Connecting rod of engine

An engine connecting rod and connecting rod cover technology, which is applied to connecting rods, mechanical equipment, shafts and bearings, etc., can solve problems such as affecting the working efficiency of the engine, adverse effects on the public environment, and cumbersome replacement of the crankshaft. Ignition start, the effect of increasing the ignition range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

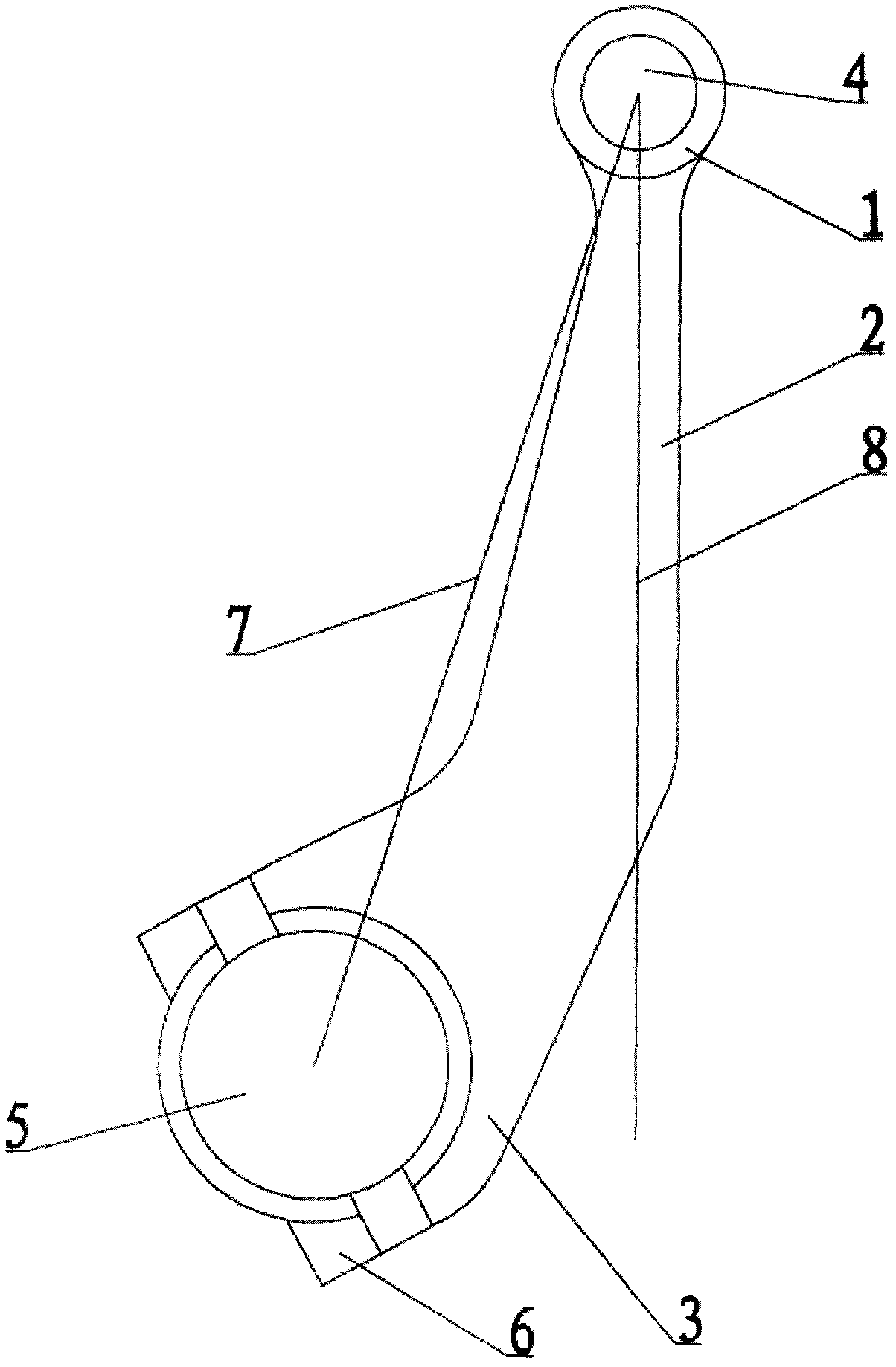

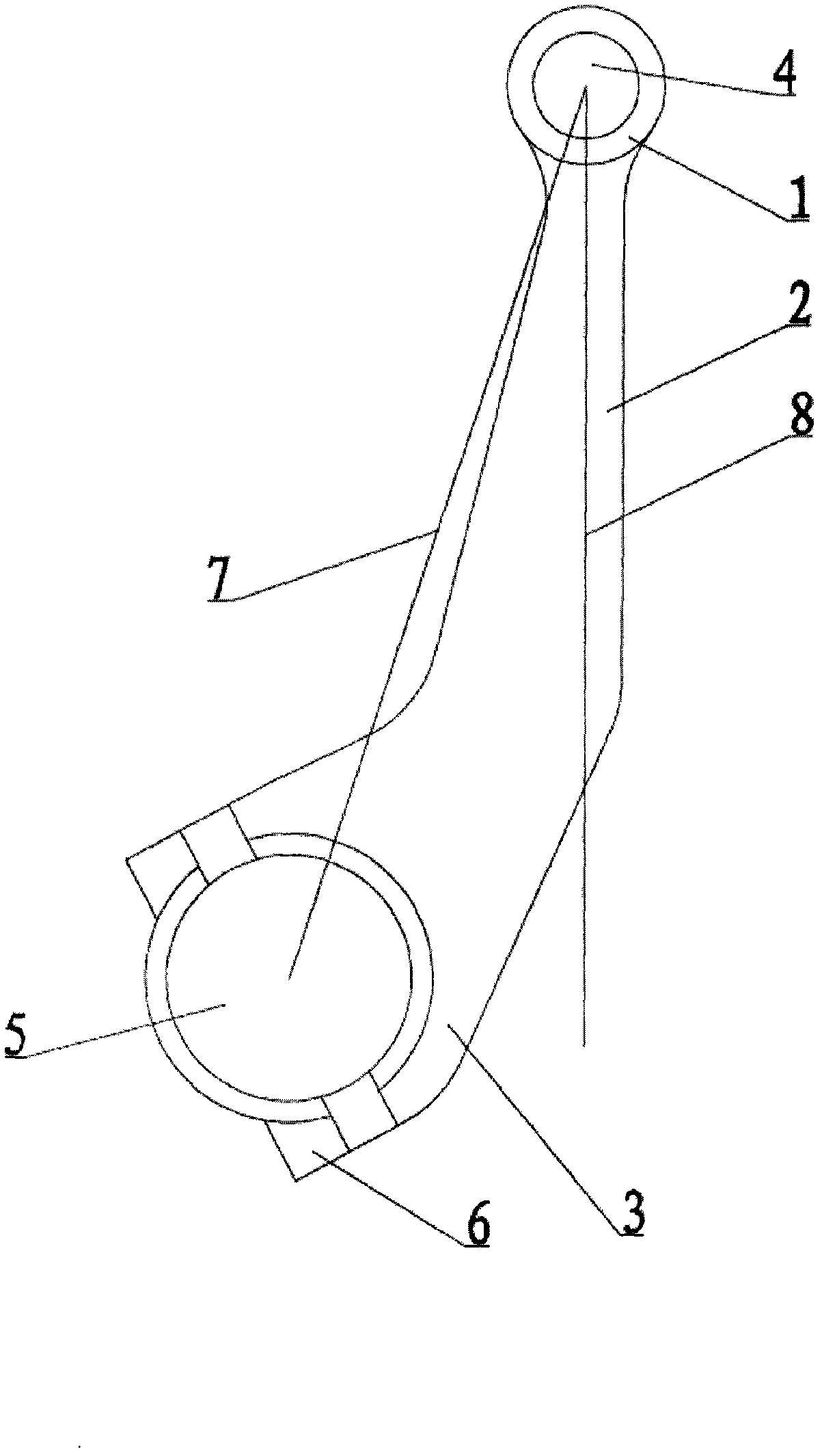

[0012] Such as figure 1 As shown, a connecting rod of an engine includes a connecting rod small end 1 provided with a piston shaft mounting hole 4, a crankshaft mounting seat 3 integrally cast with the connecting rod small end 1 through the rod body 2, and is mounted on the crankshaft mounting seat 3. There is a connecting rod cover 6, the connecting rod cover 6 and the crank mounting seat 3 form the crankshaft mounting hole 5, and the end of the crankshaft mounting seat 3 of the shaft 2 is bent to one side of the shaft 2 in an L-shape. The piston shaft mounting hole 4 An included angle is provided between the line 7 between the center of the circle and the center of the crankshaft mounting hole 5, and the vertical line 8 passing through the center of the circle of the piston shaft mounting hole 4, and the angle is 10°.

Embodiment 2

[0014] Such as figure 1 As shown, a connecting rod of an engine includes a connecting rod small end 1 with a piston shaft mounting hole 4, a crankshaft mounting seat 3 integrally cast with the connecting rod small end 1 through a rod body 2, and