Patents

Literature

254 results about "Masking tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Masking tape, also known as painter's tape, is a type of pressure-sensitive tape made of a thin and easy-to-tear paper, and an easily released pressure-sensitive adhesive. It is available in a variety of widths. It is used mainly in painting, to mask off areas that should not be painted. The adhesive is the key element to its usefulness, as it allows the tape to be easily removed without leaving residue or damaging the surface to which it is applied. The tape is available in several strengths, rated on a 1–100 scale based on the strength of the adhesive. Most painting operations will require a tape in the 50 range. Household masking tape is made of an even weaker paper and lower-grade adhesive.

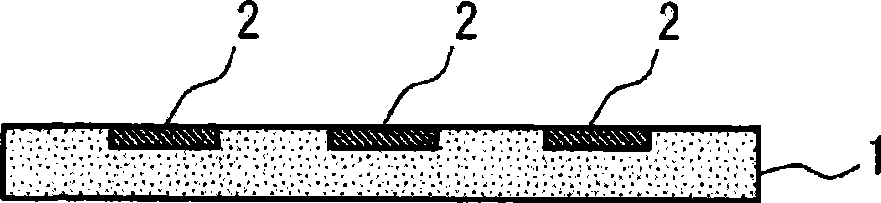

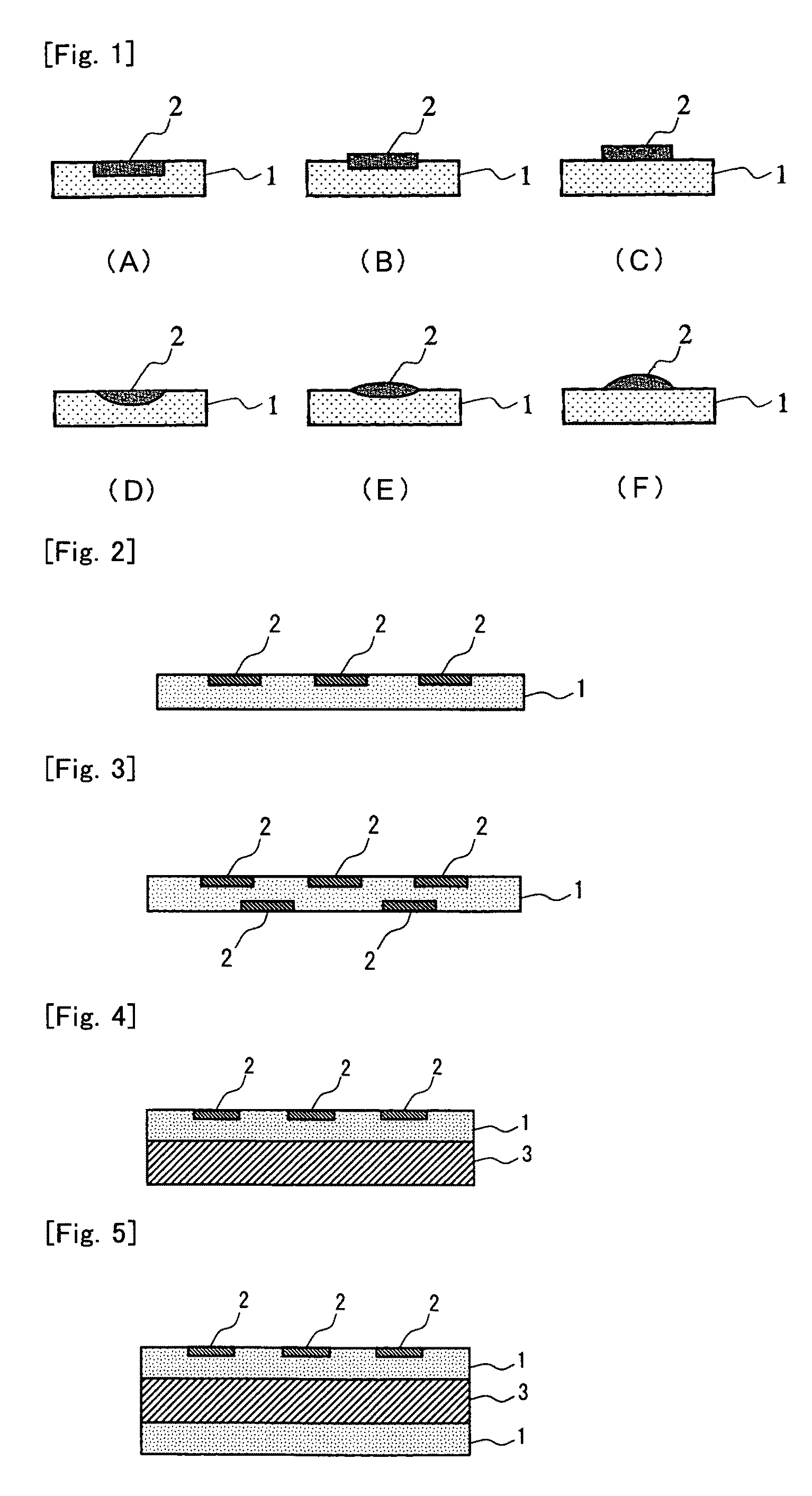

Porous Film and Multilayer Assembly Using the Same

InactiveUS20090008142A1Satisfactorily flexibleImprove porosityVacuum evaporation coatingSputtering coatingInterfacial delaminationPorous layer

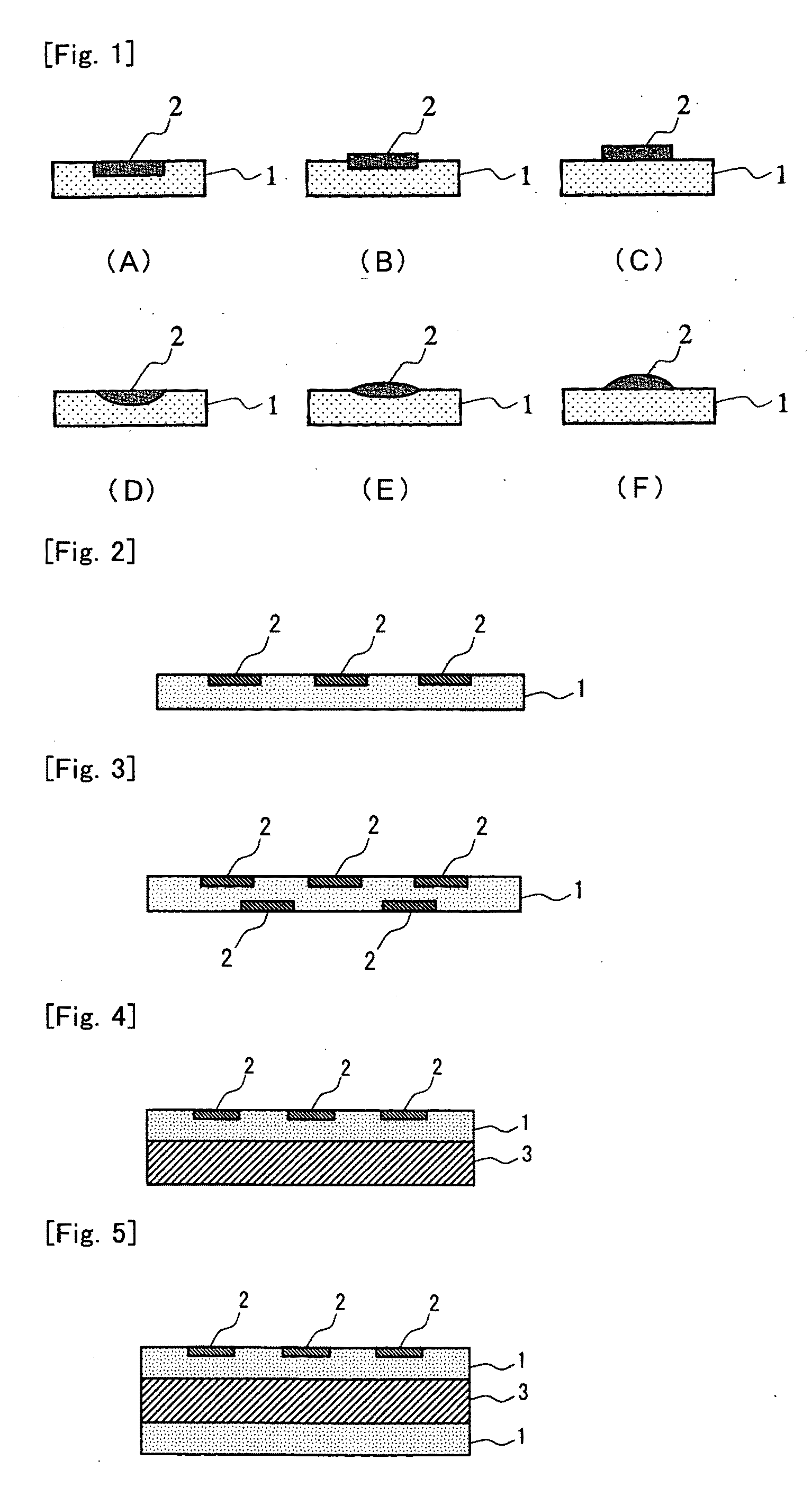

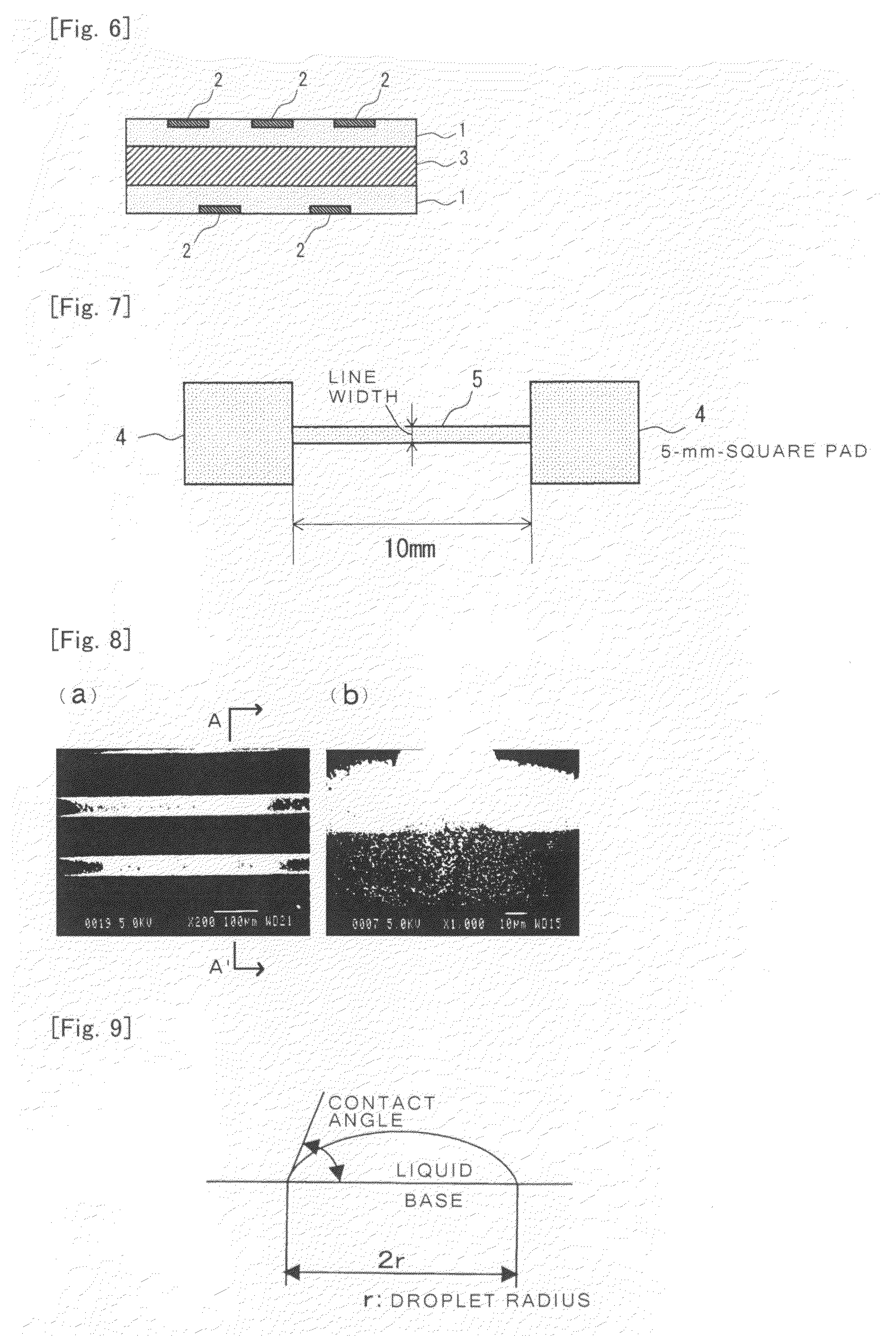

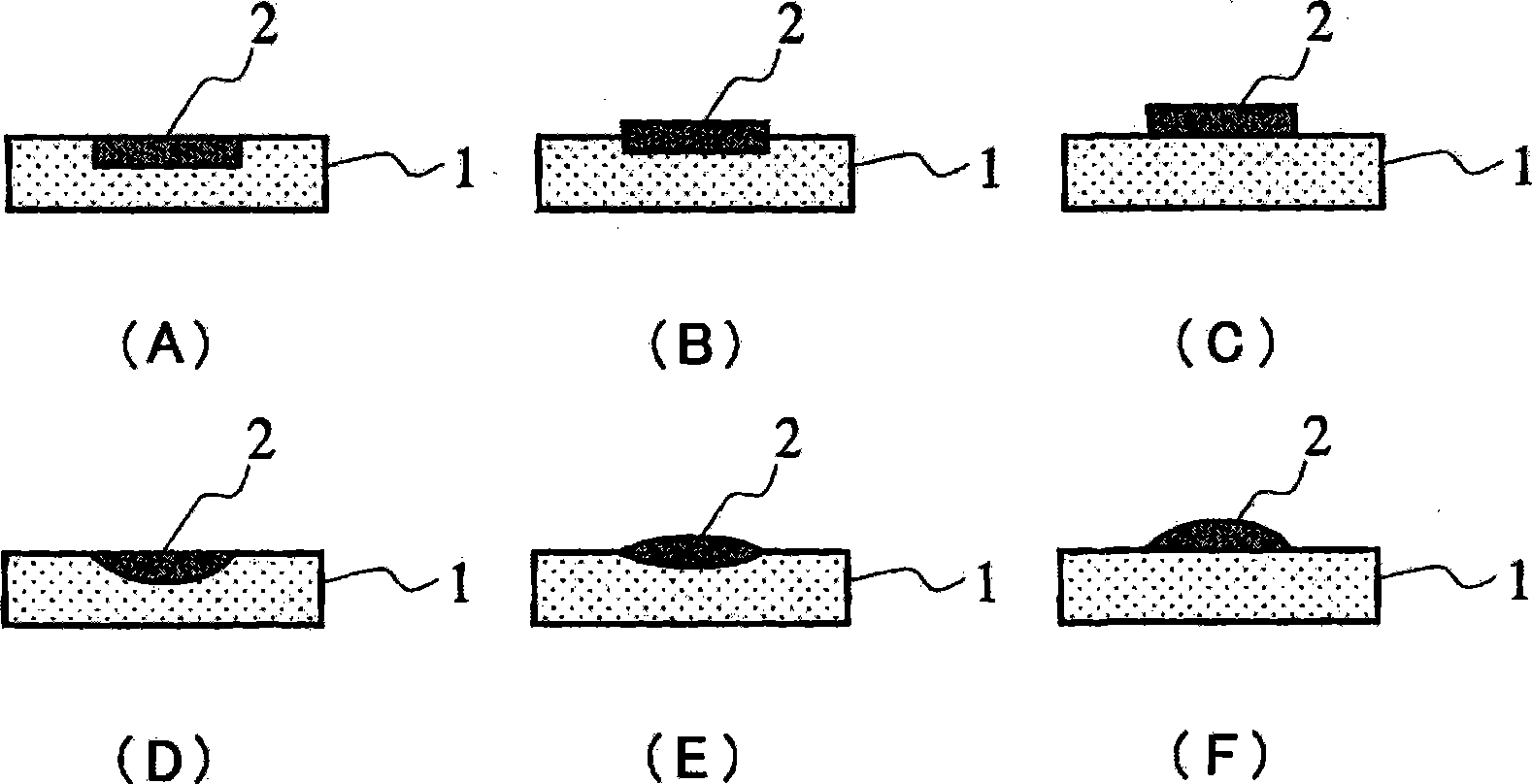

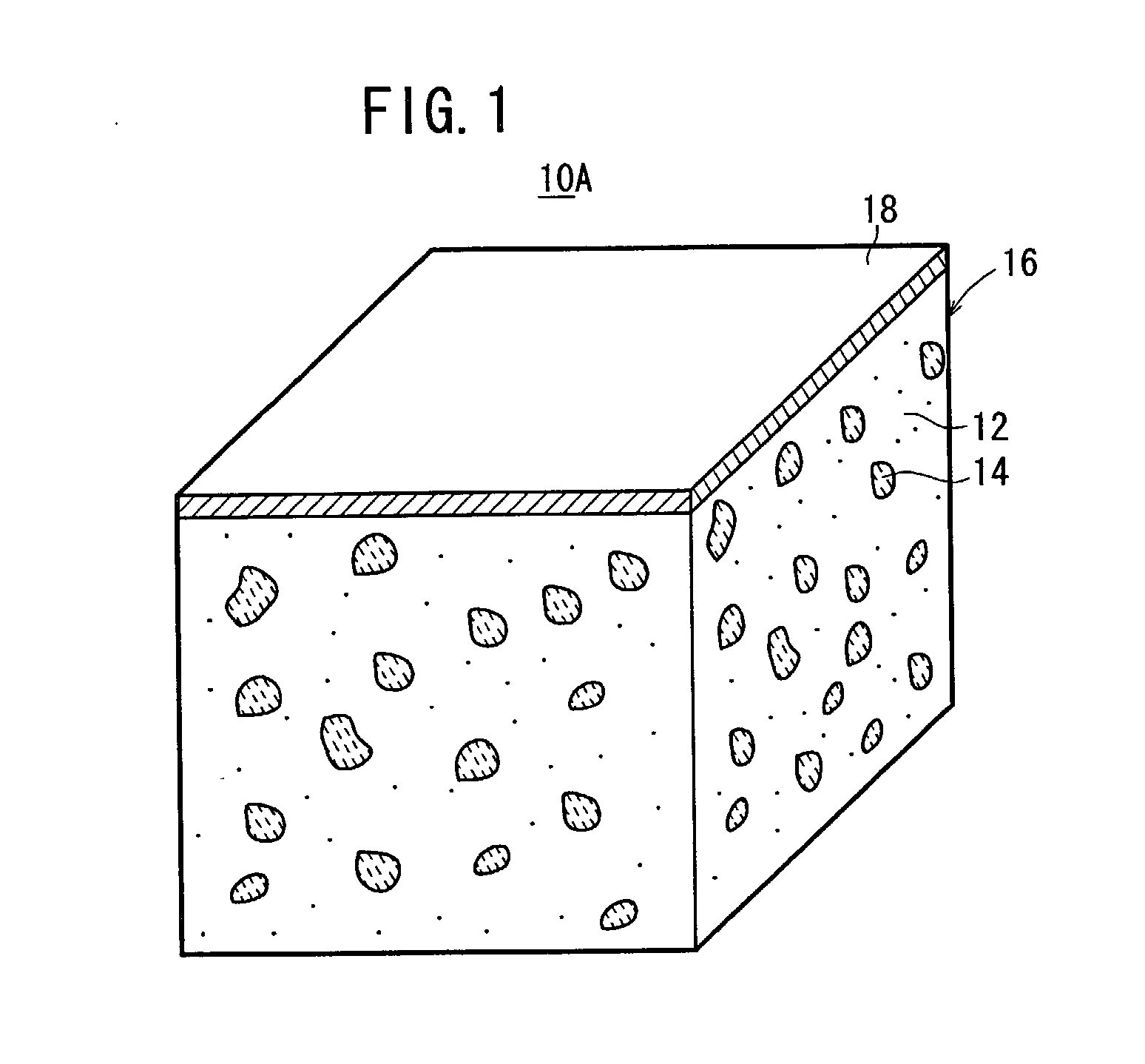

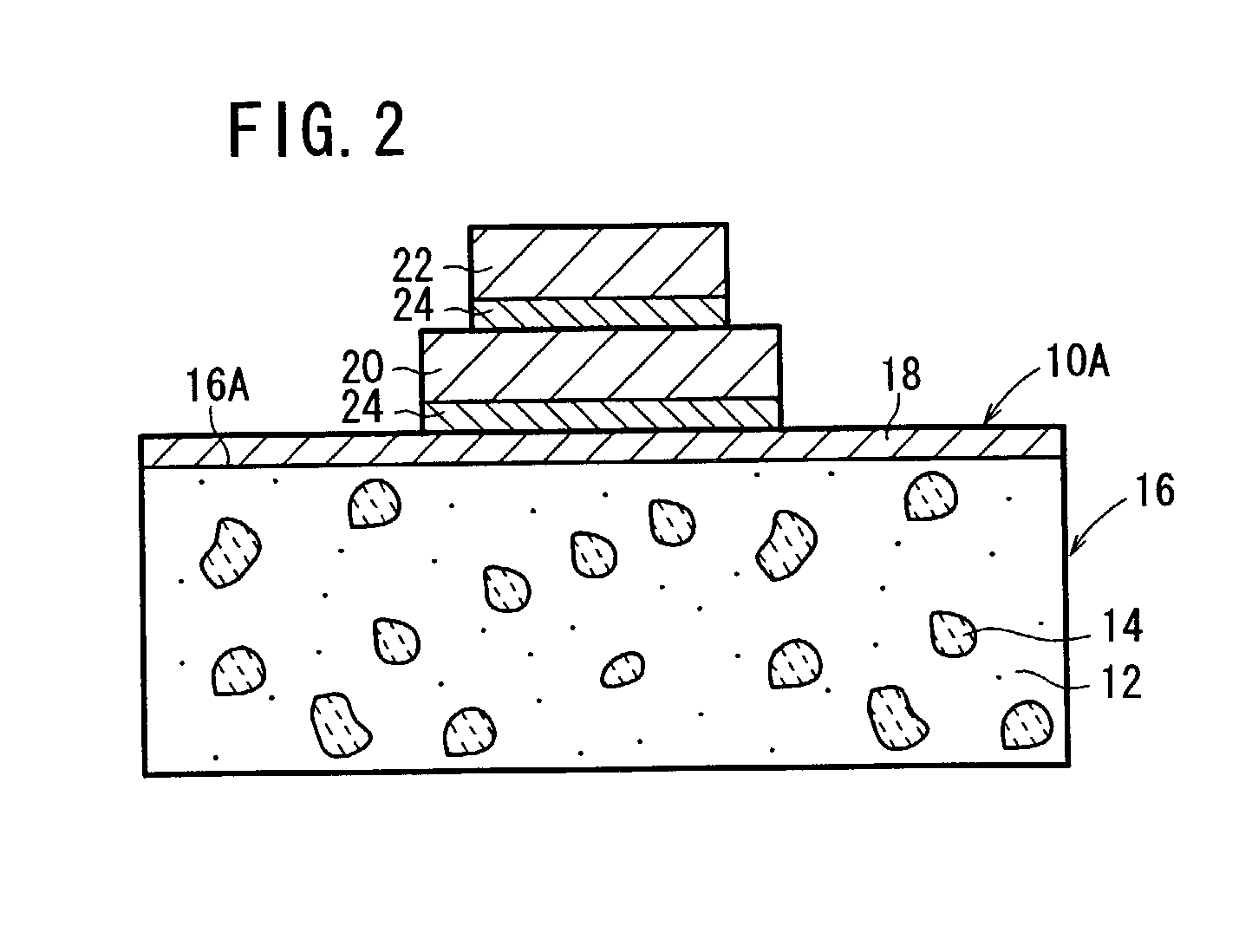

[Object] To provide a multilayer assembly that excels in pore properties, is flexible, and is satisfactorily handled and processed; and a method of producing the multilayer assembly.[Solving Means] A multilayer assembly includes a base and, arranged on at least one side thereof, a porous layer and has a large number of continuous micropores with an average pore diameter of 0.01 to 10 μm. The multilayer assembly suffers from no interfacial delamination between the base and the porous layer when examined in a tape peeling test according to the following procedure:Tape Peeling TestA 24-mm wide masking tape [Film Masking Tape No. 603 (#25)] supplied by Teraoka Seisakusho Co., Ltd. is applied to a surface of the porous layer of the multilayer assembly and press-bonded thereto with a roller having a diameter of 30 mm and a load of 200 gf to give a sample; and the sample is subjected to a T-peel test with a tensile tester at a peel rate of 50 mm / min.

Owner:DAICEL CHEM IND LTD

Porous film and multilayer assembly using the same

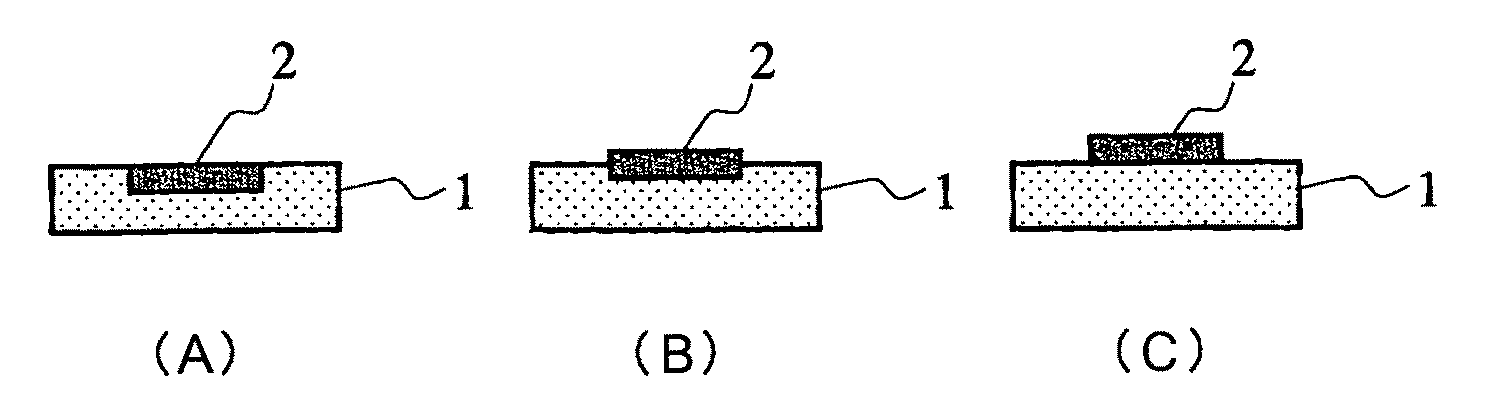

InactiveCN101384425ASmall widthImprove adhesionLayered productsPrinted circuit manufactureAdhesive beltPorous layer

To provide a porous-film layered product which has excellent porousness, has flexibility, and is excellent in handleability and formability; and a process for producing the layered product. [MEANS FOR SOLVING PROBLEMS] The porous-film layered product comprises a base and, superposed on at least one side thereof, a porous layer having many fine interconnecting pores having an average pore diameter of 0.01-10 [mu]m, and is characterized by suffering no interfacial separation between the base and the porous layer when examined in a tape peeling test by the following method. Tape peeling test A 24 mm-wide masking tape [Film Masking Tape No. 603(#25)] manufactured by Teraoka Seisakusho Co., Ltd. is applied to the surface of the porous layer of the porous-film layered product and press-bonded thereto with a roller having a diameter of 30 mm and a load of 200 gf. Thereafter, this sample is subjected to a T-peel test with a tensile tester at a peeling rate of 50 mm / min.

