Exhaust gas purifying device of internal combustion engine

An exhaust gas purification device and internal combustion engine technology, applied in exhaust devices, internal combustion piston engines, noise reduction devices, etc., can solve the problems of inability to send out air from the reductant injection device, increase of particles and unburned fuel, and difficulty in reaction, etc., to achieve suppression Generation of particulates and discharge of unburned fuel, good spray state, and effects of eliminating waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0053] 〔1-1〕Overall composition

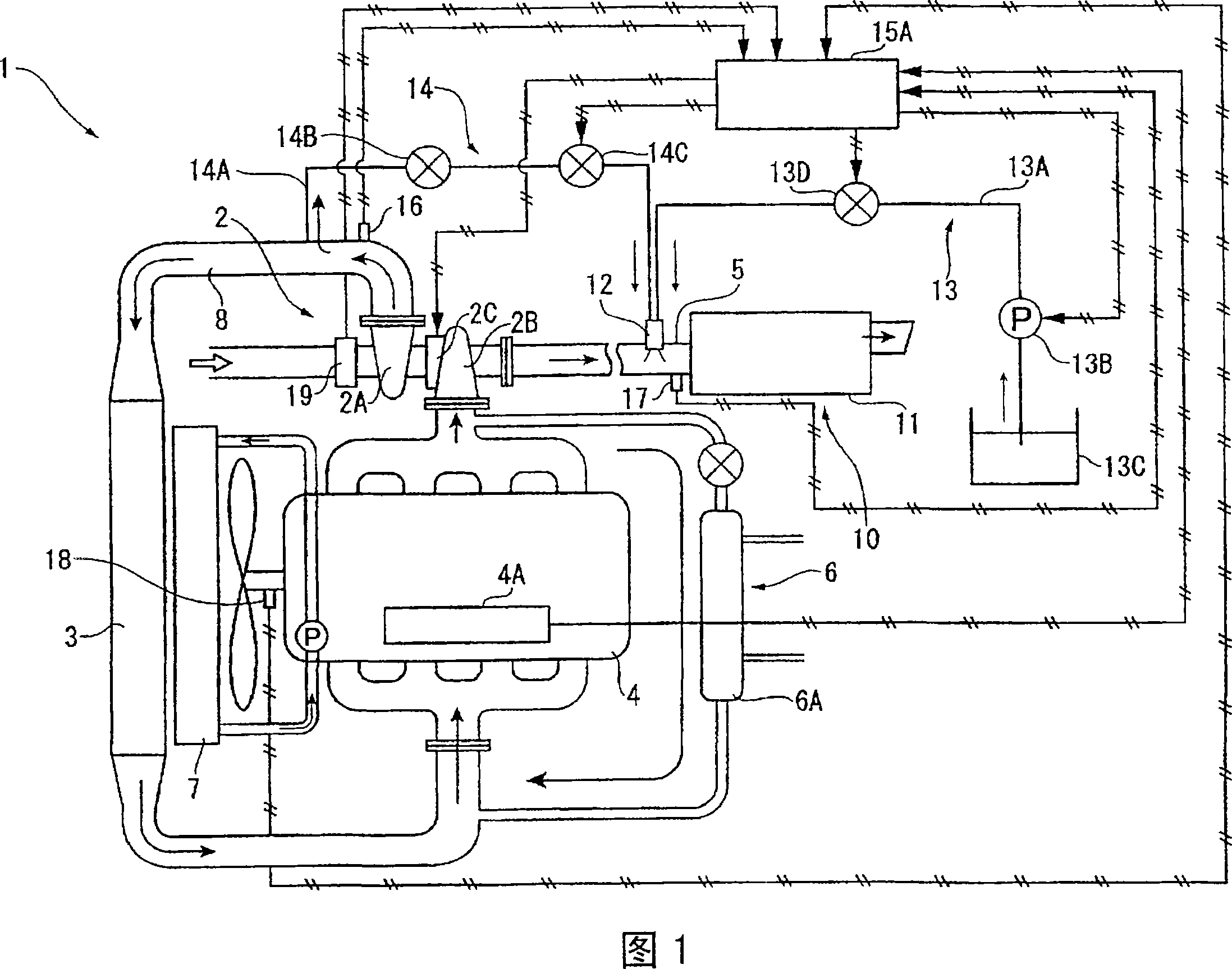

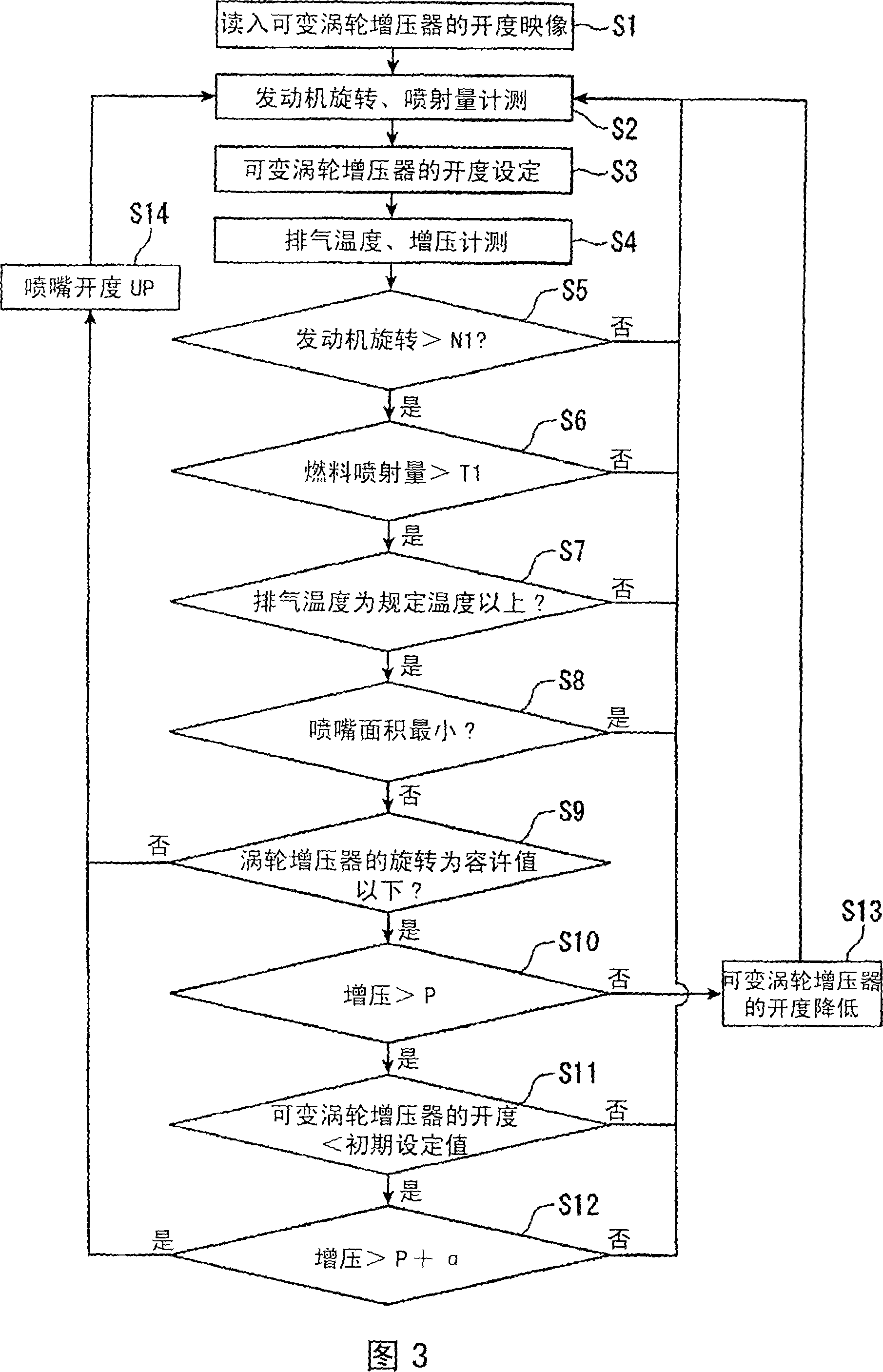

[0054] FIG. 1 is a schematic view showing one revolution of a diesel engine (internal combustion engine) equipped with an exhaust gas purification device 10 according to a first embodiment of the present invention.

[0055] A diesel engine (hereinafter simply referred to as an engine) 1 includes a variable exhaust turbocharger 2 . The supercharged air from the supercharger 2A side of the variable exhaust turbocharger 2 is supplied to the engine main body 4 through an after cooler 3, and the exhaust gas from the engine main body 4 is cooled by the variable exhaust turbocharger. The compressor 2B of 2 rotates and discharges through the exhaust gas passage 5.

[0056] In addition, in the engine 1 of this embodiment, an EGR (Exhaust Gas Recirculation) device 6 is provided, and a part of the exhaust gas returned from the exhaust manifold to the intake manifold suppresses the concentration of oxygen in the combustion chamber, and the combustion is ...

no. 2 approach

[0118] Next, a second embodiment of the present invention will be described. In addition, in the following description, the same part as what has already been explained is given the same code|symbol, and abbreviate|omits or abbreviates description.

