Atomizer, combustion device including atomizer, and gas turbine plant

A technology of spray nozzles and gas turbines, which is applied in the direction of combustion equipment, gas turbine devices, mechanical equipment, etc. It can solve the problems of shortened mixing time of the flow channel, easy wear of the wall surface, and insufficient mixing, so as to promote micronization and inhibit wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

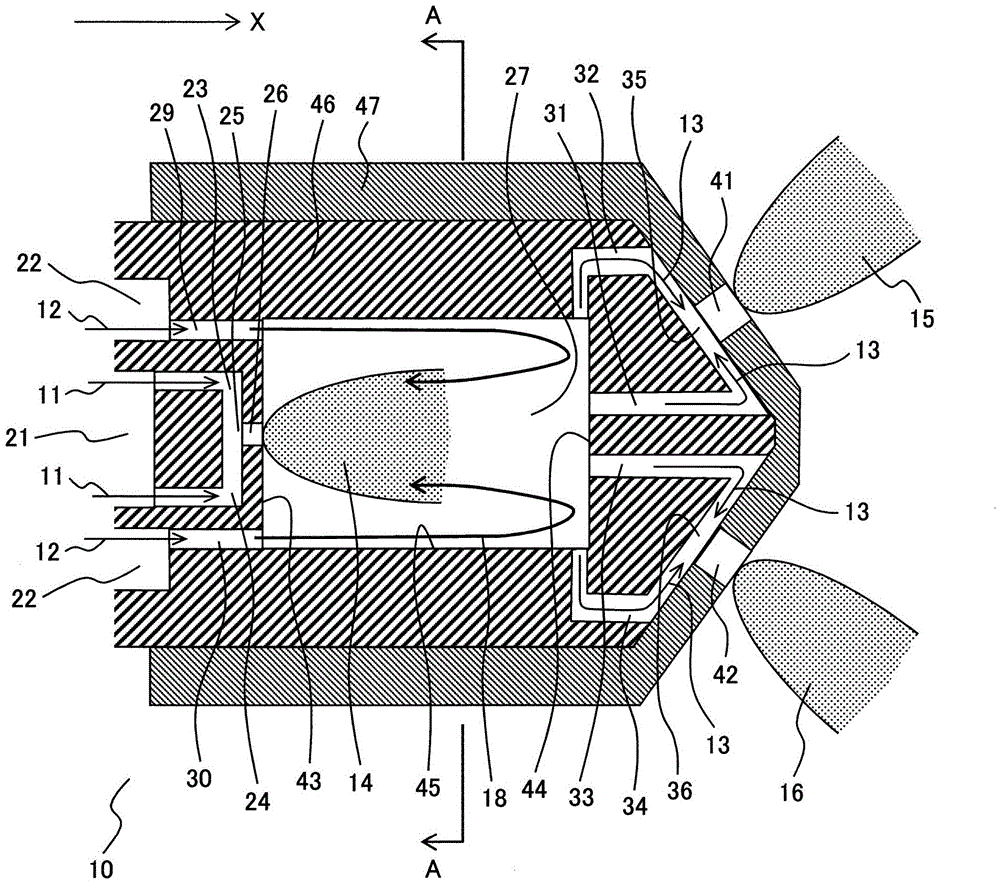

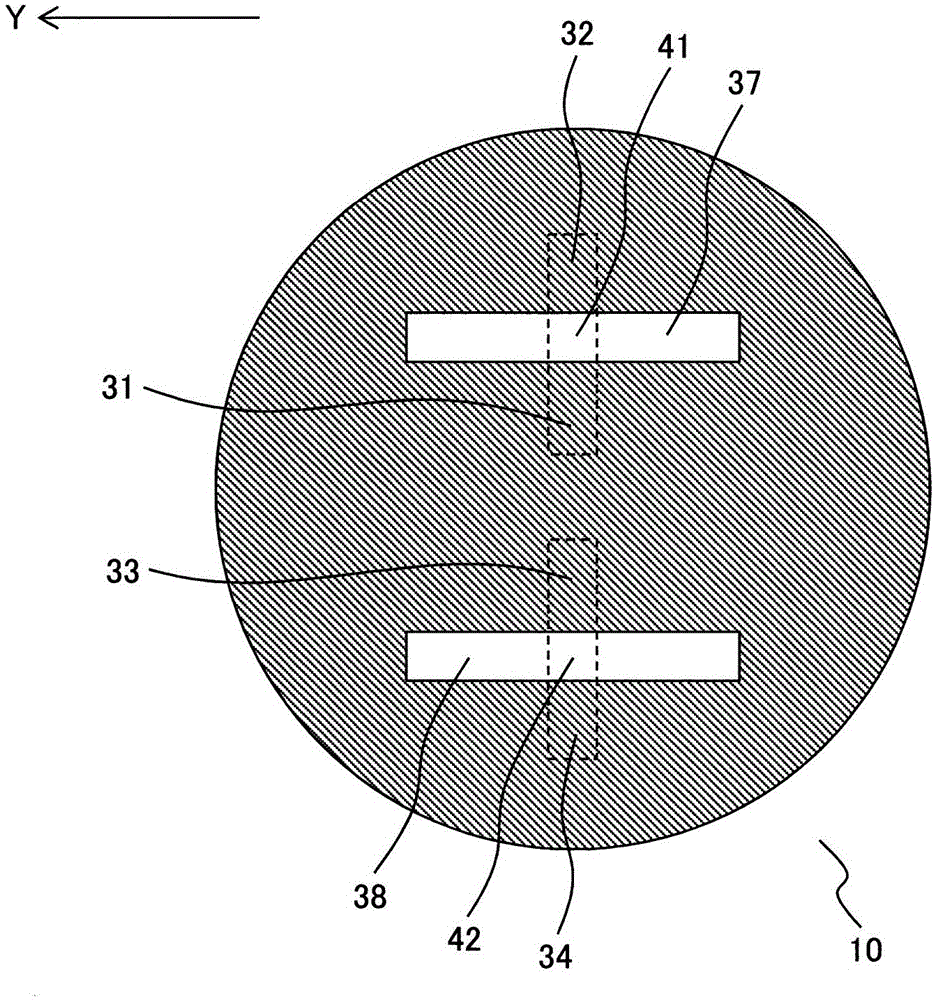

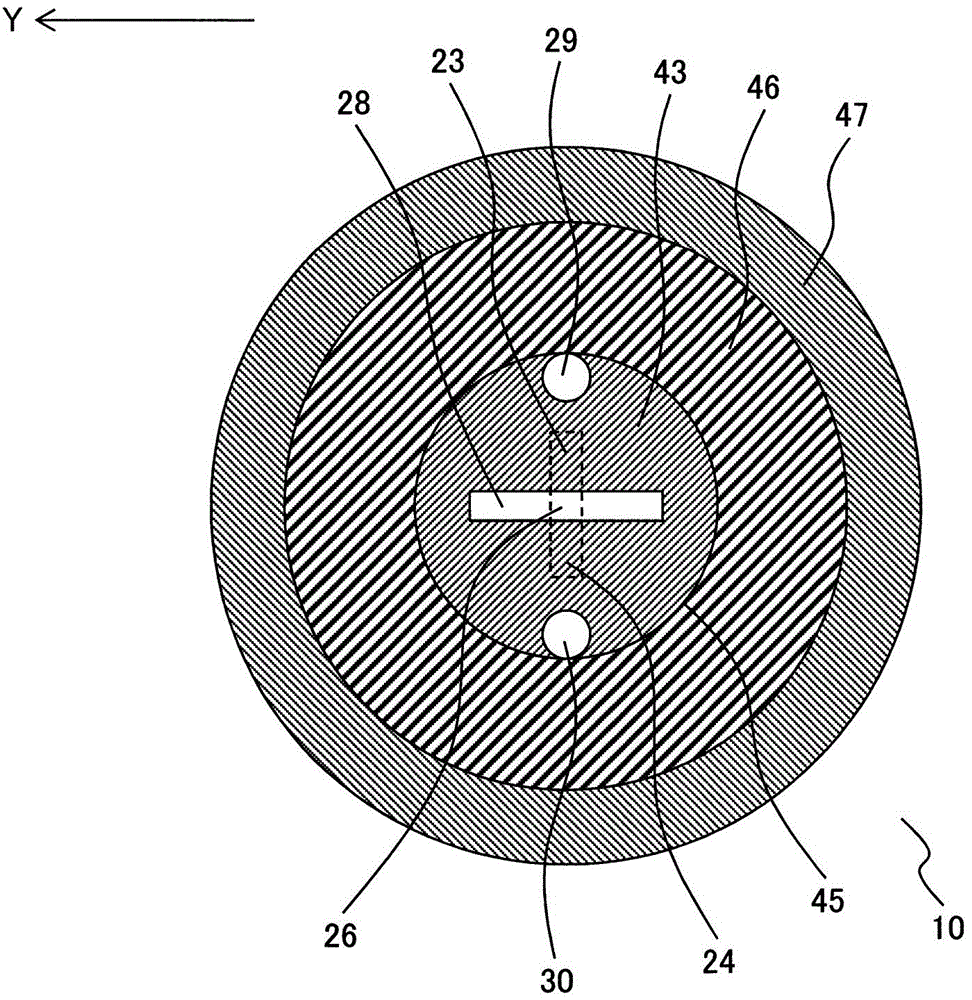

[0035] use Figure 1 to Figure 8 The spray nozzle 10 of the first embodiment of the present invention will be described.

[0036] figure 1 It is a sectional view along the axial direction (X direction) of the tip portion of the spray nozzle 10 of this embodiment. exist figure 1 Among them, the X direction is the axial direction of the spray nozzle 10 and is the supply direction of the spray fluid. figure 2 It is viewed from the downstream side of the supply direction of the spray fluid 11 figure 1 Front view of the spray nozzle 10. image 3 yes figure 1 The cross-sectional view of the spray nozzle 10 on the cutting