Owner:DAICEL CHEM IND LTD

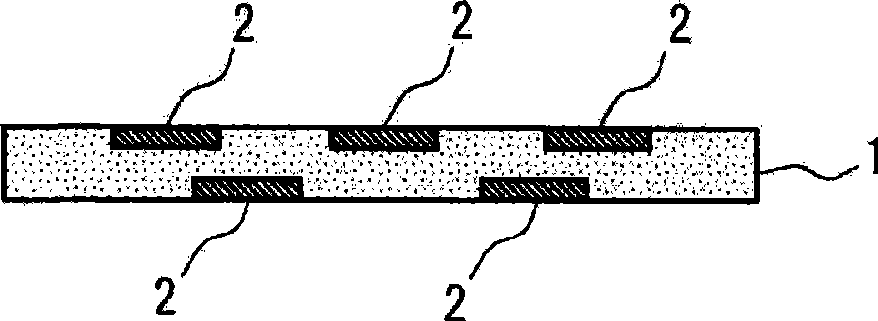

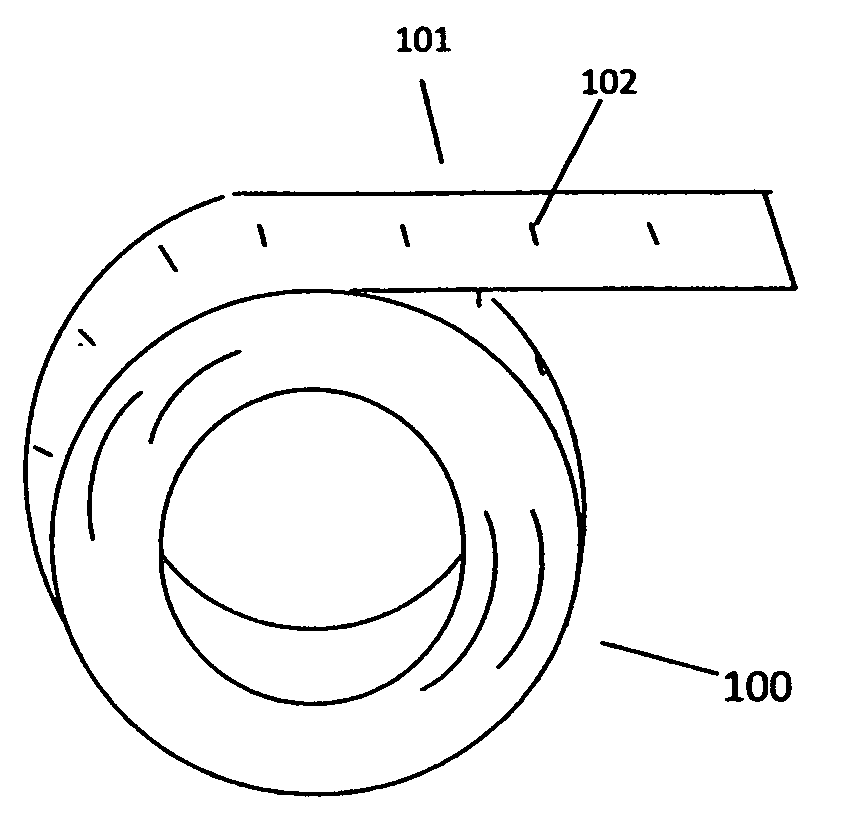

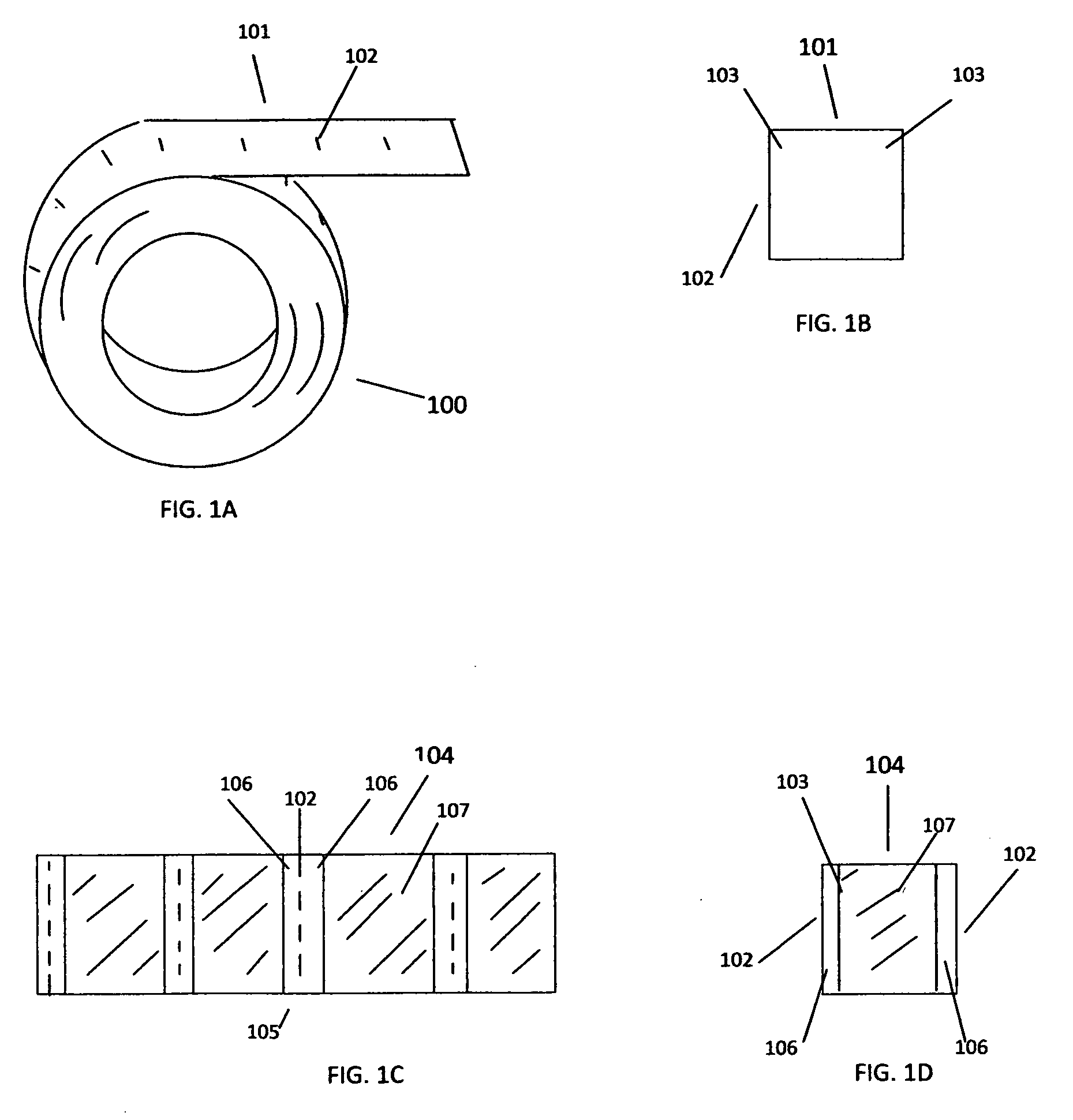

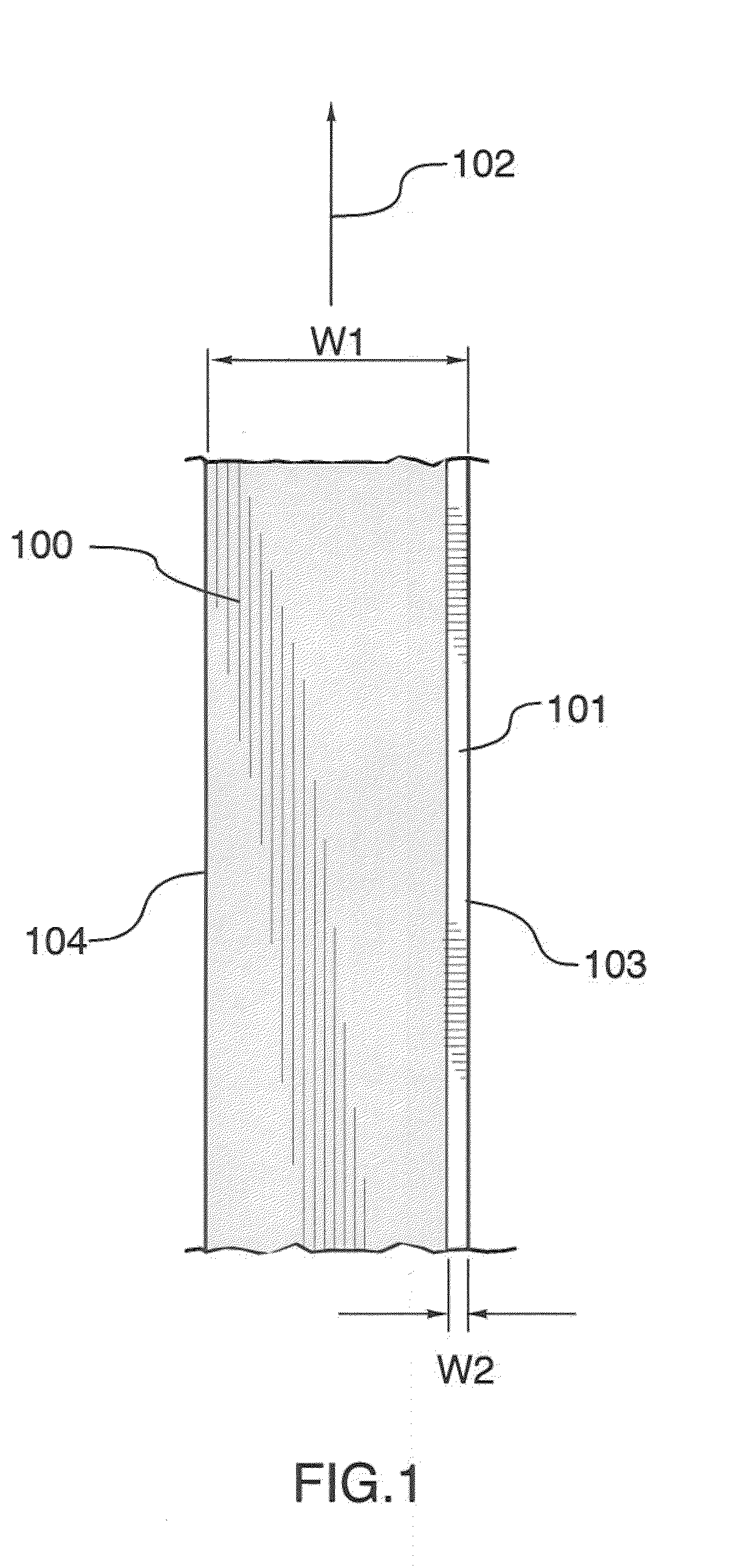

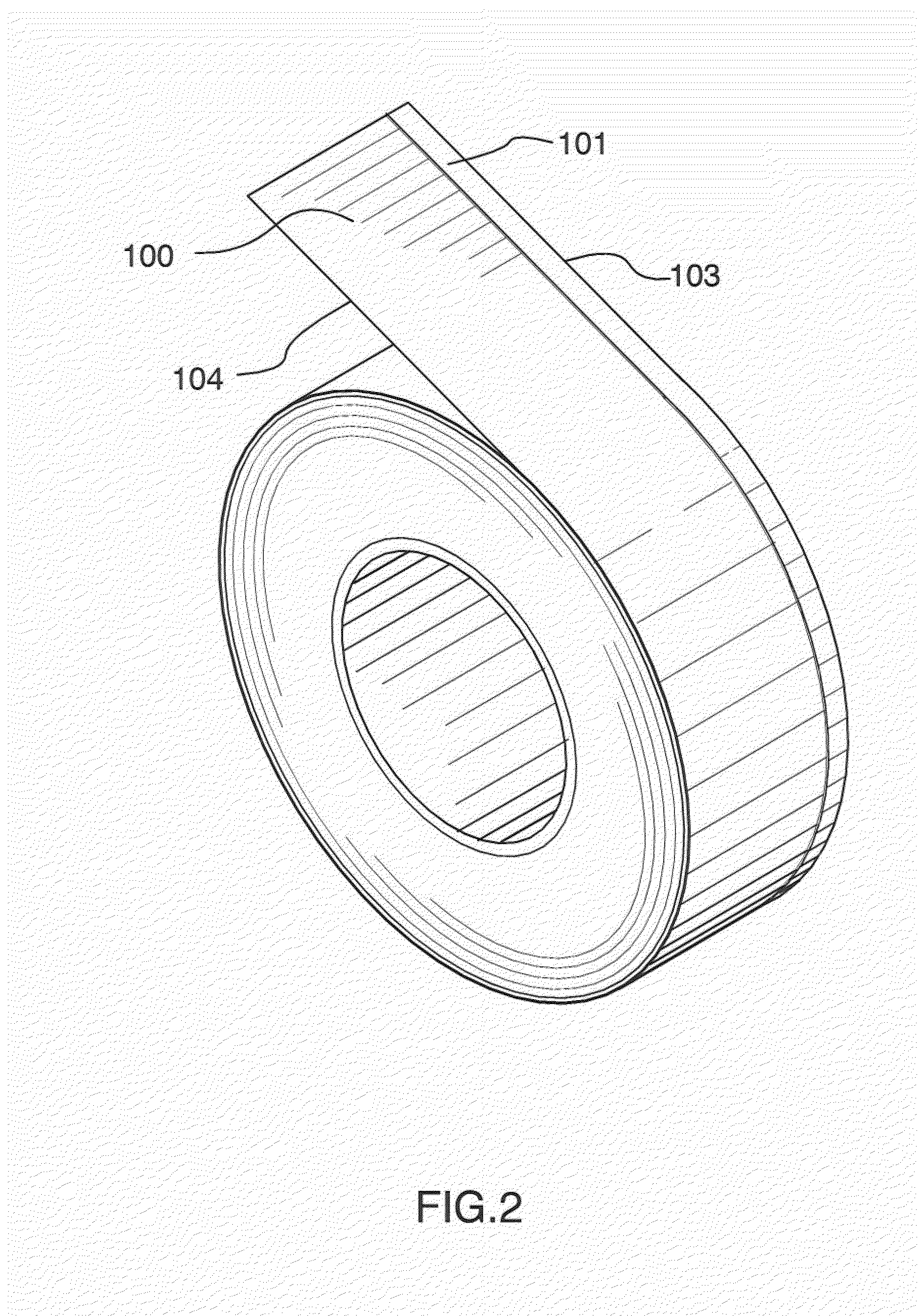

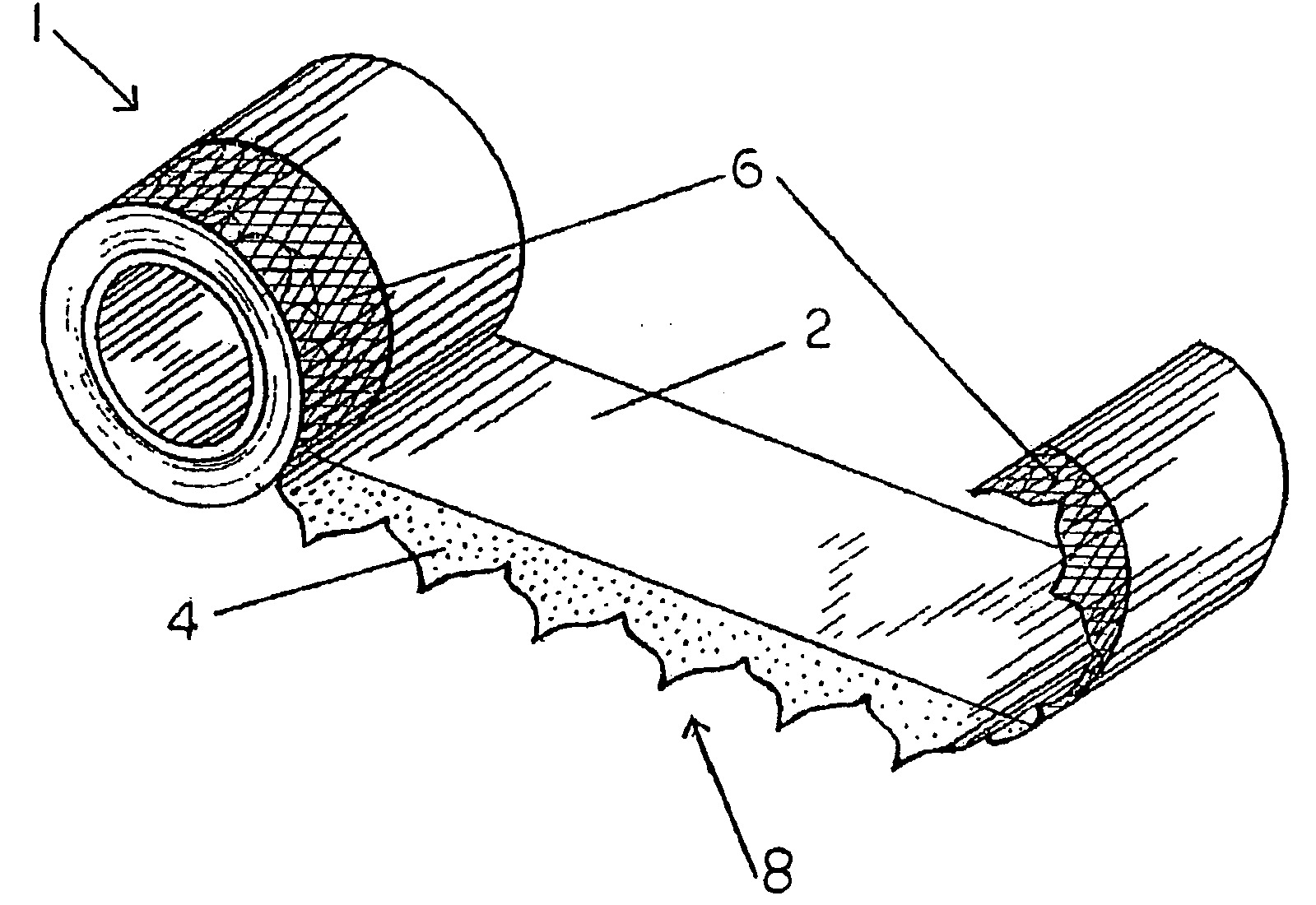

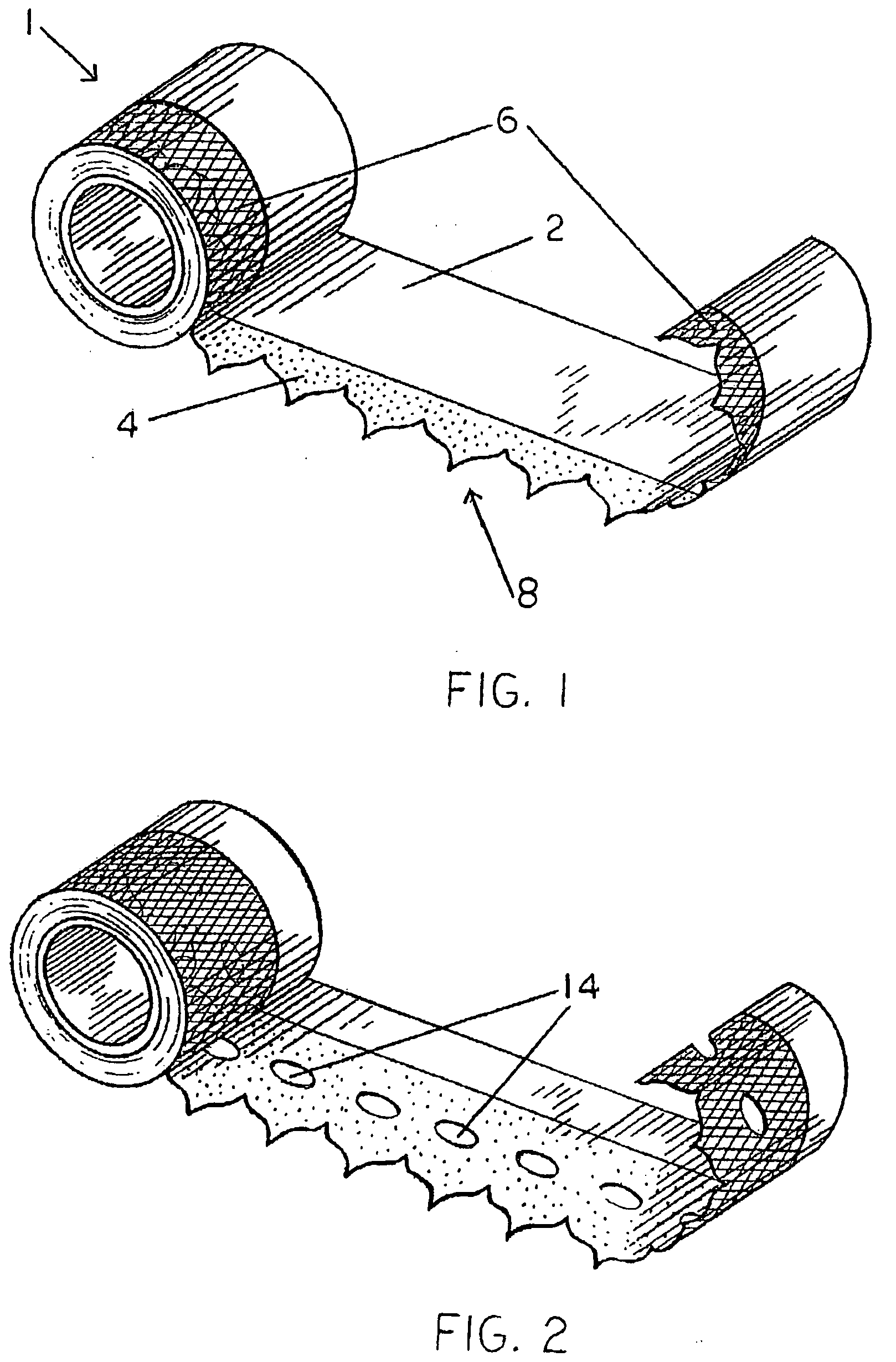

Masking tape

A window (26) is masked accurately by placing the side (44) of a tape roll (42) against a window frame (28) and pressing the outer rim (46) of the tape roll (42) against the window (26). Pressure bonds the adhesive (22a) to the window (26). The side (44) of the tape roll (42) is guided and supported against the window frame (28) and tape (100) is simultaneously unwound against the window (26). The outer longitudinal periphery of the tape (100) accurately follows the corner (36).

