Patents

Literature

70results about How to "Eliminate agglomeration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

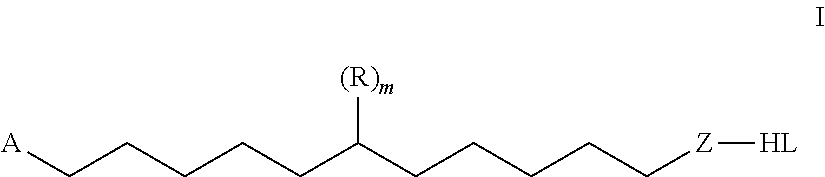

Nonaqueous drag reducing suspensions

InactiveUS6172151B1High weight percentEliminate agglomerationOther chemical processesSpecial tyresPetroleumHydrocarbon

This invention relates to improving the flow of flowing streams of hydrocarbons, such as petroleum or finished products, in a conduit such as a pipeline. The present invention also relates to a stable, nonagglomerating nonaqueous suspension suitable for improving flow of hydrocarbons in conduits, particularly finished product hydrocarbons in conduits.

Owner:LIQUIDPOWER SPECIALTY PROD INC

Method for preparing natural plant granular materials for filter tips

The invention relates to a method for preparing natural plant granular materials for filter tips, which comprises the steps of: taking dry plant stem pith, removing impurities and pulverizing and sieving the stem pith to obtain powdery materials with the mesh number greater than 80 meshes; uniformly mixing the powdery materials and auxiliary materials according to the proportion of the mass ratio being 10 / 10 to 0, obtaining the powdery mixed materials, stirring and uniformly mixing the powdery mixed materials by ethanol solution or water according to the proportion of the material liquid ratio being 4 to 0.5 / 1 and making the mixed materials into soft materials; or stirring and uniformly mixing the powdery mixed materials and water solution of the auxiliary materials according to the proportion of the material liquid ratio being 4 to 0.5 / 1 and making the mixed materials into soft materials; carrying out extrusion type granulation on the soft materials, and then drying granules; and sieving the dried granules by a sieve of 20 to 80 meshes, and the required natural plant granular materials for the filter tips are obtained. The natural plant granular materials for the filter tips prepared by the method has the advantages that when natural plant stem pith granules are thinner, static electricity and agglomeration properties can be eliminated, the powder granulation performance is enhanced, and the addition operability of the natural plant stem pith granular materials during the cigarette filter stick manufacture is improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

High copolymer pulp components for composite inorganic nanoparticles

The invention discloses a component of copolymer using in complex inorganic nanoparticles and relates to the pulp and sizing production and process technology of spinning warp sizing and paper-making glue processes. The said copolymer is a kind of ionic acrylic polymers and it is made of ionic monomers, hydrophilic monomers, acrylate monomers and few other monomers by free radical copolymerization reaction, or is made of polyacrylamide as the raw material by macromolecular chemical reaction. The said copolymer is used to prepare a new slurry component which substantial replaces PVA in the spinning warp sizing and paper-making glue processes. The said slurry contains of the mixture in a proportion of 0.1-50 % of copolymer, 0.1-50 % inorganic nanoparticles and residual water.

Owner:XUZHOU CITY ZHONGHENG FINE CHEM TECH

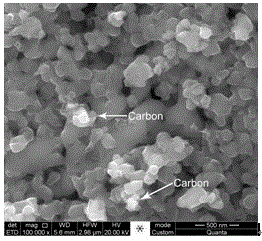

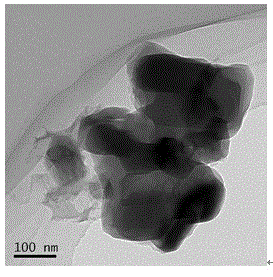

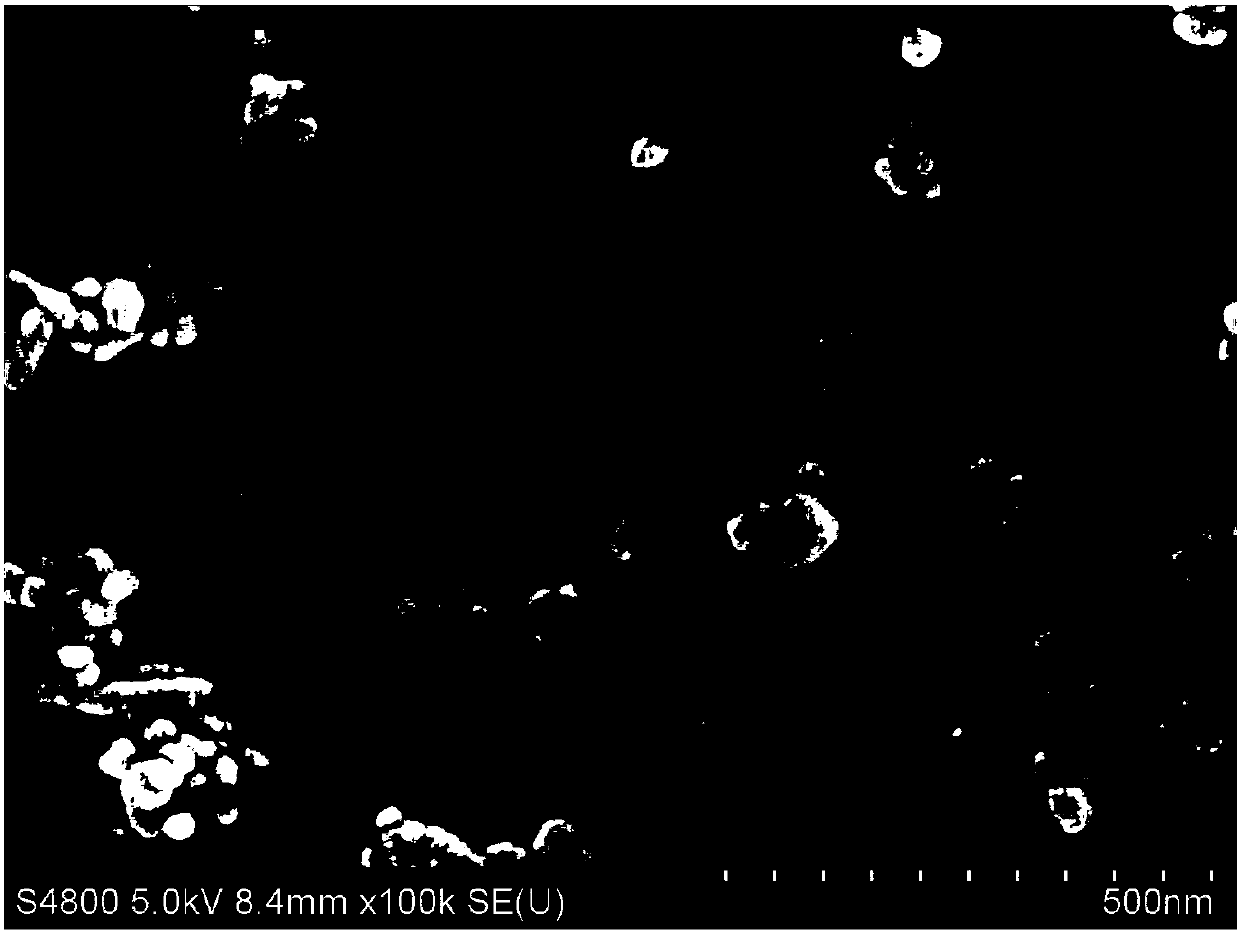

Preparation method of silver composite antibacterial material of carbon nano tube

InactiveCN103843822AEliminate agglomerationSolve the problem of mutual reunion inactivationBiocideDisinfectantsActivated carbonAlcohol

The invention discloses a preparation method of a silver composite antibacterial material of a carbon nano tube. The method comprises the following steps: 1, plasma activating of a carbon nano tube, namely soaking the carbon nano tube in absolute ethyl alcohol, cleaning and drying, and performing plasma activating in a plasma activating instrument; 2, sensitization of the carbon nano tube, namely preparing sensitizing liquid, sensitizing the carbon nano tube subjected to plasma activating in the sensitizing liquid, and drying the carbon nano tube after reaction; and 3, silver plating of the carbon nano tube, namely performing silver plating on the surface of the sensitized carbon nano tube under the protection of inert gases by adopting a vacuum plating machine to obtain the silver composite antibacterial material. According to the preparation method disclosed by the invention, the carbon nano tube is adopted as a supporting carrier, and the carbon nano tube is subjected to plasma activating and sensitizing in sequence, so that the activity of surface functional groups of the activated carbon nano tube is improved, and the silver plating is finally performed, so that agglomeration of silver nanoparticles can be eliminated, the problem of inactivation caused by mutual agglomeration of the silver nanoparticles can be solved, and the antimicrobial activity of the silver nanoparticles can be improved.

