Fuel injector nozzle plate

A fuel injection device and fuel injection technology, applied in the direction of fuel injection devices, charging systems, engine components, etc., can solve the problems of insufficient particle size, fuel is not easy to form a sharp liquid film, etc., and achieve an improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

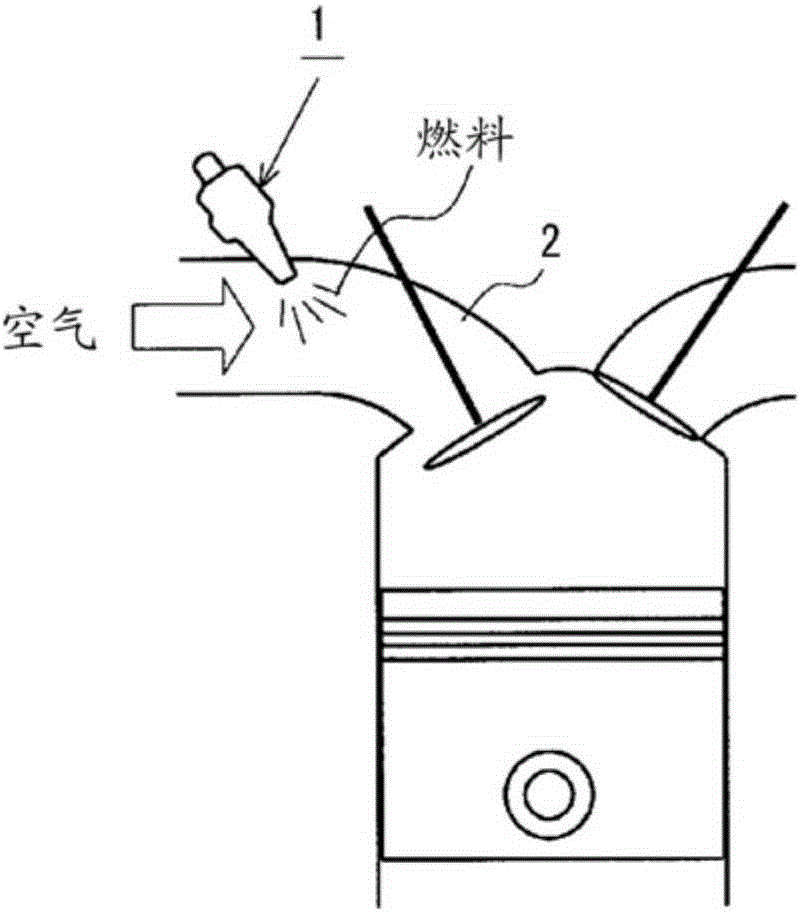

[0072] figure 1 It is a figure which schematically shows the usage state of the fuel injection apparatus 1 to which the nozzle plate for fuel injection apparatuses of this embodiment is attached. as it should figure 1 As shown, the port injection fuel injection device 1 is installed in the middle of the intake pipe 2 of the engine, injects fuel into the intake pipe 2, and mixes the air and fuel introduced into the intake pipe 2 to form a combustible mixture.

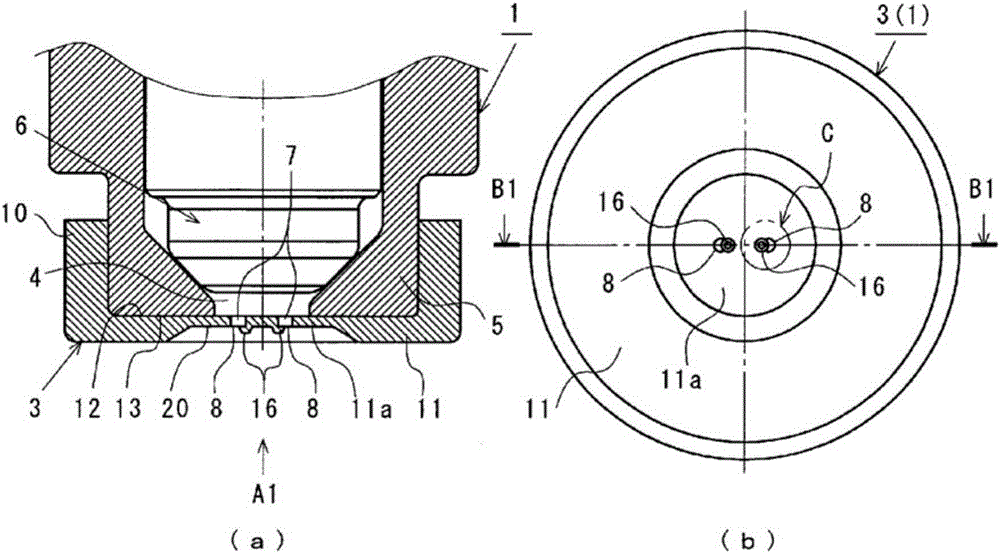

[0073] figure 2 It is a figure which shows the front-end side of the fuel injection apparatus 1 to which the nozzle plate 3 for fuel injection apparatuses (hereinafter referred to as a nozzle plate) is attached. also, figure 2 (a) is a front end side longitudinal sectional view of the fuel injection device 1 (along figure 2 (B1-B1 line B1-B1 cut off the cross-sectional view shown). in addition, figure 2 (b) is a bottom view of the front end side of the fuel injection device 1 (shown from figure 2 (a) A diag...

