Valve device for fuel injection valve

A technology of fuel injection valve and valve device, which is applied in the direction of fuel injection device, charging system, machine/engine, etc., can solve the problems of atomization of fuel spray, and achieve the reduction of fuel velocity, small pressure loss, and promotion of atomization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

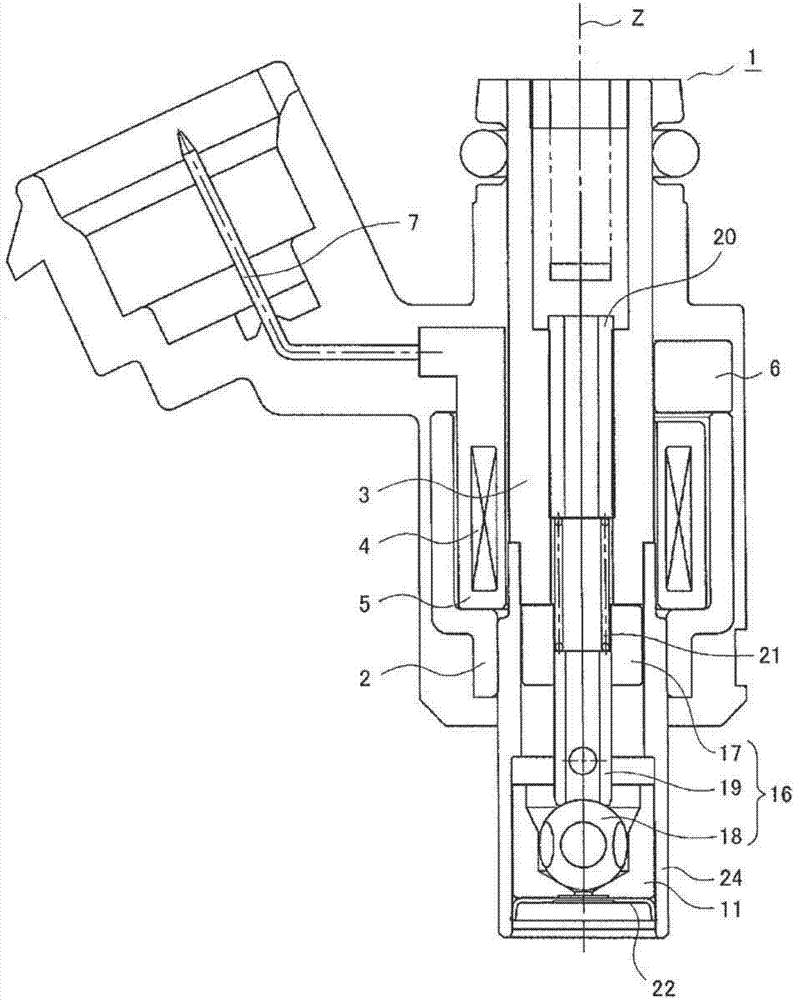

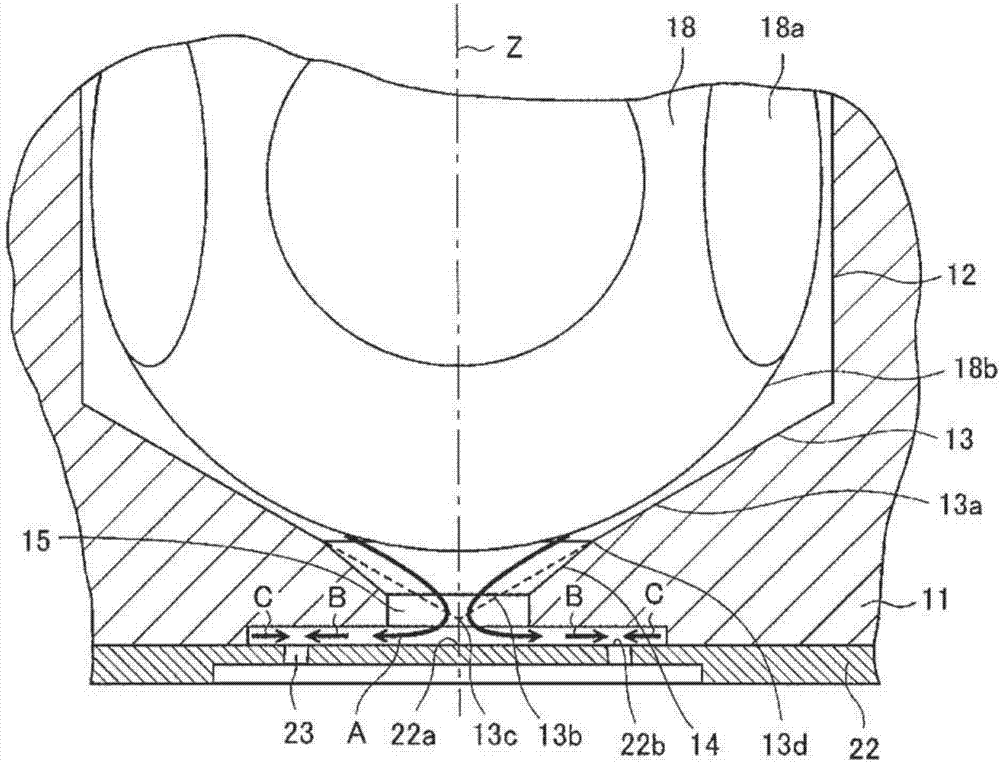

[0030] Next, the valve device of the fuel injection valve according to Embodiment 1 of the present invention will be described with reference to the drawings. figure 1 is a cross-sectional view of the fuel injection valve according to Embodiment 1 cut along a plane parallel to the central axis (indicated by Z in the figure), figure 2 is a partial cross-sectional view obtained by cutting the front end of the valve device on a plane parallel to the central axis, image 3 It is a partial cross-sectional view obtained by cutting the front end portion of the valve device along a plane perpendicular to the central axis. In addition, in each figure, the same code|symbol is attached|subjected to the same or corresponding part.

