Structural lipid for replacing lard and preparation method thereof

A technology of structural lipids and lard, which is applied in the fields of edible oil/fat, application, food science, etc., can solve the problems of increased equipment requirements and tedious preparation process, and achieve the effect of improving antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

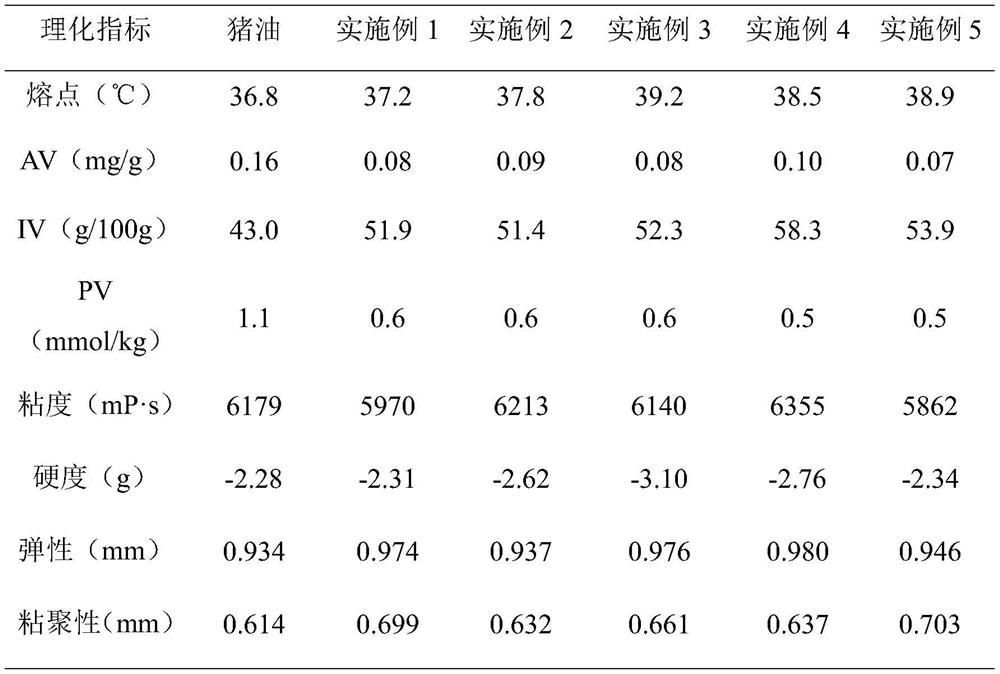

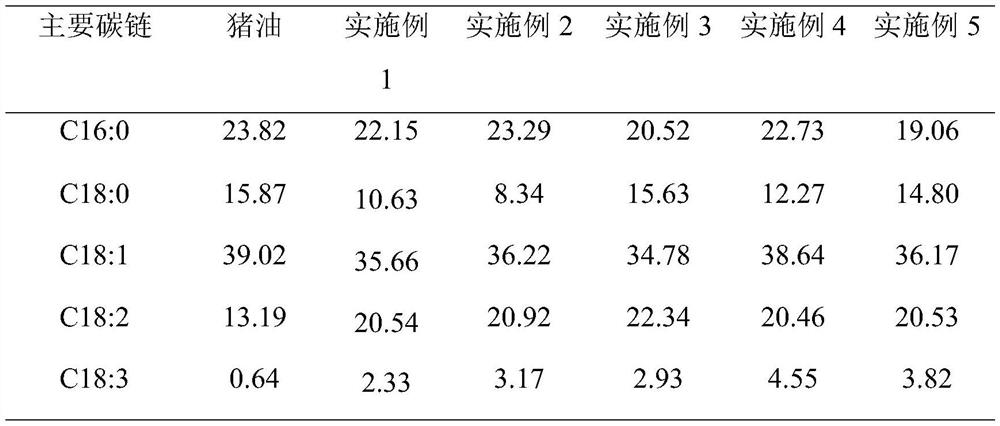

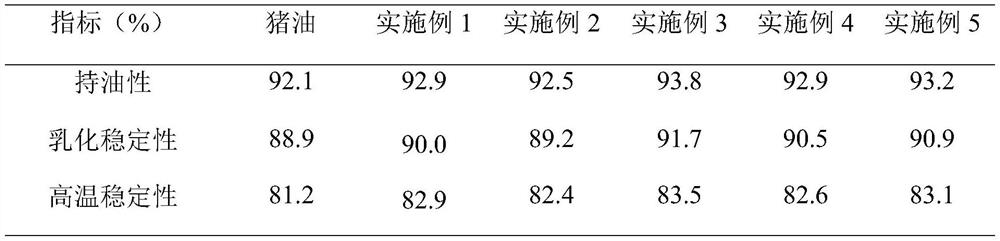

Examples

Embodiment 1

[0046] A structural lipid consisting of the following components by mass: 28 parts of palm stearin at 52°C, 30 parts of shea butter fraction at 28°C, 42 parts of soybean oil, 0.05 parts of palm wax, glycerol monostearate 0.8 part of ester, 0.3 part of soybean lecithin, 0.2 part of sucrose fatty acid ester and 0.2 part of lard essence.

[0047] Its preparation process is as follows:

[0048] 1) Melt palm stearin at 52°C, shea butter fraction and soybean oil at 28°C respectively to a homogeneous liquid state, and prepare 28 parts of palm stearin at 52°C, 30 parts of palm oil at 28°C, and 42 parts of soybean oil. Proportional mixing, then adding 0.3 parts of sodium methoxide for chemical transesterification to obtain transesterified oil;

[0049] 2) Add 0.05 part of palm wax, 0.8 part of glyceryl monostearate, 0.3 part of soybean lecithin, 0.2 part of sucrose fatty acid ester and 0.2 part of lard essence to the obtained transesterified oil, heat and stir at 80°C for 20 minutes t...

Embodiment 2

[0054] A structural lipid consisting of the following components by mass: 25 parts of palm stearin at 52°C, 40 parts of shea butter fraction at 28°C, 35 parts of sunflower oil, 0.5 parts of palm wax, monostearic acid 0.5 part of glyceride, 0.2 part of soybean lecithin, 0.1 part of sucrose fatty acid ester, 0.2 part of lard essence.