Owner:XIAN UNIV OF SCI & TECH

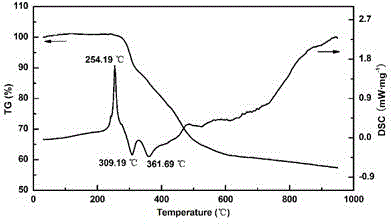

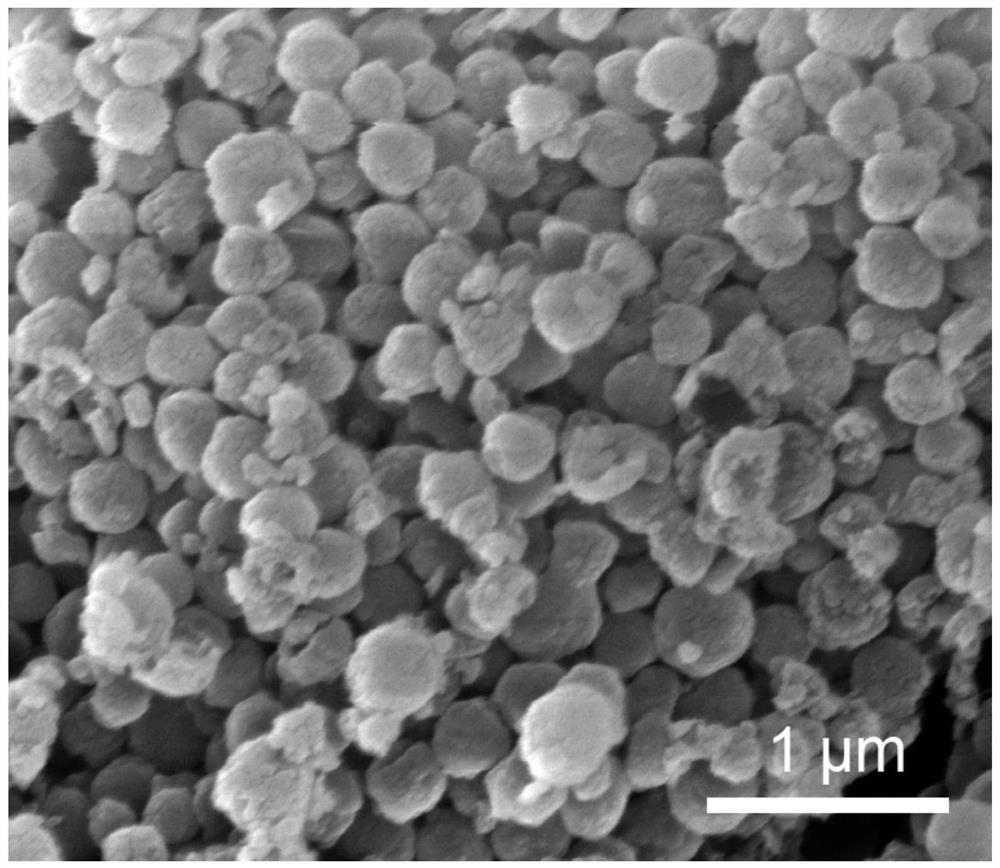

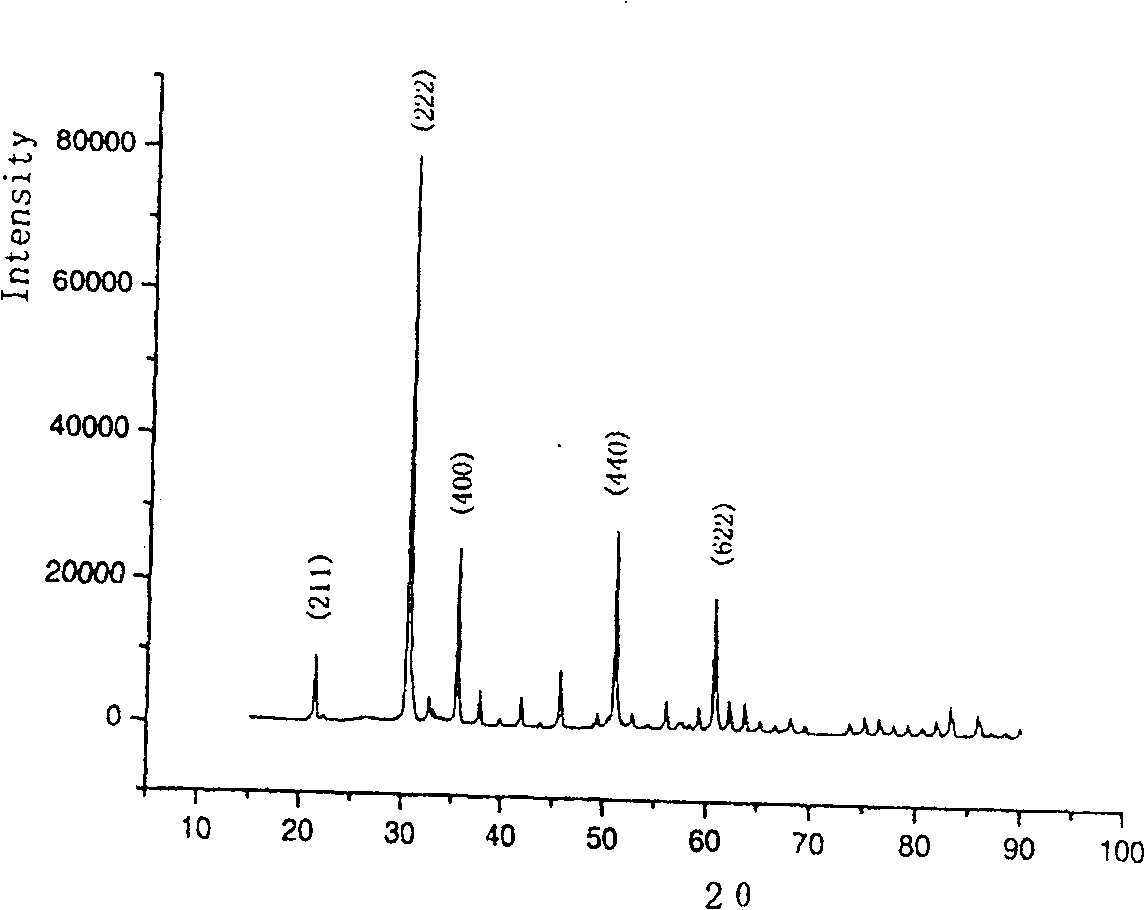

Preparation method of Li4Ti5O12/C composite material

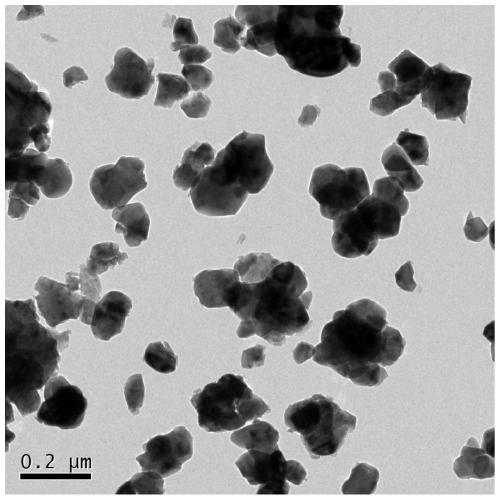

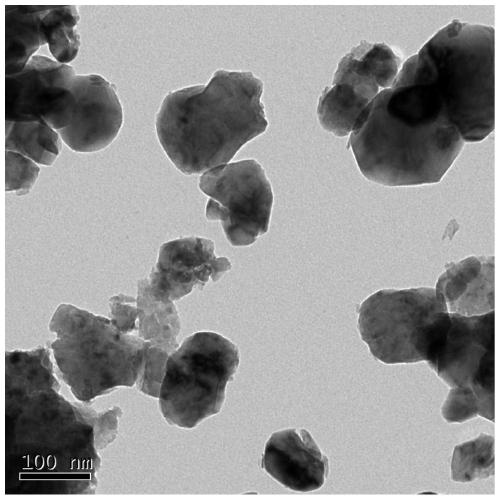

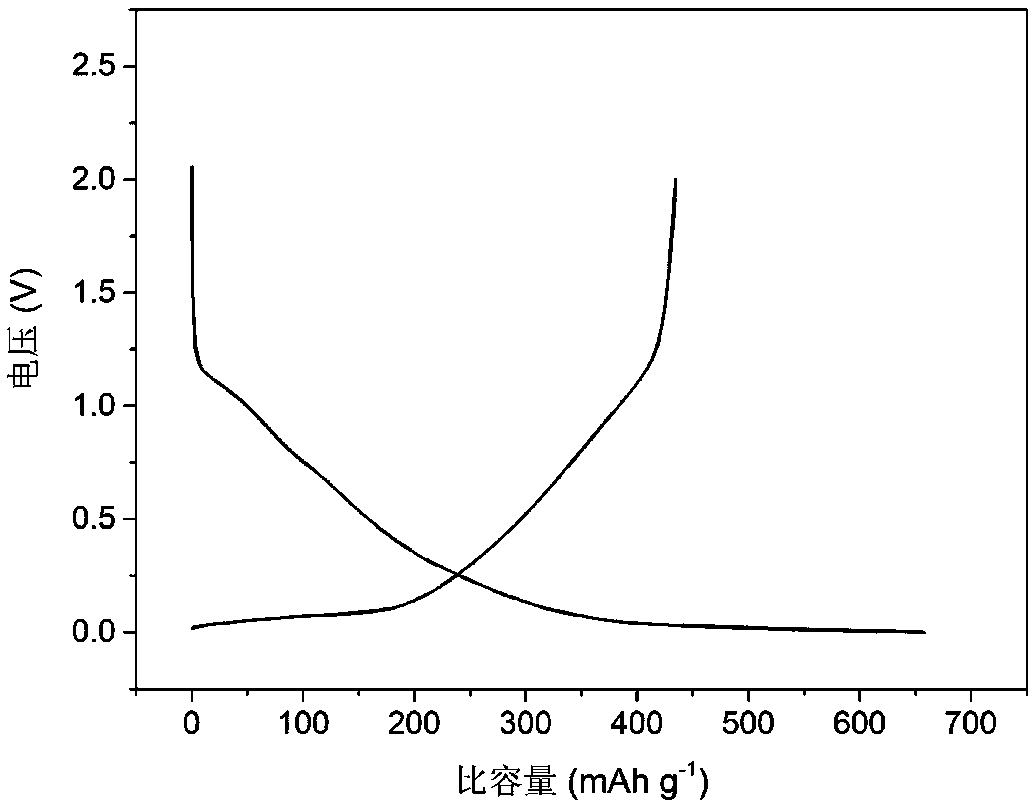

InactiveCN103560227ASimple preparation processImprove conductivityCell electrodesSecondary cellsTube furnaceCarboxylic acid

The invention provides a preparation method of a Li4Ti5O12 / C composite material aiming at the defects that the preparation process of an existing Li4Ti5O12 / C composite material is complicate and the cost is high. The preparation method comprises the following steps: on the basis of taking titanium dioxide as a titanium source and taking small molecular lithium carboxylate or a mixture of small molecular lithium carboxylate and inorganic lithium salt as a lithium source and carbon source, after adding a dispersing agent, adequately mixing by ball-milling, and firing in a muffle furnace or tube-type furnace under an inert atmosphere to obtain the Li4Ti5O12 / C composite material by adopting a subsection constant-temperature sintering method. The Li4Ti5O12 / C composite material prepared by the preparation method has the particle size of being 250-350nm and has good electrical conductivity and high-rate capacity. The preparation method is simple in process and low in cost, and is easily applied to industry because the Li4Ti5O12 / C composite material can be synthesized by a solid phase sintering method without additionally adding the carbon source.

Owner:CHONGQING UNIV OF TECH

Drag reducing compositions and methods of manufacture and use

ActiveUS20110132466A1Reduce resistanceIncrease loadOther chemical processesPipeline systemsPolyolefinPolymer science

A drag reducing composition comprising a primary polyolefin obtained by polymerizing mono-olefins containing from about 2 to about 30 carbon atoms, and a surfactant having an HLB in the range of 6.5 to 8.5 in an aqueous suspending media.

Owner:FLOWCHEM LLC

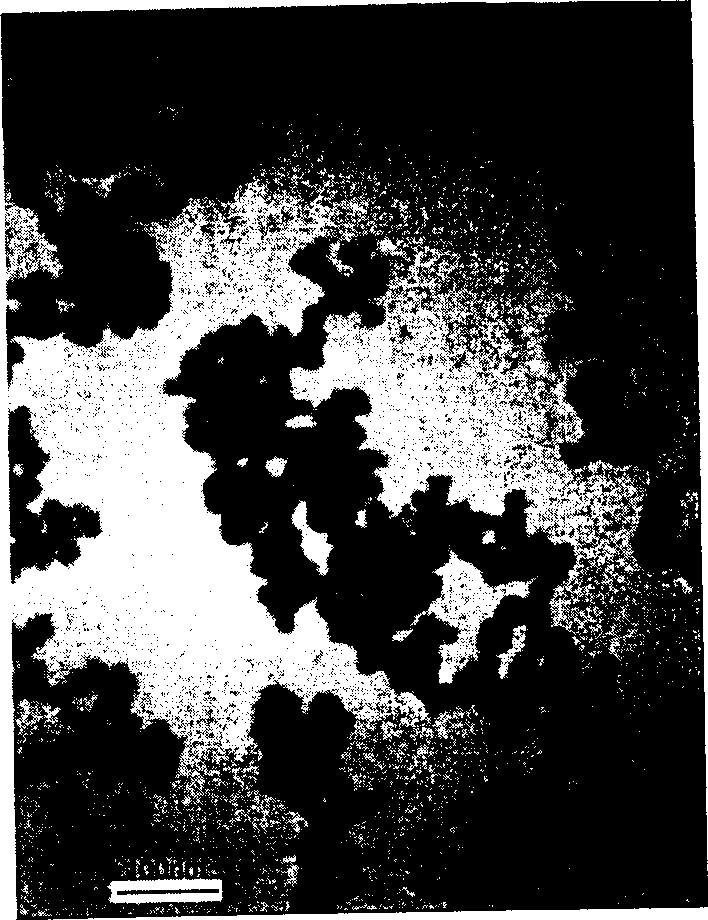

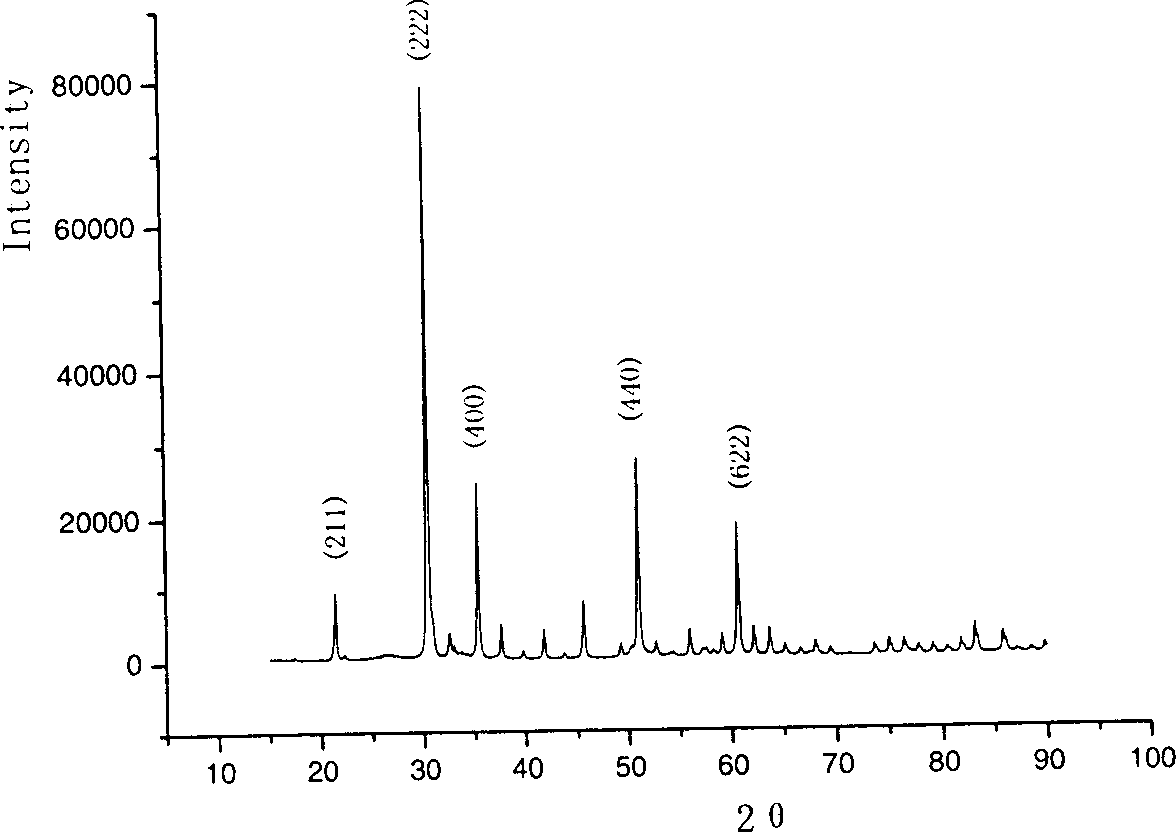

Preparation method of nanometer grade indium tin oxide composite powder

A process for preparing the indium tin oxide (ITO) nanoparticles includes such steps as respectively dissolving In and Sn in strong acid or the soluble In salt and Sn salt in water, mixing, stirring while adding precipitant to obtain InSn deposit, washing with water and organic solvent, solid-liquid separation, adding organic solvent, azeotropic distilling, drying the filtered cake, breaking and calcining.

Owner:BEIJING UNIV OF CHEM TECH +1

Nanometer hydroxyapatite dispersion body and preparation process thereof

ActiveCN107555406AImprove particle uniformityReduce reunionPhosphorus compoundsOrganic solventNano hydroxyapatite

The present invention discloses a nanometer hydroxyapatite dispersion body and a preparation process thereof. According to the nanometer hydroxyapatite dispersion body, nanometer hydroxyapatite particles are uniformly dispersed in a liquid phase medium, the solid content of the nanometer hydroxyapatite dispersion body is 1-5 wt%, the size of the nanometer hydroxyapatite particles is 40-60 nm, theaspect ratio of the nanometer hydroxyapatite particles is 1-5, and the liquid phase medium is water, an organic solvent, the mixture of a water-miscible organic solvent and water, or the mixture of different organic solvents. According to the present invention, by combining the hydrothermal method and the super gravity technology, the microcosmic mixing effect is strengthened, and the method has advantages of low production cost, simple operation and good repeatability; the prepared nanometer hydroxyapatite dispersion body has advantages of controlled particle size, good dispersion effect andgood stability; and with the technical scheme, the problems of easy agglomeration, poor dispersibility and the like of the nanometer hydroxyapatite particles can be solved, and the product can be endowed with the high application performance and the broad application range.