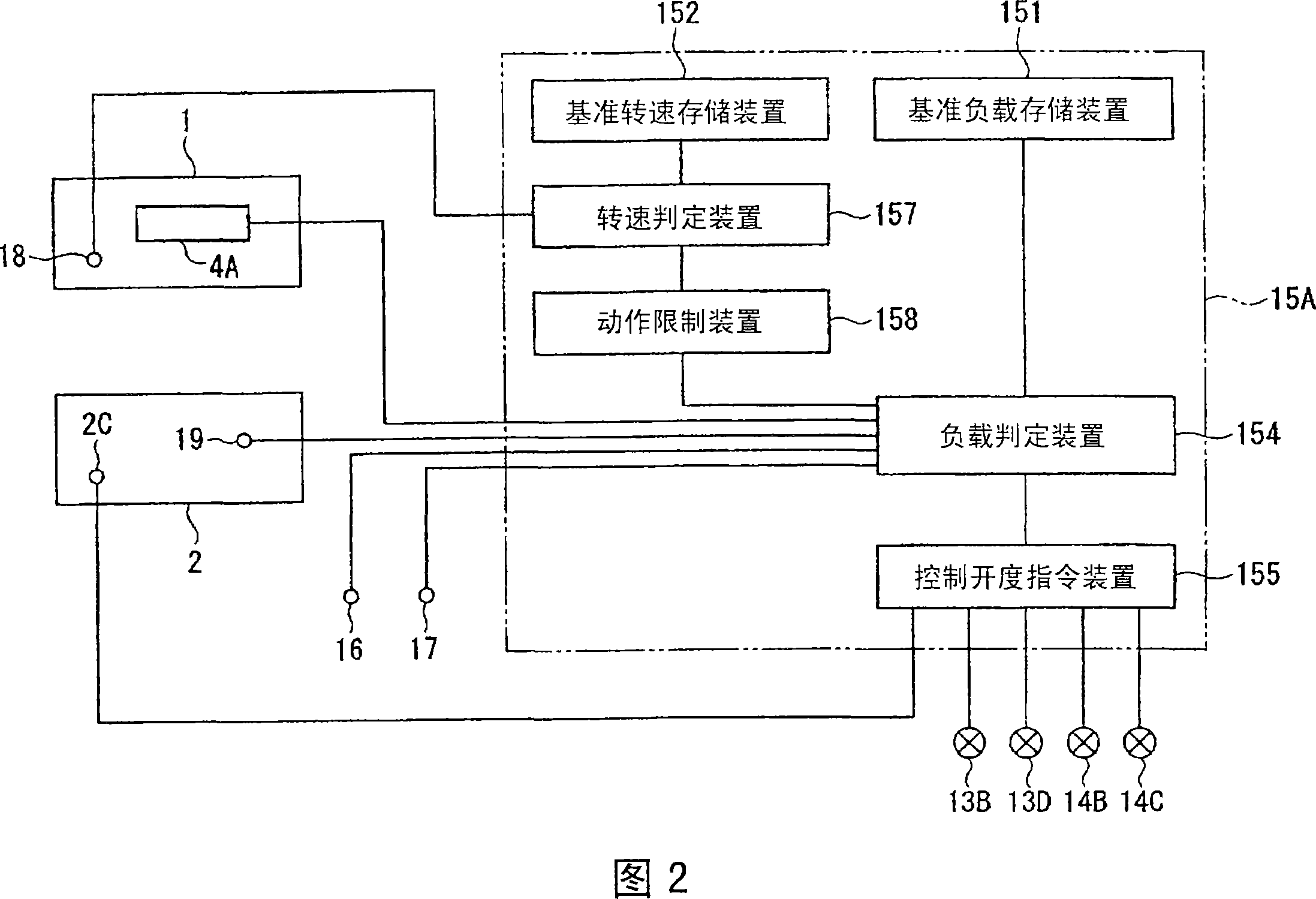

[0119] In the above-mentioned first embodiment, feedback control is performed, and the control of adjusting the nozzle opening is adopted according to the detection results of loads such as combustion injection amount, boost pressure, and exhaust temperature, and the rotational speeds of the engine and the variable exhaust turbocharger. method.

[0120] In contrast, in the second embodiment, the opening degree is uniquely controlled using the opening degree control pattern stored in the opening degree control pattern storage device 153 according to the fuel injection amount and the engine speed without feedback control, that is, the so-called Feedforward control is different from the first embodiment.

[0121] First, the structu...

no. 3 approach

[0133] FIG. 7 shows an exhaust gas purification device 10 according to a third embodiment of the present invention. In this embodiment, an air tank 14D is provided between the outlet side of the supercharger 2A and the on-off valve 14C on the air take-out passage 14A, and an air tank 14D is provided between the air tank 14D and the outlet side of the supercharger 2A. The difference from the first embodiment is that the pressure control valve 14E is not a check valve. Other configurations and control methods are the same as those of the first embodiment.

[0134] Furthermore, the air tank 14D of the present embodiment functions as an accumulator for storing air pressure for supplying to the reducing agent spraying device 12 . In addition, the pressure control valve 14E, when the accumulated pressure of the air tank 14D reaches a predetermined value or more, opens the air take-out passage 14A on the upstream side thereof, so that the air sent from the supercharger 2A side is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com