Patents

Literature

47results about How to "Promote micronization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

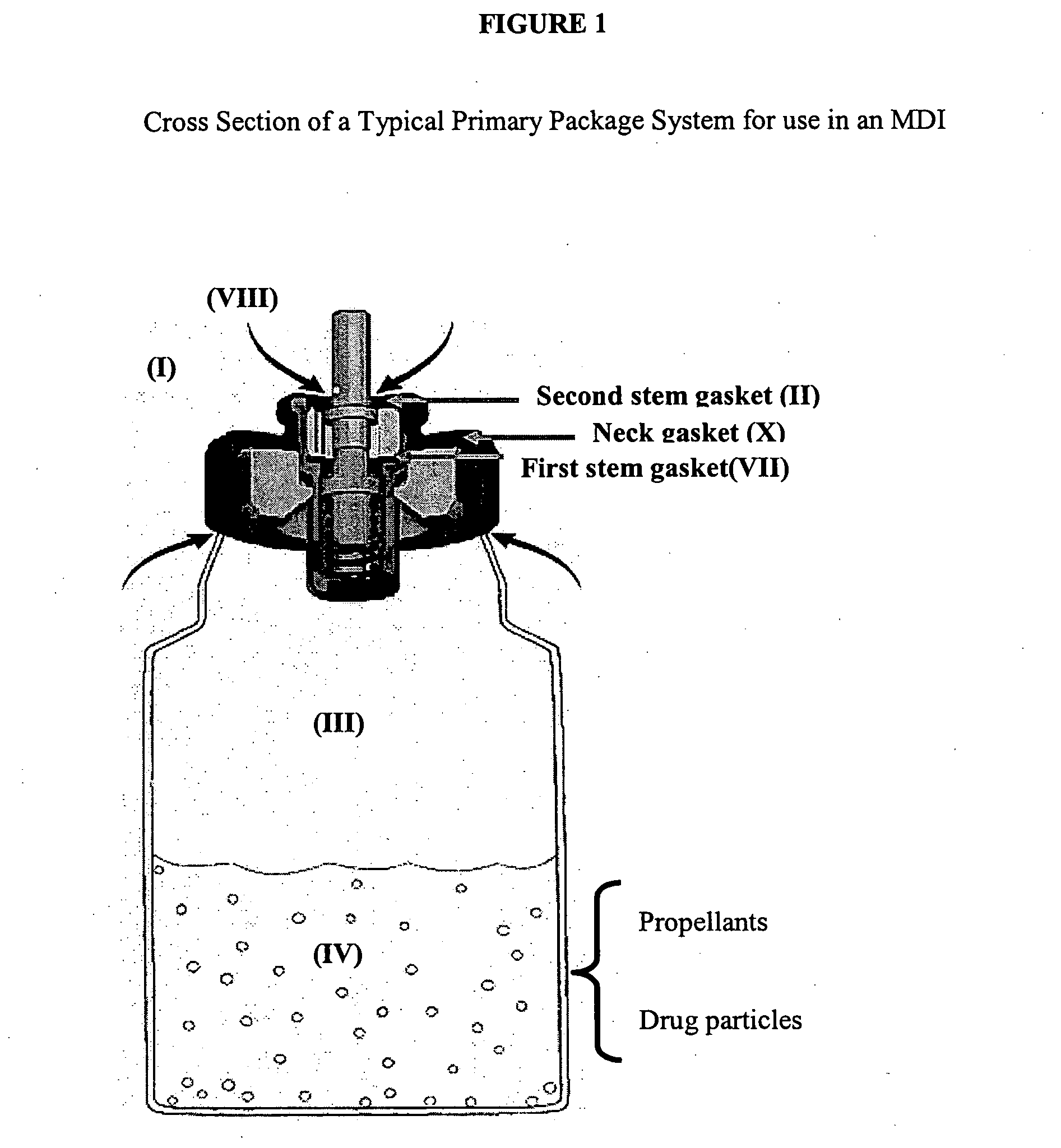

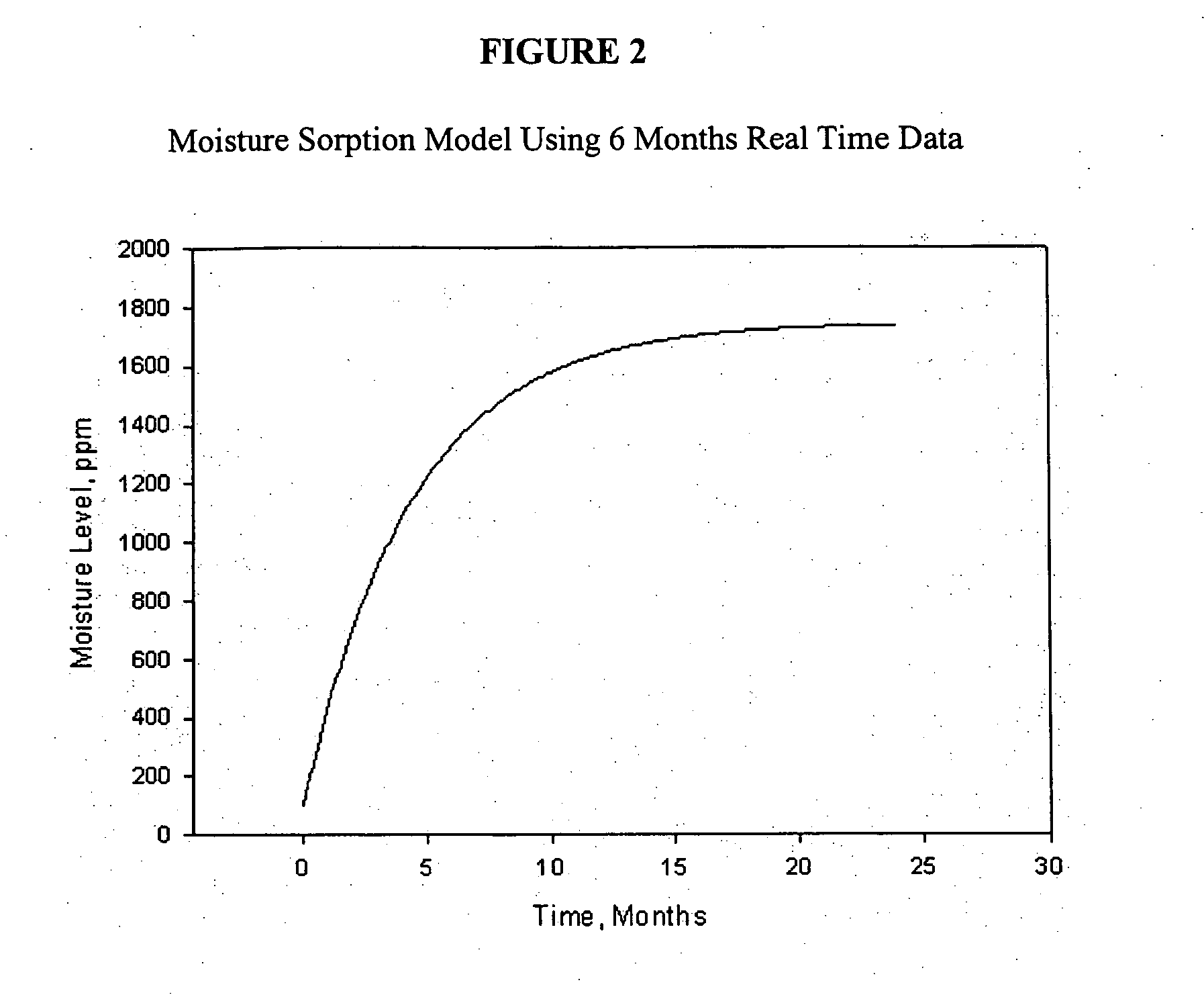

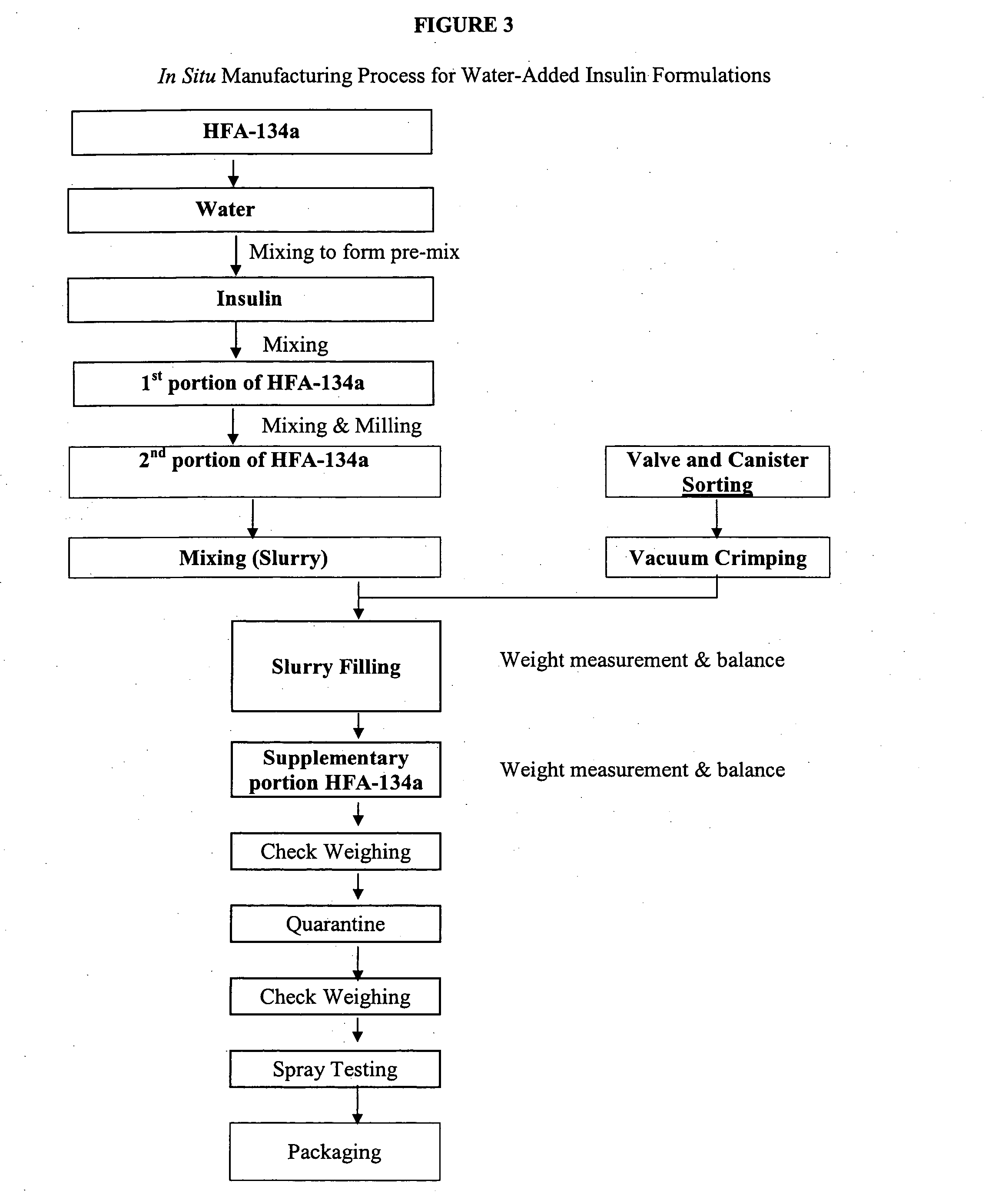

Water-stabilized aerosol formulation system and method of making

InactiveUS20060171899A1Reduce probabilityPromote micronizationPowder deliveryOrganic active ingredientsMedicineMoisture

The invention relates to an aerosol formulation system comprising a primary package system and an aerosol formulation therein wherein the aerosol formulation comprises insulin, a propellant and an amount of water sufficient to reach equilibrium quantities based on the moisture sorption rate diffusing across the primary package system in which the formulation is contained. In addition, the invention relates to a process for preparing the aerosol formulation systems as described herein.

Owner:ABBOTT RESPIRATORY LLC

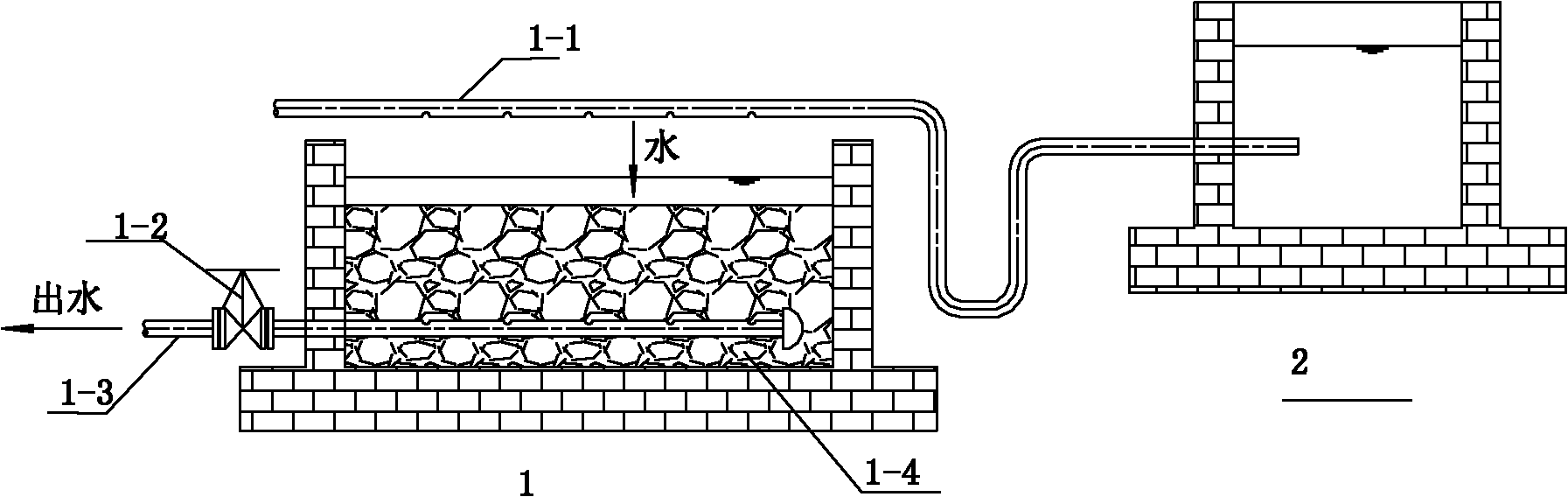

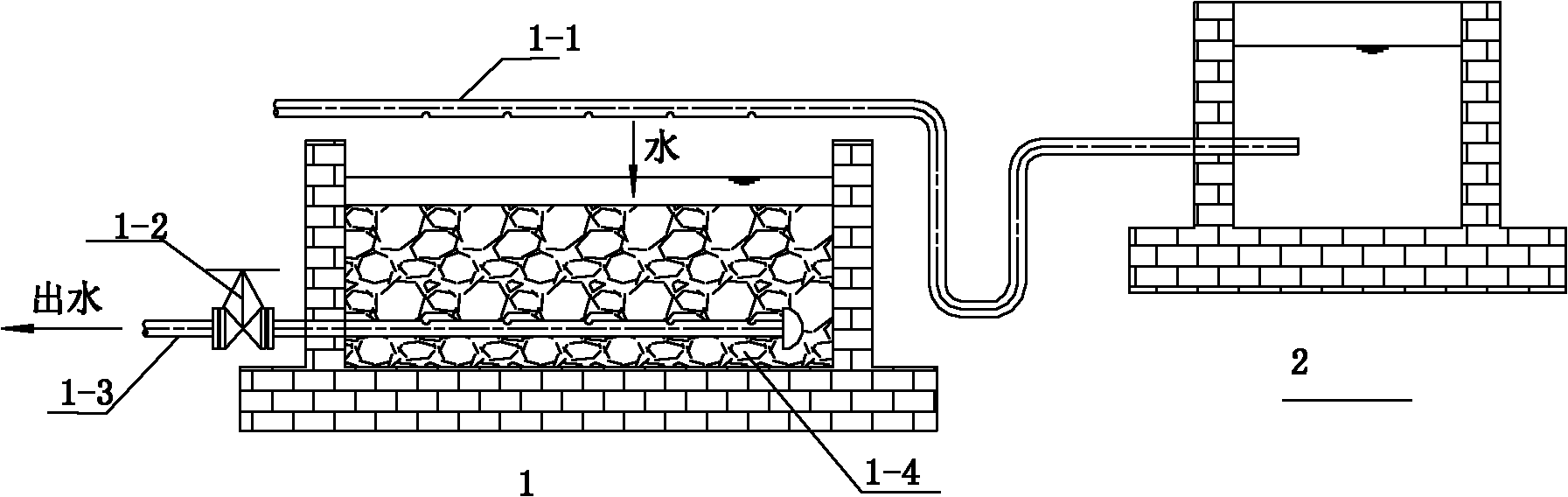

Method for improving microbial activity of artificial wetland

InactiveCN101973639APrevent compactionAvoid cloggingSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandMicroorganism

The invention discloses a method for improving microbial activity of an artificial wetland. The microbial activity of the artificial wetland is improved by adopting synergistic effect of an aquatic animal and an aquatic plant, wherein the aquatic animal is any one of earthworm, viviparus and loach; the aquatic plant is any one of reed, wild rice shoot and cress; and the method realizes the synergistic effect of the aquatic animal and the aquatic plant by certain condition control, and improves the microbial activity of the wetland and the pollutant removing capacity of the wetland. The controlled conditions comprise variety selection of the aquatic animal and the aquatic plant, quantity control, planting depth and density and the like. The method is suitable for improving the activity of various wetland microbes, can improve the treated microbe number of a wetland treatment system by one order of magnitude in domestic sewage treatment, and is particularly favorable for improving the denitrification efficiency of the wetland system.

Owner:SOUTHEAST UNIV

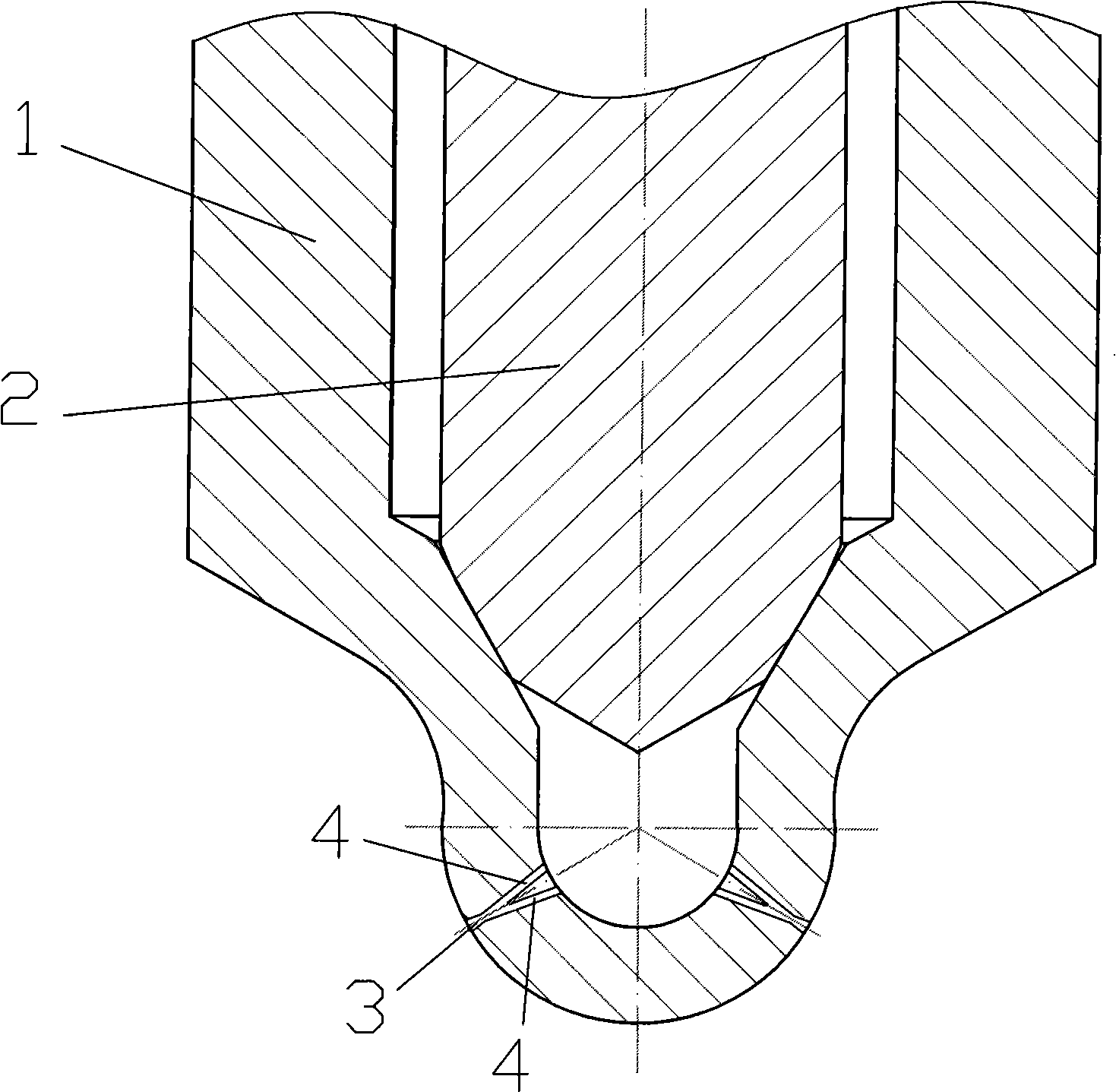

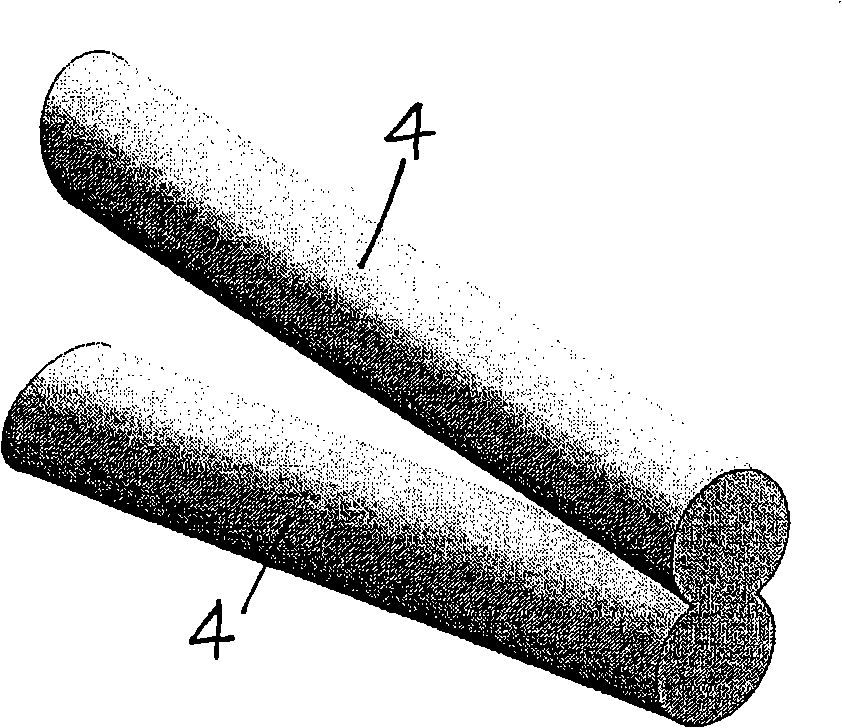

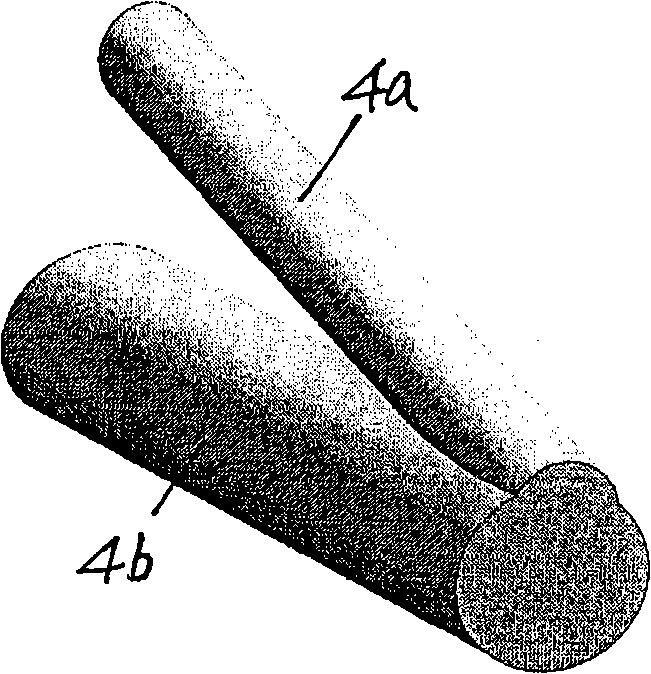

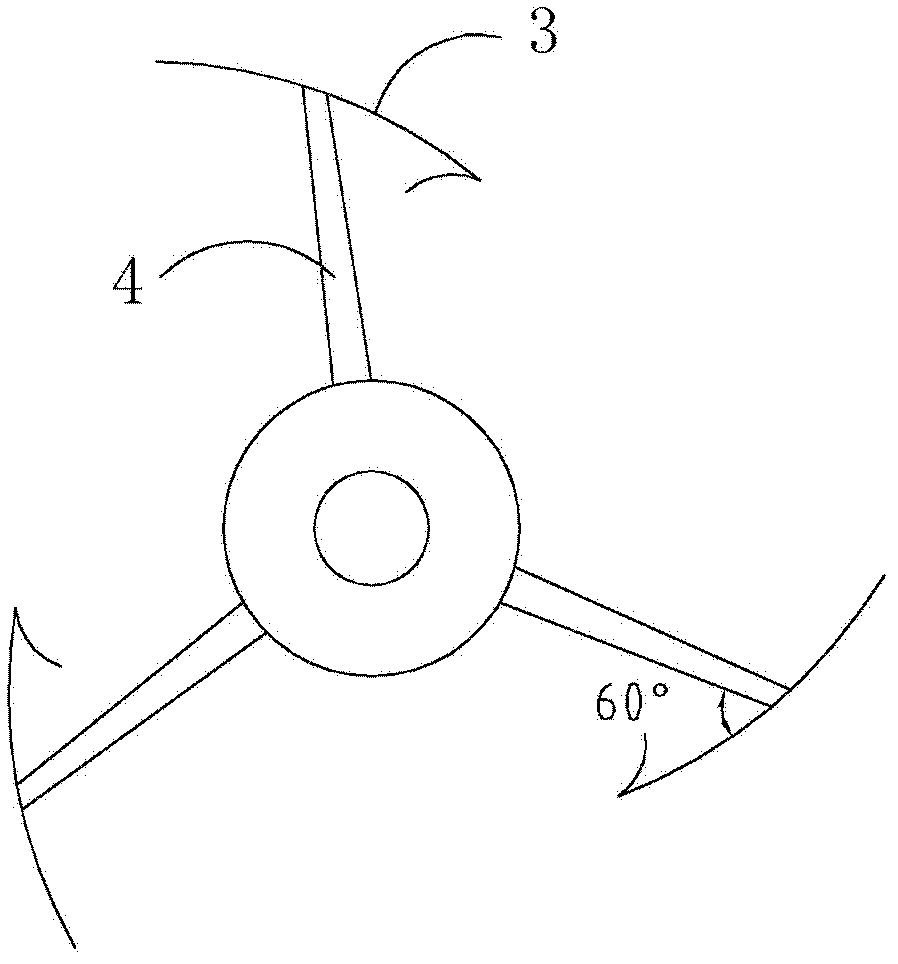

Crossing spray orifice type injection nozzle of internal combustion engine

InactiveCN101294533AIncreased turbulence intensityPromote atomizationFuel injection apparatusMachines/enginesCombustionExternal combustion engine

The invention relates to a cross orifice typed injection nozzle for an internal-combustion engine and belongs to an oil injection device of a fuel system of the internal-combustion engine. The nozzle is a precision coupling formed by an injector valve body and an injector valve. The head of the injector valve body is provided with at least one cross sub-orifice and each cross orifice is formed by crossing and collecting of at least two sub-orifices. As the collection of fuel in the sub-orifices of the cross orifice can form intense disturbance, the turbulent kinetic energy is increased and the atomization is improved; as an outlet of the cross orifice is formed by the collection of the sub-orifices, the flow area of the outlet is less than the sum of the outlet areas of all the sub-orifices, the injection nozzle is characterized by improving discharge coefficient like an analogous V-shaped gradually shrinking orifice. In brief, the crossing of the sub-orifices increases the internal flow, improves the turbulent intensity, causes the cross orifice to improve atomization, improves the quality of the mixed gas and leads to rapid, sufficient and perfect combustion, thus being beneficial to the further improvement of the economic performance, discharging performance and kinetic performance of the motor.

Owner:DALIAN UNIV OF TECH

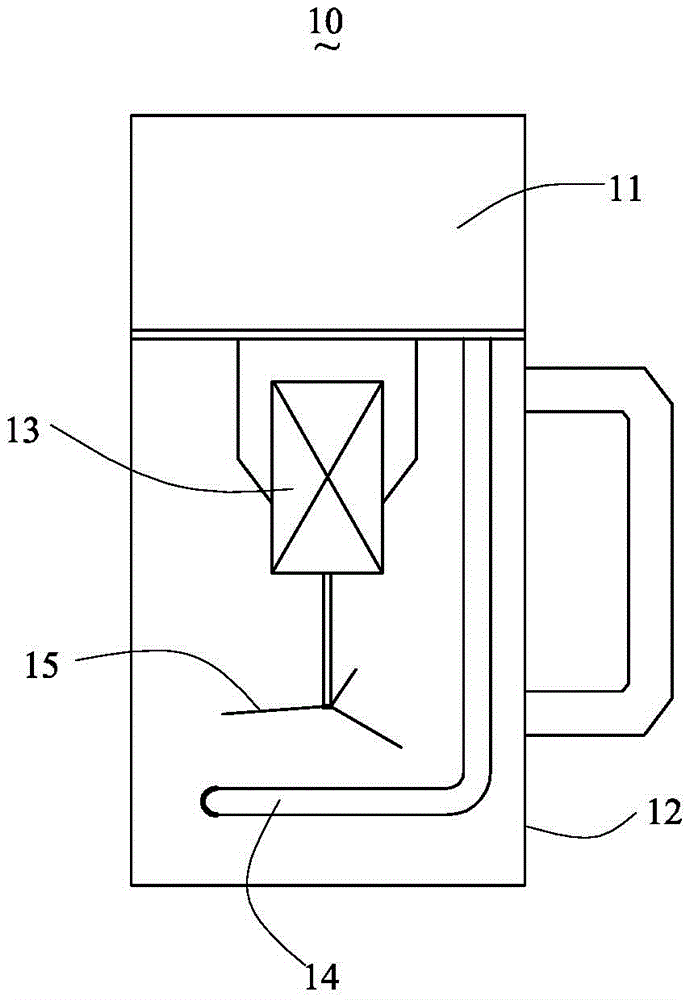

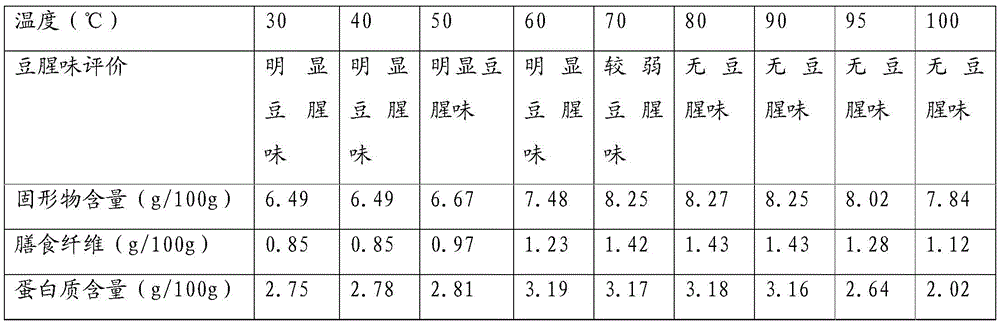

Method for preparing highly-enriched soya-bean milk by utilizing household soybean milk machine

The invention relates to a method for preparing highly-enriched soya-bean milk by utilizing household soybean milk machine. The method comprises at least following steps: a, a wall-crushing phase: a first step, keeping soybean milk material within the first temperature range of 1 to 14 minutes with the first temperature of 70 to 90 DEG C; a second step: rotating to crushing for milk by a crushing cutter at the first rotation speed of 16000 to 35000 turns / minute; b, a boiling phase: heating soybean milk till it is boiled by a heating element. Compared with the prior art, dietary fibers are highly microparticulated and dispersibility and water binding capacity of dietary fibers are greatly improved such that emulsion of soybean milk is very stabilized and soybean milk is not easily stratified after finishing preparation. Therefore, the method is adopted so that soya-bean milk is highly-enriched and not easily stratified and tastes good.