Owner:BEIJING UNIV OF CHEM TECH

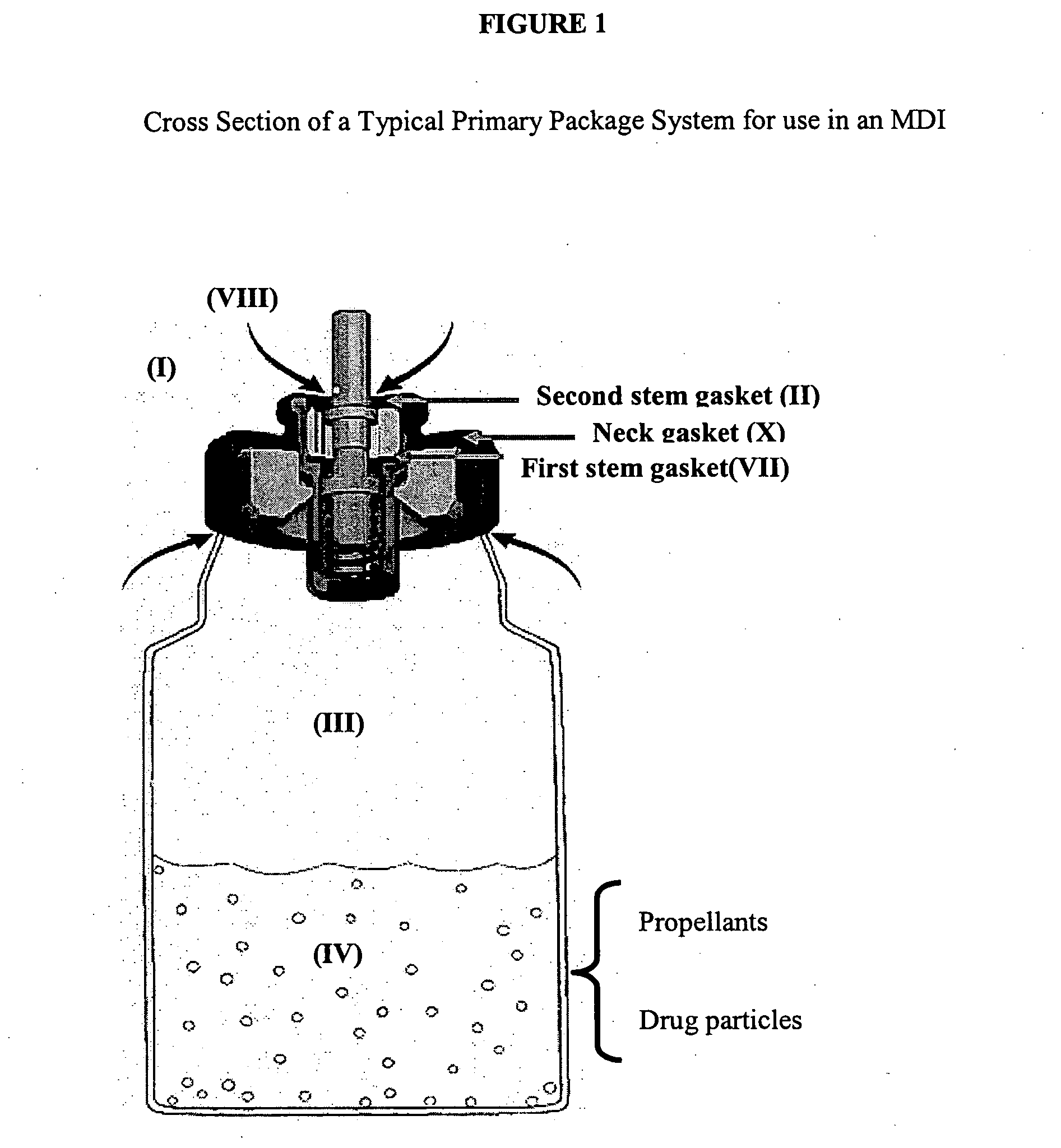

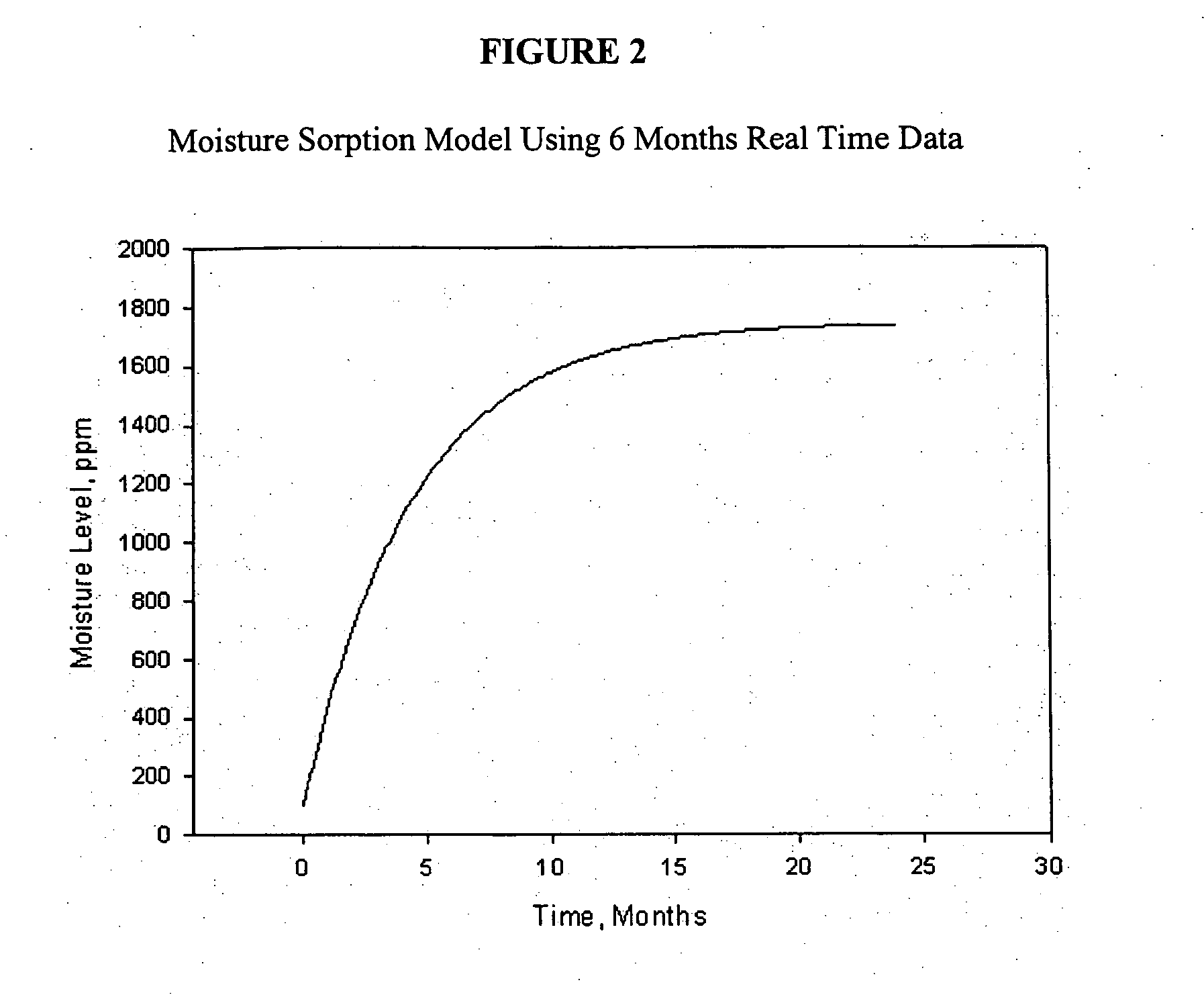

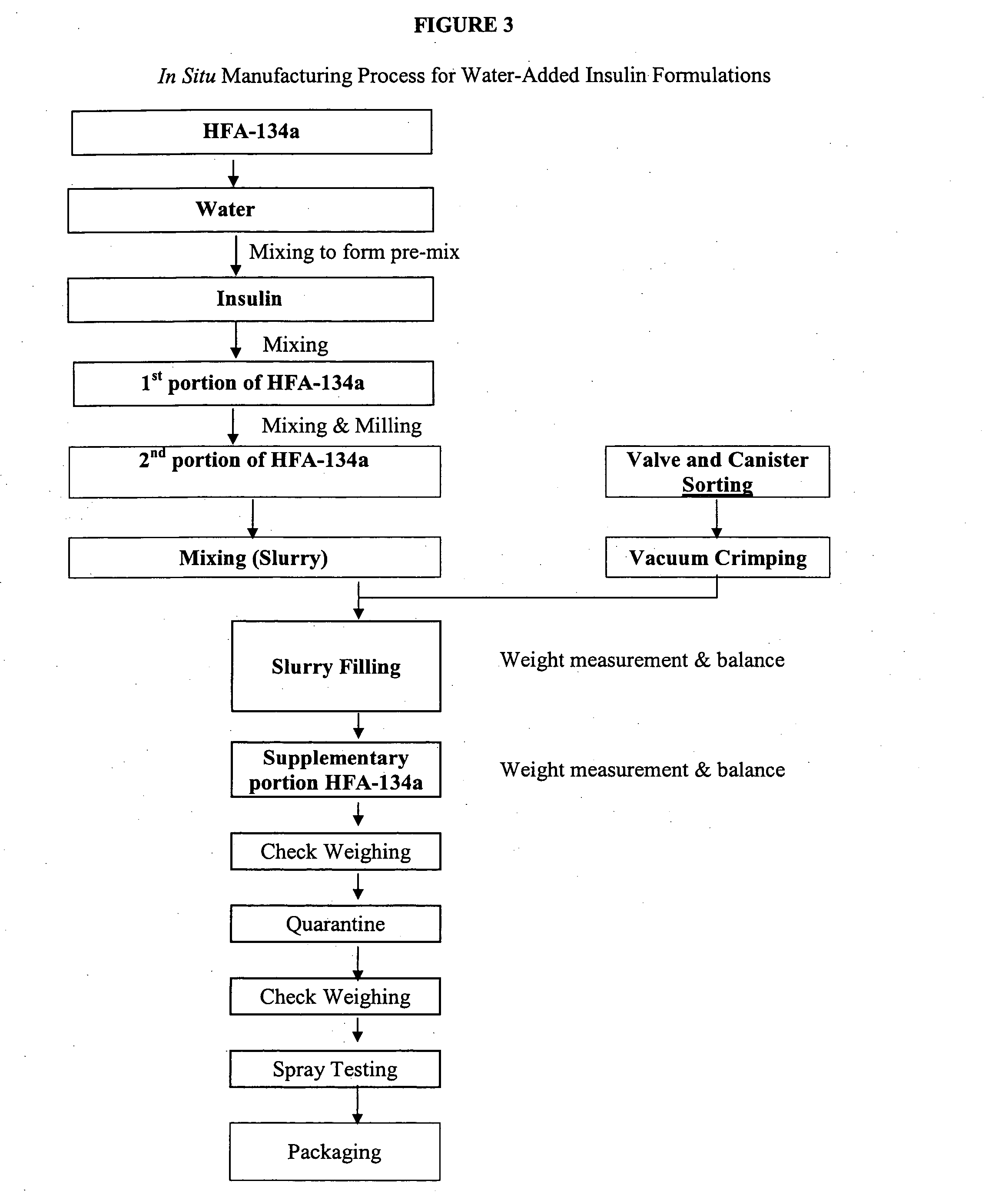

Water-stabilized aerosol formulation system and method of making

InactiveUS20060171899A1Reduce probabilityPromote micronizationPowder deliveryOrganic active ingredientsMedicineMoisture

The invention relates to an aerosol formulation system comprising a primary package system and an aerosol formulation therein wherein the aerosol formulation comprises insulin, a propellant and an amount of water sufficient to reach equilibrium quantities based on the moisture sorption rate diffusing across the primary package system in which the formulation is contained. In addition, the invention relates to a process for preparing the aerosol formulation systems as described herein.