Owner:TUORINIEMI VEIJO M

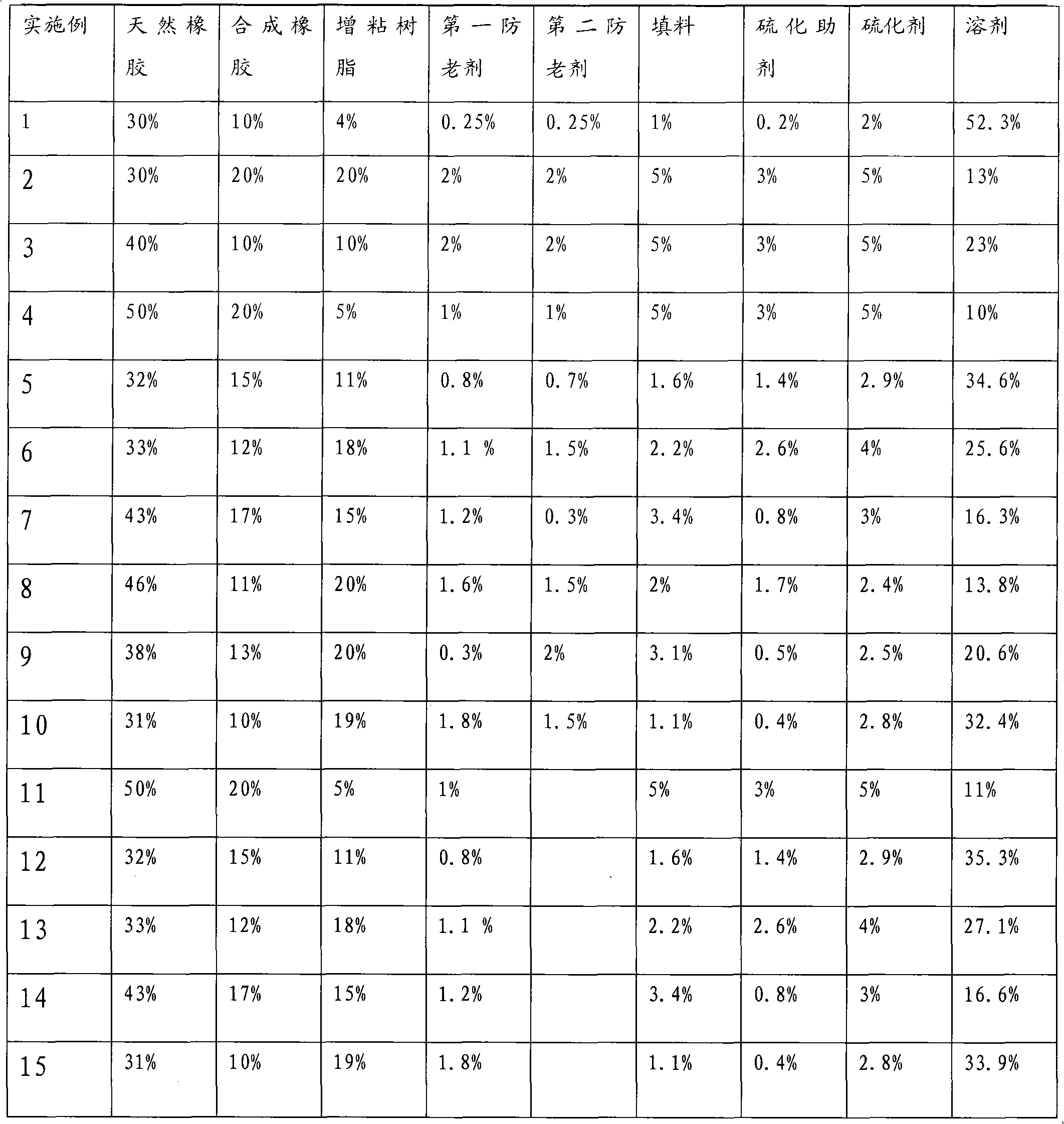

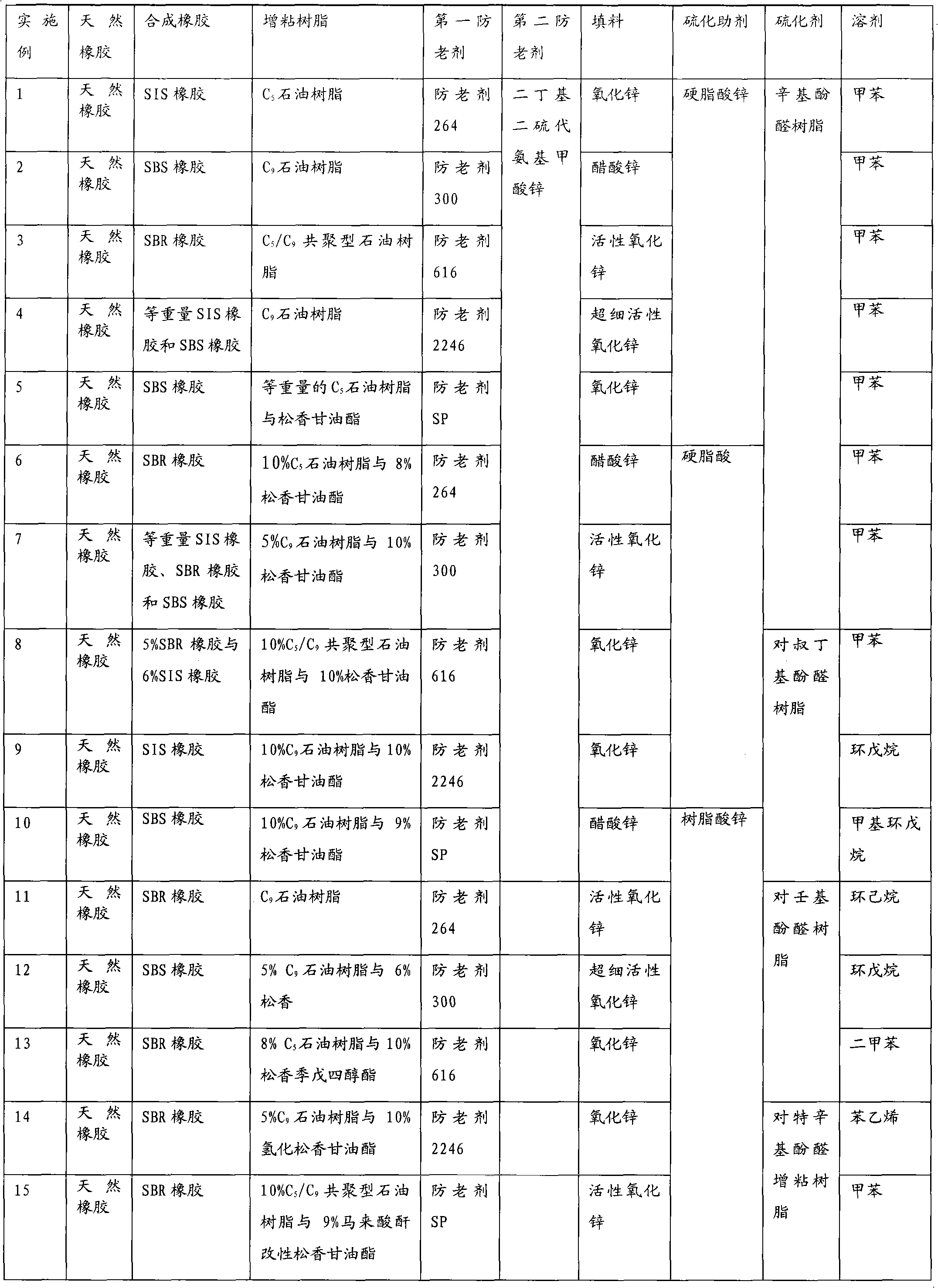

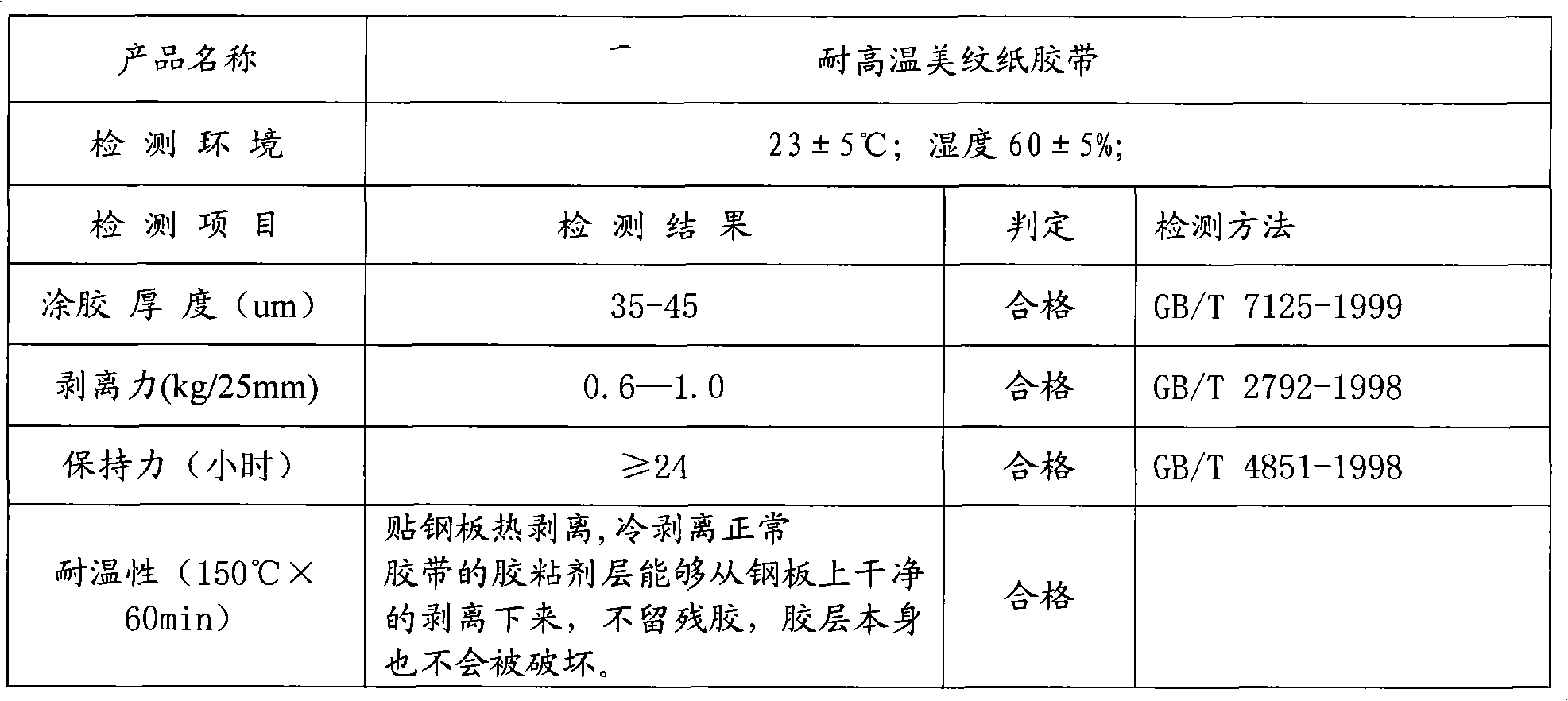

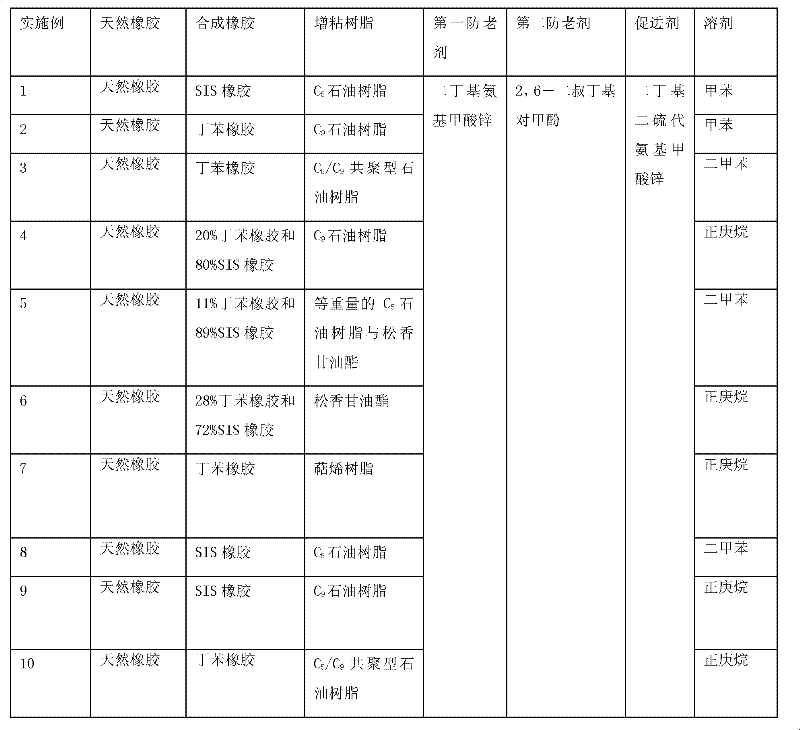

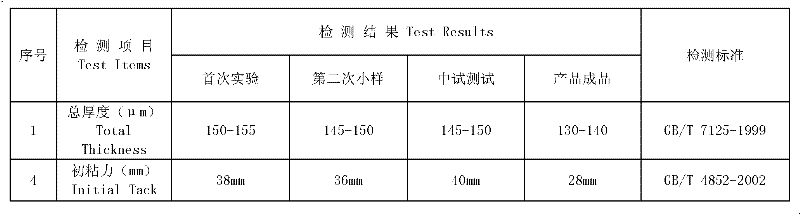

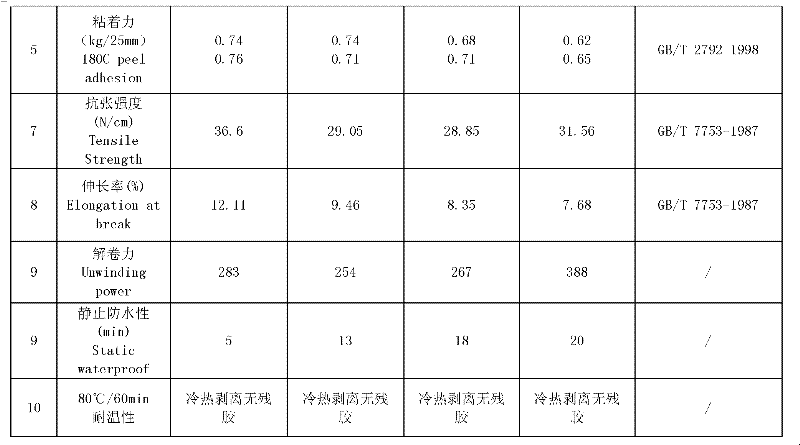

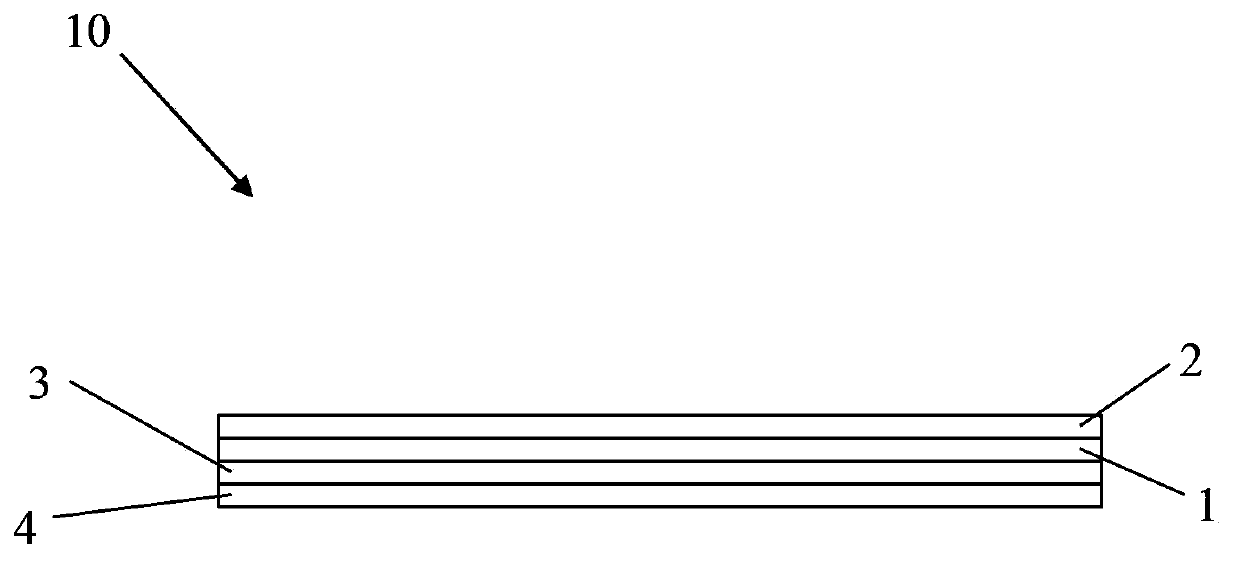

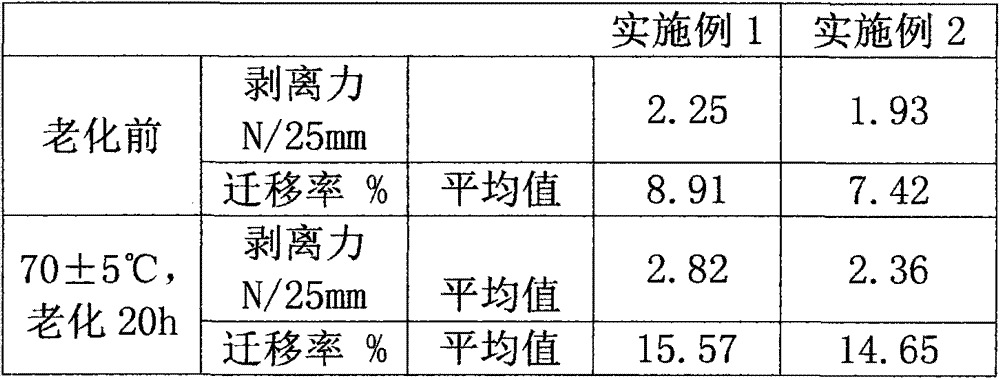

Adhesive for high-temperature-resistant masking tape and high-temperature-resistant masking tape

ActiveCN102120922AThermal peeling is normalCold peeling index is normalMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesVulcanizationMasking tape

The invention discloses an adhesive for a high-temperature-resistant masking tape. The adhesive for the high-temperature-resistant masking tape is characterized by comprising the following components in percentage by weight: 30 to 50 percent of natural rubber, 10 to 20 percent of synthetic rubber, 4 to 20 percent of viscous resin, 0.5 to 4 percent of anti-aging agent, 1 to 5 percent of filler, 0.2 to 3 percent of vulcanization auxiliary agent, 2 to 5 percent of vulcanizing agent and the balance of solvent. The adhesive for the high-temperature-resistant masking tape has high temperature resistance and normal hot stripping and cold stripping indexes after being used continuously at the temperature of 150 DEG C for 60 minutes. The adhesive is applied to adhesion at the temperature of 150 DEG C without degumming and cracking and is particularly applied to high-temperature environments such as automobile baking varnish, an electronic circuit board and the like.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

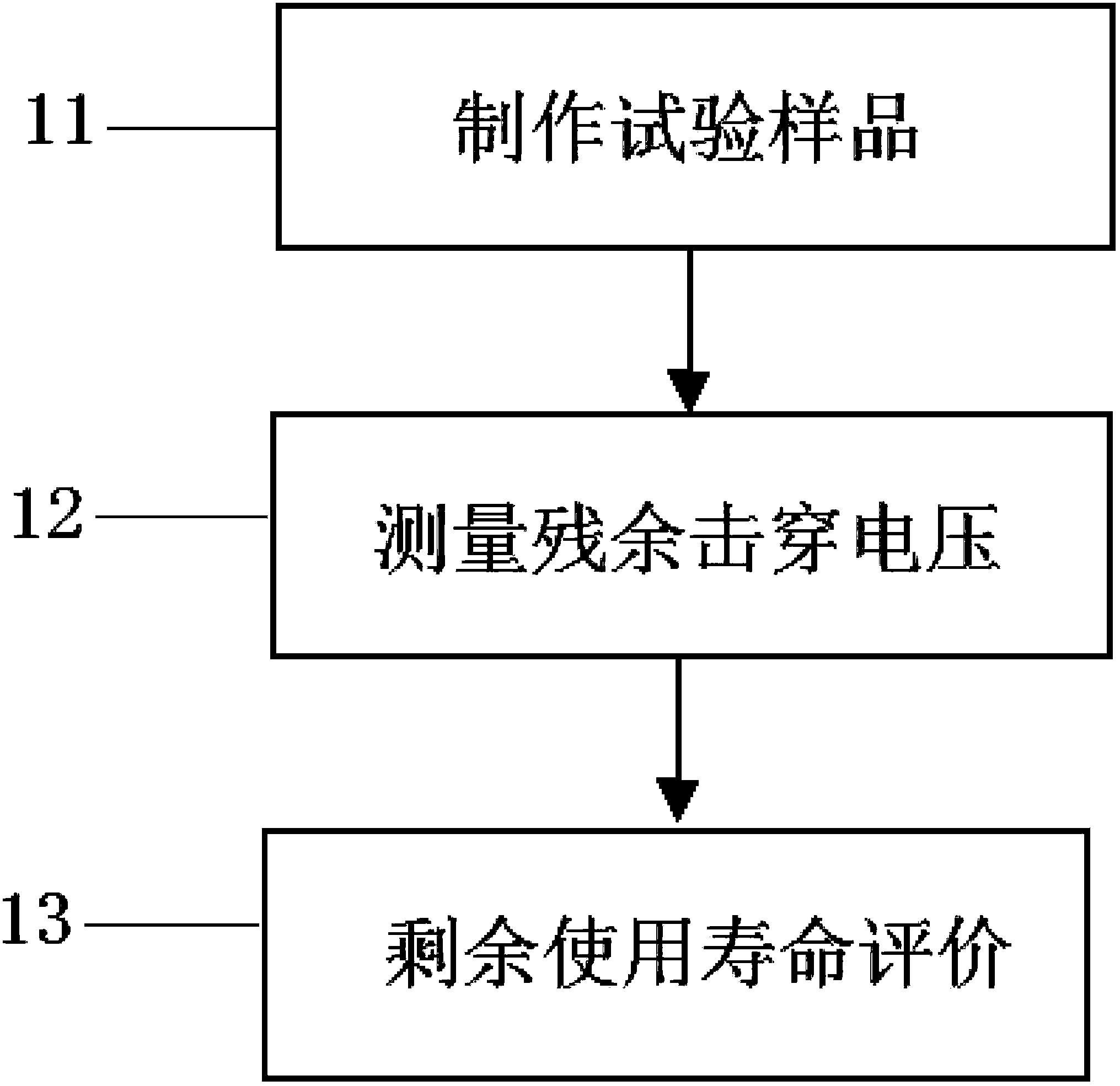

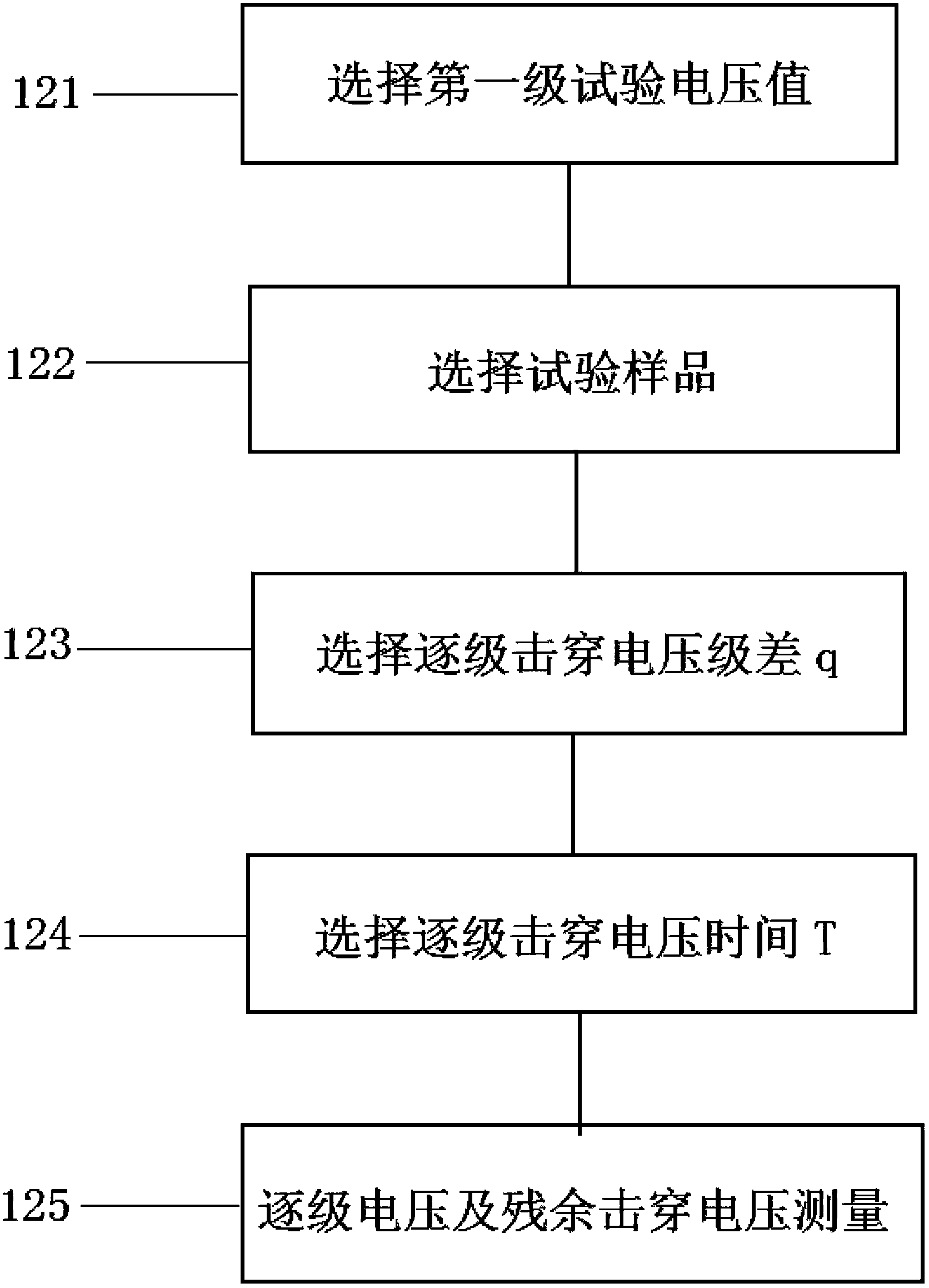

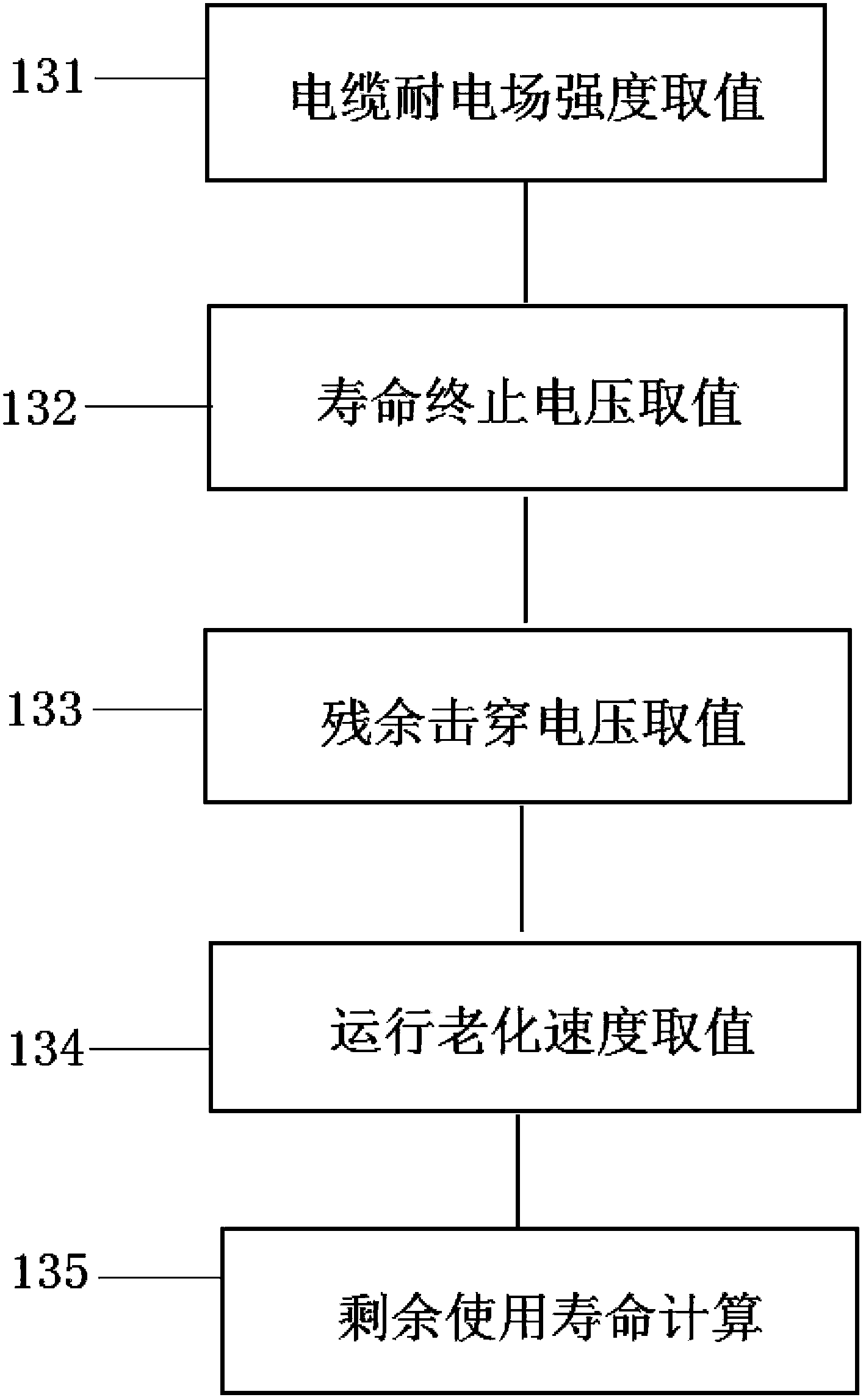

Crosslinked polyethylene cable residual life assessment method

ActiveCN103472363AAccurate evaluationObjective evaluationTesting dielectric strengthElectrical resistance and conductanceElectrical conductor

The invention discloses a crosslinked polyethylene cable residual life assessment method which comprises the following steps: residual breakdown voltage of a cable is obtained; and aging rate of the cable is calculated according to the cable aging rate formula of Sd=(H*E-Sy) / N, wherein Sd is aging rate, Sy is residual breakdown voltage of the cable, H is major insulation design thickness of the cable, E is major insulation design anti-electric field intensity and N is operational number of years of the cable; and residual useful life is calculated according to the residual useful life formula of SK=(H*E-SZ) / Sd-N, wherein SK is residual useful life of the cable and SZ is end-of-life voltage of the cable. The step of obtaining the residual breakdown voltage of the cable further comprises the following steps: major insulation resistance between each cable conductor and a copper mask tape is measured; power frequency voltage is applied between each cable conductor and the copper mask tape; and a power-frequency step-by-step breakdown voltage test is carried out so as to obtain the cable main insulation based residual breakdown voltage.

Owner:BAOSHAN IRON & STEEL CO LTD +1

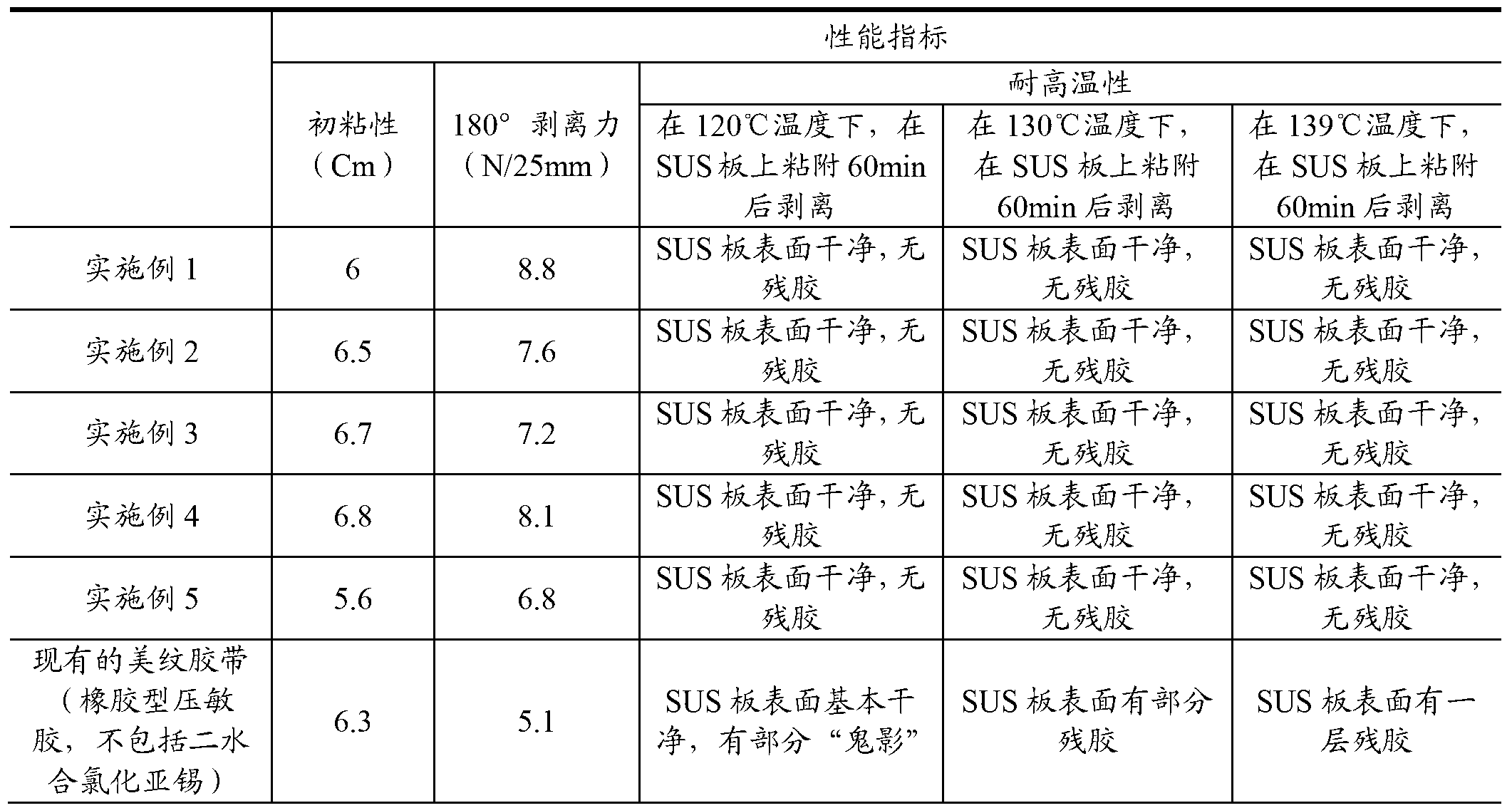

High-temperature-resisting pressure-sensitive adhesive for adhesive tape, adhesive tape and preparation process

ActiveCN103305154AGood initial adhesionTack improvement and balanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceMasking tape

The invention discloses a high-temperature-resisting pressure-sensitive adhesive for an adhesive tape, the adhesive tape and a preparation process. The high-temperature-resisting pressure-sensitive adhesive comprises main body rubber, an auxiliary material additive, a tackifying agent, a plasticizer, a solvent and a curing agent, wherein the main body rubber is composed of natural rubber and / or synthetic rubber, the auxiliary material additive comprises stannous chloride dihydrate and an anti-aging agent, mass mole ratios of the stannous chloride dihydrate and the anti-aging agent to the main body rubber are 0.2:100-8:100 and 0.1:100-10:100 respectively, the mass mole ratio of the tackifying agent to the main body rubber is 10:100-200:100, and the mass mole ratio of the plasticizer to the main body rubber is 5:100-40:100. The high-temperature-resisting pressure-sensitive adhesive is excellent in initial adhesive performance, high in cohesion, good in stripping performance, high in high-temperature resistance, especially applicable to preparation of masking tapes and capable of greatly facilitating the application of the masking tapes in high-temperature environments.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

