Biomass hard carbon negative electrode material for sodium ion battery as well as preparation method and application of biomass hard carbon negative electrode material

A technology of sodium ion battery and negative electrode material, which is applied in battery electrodes, active material electrodes, negative electrodes, etc., can solve the problem that biomass hard carbon negative electrode materials are difficult to achieve large-scale application production, unable to form intercalation compounds, and cumbersome preparation process. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method of biomass hard carbon negative electrode material for sodium ion battery, comprising the following steps:

[0046]S1. Using one or more of wood, bamboo or camellia husk as biomass raw materials, immerse the biomass raw materials in sulfuric acid solution, stir at room temperature, remove the ash in the biomass raw materials and introduce oxygen atoms to the biomass The easily oxidized functional groups in the material raw materials are oxidized and modified to obtain a suspension;

[0047] S2, dispersing the suspension obtained in step S1 in water, filtering and drying to obtain a precursor;

[0048] S3, heating the precursor obtained in step S2 to 400-600° C. under the protection of an inert gas for pre-carbonization treatment, and ball milling after cooling to obtain pre-carbon powder;

[0049] S4. Heating the pre-carbon powder obtained in step S3 to 1100-1600° C. under the protection of an inert gas for high-temperature carbonization treatment,...

Embodiment 1

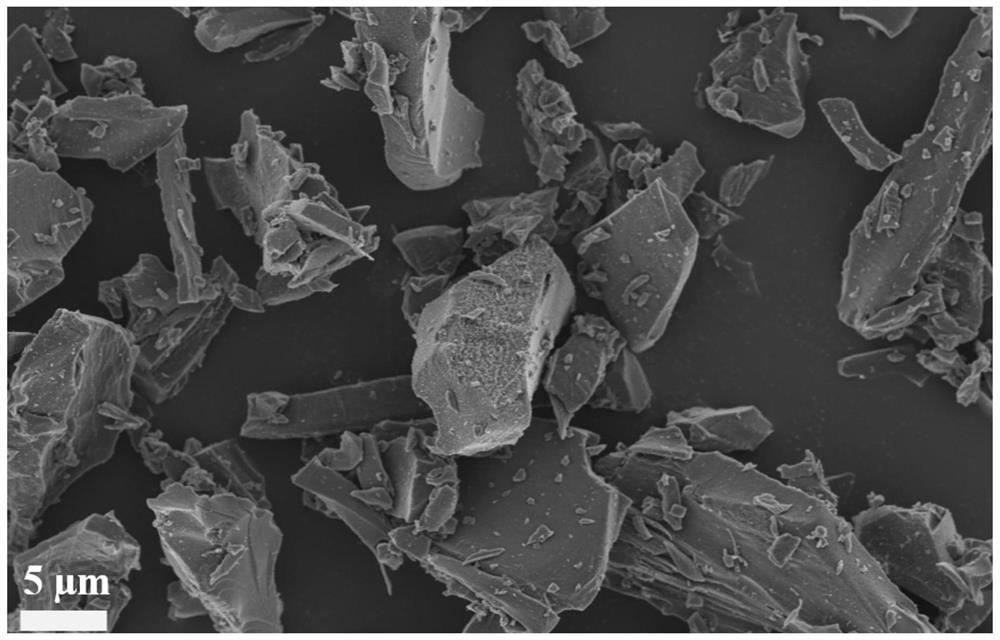

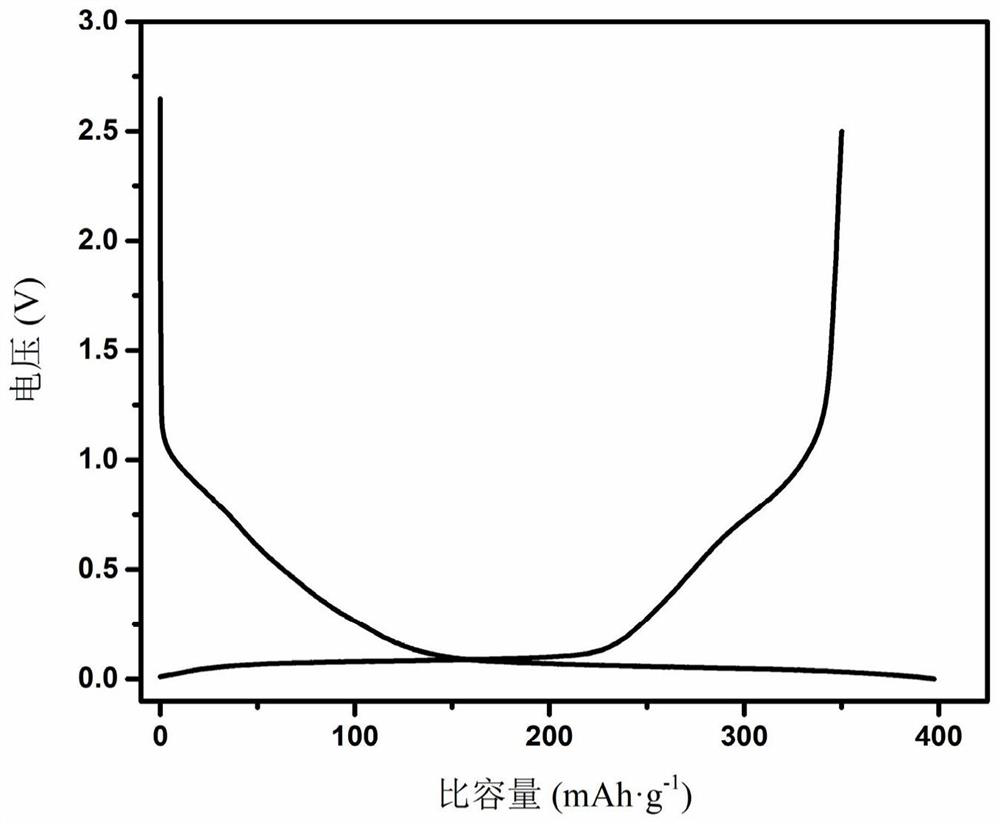

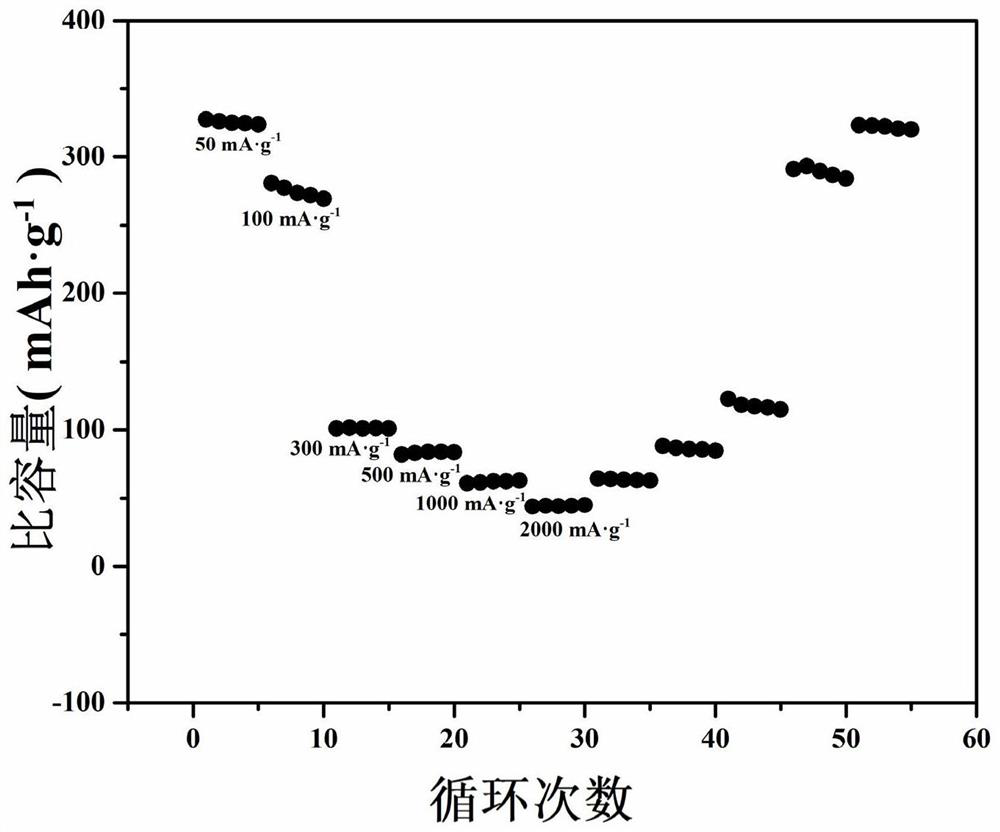

