Gas turbine combustor

a combustor and gas turbine technology, applied in the direction of hot gas positive displacement engine plants, combustion processes, lighting and heating apparatus, etc., can solve the problems of inability to achieve uniform mixing of premixed air-fuel mixtures with even concentration distribution, short premixing length, and inability to idealize leaned premixing combustion, etc., to facilitate the mixing of compressed air and fuel, facilitate the premixing, and facilitate the effect of further premixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

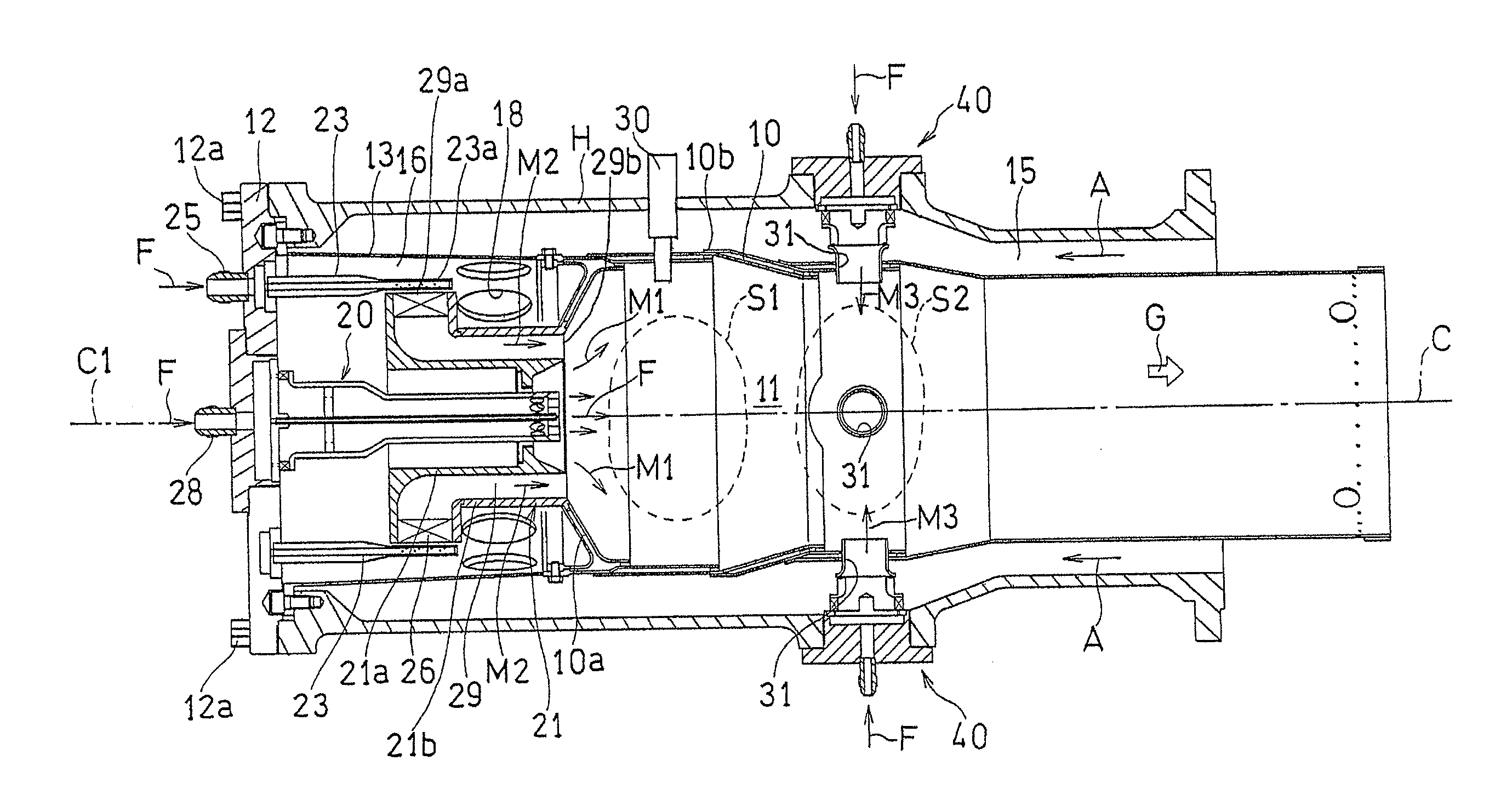

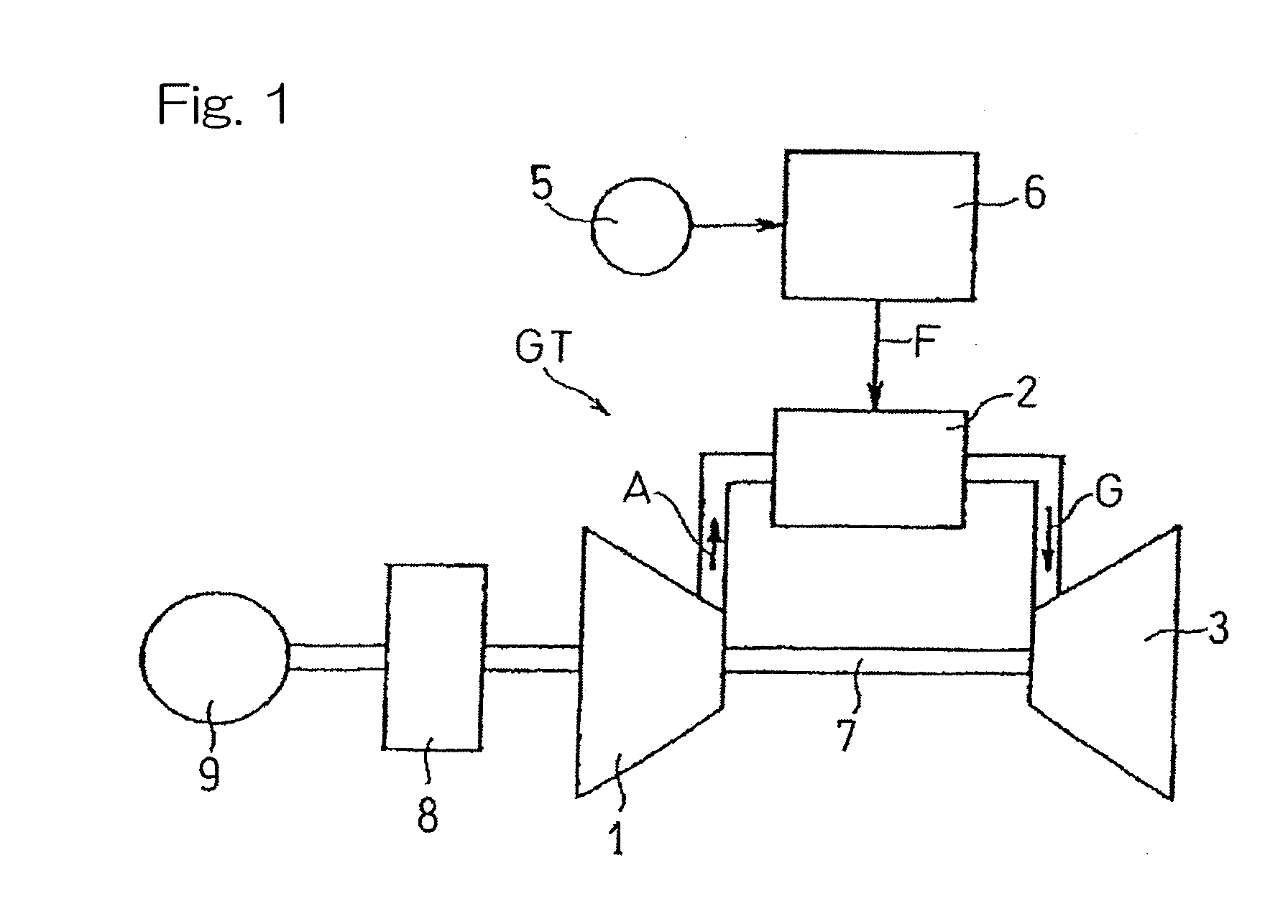

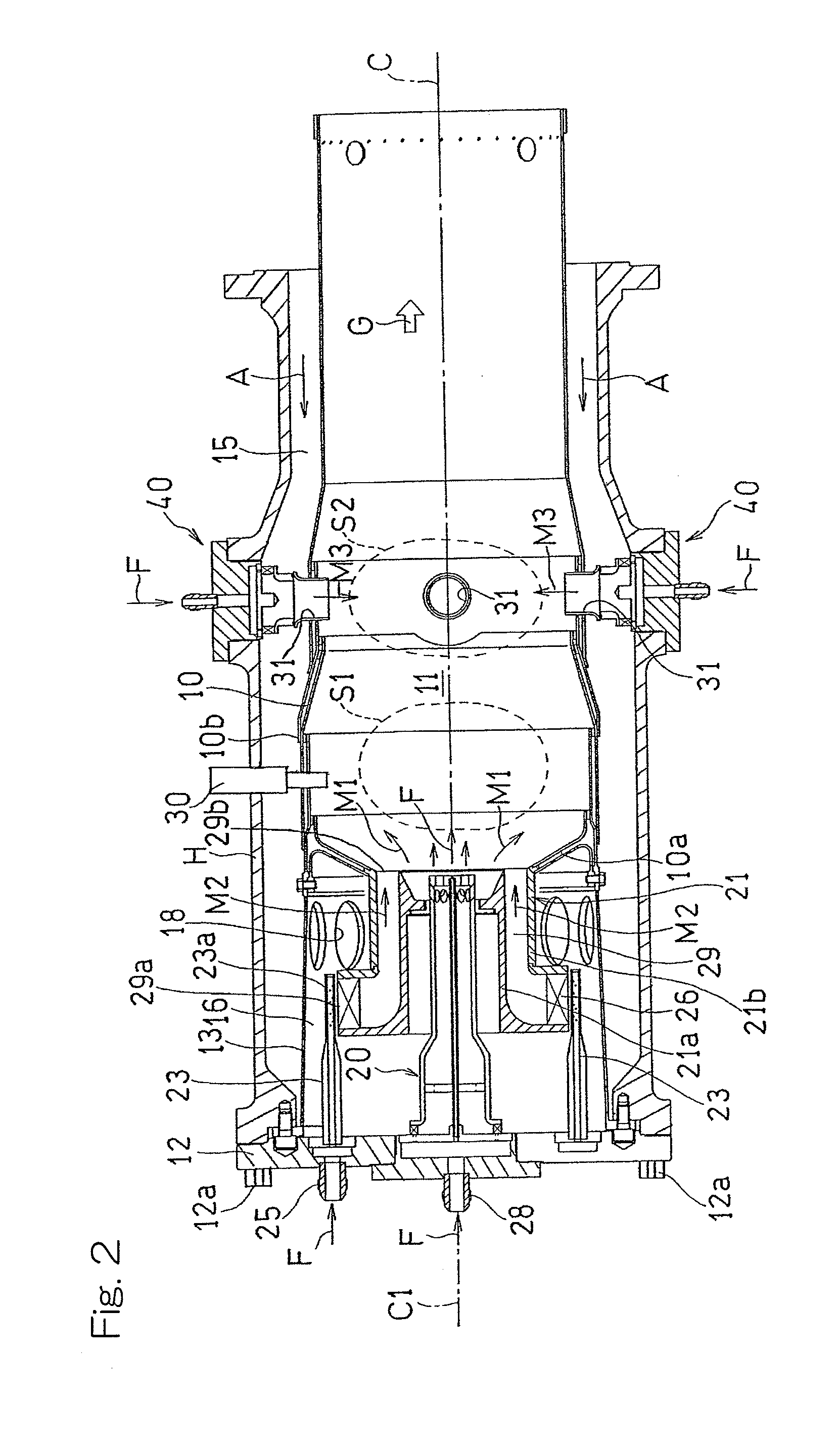

[0028]Hereinafter, a gas turbine combustor designed in accordance with an embodiment of the present invention will be described in detail with reference to the accompanying drawings. Referring to FIG. 1 showing a schematic structure of a gas turbine generator in which the gas turbine combustor of the embodiment is employed, the gas turbine generator GT includes, as principal constituent elements thereof, a compressor 1, a combustor 2 and a turbine 3. The combustor 2 is provided with a fuel supply device 5 and a fuel control device 6. A compressed air A, fed from the compressor 1, and fuel F fed from the fuel supply device 5 through the fuel control device 6 are burned within the combustor 2 to produce a combustion gas G of high temperature and high pressure, which is in turn supplied to the turbine 3 to drive the turbine 3. The compressor 1 is driven by the turbine 3 through a rotary shaft 7. The turbine 3 also drives an electric generator 9 through a reduction gear unit 8.

[0029]As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com