A kind of masking tape containing printing layer and preparation method thereof

A technology of textured paper and printing layer, applied in paper, papermaking, adhesives, etc., can solve the problems of product performance impact, performance degradation, flammability and explosion, etc., and achieve stable product performance, low production cost and good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

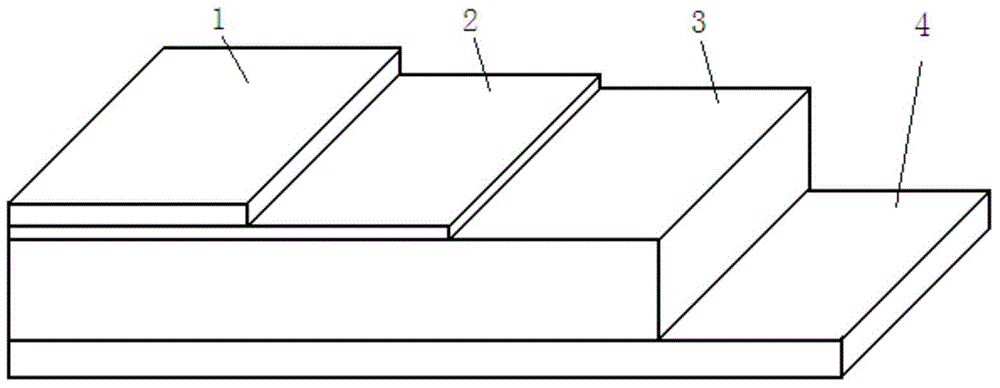

Image

Examples

Embodiment 1

[0037] A preparation method of a masking tape containing a printing layer, comprising the following steps:

[0038] Step (1): Add 45g / m 2 Base paper impregnated with hydroxybutadiene emulsion with a solid content of 25%, and the impregnation amount is 9.5g / m 2 (dry weight), heated at 118°C for 60 seconds and dried, then placed at room temperature for 24 hours to obtain the substrate;

[0039] Step (2): Perform monochrome "roller printing" of water-based ink on the substrate obtained in step (1) with an anilox roller with engraved patterns;

[0040] Step (3): Apply a water-based polyvinyl acetate-based release agent with a solid content of 18% to the printed substrate in step (2), and the coating amount is 3.5g / m 2 (dry quantity); heat at 140°C for 24 seconds, dry and place at room temperature for 48 hours;

[0041] Step (4): Coat the water-based acrylate pressure-sensitive adhesive with a solid content of 45% on the substrate treated in step (3), and the coating amount is 2...

Embodiment 2

[0045] A preparation method of a masking tape containing a printing layer, comprising the following steps:

[0046] Step (1): add 40g / m 2 Base paper impregnated with hydroxybutadiene emulsion with a solid content of 25%, and the impregnation amount is 8g / m 2 (dry weight), heated at 130°C for 50 seconds and left at room temperature for 24 hours to obtain the substrate;

[0047] Step (2): Perform 3-color "roller printing" of water-based ink on the substrate obtained in step (1) with 3 sets of anilox rollers with engraved patterns;

[0048] Step (3): Apply a water-based polyvinyl acetate-based release agent with a solid content of 22% to the printed substrate in step (2), and the coating amount is 4.8g / m 2 (dry weight); heat at 118°C for 28 seconds, dry and place at room temperature for 48 hours;

[0049] Step (4): Coat the water-based acrylate pressure-sensitive adhesive with a solid content of 50% on the substrate treated in step (3), and the coating amount is 35g / m 2 (dry ...

Embodiment 3

[0053] A preparation method of a masking tape containing a printing layer, comprising the following steps:

[0054] Step (1): add 50g / m 2 The base paper is impregnated with hydroxy-butadiene styrene emulsion with a solid content of 25%, the impregnation amount is 12g / ㎡ (dry weight), heated at 125°C for 70 seconds and dried, then placed at room temperature for 24 hours to obtain the substrate;

[0055] Step (2): Perform single-color "jet printing" of water-based ink on the substrate obtained in step (1) with an electronically controlled inkjet device;

[0056] Step (3): Apply a water-based polyvinyl acetate-based release agent with a solid content of 25% to the printed substrate in step (2), and the coating amount is 6.8g / m 2 (dry quantity); heat at 125°C for 20 seconds, dry and place at room temperature for 48 hours;

[0057] Step (4): Apply a water-based acrylate pressure-sensitive adhesive with a solid content of 56% to the substrate treated in step (3), and the coating am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| stay sticky | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com