Owner:ABBOTT RESPIRATORY LLC

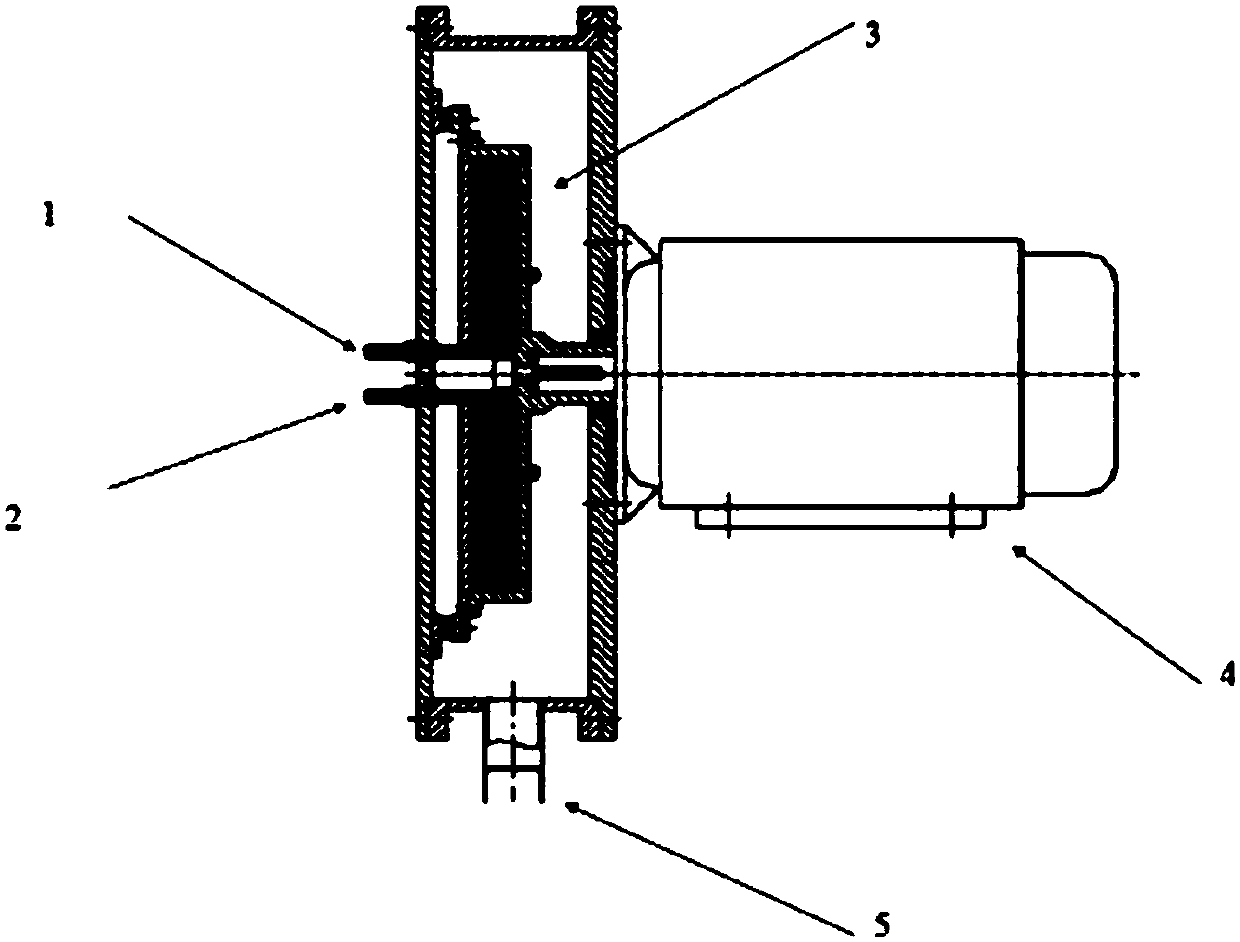

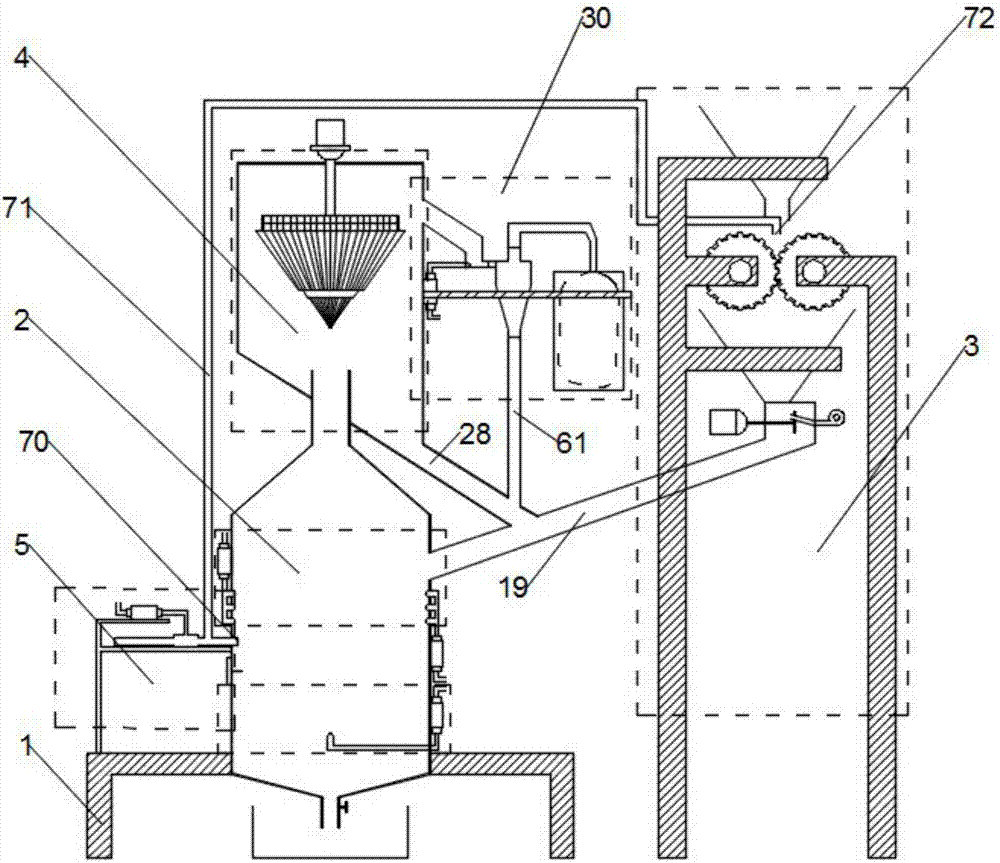

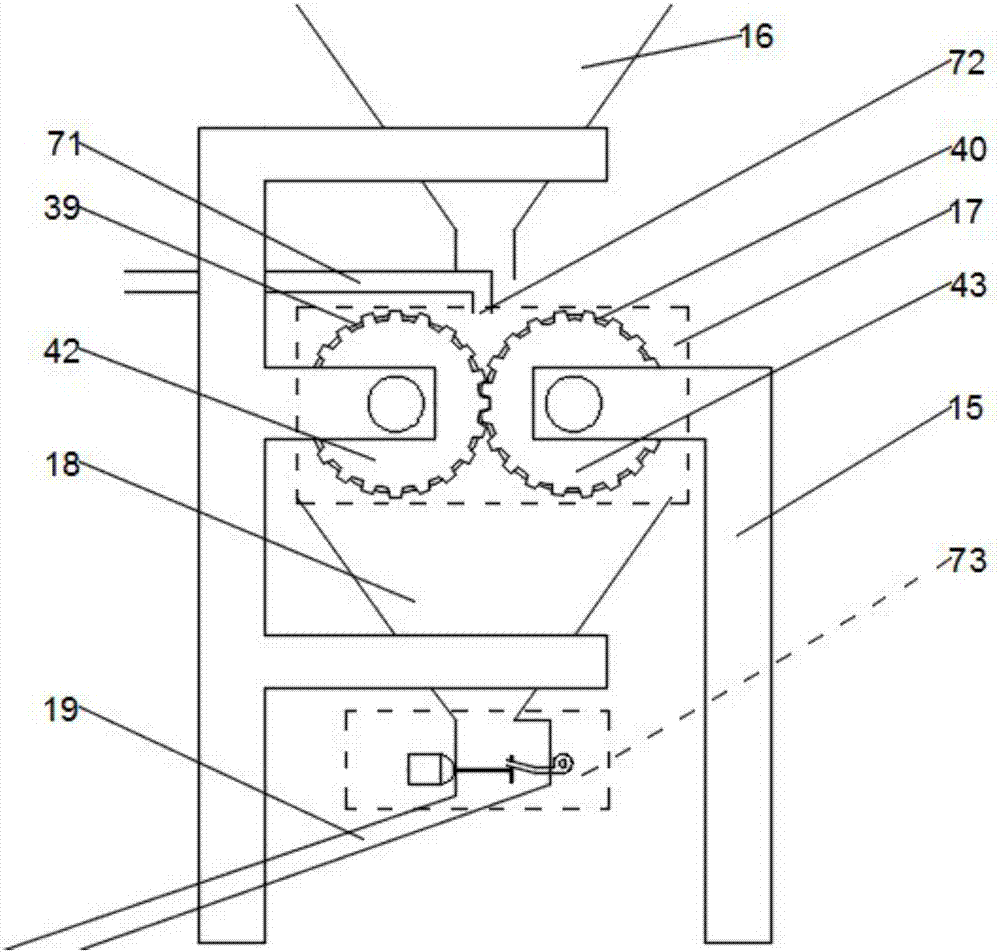

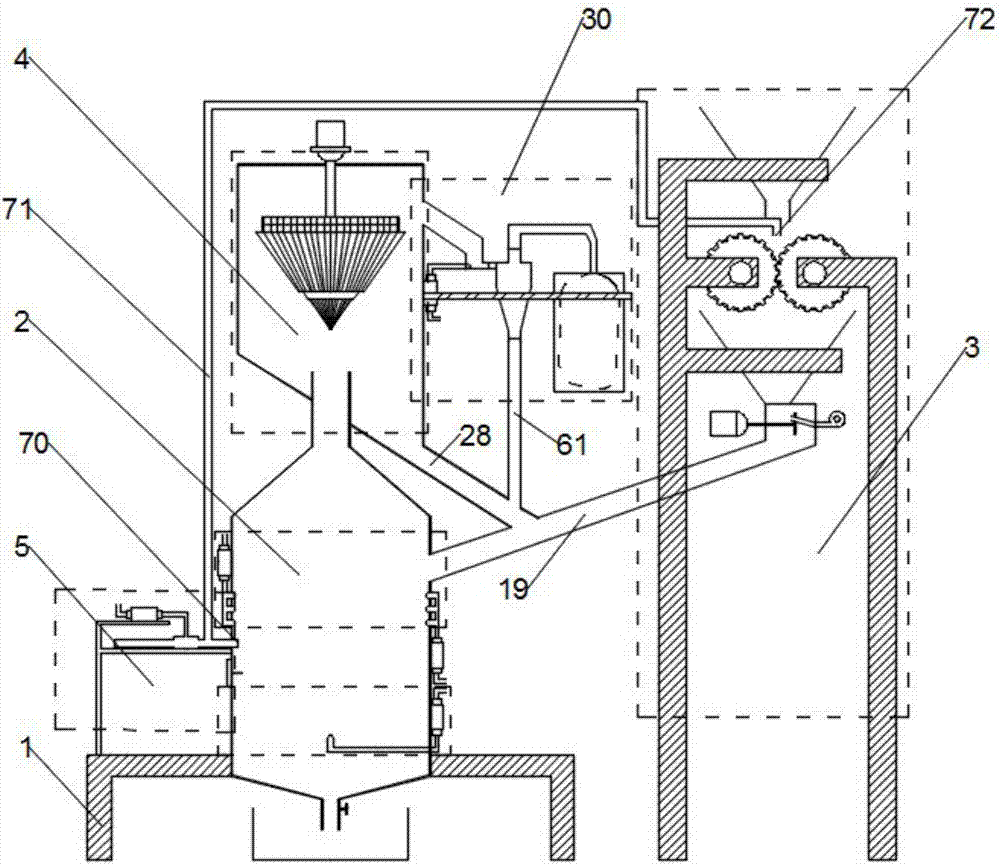

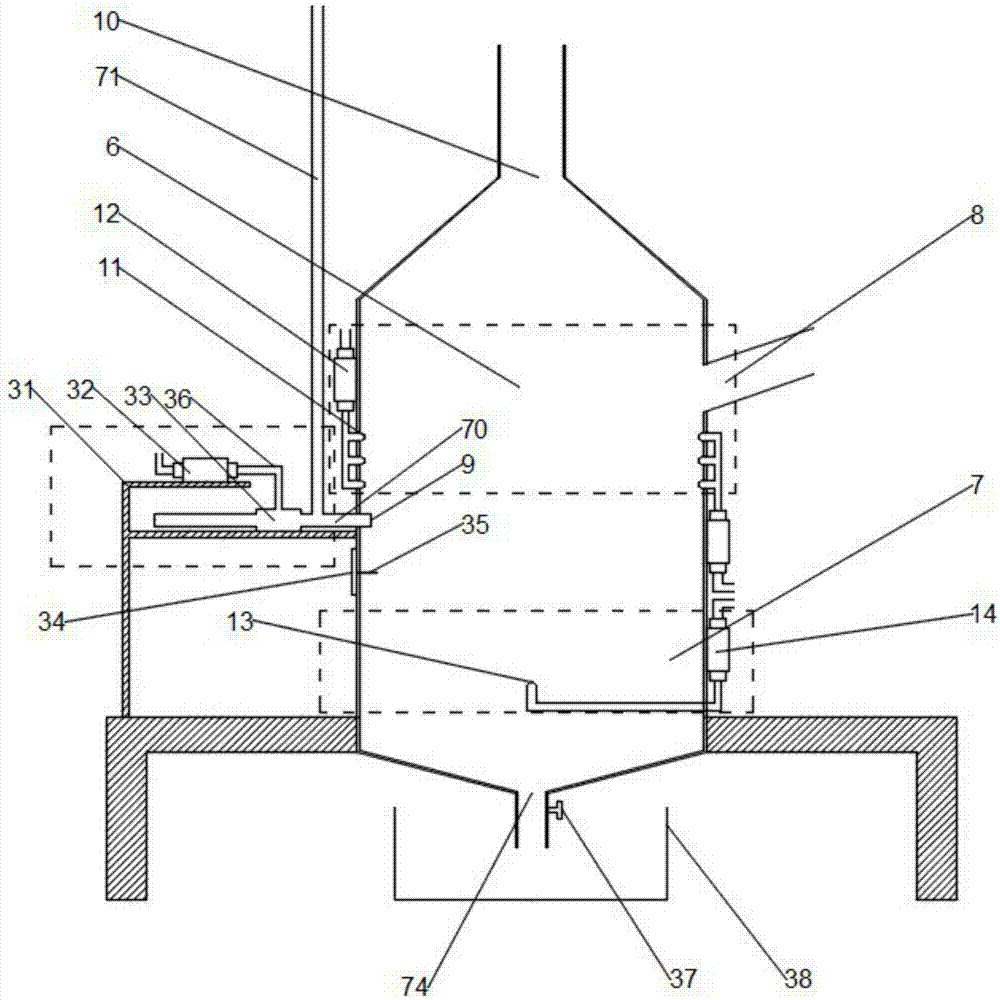

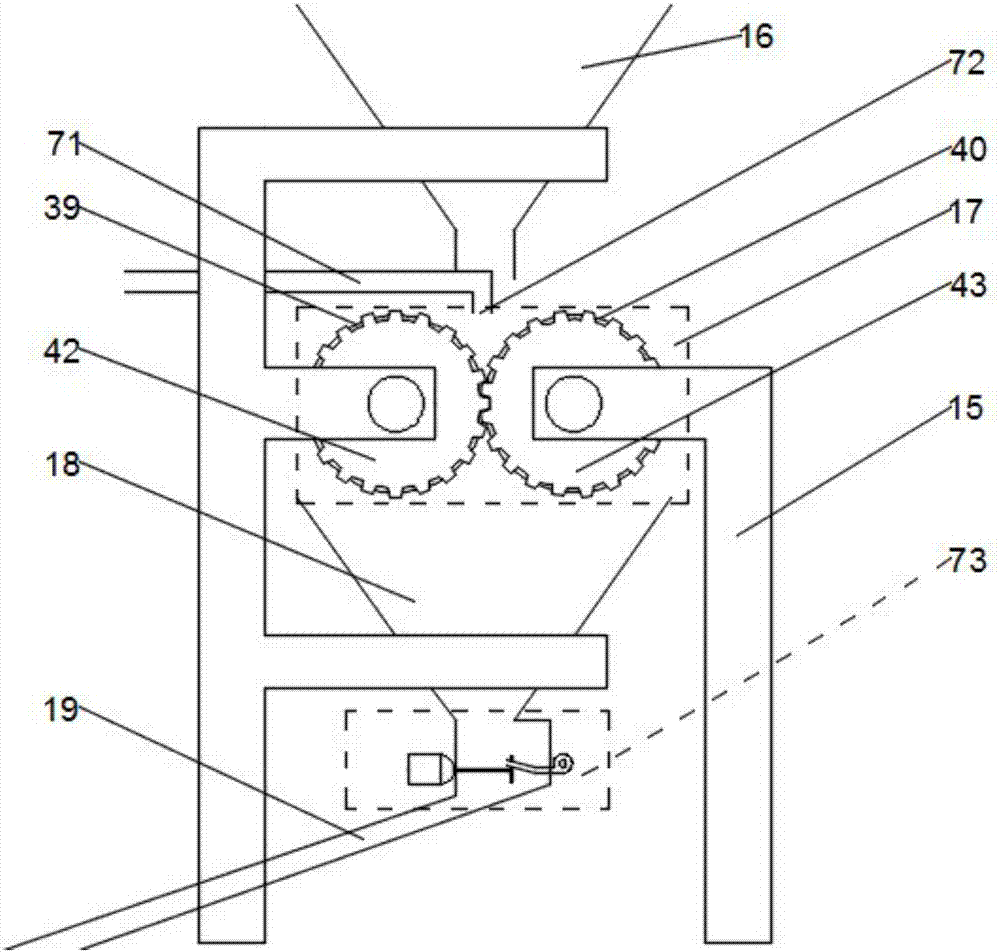

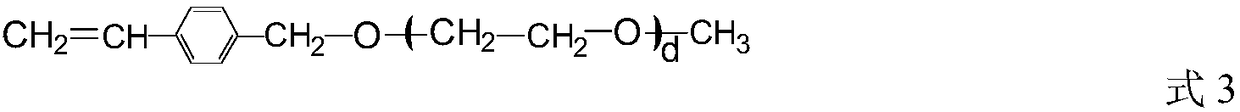

Ultrafine pulverizer capable of classifying materials by means of air flow impact mode

InactiveCN106955774AEliminate agglomerationImprove crushing effectGrain treatmentsImpellerEngineering

The invention discloses an ultrafine pulverizer capable of classifying materials by means of an air flow impact mode. The ultrafine pulverizer comprises a rack, a pulverizing device arranged on the rack, a feeding device located on one side of the pulverizing device, a classifying device located over the pulverizing device and a cooling device located on the other side of the pulverizing device; the pulverizing device comprises a pulverizing chamber arranged on the rack and an air inlet chamber located under the pulverizing chamber; the feeding device comprises a feeding support, and the feeding support is provided with a first feeding hopper, a crushing device, a second feeding hopper and a material blowing device; the classifying device comprises a classifying box, classifying impellers are arranged in the classifying box, a flow distributing device is arranged under the classifying impellers, a fine material discharging pipe is arranged above the classifying impellers, and a material collecting device is connected to the fine material discharging pipe. According to the ultrafine pulverizer, the material agglomeration phenomenon can be reduced, therefore, the pulverizing efficiency is improved, the environmental temperature in work is lowered, and then the product quality is guaranteed.

Owner:CHENGDU FUYANG TECH DEV

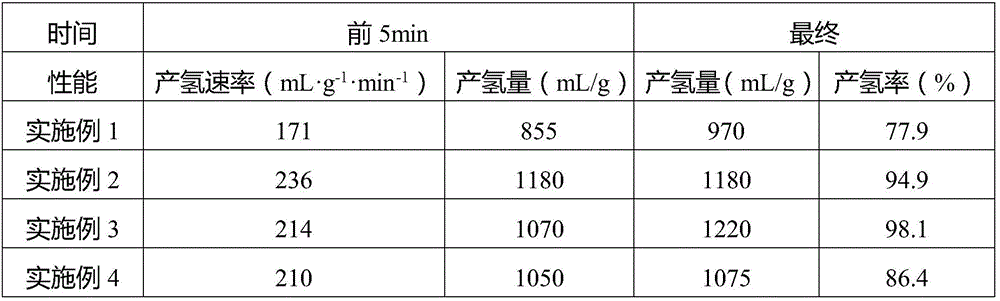

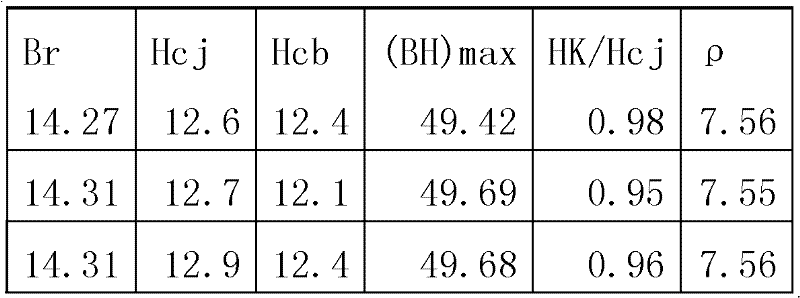

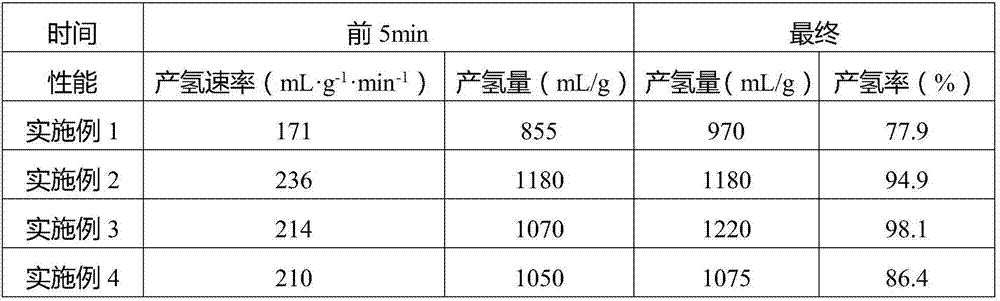

Hydrolysis hydrogen-production aluminum alloy and preparation method thereof

The invention provides a hydrolysis hydrogen-production aluminum alloy and a preparation method thereof. The hydrolysis hydrogen-production aluminum alloy adopts a mechanical alloying method and takes the following components by weight percent as raw materials: 60-95wt% of Al, 0.5-10wt% of Ga, 0.5-10wt% of In, 0.5-10wt% of Sr, 1-10wt% of Bi2O3 and 1-10% of SnC12; and the hydrolysis hydrogen-production aluminum alloy with good hydrogen production performance is obtained by carrying out ball milling. Experimental results prove that the hydrolysis hydrogen-production aluminum alloy prepared by the preparation method provided by the invention is directly subjected to a reaction after being in contact with water at normal temperature and does not have reaction delay time, the hydrogen yield of the hydrolysis hydrogen-production aluminum alloy reaches 1220mL / g, and the hydrogen production rate of the hydrolysis hydrogen-production aluminum alloy reaches 98.1%, so that the aims of producing and supplying hydrogen in real time are achieved, and the hydrolysis hydrogen-production aluminum alloy is suitable for providing a high-purity hydrogen source for a hydrogen-oxygen fuel cell automobile. The preparation method provided by the invention is low in cost as well as simple and convenient in operation, thus being applicable to industrial production.

Owner:HUBEI UNIV OF TECH

Drag reducing compositions and methods of manufacture and use

InactiveUS20080139696A1Reduce resistanceIncrease loadOther chemical processesPipeline systemsPolyolefinOrganic compound

A drag reducing composition containing a finely divided solid polyolefin friction-reducing agent formed from mono olefins containing from 2 to 3 carbon atoms, a fatty acid suspending medium and a modifier which is an oxygenated polar organic compound containing from 1 to 20 carbon atoms, water or mixtures thereof.

Owner:FLOWCHEM

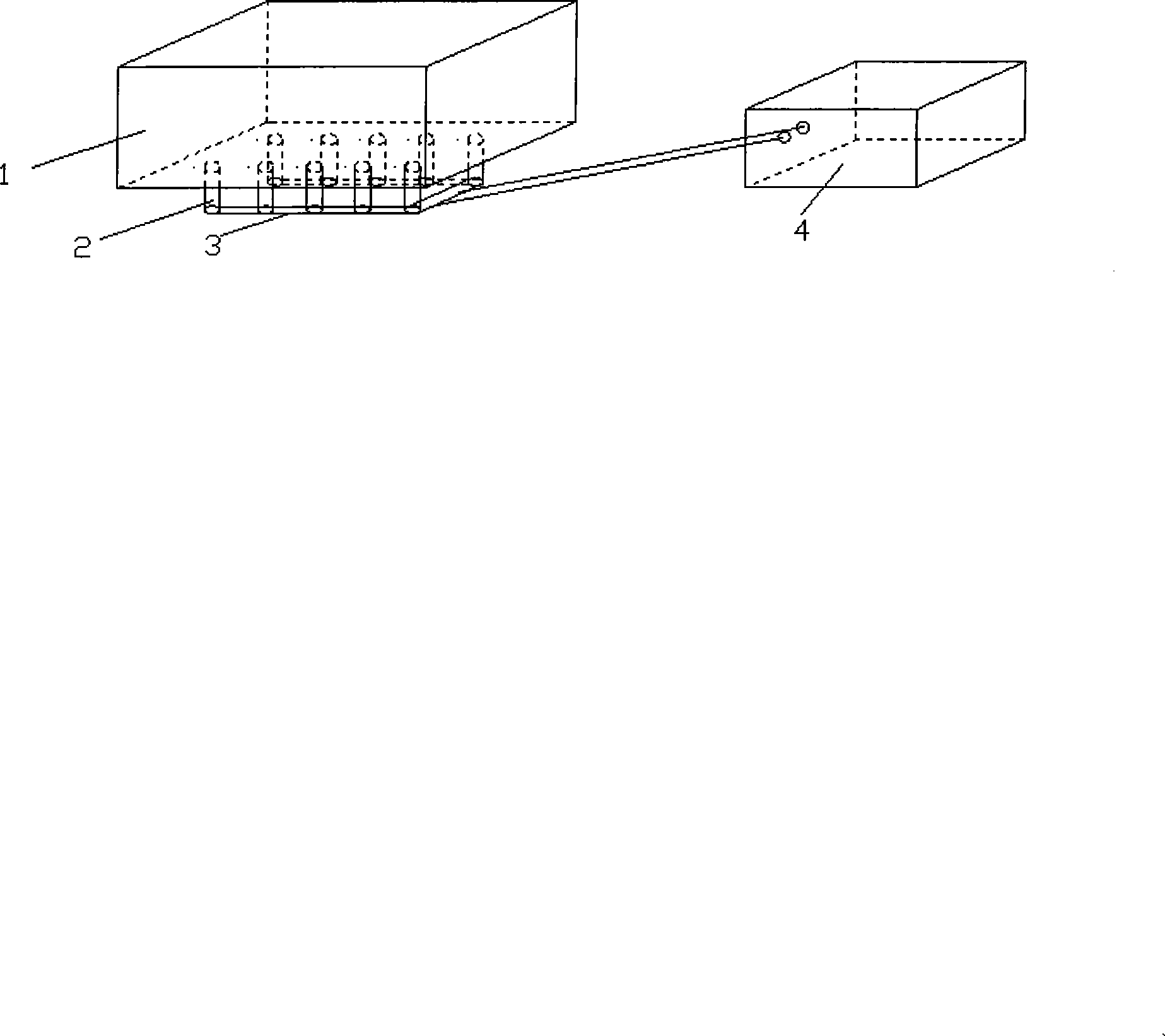

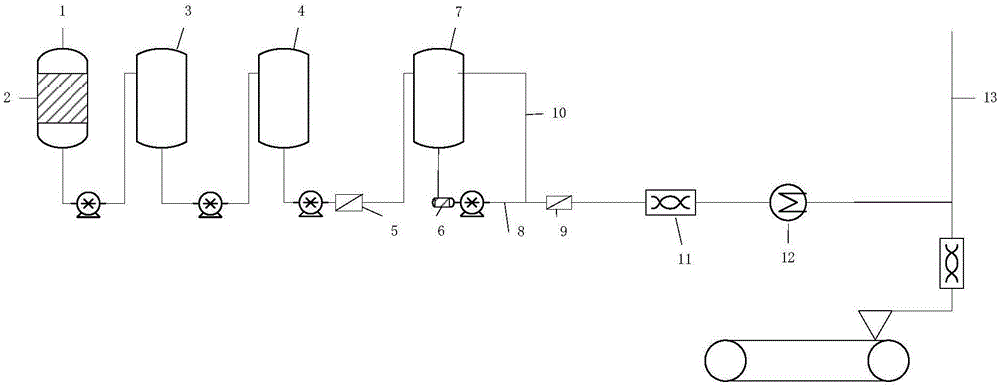

Indigotin dyeing technique for warp yarn by using nano material and ultrasonic wave and device used therefor

