Fuel injection valve

A fuel injection valve and fuel injection technology, which is applied in the direction of fuel injection devices, charging systems, engine components, etc., can solve the problems of specification changes, hindrances to swirling, and inability to spray angles, etc., to achieve good uniformity and reduce impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

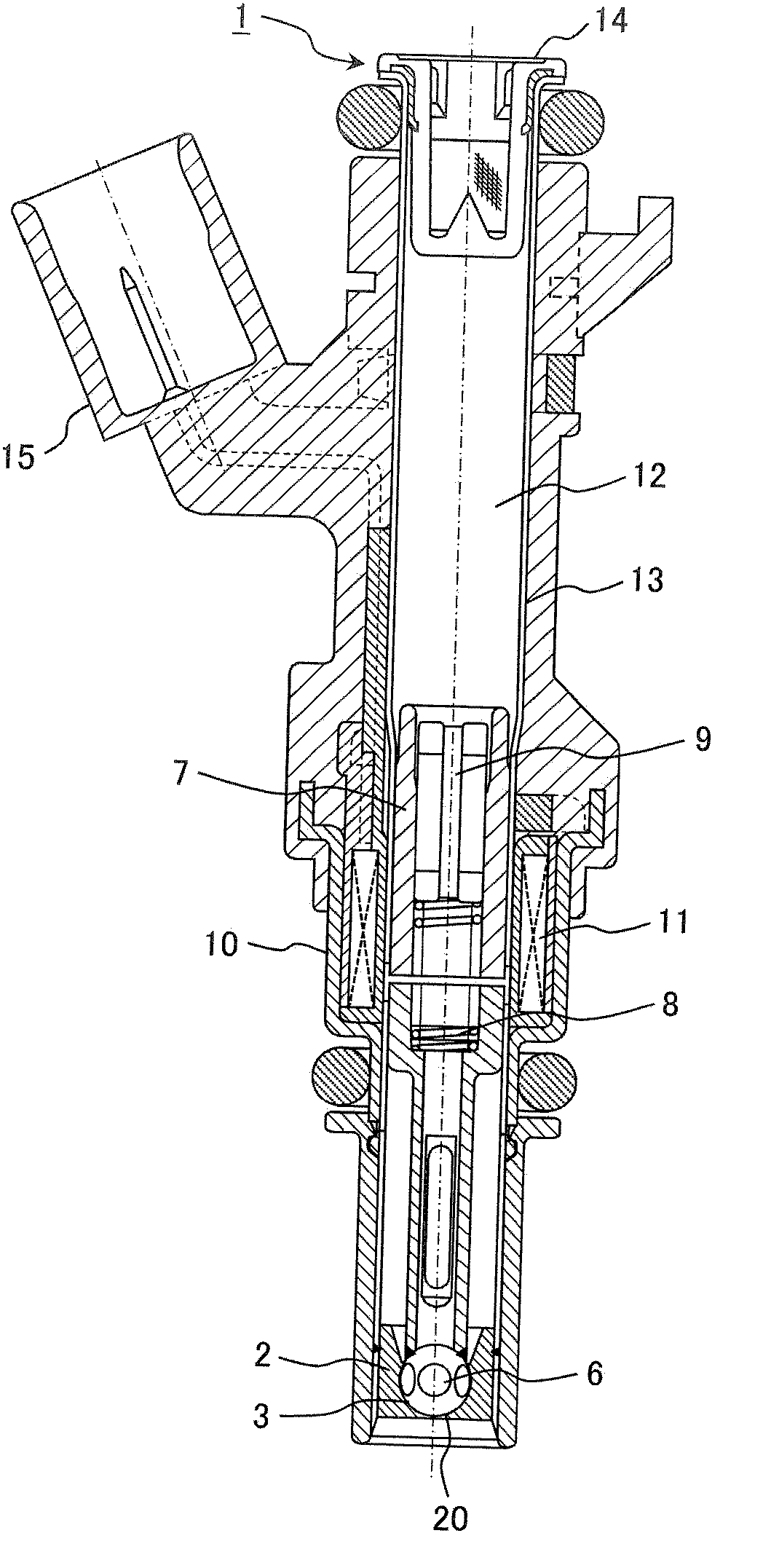

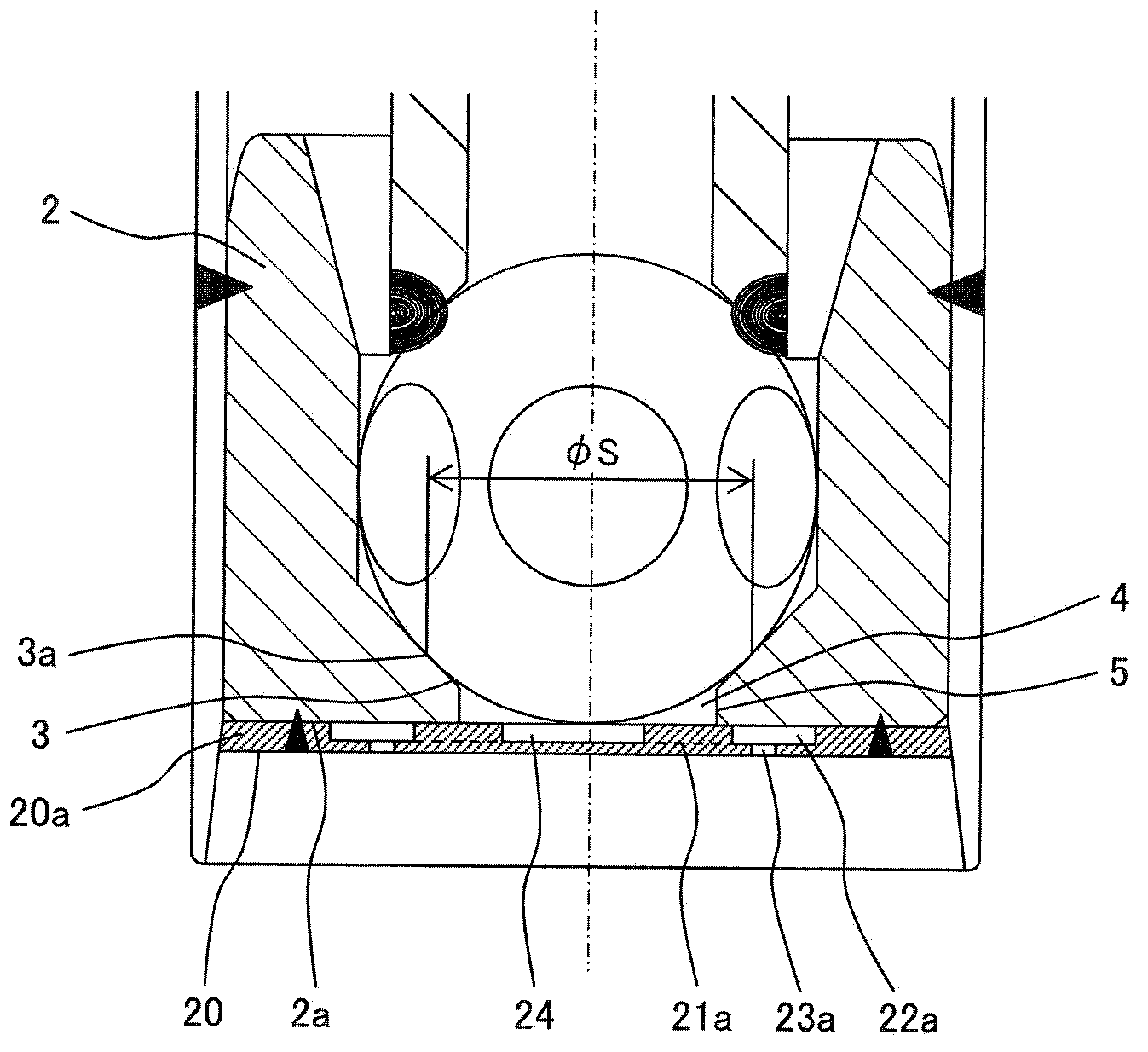

[0036] An embodiment of the present invention will be described below. figure 1 It is a longitudinal sectional view showing the overall configuration of the fuel injection valve 1 of the present invention. exist figure 1 Among them, the fuel injection valve 1 has a structure in which the nozzle body 2 and the valve body 6 are accommodated in a stainless steel thin-walled pipe 13, and the valve body 6 is reciprocated (opened and closed) by an electromagnetic coil 11 arranged outside. . Hereinafter, a detailed structure will be described.

[0037] Equipped with: a magnetic yoke 10 surrounding the electromagnetic coil 11; a magnetic core 7 positioned at the center of the electromagnetic coil 11 and having one end in magnetic contact with the yoke 10; a valve body 6 lifted by a predetermined amount; The valve seat surface 3 of the valve body 6 and the valve seat surface 3 are allowed to pass through the fuel injection chamber 4 through the gap between the valve body 6 and the v...

