Hollow carbon fiber negative electrode material for lithium ion battery as well as preparation method and application thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high rate performance of specific capacity, difficulty in taking advantage of the advantages of biomass carbon materials, long preparation time and other problems, and achieve discharge ratio Improved capacity and rate efficiency, fast radial ion diffusion characteristics, and shortened Li-ion migration paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Such as figure 1 Shown, a kind of preparation method of hollow carbon fiber negative electrode material for lithium ion battery comprises the following steps:

[0036] (1) Immerse the biomass raw material in the nitric acid solution, and perform pretreatment at 60 ℃ to 90 ℃ to remove the lignin, hemicellulose and pectin components in the biomass raw material to obtain a suspension;

[0037] (2) Ultrasonically disperse the suspension obtained in step (1) in water, filter and dry to obtain raw wood fiber, then heat it up to 700 ℃ ~ 1100 ℃ under the protection of inert gas for pyrolysis and carbonization, and cool to room temperature to obtain lithium ion battery. Hollow carbon fiber anode material.

[0038] In the above step (1), preferably, the biomass raw material includes wood and / or bamboo; the ratio of the mass of the biomass raw material to the volume of the nitric acid solution is 5 g to 15 g: 50 mL to 150 mL, and the The concentration of nitric acid solution is 10...

