Novel gripping-tape type large-inclination-angle conveyor

A technology of large inclination and conveyor, applied in the direction of conveyor, transportation and packaging, can solve the problems of large floor area of ordinary belt upper warehouse and inability to carry out closed transformation, so as to reduce the floor space, improve the applicability, and improve the inclination. The effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

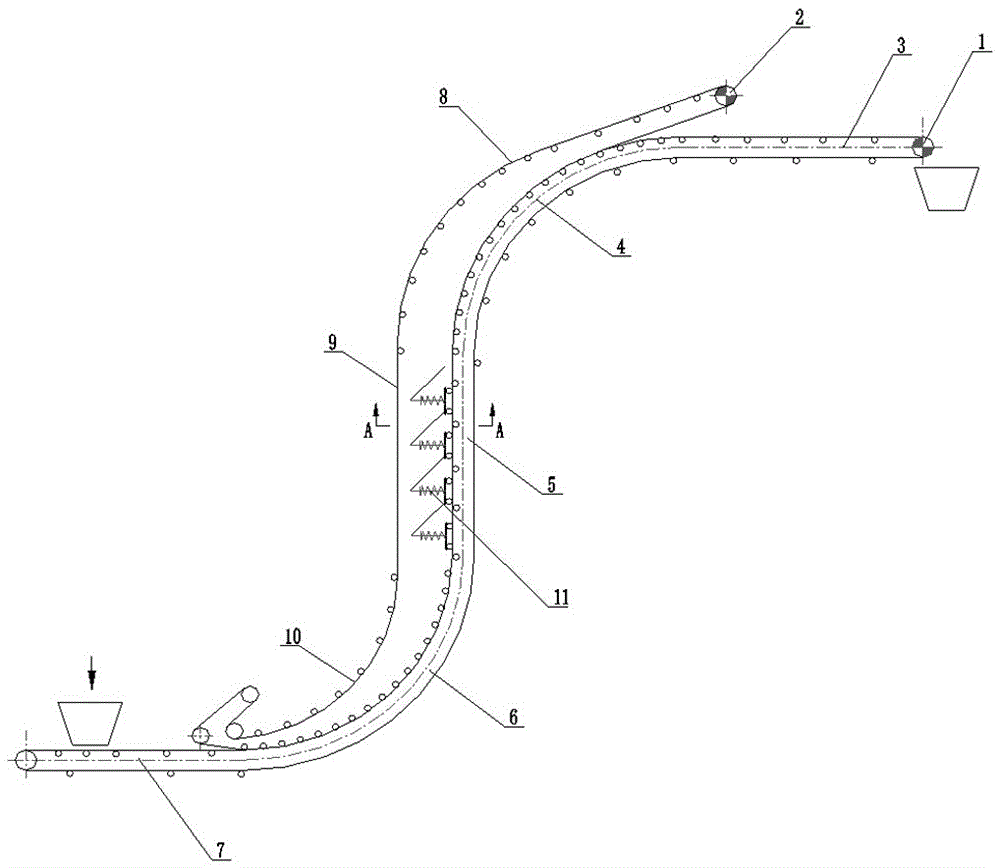

[0016] Such as Figure 1-Figure 2 As mentioned above, the new entrainment type high-inclination angle conveyor has a large conveying inclination angle, up to 90°, and is an ideal equipment for large-inclination angle conveying and vertical lifting. Therefore, it can save floor area, save equipment investment and civil construction costs, and achieve good comprehensive economic benefits. For example, if a user wants to lift coal to the top of a silo with a height of 20m, if a sidewall machine is used to transport coal at an inclination of 45°, the length of the machine only needs to be 28.3m (horizontal machine length is 20m); and if a sidewall machine for vertical transportation is used , then the horizontal captain can be controlled within 6m.

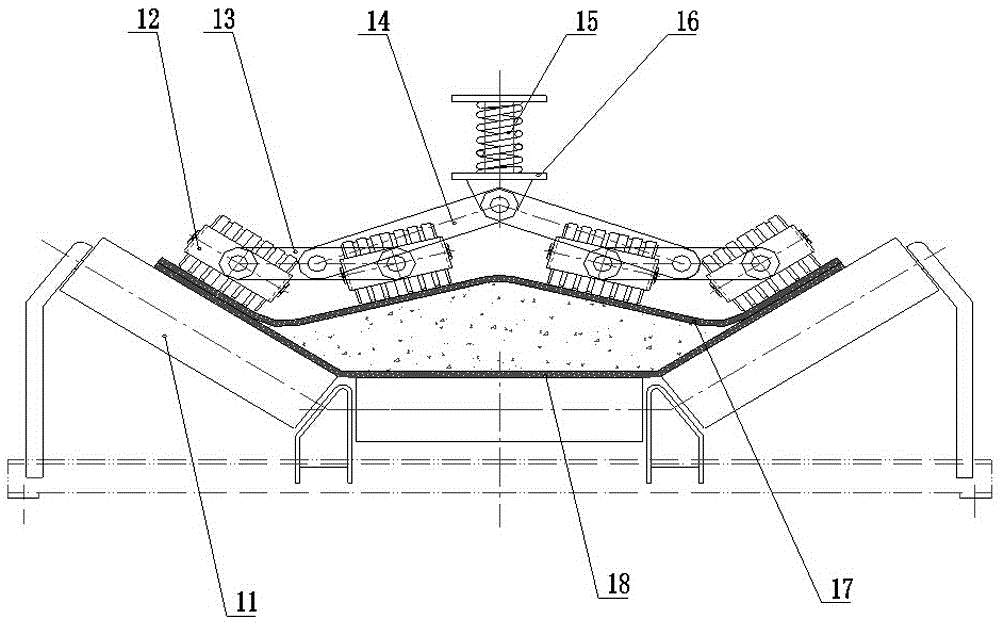

[0017] In order to achieve the above object, the present invention adopts the following technical solutions: add a cover tape to the ordinary belt conveyor, and use a belt pressing device 11 to constrain the material to be conveyed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com