Owner:JOYOUNG CO LTD

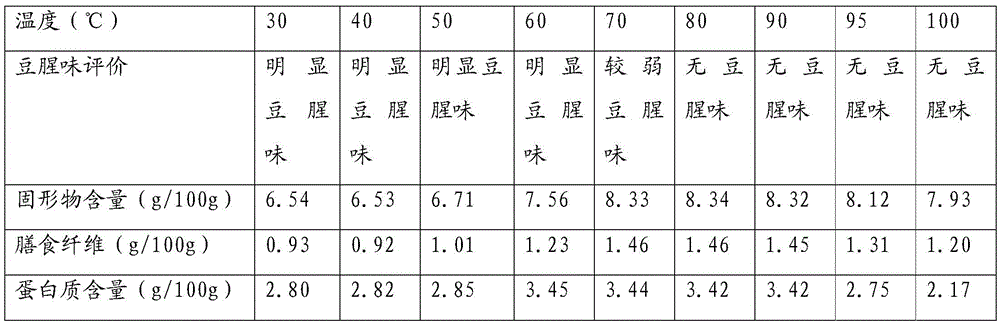

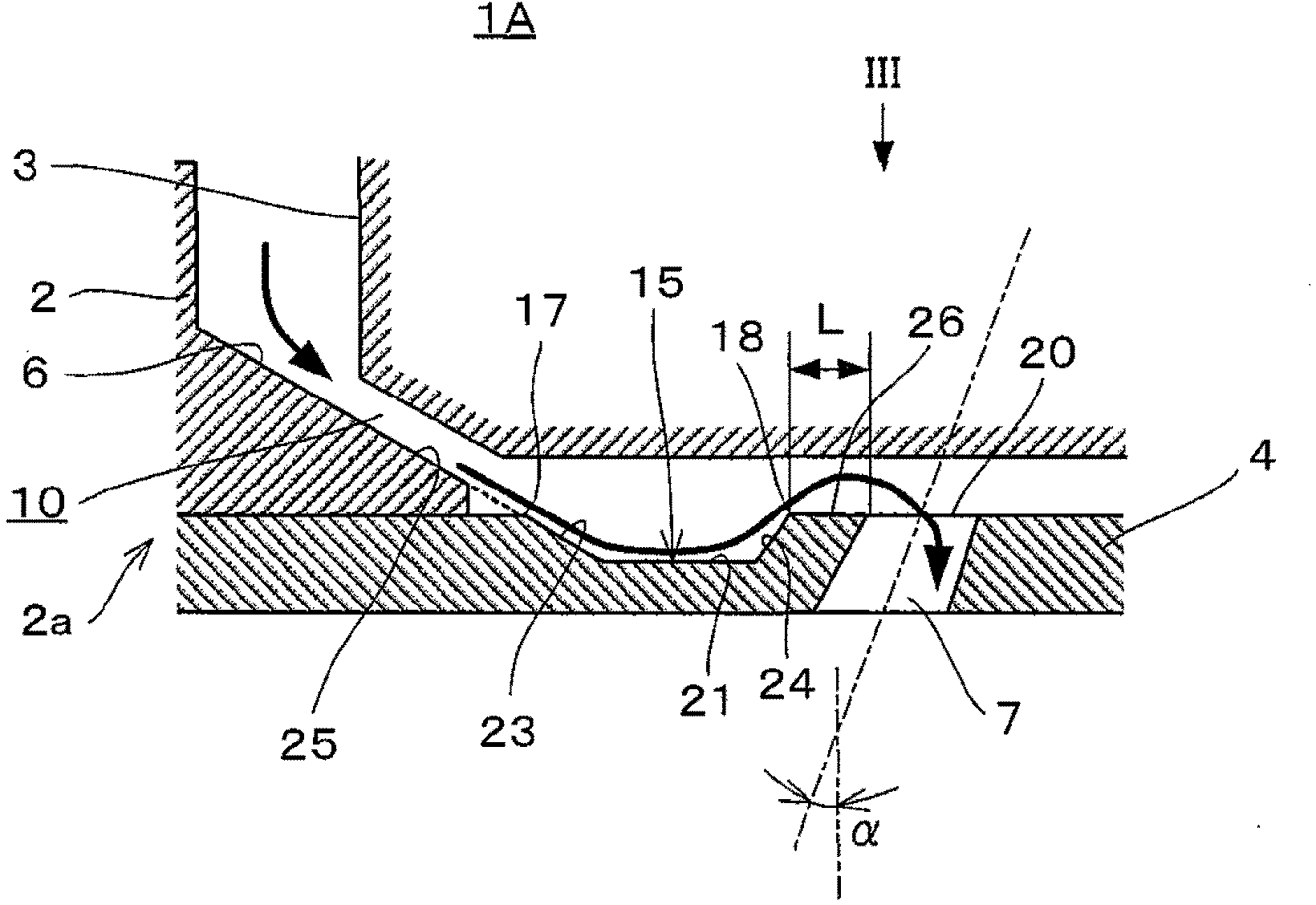

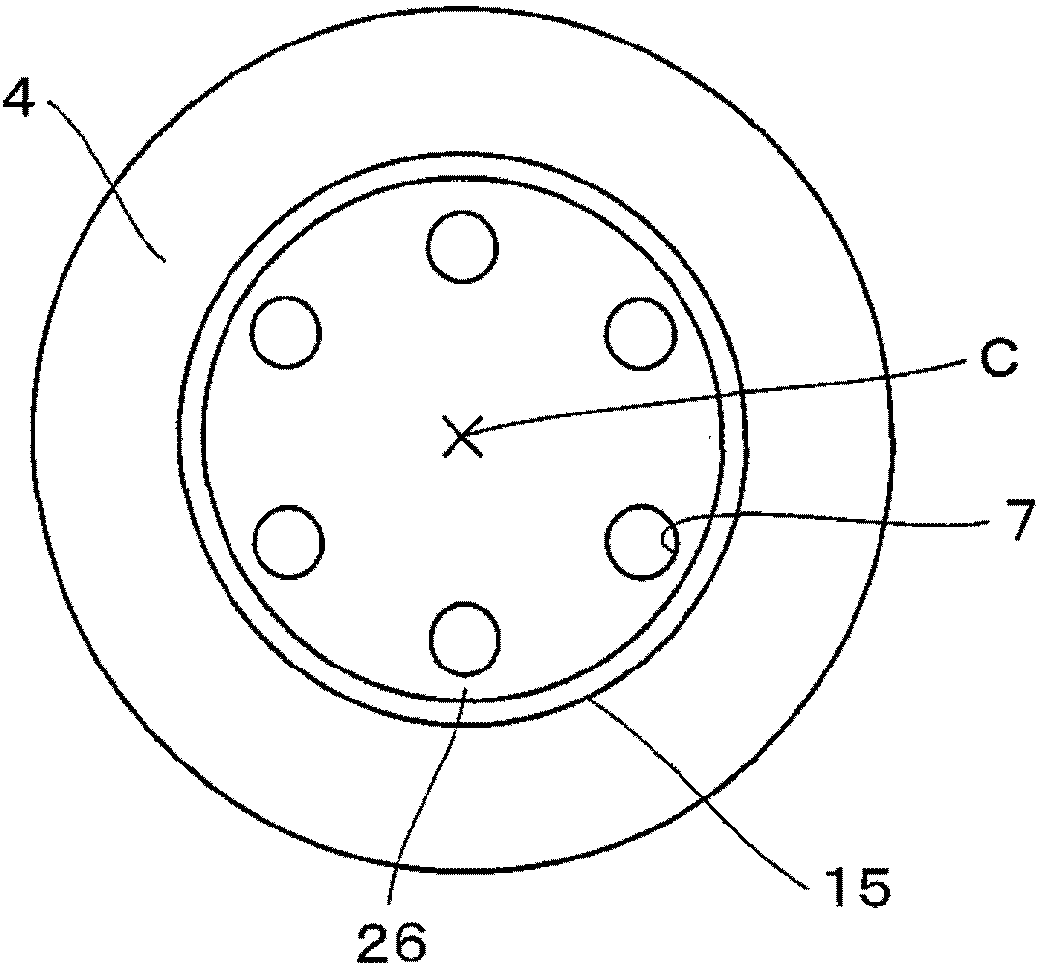

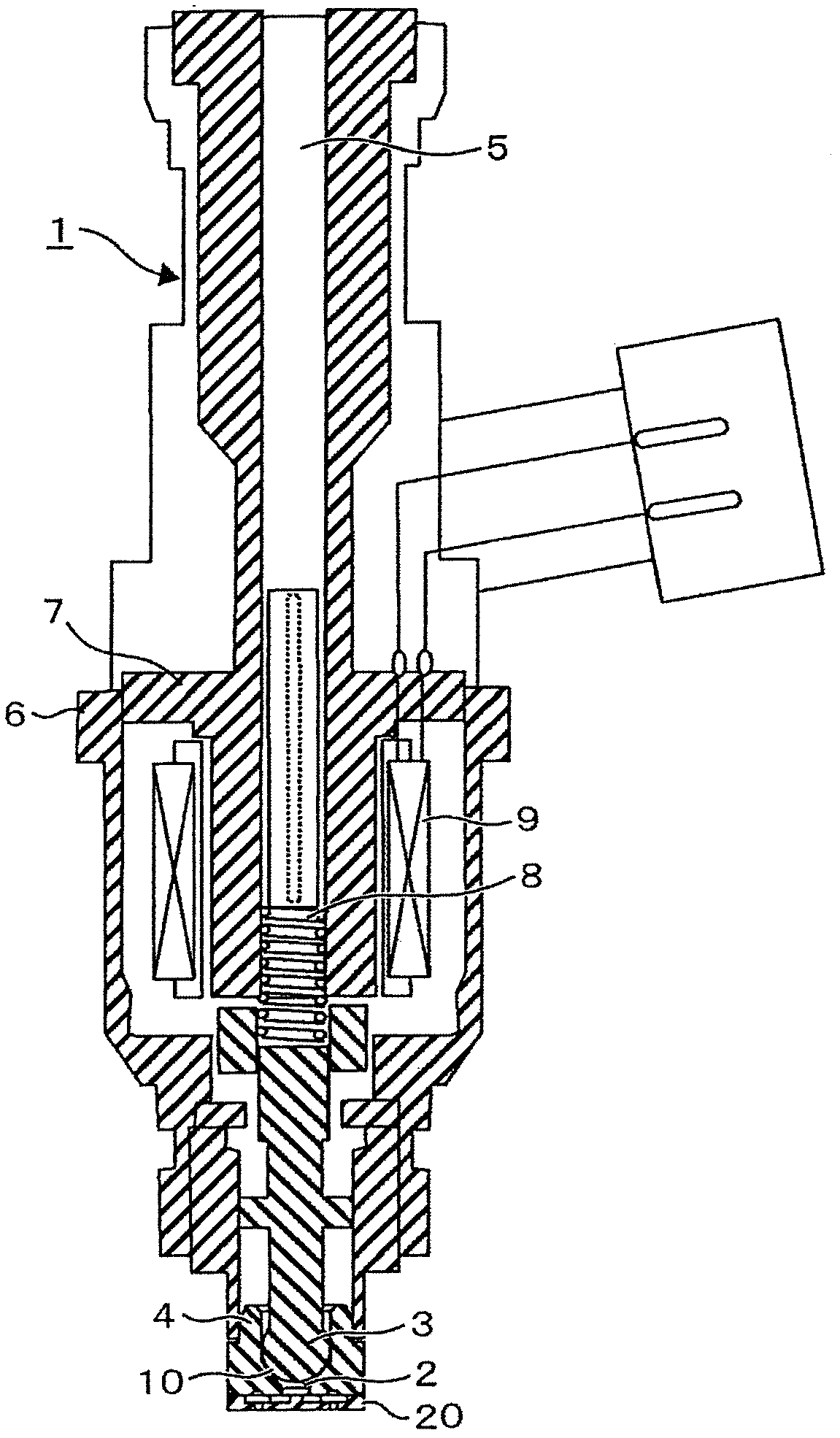

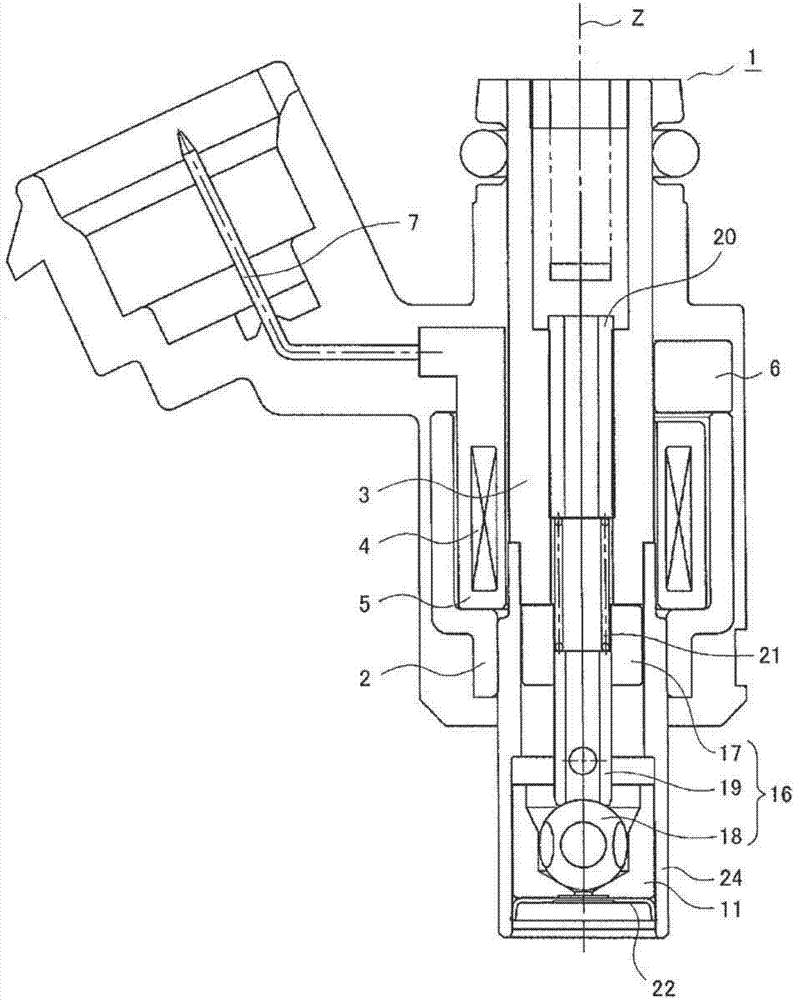

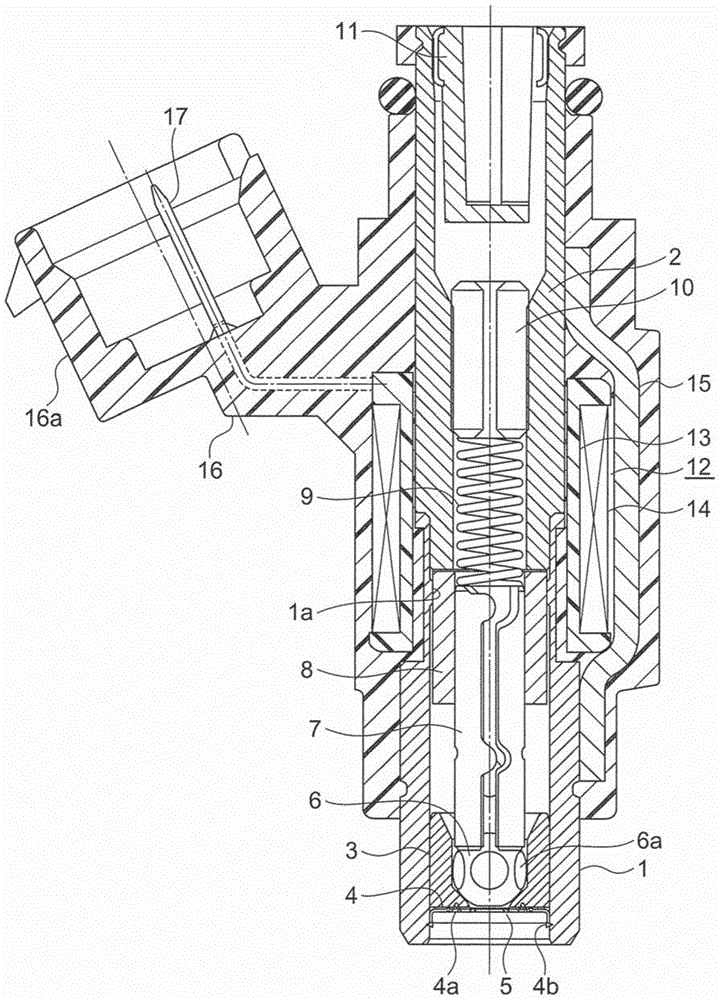

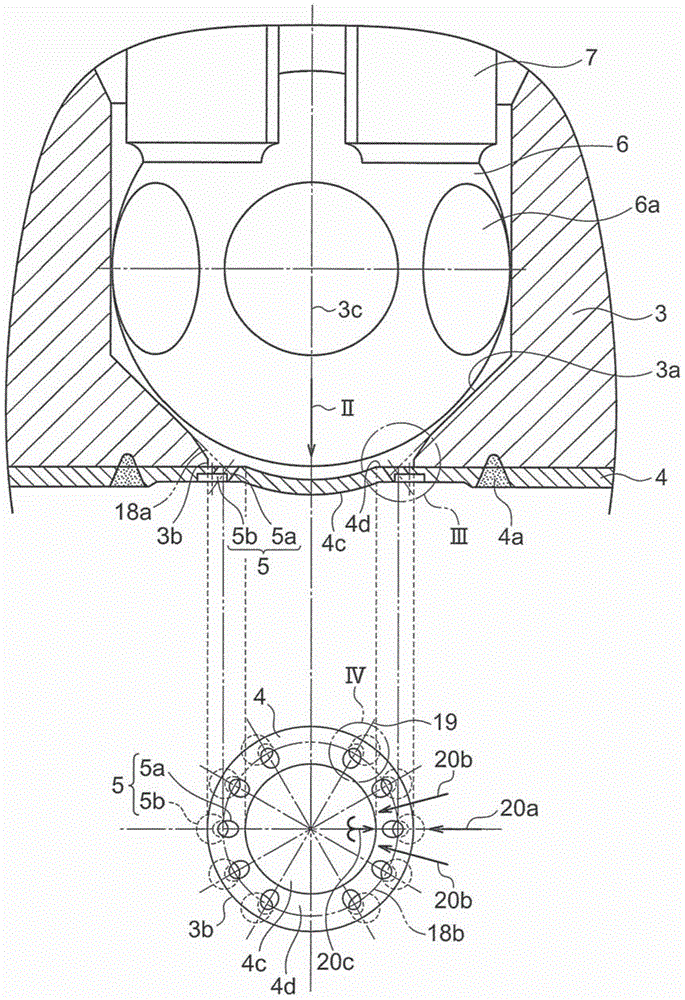

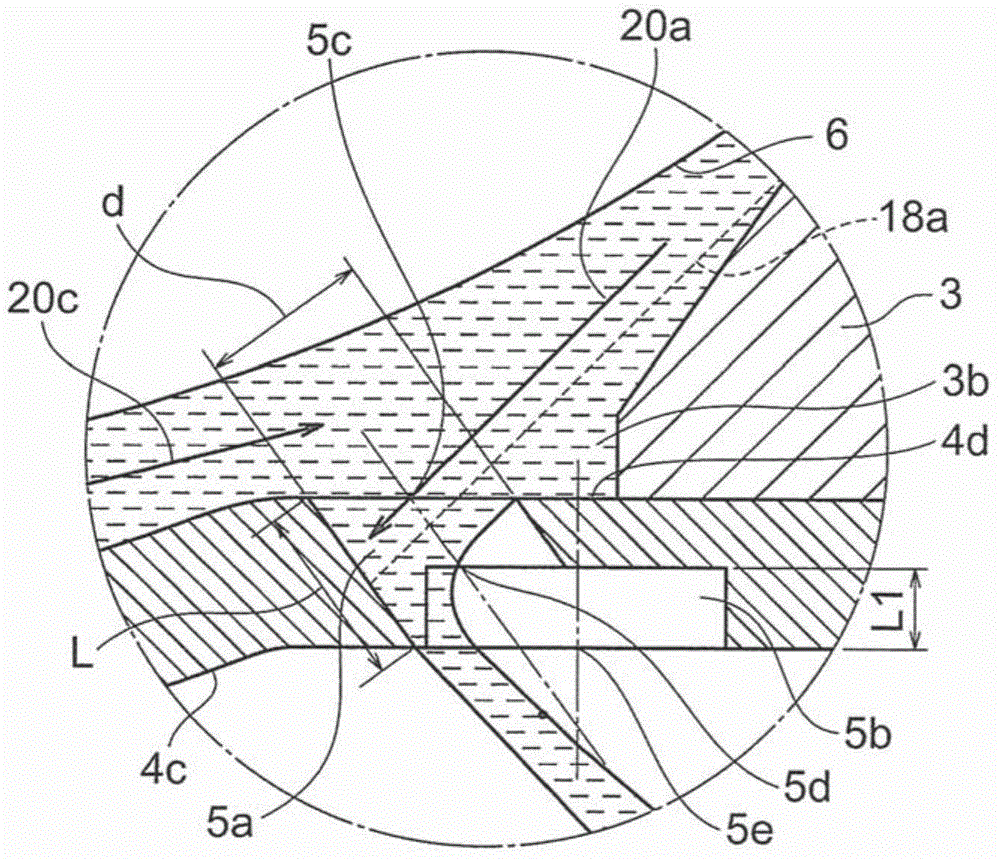

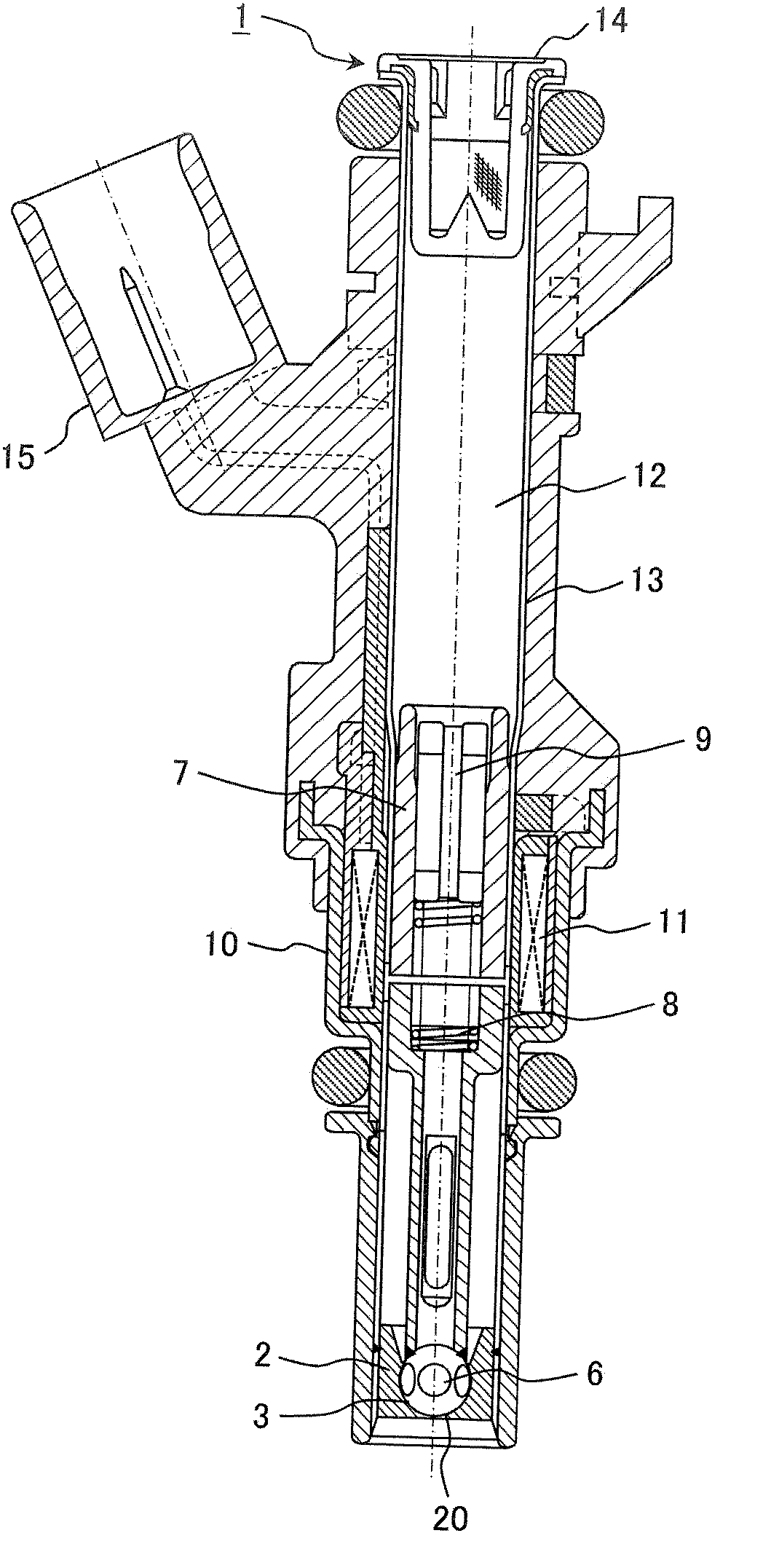

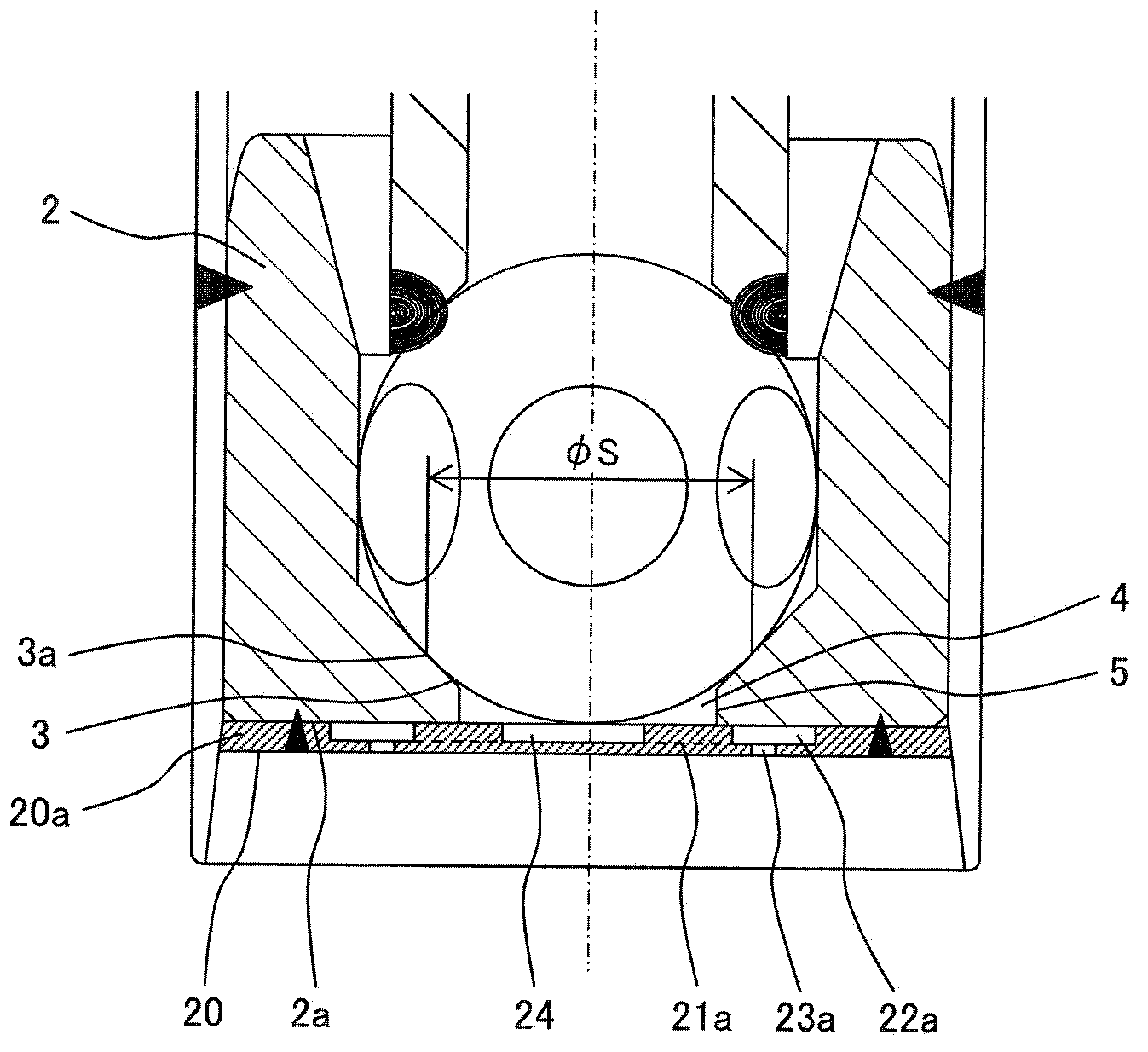

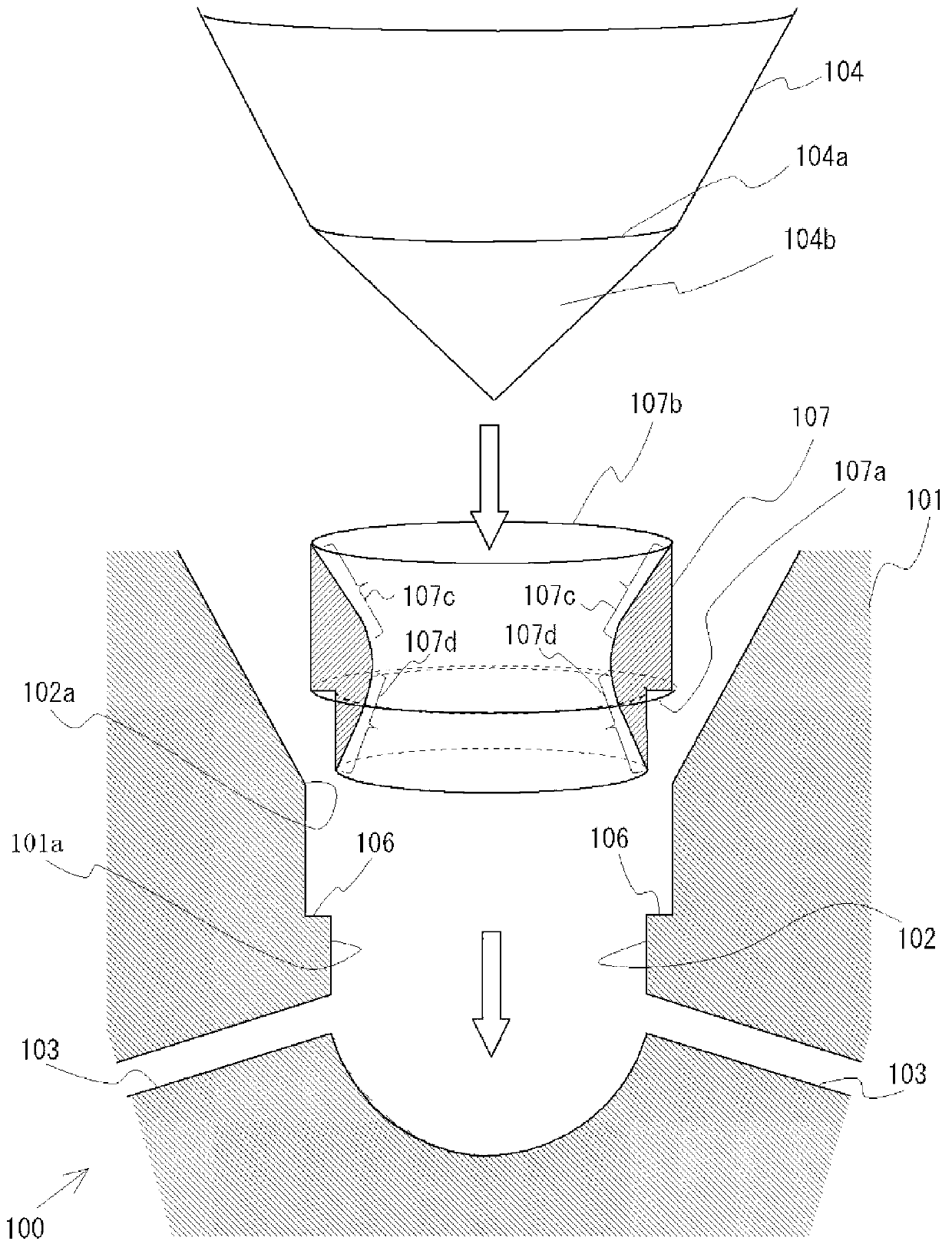

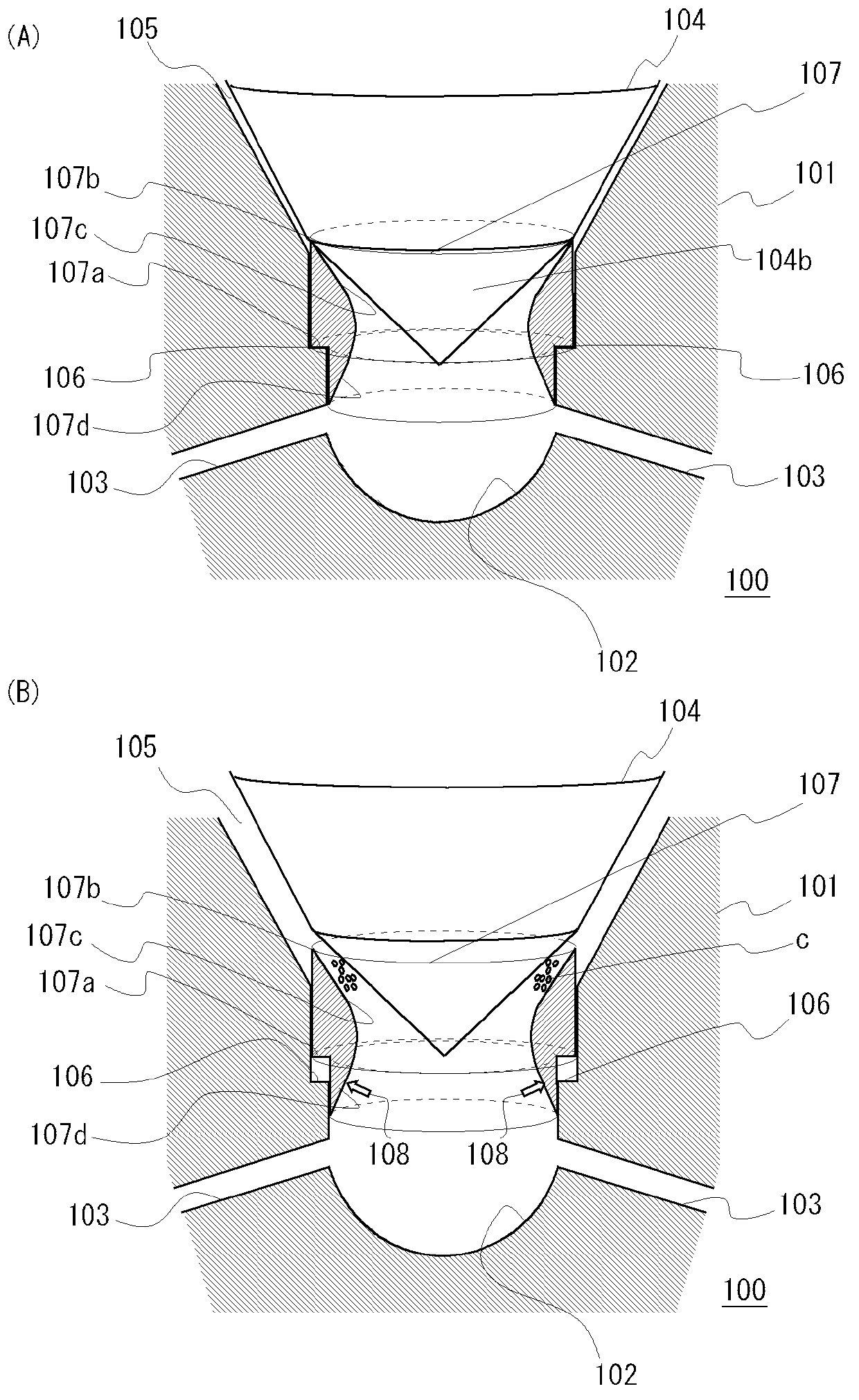

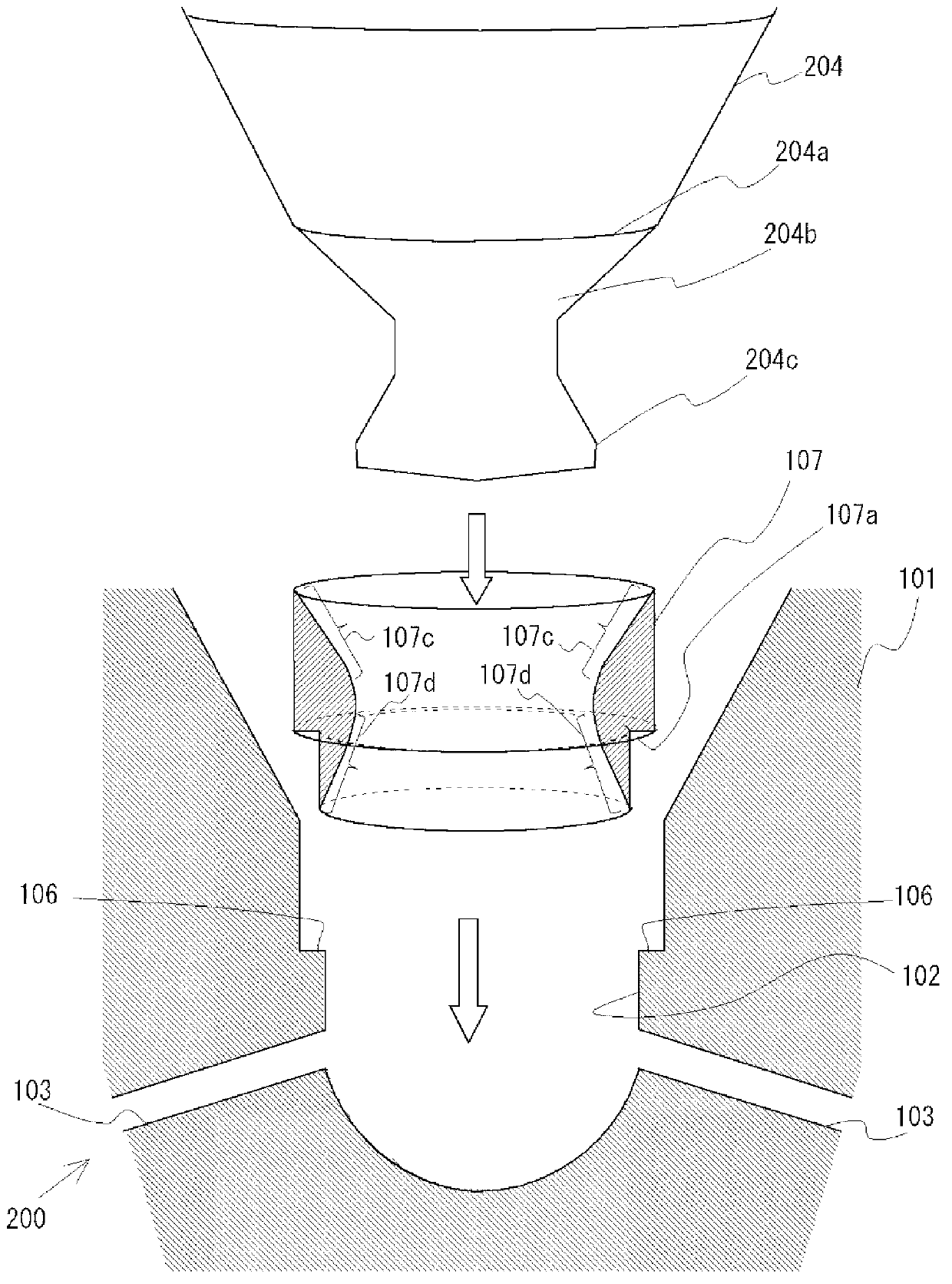

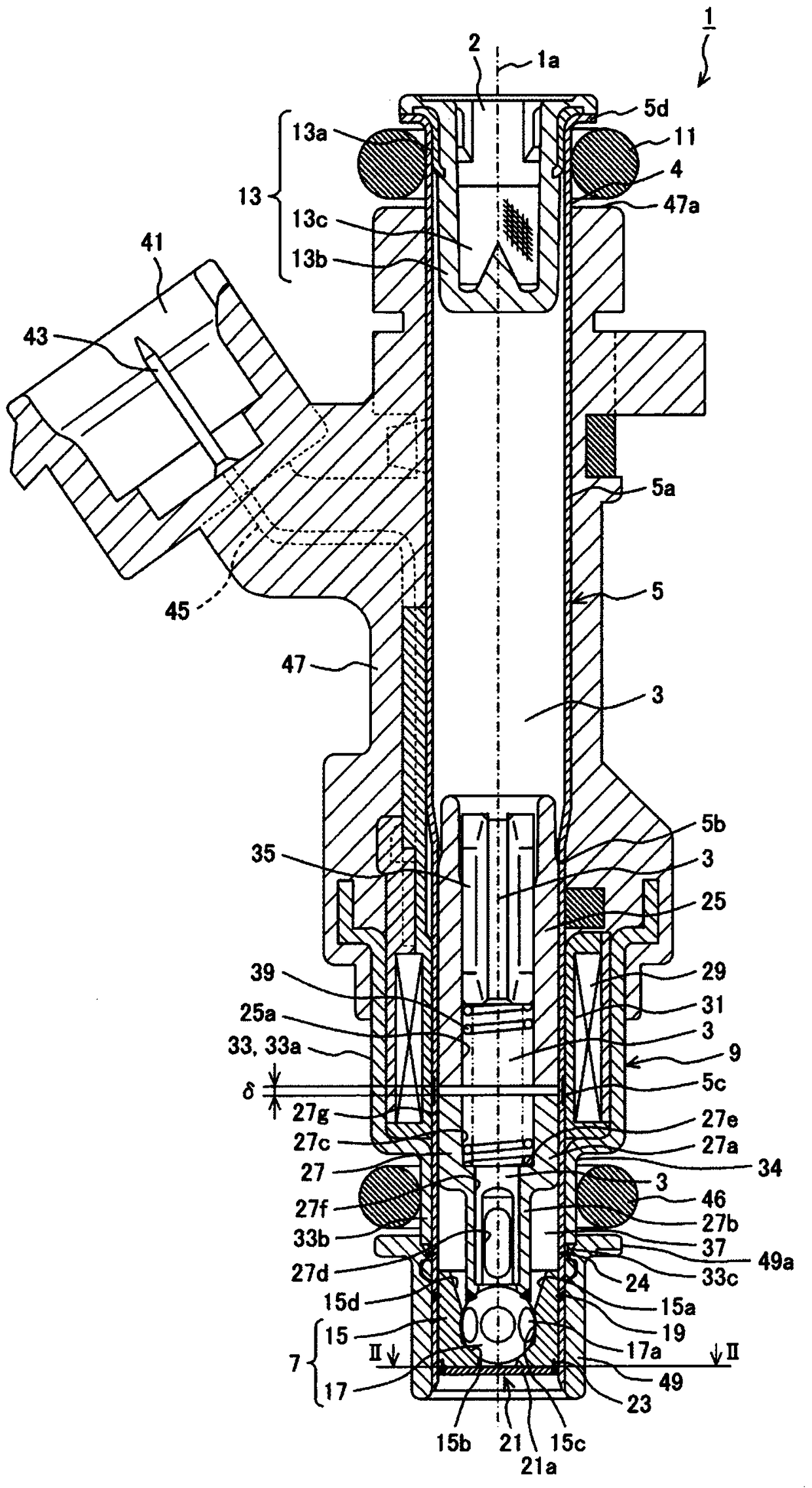

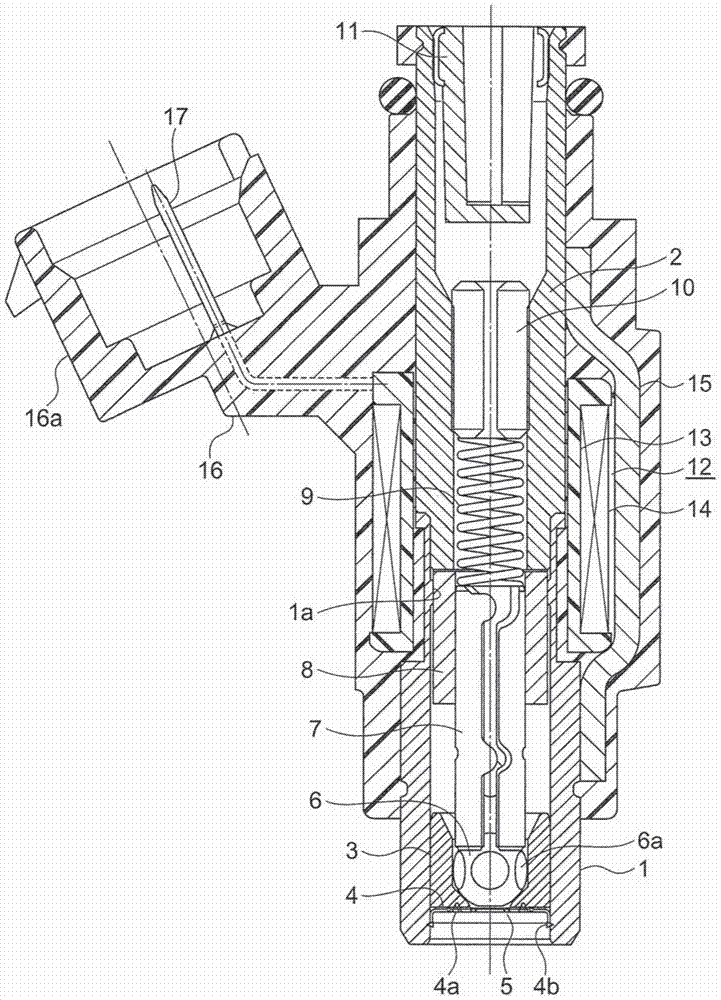

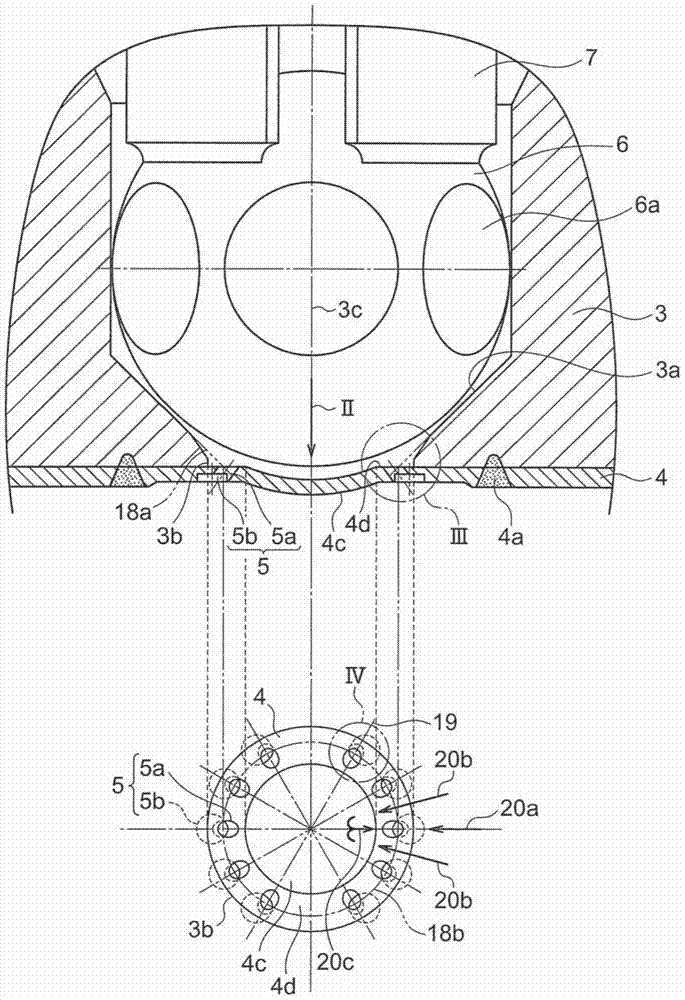

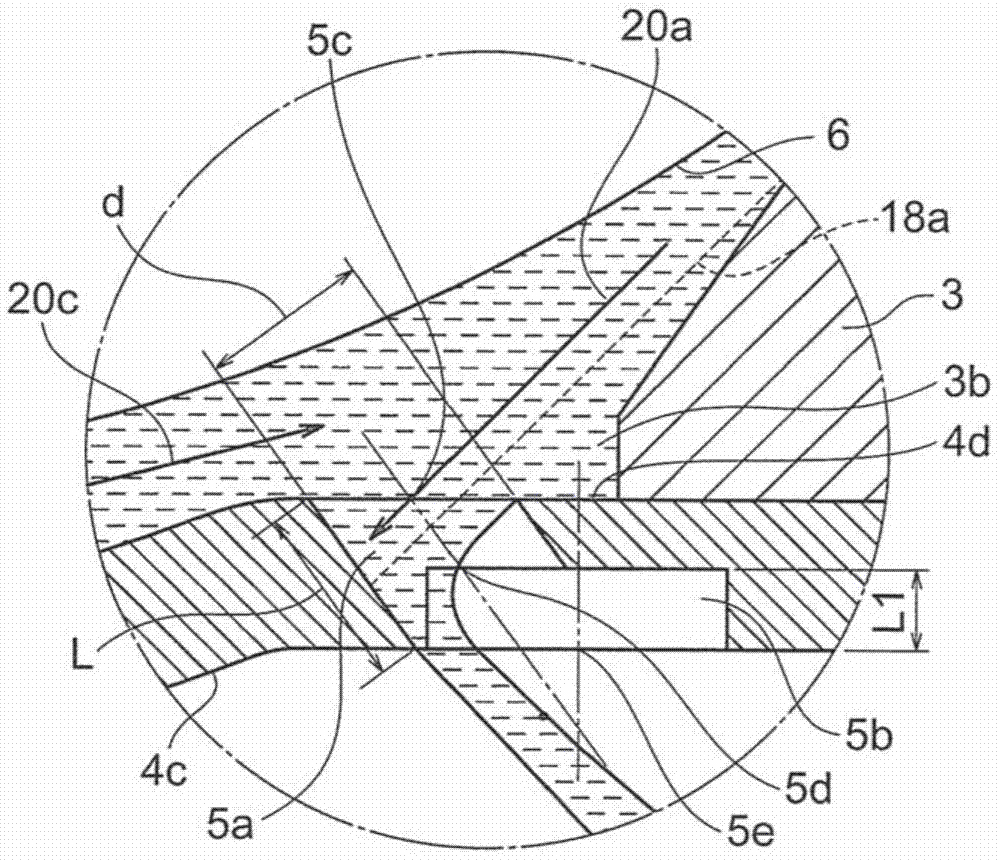

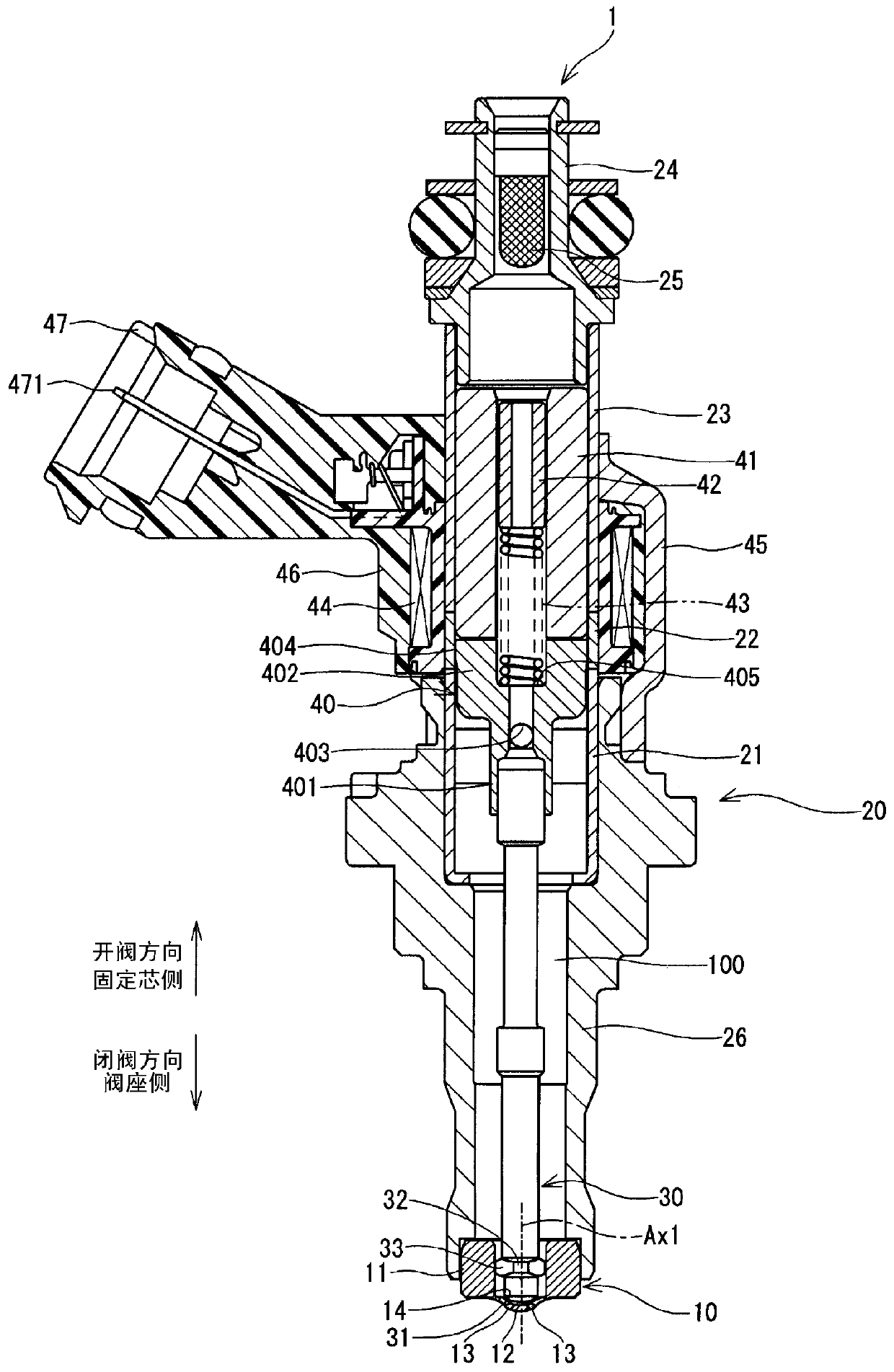

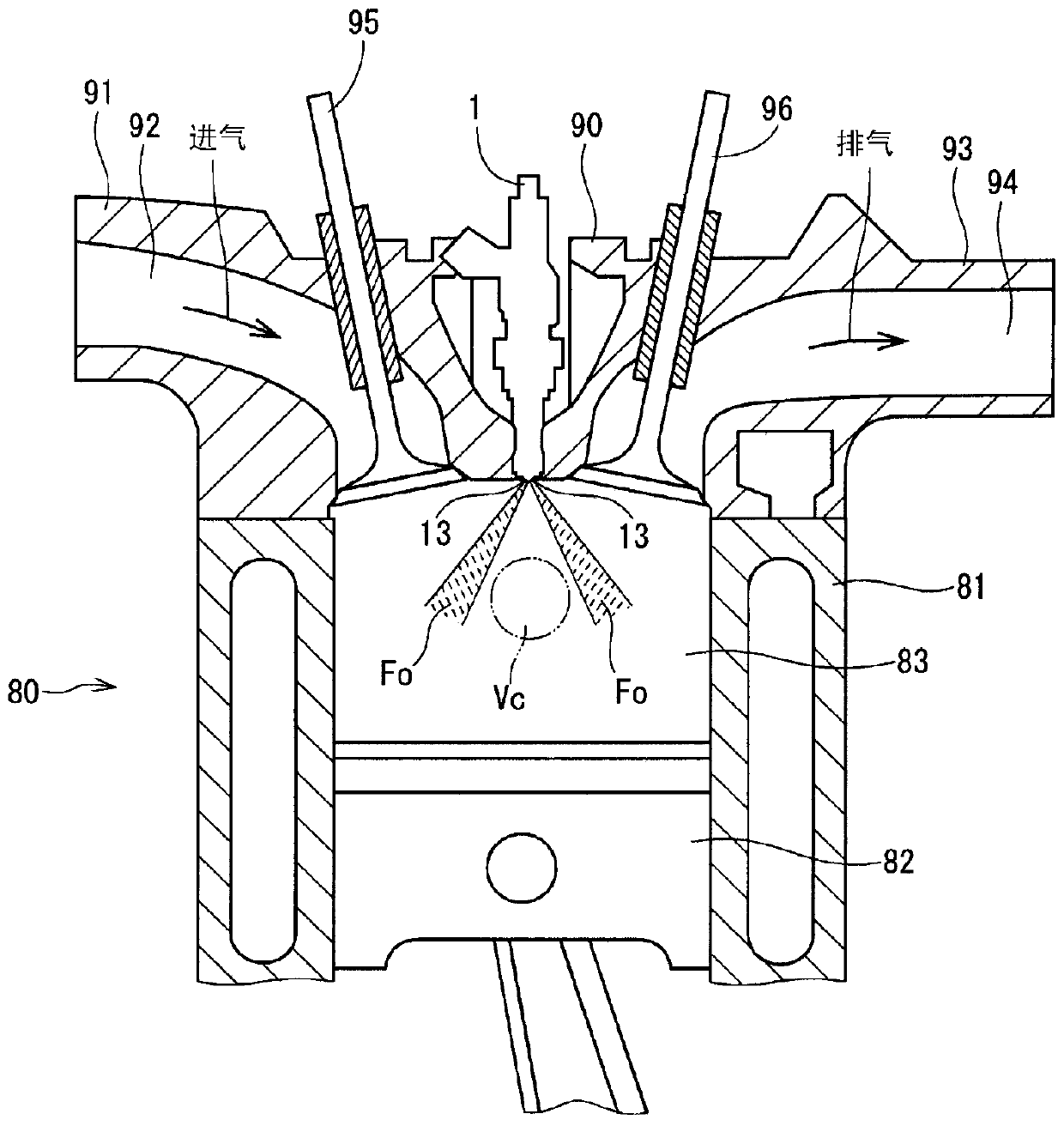

Fuel injection valve

InactiveCN102906414APromote micronizationFacilitate strippingFuel injection apparatusMachines/enginesEngineeringFuel injection

A fuel injection valve (1A) comprises: a needle (3) which is contained in a valve body (2) so as to be able to reciprocate; a nozzle plate (4) which is mounted to the front end (2a) of the valve body (2) and in which nozzle holes (7) communicating with the inside and outside of the valve body (2) are formed; and a valve seat (6) on which the needle (3) is seated and unseated so that a fuel flow path (10) which leads to the nozzle holes (7) of the nozzle plate (4) through the outer periphery of the needle (3) can be closed and opened. The nozzle plate (4) has formed therein a recess (15) which is recessed in the direction of the axis of the needle (3) so as to cause the fuel, which flows toward the nozzle holes (7) after passing through the valve seat (6), to descend along the nozzle plate (4) from the level of the inlets (20) of the nozzle holes (7), ascend, and then reach the inlets (20) of the nozzle holes (7).

Owner:TOYOTA JIDOSHA KK

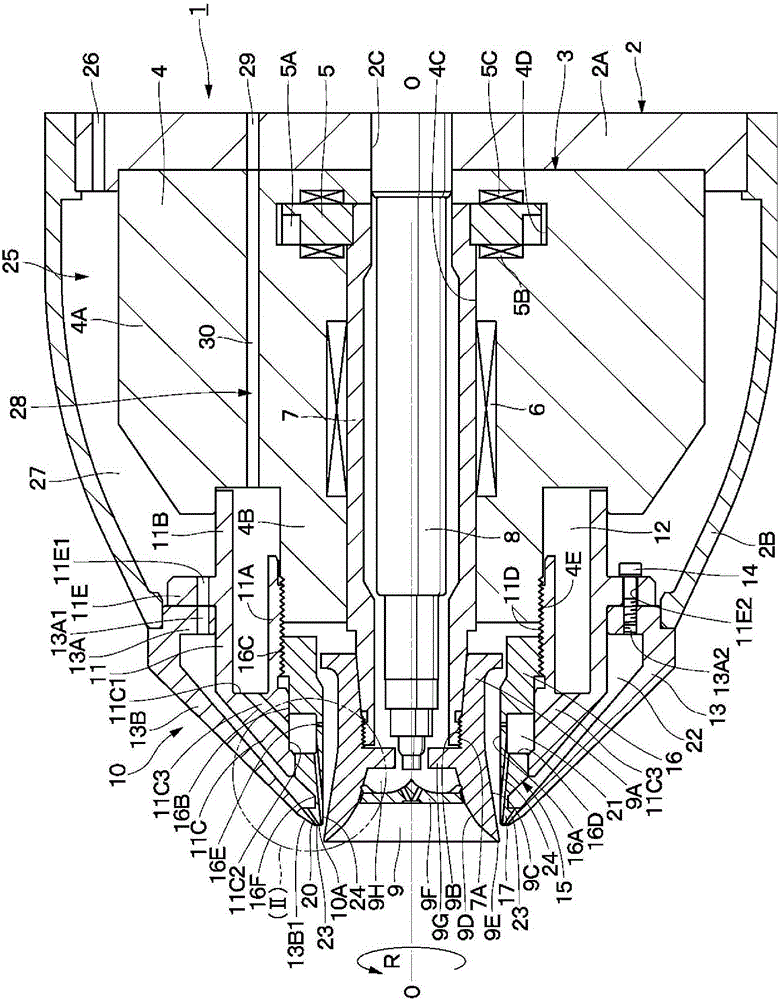

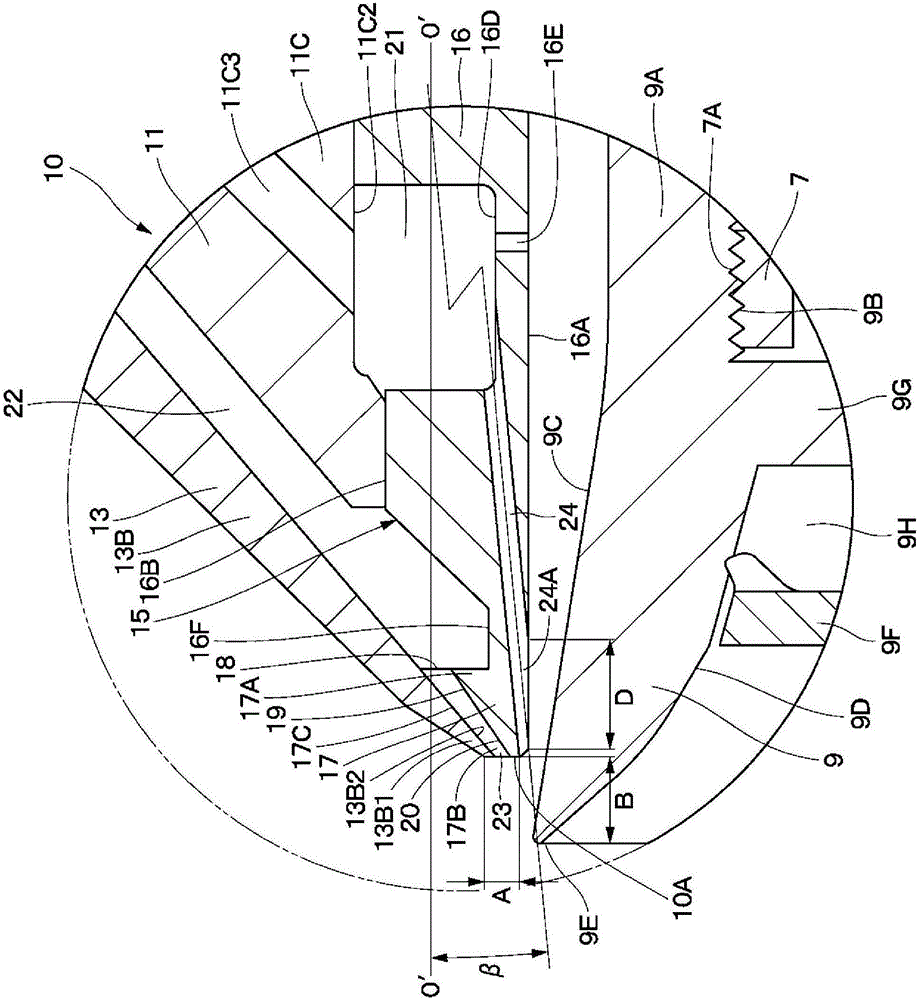

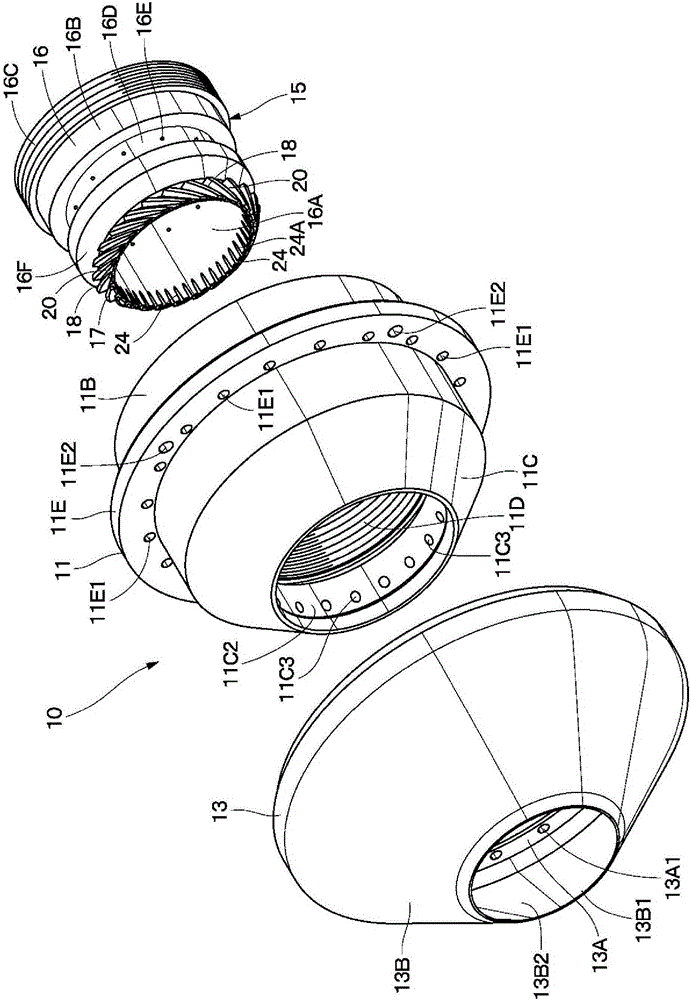

Coating machine having rotary atomizing head

