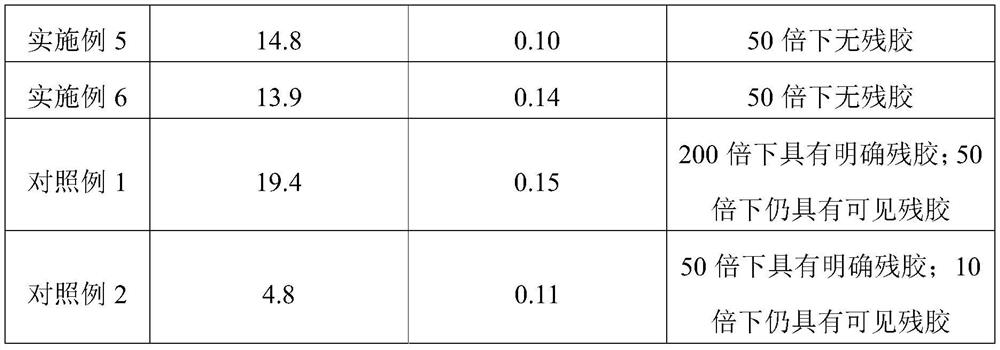

Adhesive releasing method

ActiveCN108864975AModerate peel strengthLow peel strengthNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveChemistry

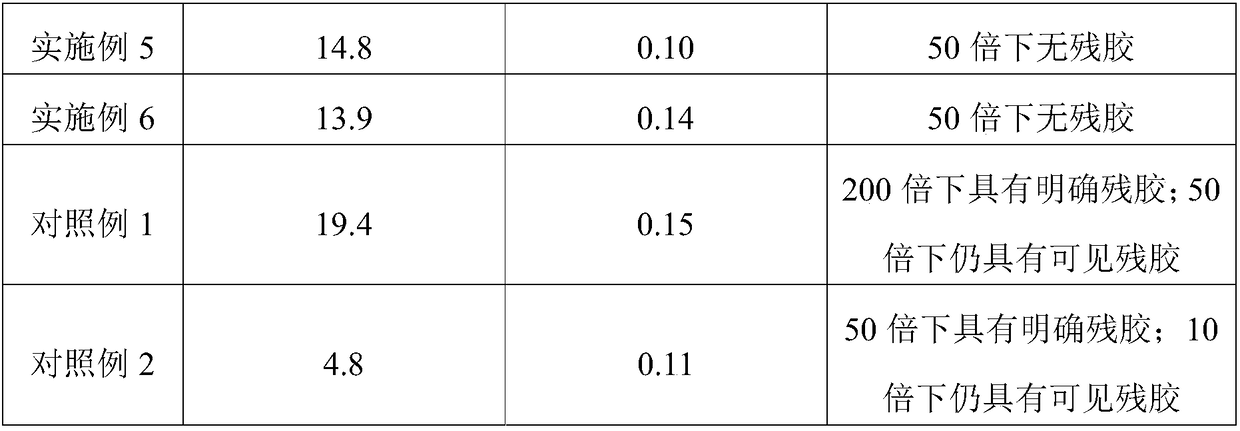

The invention provides an adhesive releasing method. The adhesive releasing method comprises the following steps of (A) sticking a UV (ultraviolet) visbreaking film to the surface requiring adhesive releasing; (B) radiating the UV visbreaking film by UV, and removing the UV visbreaking film, wherein the 180-degree releasing strength of the UV visbreaking film is 7 to 15N / 25mm before radiation by UV. The adhesive releasing method has the advantages that the residual adhesive at the surface of the adhered object can be efficiently and conveniently removed at lower risk, the adhesive releasing effect is good, and the residue rate of residual adhesive is low.