Embodiment 2

[0083] ・Effect on formation of thickness necessary for processing and flow area

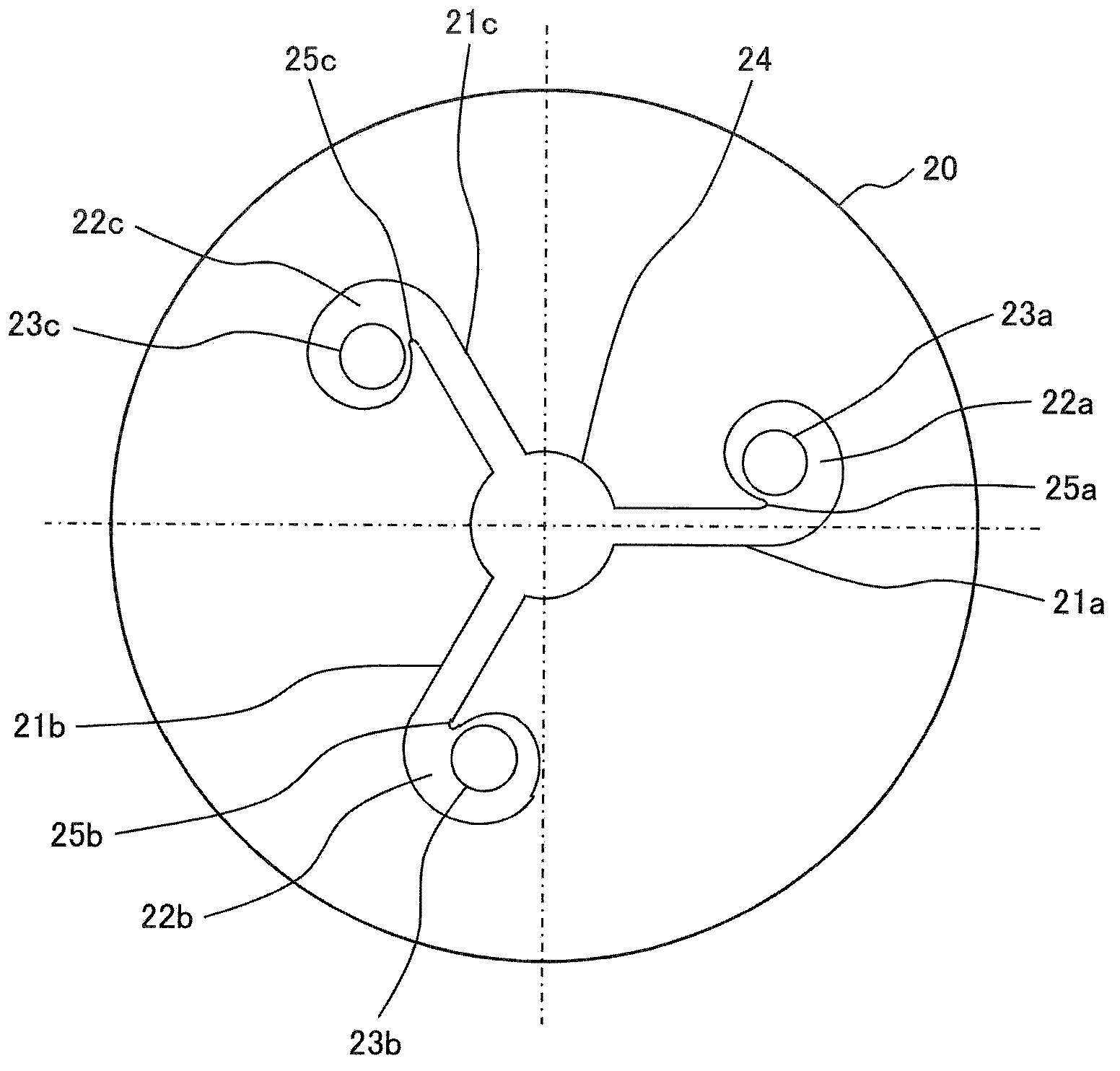

[0084] Below, combine Figure 5 , the thickness 25a necessary for processing to form the connecting portion of the swirl passage 21a and the swirl chamber 22a will be described. Figure 5 It is a figure which shows the relationship of the swirl passage 21a, the swirl chamber 22a, and the fuel injection hole 23a.

[0085] The extension line 22e of the spiral curve drawn by the side wall (wall surface along the height direction) 21ae of the swirl passage 21a and the extension line 22e of the inner peripheral wall of the swirl chamber 22a is rotated (turned) by 180 degrees or more from the starting point S sa of the spiral curve The angular ranges of do not intersect. Thereby, 25a which is a substantial thickness can be formed between the side wall 21ae and the spiral curve drawn by the inner peripheral wall of the swirl chamber 22a.

[0086]Here, the circular portion 25a, which is a thickness ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com