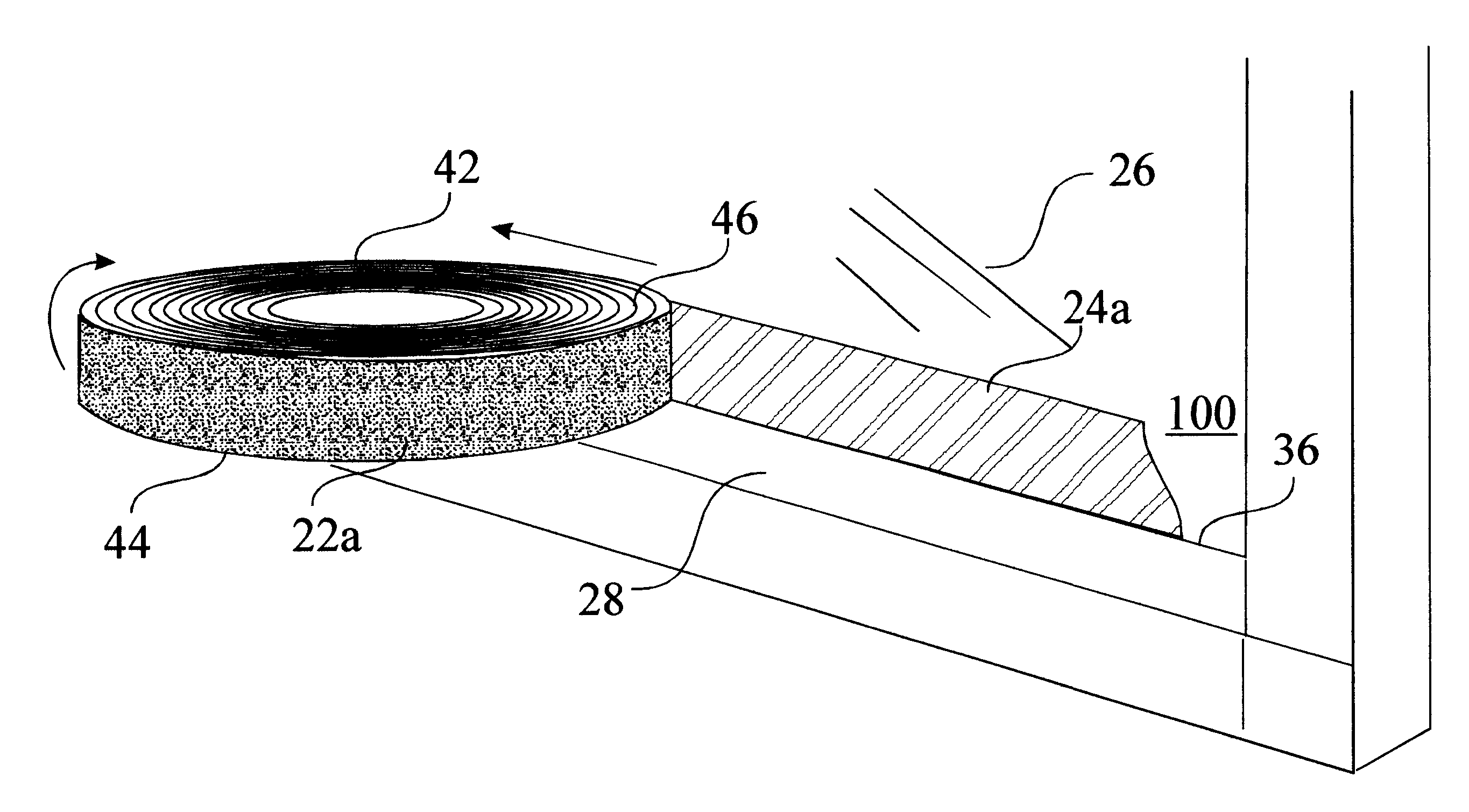

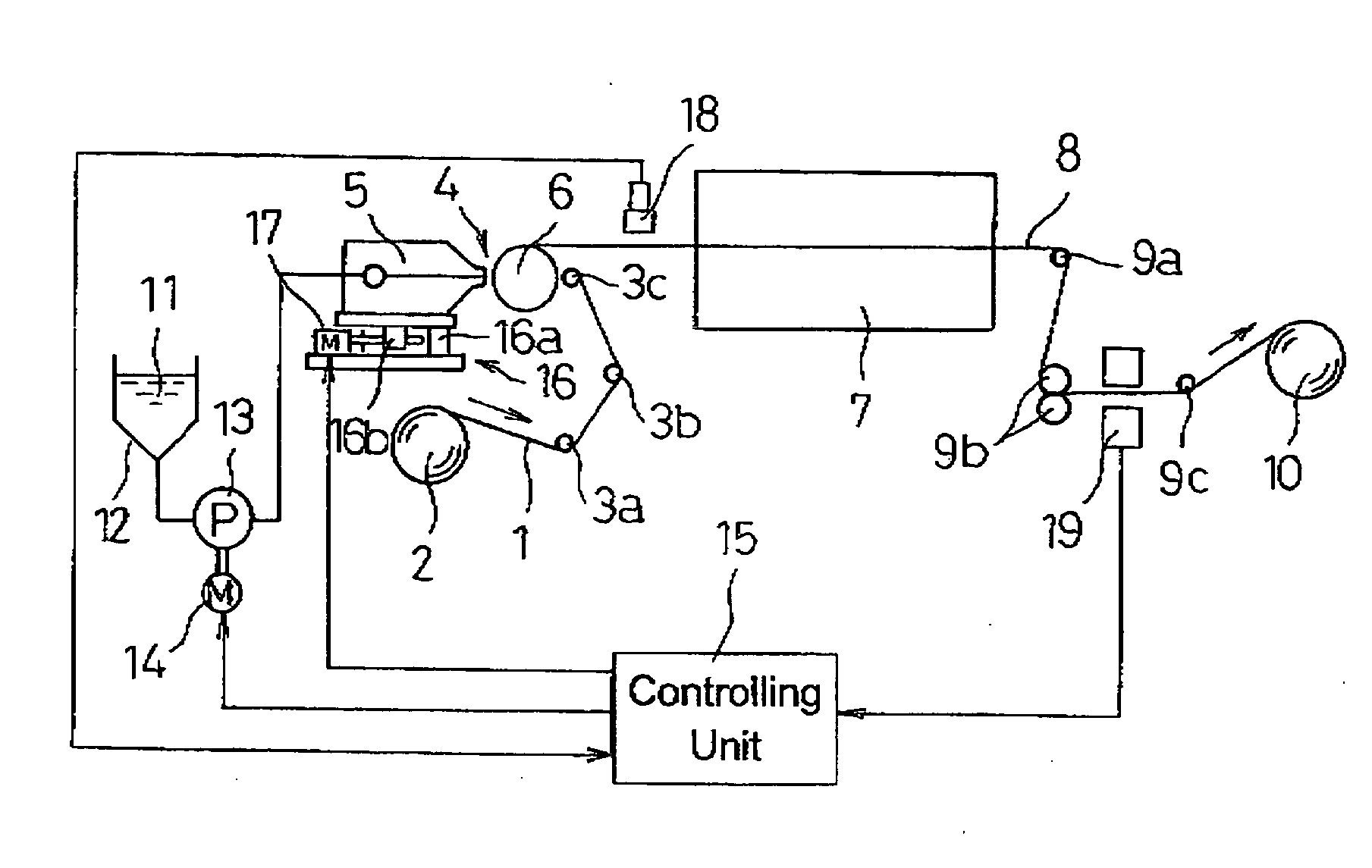

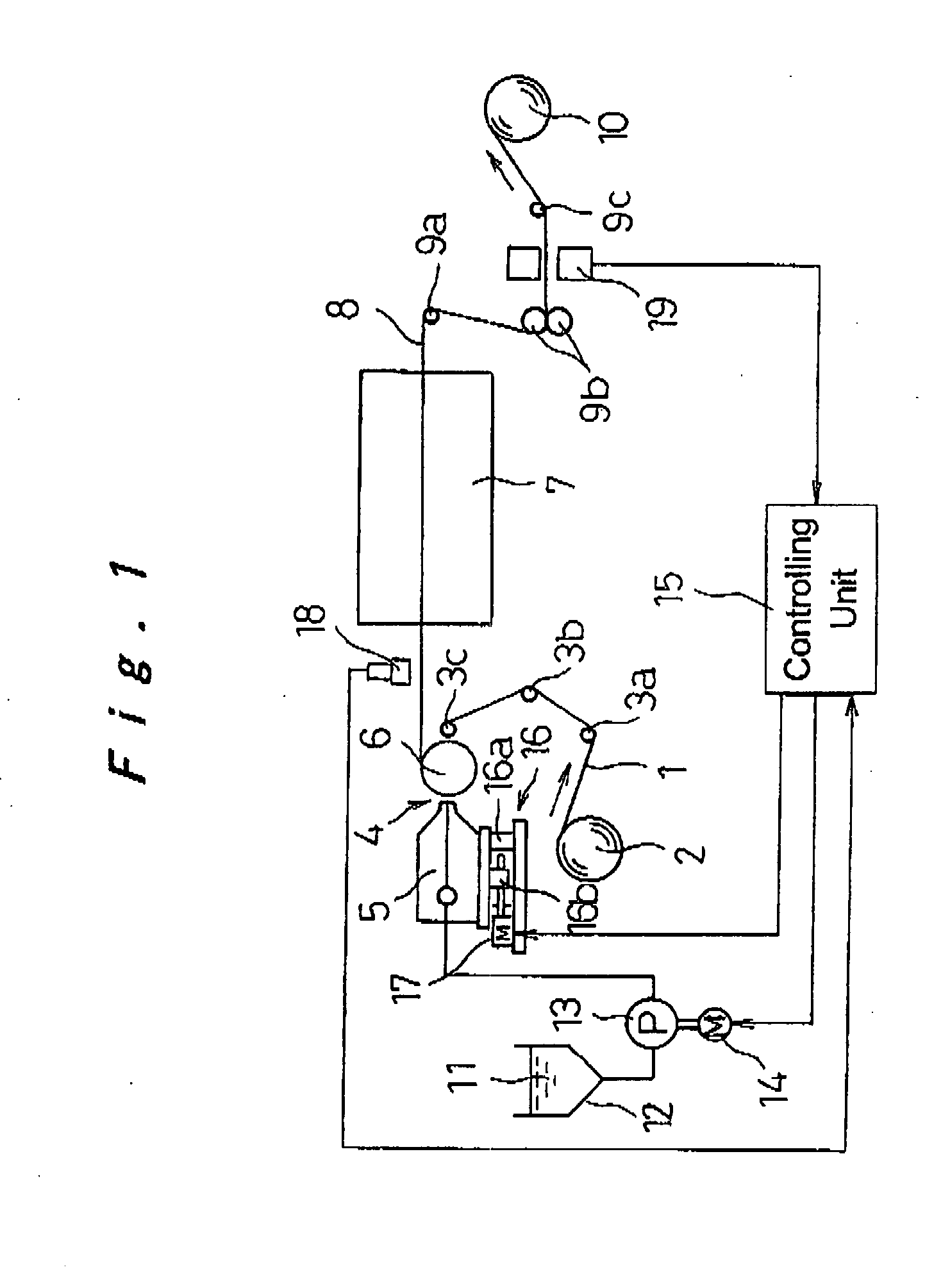

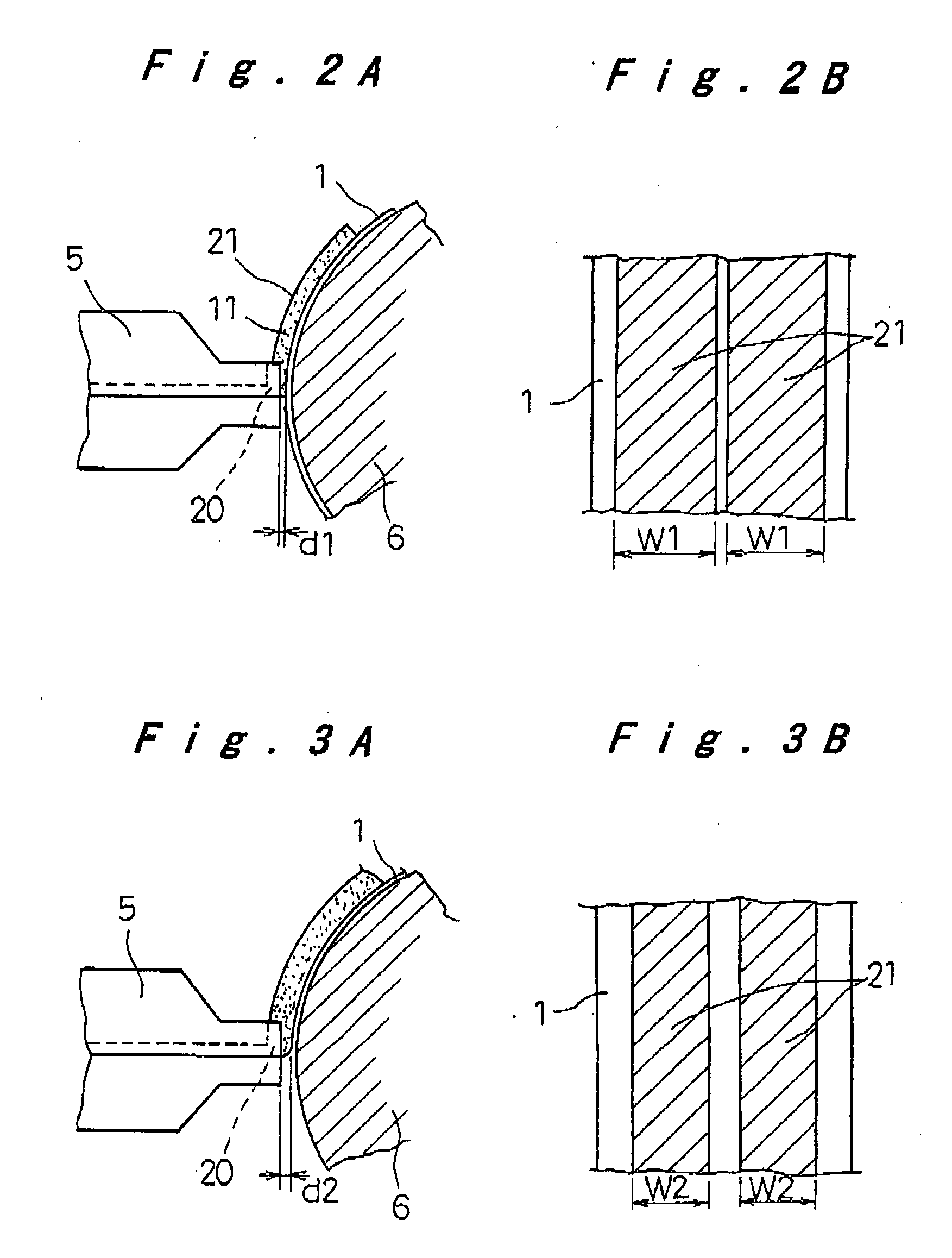

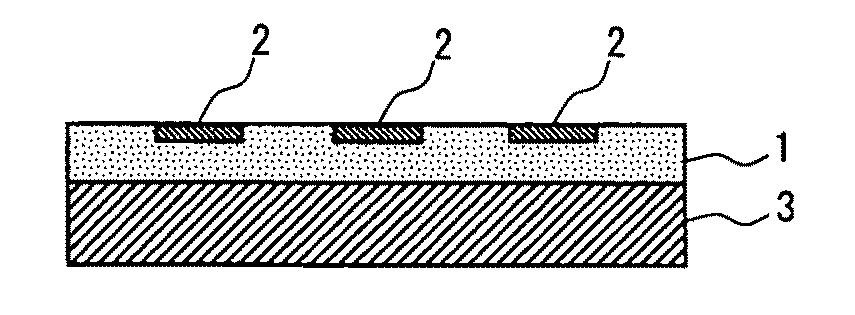

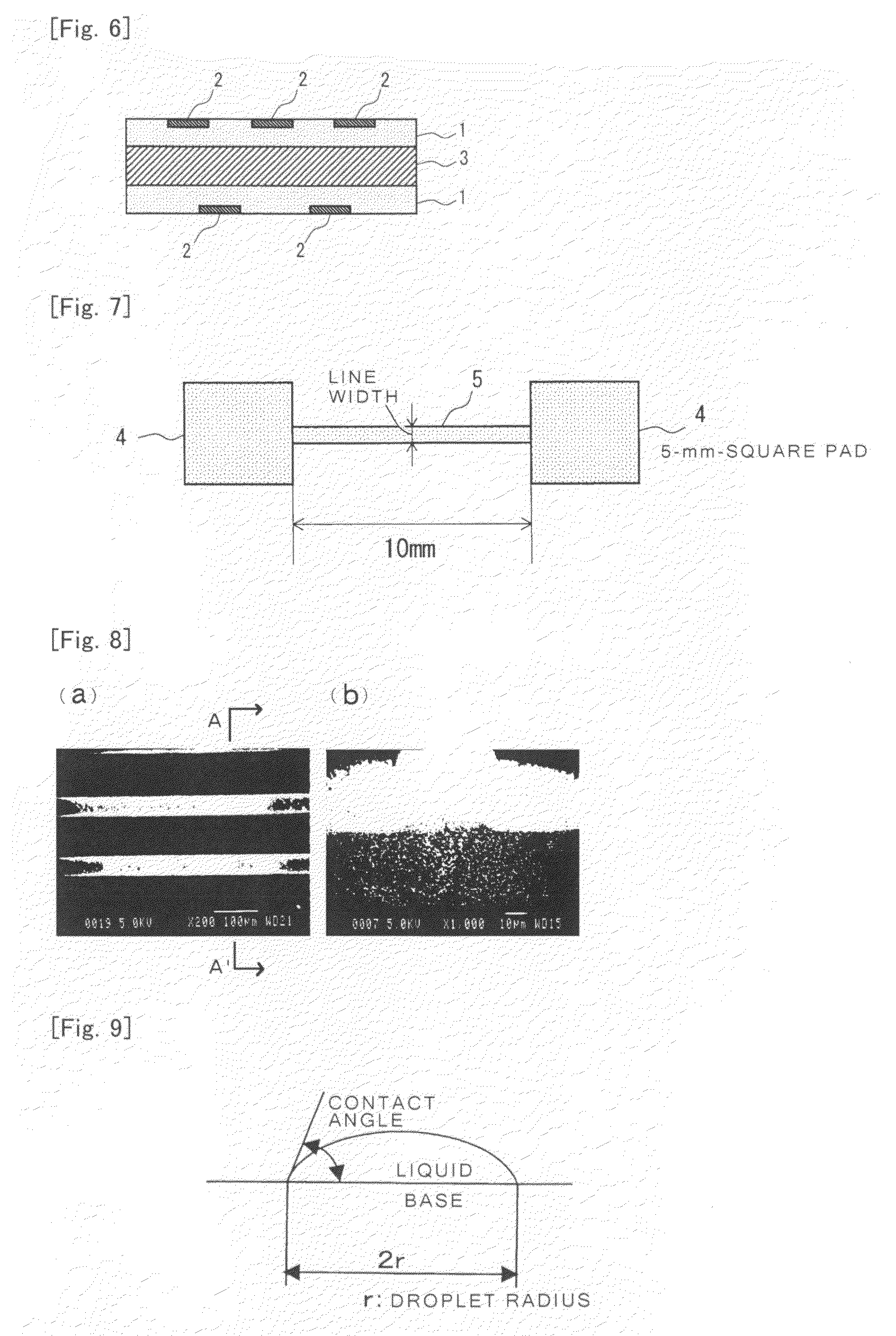

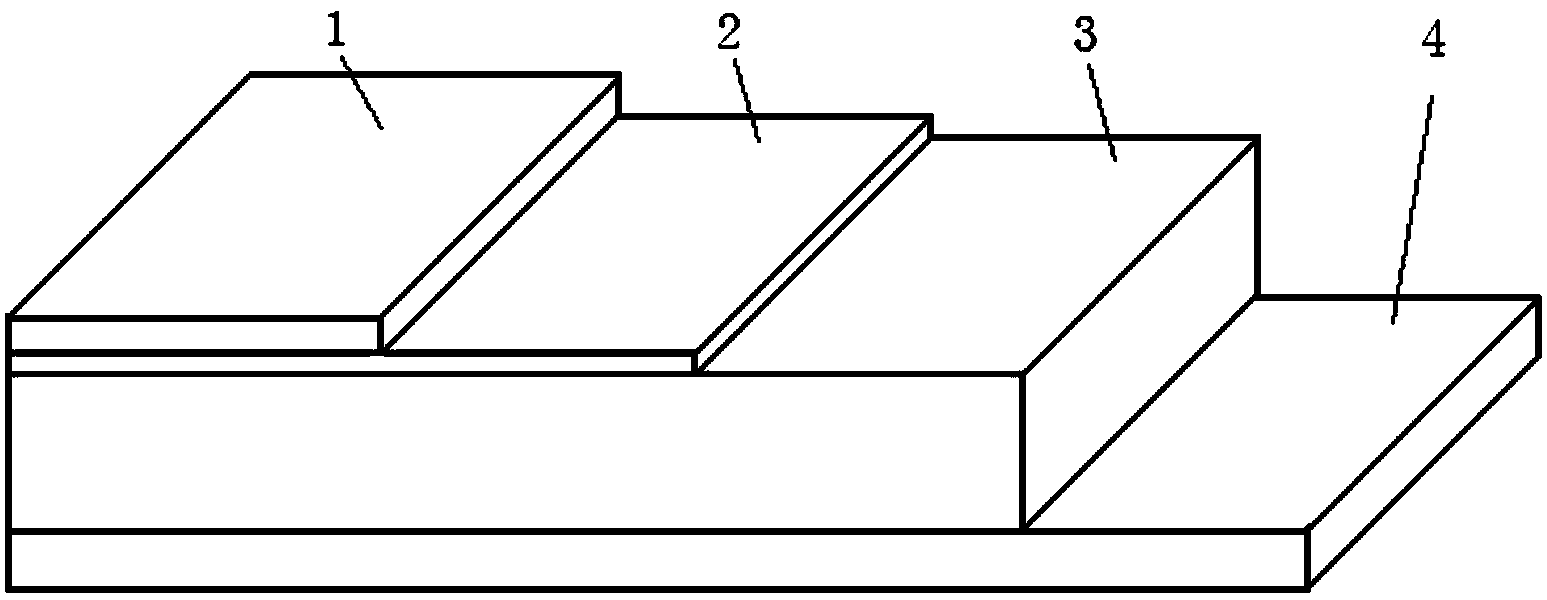

System and method for controlling coating width of electrode plate

InactiveUS20070248745A1Improve accuracyLow costLiquid surface applicatorsVacuum evaporation coatingMasking tapeSpray nozzle

A system for controlling the coating width of an electrode plate, The system includes; a coating device which ejects a paste at a predetermined width from each of a plurality of slit nozzles toward a fed core substrate to form a coating layer on the surface of the core substrate; a gap controlling device which controls the gap between the slit nozzles of the coating device and the core substrate; a coating width measuring device which measures the width of the coating layer on the surface of the core substrate; and a controlling unit which controls the gap controlling device based on the results obtained by comparing the measured coating width with a predetermined coating width. In this system, the stripe-shaped coating layer is formed without using a masking tape, and the width of the coating layer is controlled with high accuracy.

Owner:PANASONIC CORP

Porous film and multilayer assembly using the same

InactiveUS8294040B2Vacuum evaporation coatingPretreated surfacesInterfacial delaminationMasking tape

[Object] To provide a multilayer assembly that excels in pore properties, is flexible, and is satisfactorily handled and processed; and a method of producing the multilayer assembly.[Solving Means] A multilayer assembly includes a base and, arranged on at least one side thereof, a porous layer and has a large number of continuous micropores with an average pore diameter of 0.01 to 10 μm. The multilayer assembly suffers from no interfacial delamination between the base and the porous layer when examined in a tape peeling test according to the following procedure:Tape Peeling TestA 24-mm wide masking tape [Film Masking Tape No. 603 (#25)] supplied by Teraoka Seisakusho Co., Ltd. is applied to a surface of the porous layer of the multilayer assembly and press-bonded thereto with a roller having a diameter of 30 mm and a load of 200 gf to give a sample; and the sample is subjected to a T-peel test with a tensile tester at a peel rate of 50 mm / min.