Owner:WEISHIDA SEMICON TECH ZHANGJIAGANG

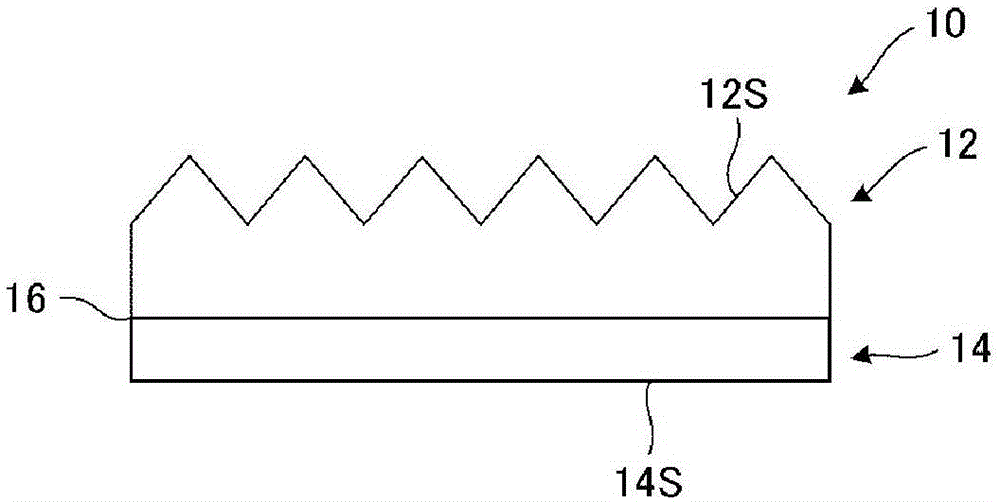

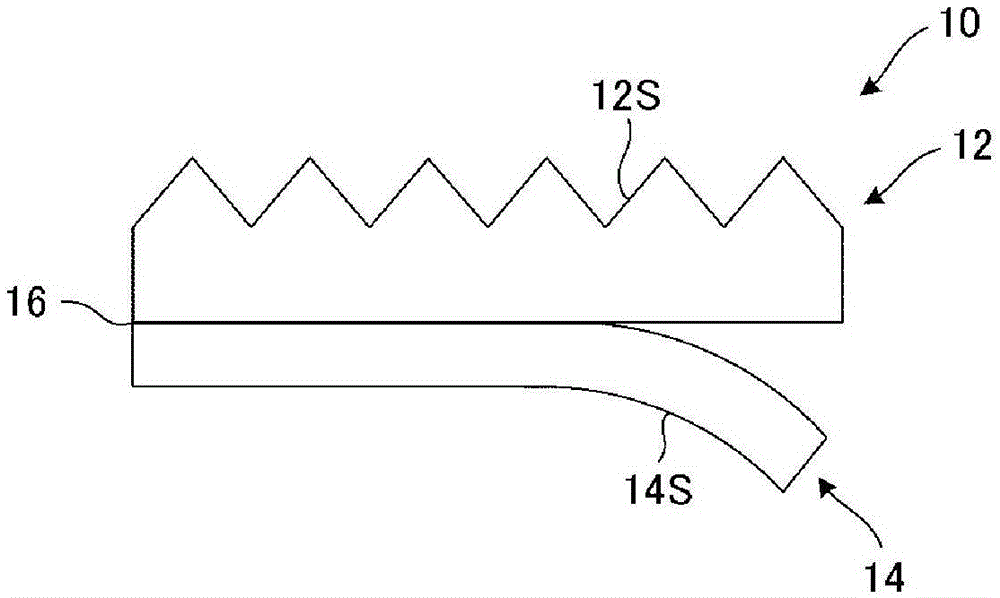

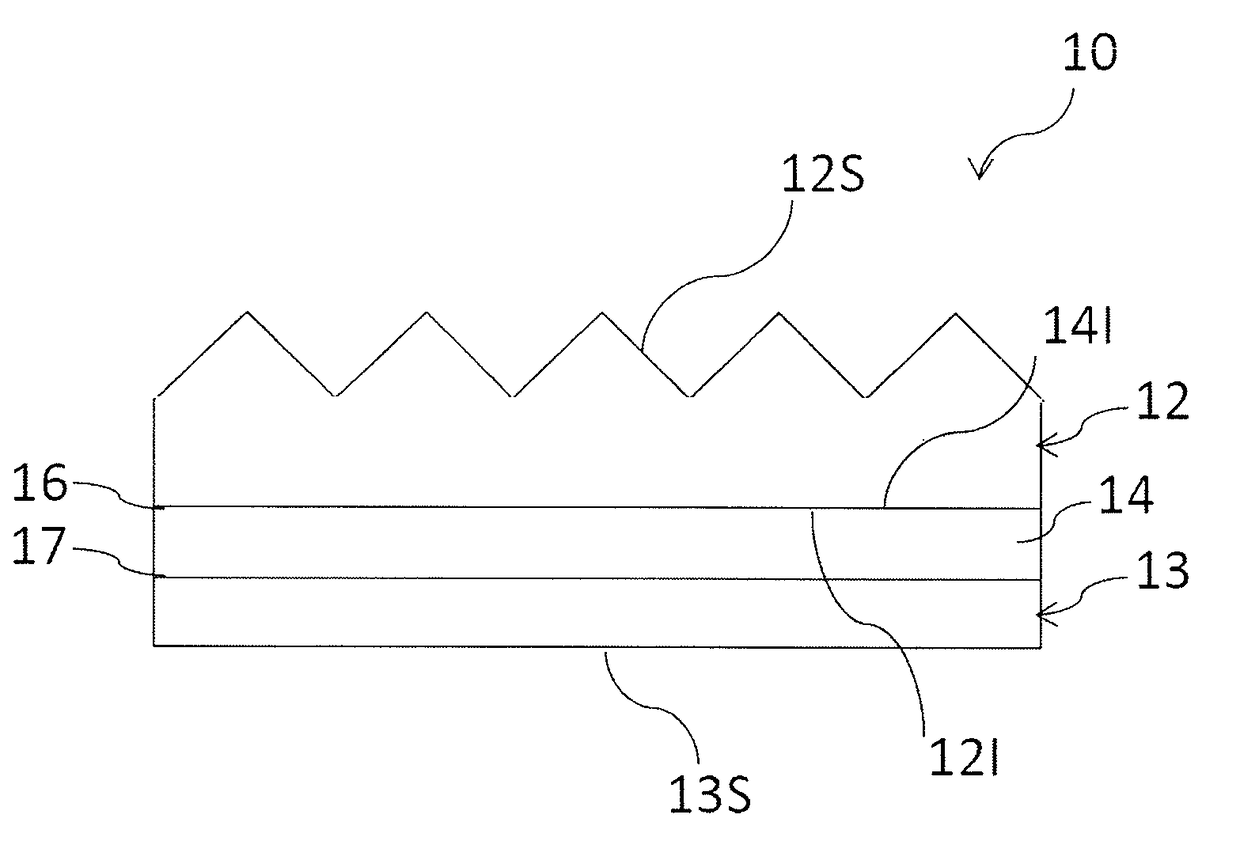

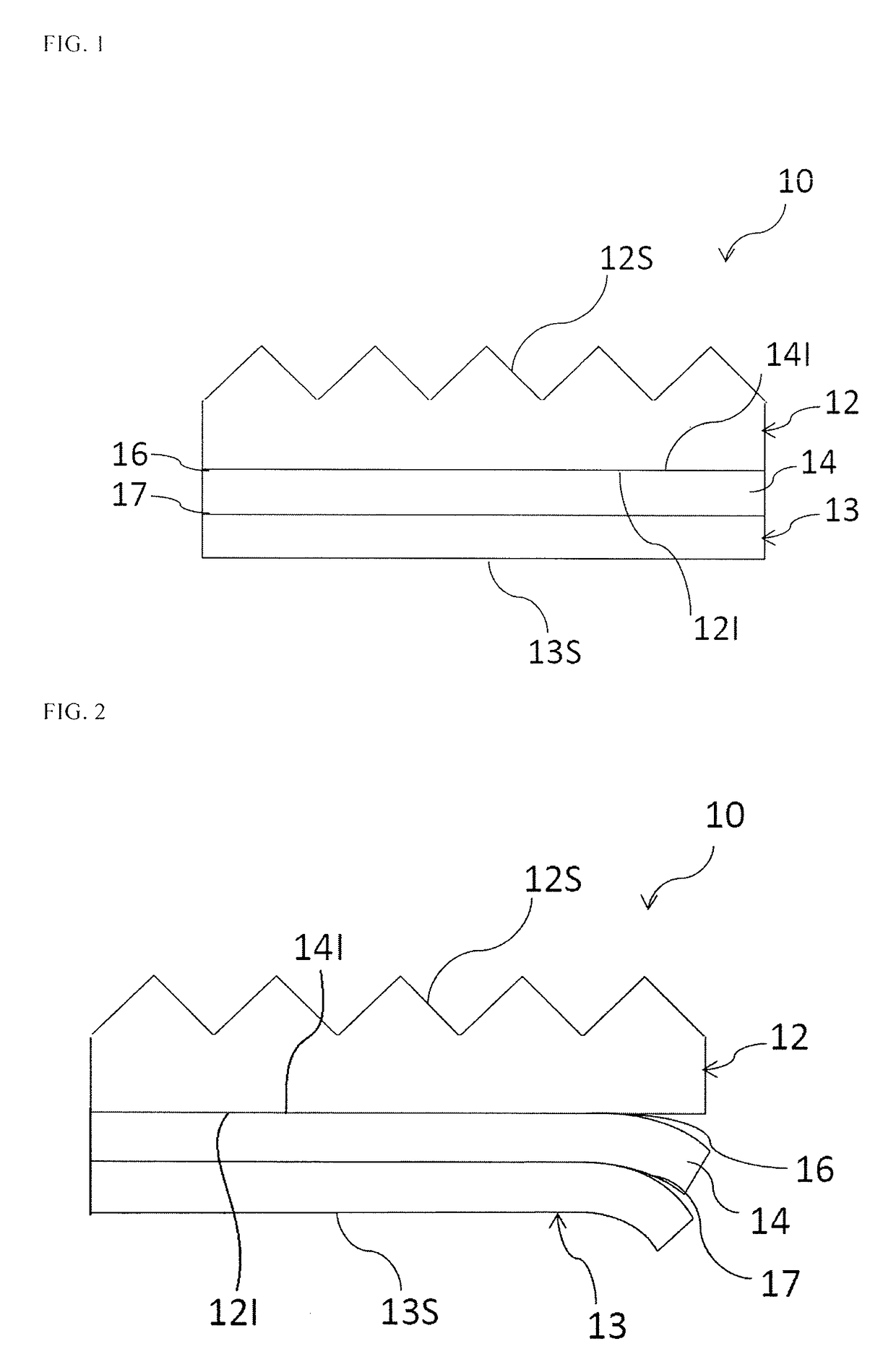

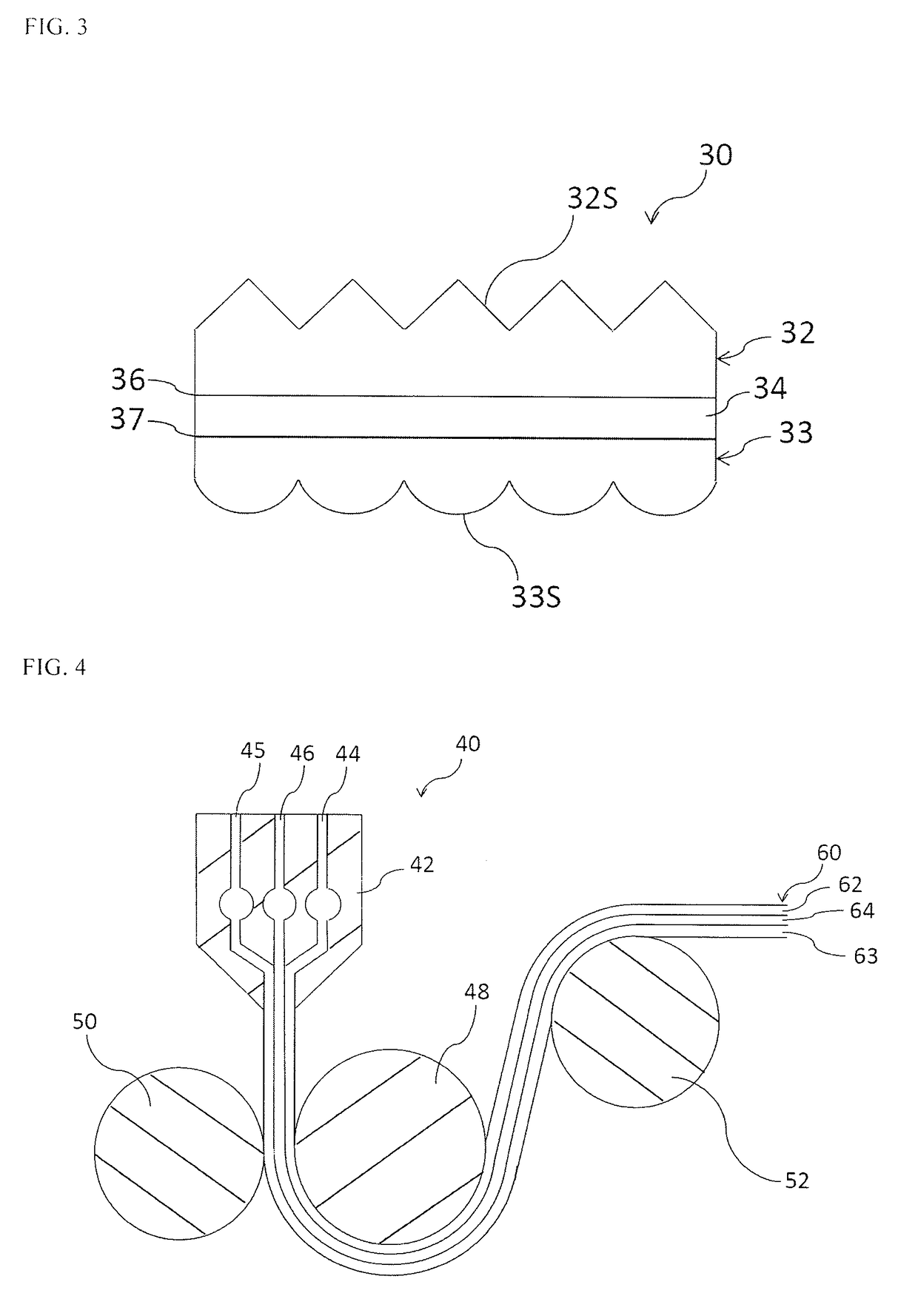

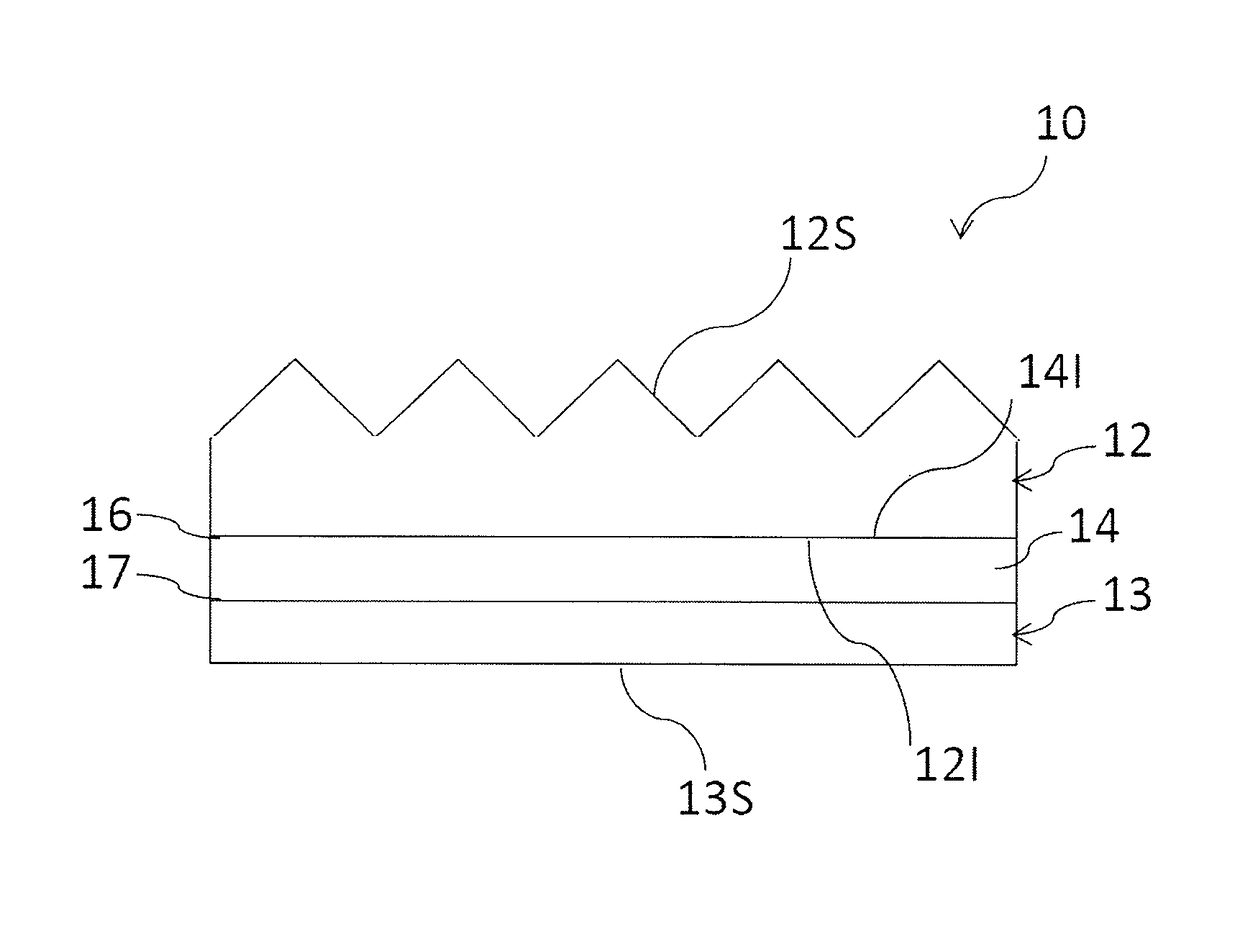

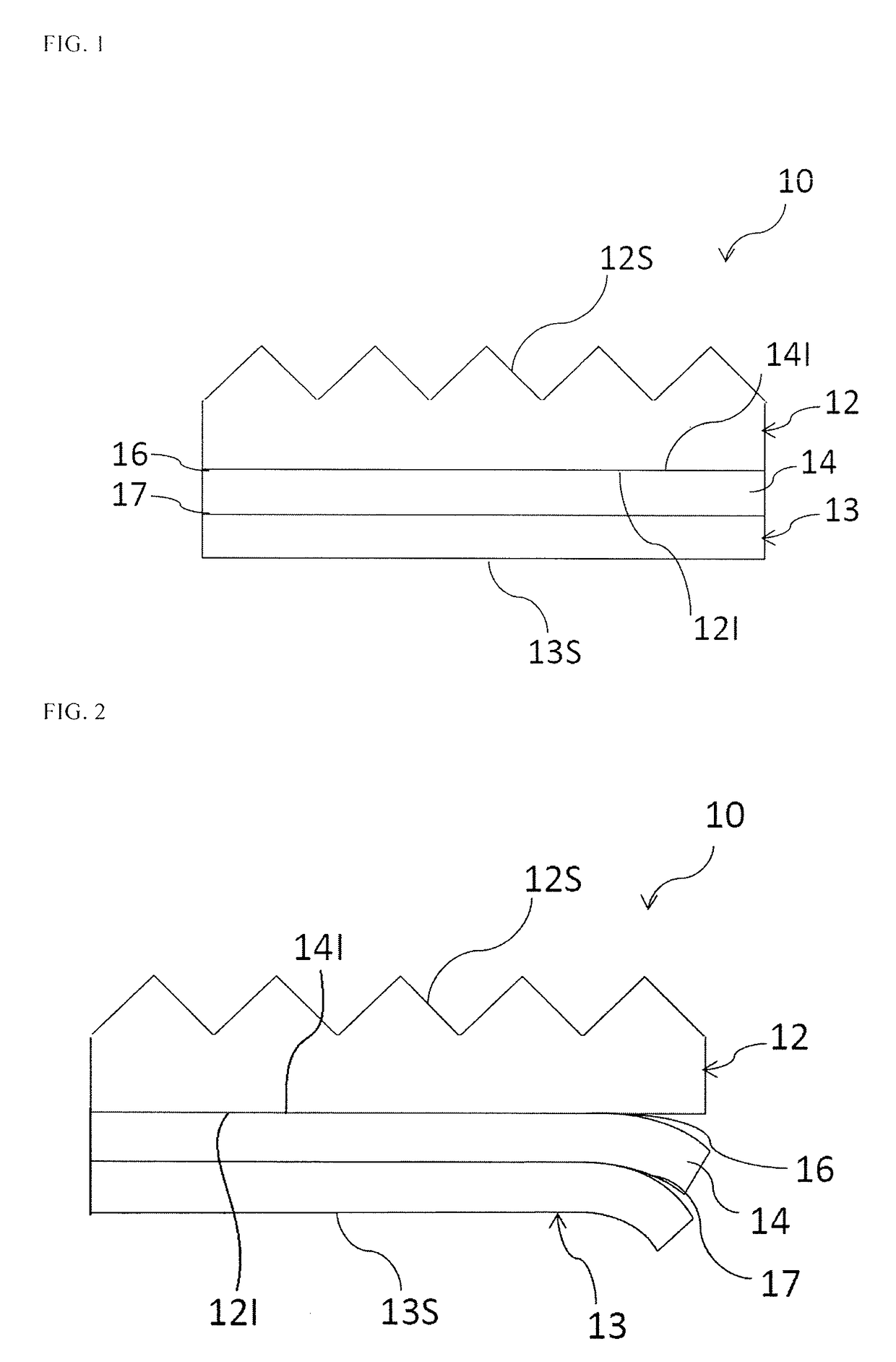

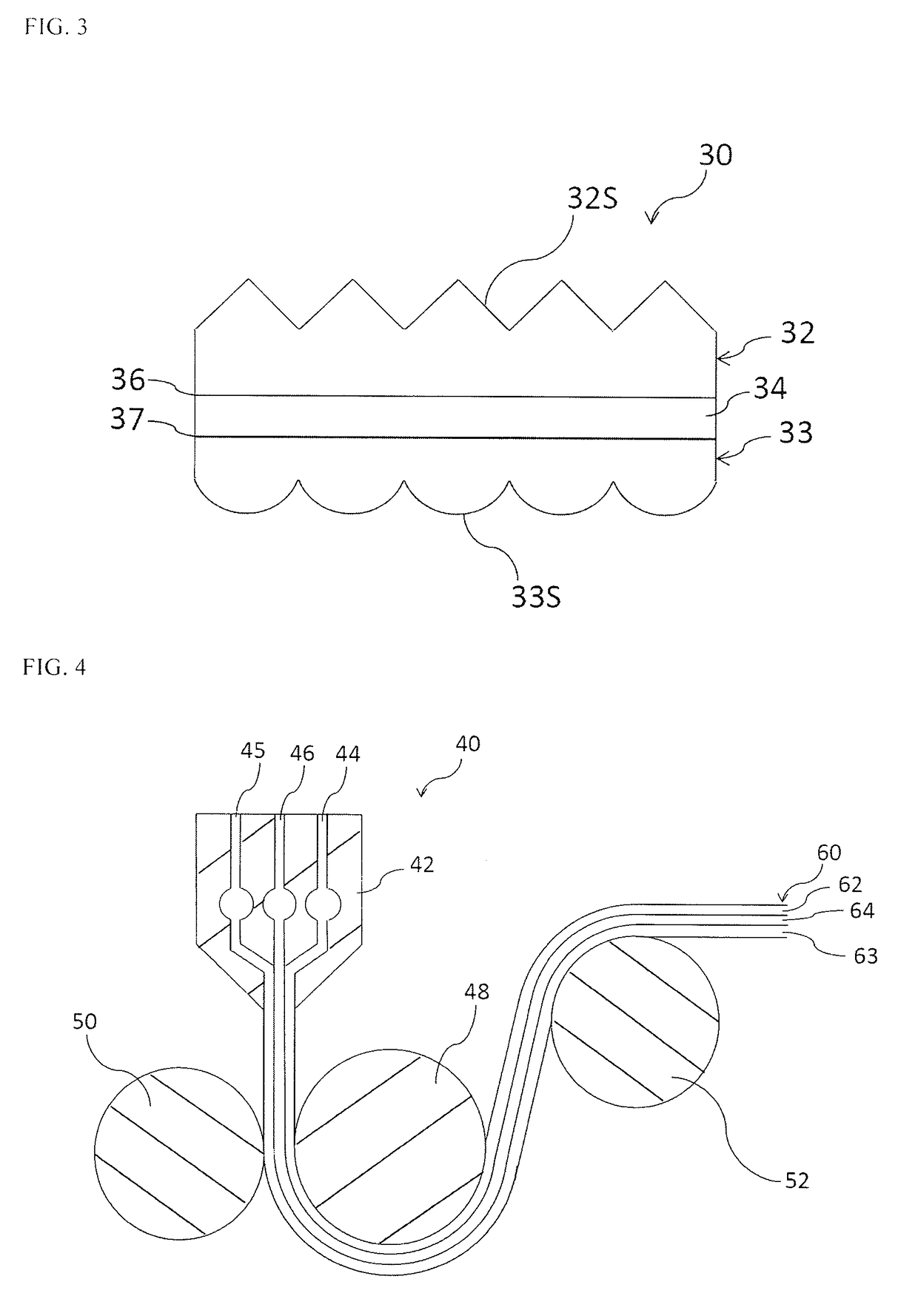

Optical sheet and method for manufacturing same

ActiveCN105103011AGood transferabilityModerate peel strengthDiffusing elementsSynthetic resin layered productsEngineeringPolycarbonate

Provided is a method for manufacturing an optical sheet capable of sufficiently improving transfer properties of a fine irregular structure, and an optical sheet formed using the method. This optical sheet is obtained by layering, using coextrusion molding, a first layer containing a polycarbonate resin and a second layer containing an amorphous polyamide resin, the boundary surface between the first layer and the second layer being separable, and a fine irregular shape being formed on the surface of the first layer and / or the second layer. The optical sheet having a plurality of layers in this manner enables making the entire sheet thicker during melt extrusion molding, thereby enabling maintaining an adequate amount of heat in the layered body during molding, and enabling improvement of transfer properties of the fine irregular structure. Further, by using only one layer due to separation, the optical sheet can also be made thinner.