The invention relates to a technique for using nanometer material and ultrasonic wave to dye warp yarn into indigo blue, which comprises: wetting, dying, cleaning and drying the warp yarn, the technique is characterized in that the dying process is carried out under the ultrasonic wave effect and under the condition that the nanometer material is added into dyeing solution. A device which is used to execute the technique is provided with a stainless dye vat, wherein 8-12 energy transducers are arranged on the bottom inside the stainless dye vat, and all energy transducers are connected in parallel through a guiding wire and connected with an ultrasonic generator through the guiding wire. The technique of the invention utilizes the chemical activity and the surface effect of the nanometer material to increase the dyeing rate of dye greatly. The cavitation effect of the ultrasonic wave and the peptization of the nanometer material eliminate the aggregate ability of the nanometer material, the dying efficiency and the color fastness are greatly increased, 5-7 dye vats in traditional dying procedures are also saved, thereby the energy is greatly saved, and the pollution is reduced.

Owner:LANYAN GROUP

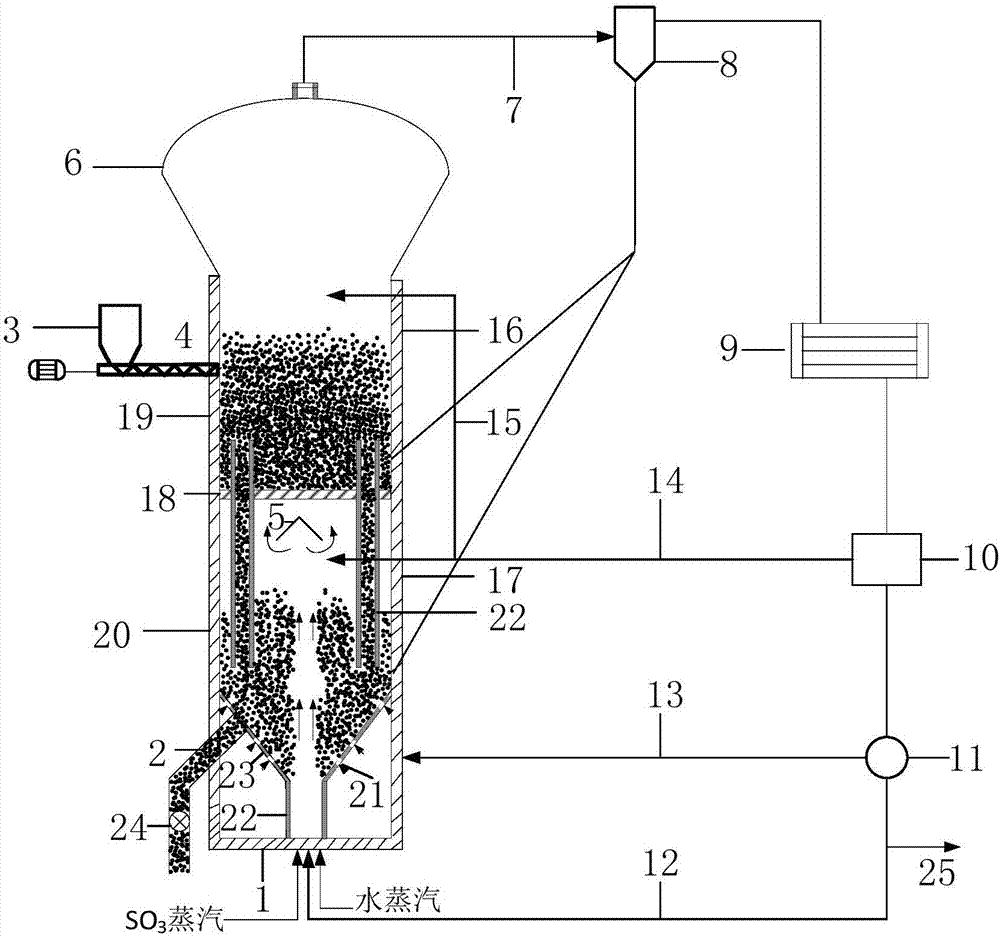

Spouted fluidized bed-fluidized bed composite reactor for producing hydrogen fluoride

InactiveCN107159066AEliminate cakingEliminate agglomerationHydrogen fluorideChemical/physical processesHydrogen fluorideStraight tube

The invention discloses a spouted fluidized bed-fluidized bed composite reactor for producing hydrogen fluoride. The reactor comprises two reaction regions comprising a spouted fluidized bed and a fluidized bed, wherein a gas distribution plate and a solid blanking pipe are arranged between the two reaction regions; the lower part of the reactor is the spouted fluidized bed; the spouted fluidized bed comprises a straight tube section and a diameter reducing section part arranged under the straight tube section. In the spouted fluidized bed reaction region, the center spouted air flow quantity is great enough, so that the impact effect on the agglomeration is strong enough; the motion of particles in the position is violent; agglomeration cannot be easily generated. On one hand, the proportion of the annular gap region fluidized flows and the spouted region flows is increased, i.e., the transformer of the total air flow to the annular gap region fluidized flows is controlled; on the other hand, the circulation gas total flow rate is increased, so that the high flow rate of the fluidized flows is maintained; the particle motion of the annular gap region is enhanced, so that the agglomeration is regulated, controlled and eliminated.

Owner:ZHEJIANG UNIV

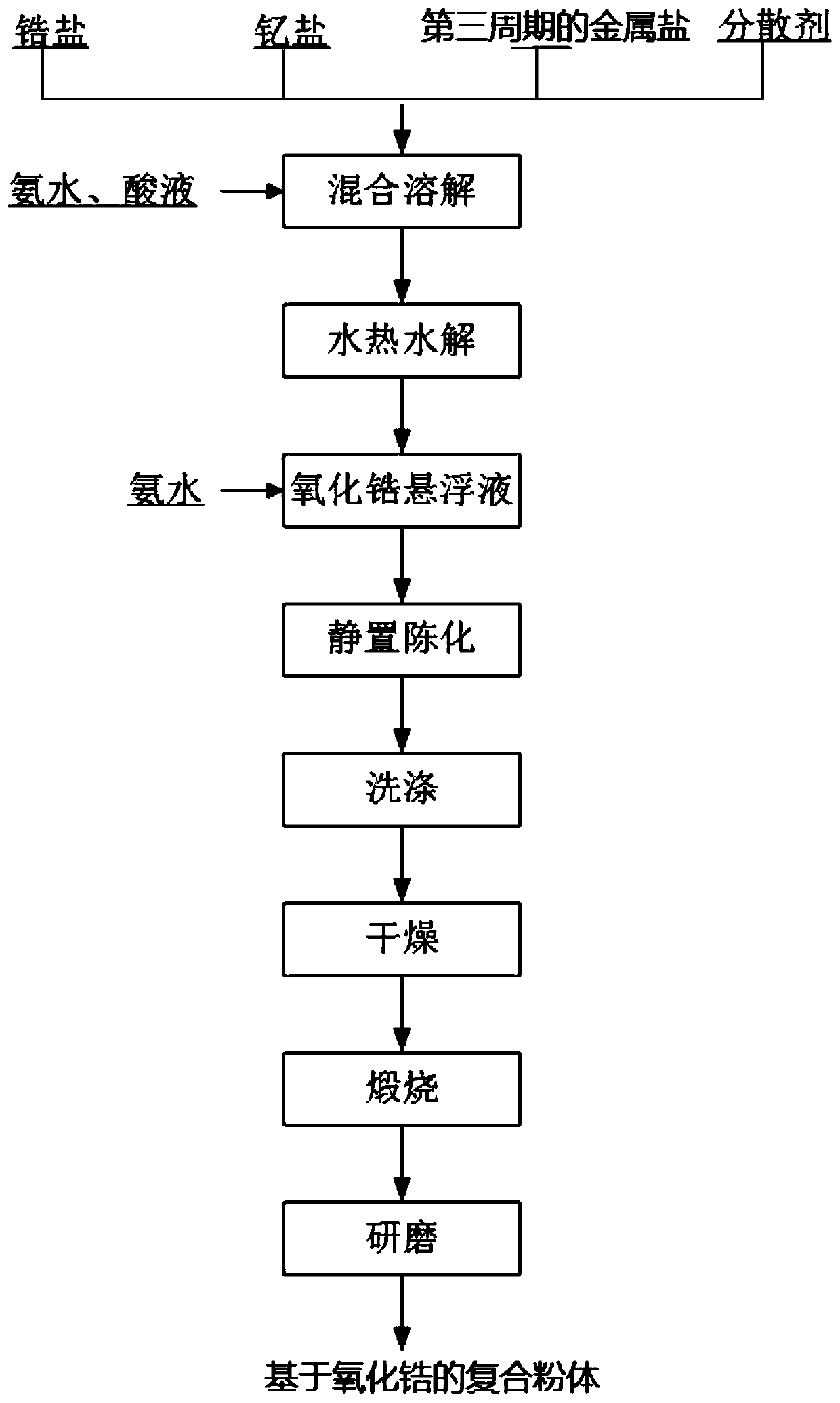

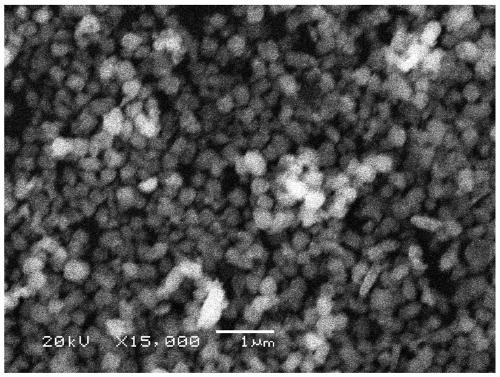

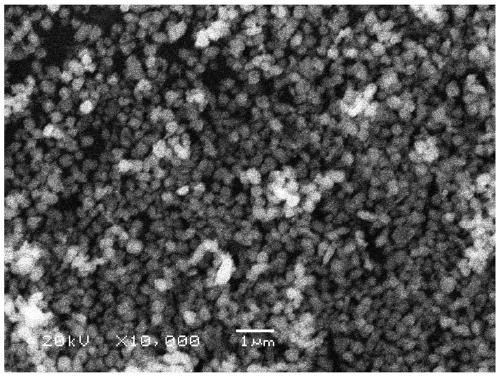

High-toughness zirconia-based composite powder and preparation method thereof

ActiveCN109704403AHigh sphericityImprove mechanical propertiesRare earth metal compoundsMagnesiaHydration reactionHigh fracture

The invention relates to a high-toughness zirconia-based composite powder and a preparation method thereof. The preparation method comprises the following steps: mixing zirconium salt, yttrium salt, third-period metal salt and a dispersant, and adjusting the concentration of H+ in an obtained mixture; carrying out a hydrothermal reaction so as to obtain a hydrated zirconia suspension; adjusting the pH value of the hydrated zirconia suspension to alkaline, and carrying out standing and aging; centrifuging an above-mentioned mixed solution, carrying out washing, drying and calcining, uniformly mixing a calcined powder with deionized water and a dispersant, carrying out ball milling so as to obtain a slurry, and subjecting the slurry to fine grinding, centrifuging, washing and drying so as toobtain the high-toughness zirconia-based composite powder. The ceramic prepared from the above-mentioned nanometer zirconia-based ceramic powder has excellent mechanical properties, especially high fracture toughness, and is specifically applicable to being used as a 5G mobile phone back sheet material.

Owner:CENT SOUTH UNIV

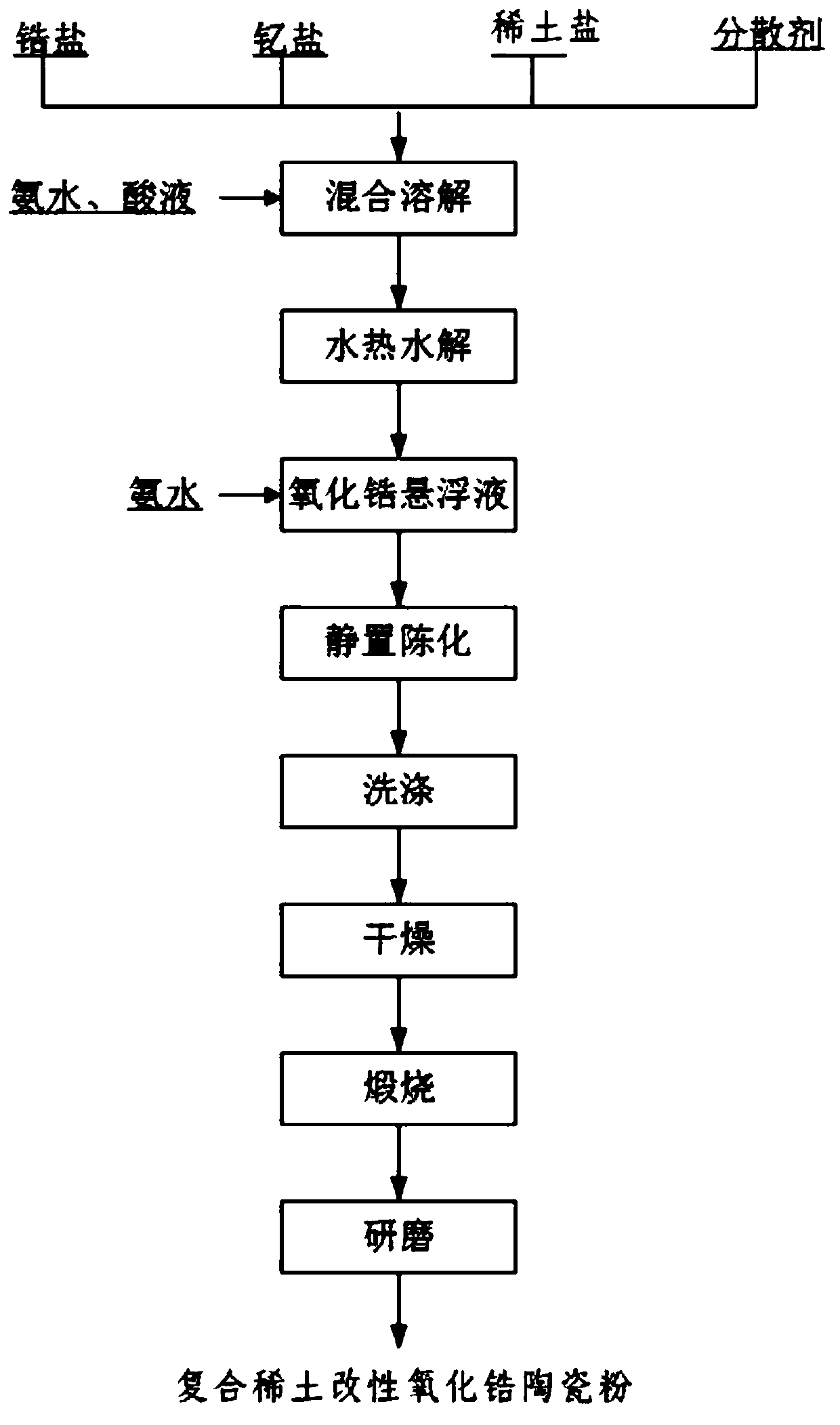

Composite rare earth modified zirconia ceramic powder and preparation method thereof

The invention relates to a composite rare earth modified zirconia ceramic powder and a preparation method thereof. The preparation method comprises the following steps: heating a mixed solution of zirconium salt, rare earth salt and a dispersant to 25 DEG C to 90 DEG C, and adding ammonia water or an acid liquid into the mixed solution so as to adjust the concentration of H+ in the mixed solutionto 0.1 to 5 mol / L; heating the H+ concentration adjusted solution, carrying out a hydrothermal reaction, and after the reaction is completed, carrying out cooling to 90 DEG C or below so as to obtaina hydrated zirconia suspension; adding ammonia water into the hydrated zirconia suspension so as to adjust the pH value of the hydrated zirconia suspension to alkaline, and carrying out standing and aging; and centrifuging the mixed solution, carrying out washing, drying and calcining, uniformly mixing a calcined powder with deionized water and a dispersant, carrying out ball milling so as to obtain a slurry, and subjecting the slurry to fine grinding, centrifuging, washing and drying so as to obtain a nanometer composite rare earth modified zirconia ceramic powder. The method provided by theinvention solves the technical problem of consumption of a large amount of ethylene glycol and polyvinyl alcohol organic matters and difficult treatment of organic-matter wastewater generated in a conventional method.

