Synthetic biodiesel and preparation method thereof

A technology for synthesizing biology and diesel, which is applied in the fields of biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of high pollutant emission, poor power performance, incomplete combustion, etc., and achieve high calorific value, good fluidity, The effect of reducing the density of diesel oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

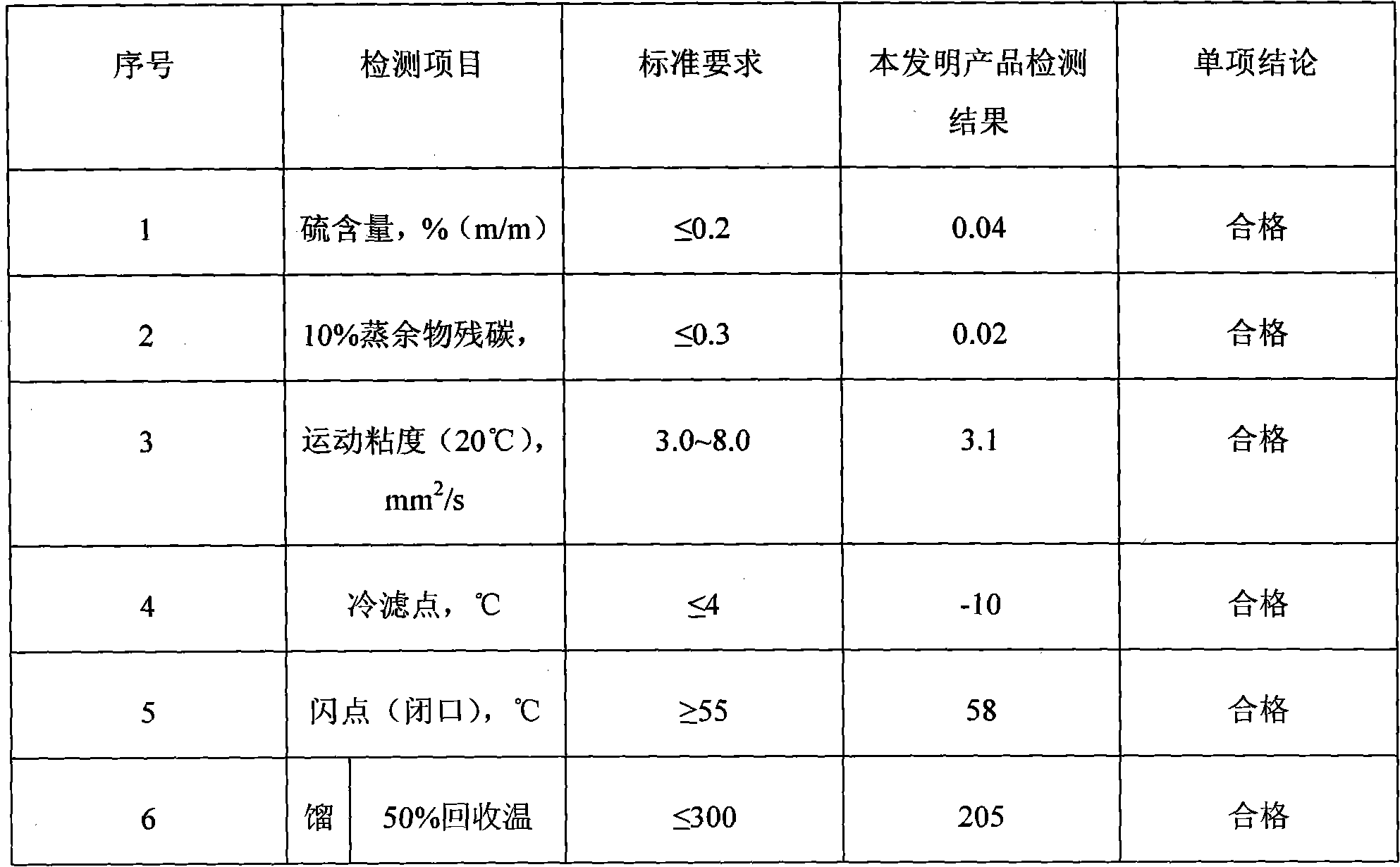

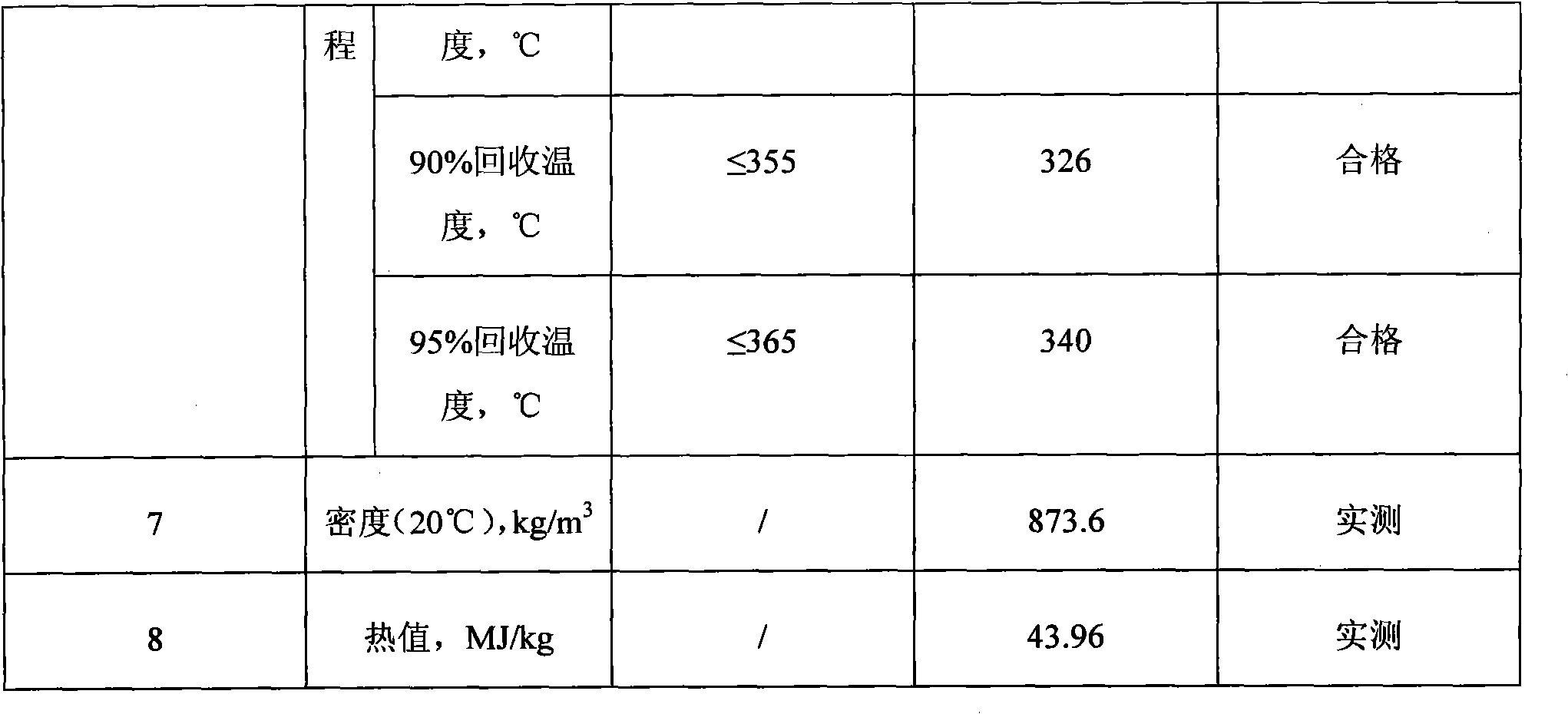

Examples

Embodiment 1

[0018] Weigh 65 parts of acidified oil (acidified oil), 17 parts of methanol, 12.5 parts of desulfurized heavy benzene, 5 parts of light oil (naphtha), and 0.5 part of catalytic additive.

[0019] The above-mentioned various raw materials are pumped into a non-pressure container by metering, and the electric heating static mixer is used to circulate at 30-50 °C for 8 hours, then stand still and filter to obtain this product.

Embodiment 2

[0021] Weigh 52 parts of acidified oil (acidified oil), 18 parts of methanol, 25.7 parts of desulfurized heavy benzene, 4 parts of light oil (petroleum ether), and 0.3 parts of catalytic additive.

[0022] Preparation method is the same as example 1.

Embodiment 3

[0024] Weigh 60 parts of acidified oil (acidified oil), 15 parts of methanol, 21.4 parts of desulfurized heavy benzene, 3 parts of light oil (atmospheric pressure gas oil), and 0.6 part of catalytic additive.

[0025] Preparation method is the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com