Preparation method of nanometer grade indium tin oxide composite powder

A technology of indium tin oxide and composite powder, which is applied in the field of preparing nano-scale indium tin oxide composite powder, to achieve the effects of good dispersion, elimination of agglomeration, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

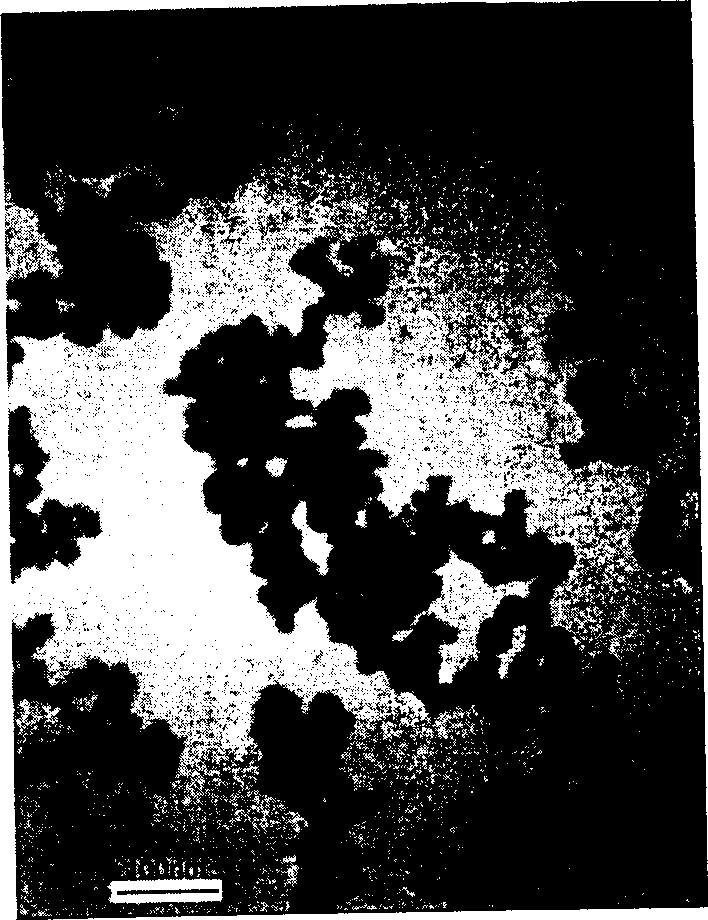

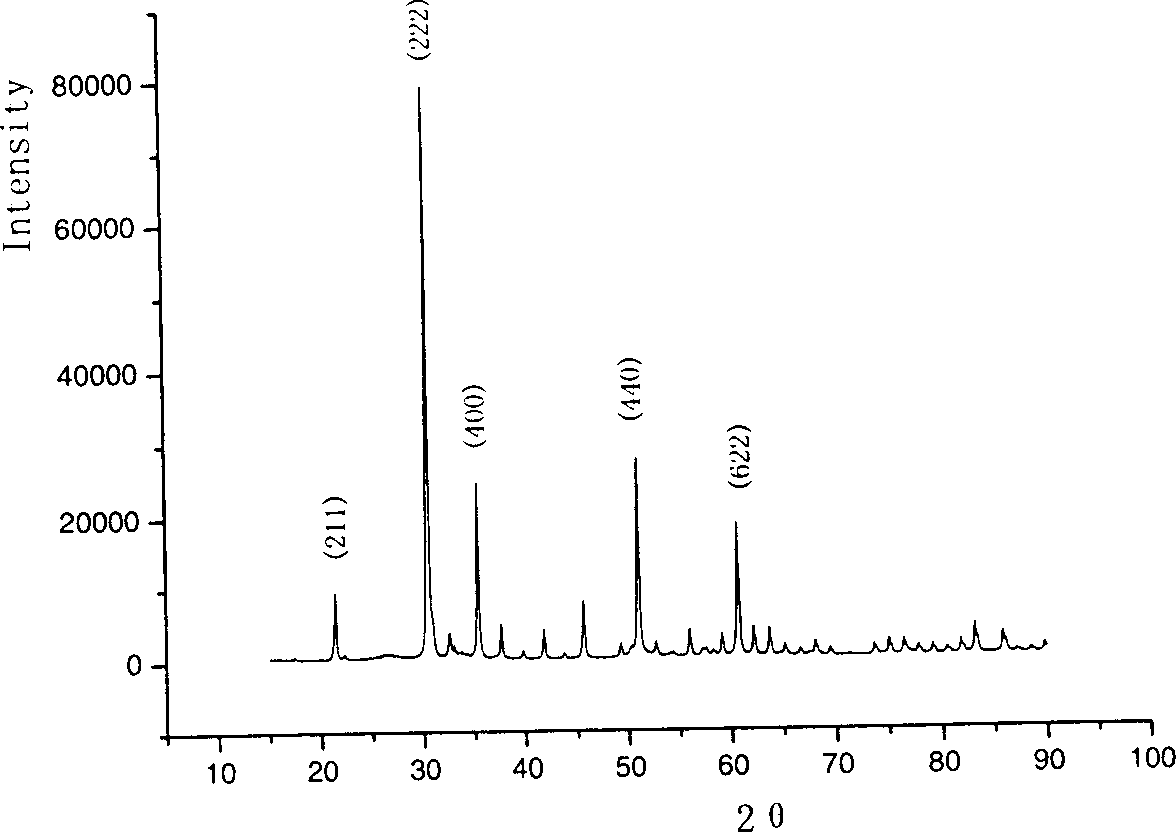

Image

Examples

Embodiment 1

[0022] a. Take 22.964 grams of metal indium (purity 99.99%) and dissolve it in the superior pure nitric acid aqueous solution, take 7.02 grams of SnCl 4 ·5H 2 O (purity 99.99%) was dissolved in an appropriate amount of deionized water.

[0023] b. The above two solutions are fully mixed and stirred, and an appropriate amount of deionized water is added. At this time, the concentration of indium and tin ions in the mixed solution is 0.8M.

[0024] c. Under the condition of vigorously stirring the mixed solution, add high-grade pure sodium bicarbonate to make the pH value of the solution 7-11. At this time, the clarified solution produces indium tin coprecipitate, and the stirring is continued for 2 hours.

[0025] d. Filter the supernatant by centrifugal sedimentation to obtain the indium-tin co-precipitate filter cake, then re-stir and wash with deionized water until there is no NO 3 - 、Na + and Cl - ions, analytically pure anhydrous methanol was added after the last filt...

Embodiment 2

[0030] a. Get 55.113 grams of metal indium (purity 99.99%) to be dissolved in the pure aqueous solution of nitric acid, and get 5.832 grams of metal tin (purity 99.99%) to be dissolved in the pure aqueous solution of sulfuric acid.