Owner:DAICEL CHEM IND LTD

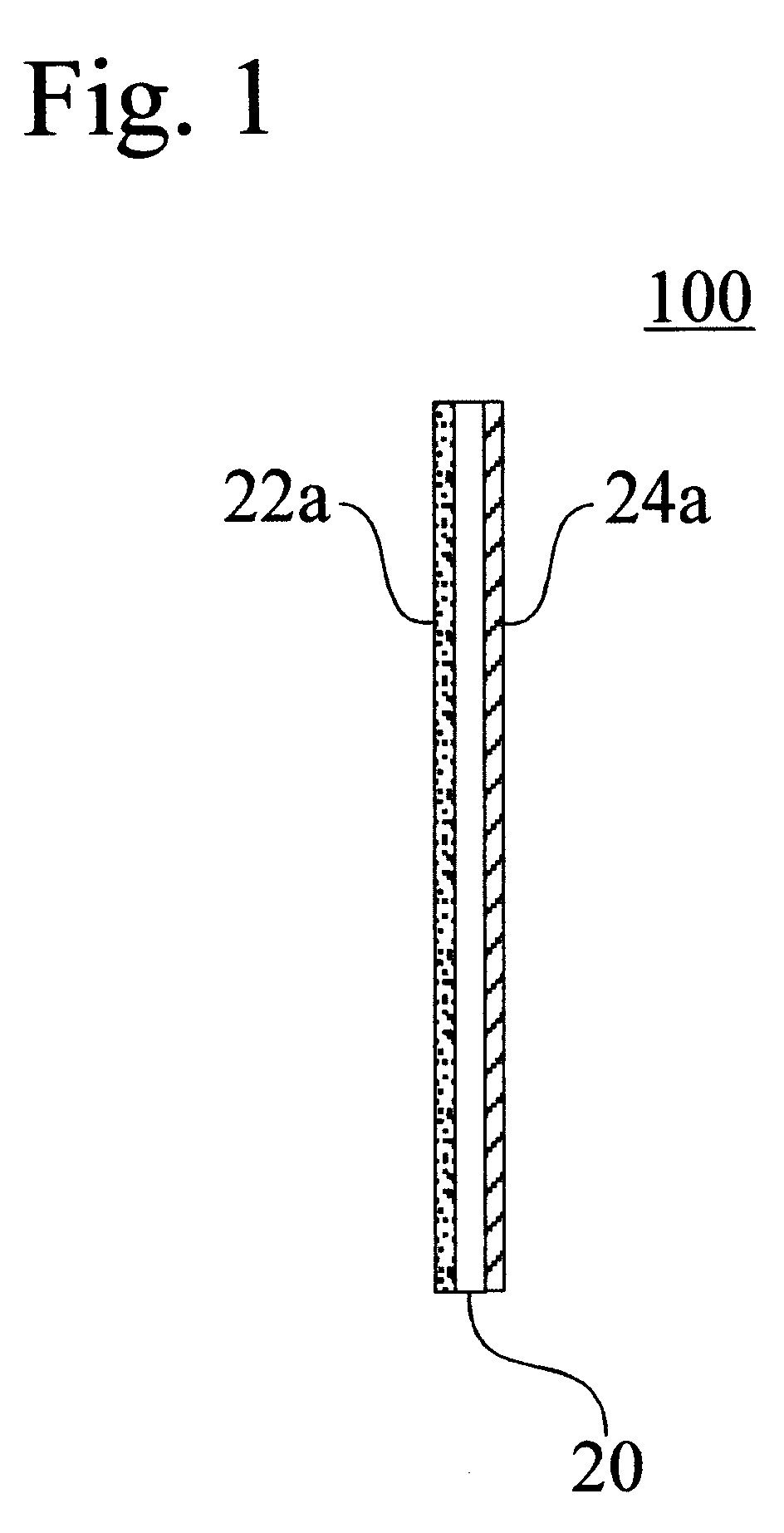

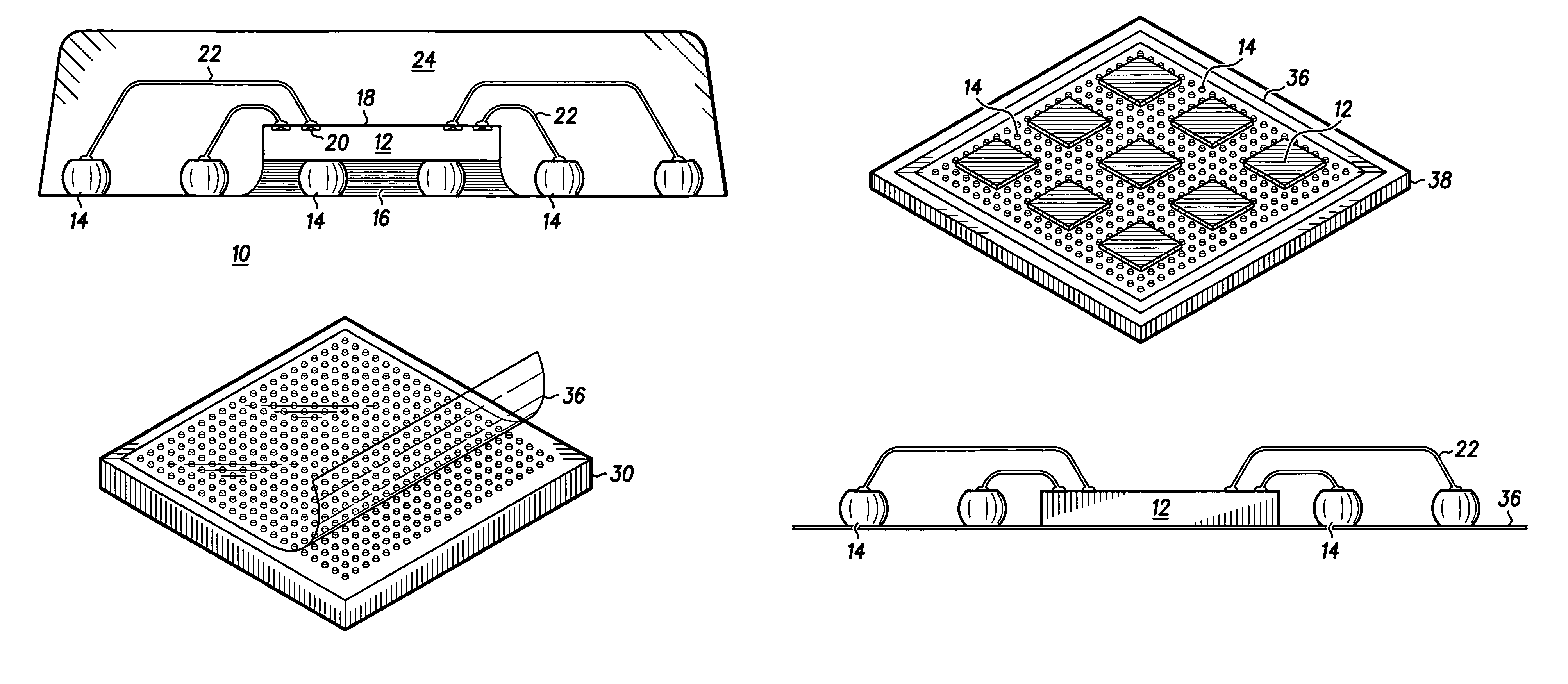

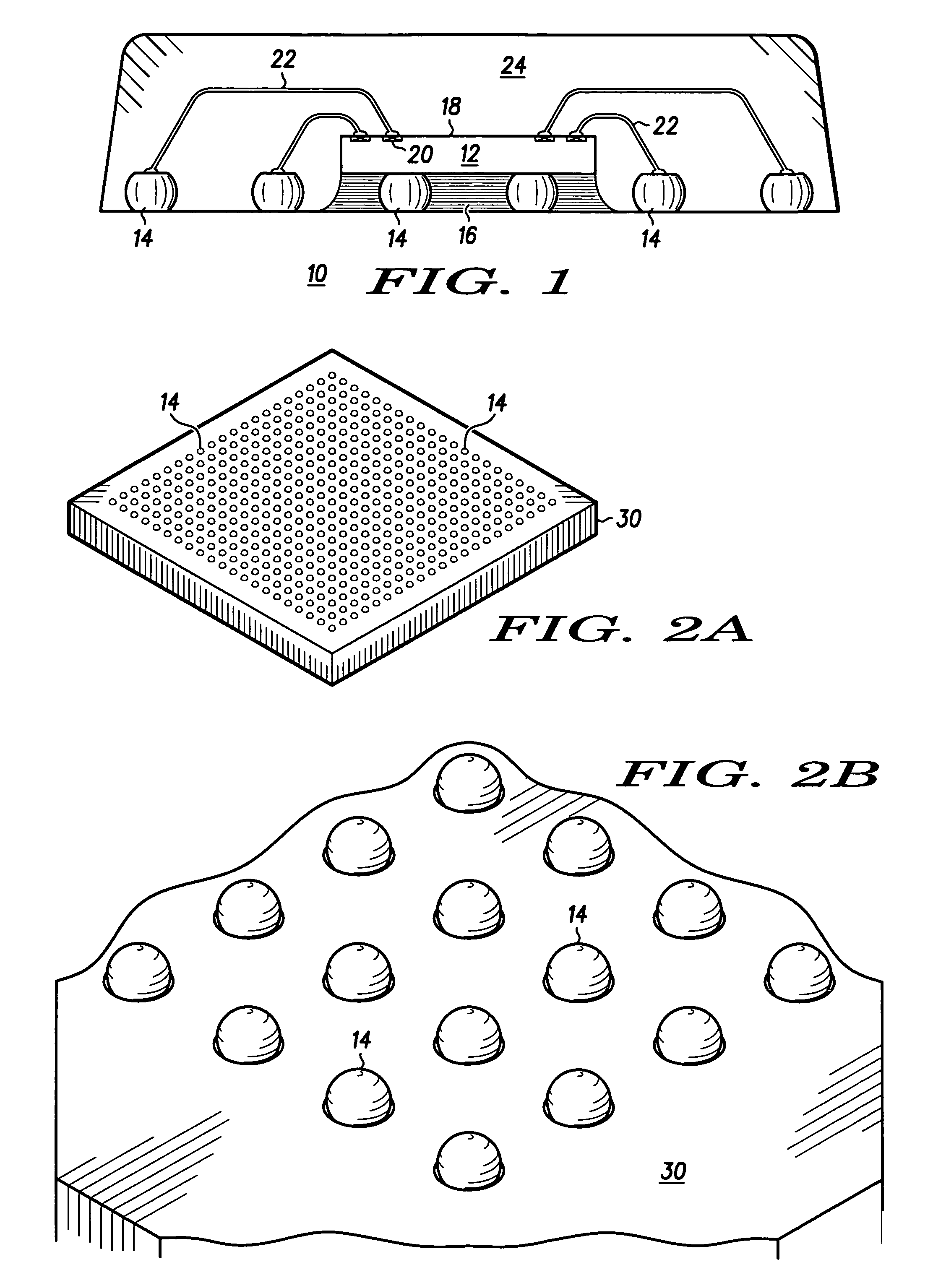

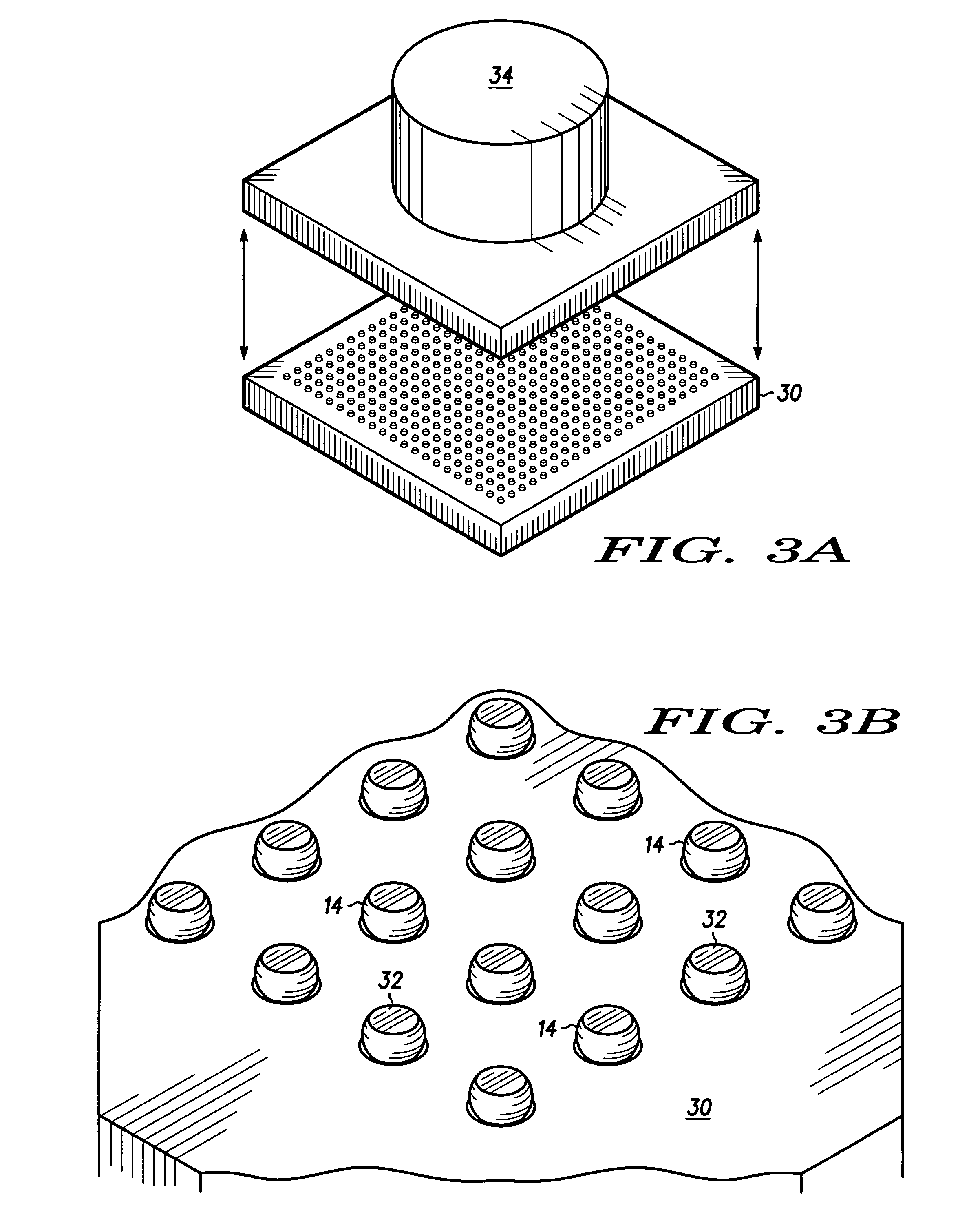

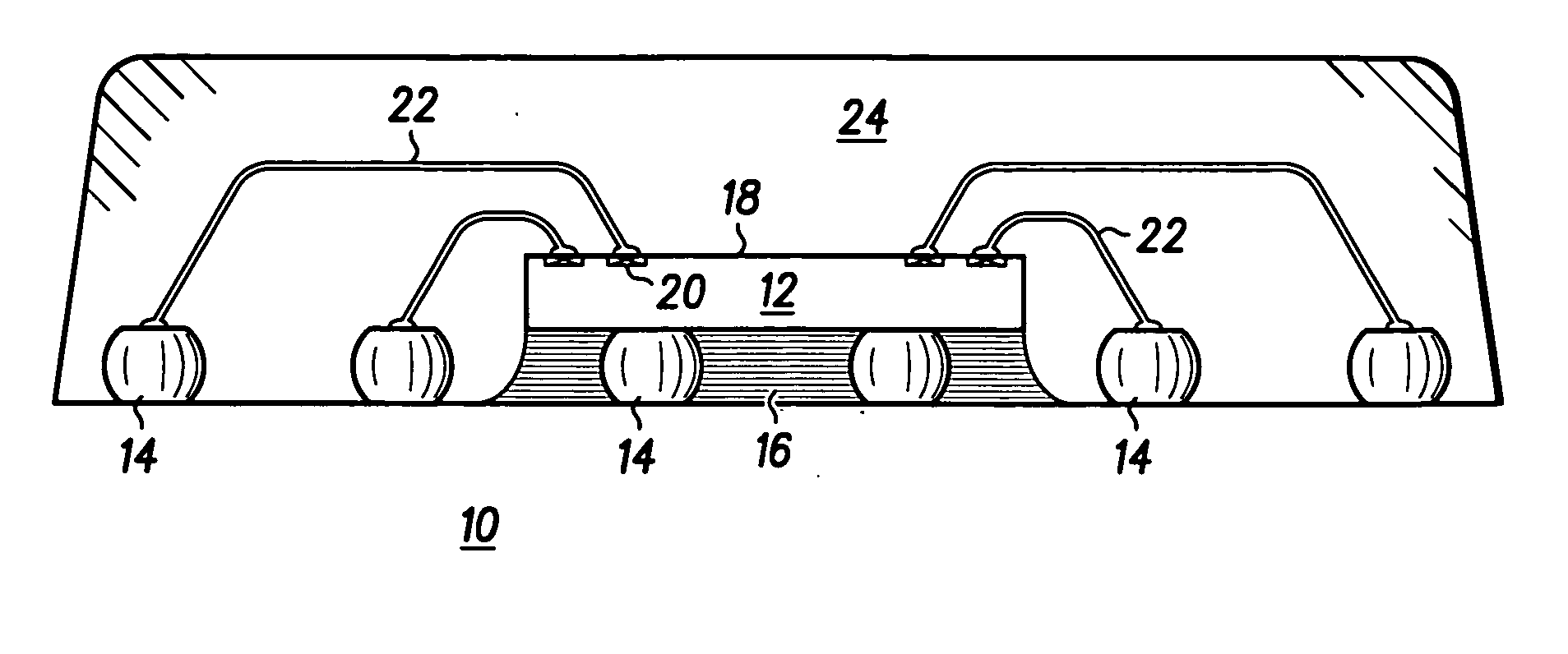

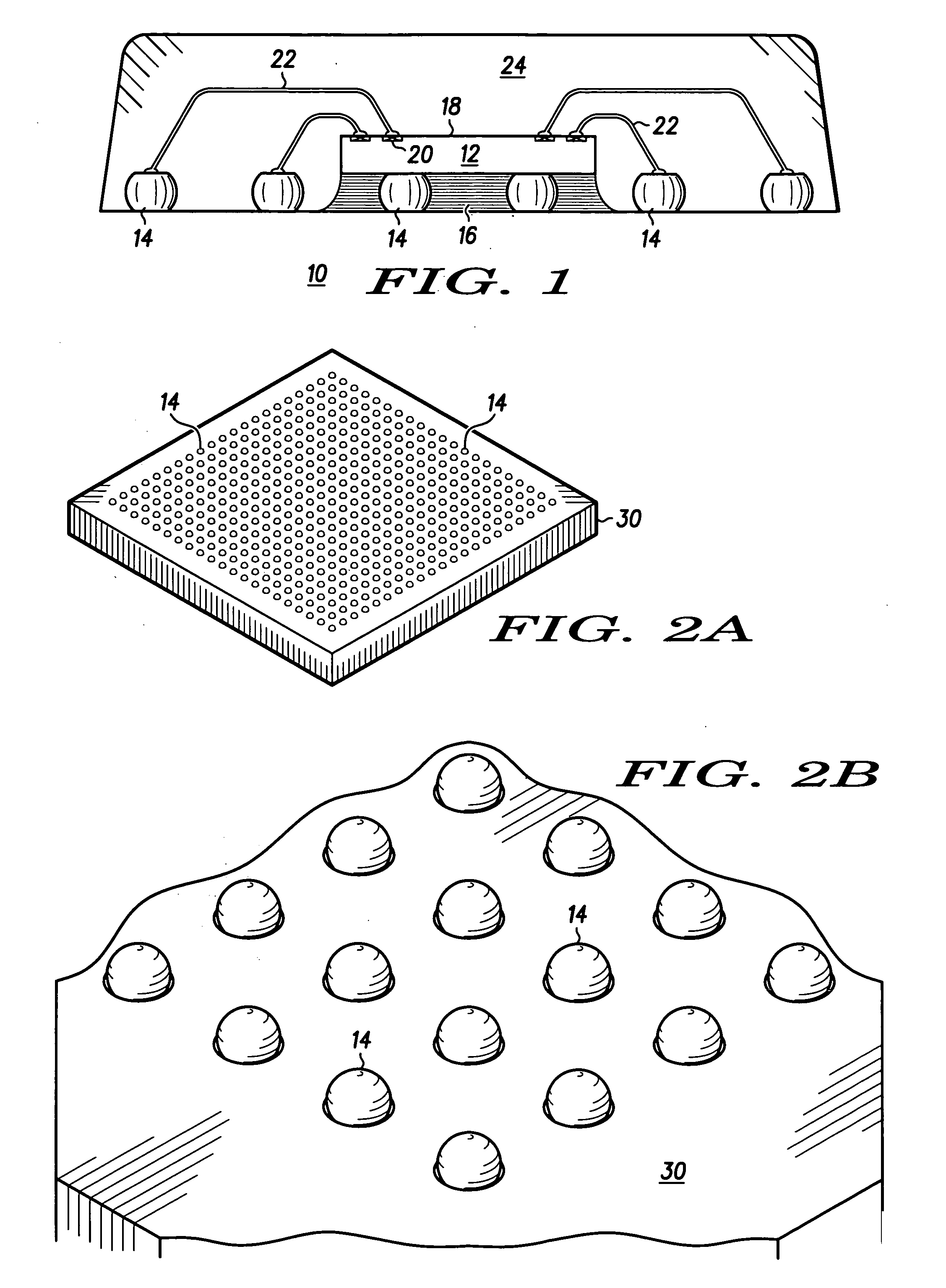

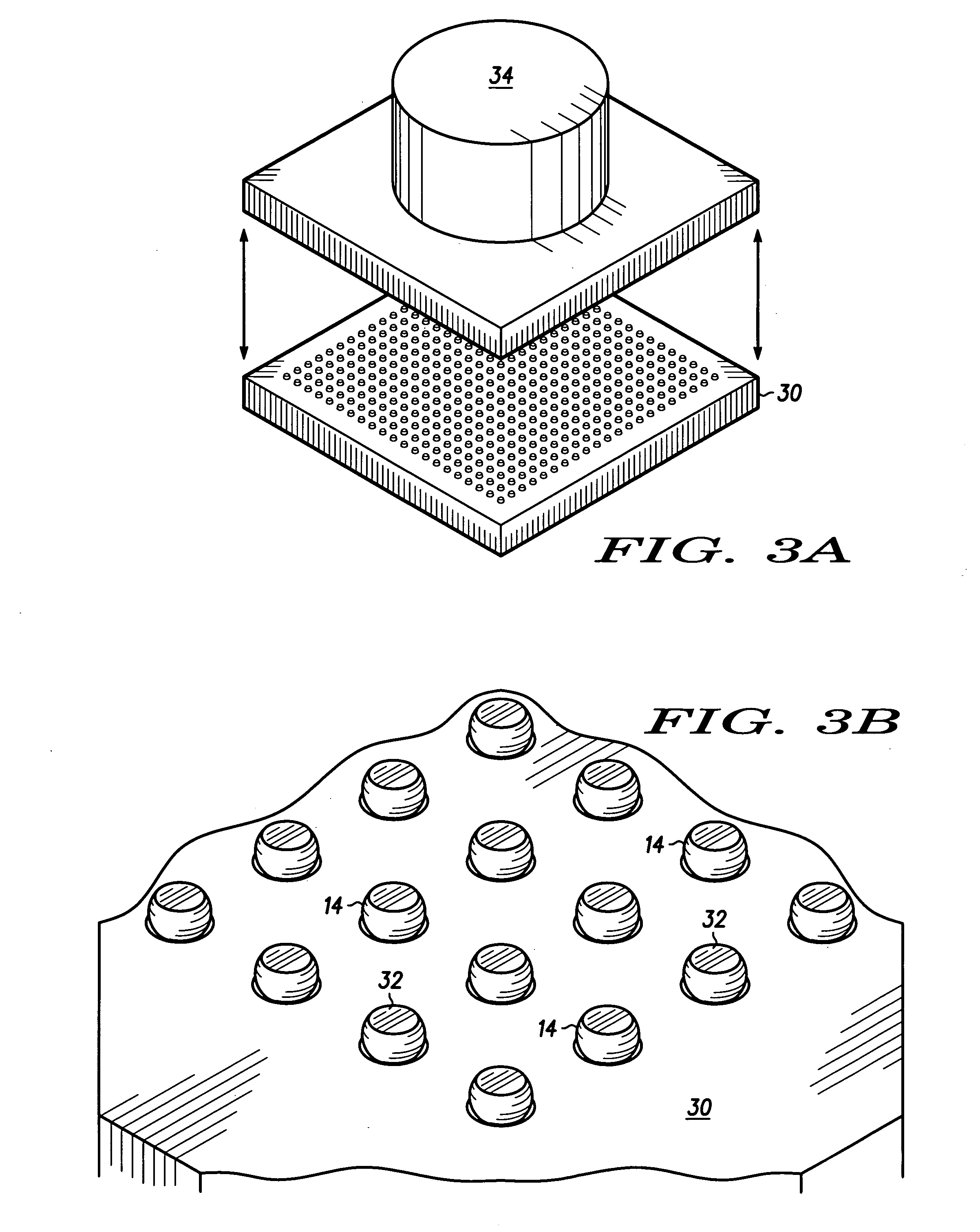

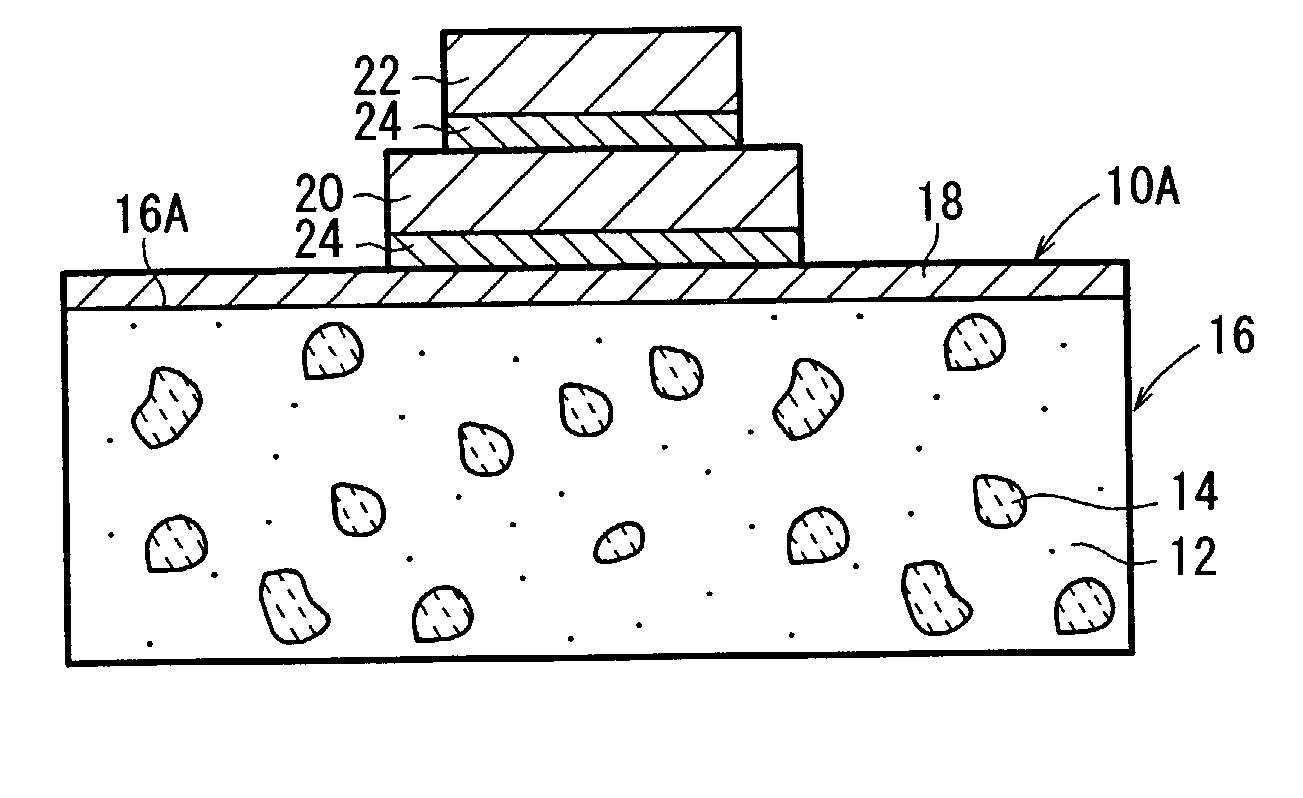

Method of forming land grid array packaged device

ActiveUS7056766B2Semiconductor/solid-state device detailsSolid-state devicesMasking tapeElectrical connection

A method of packaging an integrated circuit die (12) includes the steps of forming an array of soft conductive balls (14) in a fixture (30) and flattening opposing sides of the balls. The flattened balls are then transferred from the fixture to a mold masking tape (36). A first side of the IC die is attached to the balls with a die attach adhesive (16) and then wire bonding pads (20) on the die are electrically connected directly to respective balls with wires (22). An encapsulant (24) is formed over the die, the electrical connections, and a top portion of the formed balls. The tape is removed and adjacent, encapsulated dice are separated via saw singulation. The result is an encapsulated IC having a bottom side with exposed balls.

Owner:NXP USA INC

Land grid array packaged device and method of forming same

ActiveUS20050124147A1Semiconductor/solid-state device detailsSolid-state devicesMasking tapeElectrical connection

A method of packaging an integrated circuit die (12) includes the steps of forming an array of soft conductive balls (14) in a fixture (30) and flattening opposing sides of the balls. The flattened balls are then transferred from the fixture to a mold masking tape (36). A first side of the IC die is attached to the balls with a die attach adhesive (16) and then wire bonding pads (20) on the die are electrically connected directly to respective balls with wires (22). An encapsulant (24) is formed over the die, the electrical connections, and a top portion of the formed balls. The tape is removed and adjacent, encapsulated dice are separated via saw singulation. The result is an encapsulated IC having a bottom side with exposed balls.

Owner:NXP USA INC

Masking tape containing printing layer and preparation method thereof

ActiveCN103725222AOvercome affinityProduction process is environmentally friendlyNon-fibrous pulp additionFilm/foil adhesivesWater basedEmulsion

The invention discloses a masking tape containing a printing layer and a preparation method thereof. The masking tape comprises a substrate, wherein one side of the substrate is provided with an adhesive layer, and the other side of the substrate is sequentially provided with a printing layer and a release layer; the substrate is masking tape base paper impregnated by a hydroxy butadiene-styrene emulsion; the printing layer is a water-based ink; the adhesive layer is a water-based acrylate pressure-sensitive adhesive; and the release layer is a water-based release agent. All the raw materials are water-based materials, and thus, the production technique is environment-friendly; and the product has the advantages of stable performance, long shelf life, low production cost and high added value.

Owner:广州市白云区麒胜装饰材料厂有限公司

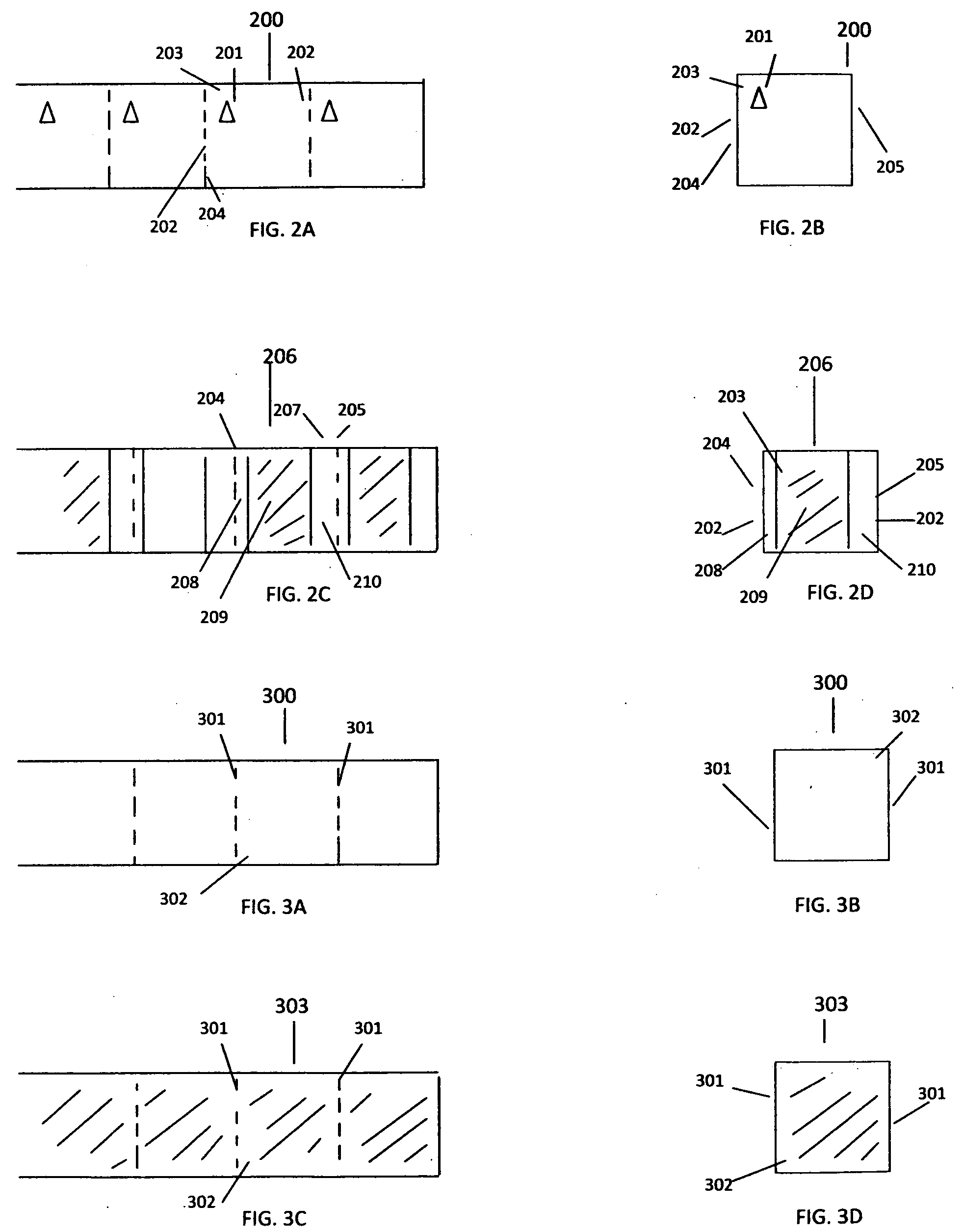

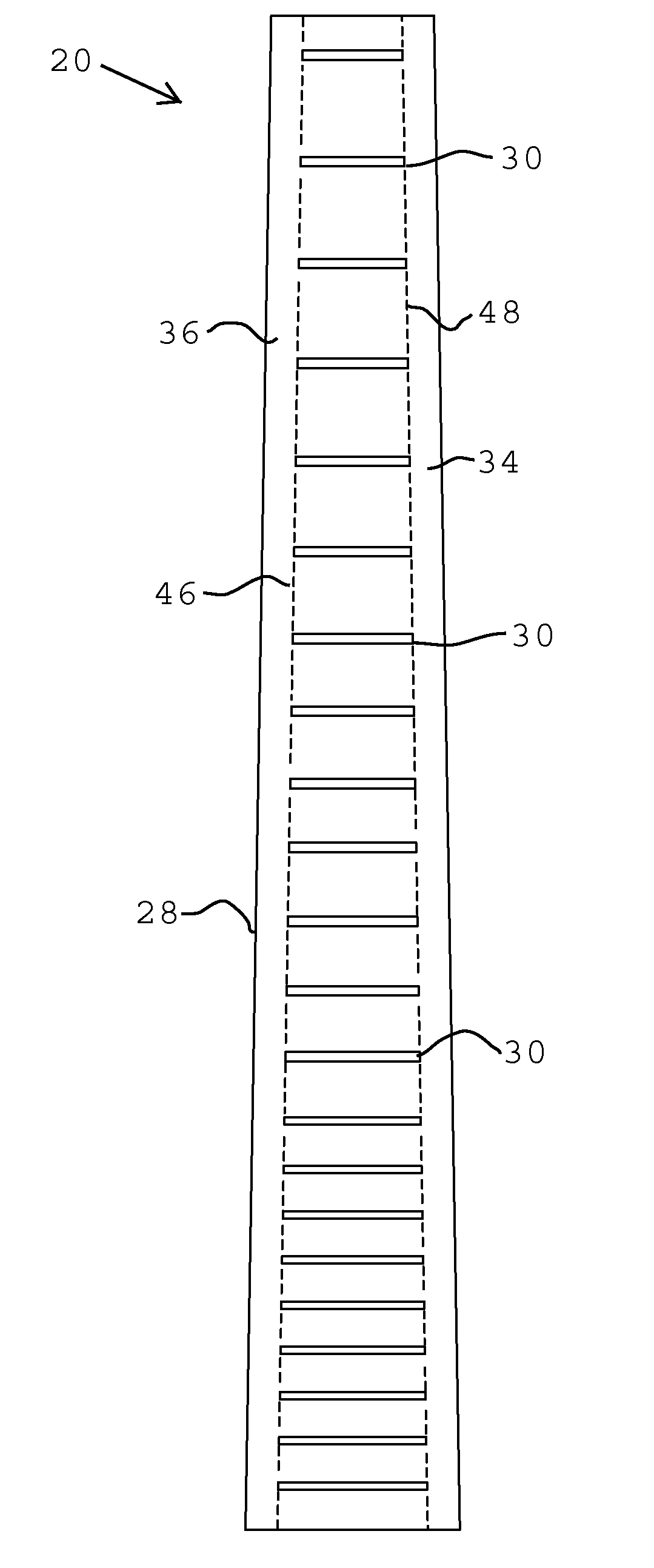

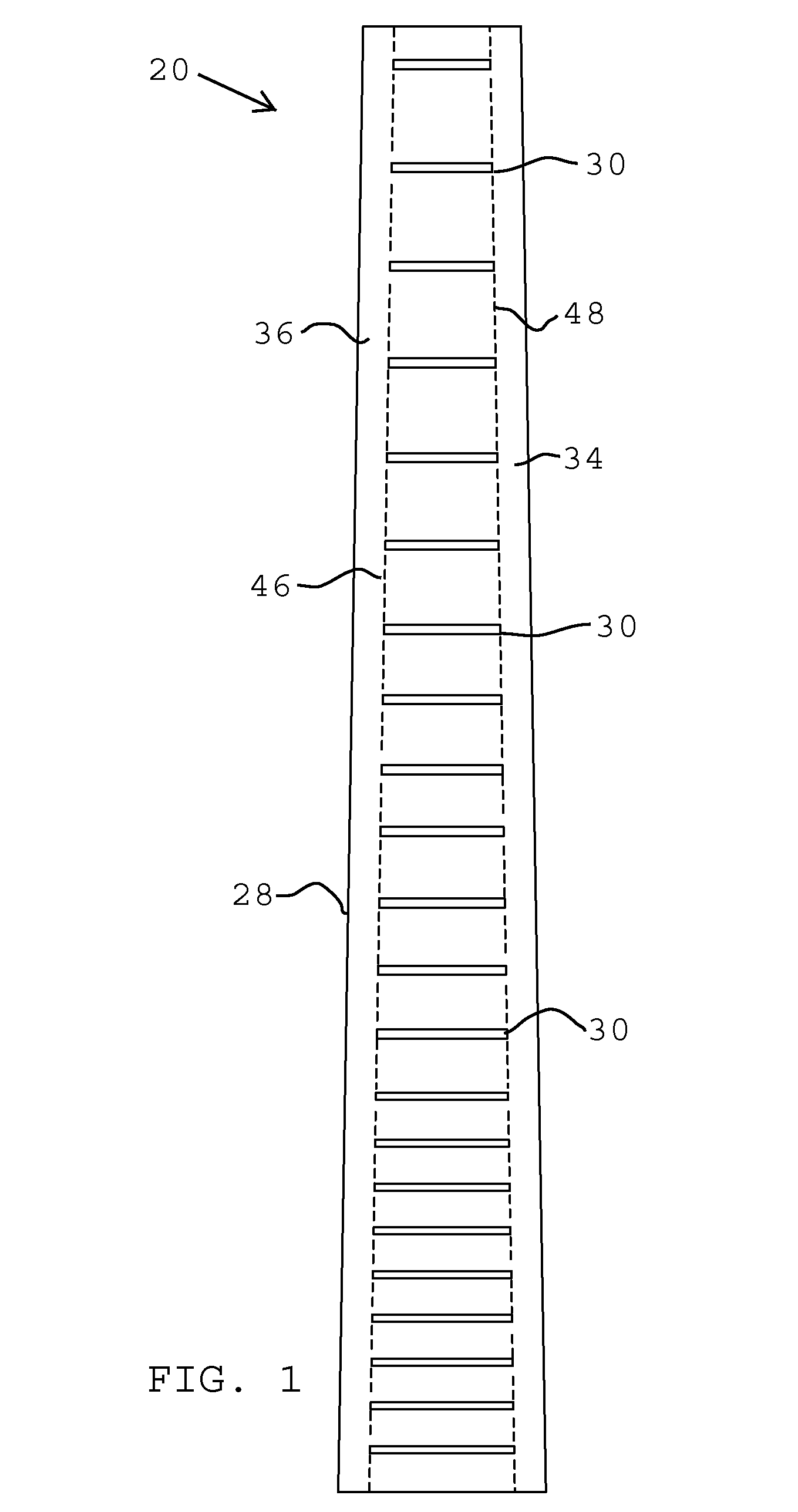

Painter's tape for corners

InactiveUS20100059162A1Shorten the timeWeaken energySpraying apparatusLaminationMasking tapeEngineering

The present invention is an improved method for applying masking tape, such as but not limited to painter's tape to surface areas wherein a 90 degree angle is encountered, such as window panes, door jambs, and corners of walls, ceilings and floors. The preferred embodiment and all alternative embodiments are comprised of easily accessed segments of material comprised of at least one 90 degree angle and releasable adhesive on part or all of the ventral aspect. The preferred embodiment and two alternative embodiments utilize a tape roll structure with the addition of perforation axes at regular intervals. The preferred embodiment and one alternative embodiment are also comprised of no adhesive zones on the ventral aspect of each tape segment. An alternative embodiment to the tape roll structure is comprised of containment of the releasable segments on a non-adhesive backing.