InactiveCN105188950APromote micronizationImprove controllabilityMovable spraying apparatusInduction-charging sprayingEngineeringInjection air

In the present invention, a shaping air ring (10) is configured from a body (11), a cover (13), and a nozzle (15). The tip of the nozzle (15) is provided with a tapered conical protrusion (17) that is abutted against the cover (13) in a gapless contacted state. A plurality of inclination grooves (20) are provided along the entire circumference of a tapered taper surface (17C) of the conical protrusion (17). Furthermore, first shaping-air injection holes (23), which inject shaping air towards a discharge edge (9E) of a rotary atomizing head (9), are provided between each inclination groove (20) and the inner circumferential surface (13B2) of the cover (13). A second shaping-air injection hole (24), which injects shaping air along the outer circumferential surface (9C) of the rotary atomizing head (9), is provided to an inner circumferential surface (16A) of the nozzle (15).

Owner:ABB (SCHWEIZ) AG

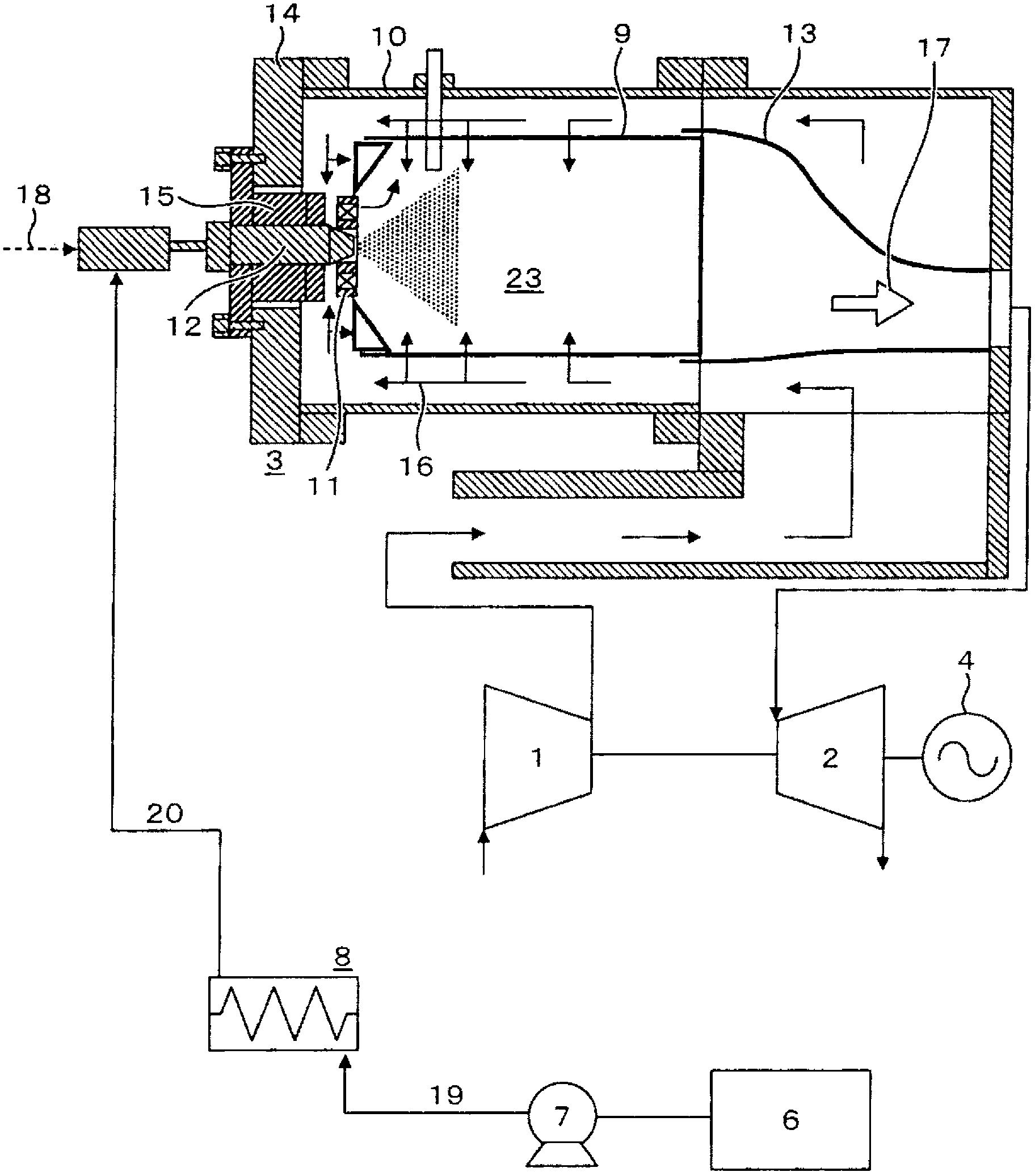

Gas turbine combustor

ActiveCN103292351ALow efficiencyPromote micronizationBurnersContinuous combustion chamberCombustorBoiling point

The present invention provides a gas turbine combustor that has, as means for atomizing liquid fuel, a fuel injection nozzle using a fluid other than liquid fuel to atomize the liquid fuel and that can suppress a reduction in power generation efficiency resulting from a heat loss while promoting the atomization of the liquid fuel. The gas turbine combustor 3 is adapted to mix liquid fuel with combustion air led from a compressor, burn the mixture and supply combustion gas generated to a gas turbine. The gas turbine combustor includes, on the upstream side thereof, a fuel injection nozzle that atomizes the liquid fuel into fine liquid droplets. The fuel injection nozzle includes a first system adapted to supply the liquid fuel and a second system adapted to supply a fluid for atomizing the liquid fuel. Low-boiling liquid fuel is supplied to the second system as the fluid. The second system is adapted to heat and supply the low-boiling liquid fuel.