[0074] The sodium ion battery of the present embodiment uses the biomass hard carbon negative electrode material, scanning electron microscope picture is as follows figure 1 Morphology shown is irregular block. When the charge and discharge current is 30mA / g, the first discharge specific capacity reaches 397.6mAh / g, the charge specific capacity is 350.2mAh / g, and the first coulombic efficiency is 88%.

[0075] A kind of preparation method of the sodium ion battery of the present embodiment uses biomass hard carbon negative electrode material, comprises the following steps:

[0076] (1) Grinding the dried pine wood into powder, weighing 10g of pine wood powder as biomass raw material, adding it to 60mL of sulfuric acid with a molar concentration of 6mol / L, and stirring at room temperature for 6h to remove ash and introduce oxygen atoms , after the end of the reaction, a brown suspension was obtained.

[0077] (2) Ultrasonic disperse the resulting brown suspension in water for...

Embodiment 2

[0084] The biomass hard carbon negative electrode material for sodium ion batteries of this embodiment, when the charge and discharge current is 30mA / g, the first discharge specific capacity reaches 373.5mAh / g, the charge specific capacity is 310.4mAh / g, and the first coulombic efficiency is 83.1%. .

[0085] A kind of preparation method of the sodium ion battery of the present embodiment uses biomass hard carbon negative electrode material, comprises the following steps:

[0086] (1) Grinding the dried pine wood into powder, weighing 10g of pine wood powder as biomass raw material, adding it to 60mL of sulfuric acid with a molar concentration of 6mol / L, and stirring at room temperature for 6h to remove ash and introduce oxygen atoms , after the end of the reaction, a brown suspension was obtained.

[0087] (2) Ultrasonic disperse the resulting brown suspension in water for 30 minutes, filter and dry to obtain the precursor, then put it into a tube furnace with argon gas for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com