line A-A is a cross-sectional view of the spray nozzle 10 viewed from the downstream side in the supply direction of the spray fluid at the position of the internal mixing chamber 27 of the spray nozzle 10 . exist figure 2 , 3 , the Y direction is the radial direction of the spray nozzle 10 .

[0037] in addition, Figure 4 It is a cross-sectional view a...

Embodiment 2

[0097] use Figures 9 to 11 The spray nozzle 50 of the second embodiment of the present invention will be described.

[0098] Figure 9 It is a sectional view along the axial direction (X direction) of the tip portion of the spray nozzle 50 of this embodiment. exist Figure 9 In , the X direction is the axial direction of the spray nozzle 50 and is the supply direction of the spray fluid. Figure 10 Viewed from the downstream side of the spray fluid supply direction Figure 9 Front view of the spray nozzle 50. Figure 10 Viewed from the downstream side of the spray fluid supply direction Figure 9 Front view of the spray nozzle 50. Figure 11 yes Figure 9 A cross-sectional view of spray nozzle 50 cut along line A-A. It is a cross-sectional view of the spray nozzle 50 viewed from the downstream side in the supply direction of the spray fluid at the position of the internal mixing chamber 27 of the spray nozzle 50 . exist Figure 10 , Figure 11 , the Y direction is ...

Embodiment 3

[0121] use Figure 12 A combustion device including a spray nozzle according to an embodiment of the present invention will be described. In this embodiment, a gas turbine combustor is exemplified as a combustion device including a spray nozzle. In this embodiment, the gas turbine combustor is provided with the spray nozzle 10 shown in the first embodiment, but may be provided with the spray nozzle 50 shown in the second embodiment.

[0122] Figure 12 It is a schematic diagram showing the overall structure of a gas turbine facility provided with a gas turbine combustor 67 according to this embodiment. Figure 12The gas turbine plant shown includes a compressor 66 , a gas turbine combustor 67 , a turbine 68 and a generator 69 . The compressor 66 compresses the air to generate high-pressure combustion air 61 , and supplies it to the gas turbine combustor 67 . The gas turbine combustor 67 is a combustion device that introduces combustion air 61 and fuel 62 (liquid fuel), bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com