Owner:MITSUBISHI GAS CHEM CO INC +1

Plastic-free coating laminating process and plastic-free coating laminating paper

ActiveCN112172372AEasy to follow upPromote degradationDuplicating/marking methodsFlat articlesColor printingWaste treatment

The invention relates to the technical field of paper coating laminating, and particularly discloses a plastic-free coating laminating process and plastic-free coating laminating paper. The plastic-free coating laminating process comprises the following process steps of preparing a film, coating, hot-pressing and recycling, and the plastic-free coating laminating paper is obtained by the plastic-free coating laminating process. The plastic-free coating laminating paper can be used for paper color printed matters and paper boxes, and has the advantages of being easy to degrade, easy to recycle,durable and resistant to abrasion; and in addition, the preparation method has the advantages of simple process, energy conservation, environmental protection and easiness in waste treatment.

Owner:中星中大印刷(深圳)有限公司

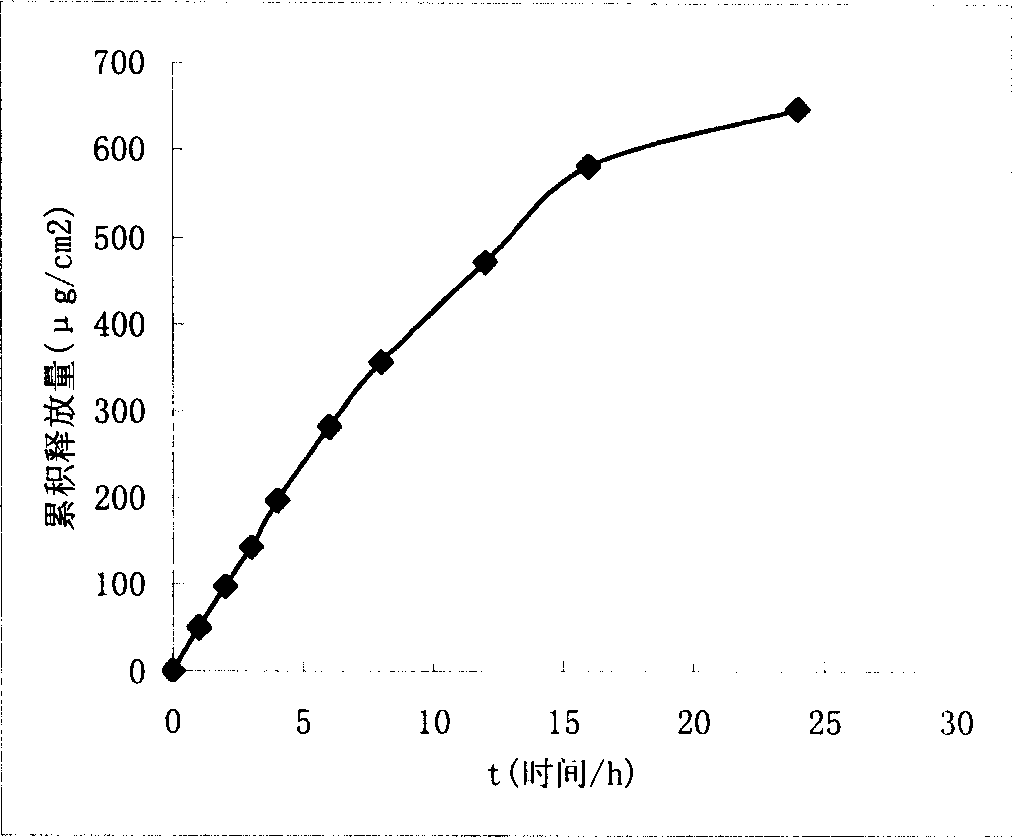

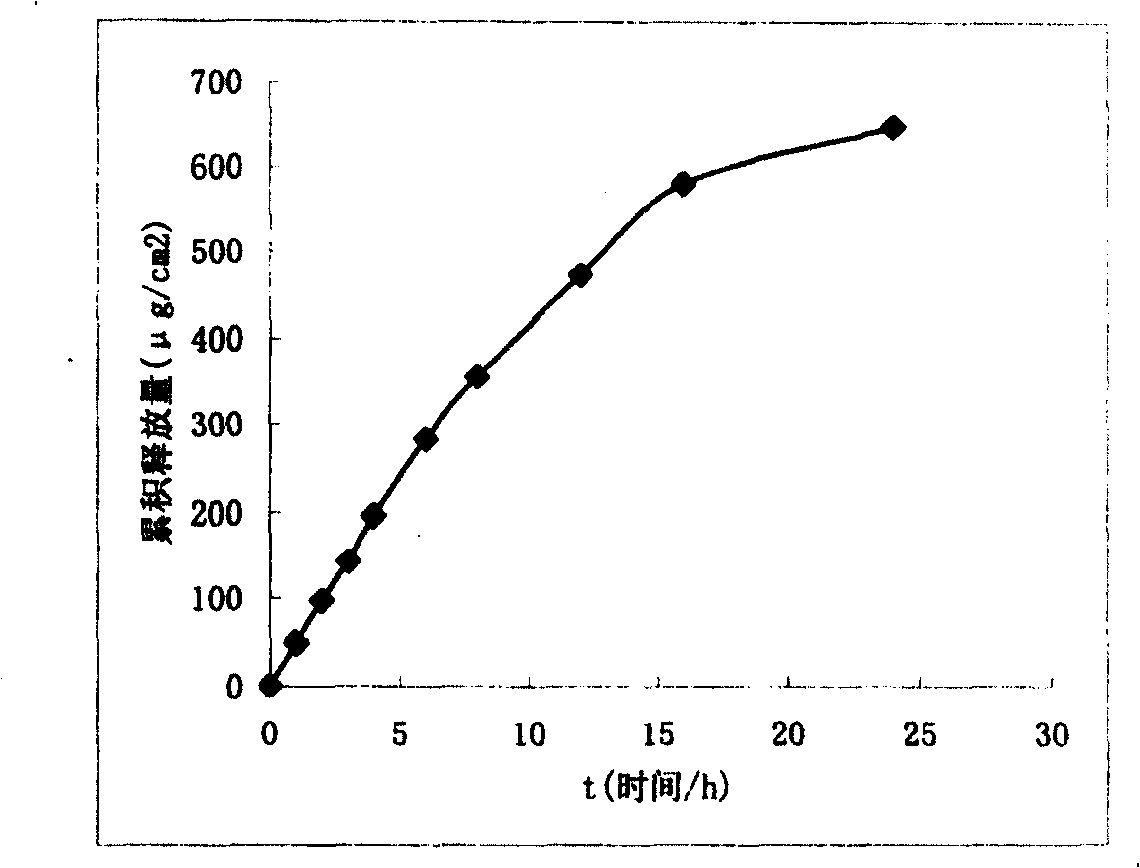

Resin ointment with high drug release, and preparation method and application thereof

ActiveCN102727421AGood skin tackImprove breathabilityAerosol deliveryOintment deliveryMicrocrystalline waxRandom combination

The invention discloses a resin ointment with high drug release. The resin ointment comprises the following components, by weight: 35%-50% of a thermoplastic elastomer SIS; 8%-30% of a tackifying resin selected from rosin resin, terpene resin, C5 petroleum resin, hydrogenated petroleum resin or random combinations thereof; 25%-45% of a plasticizer selected from liquid paraffin, Twain 80, dibutyl phthalate, lanolin, castor oil, naphthenic oil or random combinations thereof; 1%-3% of an antioxidant and / or an anti-aging agent selected from microcrystalline wax, propyl gallate, rubber accelerator or random combinations thereof; 0-24% of a filler selected from zinc oxide and titanium oxide; and 0-10% of an organic acid selected from citric acid and tartaric acid. In addition, the present invention also discloses the preparation method of the resin ointment and application thereof to a traditional Chinese medicine plaster product. The resin ointment of the invention has good skin initial tack, moderate peeling strength, no stimulation, good air permeability, high drug release performance and good compatibility with medicine.