Owner:FLANIGAN CATHLEEN BRIDGET

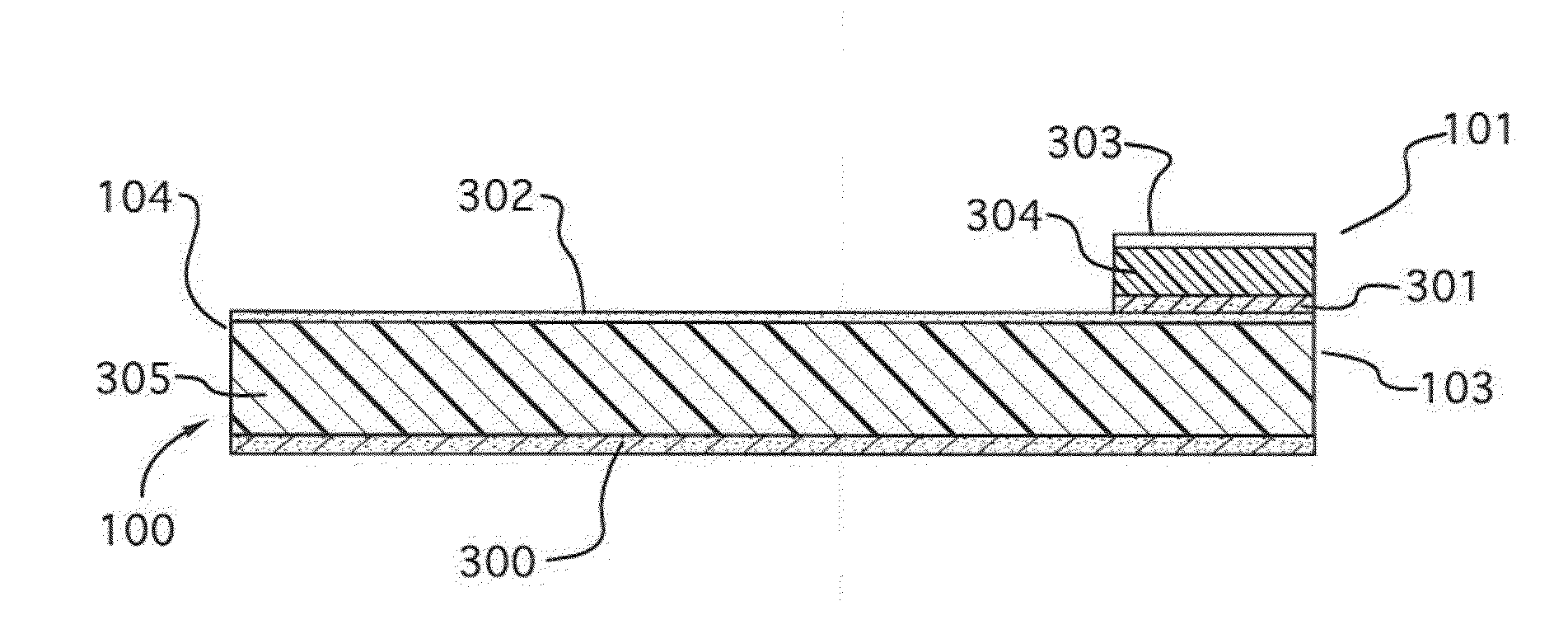

Multilayer masking tape

ActiveUS20120231167A1Lamination ancillary operationsSpraying apparatusMasking tapeMechanical engineering

A masking tape for use in applications where a coating material is applied to a surface for defining a sharp edge of the portion of the surface that is coated. A masking tape may include a reinforcing strip releasably attached to the non-adhesive side of conventional masking tape comprising a substrate with an adhesive layer on one side. The reinforcing strip extends longitudinally along the length of the substrate with one edge substantially aligned with, and preferably flush with, one longitudinal edge of the substrate and acts as a separate means to cut through a coating or film more efficiently than the masking tape alone, while subsequently leaving the masking tape in place until the preferred time of removal.

Owner:LANGEMAN MFG

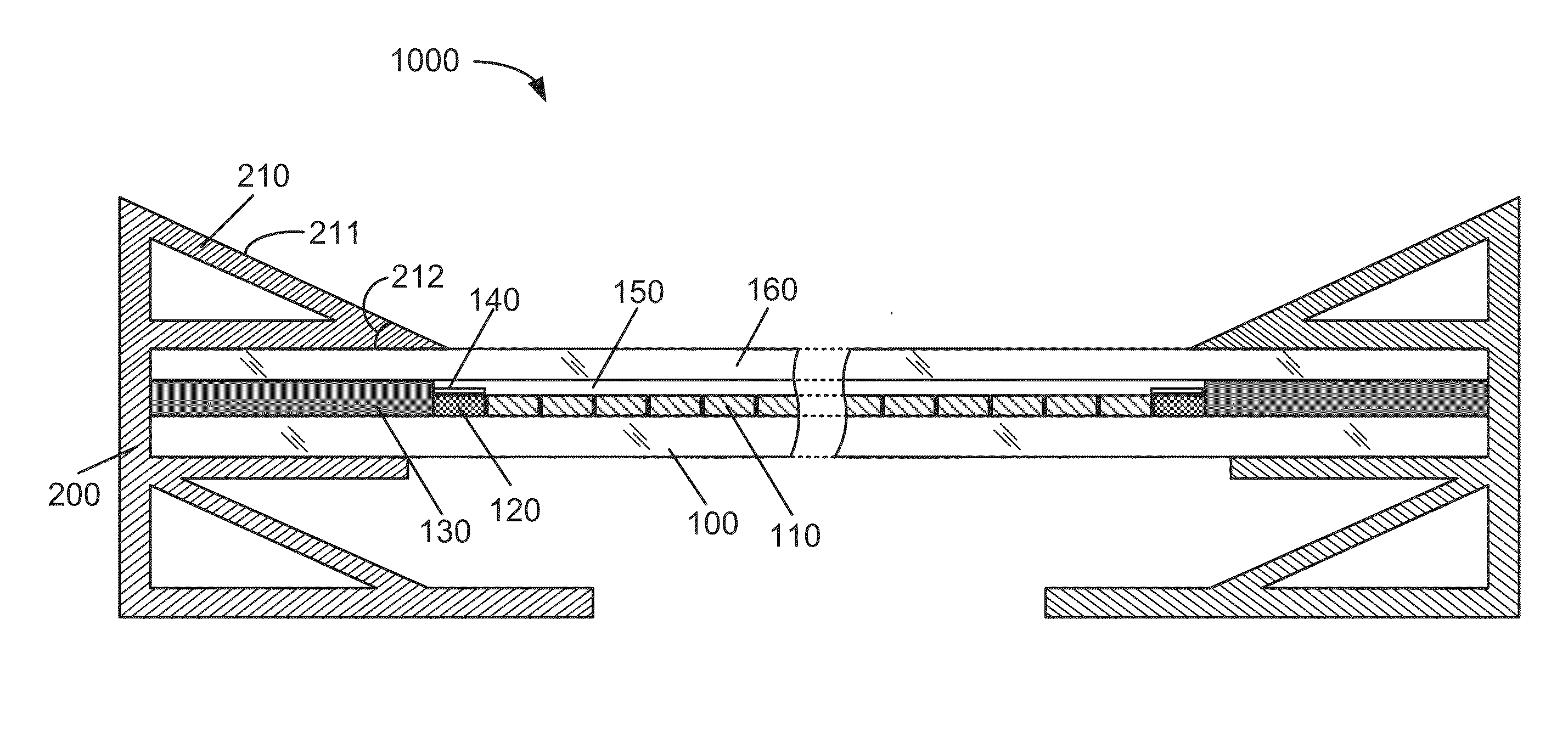

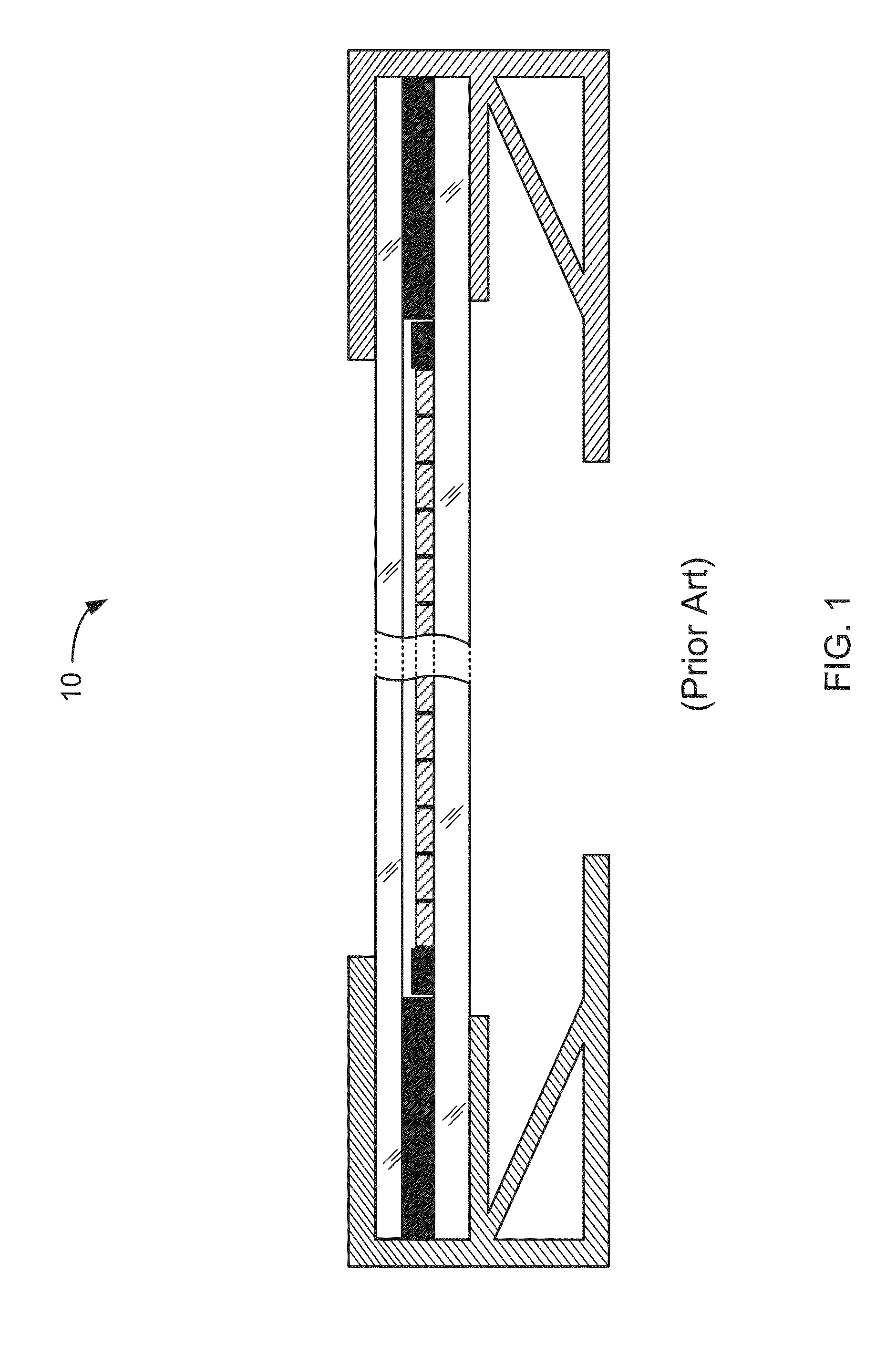

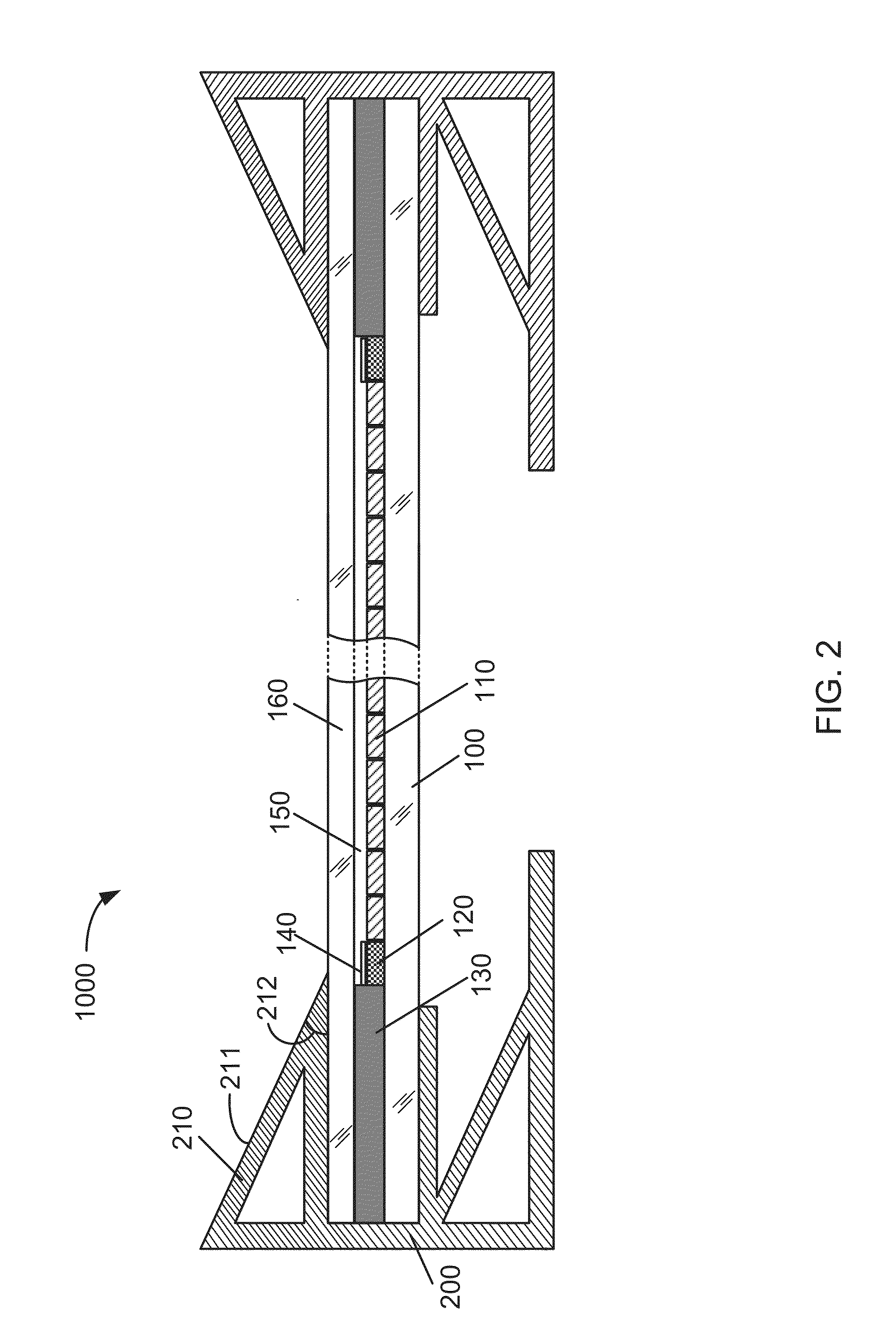

Solar module apparatus with edge reflection enhancement and method of making the same

InactiveUS20130306130A1Enhanced edge light reflectionProduce solar energyPhotovoltaic supportsPV power plantsElectrical conductorMasking tape

A monolithic integrated solar module with edge reflection enhancement includes a plurality of thin-film photovoltaic cells formed overlying a surface region of a glass substrate except in vicinities of peripheral edge regions. The solar module further includes a mask tape applied on a conductor bar disposed within the peripheral edge regions and coupled with the plurality of thin-film photovoltaic cells and an edge seal material disposed within the peripheral edge regions in a vicinity of the mask tape and an end region of the glass substrate. Additionally, the solar module includes a top glass panel disposed overlying the plurality of thin-film photovoltaic cells, the mask tape, and the edge seal material. Moreover, the solar module includes a reflector structure comprising one or more angled surfaces being configured to facilitate scattering of incoming sunlight from the vicinities of the peripheral edge regions partially to the plurality of thin-film photovoltaic cells.

Owner:CM MFG

No-solvent hot-melt pressure-sensitive masking tape and manufacturing process thereof

InactiveCN103087649AGuaranteed cohesive strengthSolve the problem of glue supplyMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesNumerical controlMasking tape

The invention provides a no-solvent hot-melt pressure-sensitive masking tape and a manufacturing process thereof. During a production process, the raw materials are prepared according to the weight percentages that: rubber 10-65%, tackifying resin 20-70%, a softening agent 5-45%, an anti-aging agent 0.2-0.8%, a coupling agent 0.1-0.3%, an inorganic filling material 0-15%, and the like; the raw materials with a precise ratio are added into an extruder, and are subjected to sufficient melt-mixing, such that hot-melt glue is produced; the extruder directly supplies the produced hot-melt glue to a coating device; and the coating device coats the hot-melt glue onto a masking tape paper, such that the no-solvent hot-melt pressure-sensitive masking tape is obtained. According to the invention, the extruder is used for replacing original kneading machine and stirring tank to produce hot-melt glue, such that secondary glue melting is not needed before glue coating. Therefore, glue cohesive strength is ensured, and a problem of supply difficulty of high-viscosity glue is solved. With the process, production numerical control is realized, and production efficiency is improved.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Cutting machining technology for semi-hole plate provided with copper plating holes at plate edges

ActiveCN102387668AEliminate copper deficiencyReduce scrapPrinted circuit manufactureCopper platingMolding machine

The invention relates to a cutting machining technology for a semi-hole plate provided with copper plating holes at plate edges. The cutting machining technology is characterized by comprising the following technology steps: inserting a drill bit used for drilling pin holes on a cutter holder, starting a forming machine, and drilling deep holes in an electric wood plate of the forming machine; placing a pulp plate on the electric wood plate, fixing four edges of the pulp plate with the electric wood plate, inserting the drill bit used for drilling large holes on the cutter holder, and drilling the large holes in the pulp plate; carrying out cutting machining on the pulp plate to fish out a groove body; selecting pins, inserting the pins on four corners of the pulp plate, sheathing a printed circuit plate, and hitting the pins well; taking out a shaft printed circuit plate to be sheathed on the pins, fixing four edges of the printed circuit plate by masking tape; and carrying out cutting machining on the plate edges of the printed circuit plate. With the cutting machining technology implemented, the requirements on the quality of a semi-hole plate provided with PTHs (plated though hole) at the plate edges can be guaranteed, waste of unqualified products and the complaints of clients are reduced, and the creditworthiness on client terminals is promoted.

Owner:GULTECH WUXI ELECTRONICS CO LTD

Masking tape for providing decorative edges

InactiveUS20050045265A1Easy to unrollEasy to useCovering/liningsLamination ancillary operationsElectrical and Electronics engineeringMasking tape

A method for using an improved masking tape is provided for use in creating a decorative painted edge on a wall near a joint between the wall and surface protruding along essentially a straight line from the wall such as a ceiling, window frame, or door frame. The masking tape has a patterned edge.

Owner:PANNELL STEPHEN S

Tape dispensing aid

InactiveUS8443862B1Good adhesionReduce manufacturing costLamination ancillary operationsFilament handlingVertical tubeMasking tape

A dispensing aid is disclosed for attachment to an annular roll of tape that has an inside radial surface and an outer radial tape surface, such as a roll of masking tape for example. A pair of side risers each have at a lower end thereof an opposing, inwardly-projecting tab that is configured for sliding along the inside radial surface of the roll of tape. A top platform laterally spans the outer radial tape surface width and is fixed with an upper end of each riser. The distance between each riser may be adjustable to accommodate different tape roll widths. A cutting blade projects away from the top platform at a forward end of the platform. One of the risers may include a central slot wherein the riser is slidably engaged within the slot. The riser may include a pivot mechanism such that the riser may pivot from a vertical closed position to a horizontal open position, thereby facilitating the attachment and removal of the aid with the tape roll.