is installed on the crankshaft mounting seat 3. There is a connecting rod cover 6, the connecting rod cover 6 and the crank mounting seat 3 form the crankshaft mounting hole 5, and the end of the crankshaft mounting seat 3 of the shaft 2 is bent to one side of the shaft 2 in an L-shape. The piston shaft mounting hole 4 An included angle is provided between the line 7 between the center of the circle and the center of the crankshaft mounting hole 5, and the vertical line 8 passing through the center of the circle of the piston shaft mounting hole 4, and the angle is 15°.

Embodiment 3

[0016] Such as figure 1 As shown, a connecting rod of an engine includes a connecting rod small end 1 with a piston shaft mounting hole 4, a crankshaft mounting seat 3 integrally cast with the connecting rod small end 1 through a rod body 2, and is installed on the crankshaft mounting seat 3. There is a connecting rod cover 6, the connecting rod cover 6 and the crank mounting seat 3 form the crankshaft mounting hole 5, and the end of the crankshaft mounting seat 3 of the shaft 2 is bent to one side of the shaft 2 in an L-shape. The piston shaft mounting hole 4 An included angle is provided between the line 7 between the center of the circle and the center of the crankshaft mounting hole 5, and the vertical line 8 passing through the center of the circle of the piston shaft mounting hole 4, and the angle is 25°.

[0017] When the piston moves upwards to the top dead center, the crankshaft is driven by the connecting rod of the engine to tilt in the direction of rotation. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com