Owner:NAT ENG RES CENT FOR TRADITIONAL CHINESE MEDICINE

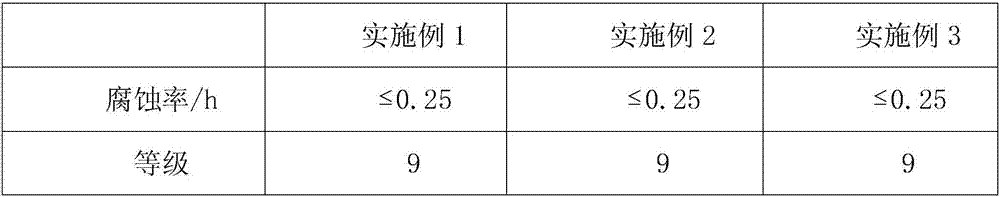

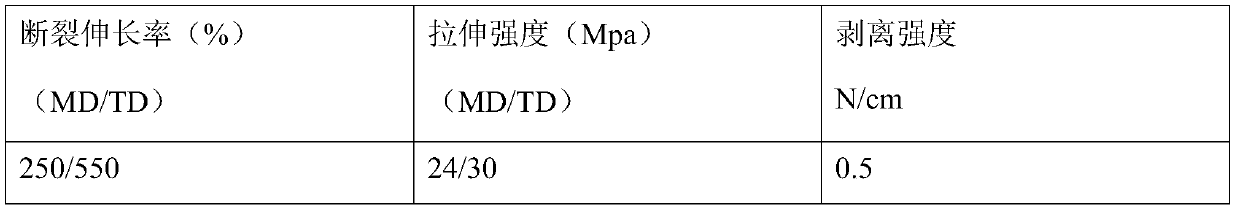

Synthetic method for corrosion-resistant water-based coating

InactiveCN107987651AHigh tensile strengthHigh elongation at breakAnti-corrosive paintsWater basedEnvironmental resistance

The invention discloses a synthetic method for a corrosion-resistant water-based coating. The method comprises following steps that acrylic resin is heated and melted, then polyvinyl alcohol is addedinto the acrylic resin, stirring is carried out for 25-30 minutes, water is added into a stirring kettle and is heated to 95-100 DEG C after the polyvinyl alcohol is completely dissolved, the stirringspeed is 450-500r / min, and stirring is carried out for 1-1.5 hours; a defoaming agent is added; sodium dodecyl sulfate and dioctyl phthalate are added, and stirring is continuously carried out for 1.5-2 hours; stirring is stopped, and nano-silicon dioxide is added into a reaction kettle; and the reaction kettle is heated to 80-90 DEG C, the constant temperature is kept for 3-3.5 hours, then diatomaceous earth, triethanolamine and a silane coupling agent are added again, the reaction kettle is closed, phosphate is added, and stirring is carried out for 1-1.5 hours so as to obtain the corrosion-resistant water-based coating. The synthetic method for the corrosion-resistant water-based coating has the advantages of being simple, easy to operate, low in cost, economical, environmentally friendly, suitable for coating of all industries and wide in application range, the corrosion-resistant water-based coating prepared by the method has good acid and alkali resistance, and a coating film ishigh in corrosion resistance and good in anti-settling property.

Owner:安徽科邦树脂科技有限公司

Self-adhered air protection adhesive tape for automobile component and preparation method of self-adhered air protection adhesive tape

InactiveCN106281085AModerate peel strengthWon't causeFilm/foil adhesivesAdhesive articlesAdhesiveEngineering

The invention relates to a self-adhered air protection adhesive tape for an automobile component and a preparation method of the self-adhered air protection adhesive tape. The self-adhered air protection adhesive tape comprises a base material layer, a middle layer and an adhesive layer, wherein the base material layer is made of polypropylene; the middle layer is made of an ethylene-alpha-olefin copolymer B; the adhesive layer is made of one or two of an ethylene-vinyl acetate copolymer and an ethylene-alpha-olefin copolymer A. The preparation method comprises the following steps: supplying raw materials of the adhesive layer, the middle layer and the base material layer to a mold head through three runners respectively, performing composite curtain coating on the adhesive layer, the middle layer and the base material layer so as to form a film through the mold head, and performing cooling molding and cutting, thereby obtaining the self-adhered air protection adhesive tape for the automobile component. The self-adhered air protection adhesive tape is appropriate in peeling resistance, simple in preparation method, low in cost and good in application prospect, and the situations that the adhesive tape is hard to peel off as the peeling resistance is upgraded as times goes on and adhesives are retained on surfaces of components and parts due to pressure impact in the rolling and stamping process can be avoided.

Owner:宁波卓胜新材料有限公司

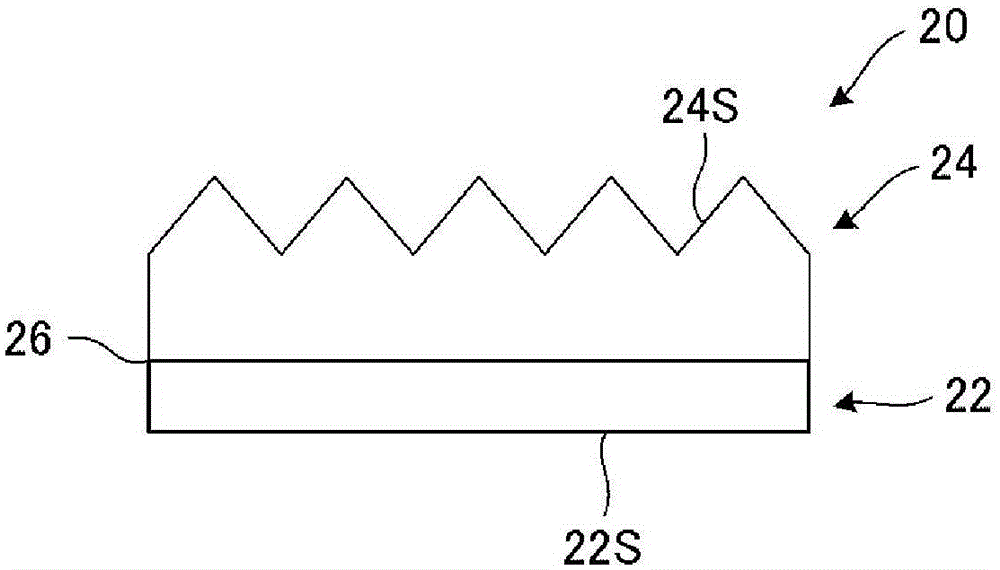

Optical sheet and method for manufacturing same

ActiveUS20170285226A1Rapid cooling is preventedImprove transmission performanceDiffusing elementsSynthetic resin layered productsEngineeringCo extrusion

An optical sheet is formed by laminating, by co-extrusion molding, a first layer containing a polycarbonate resin, a second layer containing a polyamide resin, and a third layer, wherein the second layer is laminated between the first layer and the third layer, the first layer and second layer, and the second layer and third layer can each be peeled at the interface, and the outer surface of the first layer has a fine grooved structure. The optical sheet, which is provided with a plurality of layers in such a way, is capable of retaining, a sufficient amount of heat in a laminate in a mold since the entire sheet can be made thick during melt extrusion molding, and is able to improve the transferability of the fine grooved structure. In addition, the optical sheet can be made thinner by using only the peeled first layer as an optical sheet.