Owner:CENT SOUTH UNIV

Method for recycling metal from waste circuit board

InactiveCN106111314AEliminate powder agglomerationImprove the effectWet separationGravity separationCorrosion

The invention discloses a method for recycling metal from a waste circuit board. The method comprises the following steps: mixing waste circuit board powder, water and a sodium salt type dispersant in a weight ratio being 1:50:0.25 to 1:80:0.6, and stirring until agglomerated powder is dispersed; and then, separating metal and nonmetal components in circuit board powder by use of a hydraulic shaking table to obtain metal concentrate and nonmetal concentrate; and finally, drying the metal concentrate and nonmetal concentrate to obtain recycled metal. The method has the characteristics that electrostatic acting force and surface tension of powder are damaged under the action of the sodium salt type dispersant, so that the circuit board powder within a relatively small particle size range is completely dispersed into water, and powder agglomeration is eliminated, and therefore, metal particles and nonmetal particles which are wrapped with each other are separated. Favorable conditions are provided for gravity separation of metal and nonmetal. The dispersant does not belong to a hazardous article, does not have corrosion action on metal and nonmetal on a circuit board, and can be recycled.

Owner:GUANGXI UNIV FOR NATITIES

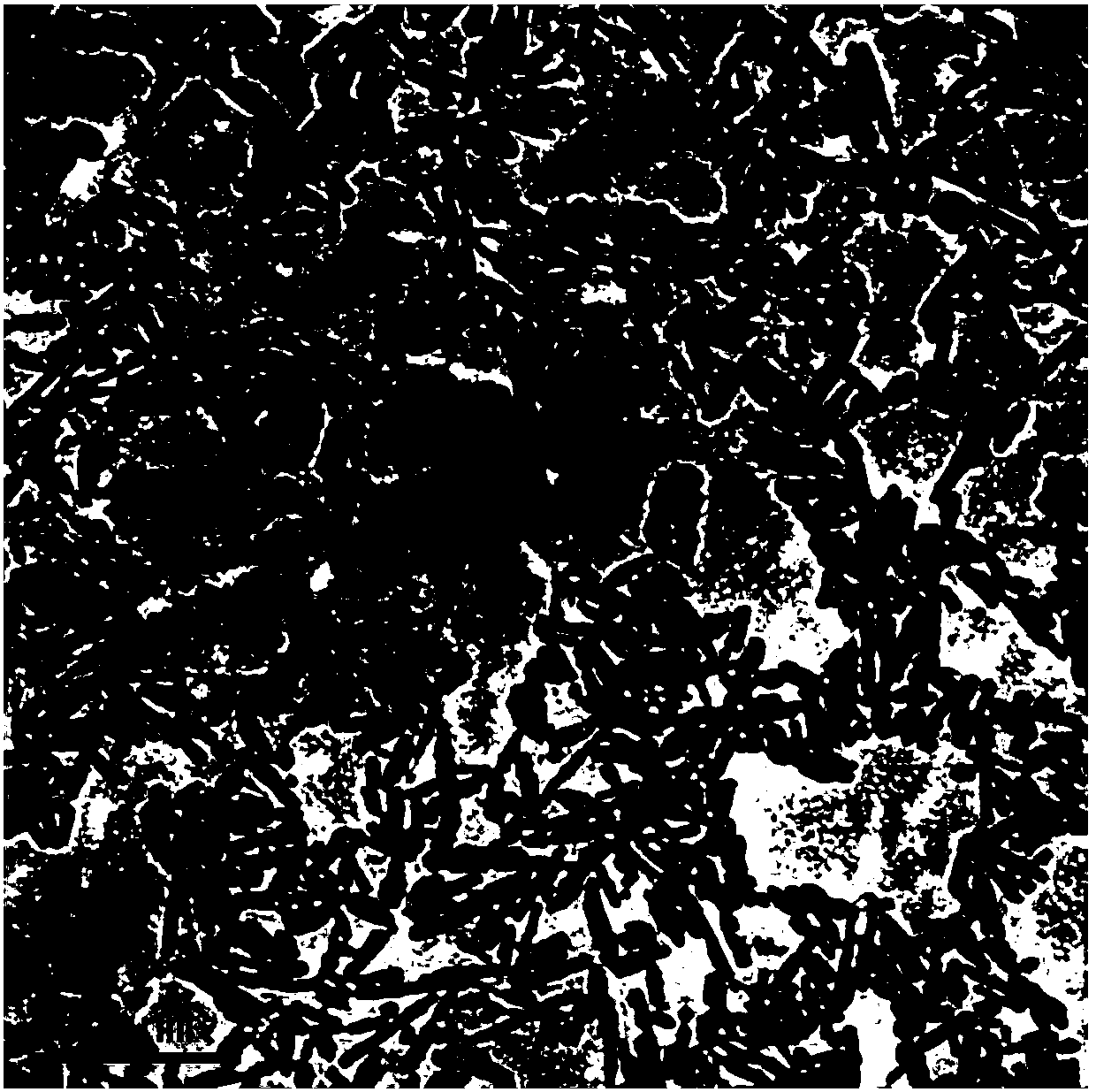

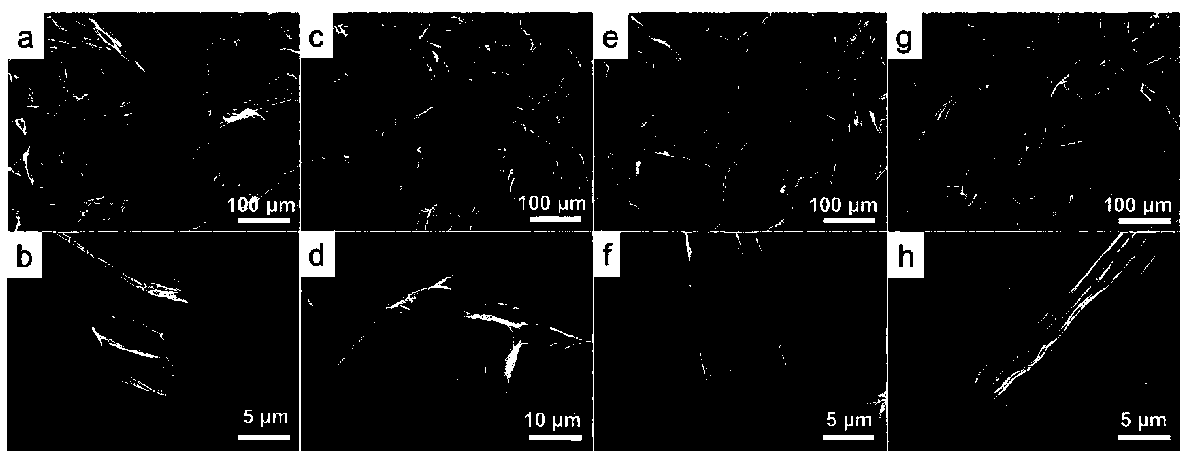

Hollow carbon fiber negative electrode material for lithium ion battery as well as preparation method and application thereof

ActiveCN108923047AShorten the migration pathImproved magnification performanceCell electrodesSecondary cellsFiberCarbonization

The invention discloses a hollow carbon fiber negative electrode material for a lithium ion battery as well as a preparation method and application thereof. A micro morphology of the carbon fiber negative electrode material for the lithium ion battery is in a hollow fiber shape. The preparation method comprises the following steps: (1) soaking a biomass raw material in a nitric acid solution, performing the lignin removal treatment at 60 to 90 DEG C, and obtaining suspension; and (2) ultrasonically dispersing the obtained suspension, filtering, drying, obtaining primary wood fibers, then heating to 700 to 1100 DEG C under the protection of inert gas, performing the pyrogenic carbonization, thus obtaining the carbon fiber negative electrode material. The negative electrode material of the invention can well reserve the hollow fibrous morphology, and has the characteristics of large specific capacity, and excellent rate capability. The preparation method of the invention is rich in source of raw materials, environment-friendly, recyclable, and capable of being widely applied to the preparation field of the lithium ion battery.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

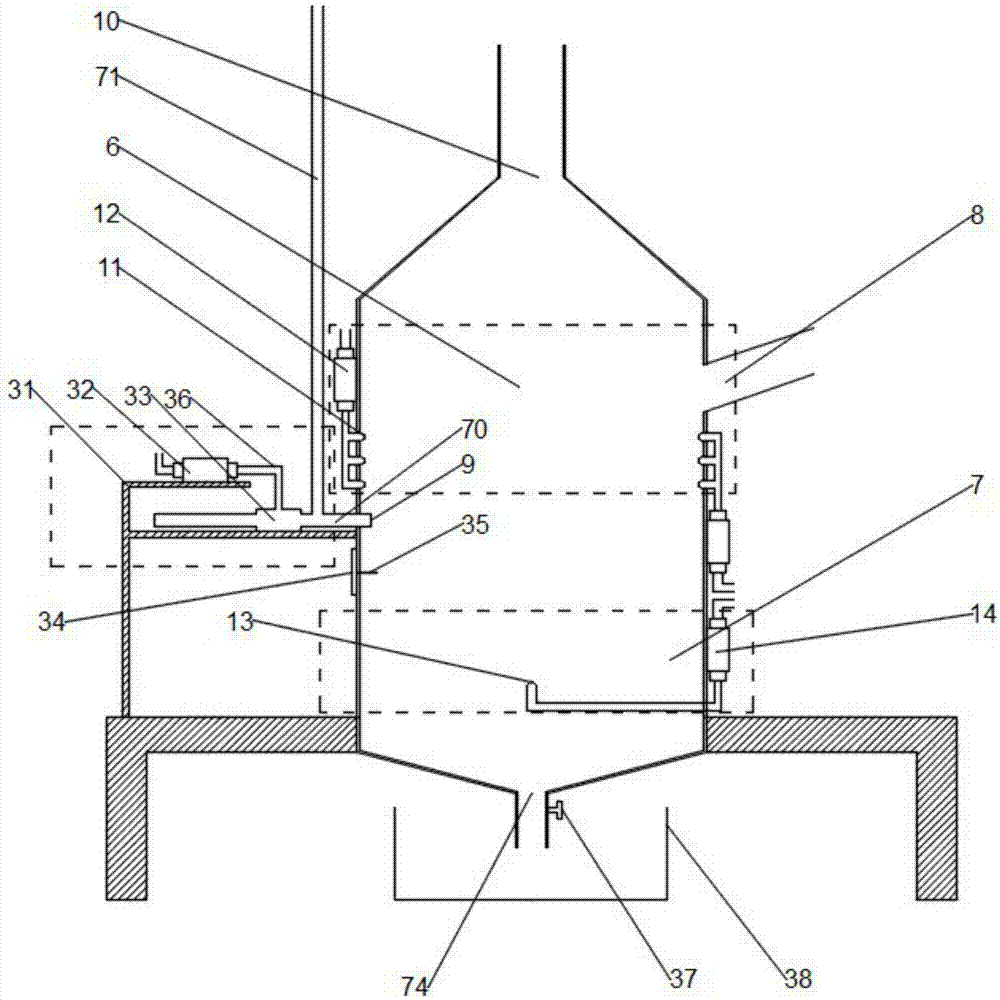

Efficient and refined medicinal material crushing machine

InactiveCN106944231AEliminate agglomerationImprove crushing effectGrain treatmentsImpellerEngineering

The invention discloses a high-efficiency and refined medicine pulverizer, which comprises a frame, a pulverizing device arranged on the frame, a feeding device located on one side of the pulverizing device, a classifying device located above the pulverizing device, and a pulverizing device located on the other side of the pulverizing device. The cooling device on the side, the crushing device includes a crushing chamber arranged on the frame and an air intake chamber below the crushing chamber, the feeding device includes a feeding rack, and the feeding rack is provided with a first feeding funnel, a crushing device, The second feeding funnel and blowing device, the classification device includes a classification box, a classification impeller is arranged in the classification box, a flow diversion device is arranged under the classification impeller, and a fine material outlet pipe is arranged above the classification impeller, and the fine material outlet pipe is connected to a receiving device. The invention can solve the agglomeration phenomenon of materials so as to improve the crushing efficiency and reduce the working environment temperature so as to ensure the product quality.

Owner:CHENGDU GUANYU TECH

Preparation method of PANI (Polyaniline)/TiO2 montmorillonite composite material integrating high-efficiency adsorption and photocatalysis

InactiveCN108786756AReduce clumpingEliminate agglomerationOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsMaterial synthesisMontmorillonite

The invention provides a preparation method of a PANI (Polyaniline) / TiO2 montmorillonite composite material integrating high-efficiency adsorption and photocatalysis. The preparation method comprisesthe following steps: preparing a TiO2 / montmorillonite composite material by utilizing a hydrolytic precipitation method, then adding aniline and ammonium persulfate, and carrying out in-situ chemicalpolymerization reaction on aniline, ammonium persulfate and the TiO2 / montmorillone composite material, thus preparing the PANI / TiO2 montmorillonite composite material integrating the high-efficiency adsorption ability and the photocatalysis. During treatment of printing and dyeing wastewater, adsorption and photocatalytic degradation can occur at the same time, the problems of low photocatalytic activity, easy agglomeration of TiO2 particles, poor adsorption effect and the like during independent treatment of TiO2 or organic modified montmorillonite on the printing and dyeing wastewater can beeffectively solved, and the treatment capacity of the printing and dyeing wastewater can be greatly improved. The invention belongs to the technical field of synthesis of novel materials.