Owner:MITSUBISHI POWER LTD

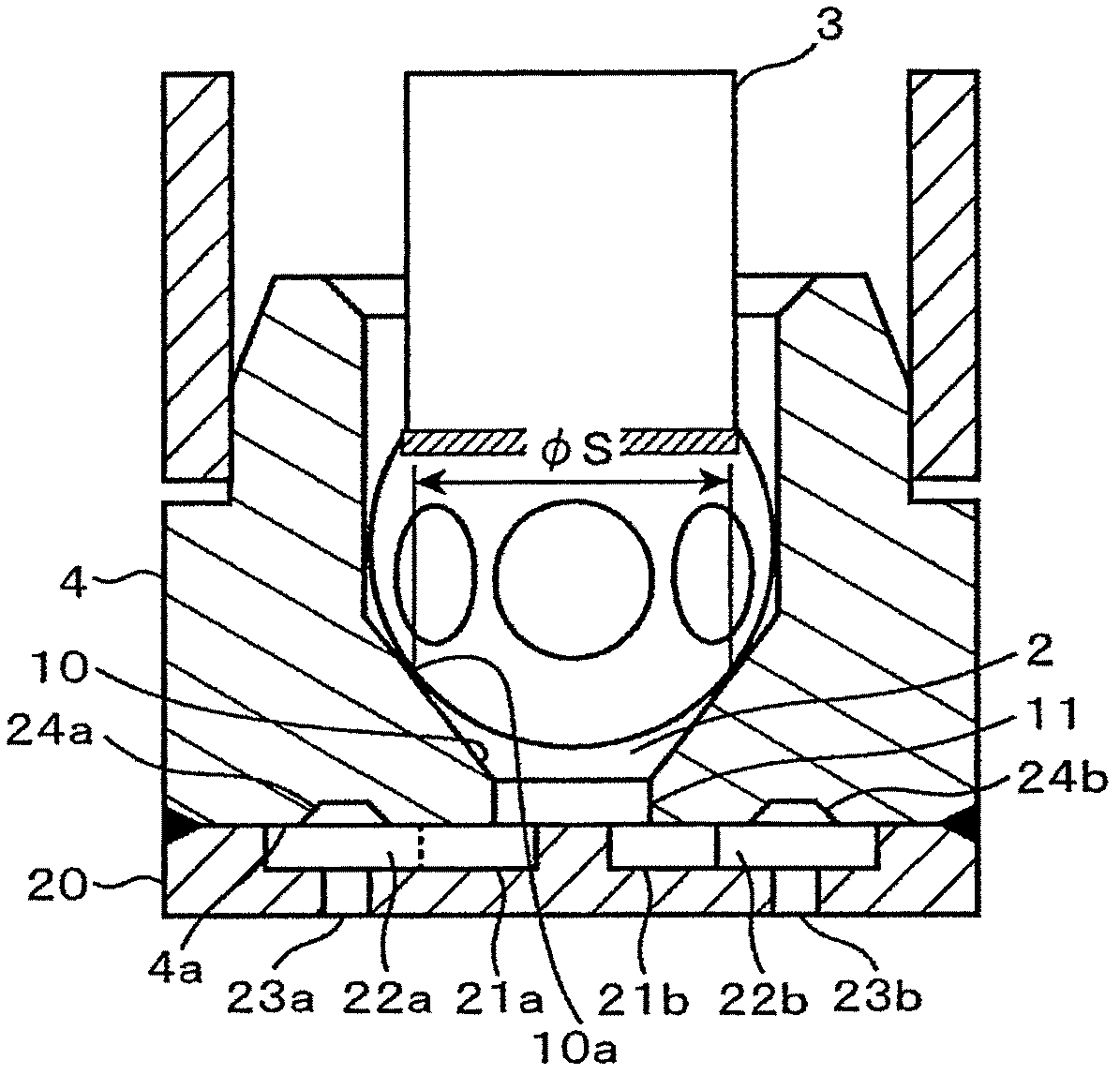

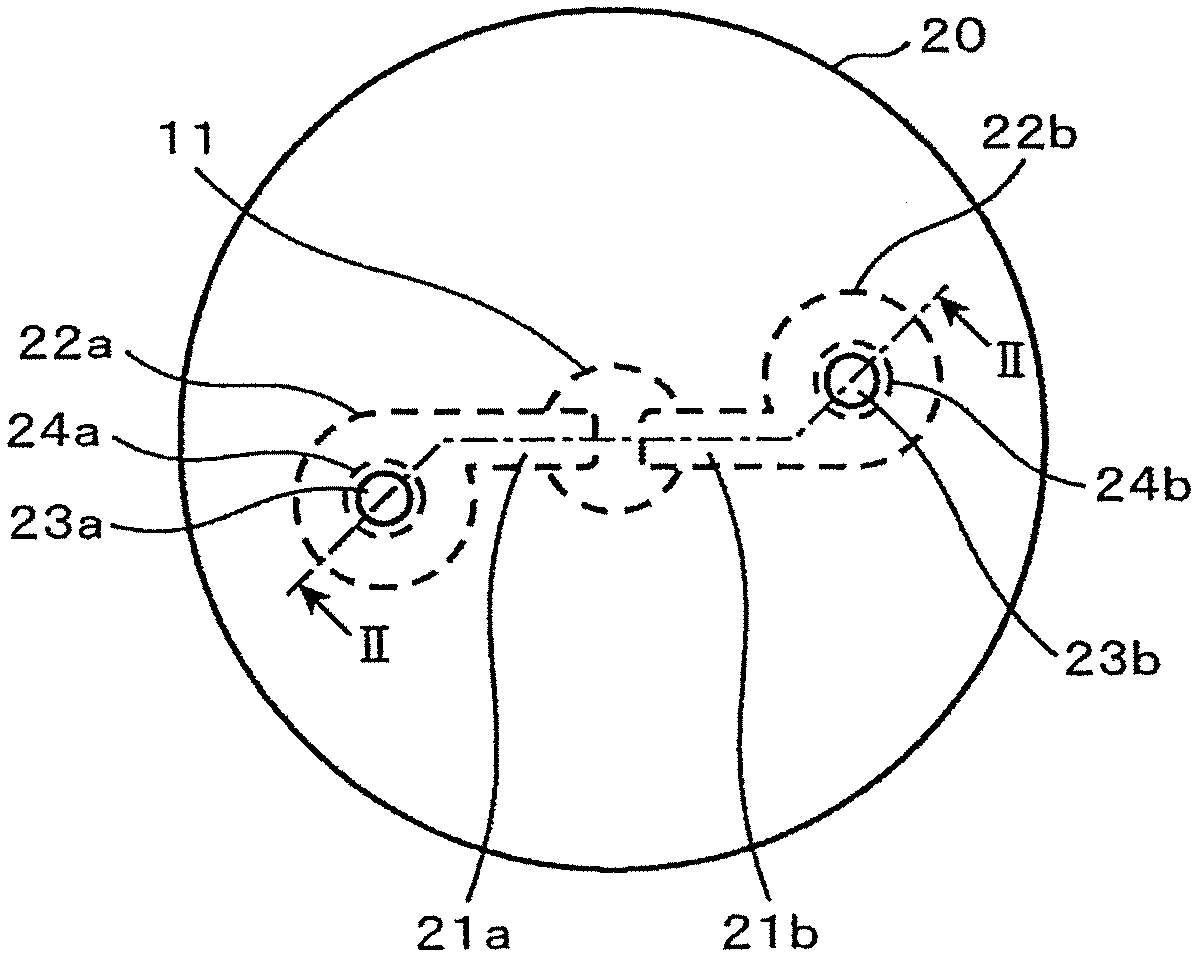

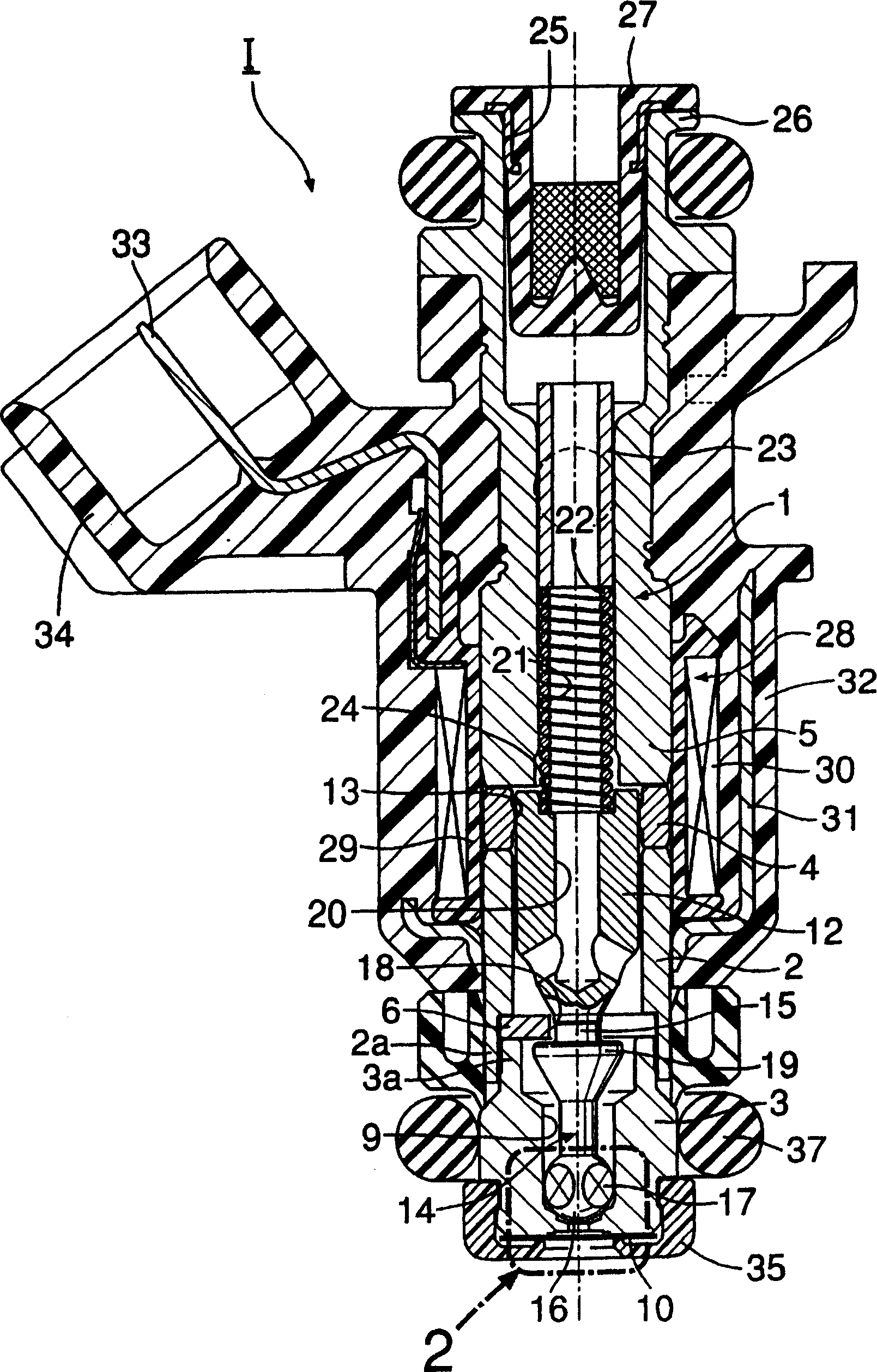

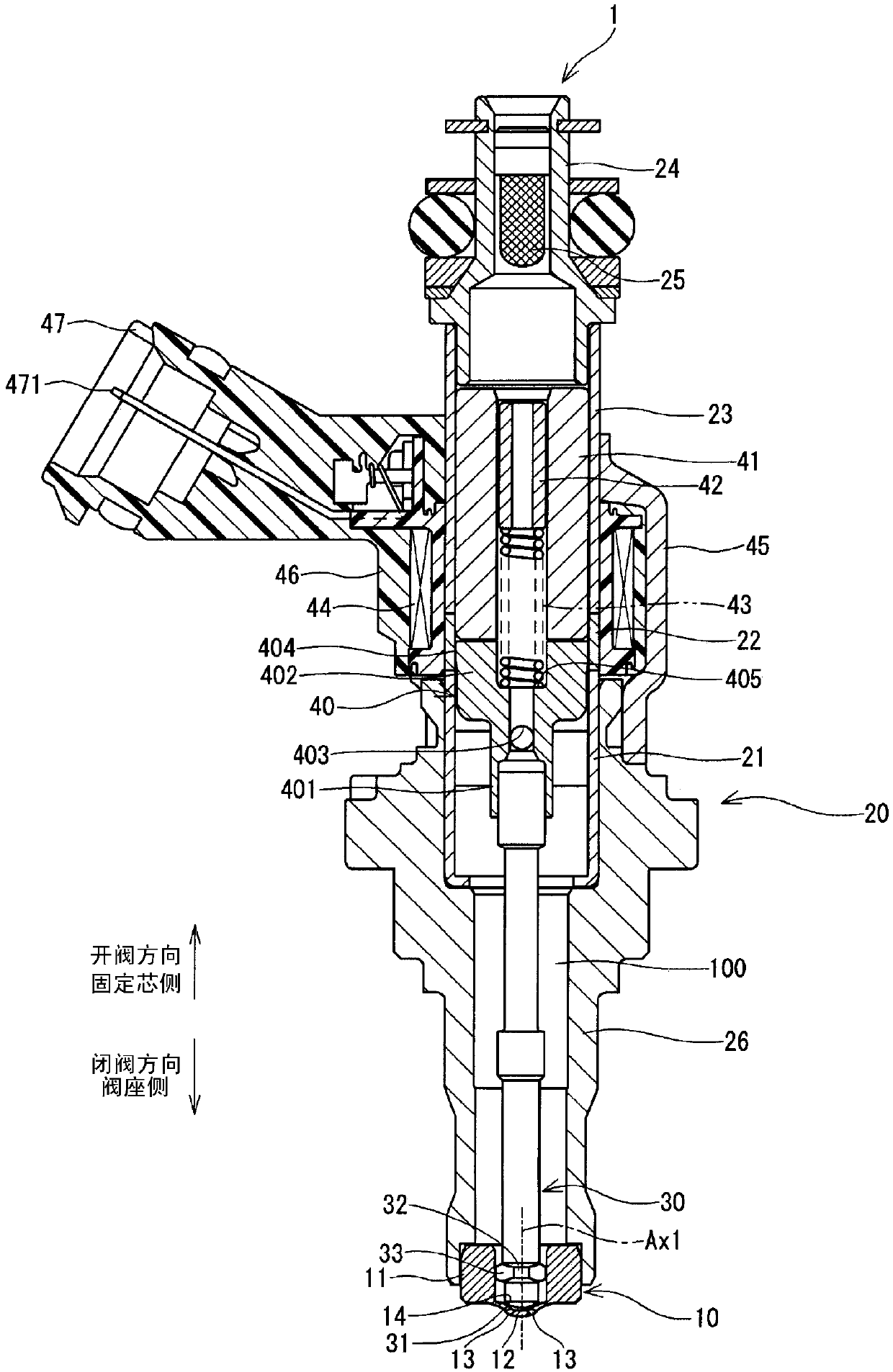

Fuel Injection Valve

InactiveCN102619664APromote micronizationFuel injection apparatusMachines/enginesValve seatFuel injection

There is provided a fuel injection valve, in which uniformity in swirl intensity in a peripheral direction of a swirl fuel is heightened. A fuel injection valve comprises a valve element (3) and a valve seat (10), which cooperate to open and close a fuel passage to perform injection of a fuel and stoppage of injection, a nozzle body (4) having the valve seat (10), a swirl passage (21) provided downstream of a seat portion (10a), on which the valve element (3) and the valve seat (10) contact with each other, and a swirl chamber (22), to which the swirl passage (21) and a fuel injection port (23) are connected, and a recess (buffer) (24) for enlargement of the swirl chamber (22) in volume is provided on a wall surface portion (4a) of the swirl chamber (22) opposed to the fuel injection port (23).

Owner:HITACHI AUTOMOTIVE SYST LTD

Preparation method of liposome with functions of fat reduction and calcium supplement

InactiveCN102204867AGood for dissolution processingFunction increasePowder deliveryMetabolism disorderFreeze-dryingLiposome

The invention discloses a preparation method of a liposome with functions of fat reduction and calcium supplement. The preparation method is characterized in that: on the basis of defining the therapeutic and health-care mechanism of a folk recipe, namely vinegar egg liquid, an ethanol injection method, an original sleeve dual-ejection technology and a homogenizing device with smeared sealing function are combined to reinforce the formation of the liposome of lecithin and the package of calcium acetate; the calcium acetate packaged by the liposome is transformed into ionic calcium hydroxide by transferring the liposome with the acetic acid through a calcium acetate gradient method; the liposome rich in the ionic calcium hydroxide is processed into an oral solution or freeze-dried powder. Compared with the traditional folk recipe, namely the vinegar egg liquid, the biological product developed by the method contributes more to massive production and long-term preservation and is more easy to absorb by a human body; the utilization of the calcium ions by the human body is greatly improved; the acidity of the human body is reduced; a healthy alkalescent environment is created in the human body; the fat-reducing function of the human body is enhanced; the target characteristic of softening blood vessels is more outstanding; and the therapeutic and health-care effect is more obvious.

Owner:ANHUI FINDSHE BIOLOGICAL PHARMA CO LTD +1

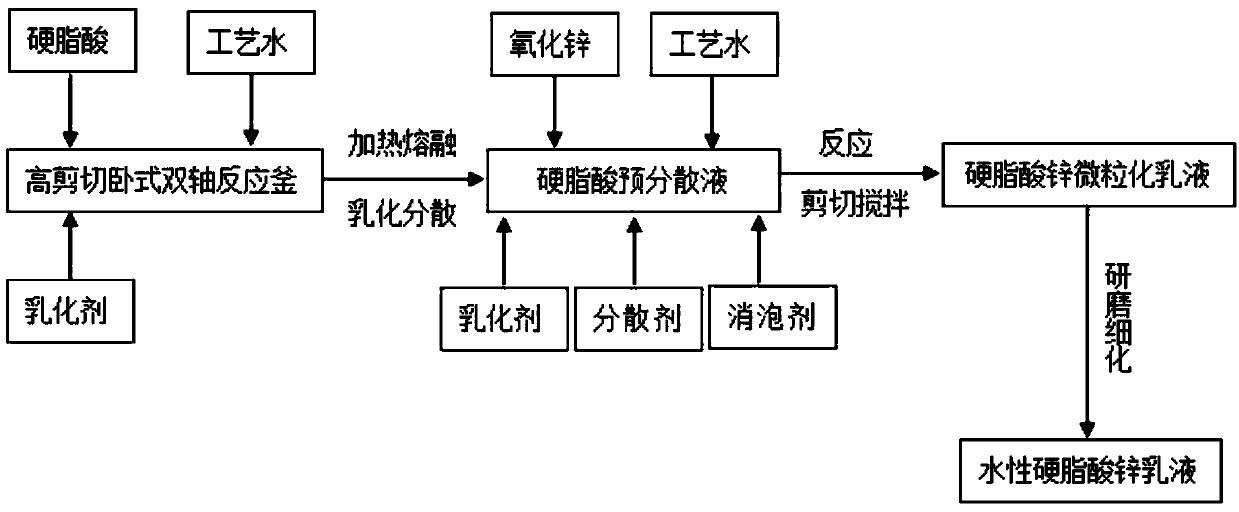

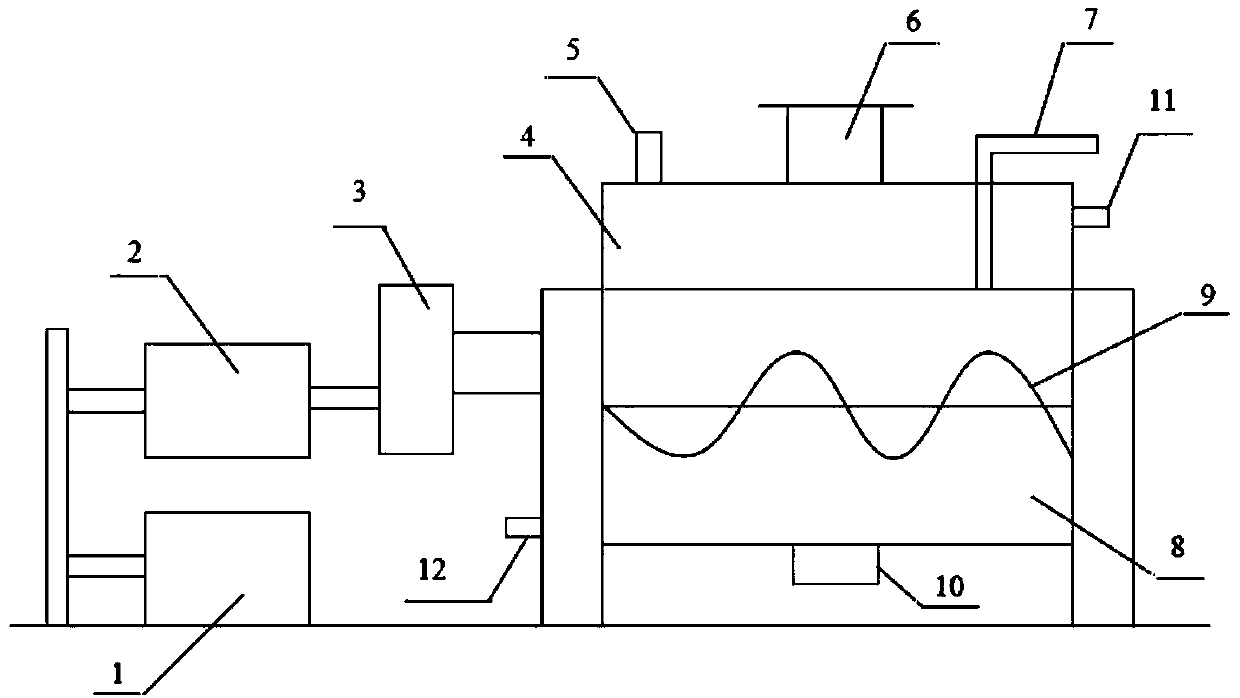

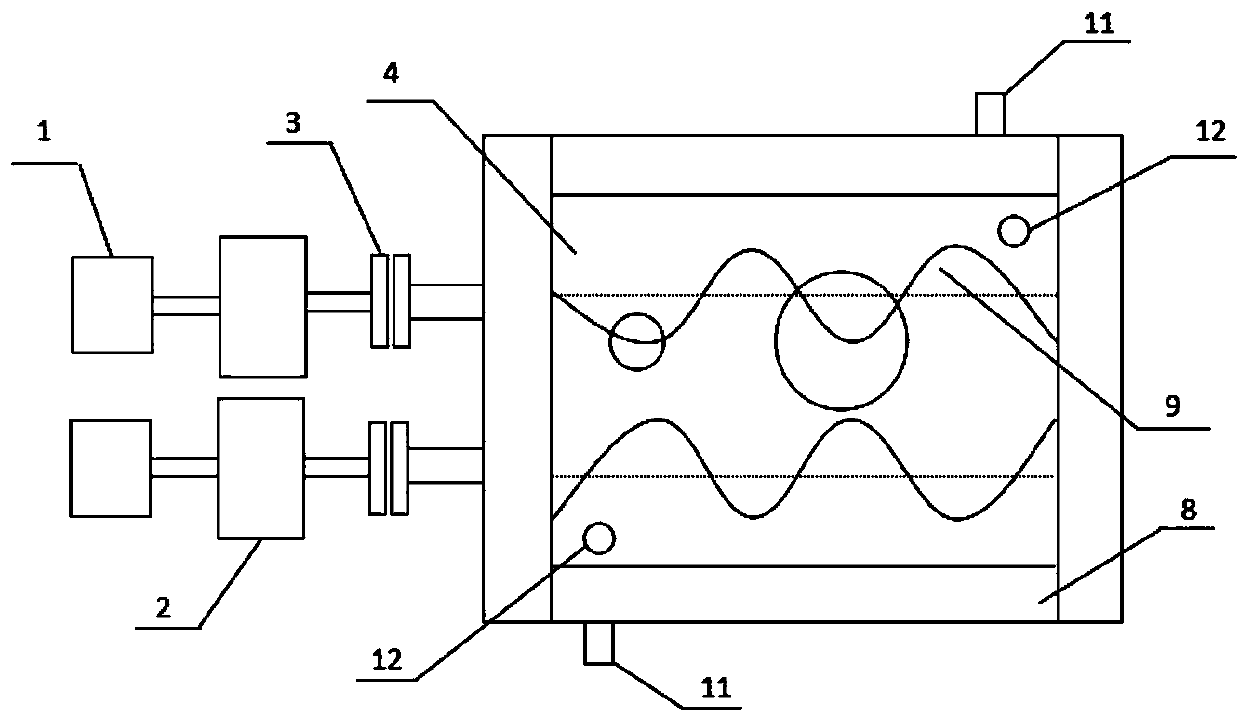

Novel waterborne zinc stearate emulsion, and preparation method thereof

InactiveCN107938427ALarge specific surface areaGood dispersionPaper coatingCoatingsEmulsionZinc compounds

The invention discloses a novel waterborne zinc stearate emulsion. The novel waterborne zinc stearate emulsion is characterized by comprising 50.0 to 60.0% of deionized water, 27.0 to 45.5% of stearicacid, 4.0 to 9.0% of a zinc compound, 1.0 to 2.0% of an emulsifier, 0.5 to 1.0% of a dispersant and 0.5 to 1.5% of an antifoaming agent. According to the invention, the above raw materials are addedin two steps; stearic acid, deionized water and the emulsifier are mixed under stirring at first so as to obtain a fully-dispersed uniform stearic acid emulsion, and a contact area of stearic acid anda subsequent reactant is increased, which allows a full reaction to take place; and the emulsifier allows the fused stearic acid to be uniformly dispersed in an aqueous medium, so a specific surfacearea is increased, and subsequent reactions are promoted.