Owner:MITSUBISHI GAS CHEM CO INC +1

Preparation method of anti-curling and easy-to-strip release paper for leather

ActiveCN106320085AModerate peel strengthGood release effectWater-repelling agents additionNon-macromolecular organic additionUltrasonic dispersionMoisture

The invention discloses a preparation method of anti-curling and easy-to-strip release paper for leather and belongs to the technical field of preparation of release paper. According to the method, firstly, fresh leaves of pittosporum tobira are made into granules and then mixed with a glutaraldehyde water solution for fixation, the mixture and n-hexane are stirred and heated and then are evaporated to be dried, a pittosporum tobira leaf wax concentrated solution is obtained and subjected to pulping, grinding and ultrasonic dispersion treatment with populus euphratica wood-pulp boards and deionized water, modified wood pulp dispersion size is prepared and subjected to papermaking and squeezing treatment, dried modified paper is obtained, a coating liquid is prepared from polyvinyl alcohol as a main raw material, the modified paper is coated with the coating liquid, and the anti-curling and easy-to-strip release paper for leather can be obtained after the paper is dried and cooled. A preparation process is simple, the prepared release paper for leather is moderate in strength and good in release property and doesn't easily curl in the moisture environment or under the wet condition, and a prepared leather product has good surface gloss, touches well and has broad application space.

Owner:肇庆凯盛电子科技有限公司

A kind of preparation method of release paper for anti-curling easy-peeling leather

ActiveCN106320085BModerate peel strengthGood release effectWater-repelling agents additionNon-macromolecular organic additionUltrasonic dispersionMoisture

The invention discloses a preparation method of anti-curling and easy-to-strip release paper for leather and belongs to the technical field of preparation of release paper. According to the method, firstly, fresh leaves of pittosporum tobira are made into granules and then mixed with a glutaraldehyde water solution for fixation, the mixture and n-hexane are stirred and heated and then are evaporated to be dried, a pittosporum tobira leaf wax concentrated solution is obtained and subjected to pulping, grinding and ultrasonic dispersion treatment with populus euphratica wood-pulp boards and deionized water, modified wood pulp dispersion size is prepared and subjected to papermaking and squeezing treatment, dried modified paper is obtained, a coating liquid is prepared from polyvinyl alcohol as a main raw material, the modified paper is coated with the coating liquid, and the anti-curling and easy-to-strip release paper for leather can be obtained after the paper is dried and cooled. A preparation process is simple, the prepared release paper for leather is moderate in strength and good in release property and doesn't easily curl in the moisture environment or under the wet condition, and a prepared leather product has good surface gloss, touches well and has broad application space.

Owner:肇庆凯盛电子科技有限公司

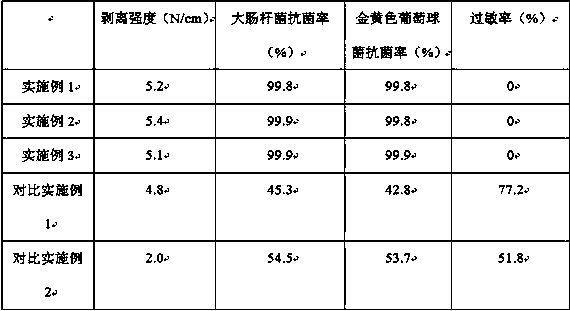

Anti-allergic pressure sensitive adhesive for medical bandages, and preparation method of anti-allergic pressure sensitive adhesive

InactiveCN109045344AModerate peel strengthHigh peel strengthAbsorbent padsBandagesRefluxDistilled water

The invention discloses anti-allergic pressure sensitive adhesive for medical bandages, and a preparation method of the anti-allergic pressure sensitive adhesive. The obtained pressure-sensitive adhesive has good anti-allergic and bactericidal effects, is moderate in peel strength, is suitable for being applied to the medical self-adhesive bandages, and can avoid the phenomenon that patients are allergic when using the self-adhesive bandages. The anti-allergic pressure sensitive adhesive is prepared by firstly freezing Chinese herbal medicines and then carrying out reflux purification sequentially by using ethanol and distilled water, so that the effective components in the Chinese herbal medicines are fully retained, and the maximum extraction and utilization of the effective components are guaranteed; Chinese herbal medicine extracts are used for swelling and spinning chitosan, so that the chitosan fully absorbs the Chinese herbal medicine extracts and is coated with the Chinese herbal medicine extracts; after spinning, the product is fibrous and participates in a reaction, so that the Chinese herbal medicine extracts are evenly distributed in the adhesive, and the problem that when being directly added, the Chinese herbal medicines can not participate in the reaction of adhesive can be avoided; furthermore, the adhesive is endowed with antibacterial and anti-allergic effects, and the peel strength of the adhesive is enhanced.

Owner:安徽玉然经编科技有限公司

Low-shrinkage photo-curable pressure-sensitive adhesive

InactiveCN111826092AProportion design is reasonableLow shrinkageNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceNitrile rubber

The invention relates to a low-shrinkage photo-curable pressure-sensitive adhesive, which is composed of the following components by weight: 50-80 parts of acrylate, 30-50 parts of isocyanate, 20-30 parts of natural rubber, 8-12 parts of styrene butadiene rubber, 2-4 parts of nitrile rubber, 10-20 parts of a rubber plasticizer, 1.5-3 parts of an anti-aging agent, 1.5-2 parts of a polymerization inhibitor, 0.5-2 parts of a photoinitiator and 0.4-2 parts of a coupling agent. The photo-curable pressure-sensitive adhesive has the advantages that: the raw material proportion design is reasonable, the prepared photo-curable pressure-sensitive adhesive is low in shrinkage rate and has a good market popularization prospect in the field of pressure-sensitive adhesives, and the adhesive tape prepared through the method is moderate in peel strength, resistant to high temperature, free of pollution, resistant to aging and high in stability, so that the prepared pressure-sensitive adhesive tape isstable in adhesive property and wide in application scene.

Owner:SHENZHEN NIKTO TAPE NEW MATERIAL CO LTD

A kind of masking tape containing printing layer and preparation method thereof

ActiveCN103725222BOvercome affinityProduction process is environmentally friendlyNon-fibrous pulp additionFilm/foil adhesivesWater basedEmulsion

The invention discloses a masking tape containing a printing layer and a preparation method thereof. The masking tape comprises a substrate, wherein one side of the substrate is provided with an adhesive layer, and the other side of the substrate is sequentially provided with a printing layer and a release layer; the substrate is masking tape base paper impregnated by a hydroxy butadiene-styrene emulsion; the printing layer is a water-based ink; the adhesive layer is a water-based acrylate pressure-sensitive adhesive; and the release layer is a water-based release agent. All the raw materials are water-based materials, and thus, the production technique is environment-friendly; and the product has the advantages of stable performance, long shelf life, low production cost and high added value.

Owner:广州市白云区麒胜装饰材料厂有限公司

A kind of metal nail strip adhesive and preparation method thereof

ActiveCN103788897BShorten the production cycleIncrease productivityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEpoxyPolymer science

The invention discloses a metal strip nail adhesive and a preparation method thereof, and relates to the technical field of adhesives based on resin. The metal strip nail adhesive comprises the following raw materials in percentage by weight: 8%-16% of carboxyl vinyl chloride-vinyl acetate resin with average molecular weight about 34000, 0%-8% of carboxyl vinyl chloride-vinyl acetate resin with the average molecular weight about 27000, 3.5%-5.5% of nitrile rubber, 4.5%-6.5% of epoxide resin, 2%-4% of methylhexahydrophthalic anhydride, 0.01%-1% of aluminium acetylacetonate, 0%-40% of methyl acetate and 30%-77% of acetone. The metal strip nail adhesive is prepared through pretreatment, mixing, heating and stirring. The metal strip nail adhesive disclosed by the invention has the characteristics of moderation in stripping strength, fast drying, stability in storage and easiness for operation; a strip nail adhered through the adhesive can not be cracked when being cut in a cutting procedure, or a manufactured strip nail can not be cracked when being encased and transported; and the strip nail is easy to shoot in a nail gun, high in nailing efficiency and increased in production efficiency.