Owner:GUIZHOU UNIV

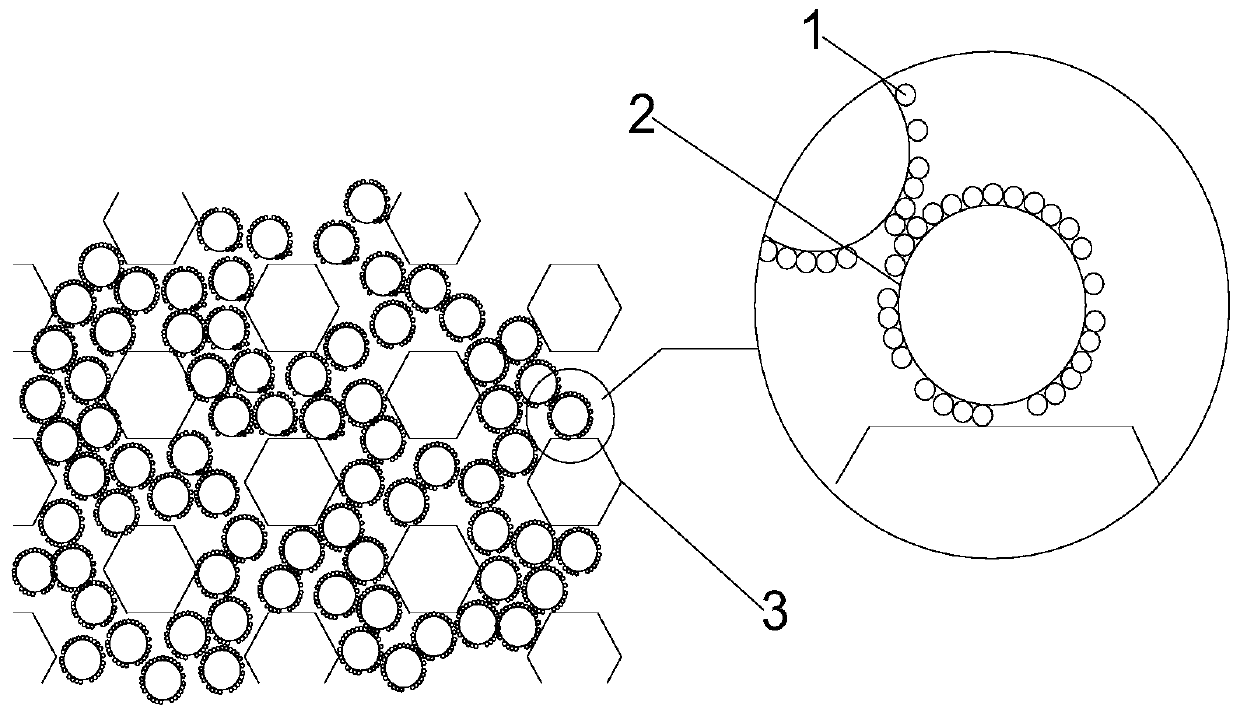

Ionic liquid grafted molecular sieve imidazole framework composite solid polymer electrolyte and preparation method thereof

ActiveCN112615048AStable crystal structureEliminate agglomerationSolid electrolytesSecondary cellsPolymer electrolytesMolecular sieve

The invention discloses an ionic liquid grafted molecular sieve imidazole framework composite solid polymer electrolyte and a preparation method thereof. A molecular sieve imidazole framework is used for graft modification, imidazole quaternary ammonium salt ionic liquid is grafted on the surface, and modified nanoparticles are uniform in size and can be uniformly dispersed in a solvent without agglomeration. The synthesized imidazole quaternary ammonium salt grafted molecular sieve imidazole framework is used as a filler to prepare the composite solid polymer electrolyte, and the porous molecular sieve filler can improve the stability and electrochemical performance of the composite polymer electrolyte. The imidazole quaternary ammonium salt molecular sieve imidazole framework disclosed by the invention can be well dispersed in a composite polymer electrolyte, and the excellent stability of the molecular sieve imidazole framework and the high ionic conductivity of the ionic liquid are combined; and the high-performance molecular sieve imidazole framework composite solid polymer electrolyte provided by the invention has high room-temperature ionic conductivity and a wide electrochemical stability window.

Owner:SOUTH CHINA UNIV OF TECH

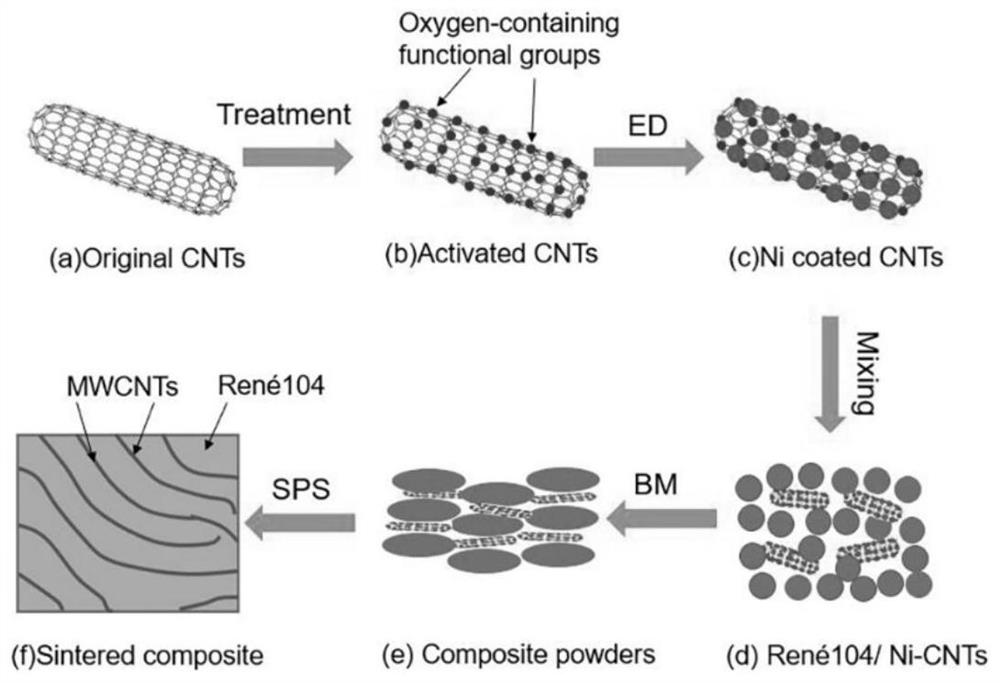

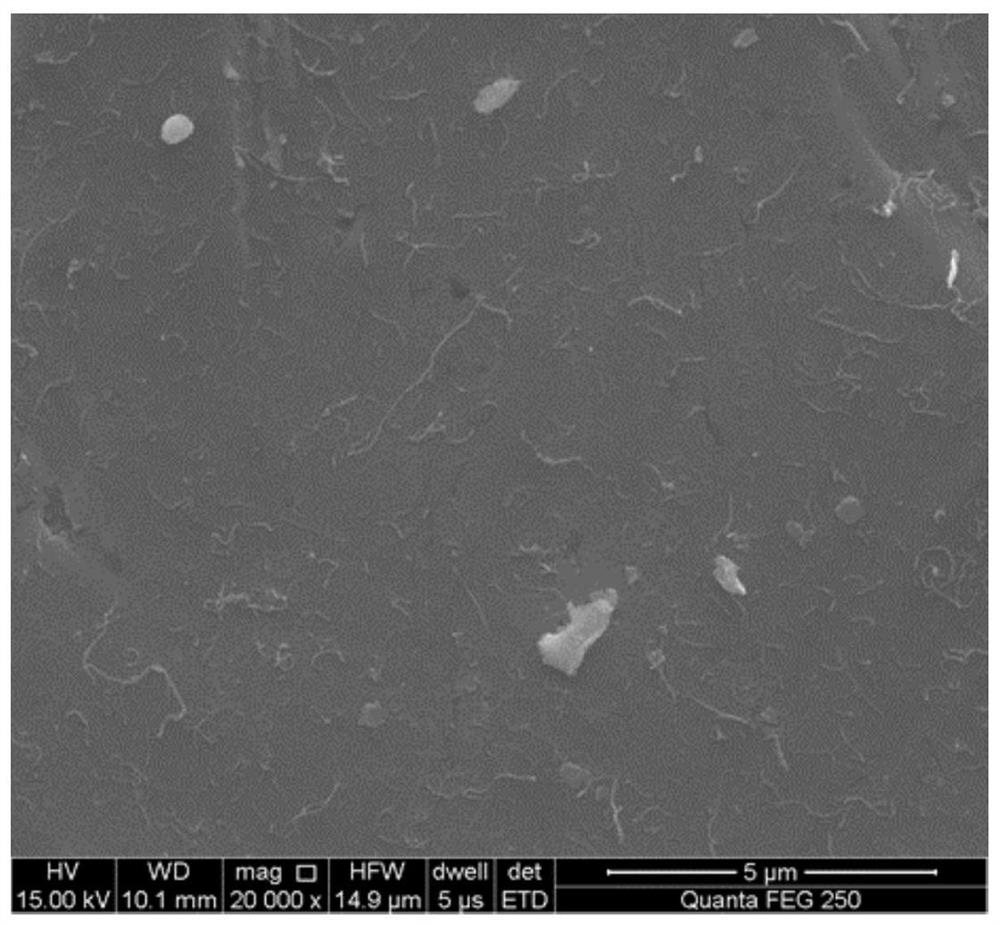

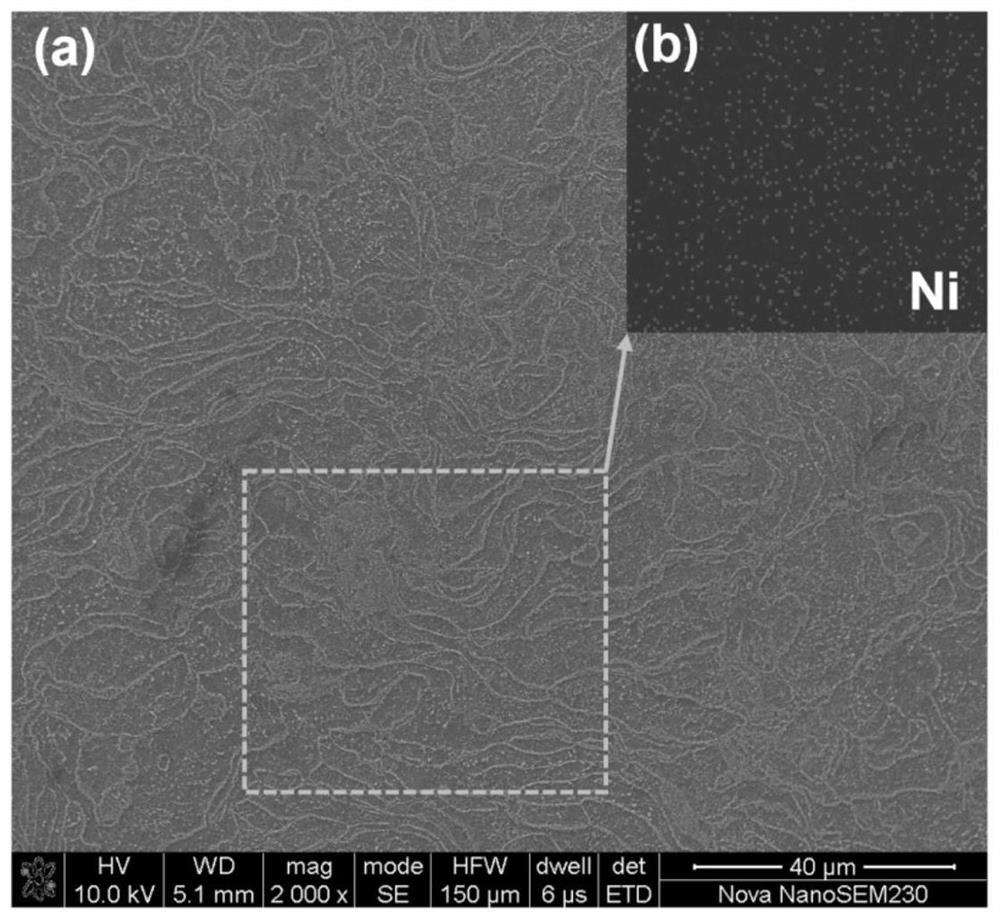

Method for improving comprehensive performance of carbon nanomaterial reinforced nickel-based superalloy

InactiveCN112008087AEliminate agglomerationEvenly dispersedMaterial nanotechnologyAdditive manufacturing apparatusOxidation resistantSuperalloy

The invention provides a method for improving the comprehensive performance of a carbon nanomaterial reinforced nickel-based superalloy, and belongs to the field of powder metallurgy and superalloy. Aiming at the problem that the high-temperature oxidation resistance of the carbon nanomaterial reinforced nickel-based superalloy is reduced, the surface of a carbon nanomaterial is coated with a compact Ni layer for the first time, so that the problems of poor mechanical property and high-temperature oxidation resistance caused by easy agglomeration of the carbon nanomaterial, poor bonding with amatrix interface and the like are solved. Through a specific ball milling process, mixed powder with uniformly dispersed carbon nanomaterials is obtained, and further uniform dispersion of the carbonnanomaterials is realized. A carbon nanomaterial reinforced Rene104 nickel-based composite material is prepared through spark plasma sintering (SPS), hot isostatic pressing, hot pressing, hot extrusion or hot forging, or 3D printing and other powder forming methods, so that the prepared material is excellent in mechanical property and excellent in high-temperature oxidation resistance, and the problem that the carbon nanomaterial reinforced metal-based composite material cannot be used as a high-temperature structural material is effectively solved.

Owner:CENT SOUTH UNIV

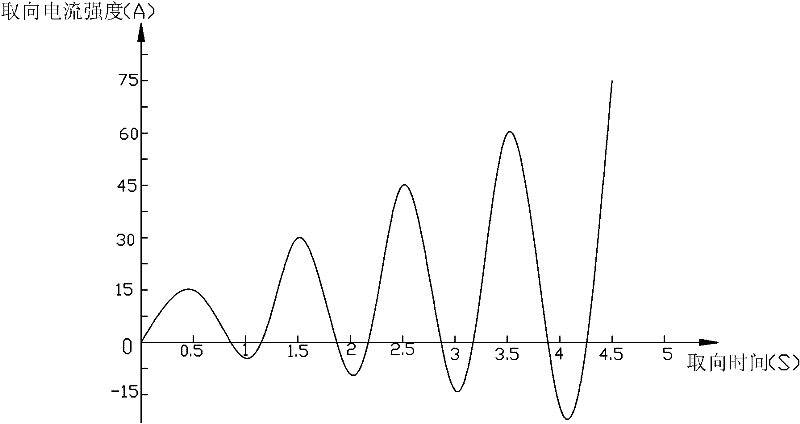

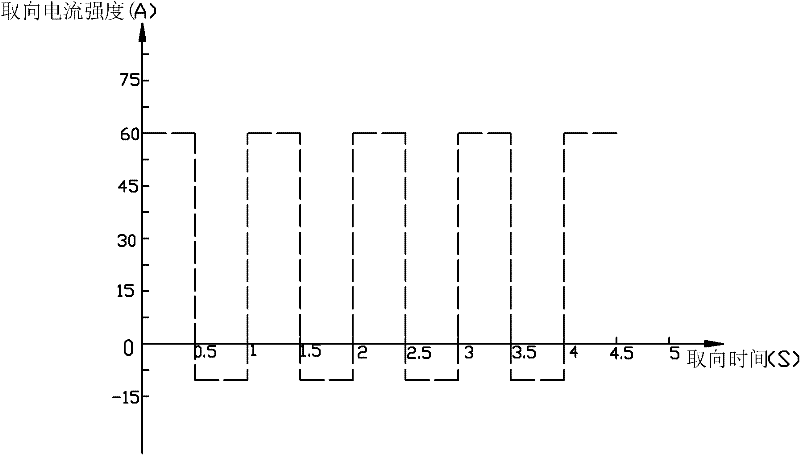

Sintered NdFeB powder orienting method

ActiveCN102225465AEliminate agglomerationGood consistency of magnetic propertiesInorganic material magnetismPosition tolerancePower flow

The invention relates to the field of machining of magnetic materials and in particular relates to a sintered NdFeB powder orienting method which comprises the following steps: a. putting the blank NdFeB powder into a mold cavity; b. leading poles at two sides of a press into vibration or alternating current to form a vibration magnetic field; c. press-fitting a mold; and d. after press fit is completed, applying a current reverse to the smaller current on poles at two sides for carrying out demagnetization, thus obtaining a bloom. The poles at two sides of the press are circularly and alternatively fed into vibration or alternating current to form the vibration magnetic filed; the NdFeB powder dithers in the mold cavity so as to remove the clustering phenomenon of the NdFeB powder to a great extent, thus improving the orientation level and achieving better consistency for all magnetism of the bloom; and during the dithering process, the filling compactness of the powder in the mold cavity is more uniform, the initial pressing intensity after compression is more uniform, the sintered bloom has better form and position tolerance, the grinding amount of the bloom can be decreased, and the cost is lowered.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

A kind of hydrolysis hydrogen production aluminum alloy and preparation method thereof

ActiveCN105970031BHigh activityImprove the performance of hydrogen production by hydrolysisHydrogen productionHydrogen fuel cellRoom temperature

The invention provides an aluminum alloy for hydrogen production by hydrolysis and a preparation method thereof. The present invention adopts a mechanical alloying method, and uses the following components as raw materials: Al 60-95wt%, Ga 0.5-10wt%, In0.5-10wt%, Sr 0.5-10wt%, Bi2O31-10wt%, SnCl21 ~10wt%, ball milling to obtain a hydrolyzed hydrogen-producing aluminum alloy with good hydrogen-producing performance. The experimental results show that the hydrolysis hydrogen production aluminum alloy prepared by the preparation method provided by the present invention can directly react after contacting with water at normal temperature, without reaction lag time, the hydrogen production amount can reach 1220mL / g, and the hydrogen production rate can reach 98.1%. It can achieve real-time hydrogen production and real-time hydrogen supply, and is suitable for providing high-purity hydrogen sources for hydrogen-oxygen fuel cell vehicles. The preparation method provided by the invention has low cost, simple and convenient operation, and is suitable for industrial production.