no. 2 approach

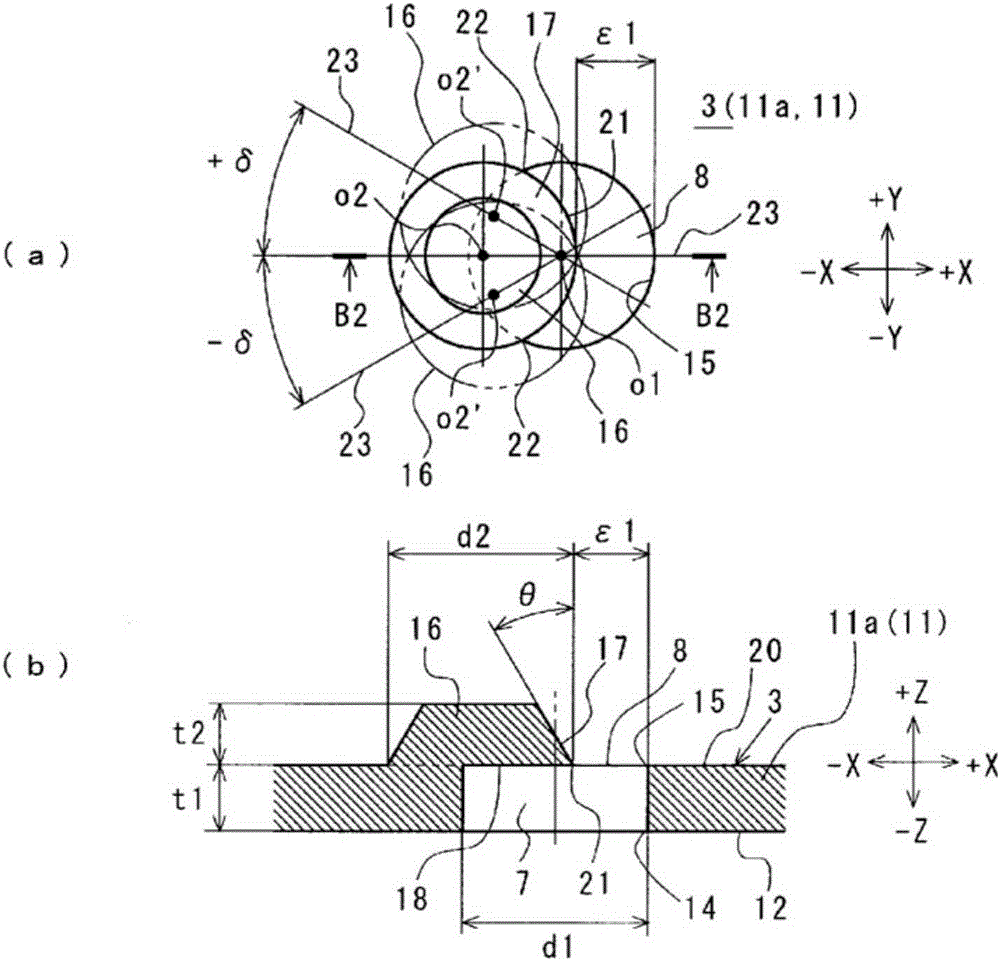

[0184] Figure 25 ~ Figure 27 It is an enlarged view showing a part of the nozzle plate 3 according to the second embodiment of the present invention. in, Figure 25 (a) is a plan view of the nozzle plate 3 (with image 3 (a) the corresponding figure), Figure 25 (b) is along Figure 25 (a) is a cross-sectional view of the nozzle plate 3 shown along the line B22-B22. in addition, Figure 26 (a) is a plan view of the first nozzle plate 3a, Figure 26 (b) is along Figure 26 (a) The sectional drawing of the 1st nozzle plate 3a cut|disconnected and shown by B23-B23 line. in addition, Figure 27 (a) is a plan view of the second nozzle plate 3b, Figure 27 (b) is along Figure 27 (a) is a cross-sectional view of the second nozzle plate 3 b cut along line B24 - B24 .

[0185] As shown in these figures, the nozzle plate 3 of this embodiment is comprised by overlapping the 1st nozzle plate 3a and the 2nd nozzle plate 3b which were press-formed metal plate (for example, stai...

no. 3 approach

[0190] Figure 28 ~ Figure 29 It is a figure which shows the nozzle plate 3 which concerns on the 3rd Embodiment of this invention. also, Figure 28 (a) is a front view of the nozzle plate 3, Figure 28 (b) is along Figure 28 (a) The cross-sectional view of the nozzle plate 3 shown by the B25-B25 line, Figure 28 (c) is a rear view of the nozzle plate 3 . Figure 29 (a) is Figure 28 An enlarged view of the central portion of the nozzle plate 3 shown in (a), Figure 29 (b) is along Figure 29 (a) is a cross-sectional view of the central portion of the nozzle plate 3 indicated by the line B26-B26.

[0191] Such as Figure 28 ~ Figure 29 As shown, the nozzle plate 3 of this embodiment is a bottomed cylindrical body in which a cylindrical wall portion 10 and a bottom wall portion 11 formed to close one end of the cylindrical wall portion 10 are integrally formed. The bottom wall portion 11 has a nozzle orifice plate portion 50 in which the nozzle hole 7 opens and an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com