[0055] Its preparation process is as follows:

[0056] 1) Melt palm stearin at 52°C, shea butter fraction at 28°C and sunflower oil respectively into a homogeneous liquid state, and prepare 25 parts of palm stearin at 52°C, 40 parts of shea butter fraction at 28°C, The ratio of 35 parts of sunflower oil is mixed, and then 0.3 part of sodium methylate is added for chemical transesterification to obtain transesterified oil;

[0057] 2) Add 0.5 part of palm wax, 0.5 part of glyceryl monostearate, 0.2 part of soybean lecithin, 0.1 part of sucrose fatty acid ester and 0.2 part of lard essence to the obtained transesterified oil, heat and stir at 80°C ...

Embodiment 3

[0062] A structural lipid, consisting of the following components by mass: 25 parts of palm stearin at 52°C, 30 parts of shea butter, 45 parts of soybean oil, 0.2 parts of palm wax, 0.6 parts of glyceryl monopalmitate, soybean 0.2 parts of lecithin, 0.2 parts of lard essence.

[0063] Its preparation process is as follows:

[0064] 1) Melt palm stearin, shea butter and soybean oil at 52°C respectively into a homogeneous liquid state, and mix according to the ratio of 25 parts of palm stearin at 58°C, 30 parts of shea butter, and 45 parts of soybean oil, and then Add 0.3 parts of sodium methoxide for chemical transesterification to obtain transesterified oil;

[0065] 2) Add 0.2 parts of palm wax, 0.6 parts of glyceryl monopalmitate, 0.2 parts of soybean lecithin and 0.2 parts of lard essence to the obtained transesterified oil, heat and stir at 80°C for 20 minutes to obtain a mixed oil, and pre-cool to 45 ℃;

[0066] 3) Place the obtained mixed oil in an ice bath for rapid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com