Owner:MANABAT GREGORIO S

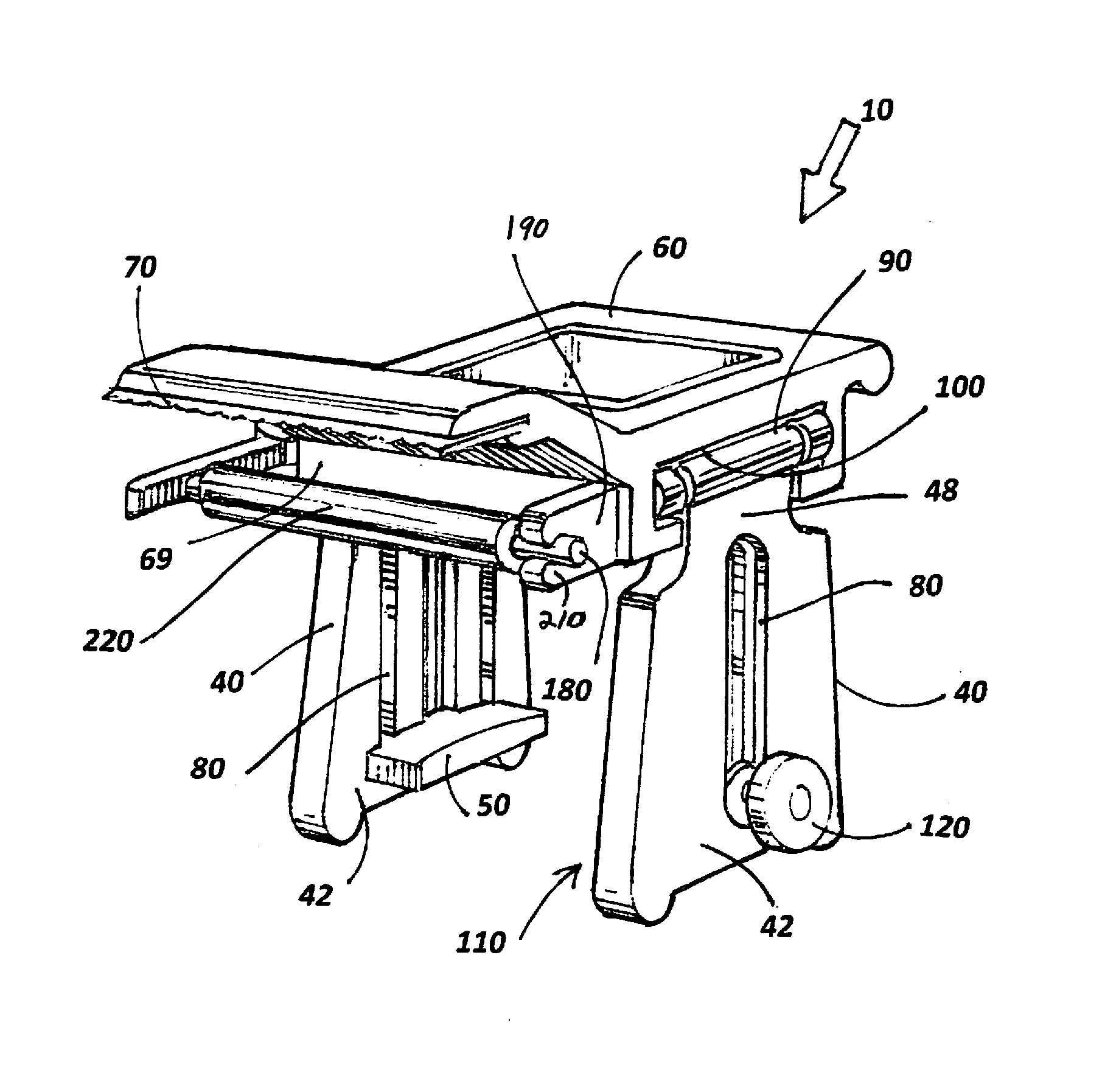

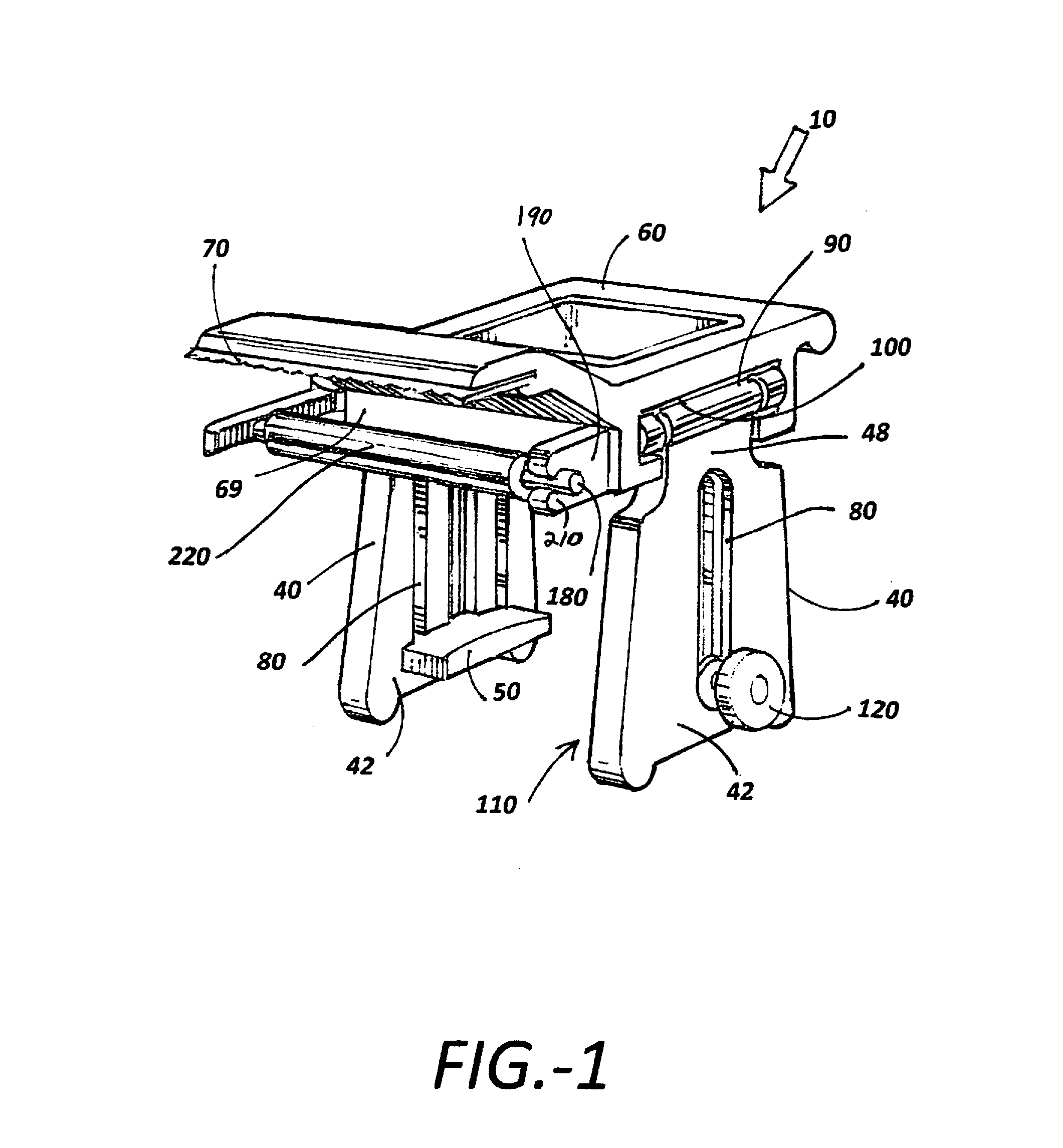

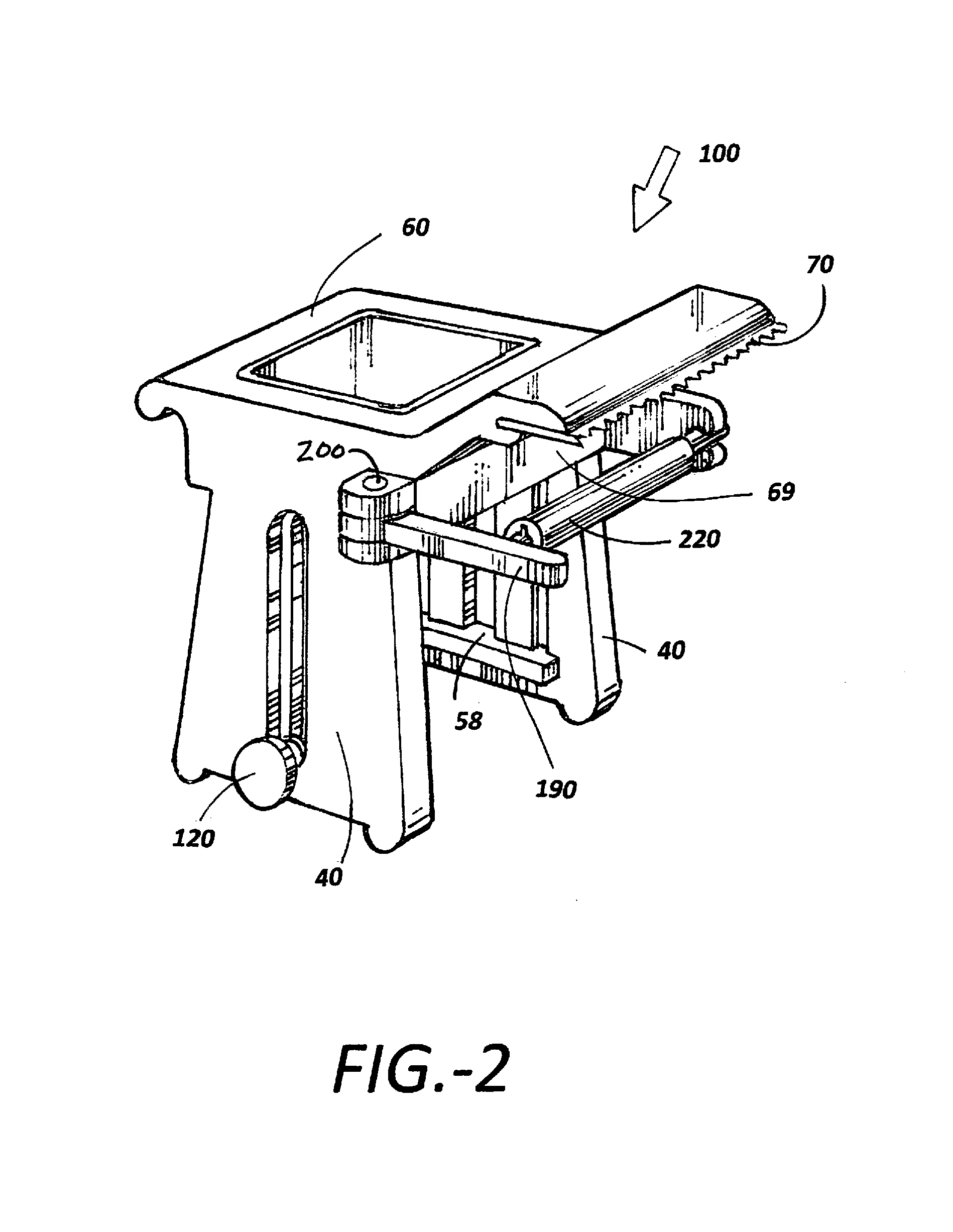

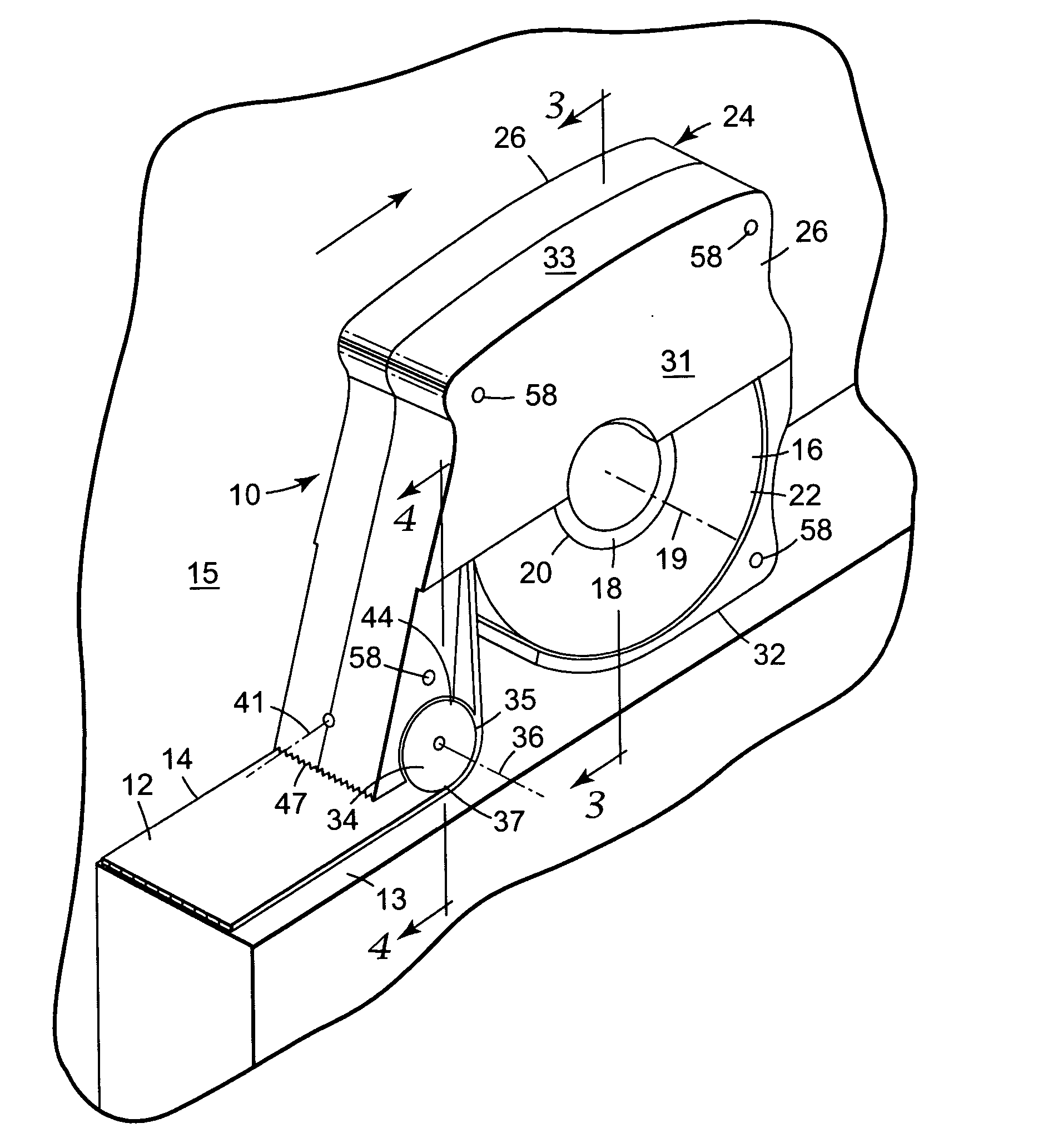

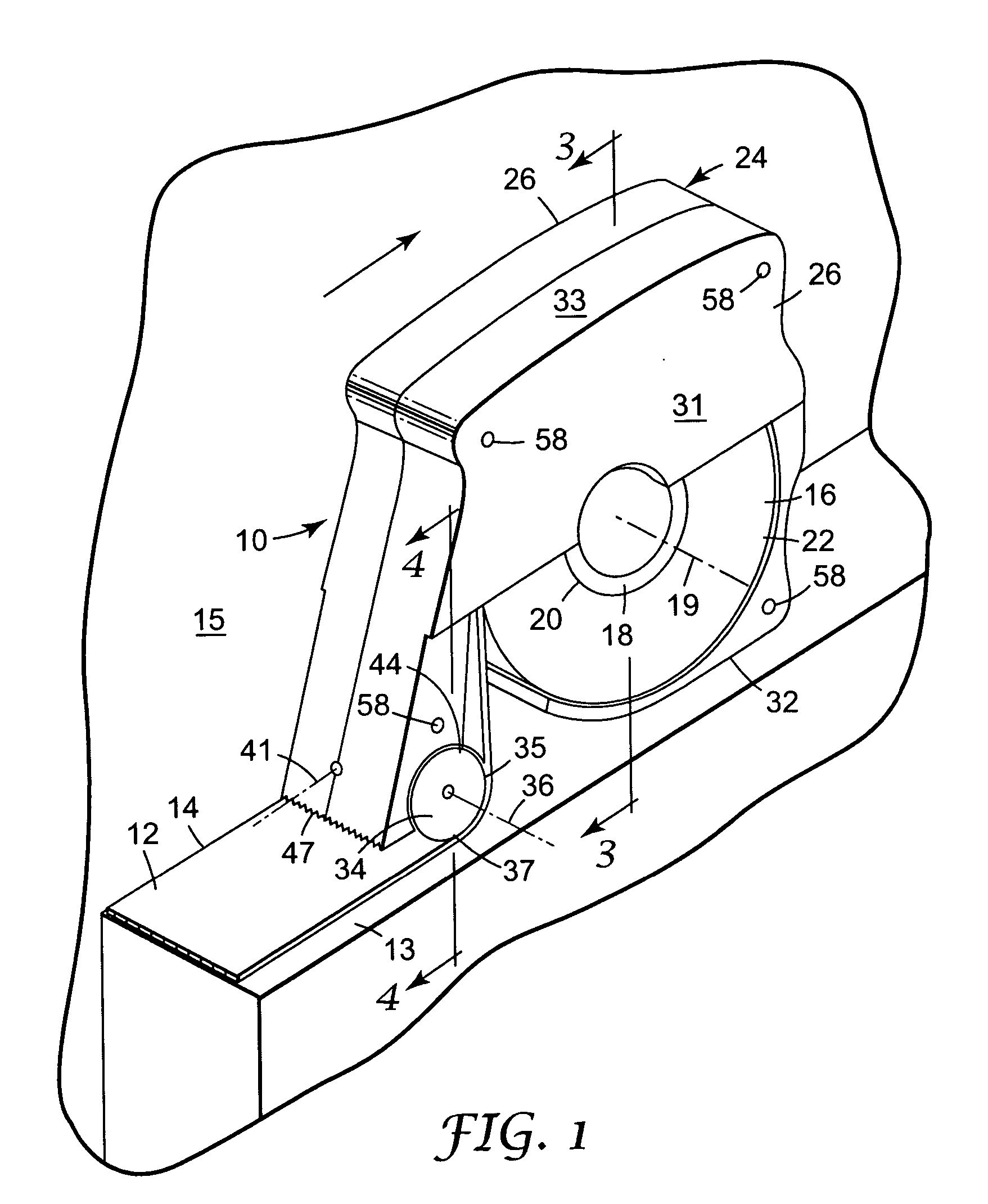

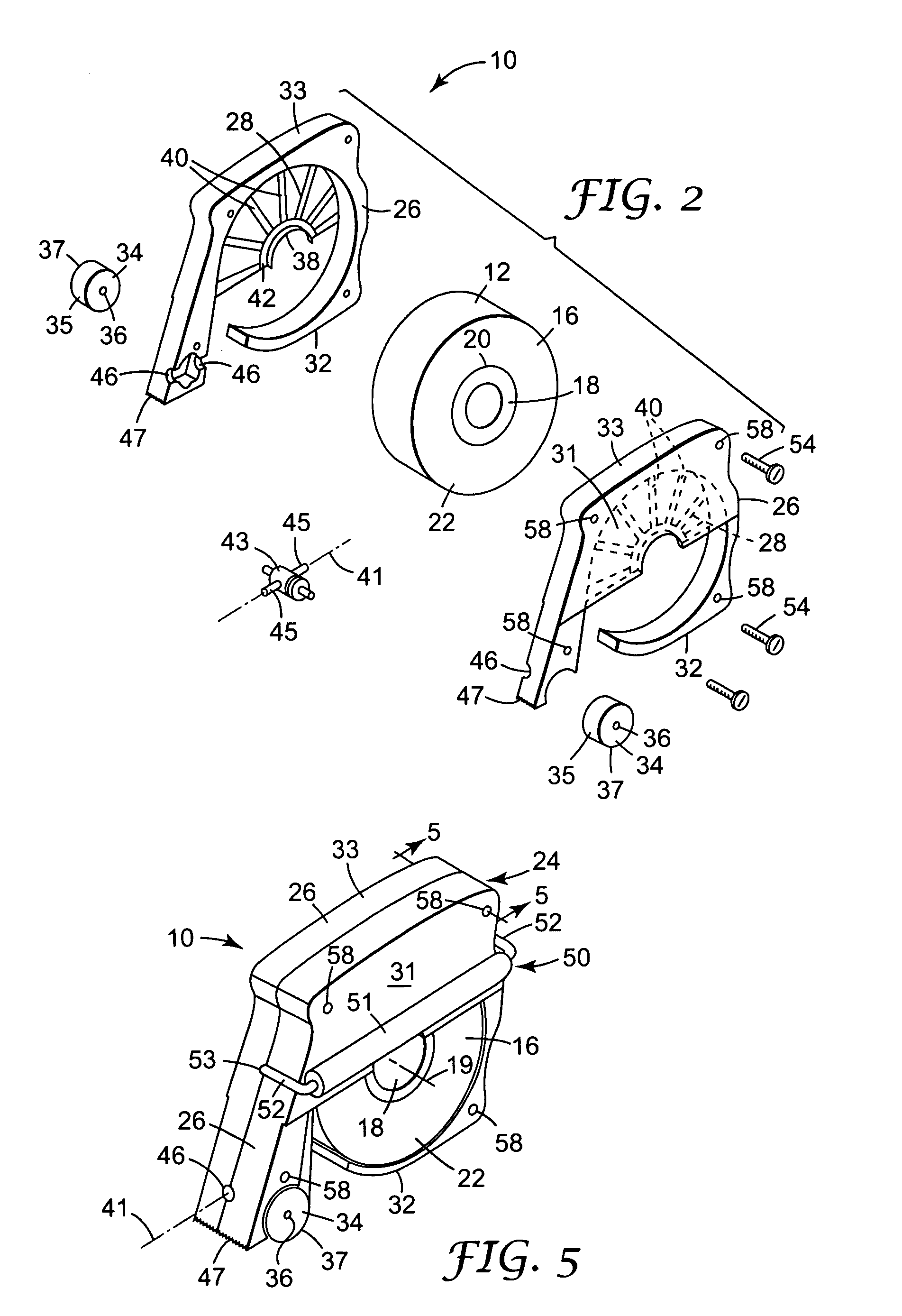

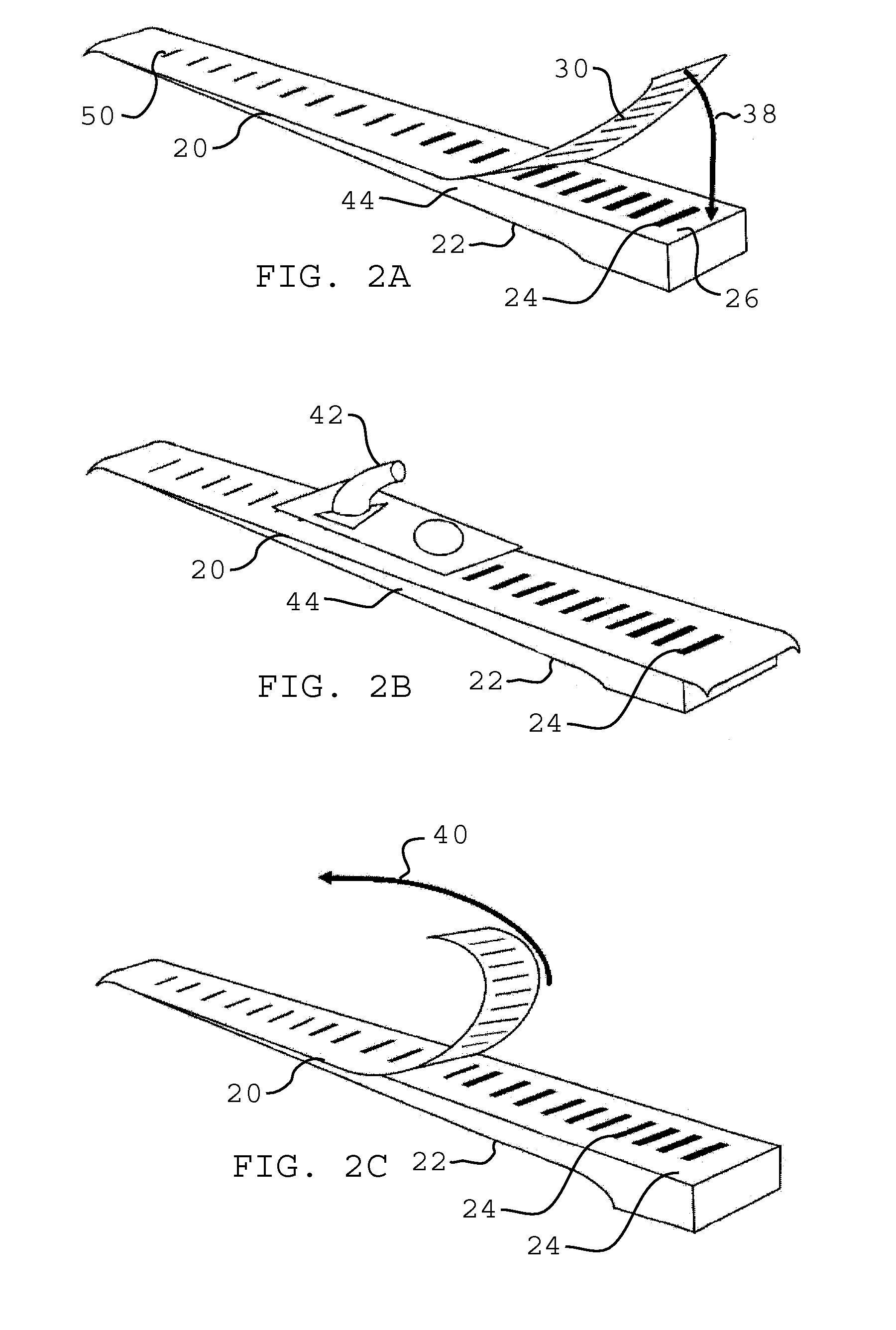

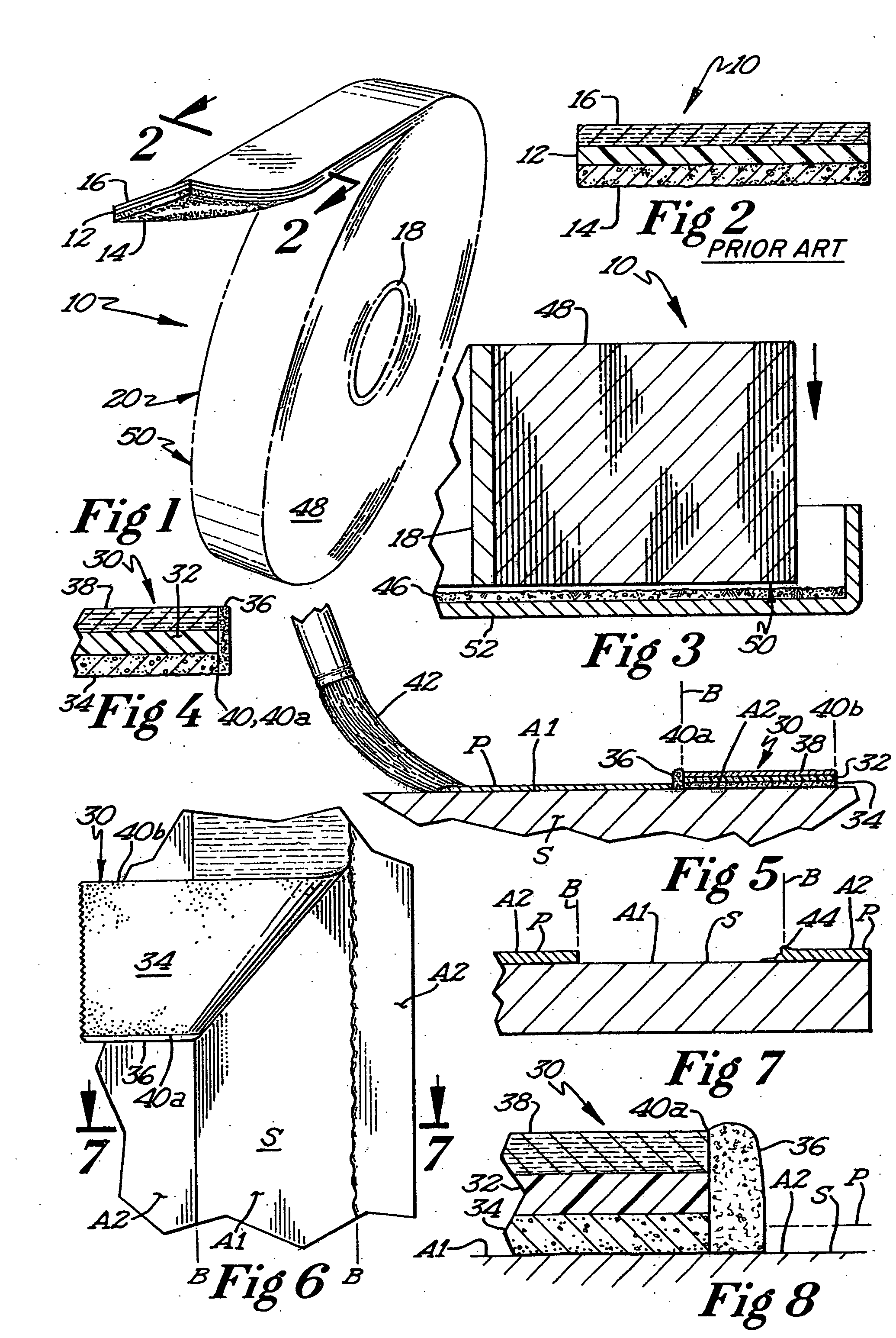

Masking tape applicator

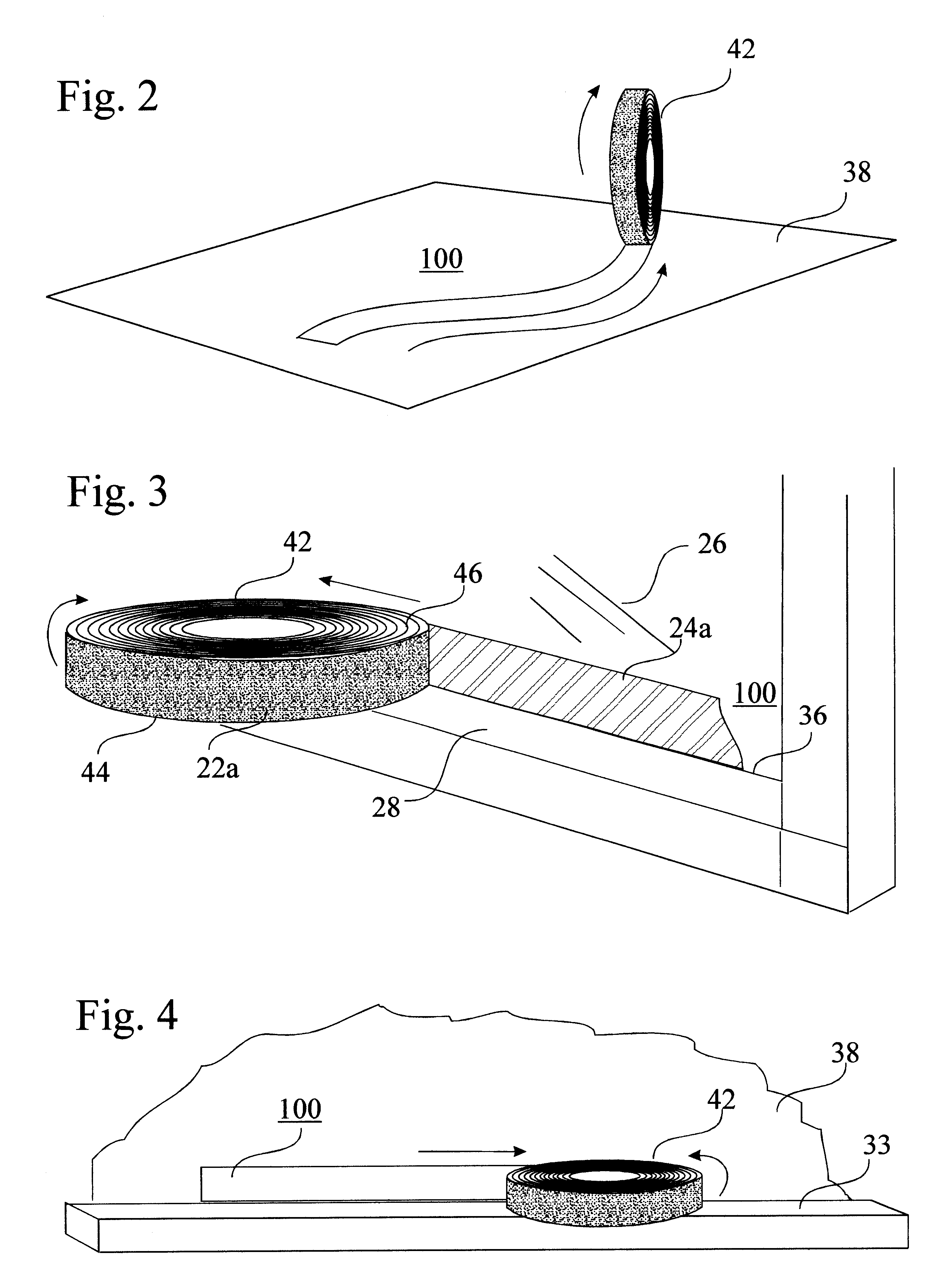

ActiveUS20050145343A1Better accommodateImprove accuracySpraying apparatusLaminationFree rotationMasking tape

A device for applying tape from a roll of tape (e.g., masking tape) along a surface to be protected with an edge of the tape extending along a juncture between the surface to be protected and a surface to be treated disposed at about a right angle with respect to the surface to be protected. The device includes a two portion housing around and journaling the tape roll, each portion having a tape contacting part of its inner surface in a first plane, and having in a second plane a guide part of its outer surface adapted to be slid along the surface to be treated. The first and second planes on each of the housing portions can be parallel or at a small angle with respect to each other so that they intersect along an application side of the housing. A pressure application structure is mounted on the housing with an outer edge each end of the pressure application structure at the intersection (if they intersect) of the first and second planes for a different adjacent one of the housing portions. The pressure application structure is mounted on the housing for limited pivotal movement in a plane at about a right angle with respect to a plane along the guide surface. The roll of tape can be mounted in the housing for free rotation and axial movement. Tape from the roll extends around the periphery of the pressure application structure so that the dispenser can be manually positioned with either housing portion against the surface to be treated and moved to apply the tape, whereupon pressures applied to the tape being dispensed by the pressure application structure in the device will cause the side surface of the roll of tape to move toward or into contact with the tape contact part of the inner surface of the housing portion being slid along the surface to be treated so that the tape is accurately applied.