[0031] b. The above two solutions are fully mixed and stirred, and an appropriate amount of deionized water is added. At this time, the concentration of indium and tin ions in the solution is 0.4M.

[0032] c. Under the condition of vigorously stirring the mixed solution, add high-grade pure ammonium carbonate to make the pH value of the solution 7-11. At this time, the clarified solution produces indium tin coprecipitate, and the stirring is continued for 2 hours.

[0033] d. Filter the supernatant by centrifugal sedimentation to obtain the indium-tin co-precipitate filter cake, then re-stir and wash with deionized water until there is no NO 3 - , NH 4 + and SO 42- ions, analytical grade absolute ethanol was added after the last filtration. ...

Embodiment 3

[0038] a. Get 55.113 grams of metal indium (purity 99.99%) and dissolve in the mixed aqueous solution of nitric acid and hydrochloric acid of superior grade, get 5.832 grams of metal tin (purity 99.99%) and dissolve in the superior grade of pure sulfuric acid aqueous solution.

[0039] b. The above two solutions are fully mixed and stirred, and an appropriate amount of deionized water is added. At this time, the concentration of indium and tin ions in the solution is 0.5M.

[0040] c. Under the condition of vigorously stirring the mixed solution, add high-grade pure ammonium bicarbonate to make the pH value of the solution 7-11. At this time, the clarified solution produces indium tin coprecipitate, and the stirring is continued for 2 hours.

[0041] d. Filter the supernatant by centrifugal sedimentation to obtain a white indium-tin co-precipitate filter cake, then re-stir and wash with deionized water, and repeat the washing until there is no NO 3 - , NH 4 + and SO 4 2- ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com