Embodiment 1

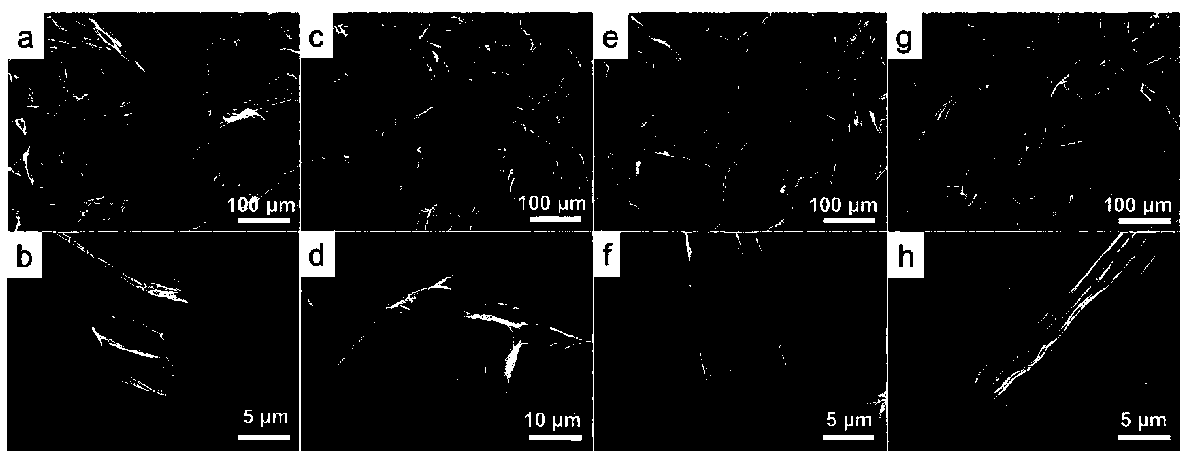

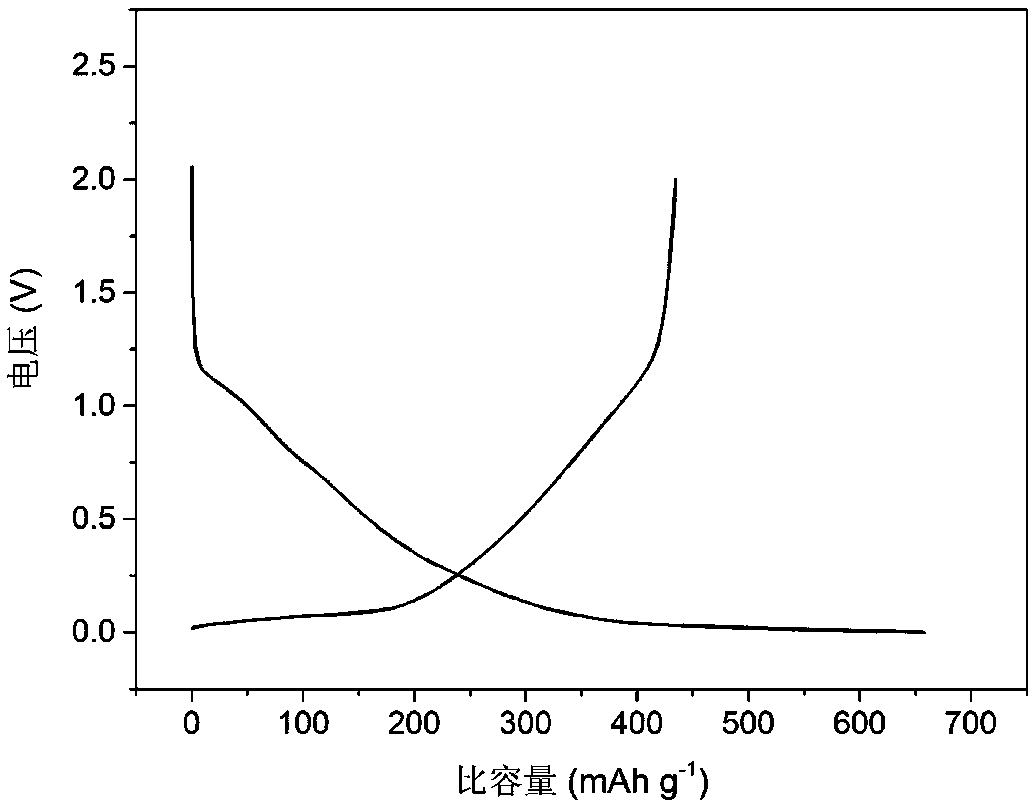

[0042] A hollow carbon fiber negative electrode material for a lithium ion battery of the present invention, the negative electrode material has a fiber-like microscopic appearance, and the diameter of the hollow carbon fiber is 1 μm to 10 μm. When the charge and discharge current is 50 mA / g, the first discharge specific capacity is 639.6 mAh / g, the charge specific capacity is 422.4 mAh / g, and the first Coulombic efficiency is 66.0%. A method for preparing a hollow carbon fiber negative electrode material for a lithium ion battery of the present embodiment, comprising the following steps:

[0043] (1) After the green bamboo was removed from the moso bamboo, it was crushed through a 40-mesh sieve, and 5 g of bamboo powder was weighed and added to 70 mL of nitric acid with a mass concentration of 30%, and stirred at 80 °C for 3 h to remove lignin and hemifibres. Ingredients such as vitamins and pectin. After the reaction was completed, it was cooled to room temperature to obtai...

Embodiment 2

[0049] A method for preparing a hollow carbon fiber negative electrode material for a lithium ion battery of the present embodiment, comprising the following steps:

[0050] (1) Crush pine wood through a 40-mesh sieve, weigh 10 g, add it to 120 mL of 30% nitric acid, and stir at 80 °C for 3 h to remove lignin, hemicellulose, and pectin. After the reaction was completed, it was cooled to room temperature to obtain a golden yellow suspension.

[0051] (2) Ultrasonically disperse the obtained golden yellow suspension in water for 30 min, filter and dry to obtain raw wood fiber, then put it into a tube furnace with argon gas for pyrolysis and carbonization, raise the temperature to 1000 °C at 10 °C / min and keep it warm 1 h. After pyrolysis and carbonization, cool to room temperature to obtain a powdery hollow carbon fiber negative electrode material for lithium-ion batteries, the microscopic appearance of which is hollow and fibrous.

[0052] The button battery was assembled acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com