Owner:HUZHOU CITY LINGHU XINWANG CHEM CO LTD

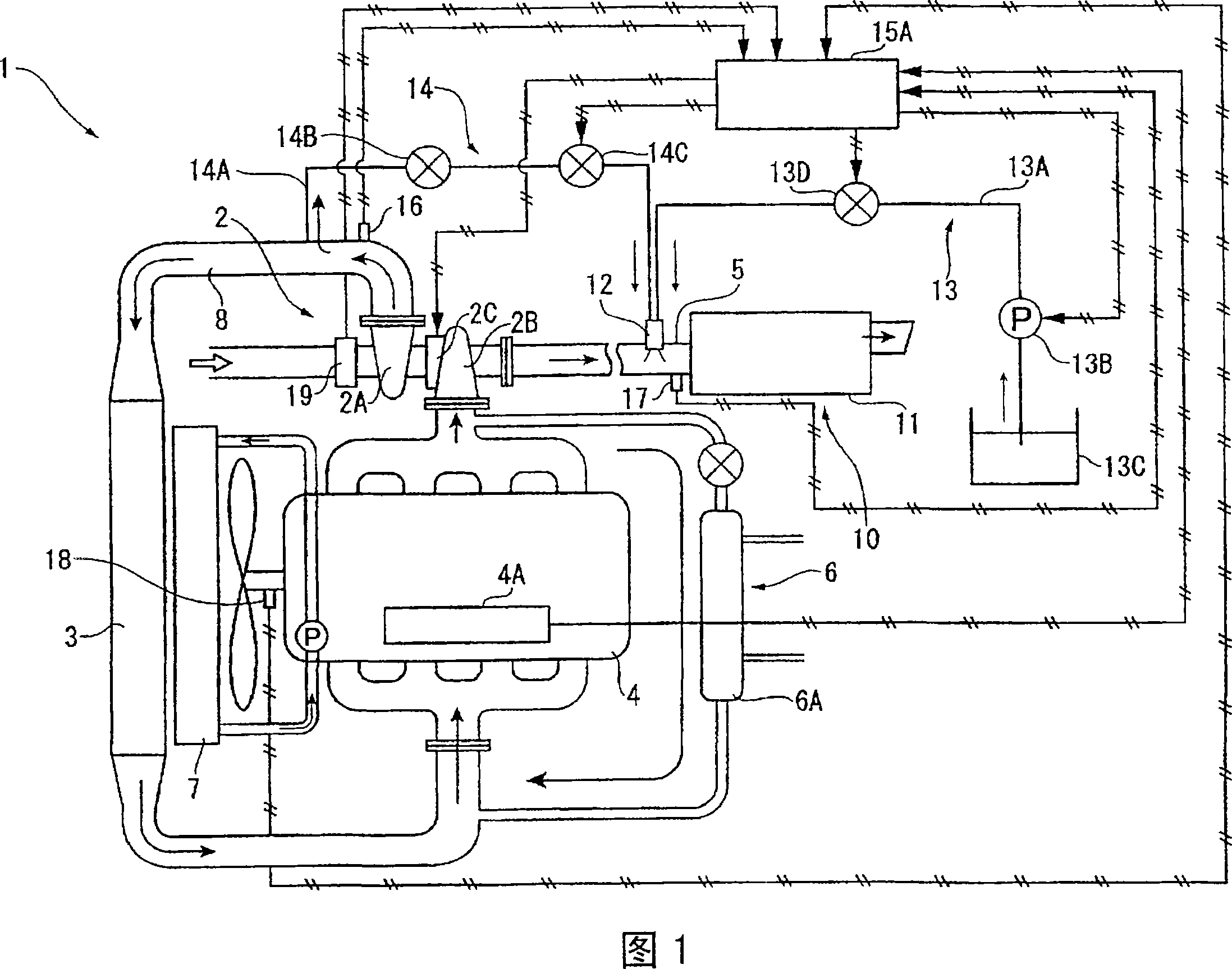

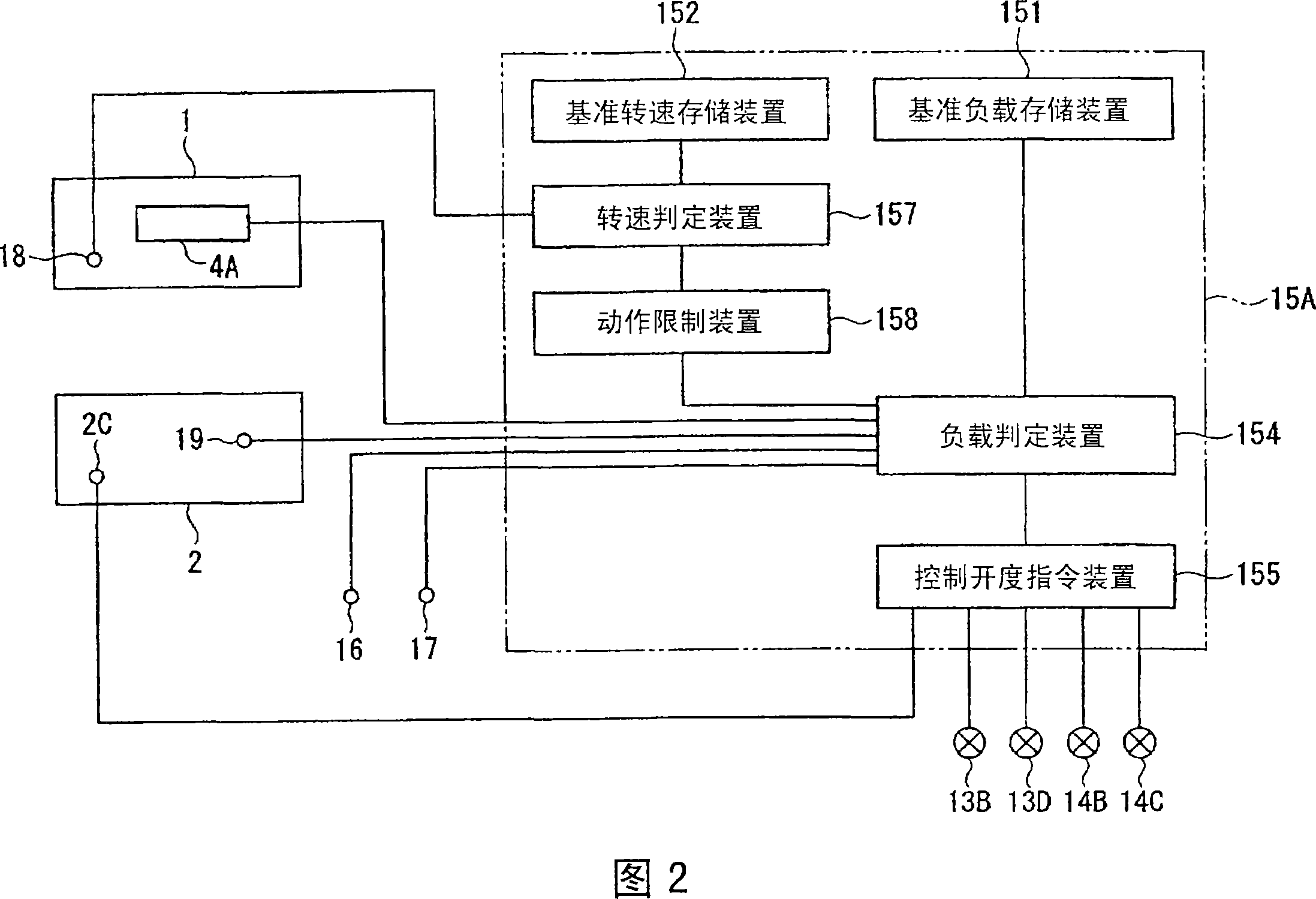

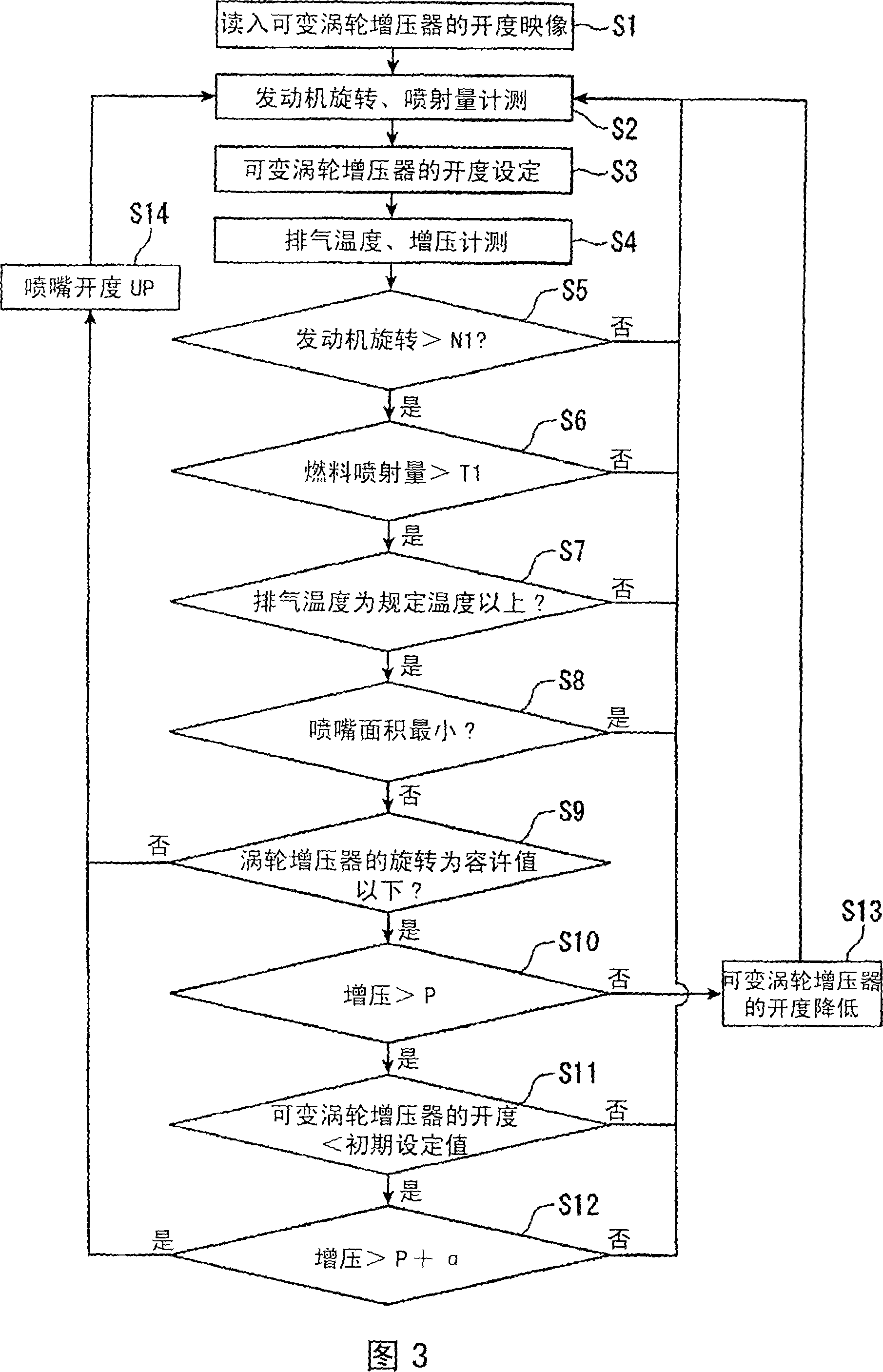

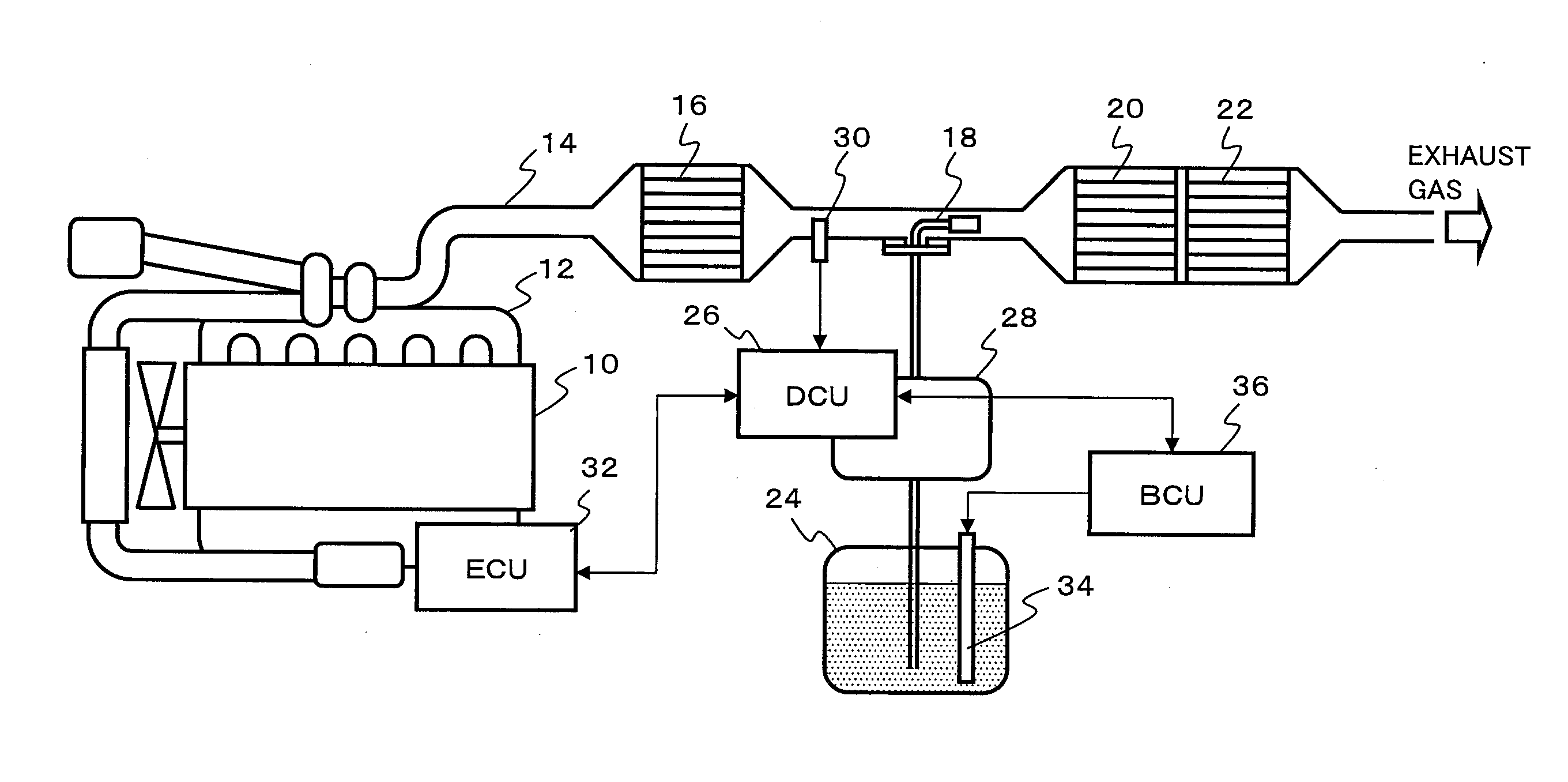

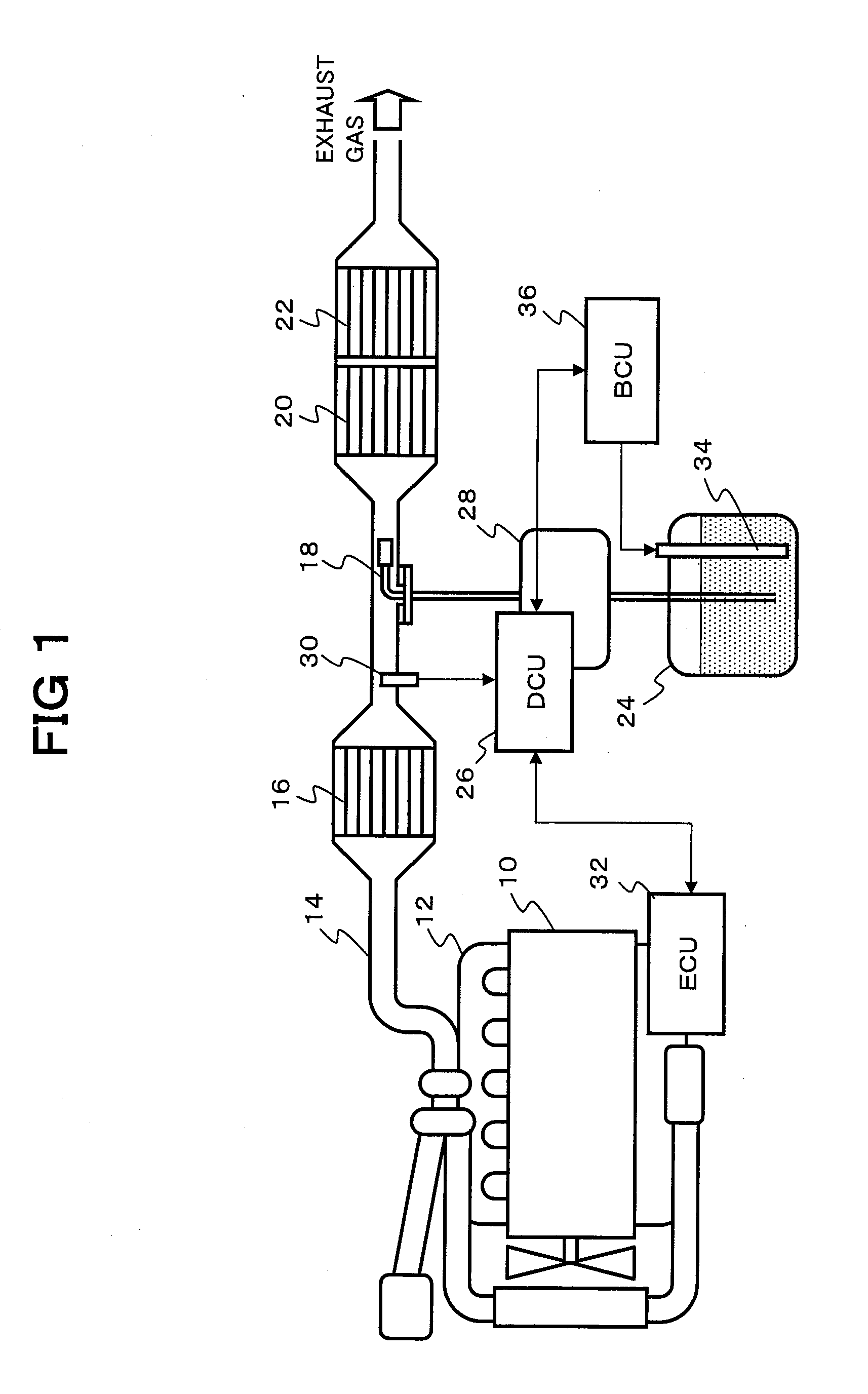

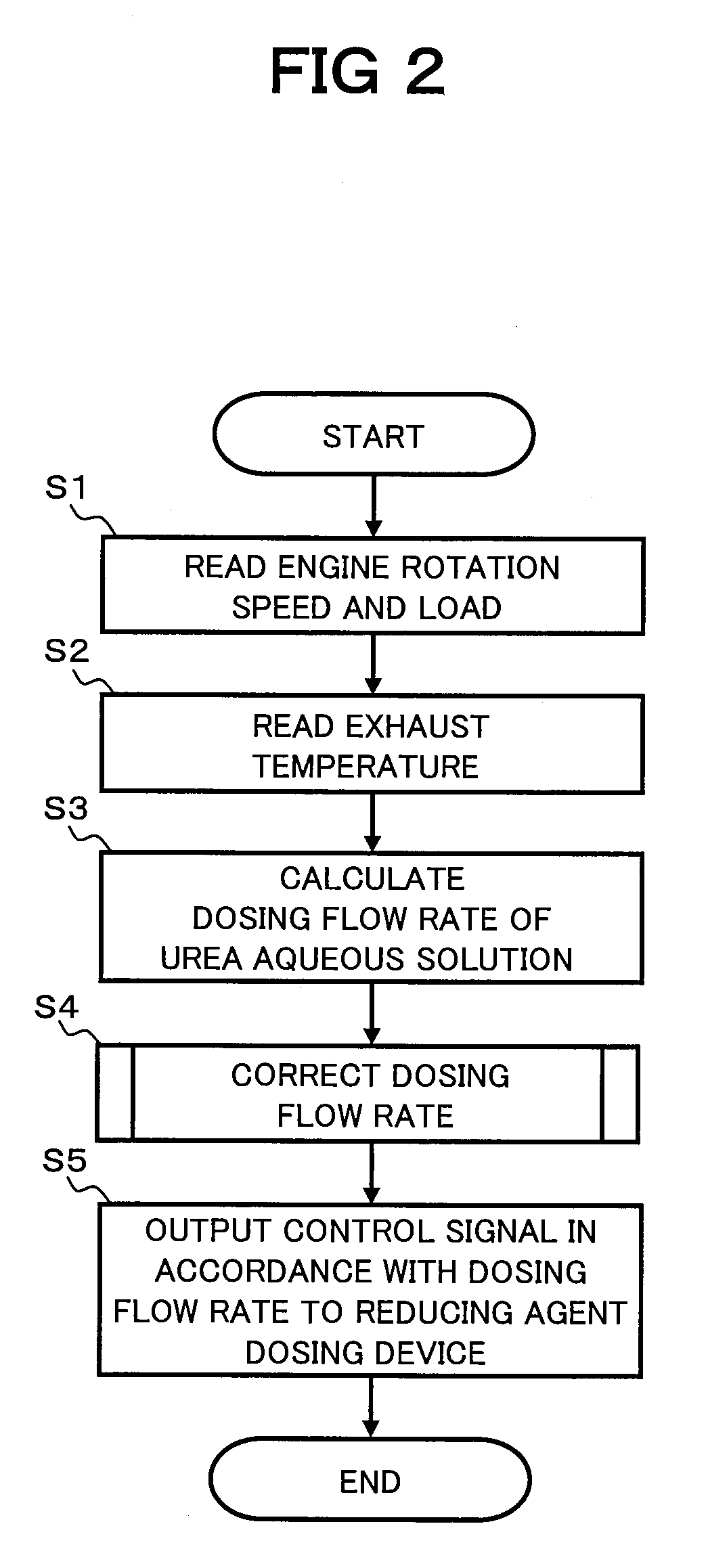

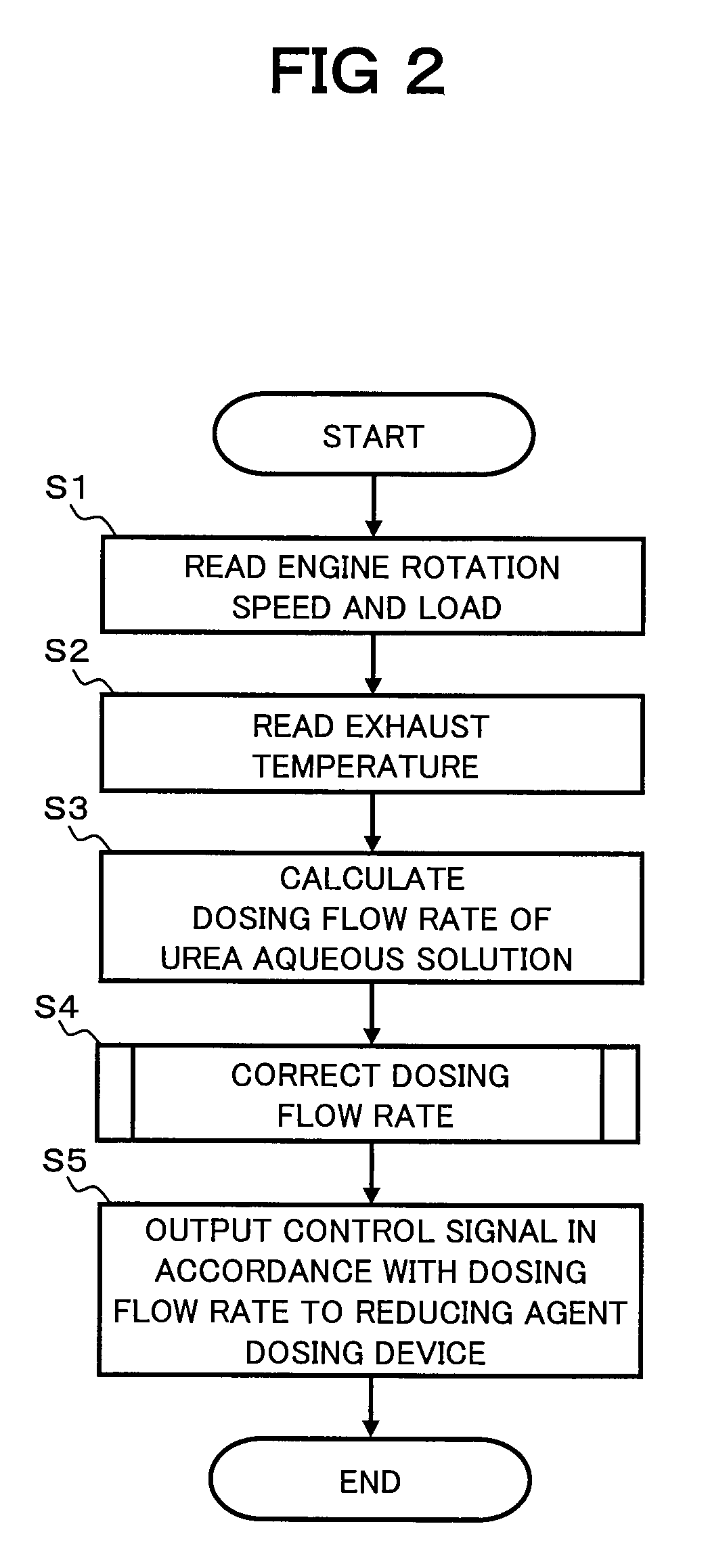

Exhaust gas purifying device of internal combustion engine

InactiveCN1938499ASuppress generationAvoid dischargeElectrical controlInternal combustion piston enginesParticulatesCombustion

An exhaust emission control device of an internal combustion engine capable of satisfactorily atomizing a reducing agent and surely securing combustion air. Since the controller of the exhaust emission control device controls the nozzle opening of a variable discharge turbo for spraying urea water, even when the engine is in a low load area of T1 to T2 and a supercharging pressure does not rise normally, the supercharging pressure P suitable for spraying the urea water can be provided by controlling the nozzle opening of the variable discharge turbo so as to be closed more than a normal one (chain double-dashed line), and the urea water can be securely atomized by a part of the supercharging air. Also, since the amount of combustion air supplied to the engine is increased by raising the supercharging pressure to P, satisfactory combustion can be realized and the generation of particulates and the discharge of unburned fuel can be suppressed.

Owner:KOMATSU LTD

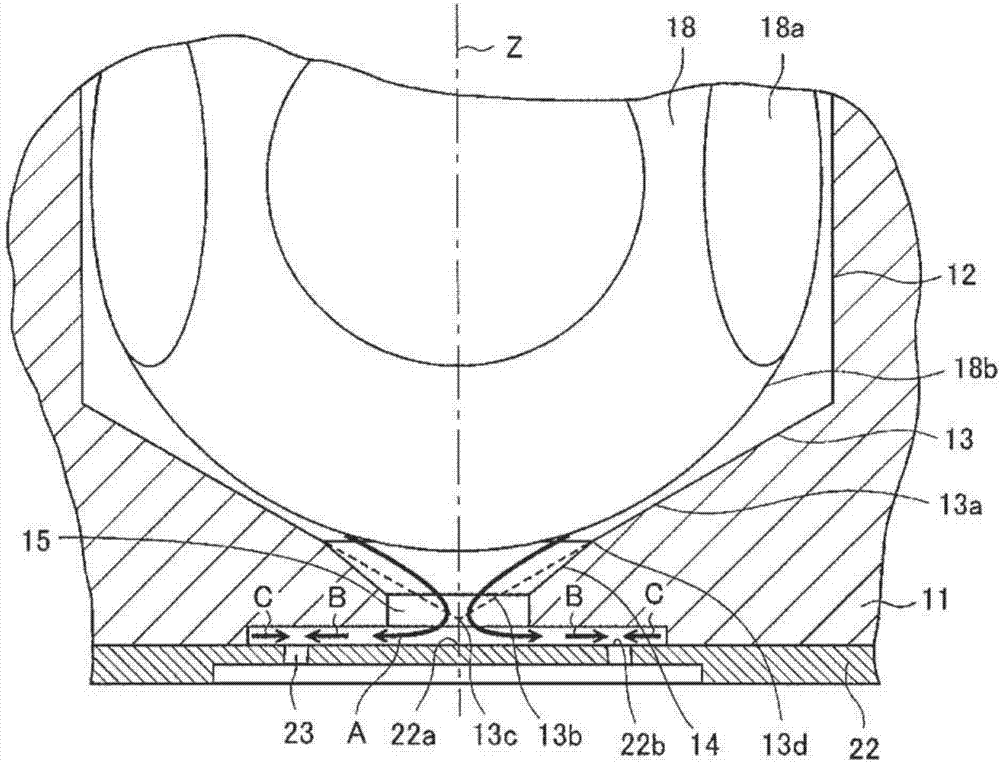

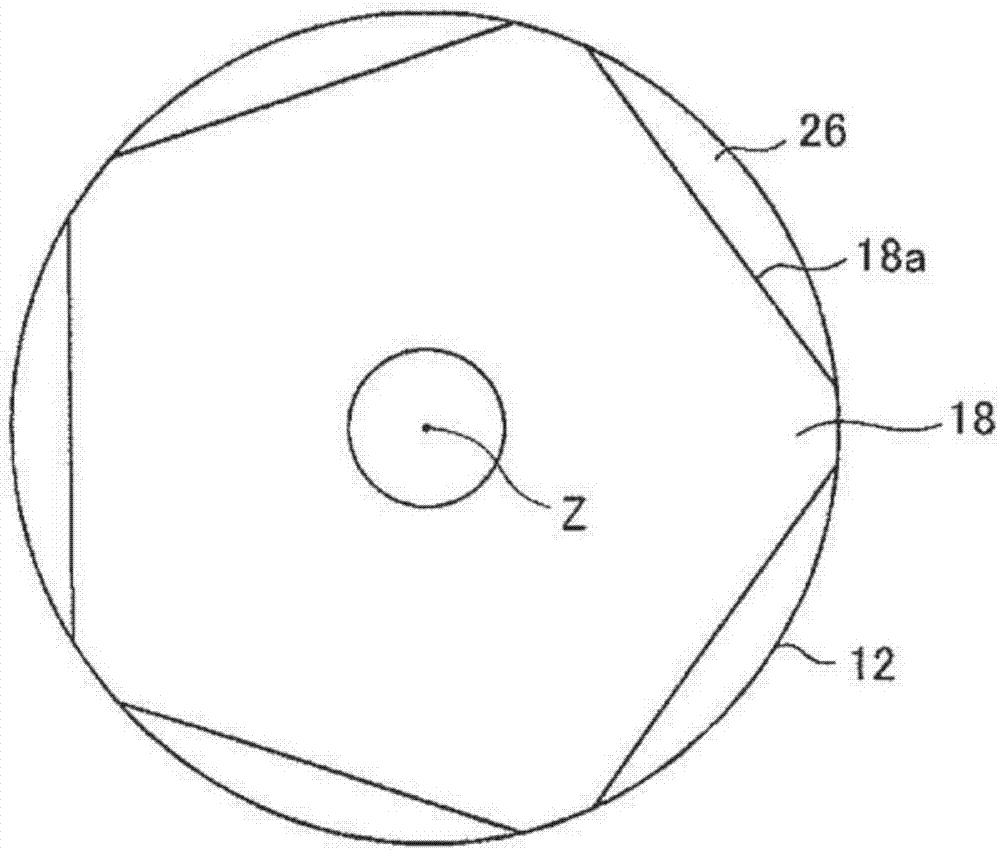

Valve device for fuel injection valve

ActiveCN107076086ASmall pressure lossSuppresses variation in spray particle sizeFuel injection apparatusMachines/enginesValve seatFuel injection

A valve device for a fuel injection valve (1), wherein the intersection point (13c) between the center line Z of the valve seat (11) and the apex of a hypothetical cone (13b) formed by extending a seating surface (13) toward the downstream side is positioned inside an aperture (15). Thus, after most of the fuel that has passed through a seat part (13a) converges at the aperture (15), the fuel reaches the upper surface of an injection hole plate (22) and smoothly changes to a flow toward the outer circumferential side, thereby minimizing the fuel pressure loss in this interval. Therefore, in this valve device for the fuel injection valve (1), a decrease in the fuel speed in the section (22b) directly above the injection hole is reduced, and atomization of the fuel spray is promoted.

Owner:MITSUBISHI ELECTRIC CORP

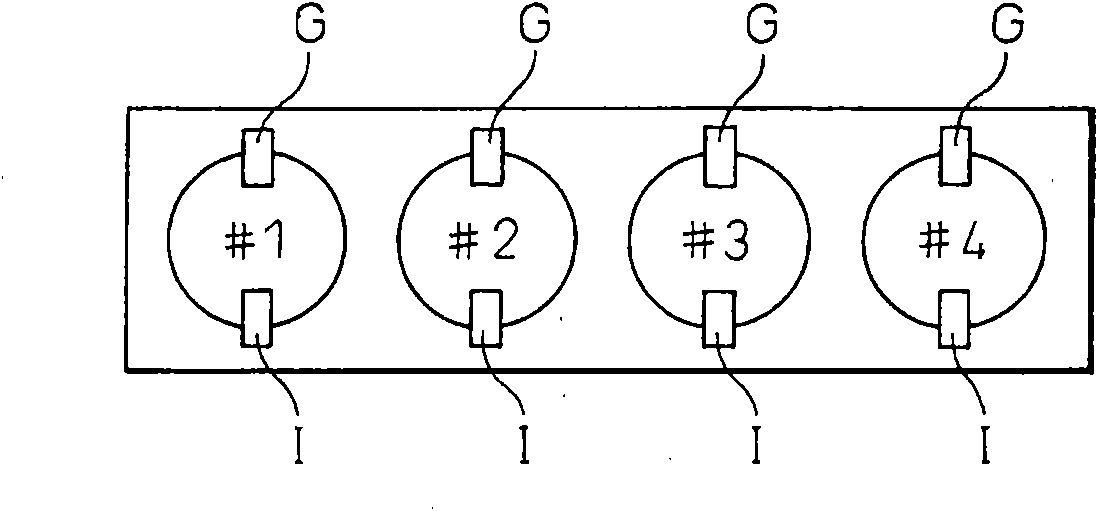

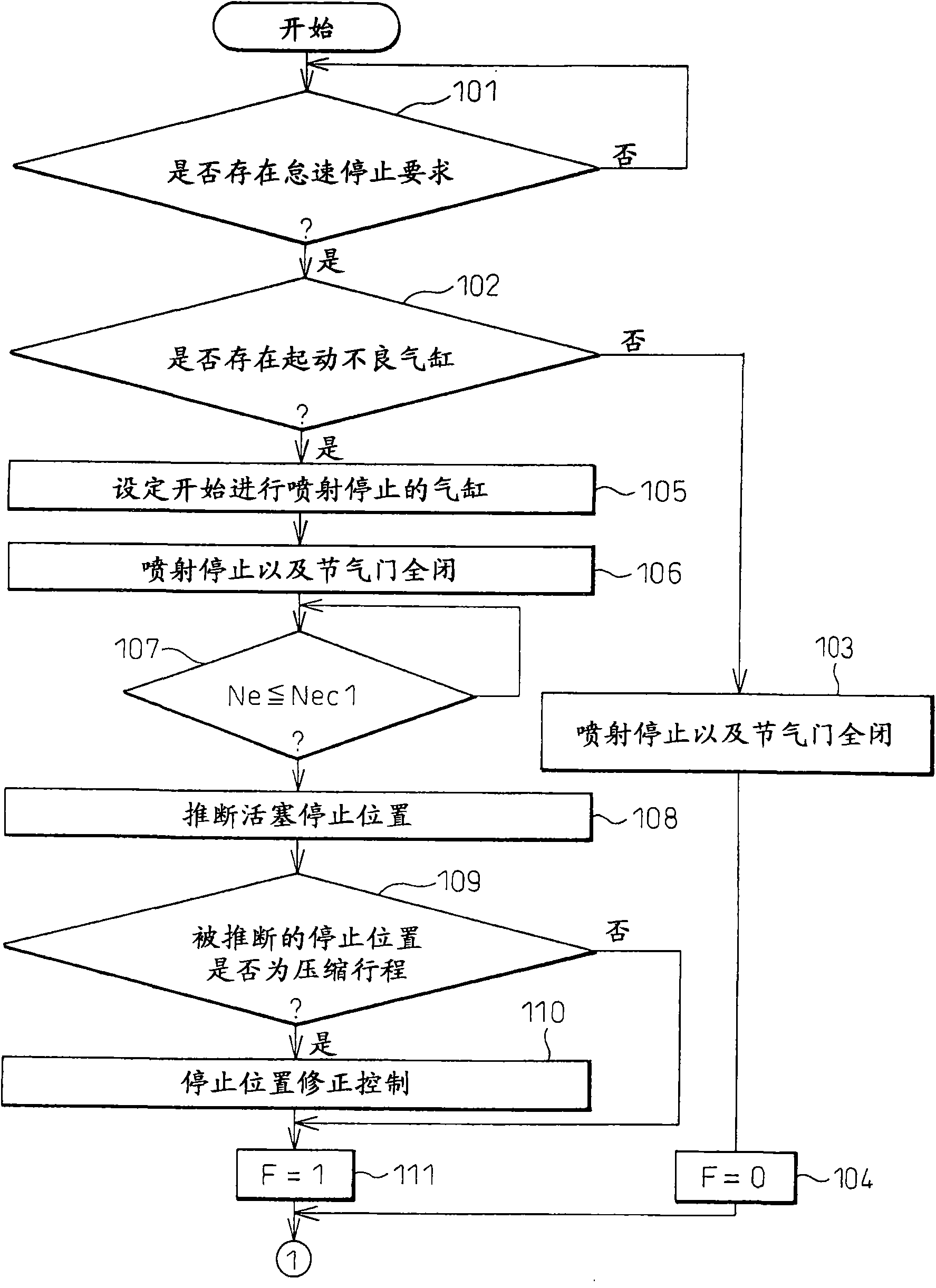

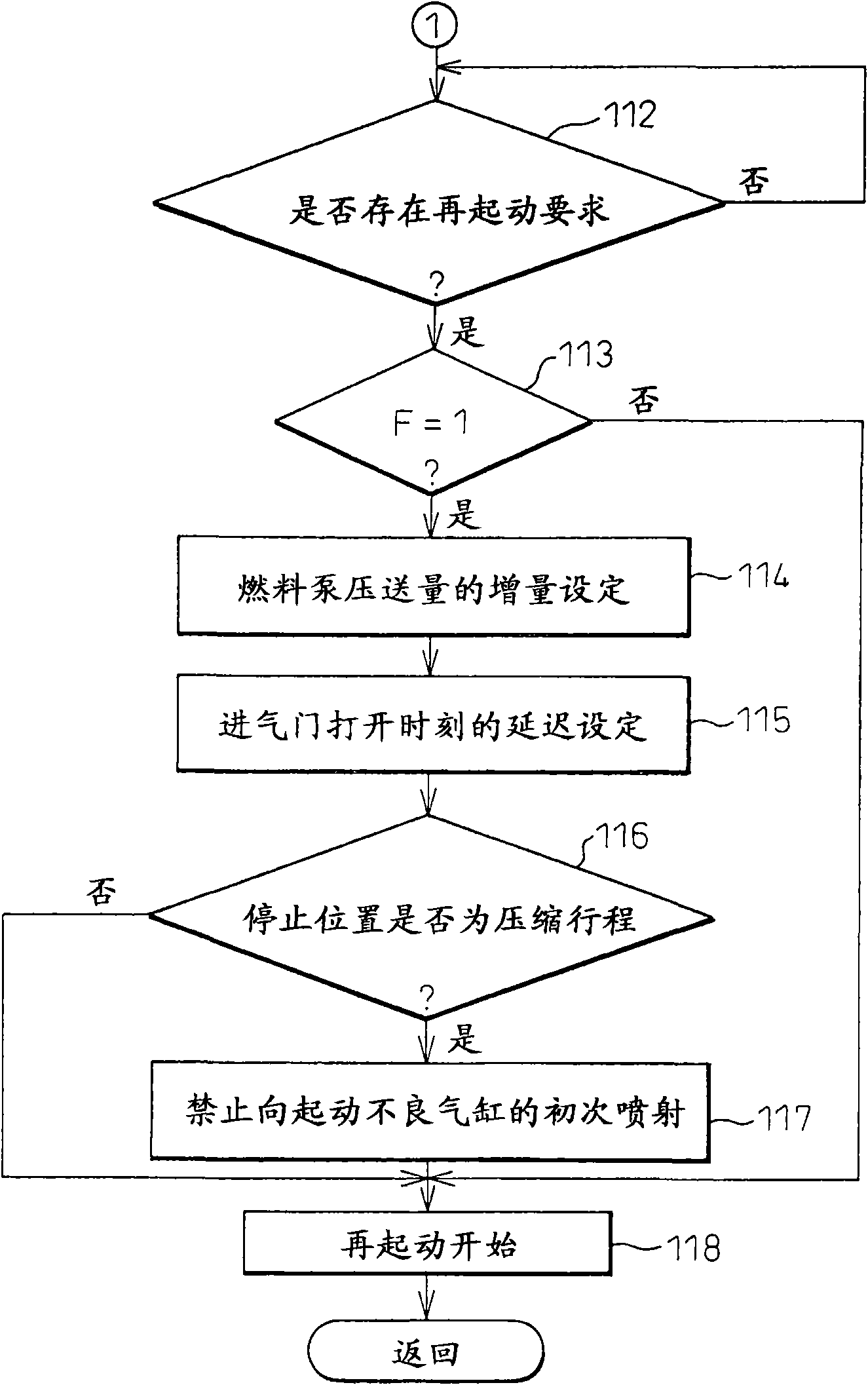

Starter for internal-combustion engine

InactiveCN101680376AInhibition of initiationAvoid dischargeElectrical controlInternal combustion piston enginesIdle speedInternal combustion engine

