Adhesive tape for masking

a technology of adhesive tape and masking tape, which is applied in the direction of film/foil adhesive, other domestic articles, synthetic resin layered products, etc., can solve the problems of degrading the ability of the adhesive to form, the tape is typically only partially successful, and the paper substrate has a tendency to absorb or wick moistur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Although the disclosure hereof is detailed and exact to enable those skilled in the art to practice the invention, the physical embodiments herein disclosed merely exemplify the invention, which may be embodied in other specific structure. While the preferred embodiment has been described, the details may be changed without departing from the invention, which is defined by the claims.

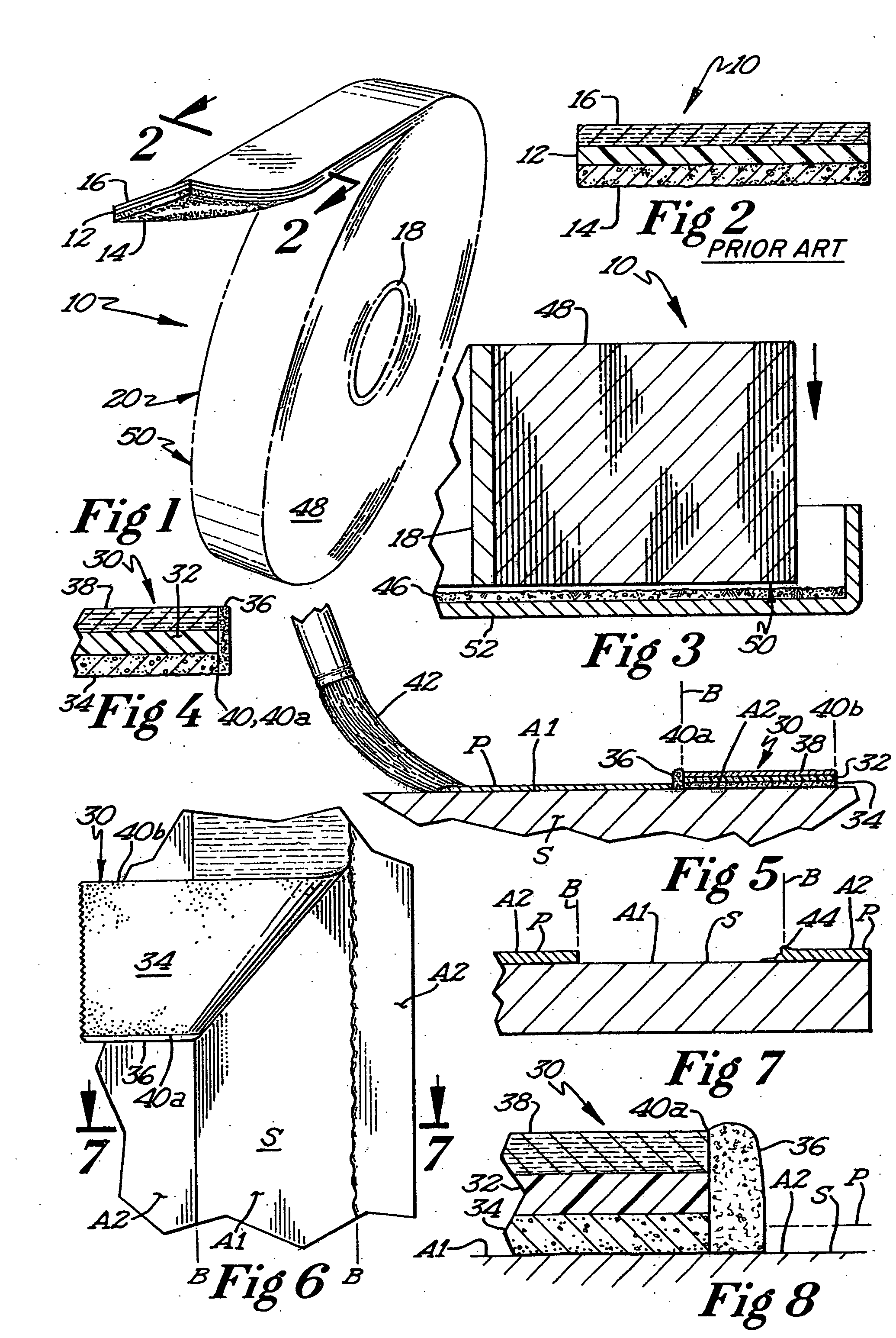

[0024]FIG. 2 illustrates a cross section of a standard, prior art adhesive tape 10 of a type commonly used for masking. Tape 10 has a middle layer or substrate 12 and an adhesive layer 14 applied to a bottom surface of the substrate 12. In some instances, tape 10 may have a top layer 16 applied to a top surface of the substrate 12 that is impervious or at least resistant to liquids. Tape 10 is most often wound on a core 18 to form a roll 20 as illustrated in FIG. 1.

[0025] The present invention comprises an adhesive tape 30 as illustrated in FIGS. 3 and 4. Tape 30 has a substrate 32, an adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com