Owner:HUBEI UNIV OF TECH

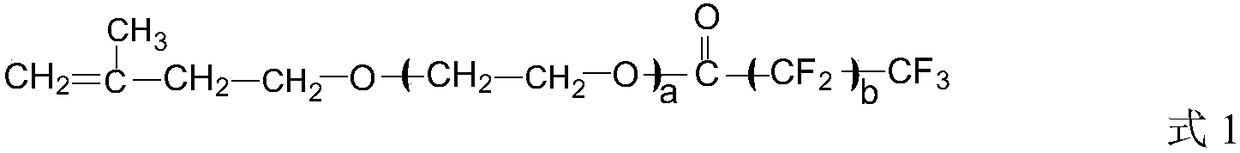

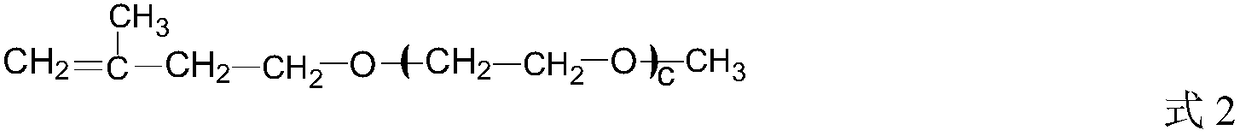

Carboxylate polymer dispersant with deforming function

The invention discloses a carboxylate polymer dispersant with a deforming function. The polymer is prepared through reactions between perfluorocarboxylic acid and a petroleum product namely polyoxyethylene. The dispersant is prepared by following steps: carrying out esterification reactions between perfluorocarboxylic acid and unsaturated polyoxyethylene monomers with terminal hydroxyl groups to prepare monomers with a deforming function; adding the monomers with a deforming function, isopentenyl polyoxyethylene, styryl polyoxyethylene, unsaturated carboxylic acid derivatives, and water into areactor to carry out free radical polymerization reactions for 4 to 5 hours at a temperature of 25 to 50 DEG C under the action of a redox initiator; and then adjusting the pH to 6.0-7.0 by a sodiumhydroxide water solution to obtain the dispersant. A fluorocarbon group with a strong deforming performance is introduced into highly water-soluble polyoxyethylene polymer; the dispersant can be applied to aqueous paints, cement mortar, ceramic, and gypsum, and the deforming function is enhanced.

Owner:东营亿鑫化工有限公司

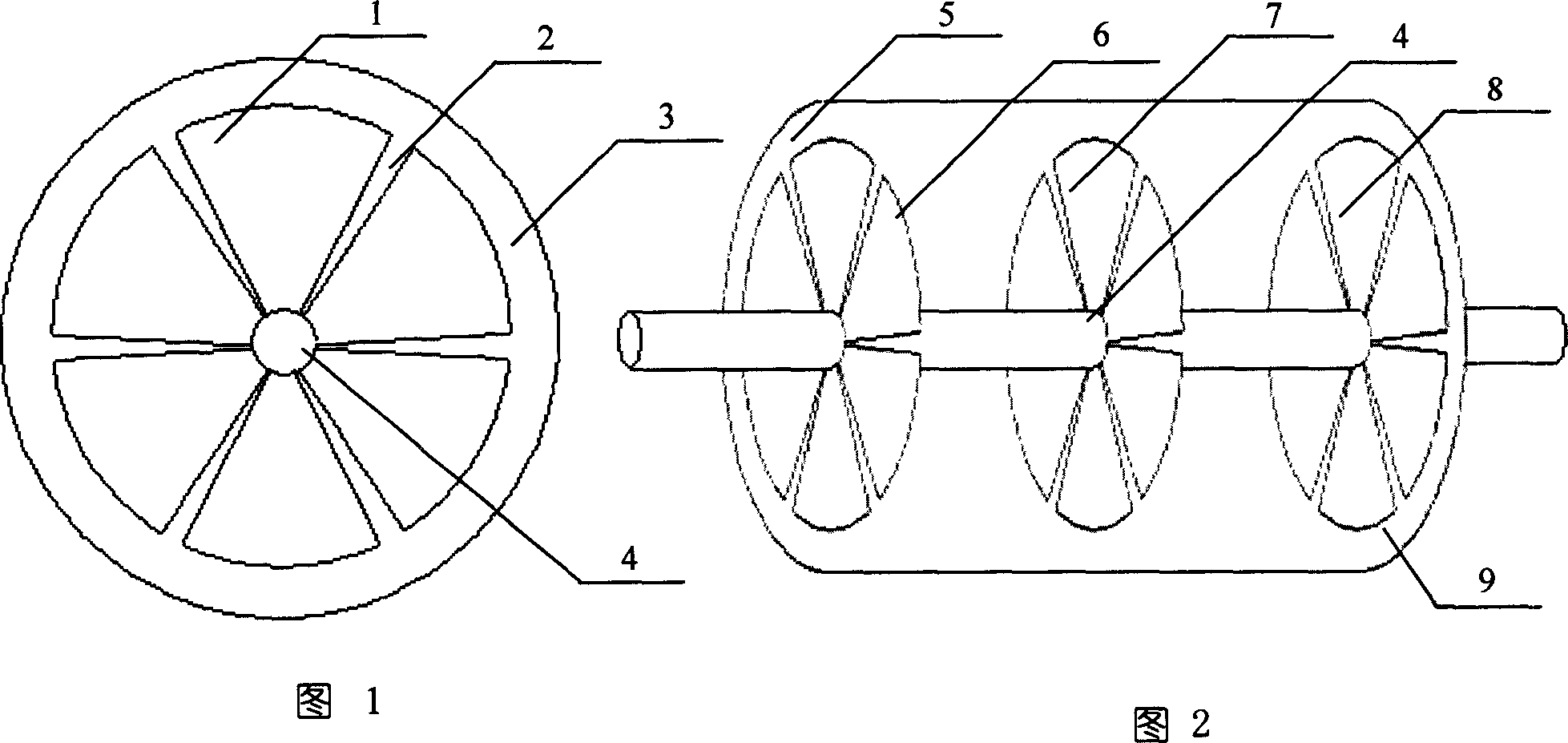

Method for preparing high performance nickel powder using shearing and breaking process

The invention relates to a method which is adopted the shearing crushing technology to prepare for producing the nickel powder with high performance. It is gained the oxidation product of the metal nickel packed by the brittle nickel oxide after the foamed metal nickel raw material is conducted the dynamic gyration oxidation treatment. The oxidation product is conducted multistage shearing crushing by the multistage shearing crusher, and generally the number of stages is from one stage to five stages. Then the crushed powder is conducted the re-oxidation treatment to gain the nickel oxide powder with fine grain. The nickel oxide powder is conducted reduction treatment in stages by cracked ammonia. Thus the high quality metal nickel powder with high purity, fine grain, and small loosing ratio is produced. The technology can be widely applied to all of the metal powder preparations adopted the oxidation reduction method. The advantage of The invention discloses that the high quality metal nickel powder with fine grain can be prepared by, the re-oxidation and the later reduction in stages after the shearing crushing of the oxidation intermediate product. The produced metal nickel powder can be widely applied to the sintered metal product (hard alloy, diamond tool, nickel iron alloy product, nickel base product) stainless steel product, battery, and chemical industry product, and so on. The features of the invention are that the non contaminant is discharged; it is good for the environmental protection; the process flow and the cost are reduced.

Owner:长沙市维优金属材料有限公司

Preparation method of nanometer grade indium tin oxide composite powder

The present invention is a process for preparing nano-scale indium tin oxide composite powder by co-precipitation method, which is characterized in that metal indium, metal tin, or soluble metal indium salt and metal tin salt are respectively dissolved by inorganic single strong acid or mixed strong acid aqueous solution Dissolve in water, mix the prepared two solutions, add a precipitant under the condition of vigorously stirring the mixed solution to produce indium tin coprecipitate, after washing with water, organic solvent washing and solid-liquid separation, add an organic solvent for azeotropic distillation, the filter cake Ultrafine ITO composite powder is obtained by drying, breaking up and calcining. The indium tin oxide powder prepared by the process of the present invention is fired by a simple process, and the relative theoretical density of the ITO target can reach more than 99%.

Owner:BEIJING UNIV OF CHEM TECH +1

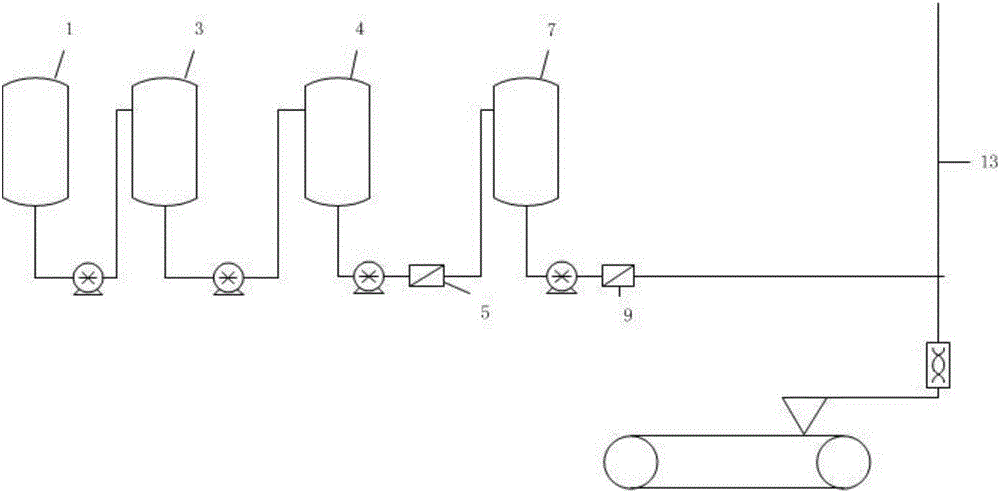

Nano-microbubble material for modifying pulverized coal in-situ consolidation and preparation method thereof

ActiveCN110564391AImprove solubilityHigh chemical activityDrilling compositionGas removalFoaming agentPortland cement

The invention discloses a nano-microbubble material for modifying pulverized coal in-situ consolidation and a preparation method thereof. The nano-microbubble material is prepared from the following components in parts by mass: 40-60 parts of Portland cement particles, 0.5-1 part of a plant type cement foaming agent, 0.2 part of polyurethane foam stabilizer, 0.8-1.2 parts of a velocity controllingagent, 1-2 parts of sodium silicate and 1-1.5 parts of an early strength agent. The preparation method comprises the following steps: adding a high-efficiency dispersing agent into the Portland cement particles and velocity controlling agent, and grinding the mixture until the grain size is nano-grade; adding the foaming agent and the foam stabilizer into a container A, performing mixing to obtain a to-be-used foaming solution; adding the nano-grade Portland cement particles and nano-grade velocity controlling agent into a container B, adding the sodium silicate and the early strength agent into the mixture, and performing stirring and mixing at a specific environment to obtain a nano-material slurry; and finally, foaming the to-be-foamed foaming solution, mixing the foamed foaming solution with the nano-material slurry in a static mixer to prepare the nano-microbubble material. A soft coal body in a coal seam has high stability and relatively good air permeating effect after being consolidated with the nano-microbubble material, and subsequent gas extraction is facilitated.

Owner:HUNAN UNIV OF SCI & TECH

Cellulose triacetate film

ActiveCN106696154AShorten dispersion timeStirring frequency is smallFlat articlesCoatingsUltrasonic cavitationCellulose acetate

The invention relates to a cellulose triacetate film. Preparation steps comprise preparation of a cellulose triacetate celloidin liquid, dispersion and addition of a matting agent and tape casting, wherein in the dispersion and addition link of the matting agent, the matting agent is mixed and dispersed through ultrasonic cavitation and mechanical stirring, the dispersing time and the grinding time of the matting agent are effectively shortened by means of a method of controlling a flow rate of a pipeline, an agglomeration phenomenon in the matting agent adding process is avoided, and in the dispersion liquid adding process, the content of particles, less than 10 [mu]m, of the matting agent is stabilized to 99.5% above, so that the service life of a filter element is effectively prolonged, and the cost is lowered. Compared with the prior art, the cellulose triacetate film prepared by the invention has the advantages of being low in haze, high in light transmittance, few in crystal points, few in moisture absorption points and the like.

Owner:CHINA LUCKY FILM CORP +1

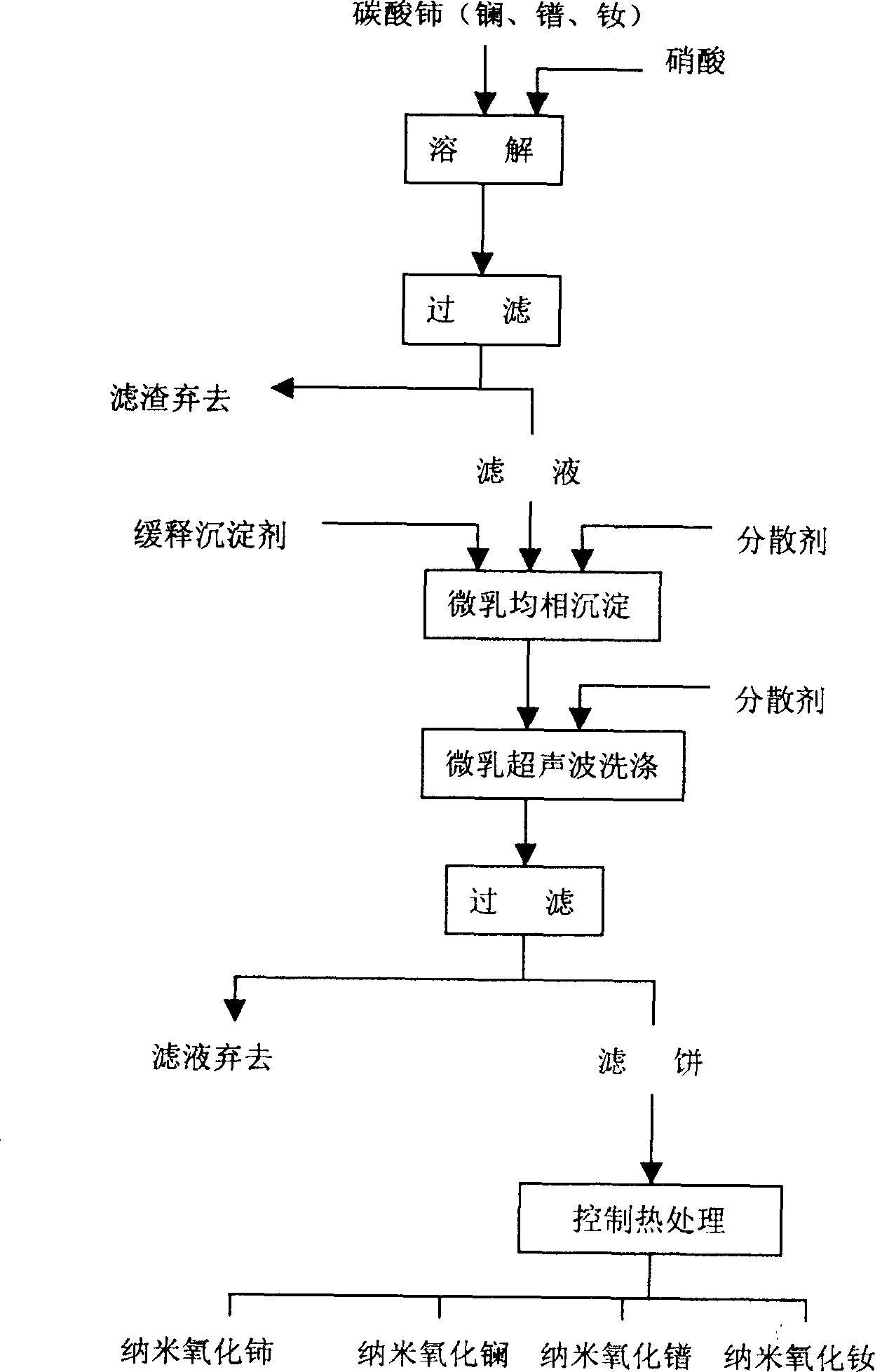

Technology for preparing nanometer rare-earth oxide

InactiveCN1296282CPromote generationGuaranteed uniformityOxygen/ozone/oxide/hydroxideRare earth metal compoundsRare earthMicroemulsion

A process for preparing nano rearearth oxide wherein the rearearth carbonic acid is used as raw material, dissolved in nitric acid, filtered, added with slow released precipitator and dispersant after being filtered, added with dispersant after obtaining fore unit, through ultrasonic wave oscillating, microemulsion ultrasonic washing, filtering, drying, calcinating to obtain said nano rearearth oxide. In said invention, microemulsion homogeneous precipitation process is used which is favour to form precipitation grain kernel and adverse to kernel growth to keep the productive grain size small and uniform and eliminate agglomeration.

Owner:BAOTOU HUAMEI RE PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com