Owner:TOYOTA JIDOSHA KK

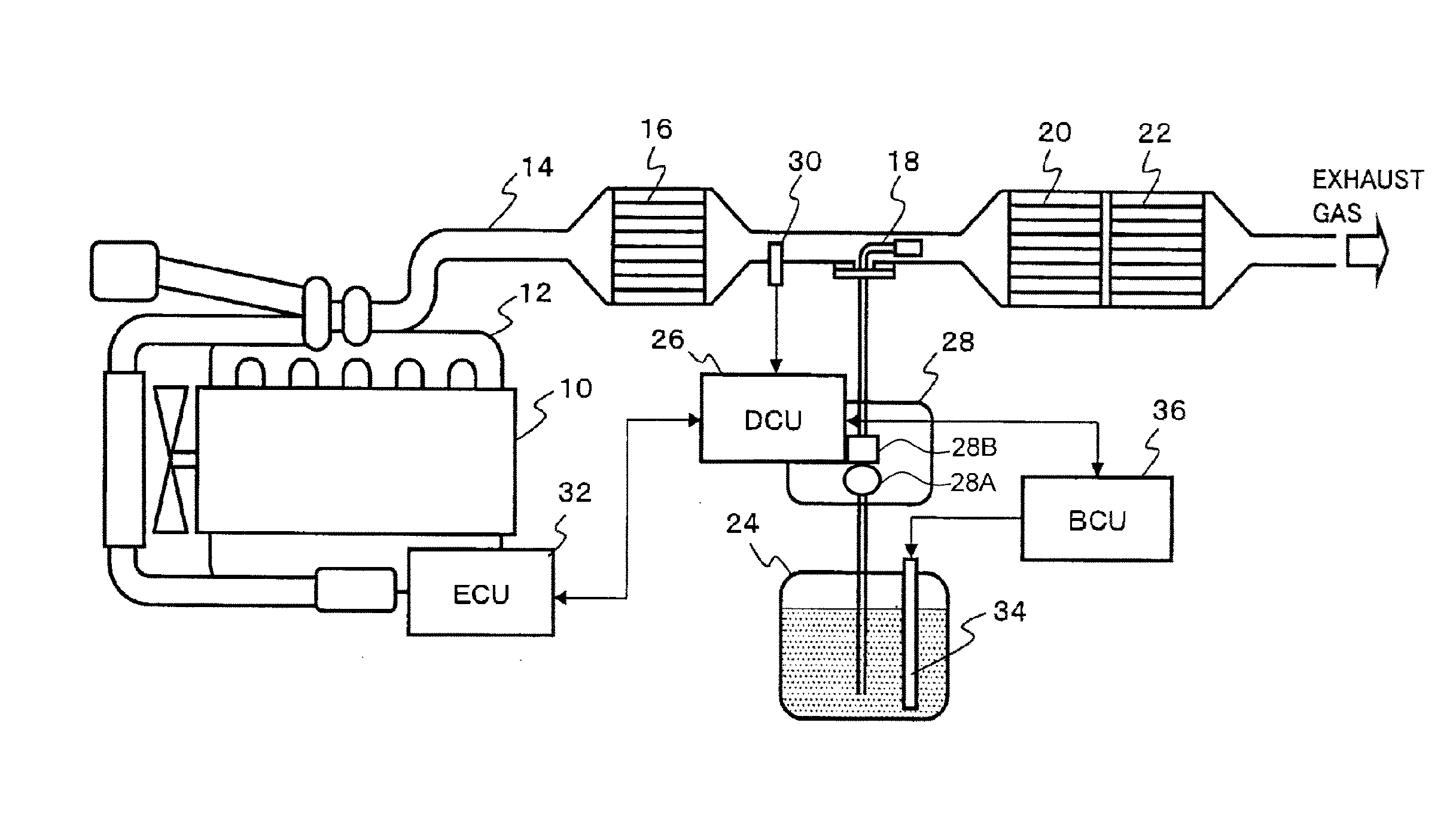

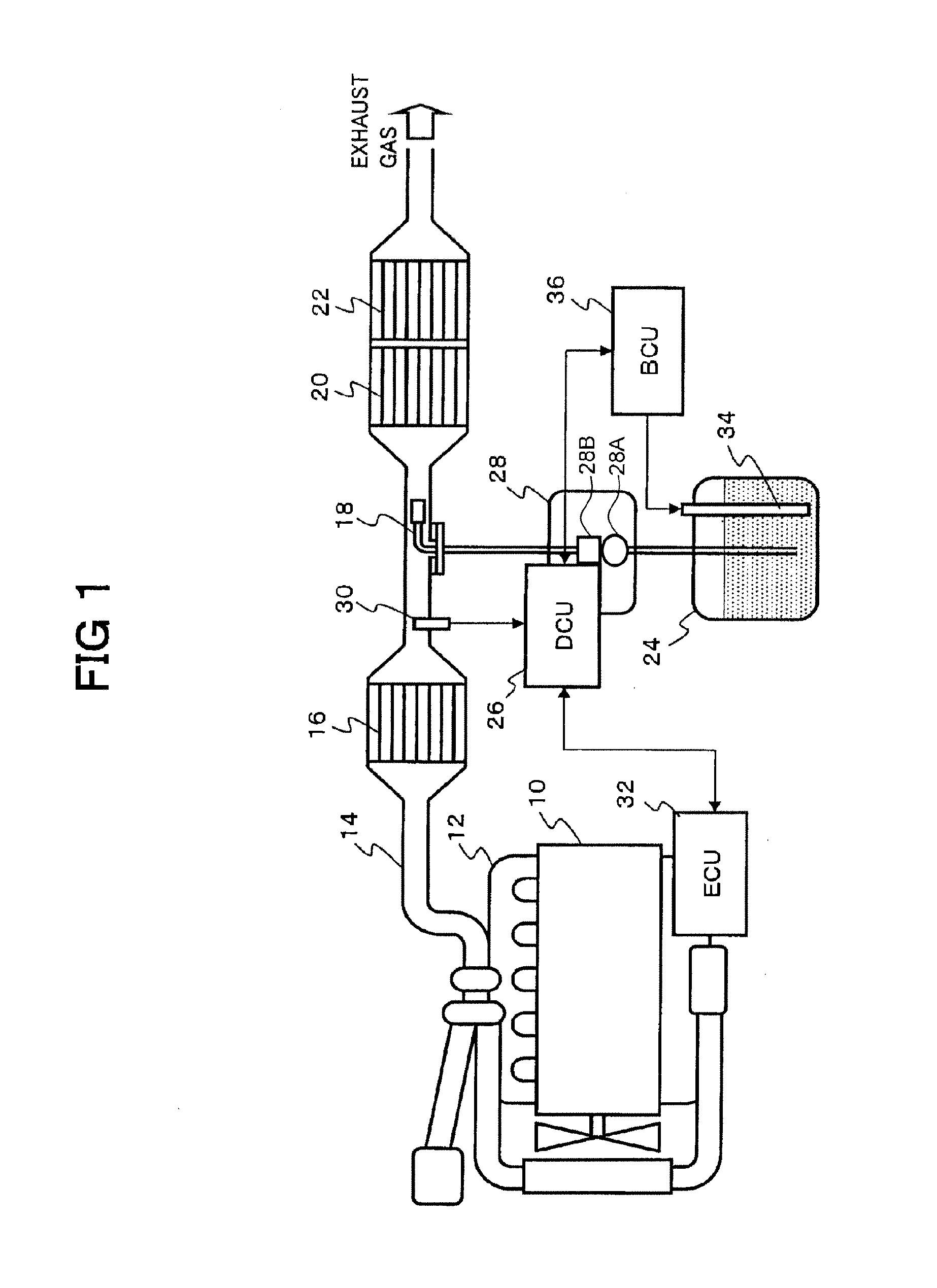

Exhaust gas purification apparatus for engine

InactiveUS20110162351A1Reduce violationsImprove purification effectInternal combustion piston enginesExhaust apparatusNano sizeExhaust fumes

In an exhaust gas purification apparatus for an engine includes a bubble generation device, the bubble generation device for mixing nano-sized to micro-sized bubbles into a liquid reducing agent or a precursor thereof injection-supplied from an injection nozzle is disposed in a reducing agent supply system running from a reducing agent tank to the injection nozzle. When the liquid reducing agent or the precursor thereof is injection-supplied from the injection nozzle, the liquid reducing agent or the precursor thereof is divided by bubbles, and the bubbles are radically inflated and burst by a pressure change and a temperature change at the time of injection-supplying, so that microparticulation of the liquid reducing agent or the precursor thereof is facilitated.

Owner:NISSAN DIESEL MOTOR CO

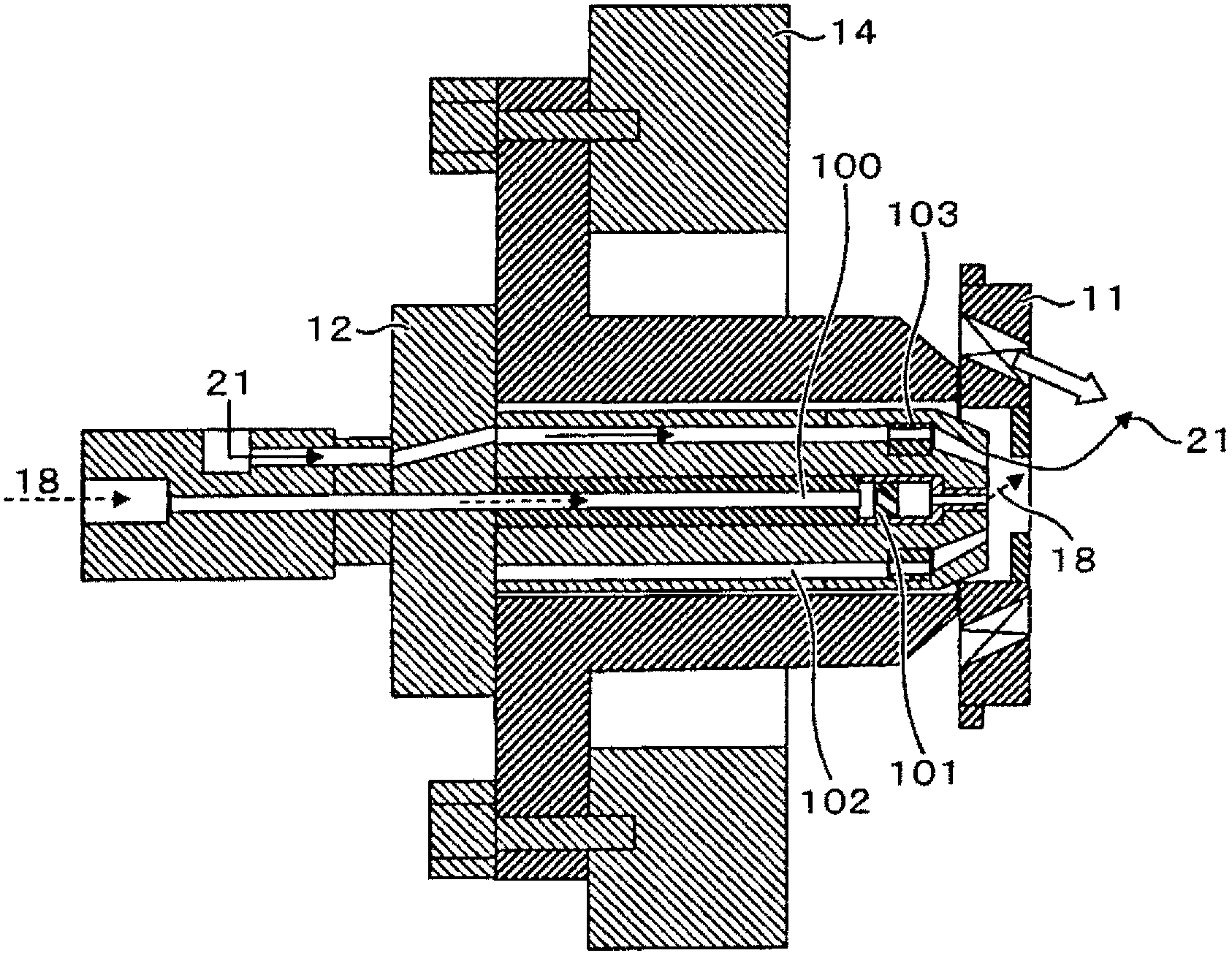

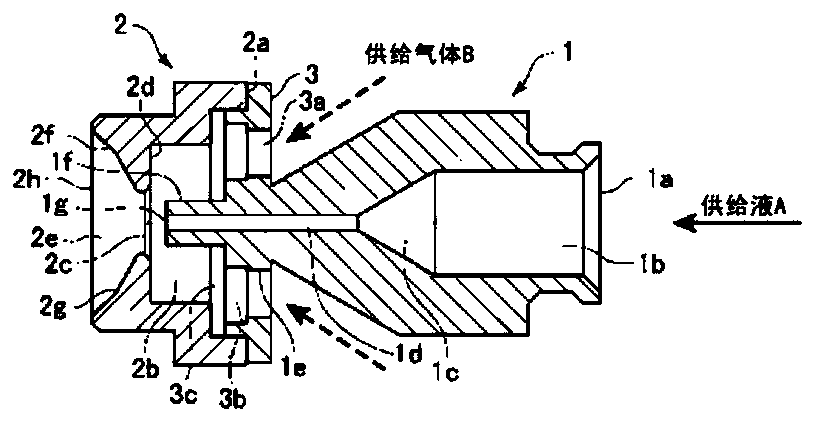

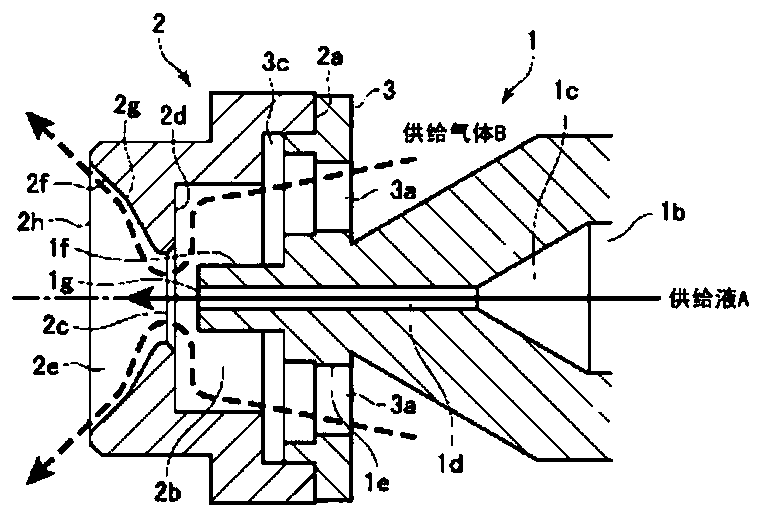

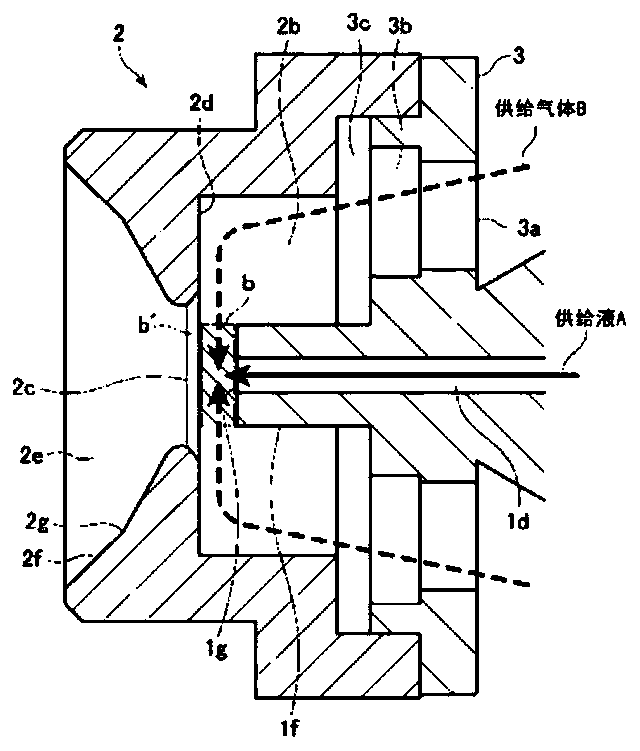

Double-fluid nozzle

InactiveCN110944756APromote micronizationReduce depositionTransportation and packagingLiquid spraying apparatusEngineeringMechanics

Provided is an internal mixing type double-fluid nozzle which is unlikely to become clogged, is capable of achieving high atomization performance, has a simple configuration, and can used be for various purposes. The double-fluid nozzle is configured to be provided with: a liquid cap body 1 which has a fluid passage formed therein and to which a supply liquid is supplied from the upstream side; and an air cap body 2 which is provided to the downstream section of the liquid cap body 1 and into which a supply gas is supplied, wherein a liquid outlet 1g is provided to the downstream end of the liquid cap body, a gas chamber 2b, into which the supply gas is supplied, is formed in the air cap body 2, a mixed gas outlet 2c is formed on the downstream side of the gas chamber 2b, and a mortar-shaped mixed gas expansion part 2e is provided immediately subsequent to the mixed gas outlet 2c.

Owner:SPRAYING SYST JAPAN

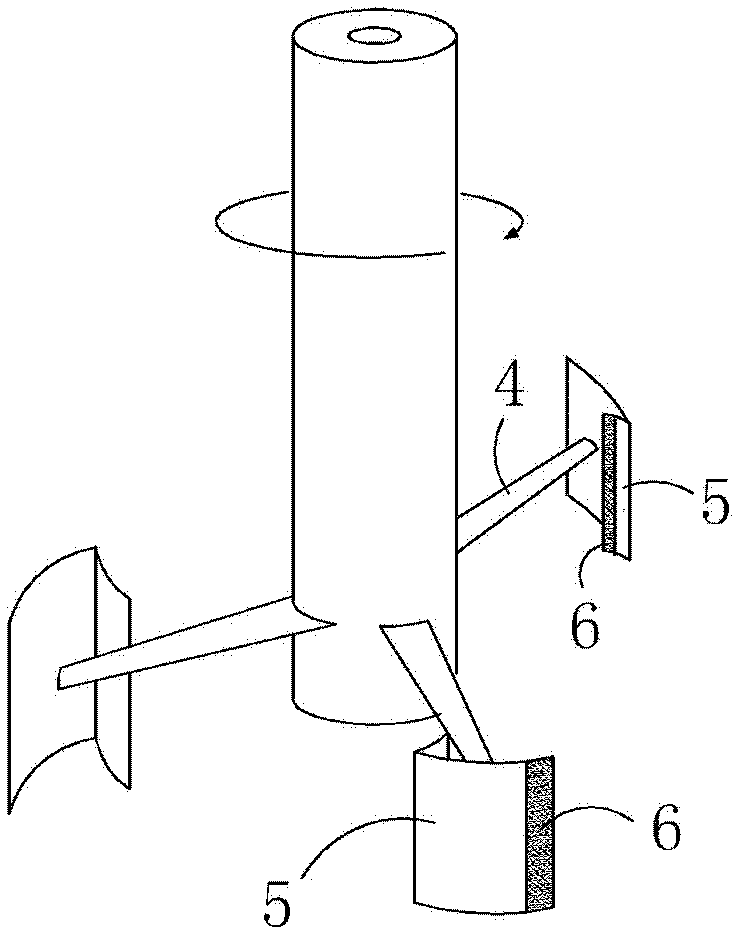

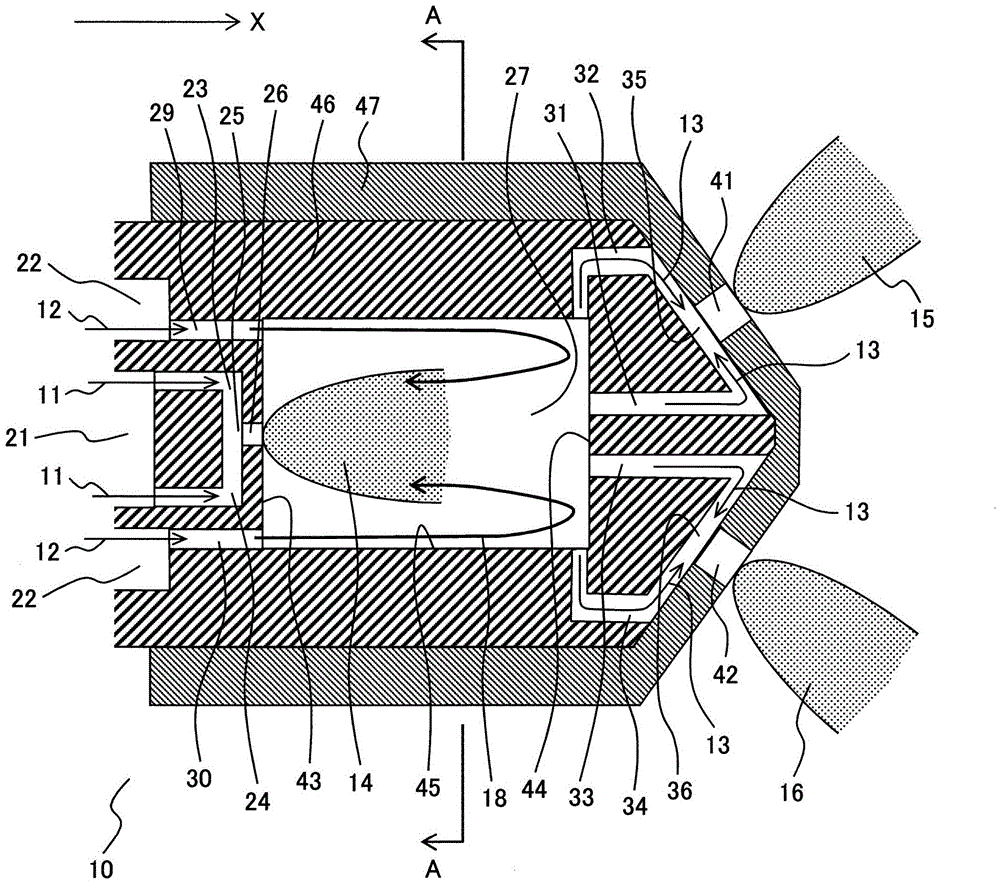

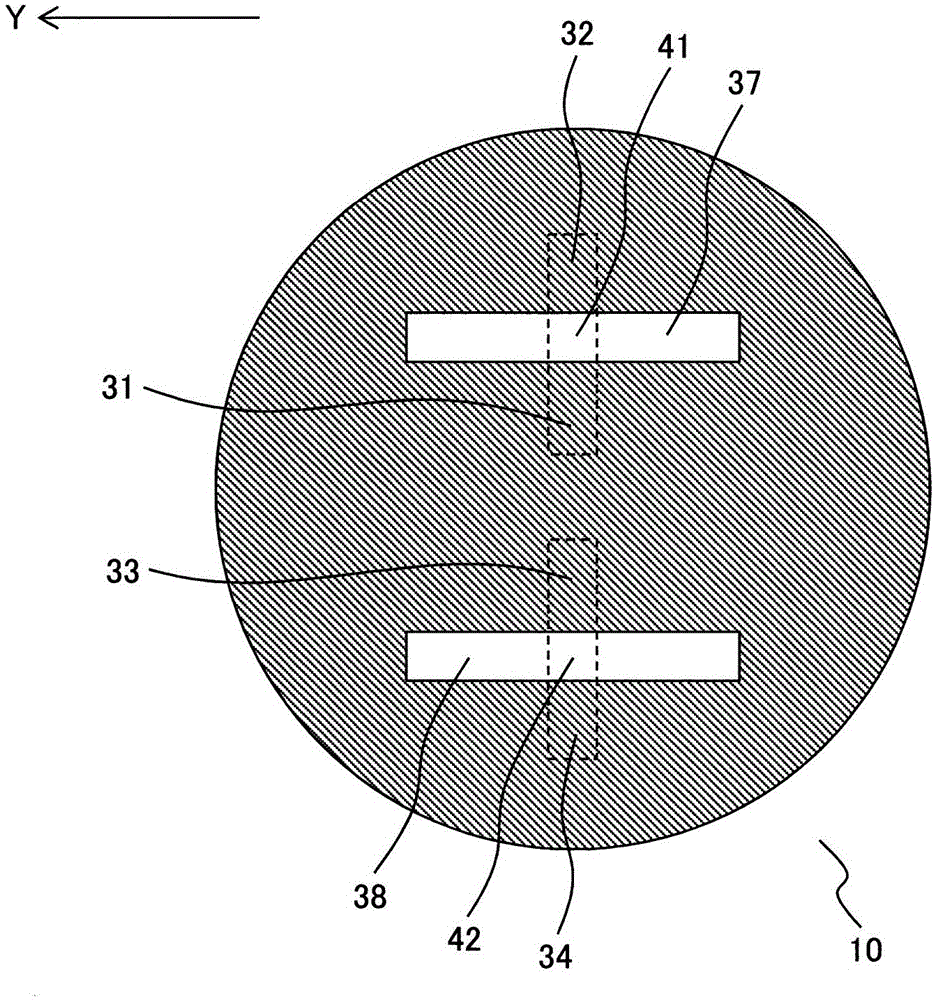

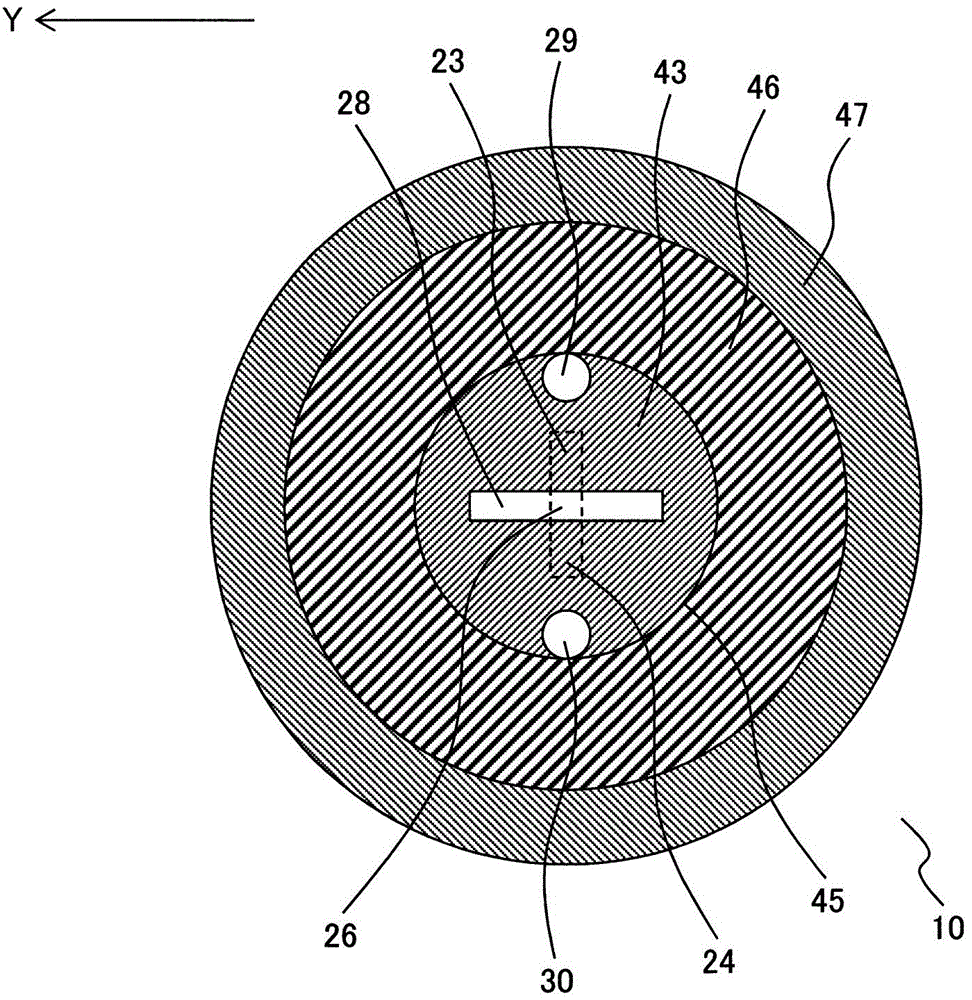

Atomizer, combustion device including atomizer, and gas turbine plant

ActiveCN105318352APromote micronizationInhibit wearBurnersContinuous combustion chamberSolid componentCombustion

The invention provides an atomizer capable of promoting microparticulation of a spray fluid and inhibiting abrasion caused by a solid component of the spray fluid and a combustion device including the atomizer. The atomizer includes a mixing chamber (27), spray fluid flow passages (23, 24) supplying a spray fluid (11) to the mixing chamber (27), a spray medium flow passage (29, 30) supplying a spray medium (12) to the mixing chamber, outlet holes (41) spraying a fluid mixture (13) of the spray fluid and the spray medium, and fluid mixture flow passages (31, 32) connecting the mixing chamber (27) and the outlet holes (41) to each other. The fluid mixture flowing through each of the fluid mixture flow passages joins with each other at a joining section (35) and is sprayed from the outlet hole. The mixing chamber (27) includes a middle ejection hole (26) spraying the spray fluid to the mixing chamber. The middle ejection hole is arranged at a joining section of the spray fluid flow passages. The spray fluid flowing through the spray fluid flow passages joins with each other at the joining section and is sprayed from the middle ejection hole.

Owner:MITSUBISHI POWER LTD

Fuel injection valve

ActiveCN105121834APromote micronizationIncrease freedomMachines/enginesSpecial fuel injection apparatusEngineeringFuel injection

A fuel injection valve is configured in such a manner that each of the injection holes comprises an injection hole body and a large-diameter section which is located adjacent to and downstream of the injection hole body and which constitutes the outlet of the injection hole. When each of the injection holes is projected perpendicularly onto a plane perpendicular to the axis of a valve seat, the center of the inlet of the injection hole body and the center of the outlet thereof are arranged on the plane in such a manner that the centers are arranged side by side on a radial straight line passing through the axis of the valve seat and in such a manner that the center of the outlet is farther from the axis of the valve seat than the center of the inlet. The center of the large-diameter section is offset from the straight line, and consequently, the length of a portion of the inner wall of the injection hole body, the portion facing the axis of the valve seat, is asymmetric relative to the straight line.