[0031] The fuel injection valve 1 includes an electromagnetic device that generates electromagnetic force, and a valve device that operates by energizing the electromagnetic device. The electromagnetic device includes: a two-stage cylindrical casing 2 that...

Embodiment approach 2

[0065] Figure 7 It is a partial cross-sectional view obtained by cutting the front end portion of the valve device according to Embodiment 2 of the present invention on a plane parallel to the central axis, Figure 8 is expressed in Figure 7 Top view of the orifice plate viewed from the side indicated by A-A in the valve arrangement shown. In addition, since the overall structure of the fuel injection valve according to the second embodiment is the same as that of the first embodiment, the figure 1 , omitting detailed descriptions of each part.

[0066] In the valve device according to the second embodiment, when the injection hole 23 is vertically projected on a plane perpendicular to the central axis Z, a straight line connecting the central axis Z and the inlet center 23a of the injection hole 23 ( Figure 8 L1 in the middle), and the straight line connecting the inlet center 23a of the nozzle hole 23 and the outlet center 23b of the nozzle hole 23 ( Figure 8 where ...

Embodiment approach 3

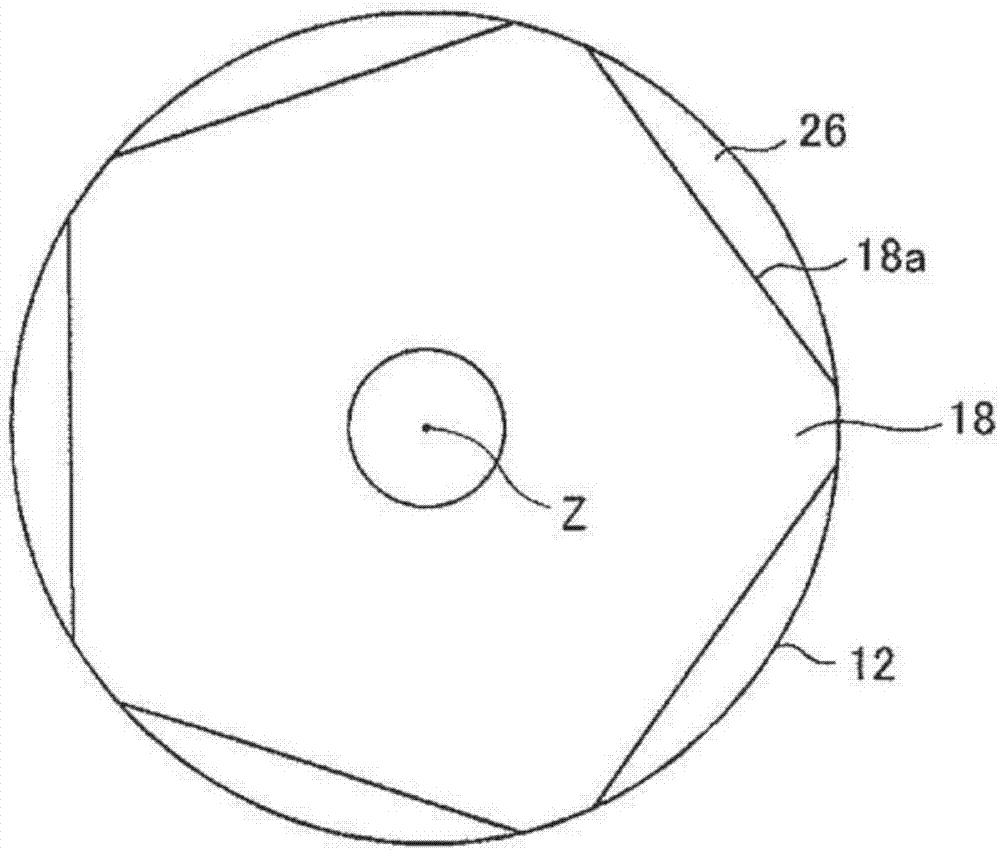

[0074] Figure 11 is a partial cross-sectional view obtained by cutting the front end portion of the valve device according to Embodiment 3 of the present invention in a direction parallel to the central axis, Figure 12 The part represented by A-A will Figure 11 A partial cross-sectional view of the front end of the valve assembly shown. also, Figure 12 In FIG. 3 , the nozzle holes 23 of the nozzle plate 22 are projected onto the valve ball 18 to show the positional relationship between the shape of the valve ball 18 and the nozzle holes 23 . The overall structure of the fuel injection valve according to Embodiment 3 is the same as that of Embodiment 1, so the figure 1 , omitting the detailed description of each part.

[0075] In the valve device according to Embodiment 3, the number of injection holes 23 is different from the number of slit surfaces 18 a. Five slit surfaces 18 a of the valve ball 18 are uniformly formed on the circumference of the valve body 16 . On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com