Owner:张志东

Water-based paper and plastic laminating/peelable adhesive and method for manufacturing same

InactiveCN103421461BModerate peel strengthHigh affinityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedWax

Owner:SOUTH CHINA UNIV OF TECH

Aquogel type thiamazole plaster preparation

InactiveCN100450480CImproves transdermal penetrationIncrease water permeability and breathabilityOrganic active ingredientsPharmaceutical non-active ingredientsUse medicationSide effect

The aquogel type thiamazole plaster includes a back lining layer, a medicine matrix layer and a protecting film. The medicine matrix layer contains medicine thiamazole in 0.2-20 wt% of the medicine matrix layer, aquogel type contact adhesive material, cross-linking agent, pH regulator, humectant, tackifier medicine, transdermal promoter and water, . The present invention has high transdermal effect of medicine, good skin compatibility, high air and moisture permeability, lowered toxicity and side effect of medicine and other advantages, and is used for treating hyperthyroidism.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Optical sheet and method for manufacturing same

ActiveUS10067271B2Rapid cooling is preventedImprove transmission performanceDiffusing elementsSynthetic resin layered productsEngineeringCo extrusion

An optical sheet is formed by laminating, by co-extrusion molding, a first layer containing a polycarbonate resin, a second layer containing a polyamide resin, and a third layer, wherein the second layer is laminated between the first layer and the third layer, the first layer and second layer, and the second layer and third layer can each be peeled at the interface, and the outer surface of the first layer has a fine grooved structure. The optical sheet, which is provided with a plurality of layers in such a way, is capable of retaining, a sufficient amount of heat in a laminate in a mold since the entire sheet can be made thick during melt extrusion molding, and is able to improve the transferability of the fine grooved structure. In addition, the optical sheet can be made thinner by using only the peeled first layer as an optical sheet.

Owner:MITSUBISHI GAS CHEM CO INC +1

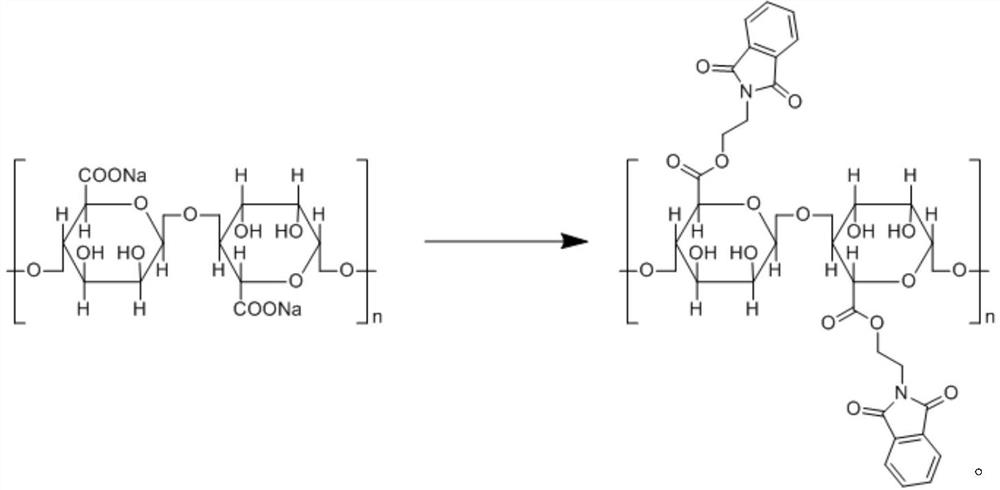

Modified sodium alginate, preparation method thereof, pressure-sensitive adhesive and patch

PendingCN113896809AGood bonding stabilitySuitable peel strengthNon-macromolecular adhesive additivesInorganic non-active ingredientsChemistryAdhesive

The invention provides modified sodium alginate, a preparation method thereof, a pressure-sensitive adhesive and a patch. The preparation method of the modified sodium alginate comprises the following steps: mixing sodium alginate with alkali liquor to obtain a sodium alginate solution; and carrying out a grafting reaction on the sodium alginate solution and N-(2-chloroethyl)phthalimide to obtain the modified sodium alginate. The pressure-sensitive adhesive prepared from the modified sodium alginate can obtain relatively good bonding stability and relatively proper peel strength. Meanwhile, due to the fact that the modified sodium alginate has good skin-friendly performance, the risk of skin allergy can be well reduced in the application process of the modified sodium alginate.

Owner:ANHUI HUIKE BIO ENG TECH

A kind of co-extrusion coated protective tape and preparation method thereof

ActiveCN106318252BModerate peel strengthWon't causeNatural rubber adhesivesFilm/foil adhesivesLinear low-density polyethylenePunching

The invention relates to a coextruded coating-type protection adhesive tape and a preparation method thereof. The coextruded coating-type protection adhesive tape comprises a substrate layer, an adhesion layer and a bonding layer, the substrate layer is composed of polypropylene and linear low-density polyethylene, the adhesion layer is vinyl-ethylene acetate copolymer, and the bonding layer comprises rubber and tackifying resin. The preparation method includes: (1), supplying raw materials of the adhesion layer and the substrate layer to a mould head respectively through two material ways, performing compositing, casting, film forming on the raw materials of the adhesion layer and the substrate layer through the mould head, and cooling and shaping to obtain a mother substrate; (2), diluting coating liquid, coating the coating liquid on the mother substrate to form the bonding layer, and folding and cutting into needed size. The coextruded coating-type protection adhesive tape is proper in stripping strength, free of being difficult to strip due to increasing of the stripping strength as time goes and free of causing adhesive residue on the surfaces of parts due to pressure impact in the process of rolling and punching. The preparation method is simple and low in cost and has good application prospect.

Owner:宁波卓胜新材料有限公司

Screen door screen window punching-free installation adhesive, and preparation method thereof

InactiveCN110157342AModerate peel strengthGuaranteed ease of useNon-macromolecular adhesive additivesMacromolecular adhesive additivesMagnesiumEthanediols

The invention discloses a screen door screen window punching-free installation adhesive. The screen door screen window punching-free installation adhesive comprises, by weight, polyvinyl alcohol of 2-6%, starch of 20-25%, pentaerythritol tetra(2-hexyldecanoate) of 10-13%, sodium dodecylbenzenesulfonate of 1-3%, diphenylmethane diisocyanate of 8-12%, vinyl acetate of 6-9%, nanometer magnesium oxideof 1-2%, ethanediol of 4-7%, triethanolamine of 3-5%, melamine of 1-2%, lignin of 1-3%, and the balance N,N-methylformamide. The screen door screen window punching-free installation adhesive can be used for forming of an adhesive layer on the back surface of a screen hook surface adhesive tape through hot coating, so that screens are fixedly arranged on iron or wood doors and windows, a problem in the prior art that removing is difficult in pushpin fixing; and in addition, the peeling strength of the screen door screen window punching-free installation adhesive is moderate, so that after dismounting, extremely less adhesive is left on doors and windows.

Owner:利辛县缘艺纱网有限公司

a degumming method

ActiveCN108864975BModerate peel strengthLow peel strengthNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The invention provides an adhesive releasing method. The adhesive releasing method comprises the following steps of (A) sticking a UV (ultraviolet) visbreaking film to the surface requiring adhesive releasing; (B) radiating the UV visbreaking film by UV, and removing the UV visbreaking film, wherein the 180-degree releasing strength of the UV visbreaking film is 7 to 15N / 25mm before radiation by UV. The adhesive releasing method has the advantages that the residual adhesive at the surface of the adhered object can be efficiently and conveniently removed at lower risk, the adhesive releasing effect is good, and the residue rate of residual adhesive is low.

Owner:WEISHIDA SEMICON TECH ZHANGJIAGANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com