FeVO4/TiO2 porous catalyst film layer material for photo-Fenton combined catalysis and preparation method of FeVO4/TiO2 porous catalyst film layer material

A technology of porous catalyst and membrane layer is applied in the field of photo-Fenton joint catalytic material preparation to achieve the effect of low cost and industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

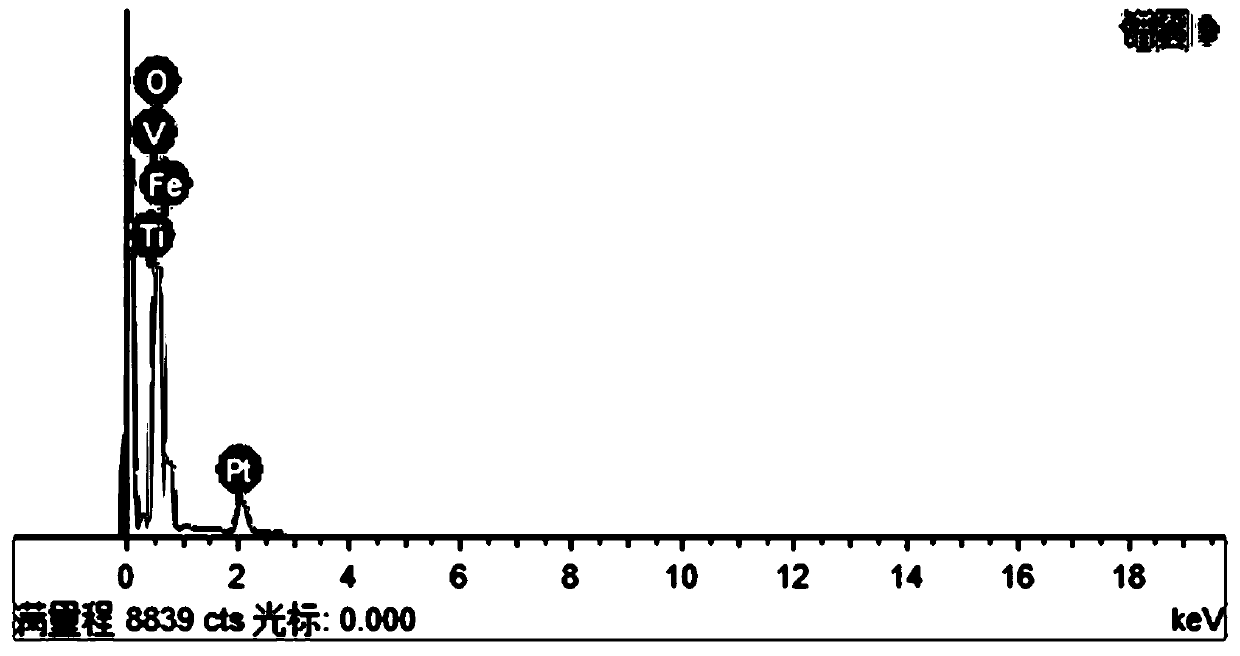

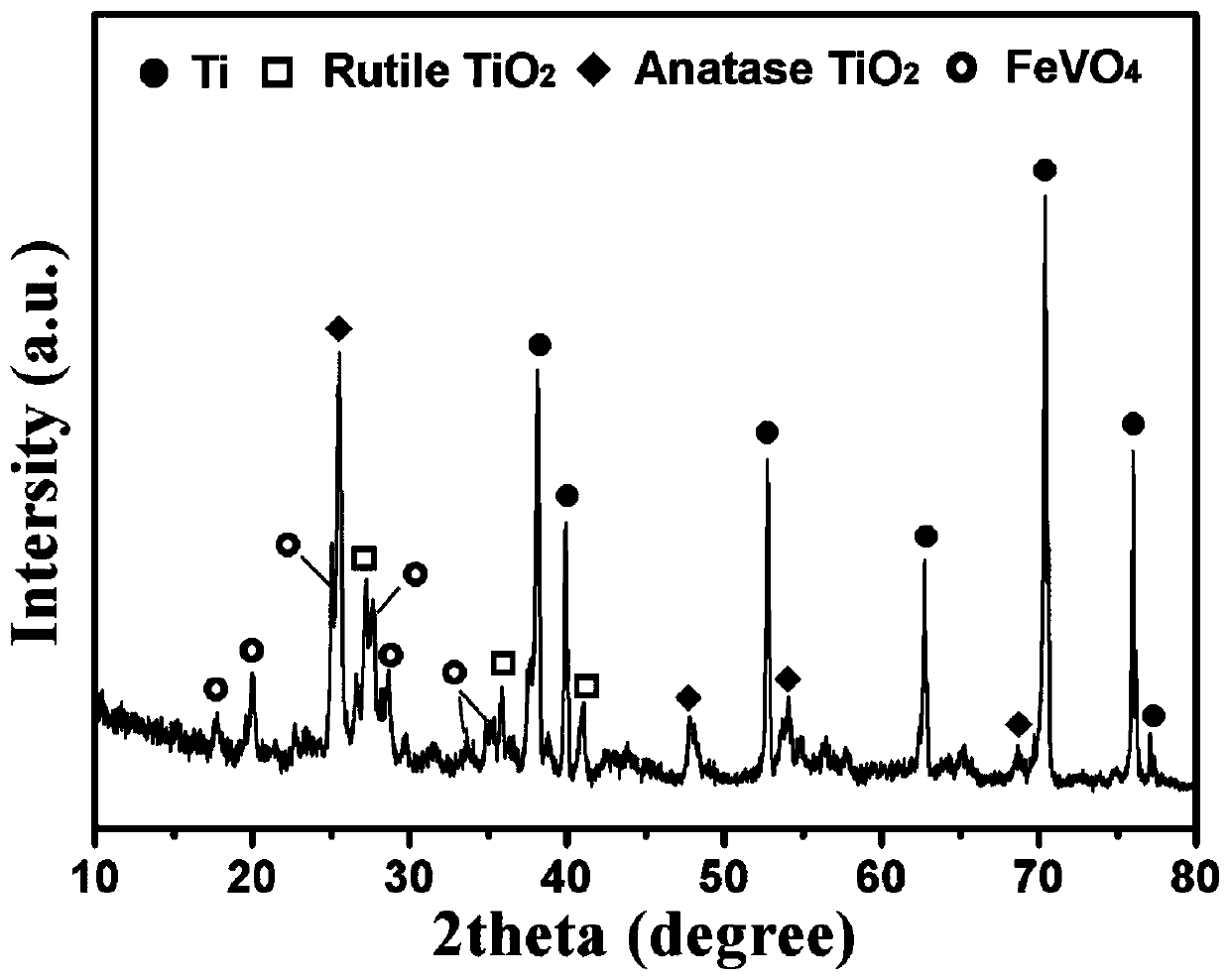

[0040] In this example, a kind of FeVO prepared by micro-arc oxidation technology for photo-Fenton combined catalytic degradation reaction 4 / TiO 2 The method for porous catalyst membrane layer material, comprises the steps:

[0041] S1, put 2cm 2 The pure titanium sample was treated with acid solution to remove oil and scale, and then ultrasonically cleaned in deionized water for 10 minutes;

[0042] S2, the pure titanium sample is connected to the positive pole of the bidirectional pulse power supply and fixed at the anode position of the electrolytic cell, and the stainless steel electrolytic cell is connected to the negative pole of the power supply as the cathode, containing sodium phosphate, sodium vanadate, potassium ferricyanate and hydrogen The solution of potassium oxide is the electrolyte solution, which is subjected to micro-arc oxidation treatment under stirring conditions; the configuration plan of the electrolyte solution is to dissolve 6g sodium dihydrogen ph...

Embodiment 2

[0048] S1, put 2cm 2 The pure titanium sample was treated with acid solution to remove oil and scale, and then ultrasonically cleaned in ethanol and deionized water for 10 minutes;

[0049] S2, using a bidirectional pulse power supply, using a pure titanium sample as an anode, and a stainless steel electrolytic cell as a cathode, firstly perform the first step of micro-arc oxidation in an electrolyte containing sodium phosphate, sodium vanadate, and potassium hydroxide under stirring conditions deal with. The configuration of the A electrolyte is to dissolve 6g of sodium dihydrogen phosphate, 2g of sodium vanadate, and 4g of potassium hydroxide in 1000mL of deionized water to obtain a clarified electrolyte. The power supply mode used in the first step of the micro-arc oxidation process is a constant voltage mode, and the treatment time is 30 minutes under a constant forward voltage of 350V. After the reaction is completed, the titanium sheet is taken out, cleaned with deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com