Owner:MITSUBISHI ELECTRIC CORP

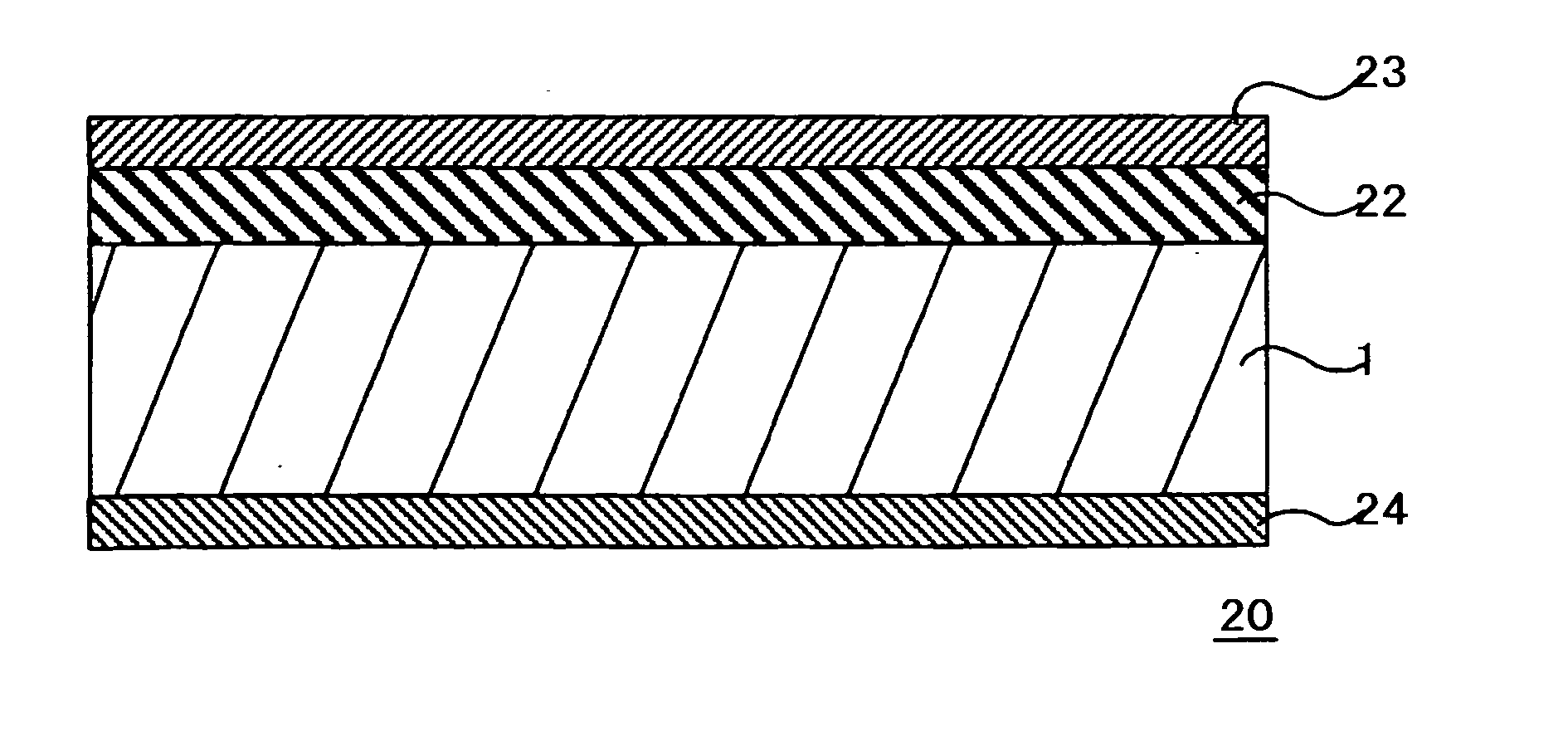

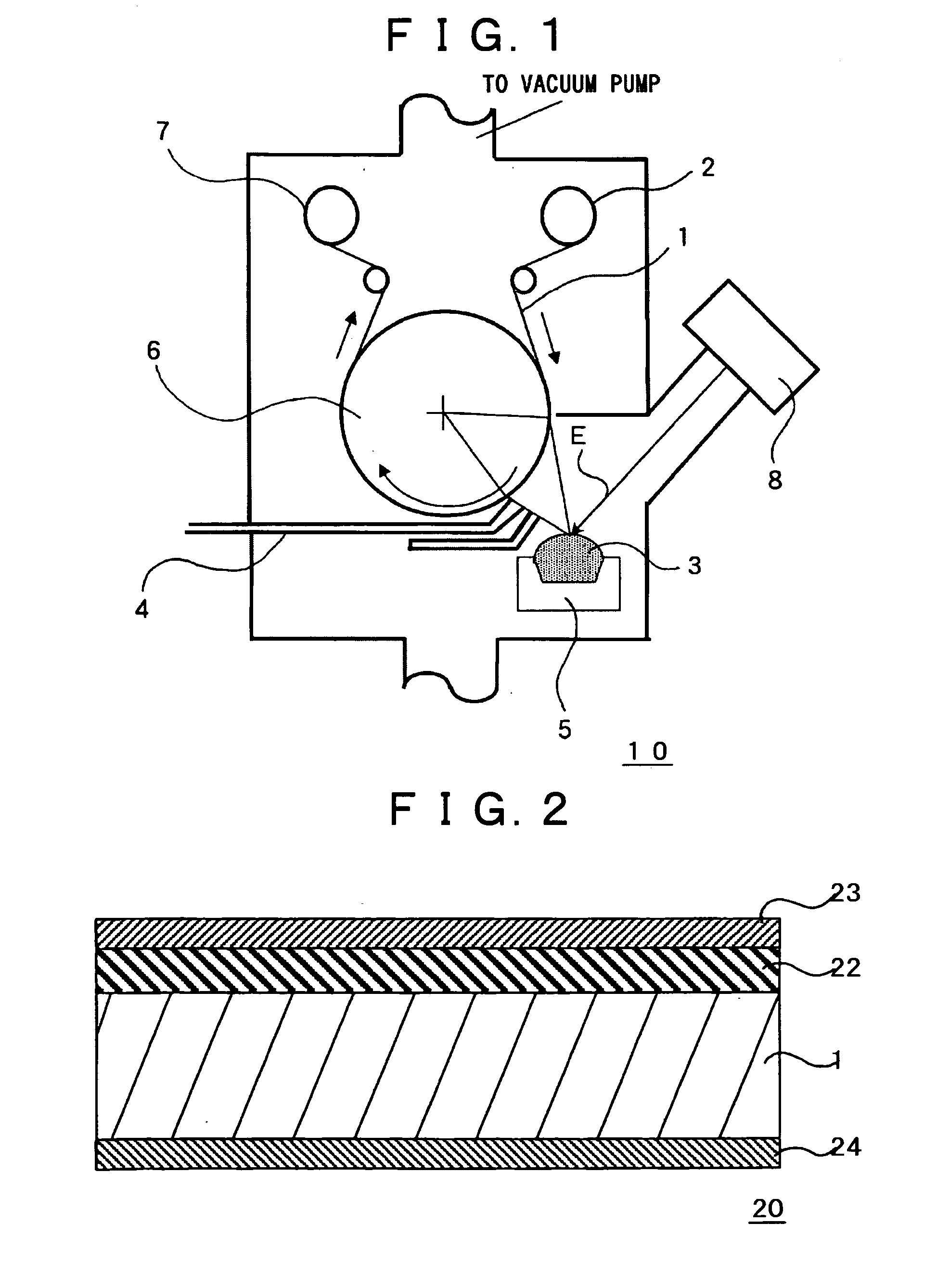

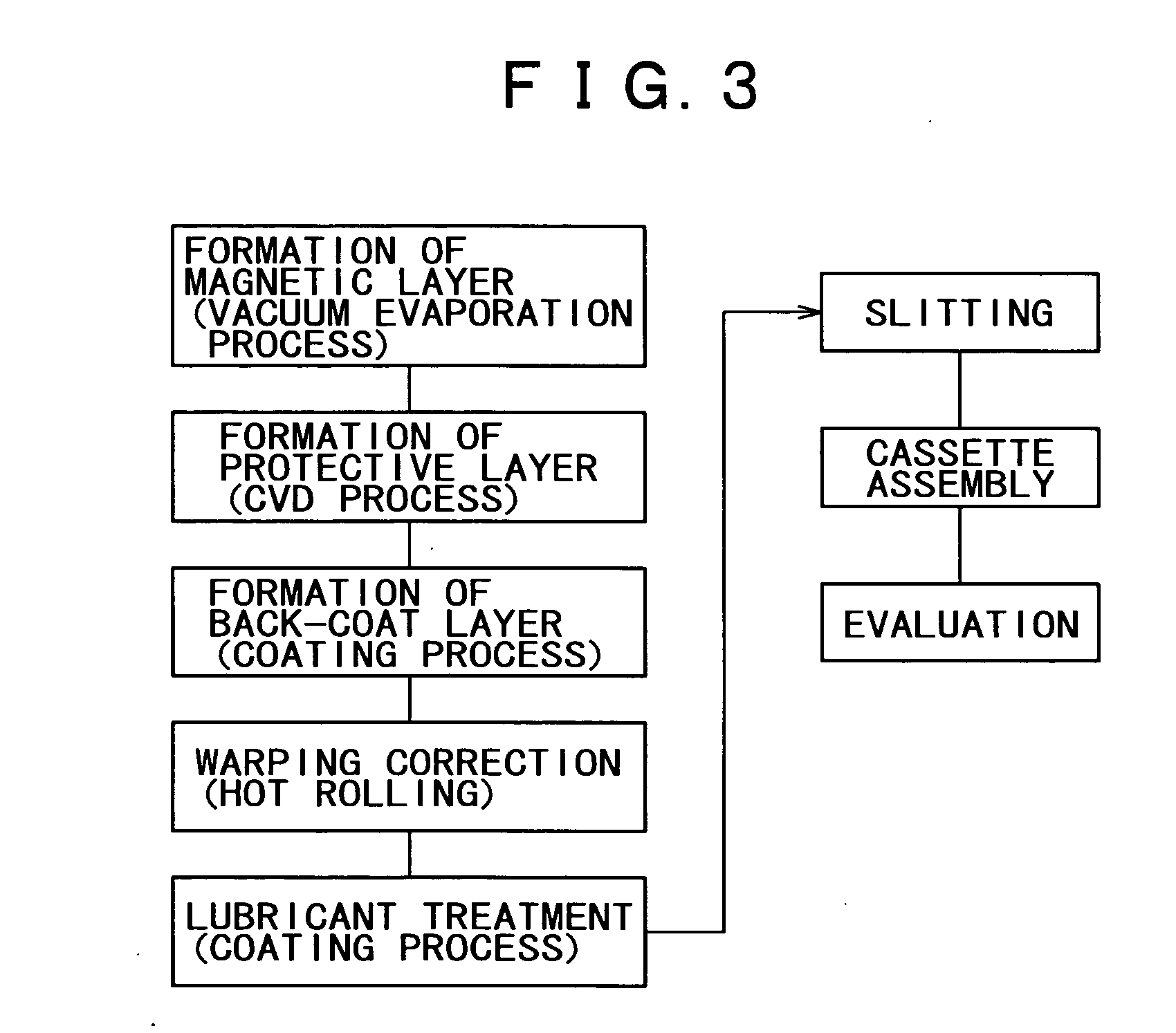

Magnetic recording medium and method of fabricating the same

InactiveUS20050031906A1Reduce block error rateImprove recording densityMagnetic materials for record carriersBase layers for recording layersPolyamideNon magnetic

In order to attain a magnetic recording medium compliant with the AIT4 format and capable of accomplishing a block error rate of 1×10−4 or below, there is provided a magnetic recording medium having a magnetic layer composed of a metal magnetic thin film formed on a non-magnetic substrate composed of an aromatic polyamide film, in which the magnetic layer has a coercive force Hc of 120 kA / m to 235 kA / m, and a square ratio Rs of 0.69 or above.

Owner:SONY CORP

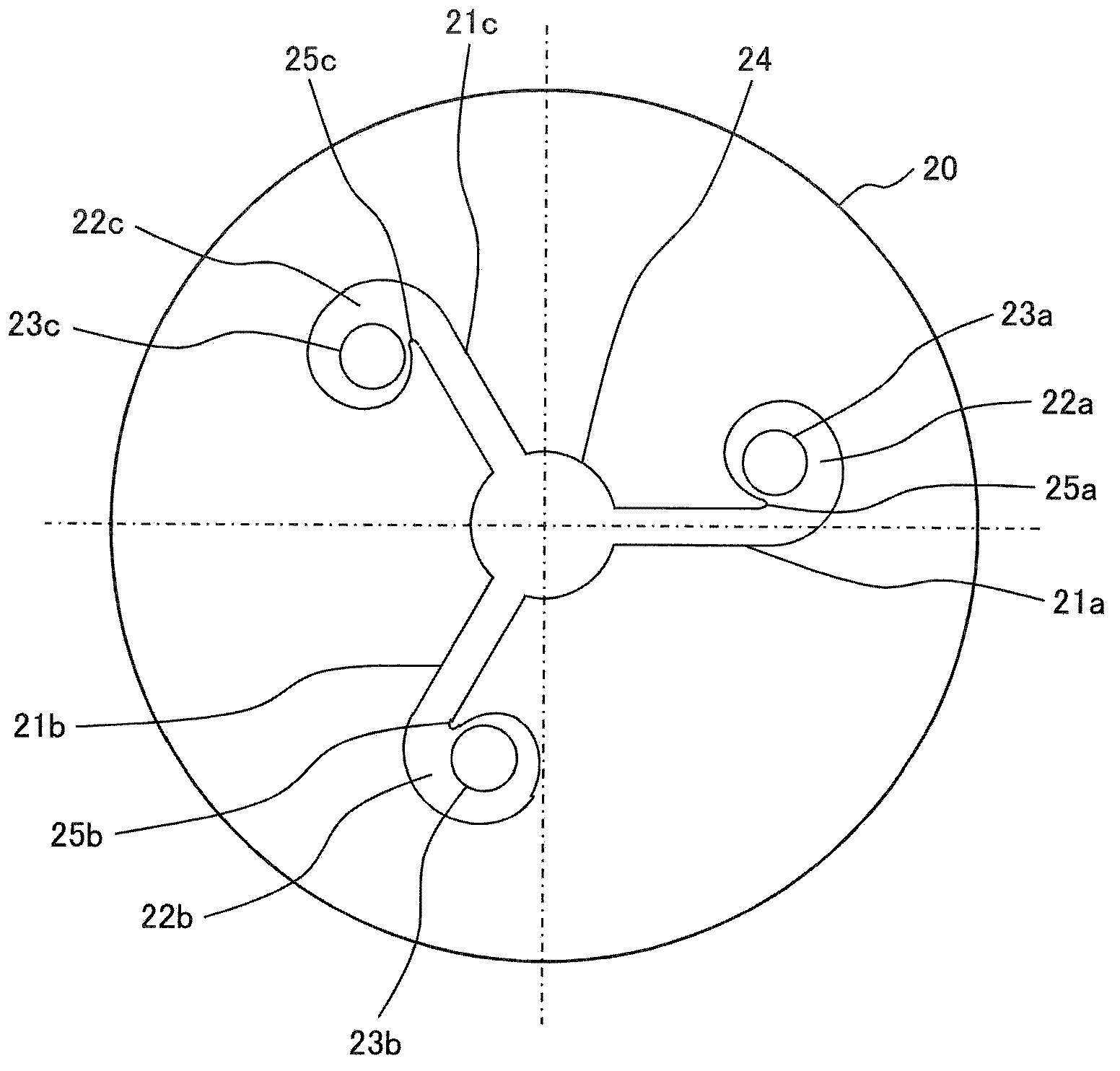

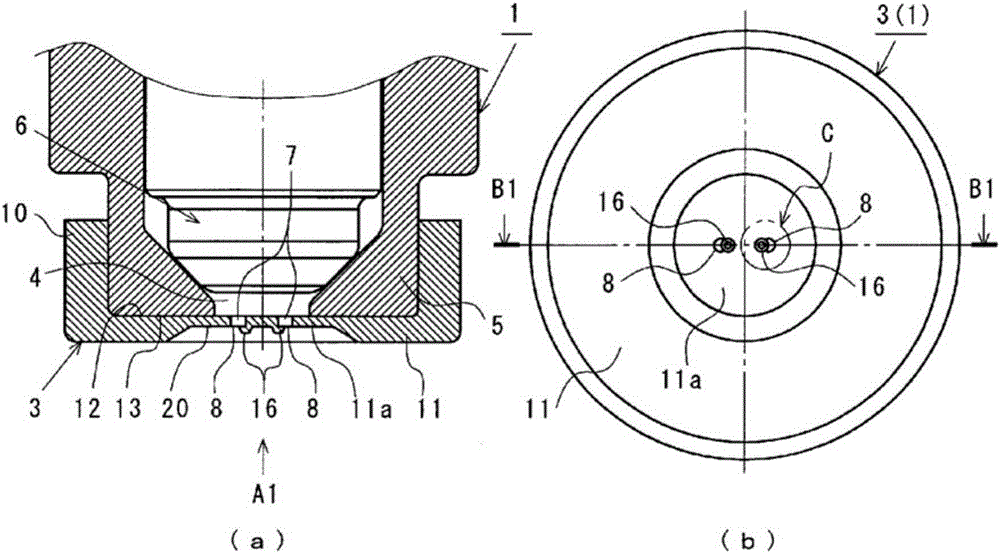

Fuel injection valve

ActiveCN103573515AInhibition biasPromote micronizationFuel injection apparatusMachines/enginesFuel injection

It is an object of the invention to provide a fuel injection valve in which the uniformity of a swirl flow in the circumferential direction is enhanced. The fuel injection valve (1) of the invention includes a swirling chamber (22a-22c) having an inner wall surface comprised of a helical curve and a passage (21a-21c) for swirling for guiding fuel into the swirling chamber (22a-22c). The fuel injection valve (1) is so formed that the center of a circle as the basis of the helical curve and the center of a fuel injection hole (23a-23c) open in the swirling chamber (22a-22c) agree with each other.

Owner:HITACHI ASTEMO LTD

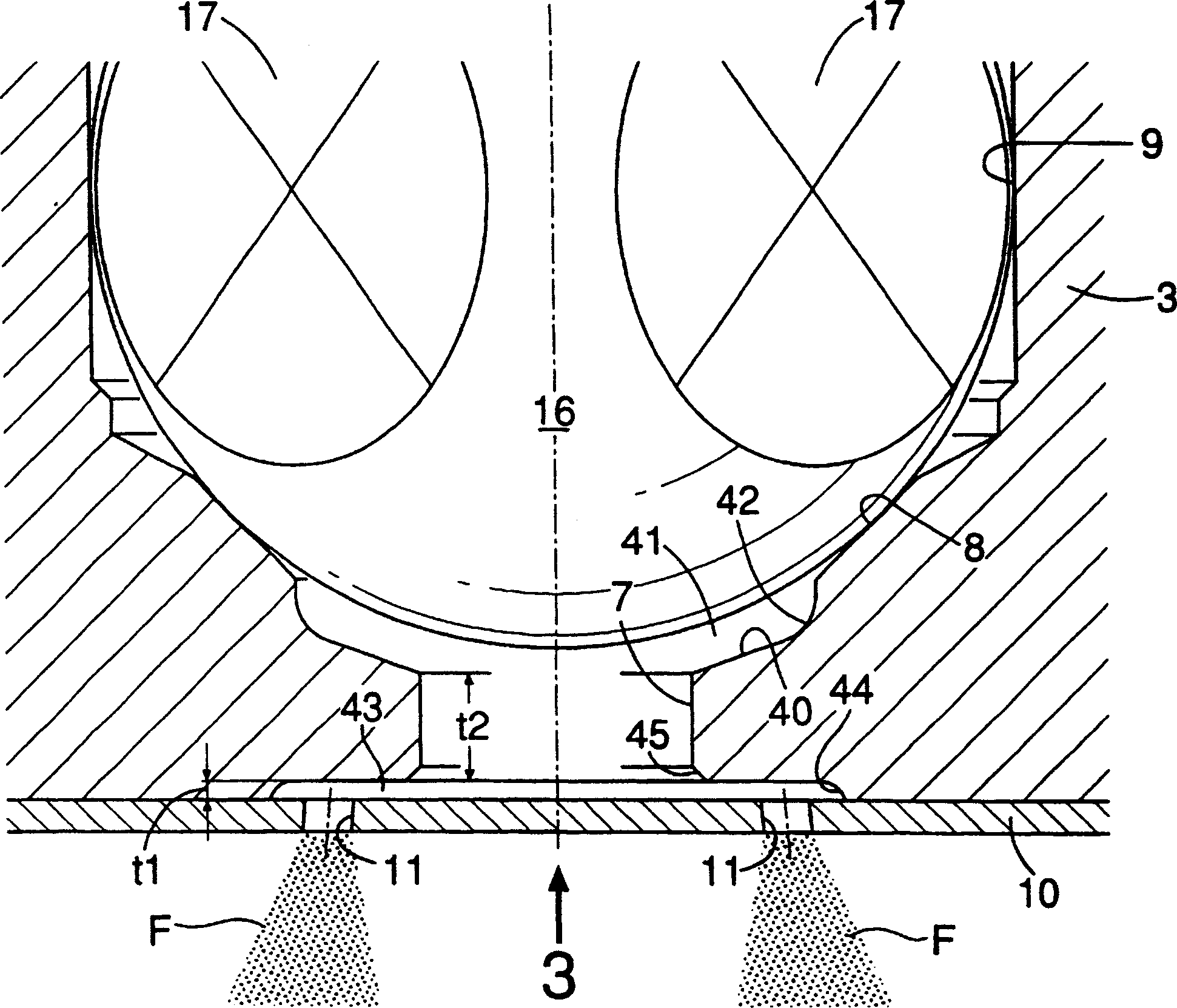

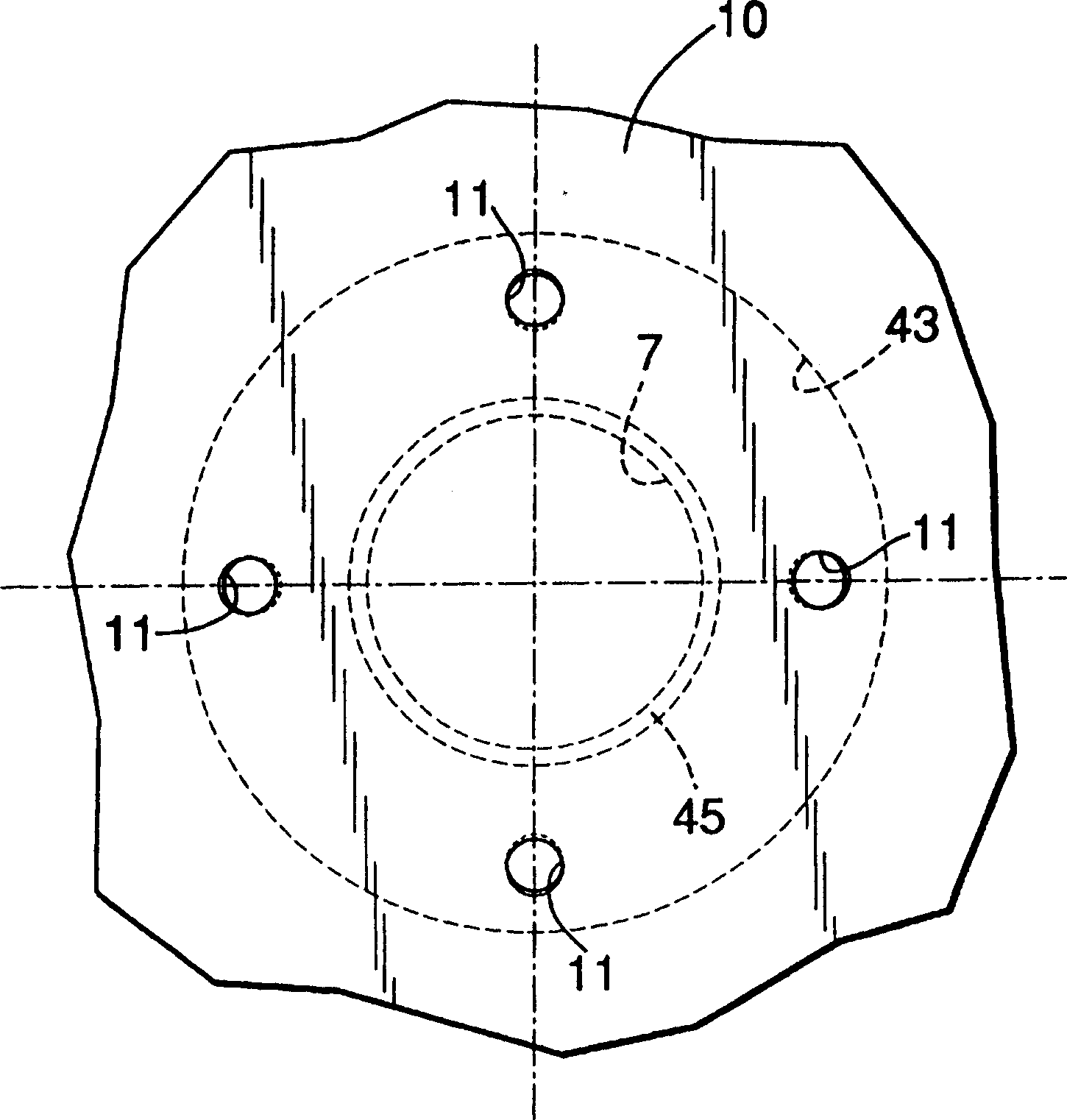

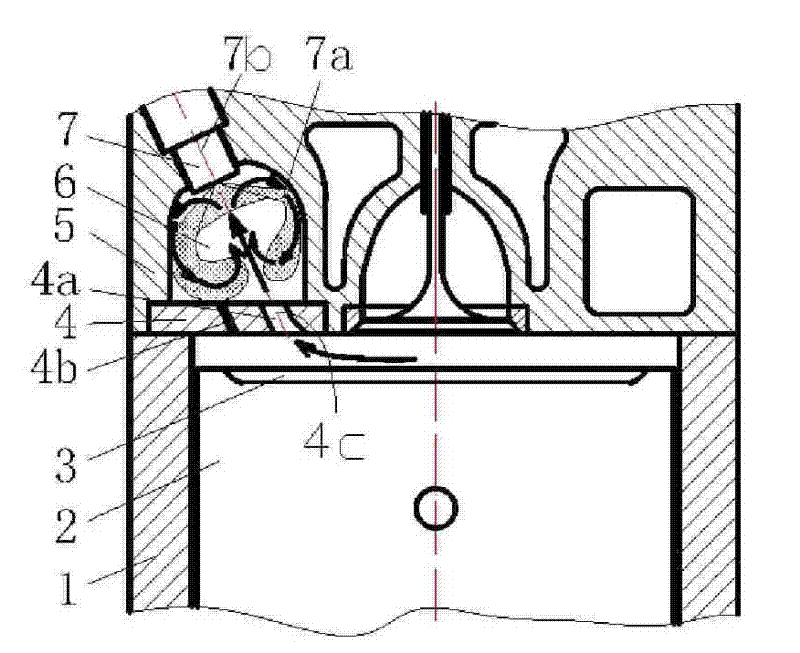

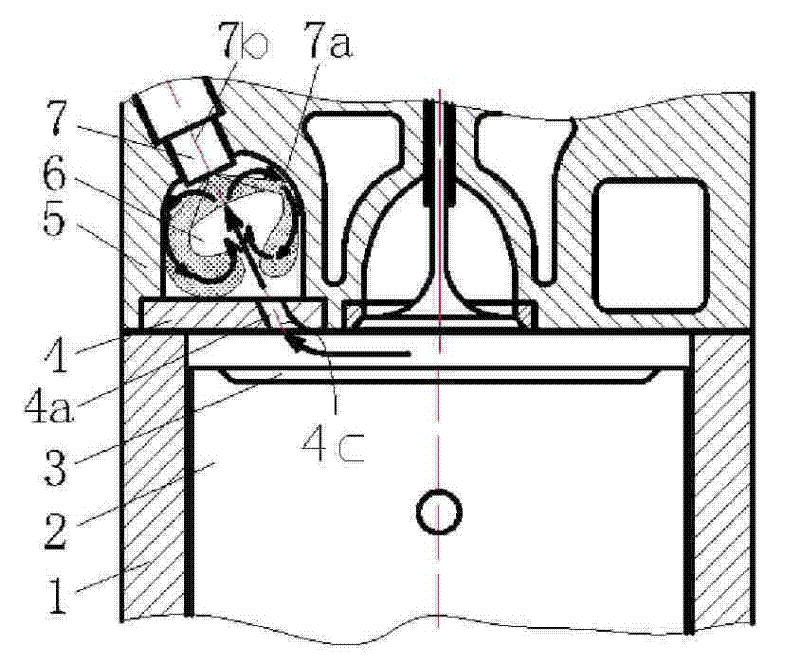

Fuel injection valve

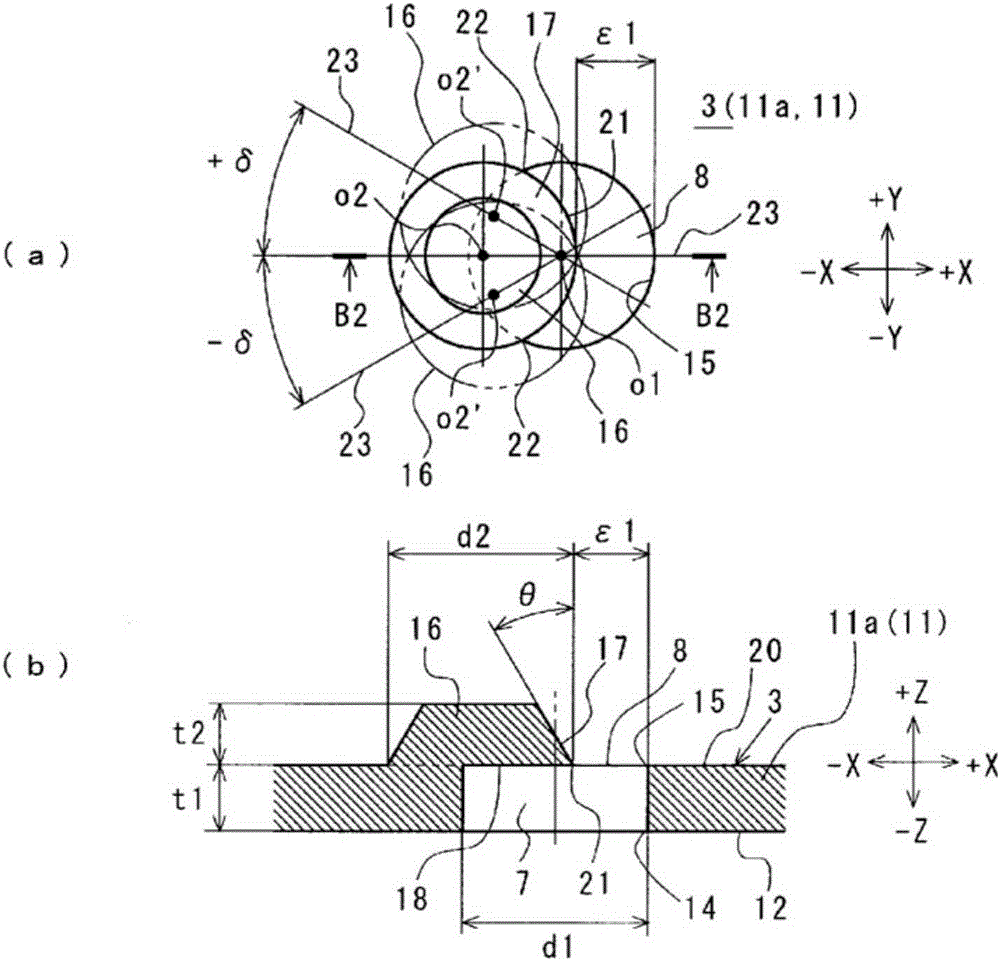

ActiveCN1864007AAvoid strandedPromote micronizationSpraying apparatusFuel injection apparatusInjectorDiffusion chamber

A fuel injection valve where a conical valve seat (8) and a valve seat hole (7) continues to the downstream end of the valve seat (8) is provided in a valve seat member (3), a flat fuel diffusion chamber (43) radially expanding from the valve seat hole (7) is formed between the valve seat member (3) and an injector plate (10), and fuel injection holes (11) opened to the fuel diffusion chamber (43) are provided in the injector plate (10). The fuel injection holes (11) are arranged to be separated radially outward from the valve seat hole (7) and at the same time to satisfy t2 / t1 >= 2, with t1 the height of the fuel diffusion chamber (43) and t2 the length of the valve seat hole (7). This reasonably sets a magnitude relationship between the length of the valve seat hole and the height of the fuel diffusion chamber and sets also a relative positional relationship between the valve seat hole and the fuel injection holes. As a result, injected fuel is effectively atomized.

Owner:HITACHI ASTEMO LTD

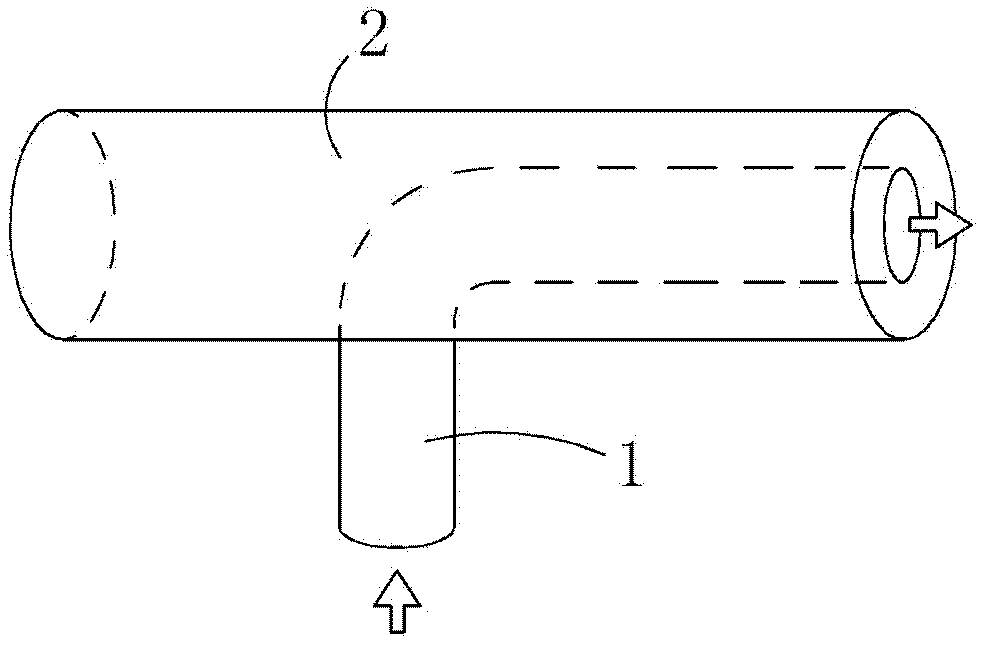

Exhaust gas purification apparatus for engine

InactiveUS8490389B2Reduce purification efficiencyPromote micronizationInternal combustion piston enginesExhaust apparatusNano sizeEngineering

In an exhaust gas purification apparatus for an engine includes a bubble generation device, the bubble generation device for mixing nano-sized to micro-sized bubbles into a liquid reducing agent or a precursor thereof injection-supplied from an injection nozzle is disposed in a reducing agent supply system running from a reducing agent tank to the injection nozzle. When the liquid reducing agent or the precursor thereof is injection-supplied from the injection nozzle, the liquid reducing agent or the precursor thereof is divided by bubbles, and the bubbles are radically inflated and burst by a pressure change and a temperature change at the time of injection-supplying, so that microparticulation of the liquid reducing agent or the precursor thereof is facilitated.

Owner:NISSAN DIESEL MOTOR CO

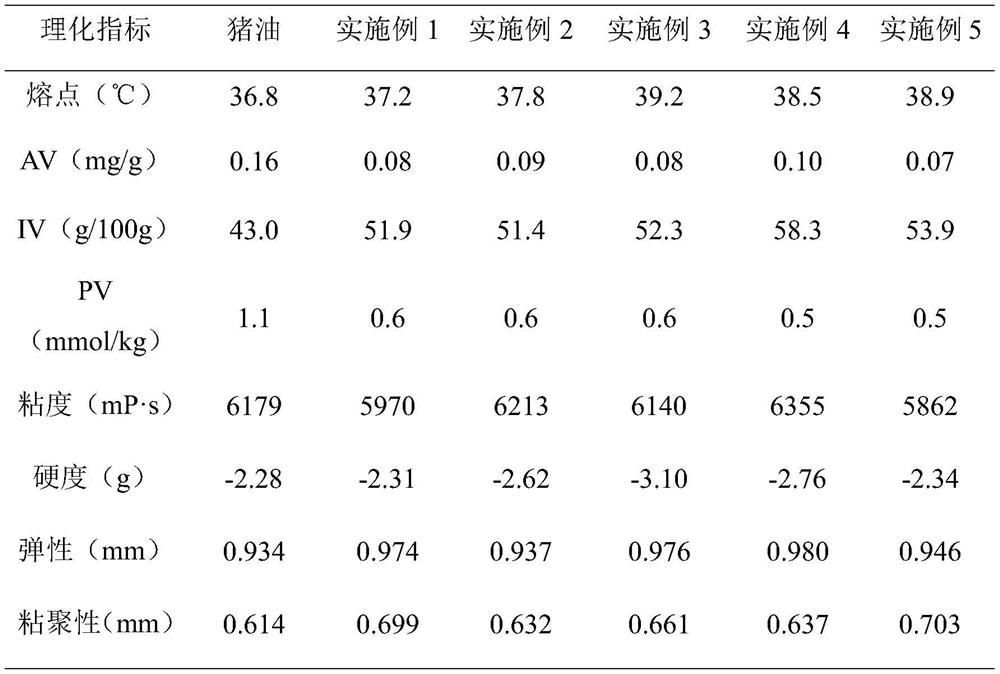

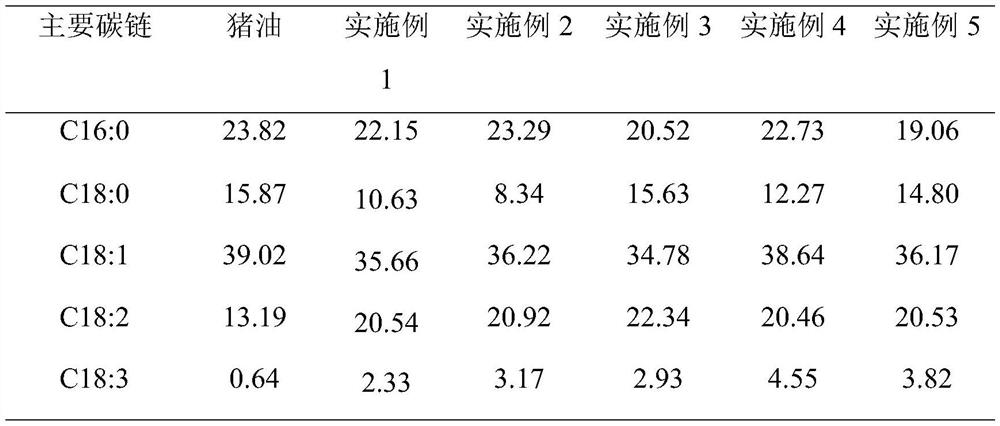

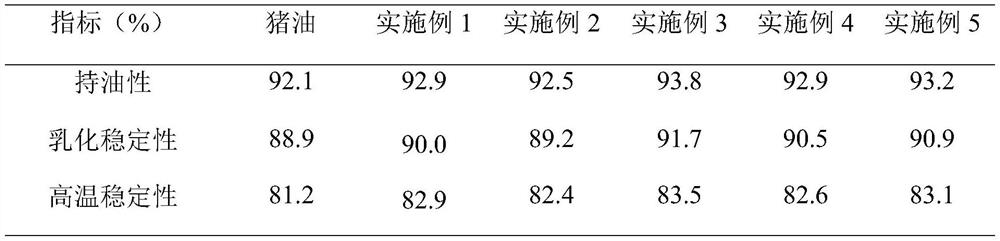

Structural lipid for replacing lard and preparation method thereof

The invention belongs to the field of food grease processing, and particularly relates to a structural lipid for replacing lard and a preparation method thereof, and the structural lipid is prepared from the following components in parts by mass: 20-40 parts of palm oil or fractions thereof, 20-40 parts of shea butter or fractions thereof, 35-60 parts of liquid vegetable oil, 0.1-5.0 parts of fat-soluble gelator and 0.1-0.5 part of edible essence. The structure lipid disclosed by the invention not only contains rich fat-soluble bioactive substances, but also has texture and taste similar to those of lard oil; the interaction between lipid proteins is enhanced by adding fat-soluble gelators, so that the lipid has good protein compatibility; and when the lipid is added into extrusion texturization processing of the vegetable protein, the protein texturization structure stability can be improved, and the taste and flavor of the product can be improved.