Owner:3M INNOVATIVE PROPERTIES CO

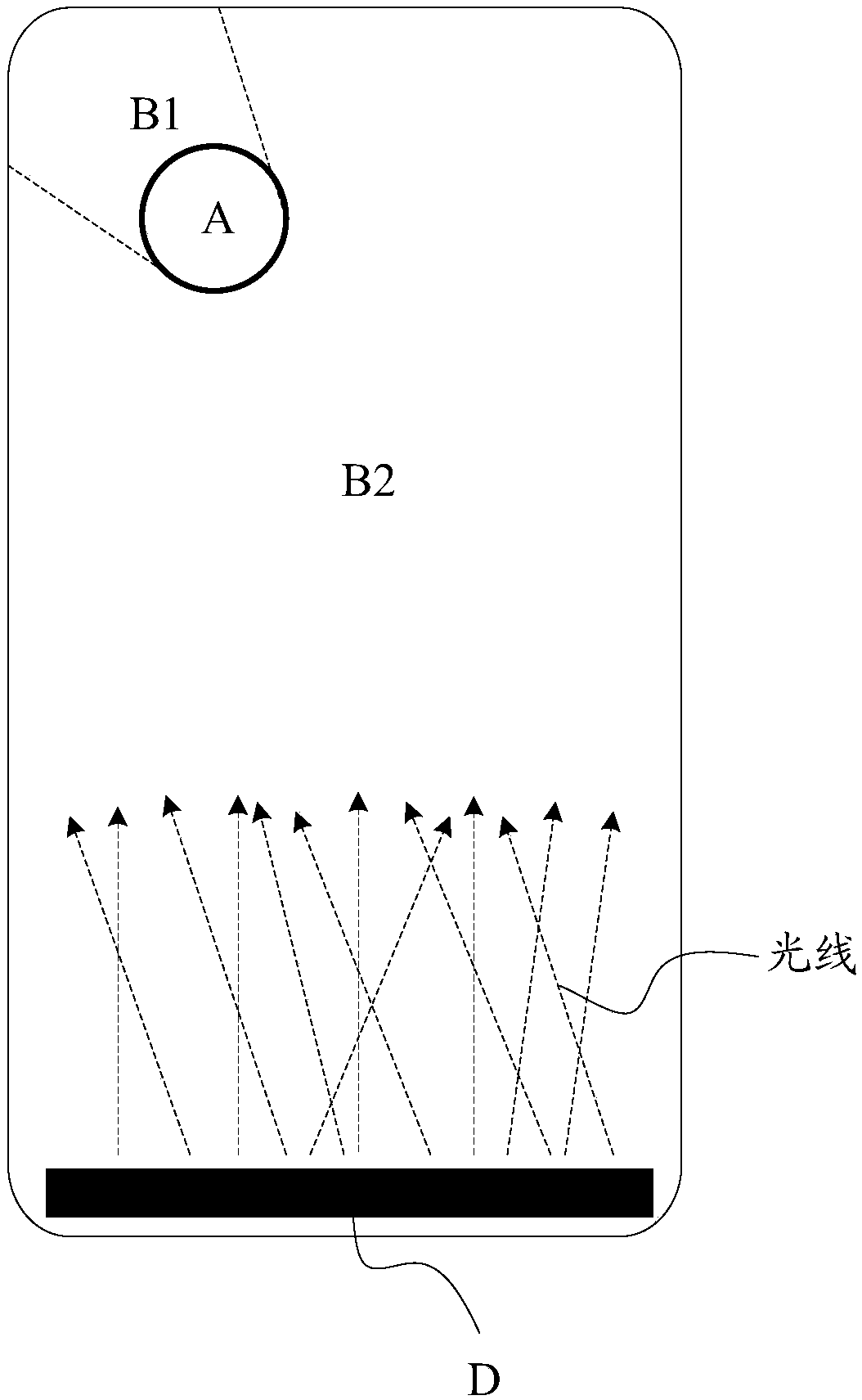

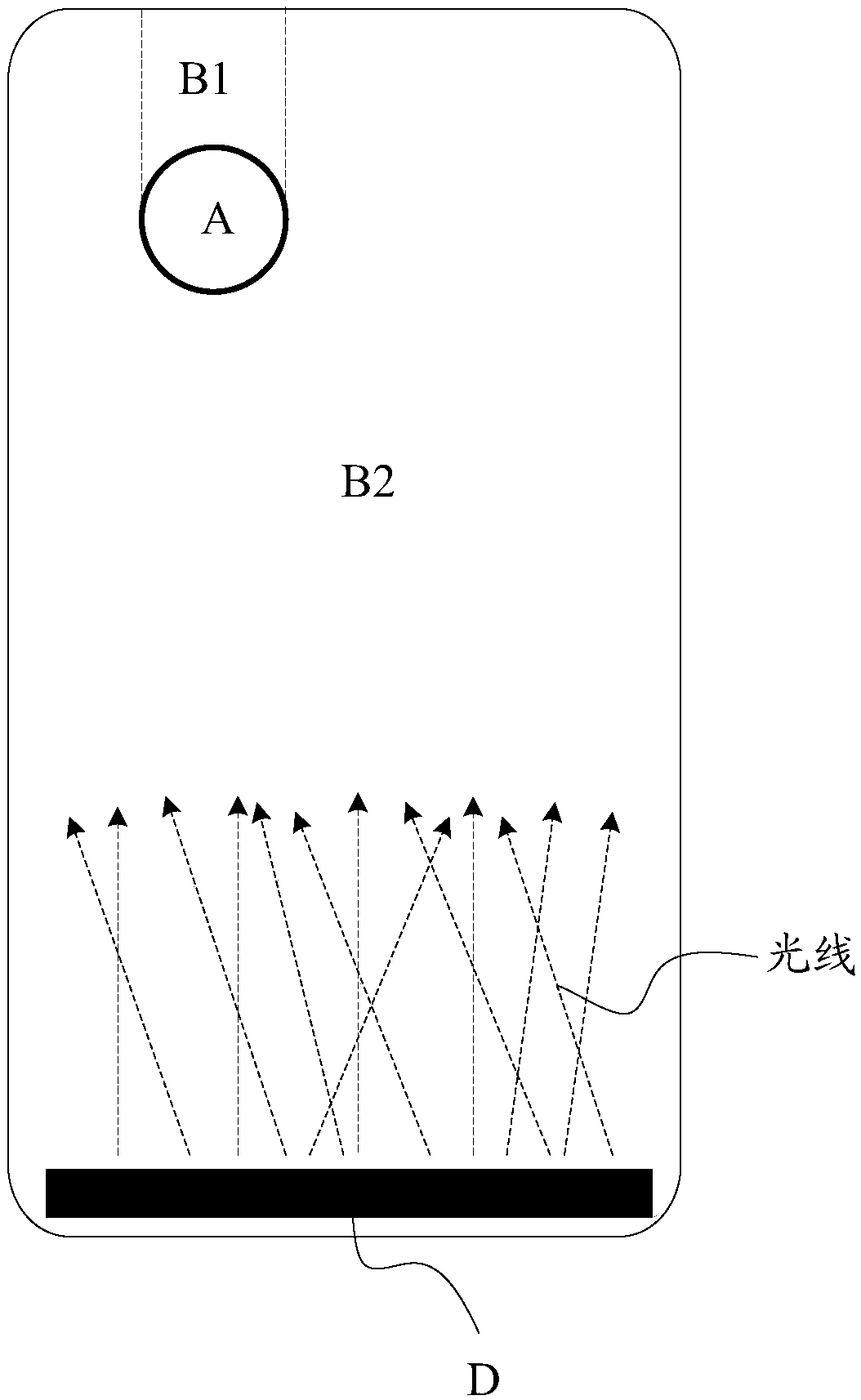

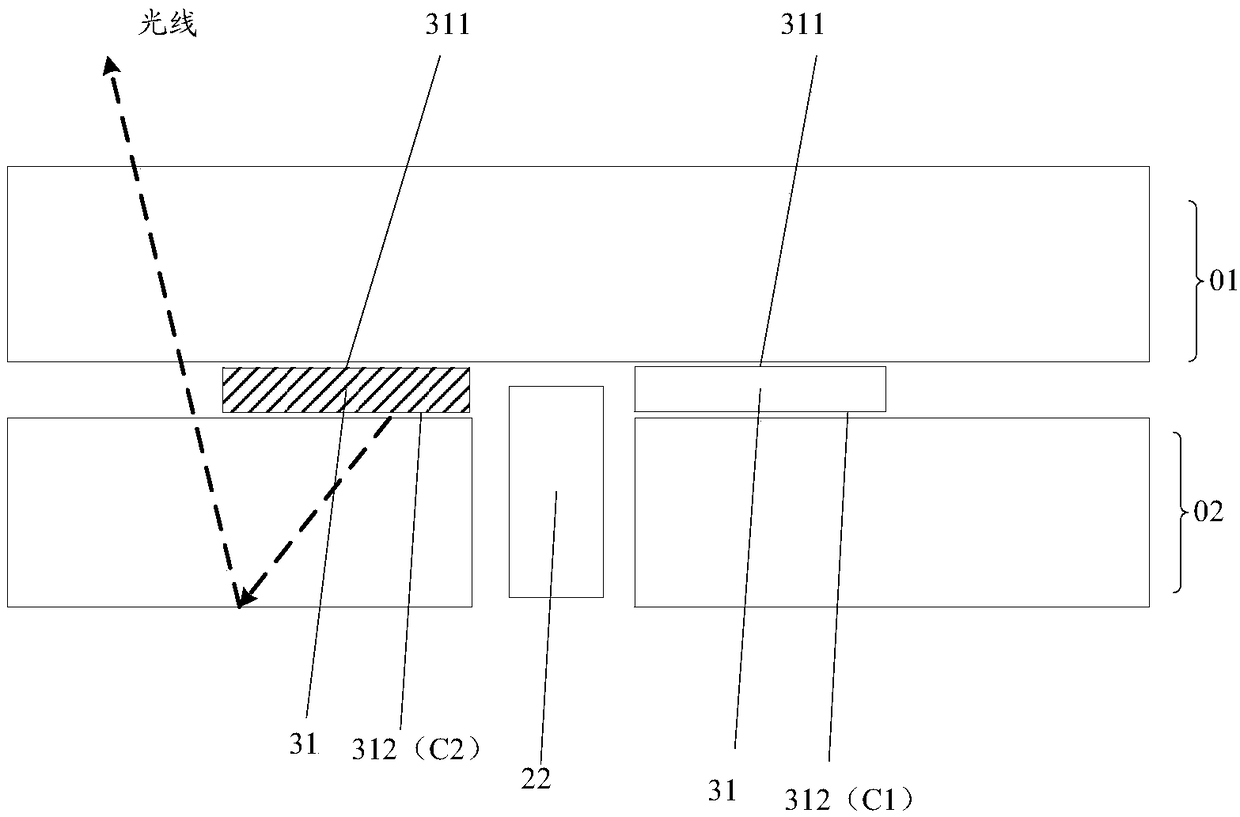

Display device

ActiveCN108826103AImprove the exit rateReduce absorption lossIdentification meansReflectorsMasking tapeDisplay device

The invention provides a display device. The display device comprises a display panel and a backlight module opposite to the display panel, wherein the backlight module comprises a lateral light source; the backlight module is provided with a through hole, which penetrates through the backlight module and are used for mounting functional modules. The display device also comprises a first masking tape which is arranged around the through hole and on the light-emitting surface of the backlight module for fixing the display panel and the backlight module; the first masking tape comprises a blackfirst surface adhered to the display panel, and a second surface adhered to the backlight module, wherein the second surface comprises a black first area and a white second area, the first area is arranged on the side of the through hole which is close to the lateral light source, and the second area is arranged on the side of the through hole which is away from the lateral light source.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

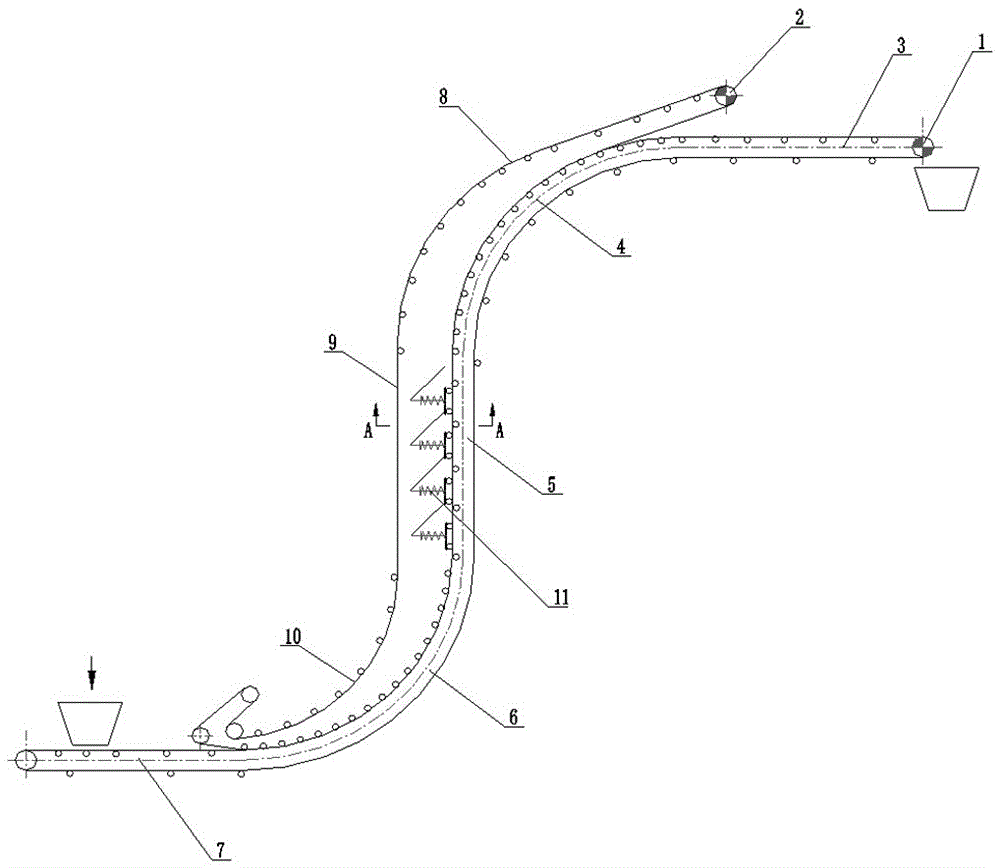

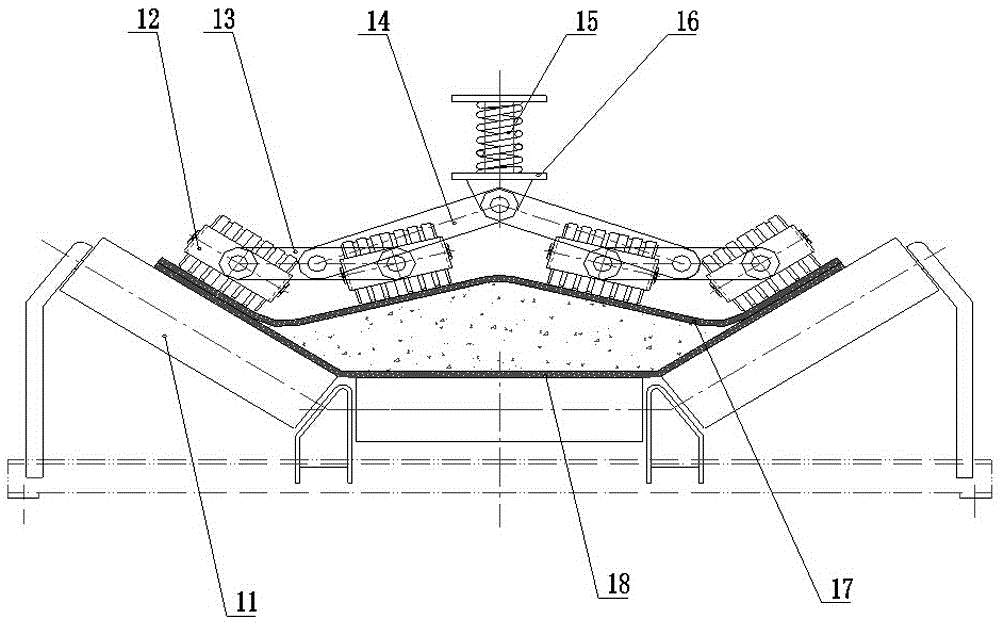

Novel gripping-tape type large-inclination-angle conveyor

The invention belongs to bulk material conveying mechanical equipment, and particularly relates to a novel gripping-tape type large-inclination-angle conveyor. The gripping-tape type large-inclination-angle conveyor comprises a carrier tape machine and a masking tape machine which are arranged on a frame, wherein a masking tape is arranged on the masking tape machine, a carrier tape is arranged on the carrier tape machine, the masking tape is tightly attached to the carrier tape on one side of the conveyed material, and the carrier tape machine is arranged in the Z shape. Compared with the prior art, the Z-shaped carrier tape machine is adopted, so as to greatly increase the inclination angle of the carrier tape machine and reduce the occupancy area of the conveyor, and especially in the material field which can not be reconstructed due to the influence of field, the large-inclination-angle conveyor has very good applicability.

Owner:HUADIAN ZHENGZHOU MECHANICAL DESIGN INST

Waterproof masking tape and adhesive for same

InactiveCN102344767AWith waterproof functionNo environmental pollutionMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesEmulsionMasking tape

The invention discloses an adhesive for a waterproof masking tape, characterized by comprising components in percentages by weight: 10%-30% of natural rubber, 10%-20% of synthetic rubber, 10%-30% of viscosity-increasing resin, 1%-3% of an accelerant, 2%-5% of an age resister and a solvent of the rest. The adhesive for the waterproof masking tape and the waterproof masking tape disclosed by the invention has a waterproof function and is suitable for the use in occasions of spraying paint in automobiles, baking varnish, spraying water to polish the paint surface, repairing the paint surface and the like. Furthermore, after the use, no residual adhesive is remained after the tape is torn off. In the automobile varnish baking process, the waterproof masking tape disclosed by the invention is suitable for the varnish baking procedure at a temperature up to 80 DEG C. The raw materials in the invention are aqueous emulsions so that no environmental protection exists in production and use processes.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Hydrophobic masking tape and preparation method thereof

ActiveCN103173157ANo pollution in the processCapable of outdoor useFilm/foil adhesivesOrganic non-macromolecular adhesiveSodium bicarbonateEmulsion

The invention provides a hydrophobic masking tape and a preparation method thereof. The hydrophobic masking tape comprises a masking tape layer and an adhesive layer which is coated on the surface of the masking tape layer, wherein the adhesive formula of the adhesive layer comprises the following components in parts by weight: 200-300 parts of butyl acrylate, 100-200 parts of 2-ethylhexyl acrylate, 2-10 parts of acrylic acid, 2-10 parts of 2-hydroxyethyl acrylate, 30-60 parts of styrene-acrylic emulsion, 5-10 parts of sodium benzene sulfonate, 300-500 parts of water, 2-7 parts of ammonium persulfate and 0.1-0.5 part of sodium bicarbonate. A hydrophobic adhesive is adopted in a preparation process to remove the conventional organic solvent, and the masking tape is subjected to ultraviolet pretreatment, so that the produced masking tape is pollution-free and environment-friendly and has an outdoor use function.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Hot melt masking tape and production process thereof

InactiveCN103666311AImprove temperature resistanceImprove waterproof performanceMineral oil hydrocarbon copolymer adhesivesNon-fibrous pulp additionPolymer scienceAdhesive belt

The invention provides a hot melt masking tape and a production process thereof. The production process comprises the following steps: firstly carrying out immersion treatment on masking paper in carboxylated styrene-butadiene latex; spraying a mixture of tackifying resin emulsion and modified styrene-butadiene emulsion as a primer onto one side of the masking paper at normal temperature and carrying out high-temperature treatment; then coating silicon on the other side of the masking paper by using a mixture of vinyl acetate-acrylic emulsion and organic silicon as a release agent and carrying out high-temperature treatment; coating hot melt glue on the surface of the primer with a knife. The hot melt masking tape produced by the production process has excellent temperature resistance and water resistance and does not have adhesive residues.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

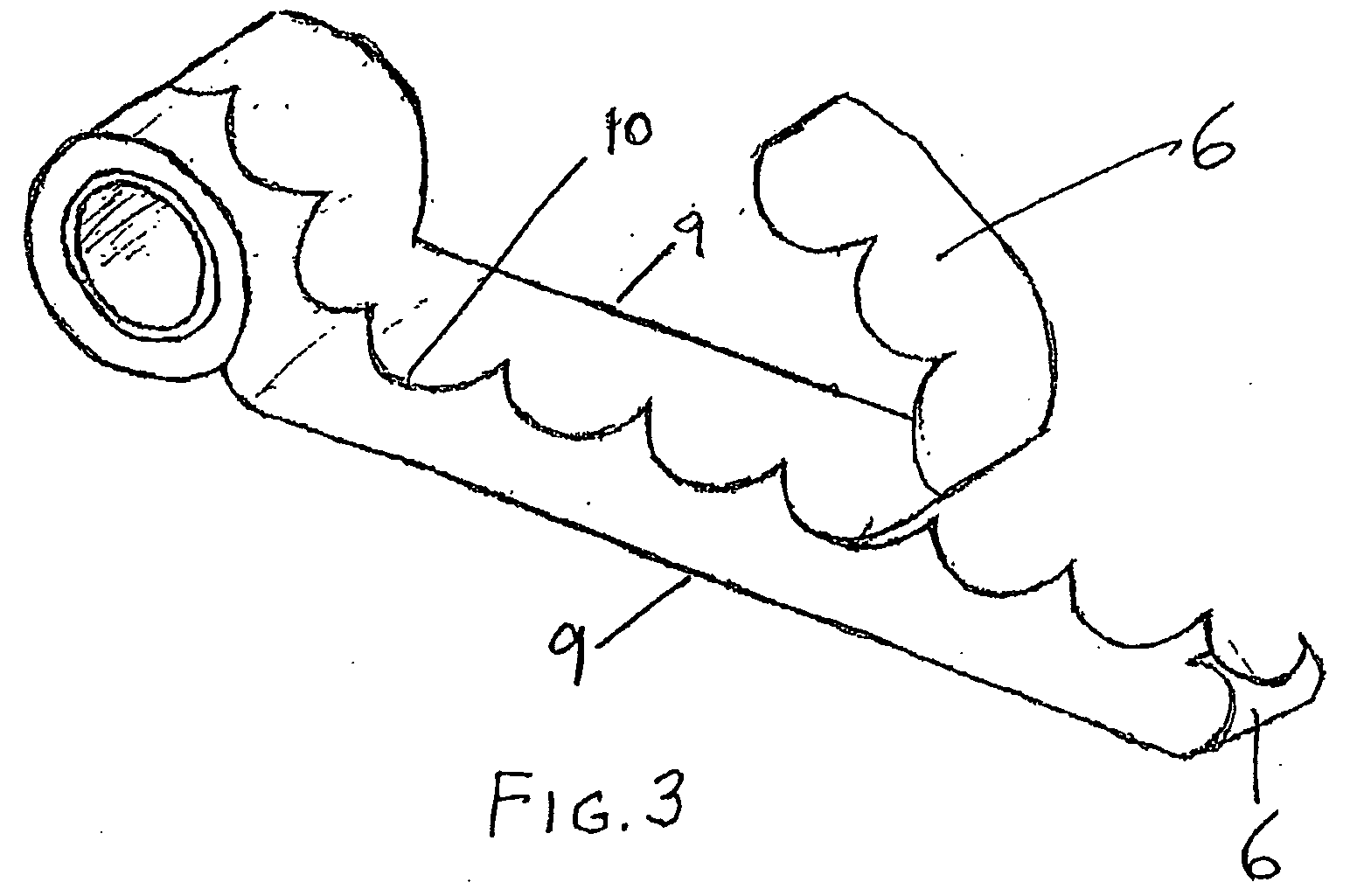

Fret Dressing Mask

Fret Dressing Masks: In the manufacturing of guitars and other fretted stringed instruments, it is necessary to file level, after installation, the 20 or more metal frets which are inserted across the wood neck. This is not a job which can be performed by machines and requires the hand work of instrument craftsmen. To accomplish this operation without damaging the neck of the instrument, several layers of paper masking tape have historically been applied. This is a time consuming, expensive process. Fret Dressing Masks are a disposable tool, approximately twenty-two inches long, cut from thick vinyl, and have slots / windows-cut and registered to fit around the frets. In one motion, they are applied to protect the neck instead of masking tape. This process takes less than two minutes, which is one tenth of the time of the current task. Once the filing process is complete, the Fret Dressing Masks can be removed in seconds. Thirty or more minutes total can be saved in the manufacturing of fretted instrument necks, thus saving time and labor costs.

Owner:CROSS JOHN AMES

Composite material and method of producing the same

InactiveUS20030096059A1Quality improvementHigh yieldSemiconductor/solid-state device detailsSolid-state devicesMasking tapeMetal catalyst

A composite raw material is subjected to masking, and then the composite raw material is pretreated. After that, a surface of the composite raw material is activated, and a metal catalyst is applied to a joining surface of the composite raw material and a surface of a masking tape. Subsequently, an electroless plating treatment is performed to form a plating layer on the joining surface of the composite raw material and the surface of the masking tape. It is preferable that the thickness of the plating layer is 5 to 100 mum. After that, the masking tape which has been stuck to the composite raw material is removed, and then a drying treatment is performed for the composite raw material having the plating layer formed only on the joining surface.

Owner:NGK INSULATORS LTD

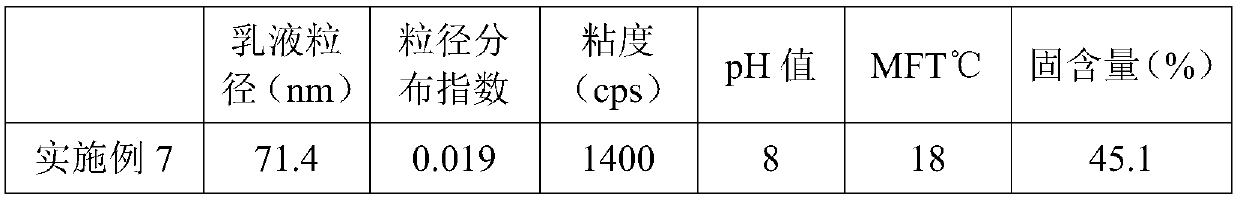

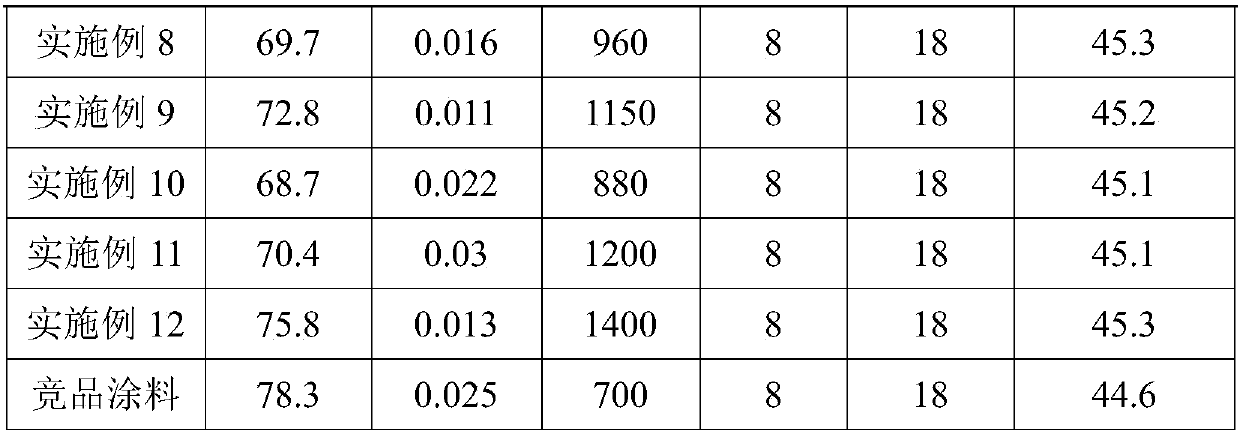

Core-shell styrene-acrylic emulsion for priming paint and preparation method and application of core-shell styrene-acrylic emulsion

The invention relates to a core-shell styrene-acrylic emulsion for priming paint and belongs to the technical field of waterproof paint. The core-shell styrene-acrylic emulsion comprises the followingingredients in parts by mass: 5.07-30 parts of core monomer, 5.07-30 parts of shell monomer, 0.6-12 parts of emulsifier, 0.02-5 parts of initiator, 0.02-5 parts of chain transfer agent, 0.02-5 partsof pH buffering agent, 0.02-2 parts of first antifoamer, 0.02-2 parts of first preservative agent and 40-50 parts of deionized water; the core monomer is a main monomer, and the shell monomer comprises 4.93-20 parts of main monomer, 0.02-2.55 parts of polar monomer, 0.02-2.5 parts of phosphate monomer and 0.05-5 parts of ureido monomer. The invention further provides a preparation method of the core-shell styrene-acrylic emulsion for priming paint and application of the core-shell styrene-acrylic emulsion for priming paint in aqueous sealing priming paint. The priming paint prepared by using the core-shell styrene-acrylic emulsion has the advantages that the film forming property, sealing property and adhesive power of a paint film can be guaranteed, and the paint film can have relativelyhigh surface hardness and masking tape tear resistance.

Owner:GUANGDONG HENGGUANG CHEM CO LTD

Adhesive tape for masking

InactiveUS20050077003A1Prevent movementFacilitated releaseAdhesive processesFilm/foil adhesivesMasking tapeElectrical and Electronics engineering

An absorbent edge coating for masking tape and other masking materials is herein disclosed. A masking tape according to the present invention comprises a substrate having a top surface, a bottom surface, and at least one masking edge. The bottom surface of the substrate has an adhesive layer applied thereto. An absorbent edge coating is applied to at least one masking edge of the substrate so as to at least substantially prevent liquids addressed to the at least one coated masking edge from being absorbed into the substrate of the tape and from passing between the bottom surface of the tape and a surface to which the tape has been applied.

Owner:GRUBER GEORGE

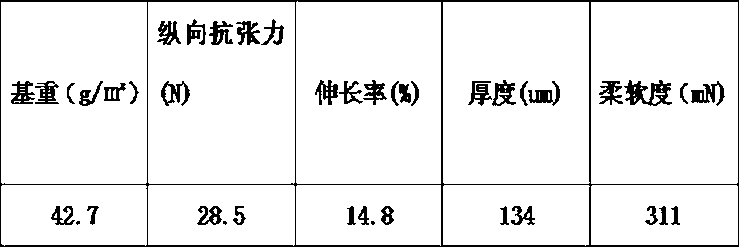

Mold release agent for masking tape, and preparation method thereof

ActiveCN103924478AIncrease productivityReduce foamingDefoamers additionFilm/foil adhesivesSodium bicarbonateWater based

The invention relates to a mold release agent for a masking tape, and a preparation method of the mold release agent. The mold release agent is prepared from the following raw materials in parts by weight: 150-270 parts of ethyl acrylate, 0-90 parts of butyl acrylate, 0-110 parts of methyl methacrylate, 0-105 parts of styrene, 5-10 parts of succinic acid, 0-7 parts of crosslinking monomer, 500-600 parts of deionized water, 0.1-0.4 part of sodium bicarbonate, 3-5 parts of lauryl sodium sulfate, 1.2-3.0 parts of ammonium persulfate, 0.5-2 parts of a defoaming agent, 30-55 parts of zinc glycinate, 5-15 parts of ammonia water, 20-100 parts of long-chain alkyl surface active agent and 0-10 parts of modified polysiloxane. The mold release agent is a water-based mold release agent, is convenient to use and can be directly coated or can be coated after being diluted by water; a catalyst is not fed into the mold release agent, and the mold release agent is capable of crosslinking at low temperature and does not contain an organic solvent, so that the mold release agent is free from environmental pollution and harmless to the human health; furthermore, the mold release agent has good heat resistance and weather resistance, is capable of providing proper mold release force for the masking tape, and is lower in migration rate; the tape prepared by the mold release agent is free from residual glue after being used, so that the protected surface is not polluted.

Owner:BLUE OCEAN & BLACK STONE TECH CO LTD FUJIAN

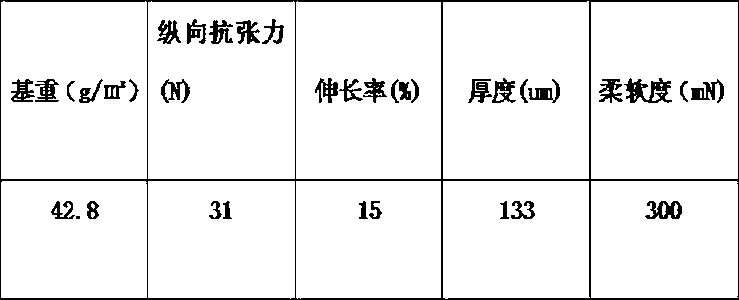

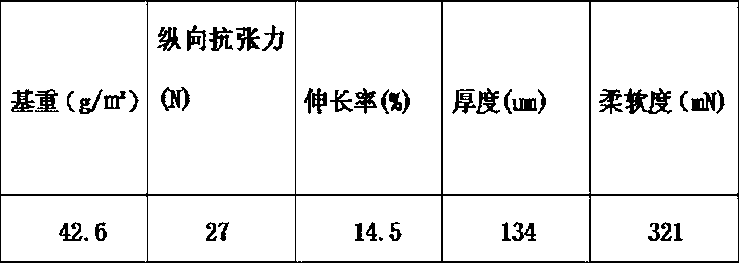

Manufacturing process for macerative masking tape

InactiveCN103015258AHigh strengthHigh bonding strengthReinforcing agents additionPaper/cardboardMasking tapeHigh intensity

The invention relates to a masking tape making and macerating process for manufacturing a masking tape, in particular to a manufacturing process for macerative masking tape. The process comprises two parts including a masking tape making part and a macerating part, wherein the masking tape making part comprises the steps as following: wood pulp untwining; pulp milling, that is, wood pulp is pulped via a double-disc refiner, wherein the beating degree is 40-70 degrees SR, the wet weight is 6-11 g, and the beating intensity is 3.5-5.0 percent; pulp preparation means that a softening agent and a wet strength agent are added into milled pulp, the use level of the softening agent is 3-8 kg / T and the use level of the wet strength agent is 30-45 kg / T; purification; screening; shaping on a net; grinding and cockling, wherein the grinding dryness degree is controlled within a range of 36-45 percent; drying; and winding and cutting. The macerating part comprises the steps of unwinding, macerating processing, drying, winding, cutting, winding, packing and warehousing. The macerative masking tape has good flexibility, high intensity and large thickness.

Owner:浙江晶鑫特种纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com