Owner:JIANGNAN UNIV

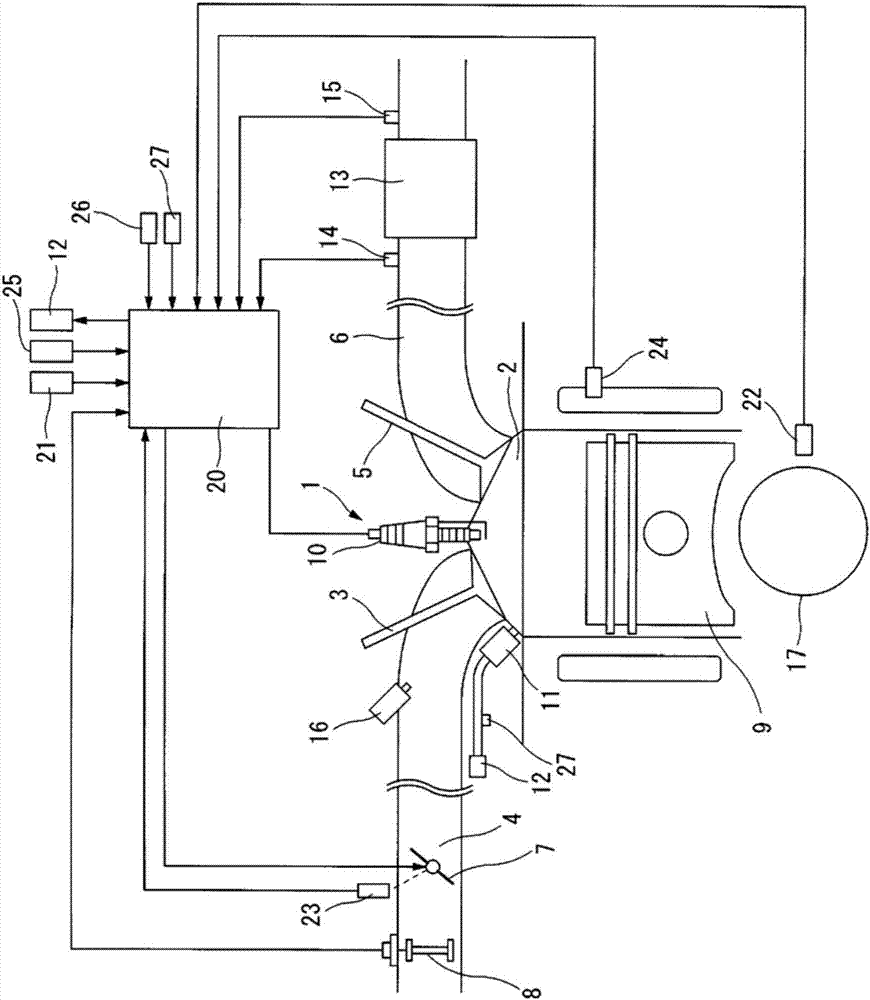

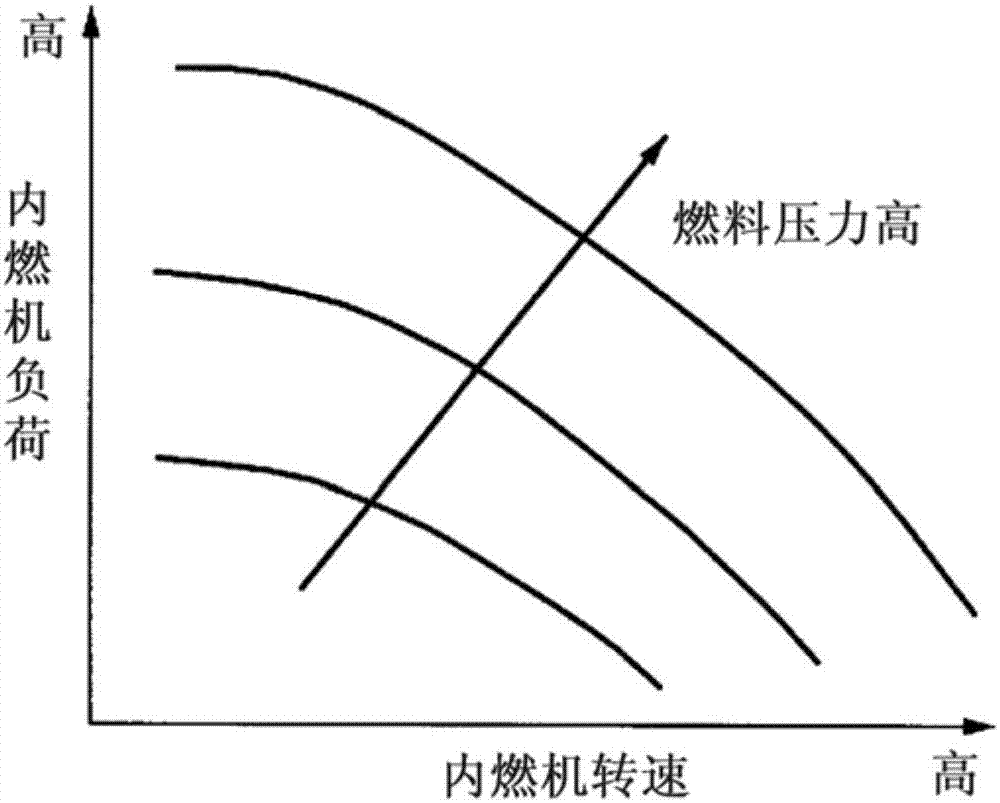

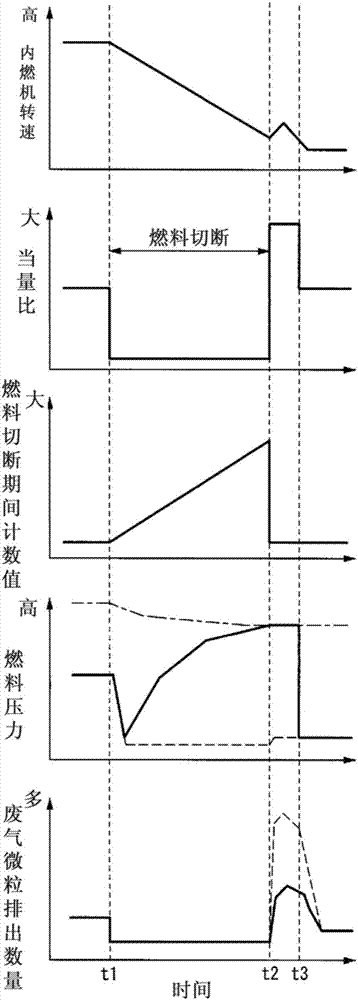

Control device for internal combustion engines

InactiveCN106922160AReduce the amount of adhesionPromote micronizationElectrical controlMachines/enginesExternal combustion engineVaporization

A control device for internal combustion engines, having: a first fuel injection valve that injects fuel directly into a combustion chamber; and a pressure regulator capable of changing the fuel pressure supplied to the first fuel injection valve. When prescribed fuel cut conditions are met, a fuel cut is implemented whereby fuel injection by the first fuel injection valve is stopped. When prescribed fuel cut recovery conditions are met during fuel cut, fuel injection by the first fuel injection valve is recommenced. When fuel injection is recommenced after fuel cut, the fuel pressure supplied to the first fuel injection valve is set higher than the normal fuel pressure determined in accordance with the driving state. As a result, spray atomization and vaporization are promoted and the exhaust particle discharge amount and the number of discharged exhaust particles can be suppressed, when recommencing fuel injection after fuel cut has ended.

Owner:NISSAN MOTOR CO LTD

Fuel injection valve

InactiveCN102893018APromote micronizationMachines/enginesSpecial fuel injection apparatusCavitationEngineering

Disclosed is a fuel injection valve with a suction chamber disposed in the tip thereof and comprising: a nozzle body with a nozzle hole that opens into the suction chamber; a needle slidably positioned in the nozzle body and which forms a fuel introduction path to the suction chamber between said needle and the nozzle body; and a cylindrical control element that is positioned by a positioning unit disposed between an upper edge section of the suction chamber in the nozzle body and the needle hole and which is displaced towards the upstream side such that the position of an upstream-side edge section approaches the needle, when the needle lifts for the fuel to flow into the suction chamber. A narrow distance between the upstream-side edge section and the needle can be maintained, cavitation can be continually generated, and atomization of fuel can be promoted, by the upstream-side edge section approaching the needle.

Owner:TOYOTA JIDOSHA KK

Fuel injector nozzle plate

InactiveCN105190020APromote micronizationIncrease the degree of micronizationFuel injection apparatusMachines/enginesInjector nozzleEngineering

Owner:ENPLAS CORP

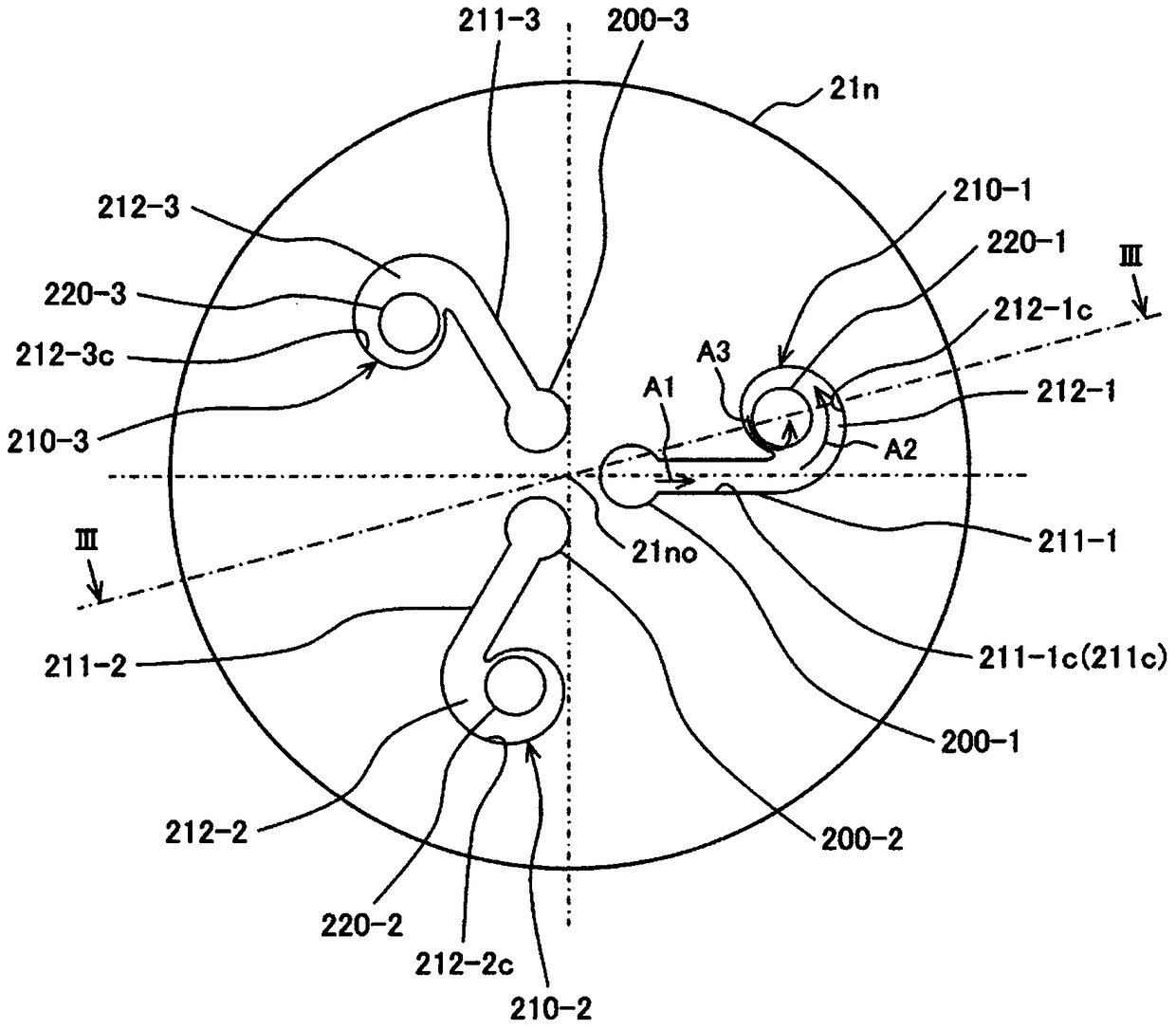

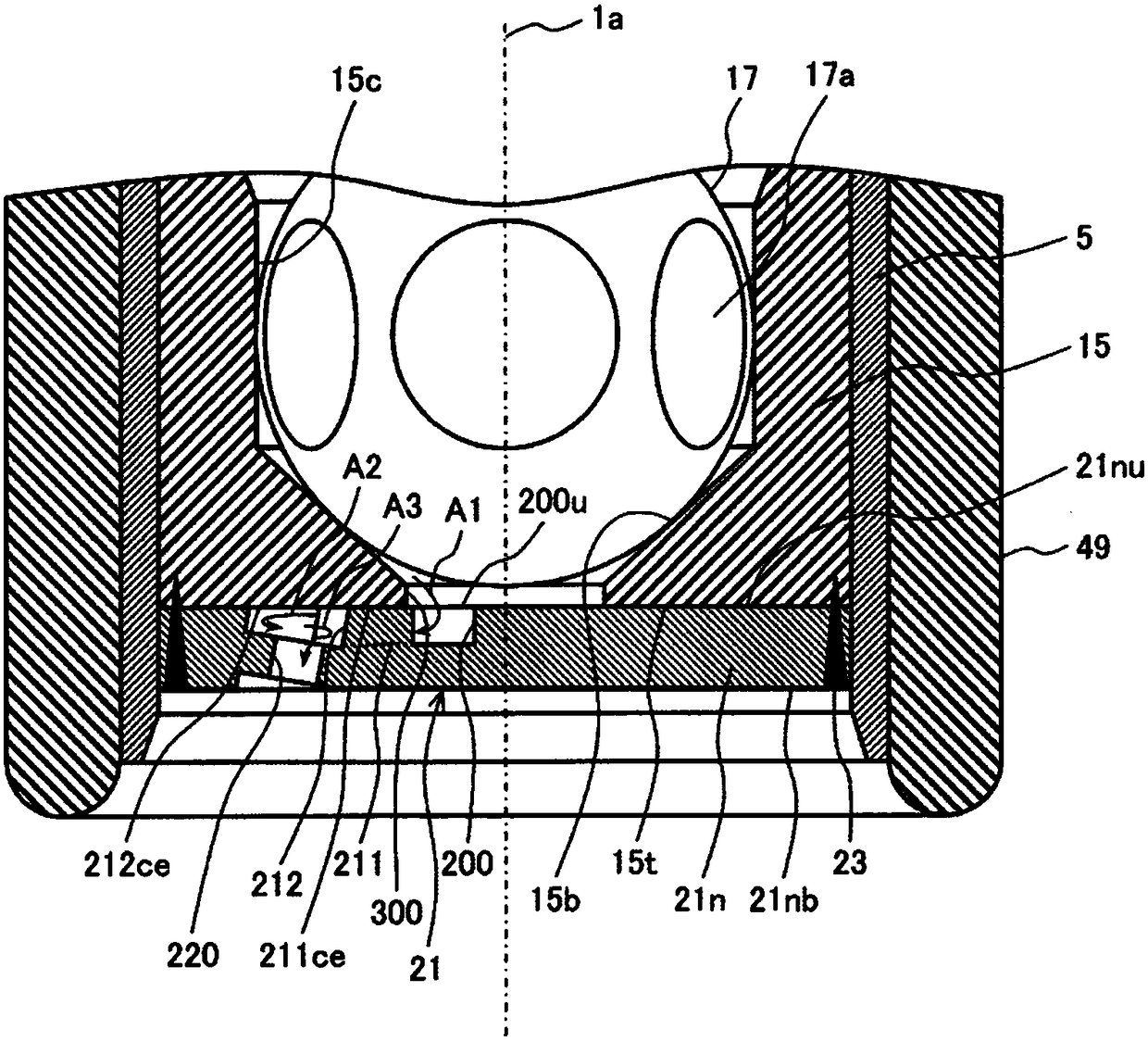

fuel injection valve

ActiveCN104895720BPromote micronizationImprove productivityFuel injection apparatusMachines/enginesPlatinum catalystOxide

An object of the present invention is to provide a fuel injection valve that can inject swirling fuel in a direction inclined with respect to the central axis of the fuel injection valve, has excellent fuel atomization, and has high productivity. The fuel injection valve has a fuel injection hole (220) and a swirl chamber (212) on the downstream side of the valve seat (15b). An inlet of the fuel injection hole (220) is opened and a fuel swirl flow path is provided around the inlet. ; The transverse passage (211) supplies fuel to the swirl chamber (212), and at least joins the plate-shaped member (21n) formed with the fuel injection hole (220), the bottom surface of the swirl chamber (212), and the bottom surface of the transverse passage (211) In the front end surface (15t) of the nozzle body side having the valve seat (15b), the contact portion (21nu) between the plate-shaped member (21n) and the front end surface (15t) of the nozzle body side is composed of a flat surface, The bottom surface of the swirl chamber (212) is formed to be inclined relative to the plane of the abutment portion (21nu), and the central axis of the fuel injection hole (220) is formed perpendicular to the bottom surface of the swirl chamber (212).

Owner:HITACHI ASTEMO LTD

fuel injection valve

ActiveCN105121834BPromote micronizationIncrease freedomMachines/enginesSpecial fuel injection apparatusFuel injectionValve seat

The present invention provides a fuel injection valve, wherein each injection hole is composed of an injection hole main body and a large-diameter portion adjacent to the downstream of the injection hole main body to form an outlet of the injection hole. When each nozzle hole is vertically projected onto a plane perpendicular to the axis of the valve seat, the inlet center and outlet center of the nozzle body on the plane are arranged on radial straight lines passing through the axis of the valve seat respectively, and the center of the outlet It is arranged in a direction away from the axis of the valve seat relative to the center of the inlet. The center of the large-diameter portion deviates from the straight line, so that the length of the inner wall of the spray hole on the side of the valve seat axis is asymmetrical with respect to the straight line.

Owner:MITSUBISHI ELECTRIC CORP

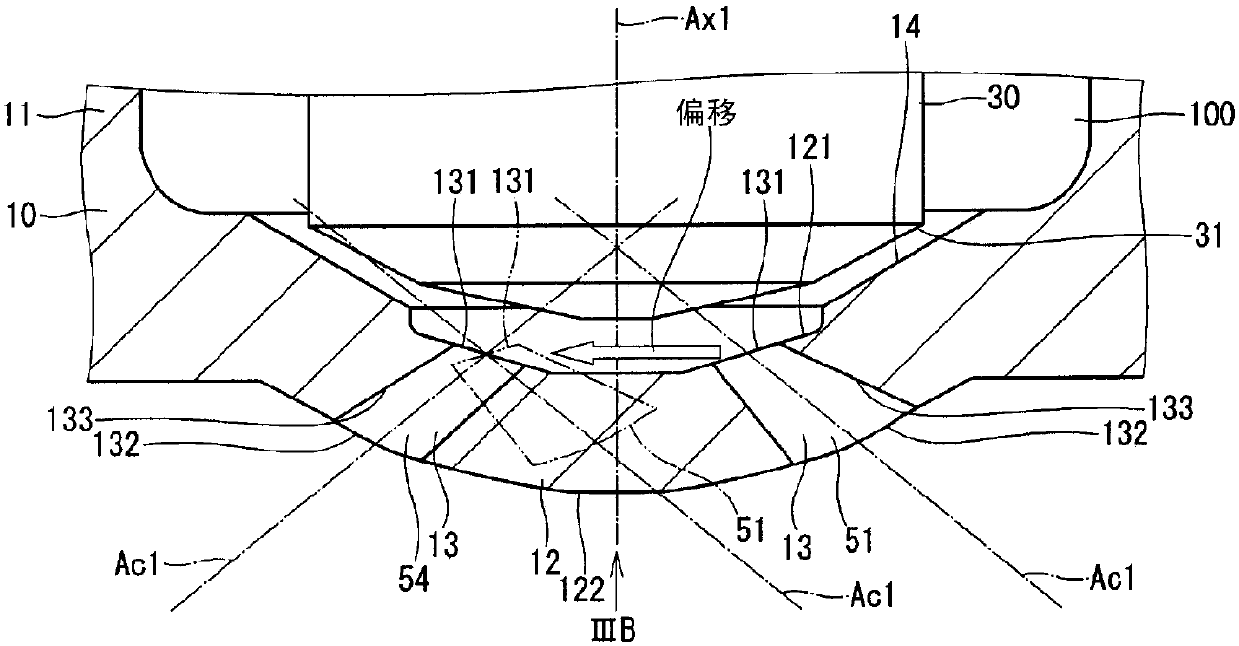

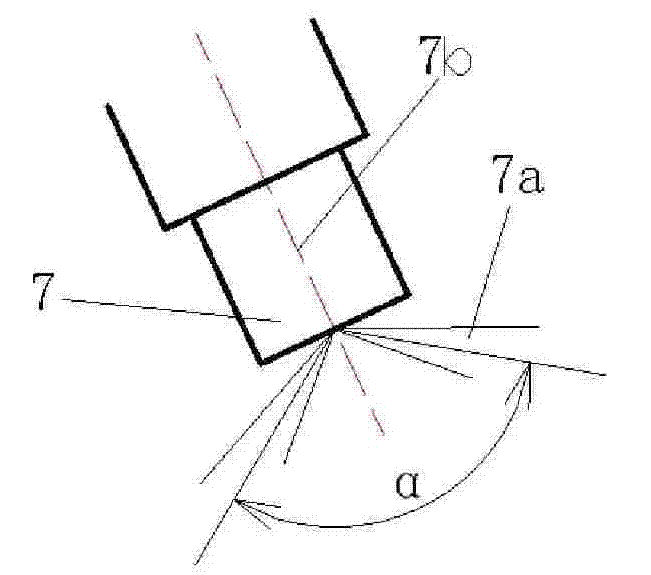

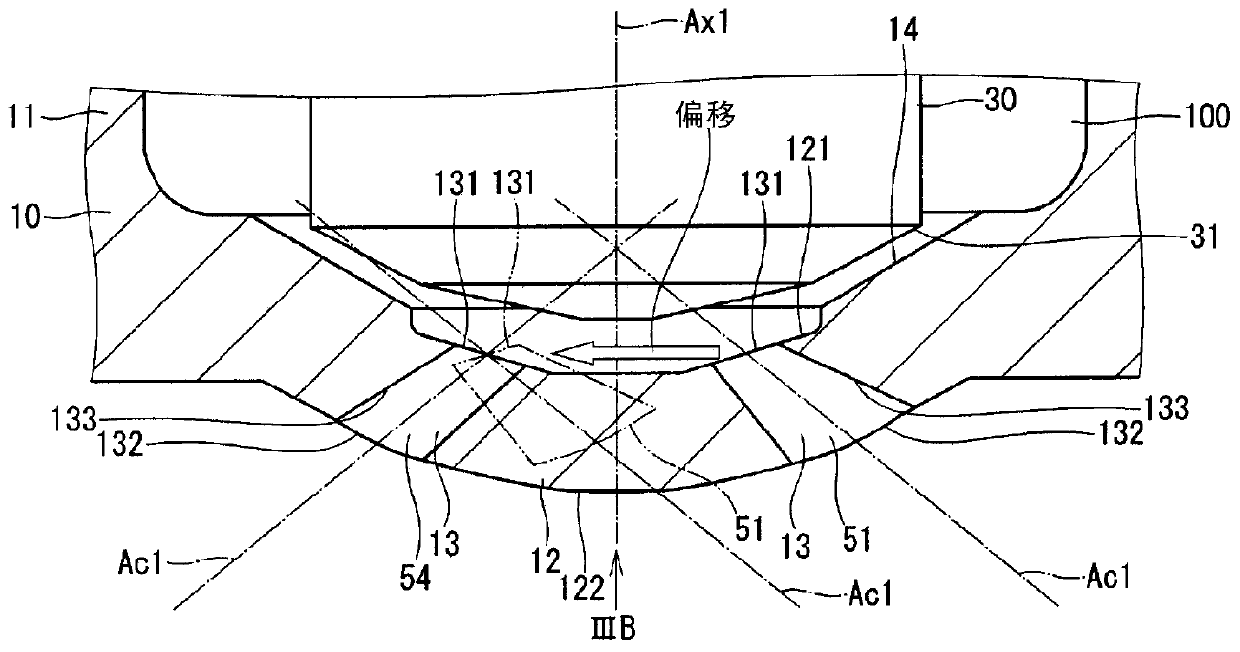

Fuel injection device

ActiveCN107850029AImprove consumption capacityImprove robustnessInternal combustion piston enginesFuel injection apparatusEngineeringVirtual plane

In the present invention, injection holes 13 are formed so as to satisfy a relationship [gamma]amin>=[theta]a1 + [theta]a2 + 0.5 * P<0.6>, where: [gamma]amin(deg) is an inter-injection-hole angle of two injection holes (13) of a combination, from among all combinations of two injection holes (13), having a minimum inter-injection-hole angle, which is an angle formed between central axes (Ac1) of the holes when offset so that the central axes (Ac1) overlap at an entrance opening (131); [theta]a1 and [theta]a2 (deg) are, respectively, taper angles that are angles formed by a contour of an injection hole inner wall (133) in a cross-section based on a virtual plane including the central axes (Ac1) of each of the injection holes (13) at which the inter-injection-hole angle is minimum; and P (MPa) is the mean pressure of fuel in a fuel passage (100) when fuel is injected from the injection holes (13).

Owner:DENSO CORP

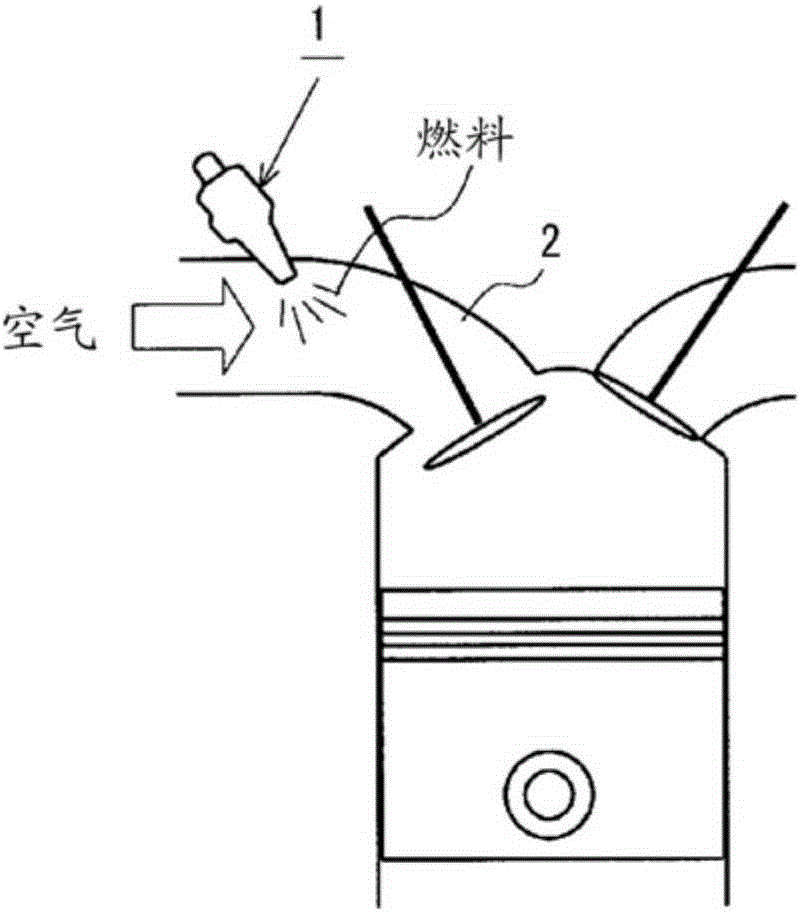

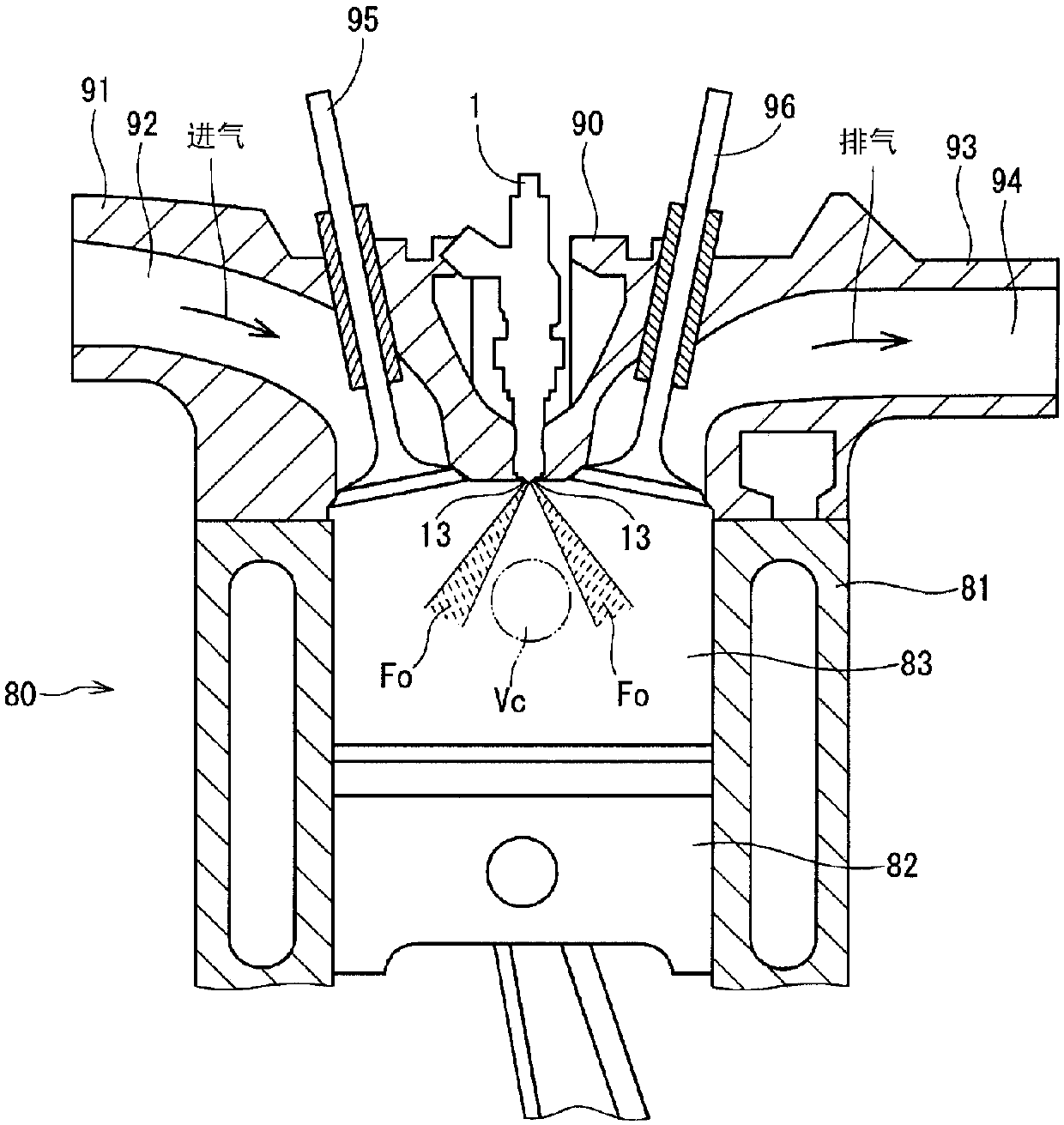

Vortex chamber combustion system utilizing umbrella-shaped spray

InactiveCN101655029BWell mixedEfficient mixingInternal combustion piston enginesCombustion systemEngineering

The invention relates to a vortex chamber combustion system utilizing umbrella-shaped spraying, which belongs to the fields of formation and combustion of engine mixing gases. The vortex chamber combustion system utilizing an oil nozzle with an umbrella-shaped spraying has the structural characteristics that the center line of the oil nozzle with an umbrella-shaped spraying way is superposed withthe center line of a main passage so that the air which flows into a vortex chamber from a compression stroke via the main passage turns back along the wall surface of the vortex chamber to form vortex after reaching the vicinity of the head part of the oil nozzle; the direction of the vortex is just along the diffused direction of the umbrella-shaped spraying so as to accelerate oil and gas mixture and improve the combustion. Because the characteristics of short penetrating distance, even circumferential distribution and high granulation of the umbrella-shaped spraying are reasonably utilized, the favorable mixture and combustion can be obtained at lower vortex strength, thereby reducing heat dissipation loss and throttling loss and further improving the heat efficiency of an engine. Experiments on a single-cylinder 195 diesel engine indicate that the power is improved by 10 percent, the oil consumption is reduced by 8 percent, the discharge of NOx is reduced by 10 percent and the discharge of soot is reduced by 20 percent after the vortex chamber combustion system utilizing the oil nozzle with a umbrella-shaped spraying way is adopted.

Owner:DALIAN UNIV OF TECH

fuel injection device

ActiveCN107850029BImprove consumption capacityImprove robustnessInternal combustion piston enginesFuel injection apparatusEngineeringFuel injection

The angle formed by the central axes (Ac1) when the central axes (Ac1) are shifted so as to overlap at the inlet opening (131) in all combinations of the two injection holes (13) is The angle between the two nozzle holes (13) of the combination of the smallest angle between the nozzle holes is set as γamin (deg), and the respective central axes (Ac1 ) on the section taken by the virtual plane of the injection hole (133), that is, the angle formed by the contour of the injection hole inner wall (133), that is, the cone angle is respectively set as θa1, θa2 (deg), and the fuel passage (100) when injecting fuel from the injection hole (13) The average pressure of the fuel is set as P (MPa), then the injection hole (13) is formed to satisfy γamin≥θa1+θa2+0.5×P 0.6 Relationship.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com